Cascade Sciences

Cascade CVO-2 Vacuum Oven

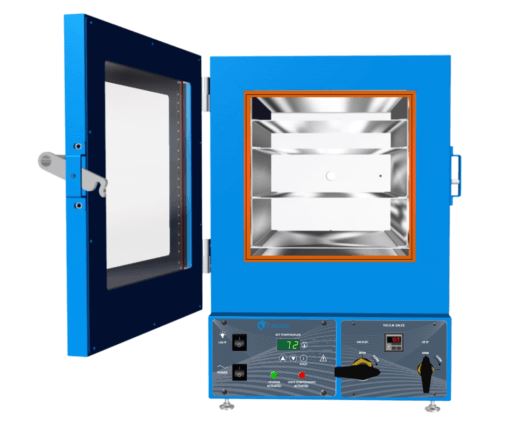

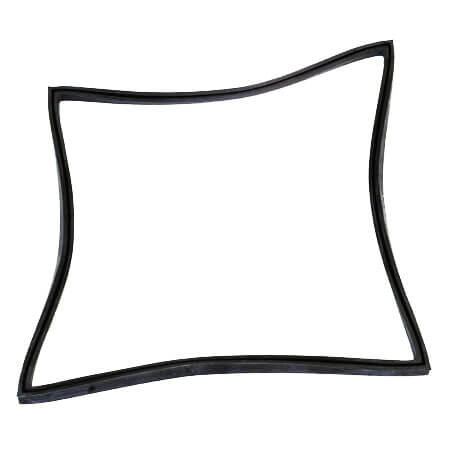

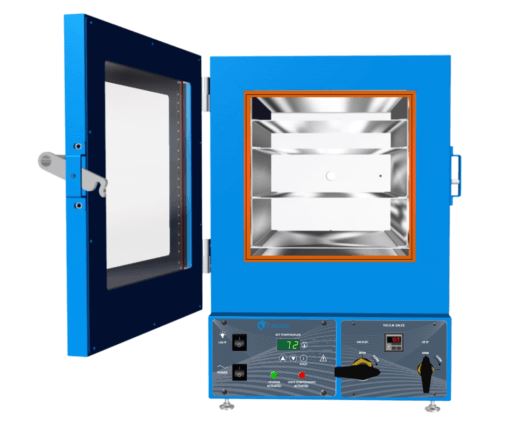

Cascade CVO-2 Vacuum Oven (Oven Only) This item carries up to a 1-2 week lead time. Model CVO-2 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, slurries, or any temperature sensitive material. This vacuum oven liberates solvents, water, and other unwanted compounds in small batch, R&D and lab environments. NRTL Certified. CVO-2 Vacuum Oven Features NRTL Certified by TUV 5 shelves (11.5″W x 19″D) in a flexible configuration. Shelves are stackable and removable Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Solvent resistant BUNA door gasket Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reads in inches of mercury Simple, set-point control Smooth, quarter-turn vacuum and vent valves Rear KF-25 port allows for rapid MAXEVAP purging or running feedthroughs inside oven for monitoring 120V (220V available) Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Adjustable leveling feet ensure oven sits solid and level in the workspace CVO-2 Connections 3/8″ Barb for Vacuum Pump 1/4″ Barb for Venting (N2 Connection OK) KF-25 Port for feedthroughs or MAXEVAP Connection Kit Need A Complete CVO-2 Vacuum Package? Cascade has taken the guess work out of pairing the right vacuum oven with the proper pump. We offer two complete CVO-2 vacuum oven packages with everything you need for vacuum drying. Both packages feature clean, quiet, Agilent oil-free scroll pumps. The CVO-2 STANDARD Package is an ideal package for vacuum drying or purging requiring a steady, gentle, non-turbulent purge. The CVO-2 PRO Package is ideal for higher thru-put, faster purge times pulling deeper vacuum. CVO-2 Comes In Low & High Temp Models Low & High Temp Specifications CVO-2 (Low Temp) Temperature Processing Range -3ºC to 121°C (26°F to 250°F) Temperature Uniformity +/- 1ºC at 40.5°C (+/- 1.5°F at 105°F) Temperature Stability +/- 0.5°C at 40.5°C (+/- 0.4 at 105°F) CVO-2-HT (High Temp) Temperature Processing Range Up to 220°C (428°F) Temperature Uniformity +/- 6.5% of setpoint The Cascade Difference Vacuum ovens have been around for decades. Basic vacuum ovens are mass-produced and sold by many large scale laboratory equipment distributors. But there are key differences between Cascade and other inexpensive, often imported vacuum ovens. Exceptional Temperature Control & Stability The Cascade CVO-2 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-2 eliminate hot and cold spots, making accurate use of every inch of shelf space. Independent Over-temp Failsafe Protection The Cascade Sciences CVO-2 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 200°C or 392°F. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. NRTL Certification #U8 170464972 077. No Extra cost. The CVO-2 Vacuum Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities. CAN/CSA-C22.2 No. 61010-1:2012 +UPD No. 1:2015-07 + UPD No. 2:2016-04 CAN/CSA-C22.2 No. 61010-2-010:2015 UL 61010-1:2012/R:2016-04 UL 61010-2-010:2015 EN 61010-1:2010 EN 61010-2-010:2014 Rigorous Quality Assurance in an ISO Certified, USA Manufacturing Facility Cascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment: Chambers are vacuum tested after welding for vacuum integrity Electrical & mechanical safety is thoroughly tested in compliance with TUV requirements Functional testing verifies user settable items consistent with most lab protocols/usage models Temperature verification includes calibration & temp chamber uniformity following ASTM standards Units are cleaned and packed in ISTA tested, certified packaging materials Digital Vacuum Gauge The digital vacuum gauge installed on the CVO-2 is factory default set to read in inches of mercury (“Hg) with a scale of 0 – 29.9”Hg. Change the unit of vacuum measurement to read in a wide variety of units from mmHg, bar psi, kPa, cm2, mmH20. Zero out the vacuum gauge to calibrate for just above sea level adjustments. Equipped for Inert Gas Backfill. Built-In Safety Relief Introduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the 1/4″ rear vent barb. The maximum backfill pressure is 15PSI. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection Ports The CVO-2 ovens offer two different vacuum oven connection points. The standard connection is a 3/8″ dia barb located at the rear of the oven. It is connected to the vacuum valve level on the front control panel. For even faster evaporation, purging or drying consider upgrading to the MAXEVAP connection kit. The MAXEVAP connection kit secures to the oven’s rear 1″ dia KF-25 port located on the back center of the chamber. The MAXEVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthroughs, or monitoring sensors inside the vacuum chamber during processing. Stackable Shelf Design For Maximum Temperature Conduction Under vacuum, there is no air inside a vacuum oven. Temperatures are achieved by a process of conduction and radiation to move temperatures into the product inside the oven. Cascade’s stackable shelf design makes the most of this opportunity by making the chamber longer and narrower, rather than square and supplies stackable shelves in multiple height configurations to allow for the fastest, most uniform transfer of heat. Ergonomically Designed, Easy Quarter-Turn Valves For anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vacuum/vent valves. Your wrists will thank you! ANSI Rated Tempered Glass + USA Made Steel Cascade ovens are made in Oregon, USA with high quality materials. Our glass is NGI-USA Tempered and certified to ANSI Z97.1.2007 16CFR / 201 11. Our door handles are rugged brushed steel, not plastic. Our vacuum vessels are constructed with American made steel. We’ve tried lower cost, imported steel, but over time, vacuum chambers made of lesser quality/lower tolerance material cannot withstand the flex and pressure changes of vacuum pumping/venting/purging. This can deteriorate vacuum integrity and the oven will lose its ability to hold vacuum. Door Gasket Options – Ideal For Your Process Cascade’s vacuum ovens come standard with a solvent resistant BUNA door gasket. For higher temp applications, we offer a cured Silicone gasket as well. Ask us about the variety of door gaskets we can supply based on your application: Silicone, BUNA, Viton, Fluorosilicone. Gaskets will eventually wear out. It’s ideal to keep a few spares on hand. Model CVO-2 Vacuum Oven Specifications: Capacity Volume 1.67 Cu Ft (47.2 L) Interior 12″W x 20″D x 12″H (305mm x 508mm x 305mm) Exterior 18.8″W x 24.5″D x 24.5″H (478mm x 622mm x 622mm) Product Weight 148 lbs (67.1 kgs) Temperature Temperature Range -3ºC to 121°C (26°F to 250°F) Temperature Uniformity +/- 1ºC at 40.5°C (+/- 1.5°F at 105°F) Temperature Stability +/- 0.5 at 40.5°C (+/- 0.4°F at 105°F) Vacuum Vacuum Valve 1/4 Turn Lever Vent Valve 1/4 Turn Lever Vacuum Gauge Digital. 0 to 29.9″Hg Temperature Controller Digital Set Point Accurate Within .5ºC (1°F) Independent Overtemp Failsafe Ports (Rear) Vacuum 3/8″ Barb Vent 1/4″ Barb Auxiliary KF-25 Port Inert Gas Introduction Use 1/4″ Vent Barb 15 psi max inlet pressure Power Options 110V – 120V / 1ph / 6A 50/60Hz (Cord Included) NEMA 5 – 15 Power Outlet Full Power 2456 BTU/hr *(220V Optional) Shelving Includes 5 shelves in a flexible configurationShelves are stackable and removable1″ High = 1 each2″ High = 2 each3″ high = 2 each Surface Area 11.5″W x 19″D Weight Capacity 50 lbs (22.7 kgs) Door Interior Lighting LED Strips (Rated to 150°C) Glass Window Tempered NGI-US to ANSI Z97.1.2007 Gasket Type 12″ x 12″ Solvent Resistant BUNA Standard Gasket Rated to 105°C (221°F) Gasket Options: High Temp Silicone Option rated to 30°C (446°F)Viton Option rated to 205°C (401°F) Shipping & Weights Unit Weight 179 lb (81.2 kg) Shipping Weight 218 lbs (99 kg) Shipping Dimensions 33″L x 33″W x 47″D (Class 85) Product Certifications: NRTL TUV #U8 170464972 077CAN/CSA-C22.2 No. 61010-1:2012+ UPD No. 1:2015-07 + UPD No. 2:2016-04CAN/CSA-C22.2 No. 61010-2-010:2015UL 61010-1:2012/R:2016-04UL 61010-2-010:2015EN 61010-1:2010EN 61010-2-010:2014 Warranty: 1 Year (Gaskets not included) *Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product. NTRL Certification PDF Manual Vacuum Pressure Chart Vacuum Gauge Manual Calibration

$6,889.00

Cascade CVO-2 PRO Vacuum Package

Cascade CVO-2 PRO Vacuum Package The CVO-2 PRO Package is a 2 cubic foot, benchtop vacuum oven with a powerful, 5.4 CFM oil-free scroll pump. It is an ideal benchtop set up for vacuum drying or purging temp sensitive material but at faster rates, with deeper vacuum and optimized vapor flow rates. This complete system will liberate solvents, water or other unwanted compounds in a small batch, laboratory environments. CVO-2 PRO Package Includes: CVO-2 vacuum oven 5 aluminum shelves in 1″, 2″ and 3″ heights for varied configurations Agilent IDP7, 5.4CFM dry scroll pump MAXEVAP vacuum oven to pump connection kit. This special connection kit optimizes flow rates with a large 1″ dia exit path out of oven, large, vacuum rated 1″ diameter lines, a large 1″ diameter vacuum valve and into the 1″ diameter vacuum pump inlet. At no time is the out-gas load restricted or flow reduced. Also includes the KF-25 hardware. The CVO-2 PRO Package allows for easy expansion Easily connect another vacuum oven to the large pumping system to increase capacity and save on future costs. Both oven and pump can run off a single dedicated 120V / 1ph / 20 AMP circuit. Both oven and pump can be built/ configured to run on 220V / 1ph CVO-2 Vacuum Oven NRTL Certified by TUV 5 shelves (11.5″W x 19″D) in a flexible configuration. Stack-able and removable Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reads in inches of mercury Simple, set-point control Smooth, quarter-turn vacuum and vent valves Rear KF-25 port allows for rapid MAXEVAP purging or running feedthroughs inside oven for monitoring 120V (220V available) Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Adjustable leveling feet ensure oven sits solid and level in the workspace CVO-2 Connections 3/8″ Barb for Vacuum Pump 1/4″ Barb for Venting (N2 Connection OK) KF-25 Port for feedthroughs or MAXEVAP Connection Kit Agilent IDP7 Dry Scroll Pump Features Oil-Free. Eliminates contamination risk. Will not smoke out exhaust, no filter required. Quiet (for a vacuum pump) 5.4 CFM pumping speed Ultimate vacuum: 2 x 10-2 Torr 120V or 220V / 1ph power – flexible configuration Adjustable “gas ballast” allows for better solvent tolerance / ingestion Maintenance requires the replacement of a single “tip seal”. Low cost of ownership. Powerful enough to accommodate a second vacuum pump Want Hotter Than 150°C (300°F)? CVO-2-HT (High Temp) has a temperature range Up to 220°C (428°F) The Cascade Difference Vacuum ovens have been around for decades. Basic vacuum ovens are mass-produced and sold by many large scale laboratory equipment distributors. But there are key differences between Cascade and other inexpensive, often imported vacuum ovens: Exceptional Temperature Control & Stability The Cascade CVO-2 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-2 eliminate hot and cold spots, making accurate use of every inch of shelf space. Independent Over-temp Failsafe Protection The Cascade Sciences CVO-2 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 200°C or 392°F. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. NRTL Certification #U8 170464972 077. No Extra cost. The CVO-2 Vacuum Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities.CAN/CSA-C22.2 No. 61010-1:2012+UPD No. 1:2015-07 + UPD No. 2:2016-04CAN/CSA-C22.2 No. 61010-2-010:2015UL 61010-1:2012/R:2016-04UL 61010-2-010:2015EN 61010-1:2010EN 61010-2-010:2014 Rigorous Quality Assurance in an ISO Certified, USA Manufacturing FacilityCascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment:Chambers are vacuum tested after welding for vacuum integrityElectrical & mechanical safety is thoroughly tested in compliance with TUV requirementsFunctional testing verifies user settable items consistent with most lab protocols/usage models Temperature verification includes calibration & temp chamber uniformity following ASTM standards Units are cleaned and packed in ISTA tested, certified packaging materials Digital Vacuum Gauge The digital vacuum gauge installed on the CVO-2 is factory default set to read in inches of mercury (“Hg) with a scale of 0 – 29.9”Hg. Change the unit of vacuum measurement to read in a wide variety of units from mmHg, bar psi, kPa, cm2, mmH20. Zero out the vacuum gauge to calibrate for just above sea level adjustments. Equipped for Inert Gas Backfill. Built-In Safety Relief Introduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the 1/4″ rear vent barb. The maximum backfill pressure is 15psi at the inlet. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection Ports The CVO-2 ovens offer two different vacuum oven connection points. The standard connection is a 3/8″ dia barb located at the rear of the oven. It is connected to the vacuum valve level on the front control panel. For even faster evaporation, purging or drying consider upgrading to the MAXEVAP connection kit. The MAXEVAP connection kit secures to the oven’s rear 1″ dia KF-25 port located on the back center of the chamber. The MAXEVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthroughs, or monitoring sensors inside the vacuum chamber during processing. Stackable Shelf Design For Maximum Temperature Conduction Under vacuum, there is no air inside a vacuum oven. Temperatures are achieved by a process of conduction and radiation to move temperatures into the product inside the oven. Cascade’s stackable shelf design makes the most of this opportunity by making the chamber longer and narrower, rather than square and supplies stackable shelves in multiple height configurations to allow for the fastest, most uniform transfer of heat. Ergonomically Designed, Easy Quarter-Turn Valves For anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vacuum/vent valves. Your wrists will thank you! ANSI Rated Tempered Glass + USA Made Steel Cascade ovens are made in Oregon, USA with high quality materials. Our glass is NGI-USA Tempered and certified to ANSI Z97.1.2007 16CFR / 201 11. Our door handles are rugged brushed steel, not plastic. Our vacuum vessels are constructed with American made steel. We’ve tried lower cost, imported steel, but over time, vacuum chambers made of lesser quality/lower tolerance material cannot withstand the flex and pressure changes of vacuum pumping/venting/purging. This can deteriorate vacuum integrity and the oven will lose its ability to hold vacuum. Door Gasket Options – Ideal For Your Process Cascade’s vacuum ovens come standard with a High Temp Silicone Door Gasket. We also offer a Solvent resistent BUNA gasket as well. Ask us about the variety of door gaskets we can supply based on your application: Silicone, BUNA, Viton, Fluorosilicone. Gaskets will eventually wear out. It’s ideal to keep a few spares on hand. Specifications Capacity Volume 1.67 Cubic Ft. | 47.2 Cubic Liters Interior 12”W x 20”D x 12"H 711mm x 609mm x 609mm Exterior 18.8” W x 24.5” D x 24.5”H 478mm x 622mm x 622mm Temperature Ranges Low-Temp Processing Range 26°F to 250°F (121°C) Temperature Uniformity +/- 1.5°F @ 105°F (40.5°C) Temperature Stability +/- 0.4°F @ 105°F(40.5°C) Heat Up / Stabilization Time to 250°F 120 minutes (to minimize overshoot) High-Temp CVO-10 (SVAC 9.3) Up to 428°F / 220°C Temperature Uniformity +/- 6.5% of setpoint *Note that ambient laboratory conditions can affect temp performance. Vacuum Valve Type Side Mounted Round Vacuum Vacuum Valve ¼ Turn Lever Vent Valve ¼ Turn Lever Lighting Interior LED Strips (Rated to 150C) On low temp CVO-10 only Window Type Glass Tempered NGI-US to ANSI Z97.1.2007 Vacuum Gauge Indication Digital 0 to 29.9″Hg Temperature Controller Screen Type Digital Set Point Accuracy Accurate Within 1°F Failsafe Independent Overtemp Failsafe Ports-Rear Vacuum 3/8″ Barb Vent 1/4″ Barb Auxiliary KF-25 Port Inert Gas Introduction Use 1/4″ Vent Barb 15 psi max inlet pressure Power Options Power 110V – 120V / 1ph / 8A 50/60Hz Cord? Cord Included Outlet Type NEMA 5-15R Power Outlet Shelving Removable? Removable Quantity Included Comes with 5 Each. Fixed. Detail Slide on rails, extend, stay in place. Aluminum Surface Area 11.5″W x 19″D Weight Capacity 50 lbs (22.7kgs) Weight Unit Weight 179 lb (81.2 kg) Shipping Weight 218 lbs (99 Kg) Shipping Details Dimensions 33″L x 33″W x 47″D Class Class 85 Certifications NRTL TUV #U8 170464972 077CAN/CSA-C22.2 No. 61010-1:2012+ UPD No. 1:2015-07 + UPD No. 2:2016-04CAN/CSA-C22.2 No. 61010-2-010:2015UL 61010-1:2012/R:2016-04UL 61010-2-010:2015EN 61010-1:2010EN 61010-2-010:2014 Vacuum Pump Agilent IDP3 Vacuum Pump Oil-Free, Scroll Pump 2.1 CFM 120V | 1ph Ultimate Pressure 29.9 ”Hg | 2.5 x10-1 torr Gasket Options Solvent Resistant BUNA Option Rated to 105°C (221°F) Viton Option Rated to 205°C (401°F) CVO-2-2 (220V) Power Specs 220 – 240V / 1ph / 4A 50/60 Hz (Cord Included) NEMA 6-15R Power Outlet Warranty Length 1 Year Exclusions Gaskets Not Incuded The CVO-2 comes in both low temp and high temp versions. The low temp version has excellent temperature uniformity for temperature sensitive material. The higher temp version, 220°C has a uniformity about 6.5% of setpoint. At time of order we will verify the high / low temp version you require.*Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product. Manual Pump Specs View NRTL Certification Vacuum Pressure Chart Vacuum Gauge Manual Calibration

$10,637.50

Cascade CVO-5 DOUBLE UP Vacuum Package, 120V

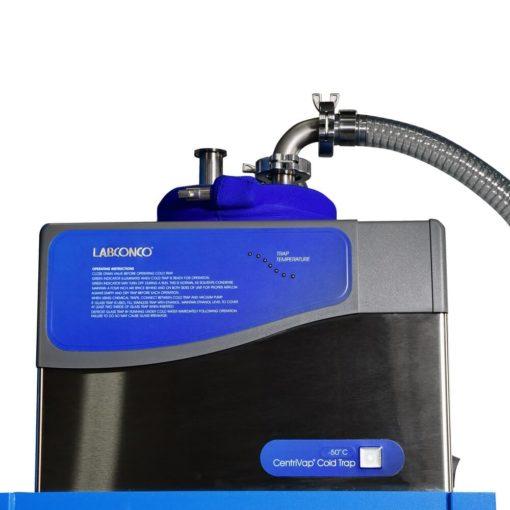

Cascade CVO-5 DOUBLE UP Vacuum Package, MAXTRAP -50C Cold Trap Cascade’s CVO-5 DOUBLE UP Vacuum Package is ideal for large volume production with the flexibility of small batch management. The package offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, slurries, or any temperature sensitive material. Cascade’s MAXTRAP Vacuum Cold Traps extend vacuum pump life by trapping excess moisture and volitales during vacuum drying or purging. Typically ships in 3-5 weeks CVO-5 DOUBLE-UP Package Includes: 2x Cascade Sciences CVO-5 Vacuum Ovens 1x Heavy-Duty Industrial Mobile Cart 10x Adjustable, Removable Shelves 2x Adjustable Side Shelves 2x MAXEVAP Connection Kits 1x Agilent IDP15 Oil-Free Vacuum Pump, 9cfm WITH MAXTRAP50 ( -50°C Cold Trap) 1x MAXTRAP50 -50°C Cold Trap 1x Mobile Trapstand for MAXTRAP50 WITH MAXTRAP105 ( -105°C Cold Trap) 1x MAXTRAP105 -105°C Cold Trap 1x Mobile Trapstand for MAXTRAP105 The 5 cubic foot vacuum ovens are stacked on an industrial grade, mobile rack for mobility and ease of cleaning the laboratory. Casters are lockable. Side mounted pump shelf allows for easy powering ON/OFF of vacuum pump. CVO-5 Vacuum Oven Features NRTL Certified by TUV 5 each adjustable shelves Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Bright LED lights in window for visibility of sensitive material Touchscreen LED Control Panel with adjustable settings Smooth, quarter-turn vacuum and vent valves Energize vacuum pump from control panel Rear KF-25 port allows for rapid MAXEVAP purging or running feedthroughs inside oven for monitoring 120V or 220V power options are available Stainless Steel option available Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Adjustable leveling feet ensure your unit sits solid and level in the workspace Made in USA Agilent IDP15 Oil-Free Scroll Pump Features 9 CFM pumping speed Quiet. Less noisy that diaphragm or oil-rotary vane pumps No Inlet / Exhaust Filters Required Hour Meter For Tracking Service Intervals 1 Year Warranty NRTL Certified /Made in USA Expert Rebuild/Maintenance Available Maintenance is the replacement of a single interior tip seal. Order our IDP15 Tip Seal Replacement Kit or ask us about our maintenance service. Pull Deeper Vacuum / Better Vapor Tolerance With Gas Ballast Positions. The IDP15 has two gas ballast ports that assist the pump in handling condensing gases such as water vapor, or other gaseous products that become liquids or solvents when reaching atmospheric pressure. MAXTRAP -50°C/-105°C Cold Trap Features Cascade’s COLDWELL 304 Stainless Steel Trap 3 Quart Capacity Viton Gasket Labconco -50°C/-105°C Refrigerated Base Green CFC / HFC Free Refrigerants KF-25 Inlet/Outlet, Connection Line & Hardware 3mm Neoprene Insulator Cap Requires 800ml (~ 3.5 cups) of a transfer fluid such as ethanol. Not Included. Quality Made in USA NRTL Certified Model CVO-5 VOLUME:4.5 Cubic Ft. (127 Cubic Liters) SHELVING:Includes 5 removable, adjustable (recommend 8 MAX)Surface Area: 18″W x 24″DWeight Capacity: 50 lbs (22.7Kg)Aluminum OVEN INTERIOR:18”W x 24”D x 18”H457mm x 609mm x 457mm OVEN EXTERIOR:33.3” W x 38.6” D x 31.8”H846mm x 980mm x 808mm WEIGHT:360 lbs / 163.3 Kg TEMPERATURE RANGE:Operating Range: Ambient +14.4°C to 150°C / +26°F to 302°F TEMPERATURE UNIFORMITY:@ 105°F +/- 2.0°F@ 200°F +/- 3.6°F@ 300°F +/- 5.5°F @ 40°C +/- 1.0°C@ 90°C +/- 2.0°C@ 150°C +/- 3.0°C TEMPERATURE STABILITY:@ 105°F +/- 0.2°F@ 200°F +/- 0.4°F@ 300°F +/- 0.2°F @ 40°C +/- 0.1°C@ 90°C +/- 0.2°C@ 150°C +/- 0.1°C HEAT UP FROM AMBIENT TO STABILIZATION TIME:To 105°F (40°C) 60 minutesTo 200°F (90°C) 126 minutesTo 300°F (150°C) 180 minutes (170 minutes for 220V version) COOL DOWN TIME:From 105°F (40°C) 345 minutesFrom 200°F (90°C) 285 minutesTo 300°F (150°C) 335 minutes (460 minutes for 220V version) *Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product, ambient lab conditions. VACUUM VALVE:¼ Turn Lever VENT VALVE:¼ Turn Lever INTERIOR LIGHTING:LED Strips (Rated to 150°C) GLASS WINDOW:Tempered NGI-US to ANSI Z97.1.2007 VACUUM GAUGE:Digital, selectable to read in inches mercury (Hg) or torr, barr CONTROLLER:Touch ScreenAccurate Within 1°FIndependent Overtemp FailsafeEasy updates with USB port PORTS (REAR):Vacuum = 3/8th BarbVent = ¼” BarbAuxiliary KF-25 Port INERT GAS INTRODUCTION:¼” Vent Barb15 psi max inlet pressure POWER:110V – 120V / 1ph / 14A 50/60HzCord IncludedNEMA 5-15 Power Outlet 1105 BTU/hrRating at max power 220V – 240V / 1ph / 7A 50/60Hz AvailableCord IncludedNEMA 6-15R Power Outlet 1228 BTU/hrRating at max power INCLUDED ACCESSORIES:5 Shelves20 Clips4 Leveling FeetPower Cord DOOR GASKET:18” x 18” Cured SiliconeTemp Silicone rated to 446°F(230°C) SHIPPING DIMENSIONS:41”L x 41”W x 45”HClass 85Shipping Weight: 449 lbs / 204 Kg Agilent IDP15 Oil-Free Scroll Pump PUMP TYPE:Oil-Free, Scroll PUMPING SPEED:9 CFM ULTIMATE PRESSURE:10 x 10-3 Torr POWER:120V / 1ph (220V available) INTAKE CONNECTION: KF-25 DIMENSIONS (L X W X H):19.08” x 9.22” x 14.3” WEIGHT: 75 lbs MAXTRAP -50°C/-105°C Cold Trap POWER:115V / 1ph / 3 AMP (60Hz)Cord IncludedCFC / HCFC Free Refrigerants DIMENSIONS:13.5″ W x 23.5″ D x 12.0″ H WEIGHT:COLDWELL Stainless Trap 14 lbsThermo Mechanical Base 60 lbsShipping Weight 95 lbs INCLUDED CONNECTIONS:1 each 4′ KF-25 flanged vacuum rated line1 each KF-25 Centering Ring1 each KF-25 Clamp User Manual CVO-5 DOUBLEUP Package with MAXTRAP Spec Sheet

$42,432.00 - $44,204.00

Cascade CVO-5 DOUBLE UP Vacuum Package

Cascade CVO-5 DOUBLE UP Vacuum Package Cascade’s CVO-5 DOUBLE UP Vacuum Package is ideal for large volume production with the flexibility of small batch management. The package offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, slurries, or any temperature sensitive material. Typically ships in 3-5 weeks 2x Cascade Sciences CVO-5 Vacuum Ovens 1x Heavy-Duty Industrial Mobile Cart 10x Adjustable, Removable Shelves 2x Adjustable Side Shelves 2x MAXEVAP Connection Kits 1x Agilent IDP15 Oil-Free Vacuum Pump, 9cfm Model CVO-5 VOLUME:4.5 Cubic Ft. (127 Cubic Liters) SHELVING:Includes 5 removable, adjustable (recommend 8 MAX)Surface Area: 18″W x 24″DWeight Capacity: 50 lbs (22.7Kg)Aluminum OVEN INTERIOR:18”W x 24”D x 18”H457mm x 609mm x 457mm OVEN EXTERIOR:33.3” W x 38.6” D x 31.8”H846mm x 980mm x 808mm WEIGHT:360 lbs / 163.3 Kg TEMPERATURE RANGE:Operating Range: Ambient +14.4°C to 150°C / +26°F to 302°F TEMPERATURE UNIFORMITY:@ 105°F +/- 2.0°F@ 200°F +/- 3.6°F@ 300°F +/- 5.5°F @ 40°C +/- 1.0°C@ 90°C +/- 2.0°C@ 150°C +/- 3.0°C TEMPERATURE STABILITY:@ 105°F +/- 0.2°F@ 200°F +/- 0.4°F@ 300°F +/- 0.2°F @ 40°C +/- 0.1°C@ 90°C +/- 0.2°C@ 150°C +/- 0.1°C HEAT UP FROM AMBIENT TO STABILIZATION TIME:To 105°F (40°C) 60 minutesTo 200°F (90°C) 126 minutesTo 300°F (150°C) 180 minutes (170 minutes for 220V version) COOL DOWN TIME:From 105°F (40°C) 345 minutesFrom 200°F (90°C) 285 minutesTo 300°F (150°C) 335 minutes (460 minutes for 220V version) *Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product, ambient lab conditions. VACUUM VALVE:¼ Turn Lever VENT VALVE:¼ Turn Lever INTERIOR LIGHTING:LED Strips (Rated to 150°C) GLASS WINDOW:Tempered NGI-US to ANSI Z97.1.2007 VACUUM GAUGE:Digital, selectable to read in inches mercury (Hg) or torr, barr CONTROLLER:Touch ScreenAccurate Within 1°FIndependent Overtemp FailsafeEasy updates with USB port PORTS (REAR):Vacuum = 3/8th BarbVent = ¼” BarbAuxiliary KF-25 Port INERT GAS INTRODUCTION:¼” Vent Barb15 psi max inlet pressure POWER:110V – 120V / 1ph / 14A 50/60HzCord IncludedNEMA 5-15 Power Outlet 1105 BTU/hrRating at max power 220V – 240V / 1ph / 7A 50/60Hz AvailableCord IncludedNEMA 6-15R Power Outlet 1228 BTU/hrRating at max power INCLUDED ACCESSORIES:5 Shelves20 Clips4 Leveling FeetPower Cord DOOR GASKET:18” x 18” Cured SiliconeTemp Silicone rated to 446°F(230°C) SHIPPING DIMENSIONS:41”L x 41”W x 45”HClass 85Shipping Weight: 449 lbs / 204 Kg User Manual CVO-5 DOUBLEUP Package with MAXTRAP Spec Sheet

$29,859.50

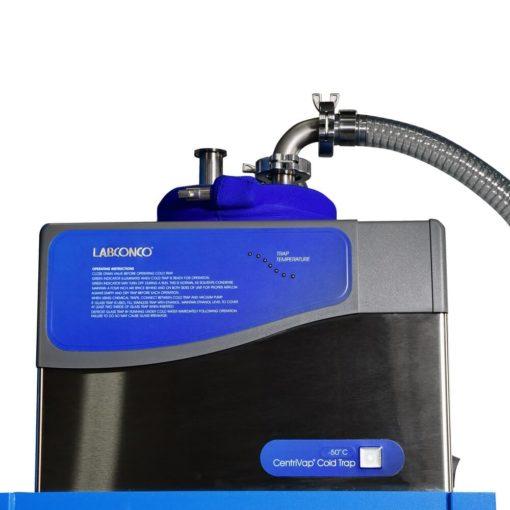

MAXTRAP50: -50°C Vacuum Cold Trap

MAXTRAP50: -50°C Vacuum Cold Trap There are numerous laboratory grade cold traps on the market and everyone agrees they are a best practice tool for preserving/extending vacuum pump life or the time between vacuum pump maintenance. Cascade’s MAXTRAP50 is not an ordinary lab-grade cold trap. Cascade has taken our extensive knowledge of vacuum best practices and integrated the features necessary for our customers with time-sensitive, high-throughput, production-focused vacuum purging or drying applications. Complete System Includes: Cascade’s COLDWELL 304 Stainless Steel Trap – patent pending baffle system. 3 Quart Capacity (2839 mliters) Viton Gasket Labconco -50°C Refrigerated Base Green CFC / HFC Free Refrigerants KF-25 Inlet/Outlet, 1 each 4′ Connection Line with KF-25 flanges, clamps, centering ring Power Cord 3mm Neoprene Insulator Cap Requires 800ml (~ 3.5 cups) of a transfer fluid such as ethanol. Not Included. Cascade recommends: ethanol, glycol, cryo-cool fluids Quality Made in USA 1 Year Warranty MAXTRAP Tips: Safety At very cold temperatures, solvents and even oxygen can re-condense back into liquid. This is potentially explosive. Liquid oxygen is a light blue color and can condense into a cold trap if a pump has sucked air through the trap when the trap is very cold. Always follow your standard operating procedures and safety guidelines. Don’t Stop: Keep Processing while trap is being reclaimed, cleaned, refreshed Cold traps can become full or the captured material freezes and blocks flow. For high moisture, outgassing, 24 hour processing/vacuum purging consider adding a second, spare COLDWELL trap. The secondary COLDWELL can be dropped into place so processing continues while the full trap is cleaned, defrosted. Quick Start Up Tips: Remove shipping foam from reservoir bottom prior to use Fill reservoir with 800ml (+/-3.5 cups) ethanol to marked line Monitor ethanol levels inside reservoir Allow at least 30 mins for trap to cool Keep side vents clear. Allow at least 4″ for airflow Monitor interior of stainless trap for clogging Short tube – attach to vacuum pump Tall tube – attach to vacuum oven MAXTRAP50 Differences: The key to quality cold trap performance is: time, surface area, and temperature. Time: Most cold traps have very narrow inlets and outlets, slowing down your process. Not Cascade’s MAXTRAP50! Full KF25 inlet and outlet connections never reduce flow. Surface Area: Most cold traps have glass or a smaller surface area to collect the matter your vacuum pump would otherwise ingest. Cascade’s MAXTRAP50 surface area is a patent pending series of filter baffles inside the COLDWELL stainless trap. Temperature: Cascade’s MAXTRAP50 features the mechanically refrigerated system built in the USA by Thermo Scientific – a leader in laboratory equipment. Specifications Coldwell Stainless Trap KF25 Inlet & Outlet 3 Quart Capacity (2839 mliters) Viton Gasket Neoprene Insulator Cap Labconco -50°C Mechanical Base 115V / 1ph / 3 AMP (60Hz) Cord Included CFC / HCFC Free Refrigerants Dimensions inches 13.5 W x 23.5 D x 12.0 H cm 34.3 x 59.7 x 30.5 *Requires approximately 800ml (~ 3.5 cups) of transfer fluid(ethanol, glycol, cryo-cool fluids) Connections 1 each 4′ KF-25 flanged vacuum rated line 1 each KF-25 Centering Ring 1 each KF-25 Clamp Weight COLDWELL Stainless Trap: 14 lbs Thermo Mechanical Base: 60 lbs Shipping Weight: 95 lbs Additional Resources: Download Specs Download Supplemental Manual NRTL Certifications

$7,049.00

MAXTRAP105 -105°C Vacuum Cold Trap, 120V

MAXTRAP105 -105°C Vacuum Cold Trap, 120V Cascade’s MAXTRAP105 is not an ordinary lab-grade cold trap. Cascade has integrated features necessary for time-sensitive, high-throughput, production-focused vacuum purging or drying applications. MAXTRAP105 Cold Trap Includes: Cascade’s COLDWELL 304 Stainless Steel Trap Insert (Patent pending baffle system) 3 Quart Capacity (2839 ml) Viton Gasket for Vacuum Integrity Labconco -105°C Refrigerated Base Green CFC / HFC Free Refrigerants Power Cord 3mm Neoprene Insulator Cap Requires 800ml (~ 3.5 cups) of a transfer fluid such as ethanol. Not Included. Cascade recommends: ethanol, glycol, cryo-cool fluids Quality Made in USA 1 Year Warranty Connection Lines and hardware: 4′ of 1″ Diameter Vacuum Tubing with KF-25 Flanges on each side. KF-25 clamps, centering rings for the connection tube MAXTRAP Tips: Safety At very cold temperatures, solvents and even oxygen can re-condense back into liquid. This is potentially explosive. Liquid oxygen is a light blue color and can condense into a cold trap if a pump has sucked air through the trap when the trap is very cold. Always follow your standard operating procedures and safety guidelines. Don’t Stop: Keep Processing while trap is being reclaimed, cleaned, refreshed Cold traps can become full or the captured material freezes and blocks flow. For high moisture, outgassing, 24 hour processing/vacuum purging consider adding a second, spare COLDWELL trap. The secondary COLDWELL can be dropped into place so processing continues while the full trap is cleaned, defrosted. Quick Start Up Tips: Remove shipping foam from reservoir bottom prior to use Fill reservoir with 800ml (+/-3.5 cups) ethanol to marked line Monitor ethanol levels inside reservoir Allow at least 30 mins for trap to cool Keep side vents clear. Allow at least 4″ for airflow Monitor interior of stainless trap for clogging Short tube – attach to vacuum pump Tall tube – attach to vacuum oven MAXTRAP105 Differences: The key to quality cold trap performance is: time, surface area, and temperature. Time: Most cold traps have very narrow inlets and outlets, slowing down your process. Not Cascade’s MAXTRAP105! Full KF25 inlet and outlet connections never reduce flow. Surface Area: Most cold traps have glass or a smaller surface area to collect the matter your vacuum pump would otherwise ingest. Cascade’s MAXTRAP105 surface area is a patent pending series of filter baffles inside the COLDWELL stainless trap. Specifications Coldwell Stainless Trap KF25 Inlet & Outlet 3 Quart Capacity (2839 mliters) Viton Gasket Neoprene Insulator Cap Labconco -105°C Mechanical Base 115V / 1ph / 3 AMP (60Hz) Cord Included CFC / HCFC Free Refrigerants Dimensions inches 24.1 W x 23.9 D x 12.6 H cm 34.3 x 59.7 x 30.5 *Requires approximately 800ml (~ 3.5 cups) of transfer fluid(ethanol, glycol, cryo-cool fluids) Connections 1 each 4′ KF-25 flanged vacuum rated line 1 each KF-25 Centering Ring 1 each KF-25 Clamp Weight COLDWELL Stainless Trap: 14 lbs Mechanical Base: 139 lbs Shipping Weight: 190 lbs Additional Resources: Download Specs Download Supplemental Manual NTRL Certifications -105C Refrigerated Base Safety Certification

$9,950.00

Cascade Mobile Stand, Large, Steel, Blue

Cascade Mobile Stand, Large, Steel, Blue This item carries up to a 2 week lead time. Mobile Cart, LargeLarge mobile cart steel, blue powder coat, fits cold trap, vacuum pump, & assorted temp control units

$1,100.00

CVO-10 PRO Vacuum Package

CVO-10 PRO Vacuum Package (With MAXTRAP105) A complete vacuum drying system designed for temperature sensitive, high-thru-put for vacuum purging large production quantities. Cascade’s MAXTRAP105 is a -105°C cold trap integrated in the system to keep the Agilent IDP15 vacuum pump operating with minimum downtime and maximum efficiency. Cascade’s Model CVO-10 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, slurries, isolates – especially temperature sensitive material. This vacuum oven will liberate solvents, pentane, water or other unwanted compounds in large batch production environments. The cold trap MAXTRAP105 (-105°C) will keep the vacuum pump running optimal and allow for capture of outgassed material in the steel trap. The entire system is set on an industrial mobile cart for easy mobility and to help keep the lab clean. NRTL Certified. Cascade Vacuum Ovens and cold trap are Made in USA. CVO-10 PRO Package with MAXTRAP105 Includes Cascade Sciences CVO-10 Vacuum Oven Heavy-Duty Industrial Mobile Carts for oven, vacuum pump and cold trap 9 Shelves, Aluminum, full extension, slide and stay in place Copper shelf bracket insert facilitates fast, stable heat transfer to shelves under vacuum MAXEVAP Connection Kit MAXTRAP105 Vacuum Cold Trap (-105°C) Agilent IDP15 Oil-Free Vacuum Pump, 9cfm All connections, hoses CVO-10 Vacuum Oven Features: Temperature Range: Ambient +26°F to 302°F / Ambient +14.4°F to 150°C Temperature Uniformity:@ 105°F +/- 2°F@ 200°F +/-5.5°F@ 300°F +/- 8°F NRTL Certified by TUV Stable temperature control. Touchscreen temperature readout with temp sensor INSIDE the oven VITON door gasket Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reads in inches of mercury or torr Smooth, quarter-turn vent valve Rear KF-25 port includes MAXEVAP Connection Kit for rapid vacuum drying or running feedthroughs inside oven for monitoring 220V / 1ph / 10AMPS NEMA 6-15R Plug Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Fast venting with larger ½” diameter vent line also allows for nitrogen or other inert gas connection Touch Panel LED control screen with user settable features, easy updates Mobile cart on heavy duty casters Agilent IDP15 Oil-Free Scroll Vacuum Pump Features: 9 CFM pumping speed Quiet. Less noisy that diaphragm or oil-rotary vane pumps Oil-Free. Eliminates contamination risk. No Inlet / Exhaust Filters Required Hour meter tracks service intervals 1 Year Warranty NRTL Certified Maintenance is the replacement of a single interior tip seal. Order our IDP15 Tip Seal Replacement Kit or ask us about our maintenance service. Pull Deeper Vacuum / Better Vapor Tolerance With Gas Ballast Positions. The IDP15 has two gas ballast ports that assist the pump in handling condensing gases such as water vapor, or other gaseous products that become liquids or solvents when reaching atmospheric pressure. MAXTRAP105 105°C Cold Trap Inlcudes: Cascade’s COLDWELL 304 Stainless Steel Trap – patent pending baffle system. 3 Quart Capacity (2839ml) Viton Gasket Labconco -105°C Refrigerated Base Green CFC / HFC Free Refrigerants KF-25 Inlet/Outlet, Connection Line & Hardware Power Cord 3mm Neoprene Insulator Cap Requires ~800ml (~ 3.5 cups) of a transfer fluid such as ethanol. Not Included. Cascade recommends: ethanol, glycol, cryo-cool fluids Quality Made in USA NRTL Certified

$38,642.00

Cascade CDO-28 Dry & Decarb Oven

Cascade CDO-28 Dry & Decarb Oven This item carries up to a 2 week lead time. Cascade’s CDO-28 is purpose-built for large-scale, industrial decarboxylation of material with additional features: 28 Cu. Ft. Built-in Humidity Sensor assists in dryness targets Stay in place sliding extension shelves NRTL Certification 6 each FDA & temperature rated fine micron mesh bags for ground material – Mesh bags are required to prevent oven contamination and material loss. This powerful, large capacity forced air laboratory oven uses heated air to remove unwanted compounds from products that are not temperature sensitive. Our ovens feature horizontal airflow that enables more consistent distribution of air. They are designed to have uniform temperatures and airflow across the shelf space from right to left. The CDO-28 includes a built-in humidity sensor and fine micron mesh bags for drying or decarboxylating powders or ground material. Ideal Uses: Industrial scale forced-air convection drying below 149ºC / 300ºF Decarboxylation processes Drying organic material. Drier material will yield better results than processing wet material. Removing as much moisture as possible pre-processing will save time in the post process of vacuum purge and winterization. Lab glassware dryer Model CDO-28 Features Horizontal Airflow. The airflow moves uniformity across the shelf space from right to left Digital set-point control, timer and overtemp failsafe protection Humidity sensor displays relative humidity levels during process Includes 6 sliding, extend and stay in place shelves for ease of loading. Stainless Steel. Includes 6 temp-rated, fine micron mesh bags for easy loading & uniform drying of messy powders, ground up or turbulent materials Fast heat-up: 24 Minutes to 149ºC (300°F) / Uniformity: +/- 2ºC (3.5°F) Stainless steel interior / Food lab grade construction. 301 SST Shelves Triple wall construction meets CE, UL and TUV requirements to keep work-spaces cool. Quality Made in Oregon USA 1 Year Warranty The Cascade Difference Basic forced-air lab ovens are mass-produced and sold by many large scale laboratory equipment distributors. But there are key differences between Cascade and other less costly, often imported lab ovens: Independent Overtemp Failsafe Protection The Cascade Sciences CDO-28 is equipped with a heating cutoff system that will automatically stop power to the heaters when the overtemp setting is tripped. This protection system will provide peace of mind for overnight or unattended drying processing. NRTL Certification. No Extra cost. The CDO-28 Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities. CAN/CSA-C22.2 No. 61010-1:2012+UPD No. 1:2015-07 + UPD No. 2:2016-04CAN/CSA-C22.2 No. 61010-2-010:2015UL 61010-1:2012-05UL 61010-2-010:2015EN 61010-1:2010EN 61010-2-010:2014 Rigorous Quality Assurance in an ISO Certified, USA Manufacturing Facility Cascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment: Electrical & mechanical safety is thoroughly tested in compliance with TUV requirements Functional testing verifies user settable items consistent with most lab protocols/usage models Temperature verification includes calibration & temp chamber uniformity following ASTM standards Units are cleaned and packed in ISTA tested, certified packaging materials Specifications Capacity Volume 28 Cubic Ft. (793 Cubic Liters) Interior 31.5″W x 60.5″H x 26″D 800mm x 1,537mm x 661mm Exterior 43”W x 85.5”H x 34.3”D 1,092mm x 2,171mm x 871mm Temperature Temperature Range 2.2ºC (36°F) above room temp to 148ºC (300°F) Temperature Stability +/- 2ºC (+/-3.5°F) Temp Recovery @ 240°F *Load Dependent* Door Open 30 Seconds: 3 min to stabilize Door Open 60 Seconds: 5 min to stabilize Power 230V – 240V / 1ph / 26AMP Oven Must Be Hardwired By Electrician Oven will also run on 208V BTUs Per Hour at Max Power 18,425 BTUs Air Stats Air Intake Adjustable. Top 2.75” Diameter Air Exhaust Adjustable. Top 2.75” Diameter Linear Shelf Space Airflow 17.1 cubic ft per min Shelving Quantity Included 6 each. Height adjustable. Surface Area 31”W x 23”D (787mm x 584mm) Weight Capacity 75 lbs (34 kg) Mesh Bags Quantity Included Comes with 6 Temp Rated Mesh Bags Dimensions 27.5″W x 21.5″D (699mm x 546mm) Polypropylene (PP) Melt Temperature 161°C (363°F) Softening Point 152°C (305°F) Heat Deflection Temperature 90°C (194°F) Glass Transition Temperature 0°C (32°F) * Mesh bags are REQUIRED to prevent oven contamination and ground material loss. * Polypropylene products produced for some filtration applications are made from resin that complies with FDA regulations for food contact. The regulation compliance is product number dependent / specific. * Impact at cold temperatures is likely to cause strand cracking or breakage Weight Product Weight 565 lbs (256 kg) Shipping Weight 640 lbs (290 kg) Certifications ISO 9001NRTL TUV #U8 170464972 077CAN/CSA-C22.2 No. 61010-1:2012+ UPD No. 1:2015-07 + UPD No. 2:2016-04CAN/CSA-C22.2 No. 61010-2-010:2015UL 61010-1:2012/R:2016-04UL 61010-2-010:2015EN 61010-1:2010EN 61010-2-010:2014 Warranty 1 Year Additional Resources: Download P-Trap Exhaust Tutorial View NRTL Certification

$15,997.00

Cascade CDO-5 Dry & Decarb Oven, 5 cu ft, 2 Mesh Bags

Cascade CDO-5 Dry & Decarb Oven, 5 cu ft, 2 Mesh Bags This item carries up to a 2 week lead time. Cascade’s CDO-5 is purpose-built for bench-top, R&D drying and decarboxylation of material with additional features: Built-in Humidity Sensor assists in monitoring dryness Adjustable stainless steel shelves – 2 each NRTL Certification 2 each FDA temp rated fine micron mesh bags for ground material – Mesh bags are required to prevent oven contamination and ground material loss. This powerful benchtop forced air laboratory oven uses heated air to remove unwanted compounds from products that are not temperature sensitive. Our ovens feature horizontal airflow that enables more consistent distribution of air. They are designed to have uniform temperatures and airflow across the shelf space from right to left. The CDO-5 includes a built-in humidity sensor and fine micron mesh bags for drying or decarboxylating powders or ground material. Ideal Uses: R&D, laboratory scale forced-air convection drying Decarboxylation processes Drying organic material. Drier material will yield better results than processing wet material. Removing as much moisture as possible pre-processing will save time in in the post process of vacuum purge and winterization. Lab glassware dryer Model CDO-5 Features Horizontal Airflow. The airflow moves uniformity across the shelf space from right to left Digital set-point control, timer and overtemp failsafe protection Humidity sensor displays relative humidity levels during process Stainless steel interior / Food lab-grade construction 1 Year Warranty Includes 2 stainless steel shelves, height adjustable with mounting clips Includes 2 temp rated mesh bags for easy loading & uniform drying of messy powders, ground up or turbulent materials Triple wall construction the CDO-5 meets CE, UL and TUV requirements to keep work-spaces cool Quality made in Oregon USA 120V / 1ph / 14FLA NEMA 5-15P Plug Supplied (220V 1 PH Version available) The Cascade Difference Basic forced-air lab ovens are mass-produced and sold by many large scale laboratory equipment distributors. But there are key differences between Cascade and other less costly, often imported lab ovens: Independent Overtemp Failsafe Protection The Cascade Sciences CDO-5 is equipped with a heating cutoff system that will automatically stop power to the heaters when the overtemp setting is tripped. This protection system will provide peace of mind for overnight or unattended drying processing. NRTL Certification No Extra cost. The CDO-5 Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities. CAN/CSA-C22.2 No. 61010-1:2012 +UPD No. 1:2015-07 + UPD No. 2:2016-04 CAN/CSA-C22.2 No. 61010-2-010:2015 UL 61010-1:2012-05 UL 61010-2-010:2015 EN 61010-1:2010 EN 61010-2-010:2014 Rigorous Quality Assurance in an ISO Certified, USA Manufacturing Facility Cascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment: Electrical & mechanical safety is thoroughly tested in compliance with TUV requirements Functional testing verifies user settable items consistent with most lab protocols/usage models Temperature verification includes calibration & temp chamber uniformity following ASTM standards Units are cleaned and packed in ISTA tested, certified packaging materials Specifications Capacity Volume 4.9 Cubic Ft. / 138 Cubic Liters Interior Dimensions 21” x 19.44” x 20.75”534mm x 494mm x 527mm Exterior Dimensions 34.1” x 28.1” x 38.75”866mm x 711mm x 984mm Temperature Temperature Range +2°C (36°F) above room temp to 180°C (350°F) Temp Stability +/-0.4 °F Temp Uniformity @ 40°C (100°F): +/- .5°C (1°F)@ 115°C (240°F): +/- 1°C (1.5°F)@ 150°C (305°F): +/- 2°C (3°F) Heat up / Stabilization Time from 25°C (77°F) to 115°C (240°F) 40 minutes Air Statistics Airflow Exchanges 220 per hour @ 80°C (176°F) Linear Shelf Space Airflow 145 Feet Per Min (44 Liters Per Min) Air Intake Adjustable side vents. Air Exhaust Adjustable. Top 2.75: Dia Exhaust Airflow @ 80°C (176°F) 18.5 Feet Per Min (523.9 Liters Per Min) Shelving 18.5 Feet Per Min (523.9 Liters Per Min) Fits 5 maximum Surface Area (W x D): 20.75″ x 19″ Weight Capacity: 50lbs Bags Comes with 2 Temp Rated Mesh Bags, fits four max Material Polypropylene (PP) Melt Temperature 161°C (363°F) Softening Point 152°C (305°F) Heat Deflection Temperature 90°C (194°F) Glass Transition Temperature 0°C (32°F) * Mesh bags are REQUIRED to prevent oven contamination and ground material loss. * Polypropylene products produced for some filtration applications are made from resin that complies with FDA regulations for food contact. The regulation compliance is product number dependent / specific. * Impact at cold temperatures is likely to cause strand cracking or breakage Certifications ISO 9001NRTL TUV #U8 170464972 077CAN/CSA-C22.2 No. 61010-1:2012+ UPD No. 1:2015-07 + UPD No. 2:2016-04CAN/CSA-C22.2 No. 61010-2-010:2015UL 61010-1:2012/R:2016-04UL 61010-2-010:2015EN 61010-1:2010EN 61010-2-010:2014 Warranty 1 Year

$7,607.00

Cascade CVO-10 Vacuum Oven

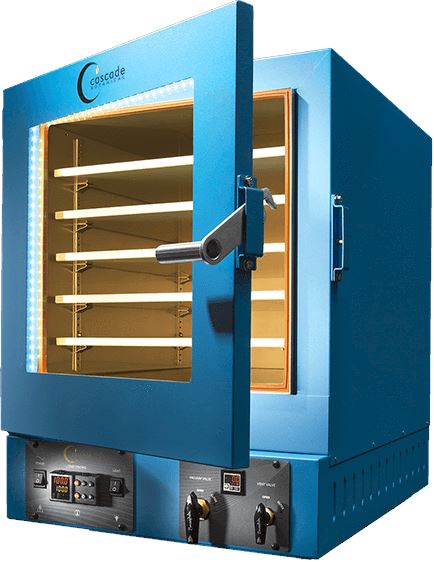

Cascade CVO-10 Vacuum Purge Oven (On Stand) This item carries up to a 1-2 week lead time. Cascade’s Model CVO-10 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, and slurries – especially temperature sensitive material. This vacuum oven liberates solvents, water, and other unwanted compounds. It’s ideal for large batch production environments. Processing Temperature Sensitive Material? The CVO-10 comes in both low temp & high temp versions. Be sure to get the low temp CVO-10 version that has excellent temperature uniformity for products such as pharmaceuticals, slurries or any product that can be damaged or destroyed by temperature fluctuations. CVO-10 Vacuum Oven Features NRTL Certified by TUV 9 sliding, removable shelves that pull out and stay in place for easy load/unload Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Easy mobility as oven sits on heavy duty industrial cart. Pump sits underneath at base of cart. VITON door gasket Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reads in inches of mercury or torr Smooth, quarter-turn vent valve Rear KF-25 port includes MAX EVAP Connection Kit for rapid vacuum drying or running feedthroughs inside oven for monitoring 220V / 1ph / 10AMPS Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Ergonomic. Turn vacuum pump on/off from oven control panel Fast Venting with larger ½” diameter vent line Rear vent barb allows for nitrogen or other inert gas connection Touch Panel LED control screen with user settable features The Cascade Difference Vacuum ovens have been around for decades. Basic vacuum ovens are mass-produced and sold by many large laboratory equipment distributors. But there are key differences between Cascade and other less costly, often imported vacuum ovens. Exceptional Temperature Control & Stability The Cascade CVO-10 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-10 eliminate hot and cold spots, making accurate use of every inch of shelf space. Independent Overtemp Failsafe Protection The Cascade Sciences CVO-10 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 392°F or 200°C. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. NRTL Certification #U8 170464972 077. No Extra cost. The CVO-10 Vacuum Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities. CAN/CSA-C22.2 No. 61010-1:2012 +UPD No. 1:2015-07 + UPD No. 2:2016-04 CAN/CSA-C22.2 No. 61010-2-010:2015 UL 61010-1:2012/R:2016-04 UL 61010-2-010:2015 EN 61010-1:2010 EN 61010-2-010:2014 Rigorous Quality Assurance in an ISO Certified, USA Manufacturing Facility Cascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment. Chambers are vacuum tested after welding for vacuum integrity Electrical & mechanical safety is thoroughly tested in compliance with TUV requirements Functional testing verifies user settable items consistent with most lab protocols/usage models Temperature verification includes calibration & temp chamber uniformity following ASTM standards Units are cleaned and packed in ISTA tested, certified packaging materials Digital Vacuum Gauge The digital vacuum gauge installed on the CVO-10 displays in is factory default set to read in inches of mercury (“Hg) or torr. Log Temperature & Vacuum With Data Port The CVO-10 features a rear mounted data port which outputs a digital log line once per minute. Viewing/logging this data requires terminal emulator software such as the open source (BSD License) emulator Tera Term. Equipped for Inert Gas Backfill. Built-In Safety Relief Introduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the ¼” rear vent barb. The maximum backfill pressure is 15PSI. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection Ports For faster evaporation, purging or drying the CVO-10 includes Cascade’s MAX EVAP connection kit. The MAX EVAP connection kit secures to the oven’s rear 1” dia KF-25 port located on the back center of the chamber. The MAX EVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthrus, or monitoring sensors inside the vacuum chamber during processing. Ergonomically Designed, Easy Quarter-Turn Valves For anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vent valve. Your wrists will thank you! Faster Venting With Large ½” Diameter Vent Lines For large capacity production environments, time is money. The CVO-10 vacuum oven has larger than industry standard vent lines. ½” diameter vent lines means operators spend less time venting the oven. ANSI Rated Tempered Glass + USA Made Steel Cascade ovens are made in Oregon, USA with high quality materials. Our glass is NGI-USA Tempered and certified to ANSI Z97.1.2007 16CFR / 201 11. Our door handles are rugged brushed steel, not plastic. Our vacuum vessels are constructed with American made steel. We’ve tried lower cost, imported steel. But over time, vacuum chambers made of lesser quality/lower tolerance material cannot withstand the flex and pressure changes of vacuum pumping/venting/purging. This can deteriorate vacuum integrity and the oven will lost its ability to hold vacuum. Need A Complete CVO-10 Vacuum Drying or Purge System? Cascade has taken the guesswork out of pairing the right vacuum oven with the proper pump. We offer two complete 10 cubic foot vacuum oven packages that have everything you need to begin vacuum drying on a large scale. The CVO-10 PRO Package pairs the CVO-10 with the clean, quiet, powerful Agilent IDP15 vacuum pump. Purchase the CVO-10 PRO Package and save $1642.86 over retail. The CVO-5 DOUBLE UP Package offers the same 10 cubic foot processing capacity, but in two ovens for smaller, multiple batch management. The TVO-5 DOUBLE UP Package is also self-contained on its own mobile, industrial cart. The TVO-5 DOUBLE UP Package saves $1642.86 over retail. A Vacuum Cold Trap for High Production Environments For high production environments, adding a vacuum cold trap keeps the vacuum pump running optimally, extends time between maintenance and allows reclamation of outgassed materials. Cascade’s MAXTRAP50 is ideally suited for trapping in these high production environments where typical lab grade traps, with small inlets and outlets can slow things down. Specifications Capacity Volume 9.3 Cubic Ft. / 264 Liters Interior 28”W x 24”D x 24”H 711mm x 609mm x 609mm Exterior (Not Including Rack) 44”W x 42”D x 40”H 1118mm x 1067mm x 1016mm 67.6”H with stand Temperature Ranges Low-Temp Processing Range 26°F to 250°F (121°C) Temperature Uniformity +/- 1.5°F @ 105°F (40.5°C) Temperature Stability +/- 0.4°F @ 105°F(40.5°C) Heat Up / Stabilization Time to 250°F 120 minutes (to minimize overshoot) High-Temp CVO-10 (SVAC 9.3) to 428°F / 220°C Available Temperature Uniformity +/- 6.5% of setpoint *Note that ambient laboratory conditions can affect temp performance. Vacuum Valve Type Side Mounted Round Vent Valve Sizes ¼ Turn Lever ½” diameter line Lighting Interior LED Strips (Rated to 150C) On low temp CVO-10 only Window Type Glass Tempered NGI-US to ANSI Z97.1.2007 Vacuum Gauge Indication Reads in inches mercury or torr(Selectable) Temperature Controller Screen Type Touch Screen Accuracy Accurate Within 1°F Failsafe Independent Overtemp Failsafe Ports-Rear Vacuum KF-25 Port Vent 1/2” Barb Data Log temp & vacuum levels Inert Gas Introduction Yes. Via 3/8” Vent Barb 15 psi max inlet pressure Power Options Power 220V – 240V / 1ph / 10A 50/60Hz Cord? Cord Included Outlet Type NEMA 6-15R Power Outlet Shelving Removable? Removable Quantity Included Comes with 9 Each. Fixed. Detail Slide on rails, extend, stay in place. Surface Area 28″W x 24″D Weight Capacity 50 lbs Weight Net Weight 663 lbs / 300.1 Kg Shipping Weight 995 lbs / 351.5 Kg Shipping Details Dimensions 63″L x 60″W x 88″H Class Class 110 Certifications - ISO 9001 - NRTL TUV #U8 170464972 077 - CAN/CSA-C22.2 No. 61010-1:2012 - + UPD No. 1:2015-07 + UPD No. 2:2016-04 - CAN/CSA-C22.2 No. 61010-2-010:2015 - UL 61010-1:2012/R:2016-04 - UL 61010-2-010:2015 - EN 61010-1:2010 - EN 61010-2-010:2014 Warranty Length 1 Year Exclusions Gaskets Not Incuded Dimensional Drawing Download Oven Manual Download DCS Controller Manual View NRTL Certification Contoller Software

$24,997.00

Cascade CVO-5 Vacuum Oven

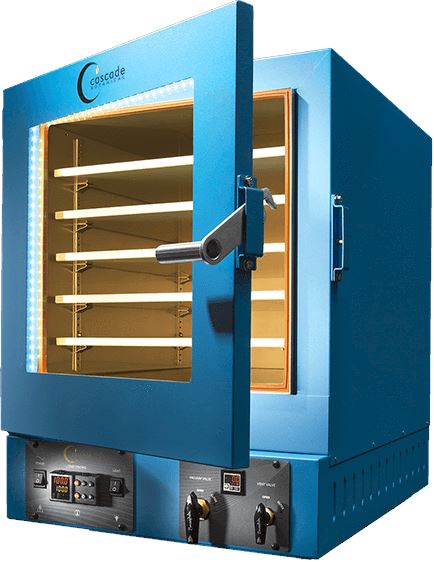

Cascade CVO-5 Vacuum Oven (Oven Only) This item carries up to a 1-2 week lead time. Cascade’s Model CVO-5 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, slurries, or any temperature sensitive material. This vacuum oven liberates solvents, water, and other unwanted compounds. It’s ideal for small batch, R&D and laboratory environments. Processing Temperature Sensitive Material? The CVO-5 comes in both low temp & high temp versions. Be sure to get the low temp CVO-5 version that has excellent temperature uniformity for products such as pharmaceuticals, slurries or any product that can be damaged or destroyed by temperature fluctuations. Low & High Temp Specifications Low Temp Specs Temperature Processing Range 26°F to 250°F (121°C) Temperature Uniformity +/- 1.5°F @ 105°F (40.5°C) Temperature Stability +/- 0.4°F @ 105°F(40.5°C) High Temp Specs Temperature Processing Range Up to 428°F / 220°C Temperature Uniformity +/- 6.5% of setpoint At time of order we will verify the high / low temp version best suited to your requirements. CVO-5 Vacuum Oven Features NRTL Certified by TUV 5 each adjustable shelves Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Solvent resistant BUNA door gasket Bright LED lights in window for visibility of sensitive material Touchscreen LED Control Panel with adjustable settings Smooth, quarter-turn vacuum and vent valves Energize vacuum pump from control panel Rear KF-25 port allows for rapid MAX EVAP purging or running feedthroughs inside oven for monitoring 120V or 220V power options are available Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Adjustable leveling feet insure your unit sits solid and level in the workspace The Cascade Difference Vacuum ovens have been around for decades. Basic vacuum ovens are mass-produced and sold by many large laboratory equipment distributors. But there are key differences between Cascade and other less costly, often imported vacuum ovens. Exceptional Temperature Control & Stability The Cascade CVO-5 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-5 eliminate hot and cold spots, making accurate use of every inch of shelf space. Touchscreen LED Smart Controller The CVO-5 controller is a flat panel touch screen with built-in, controls that minimze temperature overshoot. When the oven door is open, the controller will wait and not agressively call for heat to attempt to keep the oven interior stable. When the oven is being vented, the controller will pause as to not over-react and overshoot temperature during this temporary event. Read Temperature in degrees Celcius or Fahrenheit Read Vacuum in Torr or Inches of Mercury Energize Vacuum Pump From Oven Control Panel Turn the vacuum pump off and on from the oven control panel. No more reaching around, behind, beside to turn the vacuum pump off an on. Vacuum pump plugs directly into the back of the oven’s auxillary outlet. Independent Overtemp Failsafe Protection The Cascade Sciences TVO-5 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 392°F or 200°C. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. Log Temperature & Vacuum With Data Port The TVO-5 features a rear mounted data port which outputs a digital log line once per minute. Viewing/logging this data requires terminal emulator software such as the open source (BSD License) emulator Tera Term. NRTL Certification #U8 170464972 077. No Extra cost. The TVO-5 Vacuum Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities and is often an extra charge on low cost ovens. CAN/CSA-C22.2 No. 61010-1:2012 +UPD No. 1:2015-07 + UPD No. 2:2016-04 CAN/CSA-C22.2 No. 61010-2-010:2015 UL 61010-1:2012/R:2016-04 UL 61010-2-010:2015 EN 61010-1:2010 EN 61010-2-010:2014 Rigorous Quality Assurance in an ISO Certified, USA Manufacturing Facility Cascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment. Chambers are vacuum tested after welding for vacuum integrity Electrical & mechanical safety is thoroughly tested in compliance with TUV requirements Functional testing verifies user settable items consistent with most lab protocols/usage models Temperature verification includes calibration & temp chamber uniformity following ASTM standards Units are cleaned and packed in ISTA tested, certified packaging materials Equipped for Inert Gas Backfill. Built-In Safety Relief Introduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the ¼” rear vent barb. The maximum backfill pressure is 15PSI. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection Ports The TVO-5 ovens offer two different vacuum oven connection points. The standard connection is a 3/8th dia barb located at the rear of the oven. It is connected to the vacuum valve level on the front control panel. For even faster evaporation, purging or drying consider upgrading to the MAX EVAP connection kit. The MAX EVAP connection kit secures to the oven’s rear 1” dia KF-25 port located on the back center of the chamber. The MAX EVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthrus, or monitoring sensors inside the vacuum chamber during processing. Ergonomically Designed, Easy Quarter-Turn Valves For anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vacuum/vent valves. Your wrists will thank you! ANSI Rated Tempered Glass + USA Made Steel Cascade ovens are made in Oregon, USA with high quality materials. Our glass is NGI-USA Tempered and certified to ANSI Z97.1.2007 16CFR / 201 11. Our door handles are rugged brushed steel, not plastic. Our vacuum vessels are constructed with American made steel. We’ve tried lower cost, imported steel. But over time, vacuum chambers made of lesser quality/lower tolerance material cannot withstand the flex and pressure changes of vacuum pumping/venting/purging. This can deteriorate vacuum integrity and the oven will lose its ability to hold vacuum. Model CVO-5 Vacuum Oven Specifications: Capacity Volume 4.5 Cubic Ft. Interior 18”W x 24”D x 18”H 457mm x 609mm x 457mm Exterior 26.5” W x 34.5” D x 32.3”H 673mm x 876mm x 819mm Temperature Range Low-Temp Processing Range 26°F to 250°F (121°C) Temperature Uniformity +/- 1.5°F @ 105°F (40.5°C) Temperature Stability +/- 0.4°F @ 105°F(40.5°C) Heat Up / Stabilization Time to 250°F: 120 minutes (to minimize overshoot) High-Temp Processing Range 428°F / 220°C available Temperature Uniformity +/- 6.5% of setpoint *Note that ambient laboratory conditions can affect temp performance. The TVO-5 (CVO-5) comes in both low temp and high temp versions. The low temp version has excellent temperature uniformity for temperature sensitive material. The higher temp version, 220°C has a uniformity about 6.5% of setpoint. At time of order we will verify the high / low temp version you require. INTERIOR LIGHTING - LED Strips (Rated to 150C) GLASS WINDOW - Tempered NGI-US to ANSI Z97.1.2007 Temperature Controller Touch Screen Accurate Within 1°F Independent Overtemp Failsafe Rear Ports Vacuum 3/8th Barb Vent ¼” Barb Auxiliary KF-25 Port Data: Log temp & vacuum levels INERT GAS INTRODUCTION - Yes. Via ¼” Vent Barb. 15 psi max inlet pressure Power Options 110V – 120V / 1ph / 14A 50/60HzCord IncludedNEMA 5-15 Power Outlet 1105 BTU/hrRating at max power 220V – 240V / 1ph / 7A 50/60HzCord IncludedNEMA 6-15R Power Outlet 1228 BTU/hrRating at max power Included Accessories 5 Shelves 20 Clips 4 Leveling Feet Power Cord Door Gasket 18” x 18” Comes with Solvent Resistant BUNA Standard rated to221°F to 105°C Compatible With:High Temp Silicone rated to 446°F to 230°C Viton rated to 401°F to 205°C Weights & Shipping Weight 360 lbs / 163.3 Kg Shipping Weight: 449 lbs / 207.3 Kg 41”L x 41”W x 45”H Class 85 Certifications ISO 9001 NRTL TUV #U8 170464972 077 CAN/CSA-C22.2 No. 61010-1:2012 + UPD No. 1:2015-07 + UPD No. 2:2016-04 CAN/CSA-C22.2 No. 61010-2-010:2015 UL 61010-1:2012/R:2016-04 UL 61010-2-010:2015 EN 61010-1:2010 EN 61010-2-010:2014 Warrenty 1 Year (gaskets not included) Package Specs CVO-5 Manual CVO-Dimentions CVO-5 Calibration Procedure NRTL Certification Vacuum Pressure Chart

$11,398.00

Cascade 20L Bead Bath with 15L Lab Armor Beads

Cascade 20L Bead Bath Bye-Bye Water Bath! Traditional water baths are associated with messy condensation and the growing of harmful germicides. Cascade Sciences Bead Baths are the next generation of a decades-old lab bath technology. With the included thermal beads, this 20L Cascade Bead Bath operates in a constant, stable, broad temperature range between -80°C to +180°C. The bath itself delivers exceptional temperature uniformity up to 80°C. Zero Evaporation Saves Energy In a water bath, the water is constantly evaporating. As water evaporates, it cools. Because evaporation has a cooling effect, a water bath must heat more frequently. A bead bath uses 4X less energy when set to 65°C and 2X less energy at 37°C. The bead bath also provides more constant temperature with fewer temperature fluctuations during operation. Cascade Sciences Bead Baths and Thermal Beads and Made in the USA and NRTL Certified Cascade Sciences Bead Bath Features: High Thermal Efficiency Microbial/Biofilm Resistant Cross-Contamination Resistant Minimal Cleaning No Refilling No Rack or Accessory Needed Angled Incubation Possible Constant Volume – No Evaporation Non-Corrosive Compatible with non-water tight vessels Independent build-in over-temp, burn-out protection No Warm Up Mobile or Field Use Compatible Non-Combustible Thermal Beads Replace Water and Ice Lab Armor™ Thermal Beads are small, dry, metallic thermal beads designed to replace water in laboratory water baths and ice in ice buckets. Their high thermal conductivity technology is patented and improves energy efficiency of standard water baths by over 50%. Improve lab cleanliness when using thermal beads in place of fluid in water baths. Thermal Beads – Recyclable Lab Armor™ Thermal Beads are formed from solid recyclable metal. The raw material used in Lab Armor™ Beads can be reused in other products. Lab Armor™ Thermal Bead Features: Metal composition with smooth round surface Moisture and gas impermeable High thermal conductivity Working temperature range is -80°C to 180°C Non-toxic, non-vaporizing material Recyclable! Multiple uses – ice replacement Frequently Asked Questions Are Lab Armor™ beads autoclavable?They are not. The steam and pressure ruins the surface of the beads. We recommend a dry heat sterilization: 180°C for 2.5 hours. For a quick touch-up we recommend spritzing with 70% ethanol and stirring. If some debris falls into the beads we recommend placing them in a pail with water and a small about of Dawn, rinsing out multiple times, and then putting through the dry heat sterilization process. How long can I use Lab Armor™ Beads under normal conditions?Under normal conditions, Lab Armor™ Beads should last the life of the bath. If used incorrectly or if not maintained and cleaned properly, the surfaces of Lab Armor™ Beads can become damaged. We recommend that you avoid strong detergents, acids and bases. Bleach, for instance, may tarnish the surface of the Lab Armor™ Beads, reducing its fluidity and overall performance. Can Lab Armor™ Beads be used as an ice bath?There are a number of different ways to use thermal beads. Many customers place containers of beads in their refrigerators, incubators and ovens. When creating an ice bath, be sure to keep the beads dry. We recommend separating the beads from the ice packs, which accumulate condensation. Some kind of mesh wire or fabric helps with this as well. Also, any condensation that builds on the surface of the beads will be able to drip through the mesh. It’s important to keep the beads from soaking in water for extended periods of time. Besides attracting contamination, excessive water contact will tarnish the surface of the Beads and reduce the fluidity of the bath. Also, as an alternative to ice packs, dry ice can be used to make a colder bath (<0ºC).

$3,450.00

Silicone Door Gasket, 24in x 28in

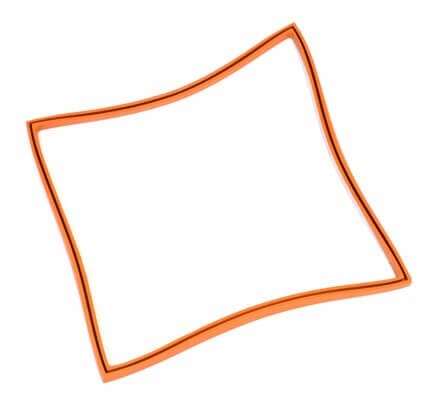

Silicone Door Gasket, 24in x 28in These 24″ x 28″ ORANGE colored door gaskets fit all Cascade CSO-10 vacuum ovens. They are made of cured silicone and are the highest temperature rated (230°C or 446°F) gaskets available for the CSO-10 vacuum oven.

$218.00

Cascade Vacuum Oven Door Gaskets

Cascade Vacuum Oven Door Gaskets Gaskets wear out. Remember to clean, rotate and have spares on hand! Our versatile collection of vacuum oven door gaskets is designed to fit the Cascade Sciences CVO-2 , CVO-5, and CVO-10 vacuum oven models, meeting your specific needs. Choose from our Solvent Resistant, VITON, and High Temp Silicone Door Gaskets, each offering superior performance! Features Viton Door Gaskets Available in sizes: 12″ x 12″ (CVO-2) and 18″ X 18″ (CVO-5) Material: VITON (FKM synthetic rubber and fluoropolymer elastomer) Max Temperature: 150°C / 302°F Ideal for Cascade 2 and 5cubic foot vacuum ovens Excellent resistance to solvents, oils, fuels, and mineral acids Low outgassing rate: 1 x 10-6 Torr-liter/cm2-s initial degassing rate Minimal weight loss of 0.07% after over 336 hours of vacuum exposure Exceptional UV resistance, protection against fungus, molds, and oxidation *The name VITON is a registered trademark of The Chemours Company Solvent Resistant Gaskets Available in sizes: 12″ x 12″ (CVO-2) and 18″ X 18″ (CVO-5) Material: BUNA (a material designed to withstand solvents) Max Temperature: 105°C / 221°F Ideal for Cascade 2 and 5 cubic foot vacuum ovens Application: Solvents Excellent resistance to many hydrocarbons, fats, oils, greases, hydraulic fluids, and chemicals High-Temp Silicone Door Gaskets Available in sizes: 12″ x 12″ (CVO-2), 18″ X 18″ (CVO-5), and 24″ X 28″ (CVO-10) Material: Silicone Max Temperature: 230°C / 446°F Ideal for Cascade 2 and 5 cubic foot vacuum ovens Application: General and High Temperature Resists moderate or oxidizing chemicals, ozone, and concentrated sodium hydroxide Specifications Viton Door Gaskets Available in sizes: 12″ x 12″ (CVO-2) and 18″ X 18″ (CVO-5) Color: Black Material: VITON (FKM synthetic rubber and fluoropolymer elastomer) Max Temperature: 150°C / 302°F Solvent Resistant Gaskets Available in sizes: 12″ x 12″ (CVO-2) and 18″ X 18″ (CVO-5) Color: Black Material: BUNA (a material designed to withstand solvents) Max Temperature: 105°C / 221°F High-Temp Silicone Door Gaskets Available in sizes: 12″ x 12″ (CVO-2), 18″ X 18″ (CVO-5), and 24″ x 28″ (CVO-10) Color: Orange Material: Silicone Max Temperature: 230°C / 446°F PRO TIP: Rotate your vacuum oven door gaskets for even wear and longer life.

$245.00 - $962.00

Cascade CVO-2 Vacuum Oven