Made by BVV

Best Value Vacs 1.5 Gallon Tall Stainless Steel Vacuum Chamber - W/GLASS LID

Best Value Vacs 1.5 Gallon Tall Stainless Steel Vacuum Chamber - W/GLASS LID This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User-friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 - 2B Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 8-5/8" Tall x 7-1/8" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. DOES NOT APPLY TO GLASS LID VERSION ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$115.00

Neocision Spectra Elite LED Grow Light - DLC Listed

Neocision Spectra Elite LED Grow Light ELITE Neocision Spectra Elite fixtures feature 20.6% blue spectra and 45.1% red spectra witha peak at 660nm for your flowering plants. This unique spectra mix creates stronger plants for nutrient uptake with maximized red for increased photosynthesis. Get increased yields, quality bud formation and high rates of cannabinoid production levels. Neocision Specta Elite Cutsheet DLC Qualified Product List Performance, Specs and Ranking FEATURES: Efficacy up to 2.85 Micromoles / J Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Folding Design for Fast and Easy Installation Leading 660nm LED Count – 150 660nm diodes Per Fixture 7 Year Limited Warranty on Fixture 8 Year Limited Warranty on Driver Looking for bulk purchases? We offer volume discounts and other value-adding services with our partners at RSX Enterprises. Call (331-281-0154) and speak with a rep for more information. SPECTRUM AND EFFICACY PPF Efficacy: 2.85 at 240 VAC Photon Flux (µmol/s) (400-700nm): 1939 Photon Flux Blue (µmol/s) (400-500nm): 400 Photon Flux Green (µmol/s) (500-600nm): 666 Photon Flux Red (µmol/s) (600-700nm): 874 Total Blue/Red - Energy Bands: 1274 % Blue: 20.64% % Green: 34.34% % Red: 45.06% POWER Power Consumption: 680W AC Driver: Sosen Power Factor: >0.95 Surge Protection: 6 KV 208V: 3.44A 240V: 2.98A 277V3: 2.58A DIMENSIONS Fixture Size (driver mounted on the fixture): (L) 43.9” x (W) 43.9” x (H) 4.1” Fixture Size (without driver): (L) 43.9” x (W) 43.9” x (H) 1.6” Power Supply Dimension: (L)23” X (W) 6.5” X (H) 3” Driver Net Weight: 10.1 lb. Fixture Net Weight: 20.4 lb. OTHER Mounting Height >6” above canopy Beam Angle 120 Degree Input Voltage 200 - 277 VAC Manual Dimming Knob Yes Built In Control Ports Yes Power Cord Length (Extensions available) AWG 18, 6 Foot Standard Plug 240 VAC - NEMA 6-15P Substitute Plugs (Upon request at order) 277 VAC, Pigtails Adjustable Height Hanging Kit Included Yes Fixture Warranty 7 Years Limited Driver Warranty 8 Years Limited ETL Safety Certified Conforms to UL 1598:2018 Ed.4Certified to CSA C22.2#250.0:2018 Ed.4*ETL Safety Certified No. 5020070 DLC Listed Yes

$550.00$496.00

10L Neocision ETL Lab Certified Rotary Evaporator

10L Neocision ETL Lab Certified Rotary Evaporator The 10L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 10L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware. Specifications: Model 10L Solvent Pro Series Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 220-240V 60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 20-130 RPM Set Temperature RT+5-99C Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 10L (10000ml) Receiving Flask Capacity 10L (10000ml) Condenser Style Main + Auxiliary Vertical Double Helix Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 3300w Dimensions 81 x 44 x 20 in. Weight 155 lbs Vacuum Connection 14mm / .55 in. Barb Condenser Connection 18mm / .70 in. Barb Warranty 90 days excluding glass parts Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$5,250.00$3,500.00

2 Gallon Aluminum SIDEMOUNT - POT ONLY

2 Gallon Aluminum - POT ONLY ***Note: 'with Hardware' Option only includes the side-mount manifold with gauge pre-installed. (Does Not Include Lid or Gasket) This is a replacement part for the following Vacuum Chambers: SVac 2 Gallon Aluminum Vacuum Chamber Best Value Vacs 2 Gallon Aluminum Side Mount Vacuum and Degassing Chamber Dimensions: 6.5" Tall x 10" Diameter Hole Size: 21/64 Material: 3004 Aluminum

$48.00 - $68.00

REFURBISHED BVV4D

Refurbished BVV™ V4D 4CFM Two Stage Vacuum Pump ***NOTE: Refurbished products are 100% re-tested at our warehouse to be fully functional. The customer acknowledges that by buying a refurbished product the item may have imperfections or slight damage to the product such as: Major/Minor Scratches Major/Minor Dents Smells or Odors (Cleaned as much as possible at warehouse) This is the BVV™ V4D 4CFM Two Stage Vacuum Pump used in botanical extraction. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Feature Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer oil life Lightweight Rubber Feet for noise dampening Reliable, economical, and efficient Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports Pump Warranty Information Customers using solvents such as stabilization resin, rotaries (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$340.00$200.00

AVS-16.75X6 Screen (No Housing) (Compare to Custom Cones)

AVS-16.75X6 Screen (No Housing) Description Please note that this screen is for use with Automtic Vibrating Sifter - Industrial 16.25 x 6" Machines ONLY. It is not compatible with the Automatic Vibrating Sifter - Commercial 15.50 x 4". Specifications: COMPATIBLE WITH: Automtic Vibrating Sifter - Industrial 16.25 x 6" (This is not compatible with the Automatic Vibrating Sifter - Commercial 15.50 x 4".) SCREEN DIAMETER: 16.75 Inches SCREEN DEPTH: 6 Inches HOLE SHAPE: Square

$80.00

Ethylene Glycol 99.9%

Ethylene Glycol 99.9%, also know as the trade name Mono-ethylene Glycol (MEG). Ethylene glycol (EG) is by far the most produced glycol product. This glycol is polyester grade which means its the highest purity 99.9% and is therefore the highest grade available. There are 3 grades available: : fibre, industrial and antifreeze. The markets for EG products are polyester fibres, polyethylene terephthalate (PET) plastics, coolants in automobile antifreeze, and resins. The excellent humectant (hygroscopicity) properties of EG products also make them ideal for use in fibres treatment, paper, adhesives, printing inks, leather and cellophane. Ethylene glycol is also a commonly used with fog generators or artificial smoke production. Ethylene Glycol Certificate of Analysis COA Ethylene Glycol Safety Data Sheet SDS

$18.00 - $2,450.00

BVV Table Top Cartridge Filler

The BVV tabletop cart filler has a fully heated stainless steel fluid path and dispenser for optimal performance. All contact surfaces are made of stainless steel and can be easily cleaned with BVV D-Limonene or Ethanol. The system comes fully assembled. The control box will control your motor plunger speed and the heat. The food pedal can be use continuously or intermittently. The syringe fills from 0.5ml- 3ml in 0.5ml increments. Tank Capacity: 1 Liter Filling Speed: 50 carts per min. Max Heat: 220°F Warm Up Time: 15 to 20 min. Connection Type: Lure-Lock *(Includes 2 starter tips) At BVV we keep 1 in stock In stock ready to ship today or for overnight express shipping!

$4,850.00

BVV Bead Bath

BVV Bead Bath Introducing the BVV's Bead Bath - A cost-effective Bead Bath for Precise and Contamination-Free Laboratory needs. The Bead Bath is a cost-effective bead bath that allows for precise temperature application to warm your extracts, distillates, and isolates faster than a traditional hot plate eliminating water contamination. Unlike traditional water baths, bead baths replace water with reusable metallic beads, eliminating the risk of experimental contamination and ensuring accurate results. With the Bead Bath, you can say goodbye to high electricity consumption and frequent cleanup. The bead bath's efficient design minimizes power usage, as the beads do not evaporate, and require less maintenance, saving you time and resources. Experience rapid start-up times and uniform heating with the Bead Bath's surround heating feature. This cutting-edge technology guarantees even temperature distribution, preventing hotspots and ensuring consistent and reliable outcomes for your samples. Safety is our top priority, and the Bead Bath is no exception. Equipped with over-temperature protection, this bead bath maintains safe and stable conditions for your valuable samples throughout the entire experiment. Discover the benefits of the BVV Bead bath and revolutionize your laboratory work with contamination-free, precise, and efficient temperature control. Join researchers and professionals worldwide in experiencing the power of the #1 bead bath ranked on Google. Upgrade your experiments with the BVV's Bead Bath. Bath internal dimensions: 2 quart: 6.75” Tall X 4.75” Diameter 1.5 Gallon: 8-5/8" Tall x 7-1/8" Diameter 3 Gallon: 9" Tall x 10" Diameter 7 Gallon: 8" Tall x 16" Diameter Does not include Beads If the option is selected to include aluminum beads, the quantities will be: 2 quart: 2 liters 1.5 Gallon: 4 liters 3 Gallon: 9 liters 7 Gallon: 18 liters

$130.00 - $2,075.00

Extraction RACK #7

Extraction RACK # 7 Rack 7 has 4.5" thick vertical support bars and 3x horizontal bars to complete our strongest standard extraction rack. This rack includes 4x locking caster wheels that can also be adjusted to be level on uneven surfaces. For ease of mounting equipment, we recommend our pipe hangers with hang on brackets Rack Dimensions (L x W x H) 30" x 39" x 60" (Assembled units come with a 30-day warranty) Note: The unit does not come assembled - select "pre-assembled" from the drop-down menu to have the unit assembled by BVV before shipping Pipe hangers are not included There is no warranty on unassembled units Shipping Notice: If the customer orders the rack as assembled, then the item will only ship via freight and there will be additional shipping charges.

$1,650.00

Kuritech 3/4 ID PVC Reinforced Braided Hose

Kuritech 3/4 ID PVC Reinforced Braided Hose 3/4" Flexible hose that is ideal for heat transfer applications utilizing mixtures of water and propylene glycol. Specifications: Max Pressure: 150 PSI @ 20° Working Temperature: -4°C - 65°C

$17.00 - $320.00

Large 1-Micron Refinement Filter

Large 1-Micron Refinement Filter Filter large volumes of solutions with ease with our Large 1-micron Refinement filter. complete with our 1-micron Dutch Weave sintered disk these refinement filters provide complete retention of the filter paper making it impossible for suspended particles to bypass the filter paper. Made from the highest quality 304 stainless steel parts this large refinement filter is built to last making it a great alternative to polypropylene filter trolleys. Our Large 1-Micron Refinement filter is available as a complete kit with and without the a Welch BTpro100 Diaphragm Pump. Processing Power Funnel Capacity: 22.24 Liters/5.88 Gallons Collection Capacity: 50 Liters/13.2 Gallons Specifications 12"x12" Funnel Body 12" 1um Dutch Weave Sintered Disk 12" Hemispherical Ring stand 1/2" JIC Drain Valve 50L Stainless Steel Carboy Collection base -30Hg Vacuum Gauge 1/2" JIC Vacuum Port 3/8" JIC Diptube Valve 1/4" JIC Butterfly Accessory Valve 350MM Ashless Filter Paper Silicone Gaskets

$2,300.00 - $5,600.00

BVV Gift Certificate

Don't know what to get for Christmas? Give a gift certificate

$10.00 - $500.00

Sleeved Recovery Tank

Sleeved Recovery Tank Built for optimized recovery performance and efficient use of dry ice, these sleeved recovery spools are the perfect prechilling and recovery solutions for hydrocarbon extraction. Available in 5LB,10LB, & 22LB butane capacities these sleeved recovery tanks are a great upgrade for any of our 1-5lb extractors. All models of our Sleeved Recovery tank come complete with a 1/2" JIC recovery port, a 1/4" JIC drain port, 2X 1/4" JIC accessories ports, 2X Borosilicate sight glasses, a single -30hg-250PSI Compound Pressure Gauge, and a 125 PSI ASME pressure relief valve to provide maximum compatibility and versatility across processing platforms. Specifications 6"x12", 6"x24", 12"x12" Sleeved spool Hemi ring stand with 1/4" JIC drain valve 2X Borosilicate Sight Glasses 1X 125 PSI ASME pressure relief valve 1X -30hg-250PSI Compound Pressure Gauges 1X 1/2" JIC Recovery Valve 2X 1/4" JIC Accessory Valves 1X JIC Drain Valve Maximum Pressure Rating: 125PSI

$1,000.00 - $1,800.00

55 Gallon Hash Ice Water Extraction Washing Vessel

BVV's 55 Gallon Ice Water Extraction Washing Vessel Made in USA Designed with durability and ease of use in mind our Ice Water Extraction Washing Vessels are manufactured from 16 gauge 304 stainless steel crafted with seamless welds for a 100% sanitary construction. Our easy drain barrels come complete with 4X 1.5" Triclamp drains mounted as low as possible for effortless draining of its 55-gallon volume capacity. Perfect for medium to large-scale ice water extraction labs this stand-alone vessel pairs nicely with Boldtbags Large Open Top Wash Bags & Boldt bags 44 gallon Lock-top Full Mesh Stackers. Processing Power Material Capacity Per Batch: 20-30LB Water Capacity: 55 Gallons Cycle Time: 60-90 Minutes Daily Extraction Capacity: Up to 60 lb, per 8-hour shift Specifications 23"x36" 55-gallon Stainless Steel Washing Vessel Seamless 304 Stainless Steel Construction 4X 1.5" Tri-clamp ports for draining, filling, temperature sensing, or sight glasses Performance Low-mounted drain ports for complete draining

$1,500.00

5/16-18 Grade 2 Steel Nylon Locknut - 5 Pack

5/16-18 Grade 2 Steel Nylon Locknut 5/16 - 18 Low Profile Lock Nut. This nut fits on vacuum chamber gauges and manifolds. SOLD AS A 5PACK

$2.00

50L Pre-Built Collection Base

50L Pre-Built Collection Base Designed with hydrocarbon extraction in mind. This pre-build collection base boasts a 50lb butane capacity at an 80% fill making it the perfect fit for extractors looking to process up to 10 lbs of biomass material at a 5:1 Butane to biomass ratio. Complete with 1/2" JIC drain and recovery ports, a 1/4" JIC accessory port, a -30hg -250 PSI compound gauge, and a 125 PSI ASME Pressure relief this collection base is versatile in use and highly compatible with most systems. A main staple in our Research & Development lab and standard with our 10LB ECO Closed Loop Extractor this 50L Pre-built Collection Base is perfect for anyone looking to expand their processing capabilities. For speedy hydrocarbon solvent recovery rates this reactor pairs well with our 11KW Express Extraction Heater for passive recovery rates past 1lb/min. Processing Power Volume: 50 Liters Capacity: 50LB of butane @80% Fill Maximum Pressure Rating: 125PSI Jacket Capacity: 15 liters Specifications 2X Borosilicate Sight glasses 1X 1/2" JIC Drain Port 2X 1/2" JIC Lid Ports 1X 1/4" JIC Lid Port 2X 1/2" Barbed Jacket Connections 1X 125 PSI ASME Safety Valve 1X -30hg-250PSI Compound Pressure Gauges

$2,000.00

5/16 USS Flat Washer

5/16 USS Flat Washer 5/16 replacement washer for vacuum chamber bulkheads made out of metal.

$0.50

$550.00

ASME 150L - 350 MAX working pressure, Pneumatic PSIG 385

ASME 150L - 350 MAX working pressure, Pneumatic PSIG 385 This is a custom manufactured made ASME Certified 150L Jacketed Solvent Tank with ASME Stamp and made out of 304 Stainless Steel. This base is designed to be configured to any application and can even be used as a solvent tank. This tank comes bare with no fittings and will hold 150LBS of liquid butane and is able to have fluid circulated around the outer jacket to increase recovery speeds in the extraction system. This unit also has welded lift points on the top of the tank. Specifications Material 304 Stainless Steel Certification: ASME MAWP @ 100°C / 212°F: Inside 350 PSI / 2.42 MPa Jacket 150 PSI / 1.1 MPa MDMT -40°C / -40°F MIN TEMP -20°F at 350PSI Butane Capacity 150LBS Connection Sizes: (3) 6" Tri-Clamp (2) 1.5" Tri-Clamp (2) 1/2" FNPT Weight 108LBS Outer Dimensions: 44.5" Tall 32.5" W x 32.5" L **This Item will ship Via FREIGHT ONLY.

$8,000.00

1LB EVO Closed Loop Extraction Kit

1LB Evo Closed Loop Extraction Kit (System comes with 1 yr. limited warranty) The EVO series of 1LB closed-loop extractors was designed with the evolution of stand-up extractors in mind. The aim of the EVO series of extractors is to provide unparalleled utility and ease of use within a traditional stand-up design. The EVO series was designed to tackle the two most common plights with stand-up extractors, difficulty in extract harvesting, and integration of adsorbent filtration. The Evo series accomplishes both through the use of its elevated extract pour spout and its optional inline color remediation column. Beyond the elevated pour spout and optional inline color remediation column. The EVO series aims to provide unbridled safety and solvent recovery speed through the integration of ASME pressure relief valves on both the material column and collection base standard and full bore 1/2" recovery lines found on the professional, elite, and active explorer models. The 1lb EVO Closed Loop Extraction kit comes complete with a top fill injection manifold including a compound gauge, a 125 psi ASME pressure relief valve, and two full bore ball valves complete with 2x 1/4" Male JIC connections on the explorer and both 1/4" & 1/2" Male JIC connections on the professional and elite models. Just below the injection manifold, all 1lb EVO models have a solvent dispersion plate that evenly disperses solvent into the 3"x 24" 1lb material column which is enclosed by 2x 100 micron Buna-N mesh gaskets. Both the Professional and Elite models come complete with an inline 3" x 6" color remediation column just below the material column with a 300-gram media capacity and a filter stack utilizing both a 5 micron & 1 micron sintered disk. Professional and Elite models also include 25-micron filter paper and a 500-gram sample of Pure-Flo B80 Below the 1lb material column and optional inline color remediation column the 1lb Evo includes the jacketed and elevated pour spout collection base that allows for easy extract harvesting and speedy solvent recovery. The elevated base can accommodate up to a 5:1 solvent to biomass ratio and accept a standard round pyrex dish or a small parchment paper boat below the pour spout. Upon completion of the run, extract removal is made easy by simply draining the extract from the elevated extract pour spout. Both the professional, elite, and active explorer models have increased solvent recovery capability from the jacketed collection base through full bore 1/2" recovery MJIC connections and stainless steel recover hoses. Beyond the larger recovery lines and inline color remediation column the 1lb EVO Elite options come paired with our ETL listed 5 liters Neocision heated circulator and the sleeved EVO recovery tank that allows for the pre-chilling of solvent and speedy solvent recovery, reaching sub 20 minute recovery times on high heat. All varients of the EVO Extraction Kits come equipped with a 1.9CFT vacuum oven, a 7CFM single-stage vacuum pump, a 5' HVAC hose, and an 8"x8" silicone pad. The Explorer & Professional models come with the ECO model vacuum ovens and the Elite versions equipped with the ETL list Neocision 1.9CFT vacuum oven. All EVO closed-loop extraction kits come available with an active recovery option including: BVV 2 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified BVV Large Condensing Coil 1/2" x 24" SS JIC Braided Hose (2) 1/2" x 48" SS JIC Braided Hose (2) 1/2" x 60" SS JIC Braided Hose Molecular Sieve Filter Drier BVV 5' HVAC Hose BVV Vacuum Tee ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. KEY BENEFITS Meets or exceeds all industry listed standards Versatile in running butane, propane, and other blended solvents Perfect for mid to large-scale extraction/production facilities Faster run times and less degradation in the process Easy extract harvesting using the elevated pour spout Inline color remediation Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry-level extractor on a budget. Comes with the jacketed and elevated collection base and 1/4" Male JIC connections on the injection manifold and collection base. The explorer options include a 1.9CFT ECO Vacuum Oven, a 5' HVAC hose, and a 7CFM single-stage vacuum pump. This model does not include the inline color remediation column or 1/2" Male JIC recovery/ injection connections. The Explorer model is forward compatible and can be easily upgraded to include 1/2" lines and the inline color remediation column. *This model does not come with a heated circulator* Professional: This model includes all the features of the explore model with the increased functionality of an inline color remediation column Just under the material column that comes with 25micron filter paper and a 500-gram sample of b80, an upgraded stainless steel recovery tank, and a full bore 1/2" Male JIC connection included on the injection manifold and collection base. The Professional extraction kit options include a 1.9CFT ECO Vacuum Oven, a 5' HVAC hose, and a 7CFM single-stage vacuum pump.*This model does not come with a heated circulator* Elite: The Elite series is the premium version of the Professional. It features the same 1/2" Male JIC, and inline color remediation column upgrades. But also includes the EVO recovery tank and 5 liter ETL listed Neocision heated circulator that allows for pre-chilling and speedy recovery of solvent. The Elite options include a 1.9CFT ETL Listed Neocision Vacuum Oven, a 5' HVAC hose, and a 7CFM single-stage vacuum pump. Passive: Passive recovery is the standard option on the extraction kit with the explorer model coming with 1/4" recovery lines and the professional and elite models coming equipped with 1/2" recovery lines. Active: The Active Recovery Upgrade Kit will increase recovery times by condensing the vapor a lot faster than just a hot/cold differential. All active models come equipped with 1/2" recovery lines and the inclusion of our BVV 2 Cylinder Butane recovery pump, BVV Large Condensing Coil, Molecular Sieve Filter Drier, and all the associated hosing to perform active recovery. Explorer Professional Elite Jacketed & Elevated pour spout collection base Jacketed & Elevated pour spout collection base Inline Color remediation column 25-micron filter paper 500 gram B80 sample 1/2" recovery lines 30# Stainless steel Recovery Tank Jacketed & Elevated pour spout collection base Inline Color remediation column 25-micron filter paper 500 gram B80 sample 1/2" recovery & Injection lines EVO Recovery Tank 5 liter ETL listed Neocision heated circulator with insulated hoses Unit Includes: Full bore injection Manifold complete with a compound gauge,125 PSI ASME pressure relief valve, and 2x 1/4" MJIC connections (1x1/2" MJIC connection on professional & elite models) 3"x24" 1lb Material column with solvent dispersal plate. 3"x6" Color remediation column 300g gram media capacity complete with a filter stack including 5 micron and 1 micron sintered disks (Professional & Elite model) 25-micron ashless filter paper (Professional & Elite) Jacketed & elevated collection base with extract pour spout 6" hemispherical collection base lid complete with borosilicate sight glasses, a compound gauge, 125 PSI ASME pressure relief valve, and full bore ball valves with MJIC Connections. 30# LP storage and recovery tank (Explorer) 30# stainless steel LP tank (Professional) & EVO Recovery tank (Elite) (1) 1/4" 72" FJIC Stainless Steel Injection hose (Explorer & Professional) 1/2" 96" FJIC Stainless Steel Injection Hose (Elite) (1) 1/4" 60" FJIC Stainless Steel Recovery Hose (Explorer) 1/2" 60" FJIC Stainless Steel Recovery Hose (Professional & Elite) High-pressure clamps Specifications: 3"x 24" 304 Stainless Steel Material Column-1lb capacity (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple 37 degree FJIC port connections 304 Stainless jacketed & elevated collection base Tri-Clamps at all interfaces make for a high pressure/standard pressure, easy-clean unit BUNA-N Gaskets are designed for Oil Processing Temp range -40-200F, and have superior solvent resistance Construction: All components are made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$4,275.00 - $10,979.00

300L ASME Single Jacket Solvent Tank 350psi Max - Bare

300L ASME Single Jacket Solvent Tank 350psi Max - Bare This is a custom manufactured made ASME Certified 300L Jacketed Solvent Tank with ASME Stamp and made out of 304 Stainless Steel. This base is designed to be configured to any application and can even be used as a solvent tank. This tank comes bare with no fittings and will hold 300LBS of liquid butane and is able to have fluid circulated around the outer jacket to increase recovery speeds in the extraction system. This unit also has welded lift points on the top of the tank. **This Item will ship Via FREIGHT ONLY. Specifications Material 304 Stainless Steel Certification: ASME MAWP @ 100°C / 212°F: Inside 350 PSI / 2.42 MPa Jacket 150 PSI / 1.1 MPa MDMT -40°C / -40°F MIN TEMP -20°F at 350PSI Butane Capacity 300LBS Connection Sizes: (3) 6" Tri-Clamp (2) 2" Tri-Clamp (2) 1/2" FNPT Weight 750LBS Outer Dimensions: 64" Tall 32" W x 32" L

$11,000.00

NEO Oven PID

NEO Oven PID Specifications NEO PID Temp Range: 0-225°F Temp Accuracy: +/- 1° Built-In Calibration: Yes Temp Display Unit: C or F Timer Range: 0-999 Electrical Requirements: 110v @ 60Hz Compatible Ovens: 09NEO / 19NEO / 32NEO / 75NEO Shipping Dimensions: 5 x 5 x 5 - 1lbs SKU: NEOPID

$200.00

Cryogenic 45L Centrifuge Extractor Kit

Cryogenic 45L Centrifuge Extractor Kit EXPECT 3-WEEK LEADTIME Cryogenic 45L Centrifuge Extractor Kit Overview: The BVV Cryogenic 45L Centrifuge Extractor Kit is a modular closed loop alcohol extraction system with low temperature extraction in mind. It features low temperature rated (-60°C) components including PTFE envelope gaskets, pneumatic diaphragm pumps and cryogenic rated ball valves for longevity. The centrifuge controller and motor are EX rated and come with supporting documents making it easier to get approved for operation. Load centrifuge bags with 8-15lb (10lb avg.) biomass and line them up for an efficient extraction process. This system makes repeatability easier by letting the operator control extraction parameters including soak/agitation time, spin dry time, target alcohol temperature, and different pore material bags and filtration socks in our Pressure Filtration System (PFS). The system also allows operators to re-direct the first wash back to the holding vessel to re-chill if needed and go for a second extraction. This allows full use of alcohol’s extraction ability and minimize time spent recovering solvent in a rotary evaporator or falling film. Users will have to dial in their parameters and washes based on biomass potency. Low temperature extraction leads to less refinement after the extraction process. Inline PFS allows for fine particulate refinement down to 1µm. Higher potency will require further post processing for the removal of unwanted compounds. NOTE: CHILLER AND AIR COMPRESSOR NOT INCLUDED IN THE KIT. CALL IN FOR RECOMMENDED CHILLER AND AIR COMPRESSOR. Insulation: Insulation package is included with the order but does not come installed upon arrival. Insulation included are straight tubing, tees, and elbows. BVV can install insulation as an add on prior to shipping the system out. This will also include color coordinated zip ties that help assembly process. Assembly diagrams will also be included with the system. Installation requires taping seams cutting tubing to length, and zip tying tees and elbows. Holding vessel and centrifuge are vacuum insulated via the jacket. Supporting documents included: Standard Operating Procedure for CF45L-CRYO-01 Centrifuge Wiring Instructions CF45L-CRYO-01 Manual CF45L-CRYO-01 Assembly Diagram Centrifuge Controller EX Certificate Centrifuge Motor EX Certificate Pneumatic Pump specification sheet with operating pressure/flow chart CALL IN TO SCHEDULE A FULL PRESENTATION WITH ONE OF THE CRYOGENIC 45L CENTRIFUGE EXTRACT KIT. QUESTIONS CAN BE ANSWERED BY OUR ENGINEERING TEAM. Specifications Centrifuge Controller Power Requirements 220v 1PH 60Hz, 20A Circuit Liquid Transfer Pumps Pneumatic (Compressor Required) Drum Volume 45L Drum Dimensions 17.7" (450mm) Diameter x 11-7/8" (300mm) Deep Centrifuge Bags Included 1 of Ea: 1, 10, 50, 100, 200 Micron Max Biomass Capacity 15lbs (6.8Kg), Recommended 10lbs Solvent Capacity per Run 17 Gallons Centrifuge Speed 1500 RPM Centrifuge Weight 794lbs (360Kg) Overall System Dimensions 12'6" x 13'8" x 71" (3810mm x 4166mm x 1804mm) **with chiller next to system System Temperature Rating -60C (-76F) Material in Contact with Solvent and Extract PTFE envelope, Silicone, 304SS, BIIR(butyl) *FDA & USDA compliant Footprint: NOTE: CHILLER INCLUDED IN EXTRACTION SPACE WILL NEED TO BE APPROVED FOR USE IN C1D2 SPACE. AIR COMPRESSOR FOR PNEUMATIC PUMPS NOT INCLUDED IN DIAGRAM.

$59,000.00

20L Neocision ETL Lab Certified Rotary Evaporator Turnkey System

20L Neocision ETL Lab Certified Rotary Evaporator Turnkey System 20L NEO Rotary Evaporator Turnkey System setup includes all the necessary components to successfully perform solvent recovery via rotary evaporation. A cold trap should always be used inline between your vacuum system and application to protect the pump from volatile vapors. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram 20L NEO Rotary Evaporator Turnkey System setup includes: 20L Neocision ETL Lab Certified Rotary Evaporator Polyscience 6160T 1HP Chiller 3/8" Gum Rubber - 25ft 3/8" Tubing - 25ft Welch BTpro100 Diaphragm Pump Adjustable Stainless Steel Hose Clamps Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$19,450.00 - $22,500.00

10L Premium Short Path Distillation Kit with P10 Distillation Head

10L Short Path Distillation Kit with P10 Distillation Head This unit carries a 2 day lead time. (Note: Stainless Steel Table NOT Included.) The 10L Short Path Distillation Kit features our USA made P10 Distillation Head. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Kangaroo digital thermometer which is very rugged and reliable. You will also receive a Ribbed Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Kit gives you the basic necessities of a short path distillation system and allows you to add on a temperature control system and vacuum pump to fit your needs. The 10L Neo Kit Includes: 10L Short Path Distillation Kit including glassware, labware, and P10 Distillation Head. 10L Digital Heating and Stirring Mantle. Valved Vacuum Adapter. Ribbed Dewar Style Glass Cold Trap. Kangaroo Digital Thermometer. Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$4,100.00

ASME Certified 50L Jacketed Solvent Tank 304L - Bare

ASME Certified 50L Jacketed Solvent Tank 304L - Bare This is a custom manufactured USA made ASME Certified 50LB Jacketed Collection base with UM Stamp and made out of 304L Stainless Steel. This base is designed to be configured to any application and can even be used as a solvent tank. This tank comes bare with no fittings and will hold around 50LBS of liquid butane and is able to have fluid circulated around the outer jacket to increase recovery speeds in the extraction system. **This Item will ship Via FREIGHT ONLY. Specifications Material 304L Stainless Steel Certification: ABILITY ENGINEERING TECHNOLOGY INC. ASME / UM / NB MAWIWP 350 PSI at 150°F MAWEWP N/A MIN TEMP -20°F at 350PSI Butane Capacity ~50LBS Connection Sizes: 6" Tri-Clamp (2) 1" NPT (2) 1/2" NPT - Outer Jacket Ports (2) 3/8" NPT Weight 146LBS Outer Dimensions: 32-7/8" Tall 14" Diameter Inner Dimensions: 24" Tall 12" Diameter

$1,800.00$1,000.00

3 Gallon Aluminum SIDEMOUNT - POT ONLY

3 Gallon Aluminum SIDEMOUNT - POT ONLY ***Note: 'with Hardware' Option only includes the side-mount manifold with gauge pre-installed. (Does Not Include Lid or Gasket) This is a replacement part for the following Vacuum Chambers: Best Value Vacs 3 Gallon Aluminum Side Mount Vacuum and Degassing Chamber Glass Vac 3 Gallon Aluminum Vacuum Chamber Dimensions: 9" Tall x 10" Diameter Hole Size: 21/64 Material: 3004 Aluminum

$50.00 - $70.00

2L BVV™ Rotary Evaporator Turnkey Setup

2L BVV™ Rotary Evaporator Turnkey Setup 2L Electric Lift Rotary Evaporator turnkey setup includes all the necessary components to successfully perform solvent recovery via rotary evaporation. A cold trap should always be used inline between your vacuum system and application to protect the pump from volatile vapors. 2L Rotary Evaporator Turnkey Setup includes: 2L Electric Lift Rotary Evaporator 90-day limited warranty (excludes glassware, consumables & moving parts) BVV NEO 1.4 CFM Diaphragm Pump ETL Rated OR. 3.5CFM Dry Floating Scroll Vacuum Pump Polyscience LS -20C to 40C 1/2HP Chiller w/ Turbine Pump OR BVV NEOCISION 20L Chiller (-40C) - ETL Rated 10ft of Vacuum Tubing 20ft of Chiller Tubing 10 Pack of Adjustable stainless steel hose clamps 3/8" Vacuum Manifold Optional add-on : BVV™ CT40 -40°F 300ml x 3 Cold Trap, BVV™ CT80 -112°F 300ml x 3 Cold Trap Optional add-on: J-KEM DVR-200 Digital Vacuum Regulator Optional add-on: Heat Transfer Fluid -- NuTherm PF-50 or Dynalene HC-50 Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to the condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of the condenser, chiller input to bottom of the condenser). Connect vacuum pump to cold trap and connect cold trap to the vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller, and cold trap have reached desired temperatures, turn on the rotovap motor and set the speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once the vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow the solution to enter the evaporating flask. At this point, you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$7,000.00 - $13,500.00

Sodium Bicarbonate (Baking Soda) USP/Food Grade

Sodium Bicarbonate USP No. 1 Powdered, a trusted and versatile product. Sodium Powdered sodium bicarbonate is an essential ingredient in baking, pharmaceuticals, health and beauty aids, and various industrial processes. Additionally, it serves as an effective alkalinity booster for drinking water and helps maintain optimal chemistry in pools. Sodium Bicarbonate USP No. 1 Powdered is an ideal choice for professional bakers when it comes to baking cookies and cakes. Its reliable performance ensures consistent results, making it a go-to ingredient for creating delicious and perfectly textured baked goods. Beyond the culinary realm, Sodium Bicarbonate USP No. 1 Powdered finds extensive use in the production of pharmaceuticals and health and beauty aids. Its versatile nature makes it a key component in various medications, personal care products, and cosmetics. The high purity of this product ensures its suitability for a wide range of applications, meeting the stringent quality requirements of the pharmaceutical and beauty industries. In addition to its role in baking and personal care, Sodium Bicarbonate USP No. 1 Powdered plays a vital role in many industrial processes. Its alkaline properties make it an essential ingredient in chemical reactions, waste treatment, and metal cleaning processes. Its effectiveness and reliability have made it a preferred choice across industries, contributing to efficient and high-quality production processes. Sodium Bicarbonate USP No. 1 Powdered is also widely utilized as an alkalinity booster in drinking water. Its ability to balance the pH level ensures clean and safe water for consumption. Furthermore, in pool maintenance, Sodium Bicarbonate USP No. 1 Powdered helps to stabilize the water chemistry, maintaining proper pH levels and supporting sanitizer activity. Chemical Formula: NaHCO3 Molecular Weight: 84.01 CAS Registry Number: 144-55-8 Appearance White Crystalline Powder Odor: Odorless Density 62 lb/ft3 (993 kg/m3) Boiling Point: None Solubility in water: Water: 8.6 g/l00ml @ 20 °C (68 °F) GHS Pictograms: None GHS Signal Word: None GHS Hazard Statements: None GHS Precautionary Statements None UN Identification Number: None Proper Shipping Name: Sodium Bicarbonate Transport Hazard Class: None Packing Group: None DOT Placard: None Sodium Bicarbonate Specifications (Spec) Sodium Bicarbonate Certificate of Analysis (COA) Sodium Bicarbonate Safety Data Sheet (SDS)

$8.00 - $60.00

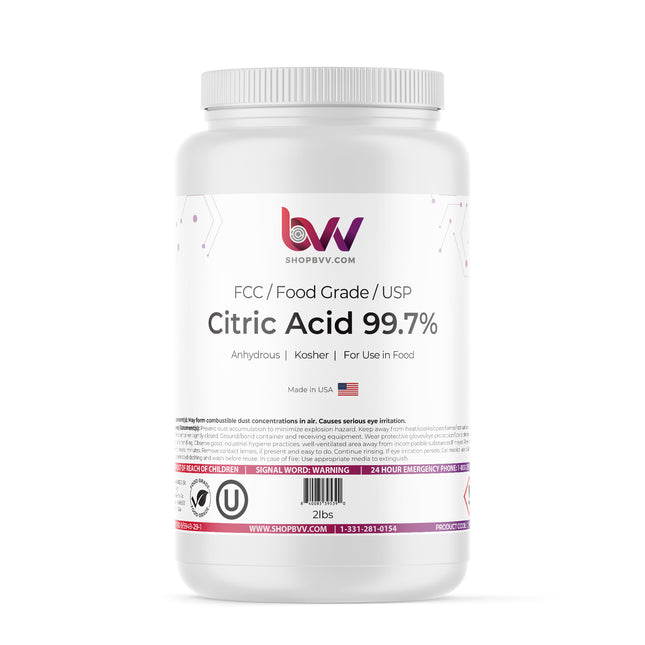

Citric Acid 97% USA - High Purity - Anhydrous FCC, USP, Kosher

Citric Acid 97% Kosher | USP/GMP/FCC Food Grade | Anhydrous | USA Made (in Iowa) Our citric acid is granular, and has the look and feel like granular sugar that were all familiar with. The citric acid is a translucent white crystals and is a tart acidic taste. Its slightly hydroscopic and melts at 307°F. The citric acid is manufactured using a submerged fermentation process from a glucose and /or sucrose carbohydrate substrate. It's produced in accordance with good manufacturing practice and is considered "GRAS" Generally Recognized As Safe by the Food and Drug Administration (FDA). Chemical Formula: C6H8O7 Molecular Weight: 192.13 CAS Registry Number: 77-92-9 Appearance Solid White Granules Odor: Odorless Density 1.66 g/cm³ Boiling Point: None Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Warning GHS Hazard Statements: H319, H335 GHS Precautionary Statements P261, P264+P265, P271, P280, P304+P340, P305+P351+P338, P319, P337+P317, P403+P233, P405, and P501 UN Identification Number: None Proper Shipping Name: None Transport Hazard Class: None Packing Group: None DOT Placard: None Cargill Technical Data Sheet Citric Acid Anhydrous 99.7% Food Grade Certificate of Analysis (COA) Citric Acid Anhydrous 99.7% Food Grade Safety Data Sheet (SDS)

$12.00 - $120.00

30% Food Grade Distilled White Vinegar - Non GMO

30% Distilled White Vinegar Food Grade - Kosher - Non GMO This is 300 grain White Distilled Vinegar. This vinegar is the result of the natural acetous fermentation of dilute ethyl alcohol from agricultural origin. The alcohol is converted to acetic acid by the microorganism Acetobacter aceti in vinegar generators or acetators. The product is prepared in accordance with the best commercial practice under strict sanitary conditions and the Federal guidelines for Good Manufacturing Practices. It is free of clarifiers, preservatives or other impurities and is Kosher certified. Ships in HDPE FDA Compliant Bottles. Chemical Formula: CH3COOH Molecular Weight: 60.05 g/mol CAS Registry Number: 64-19-7 Appearance Colorless Liquid Odor: Vinegar Density 1.01 to 1.04 (water = 1) Boiling Point: 215F @ 760 mm Hg and 100 grain Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Warning GHS Hazard Statements: H320, H315, H332, H402 GHS Precautionary Statements P261, P264, P280, P304+P340,P305+P351+P338, P273 UN Identification Number: 2790 Proper Shipping Name: Acetic Acid Solution Transport Hazard Class: 8 Packing Group: III DOT Placard: 30% Vinegar Food Grade - Certificate of Analysis (COA) 30% Vinegar Safety Data Sheet (SDS)

$13.00 - $891.00

Replacement Separator for the BVVC750 Centrifuge

This is 1 qty separator (cup and perforated basket) to fit our BVV C750 Centrifuge Each centrifuge can hold 4 separators. Centrifuge is not included.

$185.00

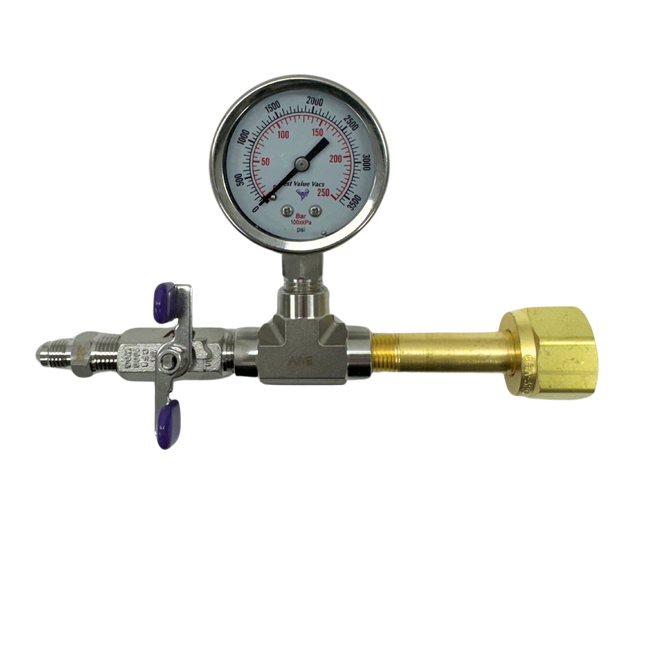

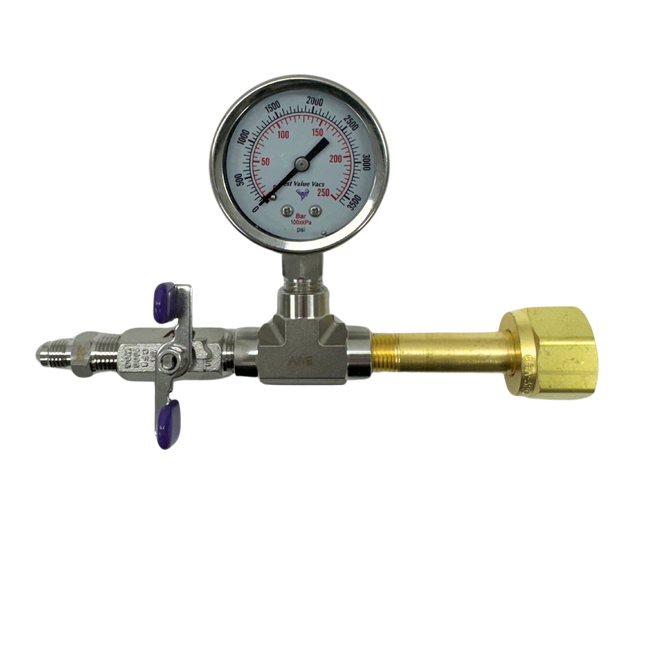

CGA 320 CO2 Tank Regulator

This tank regulator will control the rate of fluid or gas flow using a butterfly valve. Our BVV butterfly valve is rated to 1000 psi, and is made of 304 stainless steel and features a PTFE valve seat making it compatible with CO2. The output will connect to a 1/2" JIC flare hose (seen here BVV JIC 1/4" Hose).

$88.00

KF-40 Stainless Steel Ball Valve (Nitrogen Tested)

KF-40 (NW40) Stainless Steel Ball Valve This ball valve has a KF40 (NW40) High Vacuum Flange to adapt to any other KF40 pump or manifold if needed and is made out of 304 stainless steel with a PTFE seat and seals.

$95.00

High Pressure Heated Stainless Steel Hose, 4FT JIC Fittings, up to 450°F

This item is sold with or without a PID controller. The hose is heated and insulated. The hose temperature is controlled by an Digital PID. The hose and PID controller are made in the USA, and of the best quality. The hose uses Platinum Thermocouples for durability and accuracy, for many many years of service. Hose Temperature Rating: 50°F - 450°F Controller Temperature Range: 50°F -450°F 120 VAC w/ 6ft cord The overall length of the hose is 4ft The hose is Made in the USA. HOSE ID - 0.187" (1/4"Style) HOSE ID - 0.312" (3/8"Style) HOSE ID - 0.406" (1/2"Style) Each side of the heated hose assembly is a JIC 37° Fitting

$600.00 - $1,405.00

SSP - Union Elbow - 1/2" Tube x 3/8"

Stainless Steel SSP -Union Elbow 1/2" x 3/8" Duolok

$55.00

Brass Bulk Head Short

Brass Bulk Head Short This bulkhead is made to seal through a vacuum chamber wall up to 1/2" thick. The threads on the stem are 5/16" - 18, and on the outside of the chamber there will be 1/4" NPT threads to connect a variety of fittings.

$6.00

Centrifuge Belt

Centrifuge Belt Replacement Belt for the 160L & 45L Centrifuge. *Each centrifuge may have multiple belts

$130.00 - $175.00

Lattice Clamp

Lattice Clamp This clamp will connect two lab stands/ rods perpendicular to each other to create a lattice structure to have many more mounting points on your laboratory glass.

$5.00

120W Motor/gearbox with FWD/REV controller

This controller/ motor can be retrofitted to fit a 20 or 50 liter glass reactor to have additional control to your process.

$850.00

2L Standard Short Path Parts Kit

Short Path Distillation Setup Short path distillation is used for compounds that are not stable at high temperatures. It can also be used to purify small amounts of a compound. The 2L Distillation Kit gives users an easy to use system that will get them up and running at an affordable price. It includes all stands, clamps, clips, This Kit Does NOT include a vacuum pump, circulator, or heating source. Please see the below recommendations for both as well as recommended add-ons. Or check out our 2L Standard Distillation Turnkey Setup which includes vacuum pump, circulator, and mantle. Recommended Vacuum Pumps: Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (economy option) Best Value Vacs VE280 9CFM Two Stage Vacuum Pump (economy option) Recommended Circulators: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter MX Refrigerated Circulator (premium option with chilling capability) Recommended Heating Mantle: BVV 2L Heating Mantle Recommended Add-Ons: Glass Dewar Style Cold Trap (recommended cold trap) Bullseye Precison Vacuum Gauge (premium vacuum gauge for measuring depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) Short Path Distillation Kit Specifications: Boiling Flask Size: 2L Recieving Flask Size: 250ml Batch Capacity approximate: 2L = 400-1000 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Comes Standard With The Following: Glass Components: 2L 2-Neck Boiling Flask Short Path Head Triple Neck Cow 3x 250mL Single Neck Receiving Flask 1/8" 14/20 PTFE Thermometer Adapter 1/4" 24/40 PTFE Thermometer Adapter 120mm Glass Funnel Accessories: Magnetic PTFE Stirring Bar Retriever Keck Clips 3 Finger Clamp Adjustable 0-70mm Boss head 6" x 6" Scissor Jack 250-500ml Cork Stand Traceable Kangaroo Thermometer - Digital Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. Learn more about short path distillation components and FAQs with this distillation guide. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$475.00

Beaker and Wrench Explosion Proof Oil Pump

Explosion Proof Oil Pump Optimized for Falling Film Evaporators C1D2 VFD (variable frequency drive, not C1D2 rated) cord is approximately 15′ Motor: 1/4 Horsepower Customizable mounting When ordering: Please indicate in the Note section what machine you will be attaching the Explosion Proof Oil Pump to. We need this information to assure the correct Inlet Adapter is provided and also the dimensions of the mounting configuration you will need. Hazardous Location Clas 1 C,D / 2 E,F,G Nominal Efficiency 85.5% Frame 56CZ Motor Application Hazardous Location Lead Length 6" RPM Range 1101-1200 Standards UL listed (E12044), CSA Certified (LR47504) Frame Material Rolled Steel Duty Continuous HP 1/4 Voltage Compatibility 115/208-230, 120/240 Length Less Shaft 11-7/8" Includes Conduit Box (Unmounted), Leads Through 1" NPT Nipple Motor Shaft Design Keyed Shaft Length 2-1/4" Item Harazardous Location Motor Motor Service Factor: 1.00 1.00 Motor Thermal Protection auto Motor Shaft Rotation CW/CCW Full Load Amps 6.8/3.1-3.4 Overall Length 14-5/16" Voltage 115/208-230 Motor Frame Material Rolled Steel Ins. Class B Motor Mounting Type Face Motor Design Capacitor- Start Shaft Dia 5/8" Hz 60 Motor Bearing Ball Temp. Code T3B Motor Enclosure Design Totally Enclosed Fan-Cooled Nameplate RPM 1140 Max. Ambient Temp 40 Degrees C Phase 1

$7,600.00

Eccentric Recovery Pump Shaft Adapter

Eccentric Recovery Pump Shaft Adapter Replacement Eccentric adapters for TRS or BVV recovery pumps. Model numbers shown below- BVV-EC-TRS: TRS21 BVV-EC: BVV2CYL BVV4CYL BVVCMEP-RETRO

$75.00 - $105.00

Ice Water Extraction Kit

BVV's Ice Water Extraction Kit Designed with our solventless extractors in mind BVV's Ice Water Extraction Kit was engineered for durability and ease of use. Comprised of our sanitary grade seamless 55-gallon 304 stainless steel washing vessels. Our easy drain barrels come complete with 4X 1.5" Triclamp drains mounted as low as possible for effortless draining of its 55-gallon volume capacity. Perfect for medium to large-scale ice water extraction labs this kit comes complete with industry-leading Boldtbags Lock-top Full mesh stacker grading bags and a 20lb capacity Large BoldtBags Open Top Washing Bag for unbridled durability and ease of use. The ice Water Extraction Kit comes with your choice of either a low shear Multi-stage pump ideal for gravity draining or a hash-safe pneumatically driven diaphragm pump. Processing Power Material Capacity Per Batch: 20-30LB Water Capacity: 55 Gallons Cycle Time: 60-90 Minutes Daily Extraction Capacity: Up to 60 lb, per 8-hour shift Specifications 2X 23"x36" 55-gallon Stainless Steel Washing Vessel 4X 1.5" Tri-clamp ports 4X BoldtBags Lock-top Full mesh stacker grading bags (190um(Green),160um(Red),90um(Black),45um(White)) 1X Large Boltd Open Top Wash Bag (20lb Capacity) 1X Food grade PTFE mixing paddle 1X 27 GPM Low shear Multistage pump or 16 GPM hash-safe pneumatically driven diaphragm pump. 1X 25Ft 1" Clear Braided PVC Hose 1X 1.5" Tri-clamp Thermometer (0-220F/0-100C) 4X Polycarbonate Sight glasses 2X 1.5" Tri-Clamp Butterfly valves with 1" barbed fittings Performance Seamless sanitary construction Low-mounted drain ports for complete draining Tri-Clamp Thermometer for water temperature measurement Polycarbonate sight glasses for visual monitoring of the process Open Top Wash Bag for easy loading & unloading Low-shear force Multistage pump for gentle water transfer or a hash safe pneumatically driven diaphragm pump

$5,750.00 - $7,400.00

BVV 2540 Nanofiltration Skid

BVV 2540 Nanofiltration Skid Note: This product carries 8 - 12 week lead time Perform organic solvent recovery or botanical extract purification with ease with our 2540 nanofiltration skid. Replace up to 7X 50L Rotary evaporators with a single Skid. BVV's 2540 Nanofiltration Skid is designed to meet Class 1 Division 1 standards. With the ability to recover 30 gallons of ethanol per hour without the application of heat, preserving target compounds and utilizing a fraction of the energy consumption of a traditional falling film qualifying our 2540 Nanofiltration Skid for energy saving rebates. Processing Power Capacity: 15 GPH or 30 GPH of solvent recovery. Solvents: Ethanol, Methanol Specifications 4X 2540 nanofiltration housings Stainless steel 6GPM pump with PTFE seals 7.5HP C1D1 1750 RPM Motor 7.5HP VFD 1/60/230 NEMA 4X enclosure (13A) Insulated 2"x18" Heat Exchanger Polyscience 1.5HP Chiller 230/60/1/23.1 700PSI Pressure Relief Valve C1D1 Flowmeter 2X 0-1000 PSI Pressure Gauges 1.5" Intake & Retentate Lines 1/2" Permeate & Pressure Relief Lines Footprint (DxWxH) 30"x39"x79" Weight: 400 lb Maximum Pressure Rating: 700PSI Performance Variable Frequency Drive-based flow control Complete pressure control with manual pressure controls Retentate cooling with inline Heat exchanger & chiller 700PSI pressure relief valve with diversion line *Components shown are subject to change**This unit is meant for bulk solvent recovery, 90% of the total volume of solvent an additional solvent recovery apparatus is recommended to evaporate to dryness*

$41,000.00 - $45,000.00

BVV Space Saver Mobile Oven Cart with Ovens

BVV Space Saver Mobile Oven Cart with Ovens The BVV Space Saver Mobile Oven Cart allows users to greatly increase their output and more efficiently all in one place! There are a total of 12 options in this listing: 1) Three 1.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 2) Two 1.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 3) Three 0.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 4) Two 0.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 5) Three 1.9 Eco Ovens + 1 BVV 9CFM Vacuum Pump 6) Two 1.9 Eco Ovens + 1 BVV 9CFM Vacuum Pump 7) Three 0.9 Eco Ovens + 1 BVV 9CFM Vacuum Pump 8) Two 0.9 Eco Ovens + 1 BVV 9CFM Vacuum Pump 9) Three 1.9 Eco Ovens + 3 BVV 4CFM Vacuum Pump 10) Two 1.9 Eco Ovens + 2 BVV 4CFM Vacuum Pump 11) Three 0.9 Eco Ovens + 3 BVV 4CFM Vacuum Pump 12) Two 0.9 Eco Ovens + 2 BVV 4CFM Vacuum Pump If these options don't fit your needs, we also encourage you to expand your options by ordering parts individually or reach out to us (331-281-0154) so we can help create the kit right for you. Included in all the kits is the Heavy Duty Steel Mobile Cart that was designed by us to hold up to three ovens! It also has three height adjustable shelves to suit your needs and can be placed on either side of the bracket. The cart is mobile with its swivel caster wheels and they can can support up to 1,100lbs! The cart can house oven sizes such as the 0.9 and 1.9, Neocision and ECO oven. The oven shelves are made of aluminum and we recommend covering the shelves with silicone pads or a PTFE sheet that can be cut to size. The oven shelves are made of aluminum and we recommend covering the shelves with silicone pads or a PTFE sheet that can be cut to size. It is recommended to change the oil when the color starts to get noticeably darker in the pump. Also included in the kit is our premium Mobil Vacuum Pump Oil. This oil has a longer usable life and does not generate any additional vapor or odor, which will be sure to help your vacuum pump exhaust filter live longer too! Note: The Heavy Duty Steel Mobile Cart shipped does NOT come with the side shelves assembled. Required tool: 5mm ball hex (NOT INCLUDED). ECO Oven Vacuum Adapter Build Instructions: BVV™ 3 ECO Ovens and 1 Pump BVV™ 2 ECO Ovens and 1 Pump

$4,396.00 - $11,260.00

Jacketed Reactor with Motor and Collection Vessel

Jacketed Reactor with Motor and Collection Vessel This jacketed reactor kit includes your choice of a C1D1 motor, standard motor, or non-electric air powered motor (air compressor required). If using an electric motor it will require wiring to the included speed controller. Using the jacketed reactor to heat your solution, use your reactor to mix your solution during the heating process. The condenser and collection vessel allow you to recover residual solvents up to 100L. The collection vessel includes a dip tube to empty the vessel and a 1/4" JIC flare to input pressure into the base to assist in emptying the tank through the dip tube. This system does NOT include a heater or chiller, please inquire with your account representative for recommendations based on your application! Jacket connections are 1/2" hose barbs. Mixer Type Pneumatic Electric C1D1 Electric Horsepower 3/4 HP 3/4 HP 1 HP Power Air Compressor 120V 220V 1ph Reactor Size 150L Collection Size 50L / 100L Jacket Connections 1/2" Hose Barb

$7,022.00 - $13,690.00

You have seen 1008 out of 1090 products