Non BVV product for sale

Bullseye Precision Gauge with Bluetooth | Wireless Vacuum Gauge NPT, KF25

Bullseye Precision Gauge with Bluetooth | Wireless Vacuum Gauge NPT, KF25 The DigiVac Bullseye Precision Gauge with Bluetooth is the world’s first wireless vacuum gauge featuring one-of-a-kind patented vacuum graphing and DigiVac’s ‘Vacuum Gauge’ app Versatile wireless vacuum gauge that you can monitor right from your phone or tablet (Apple ios and android) Enables remote monitoring and troubleshooting Set low and high alarm from your phone Email vacuum data to document leaks, baseline pressure or pump-downs Use battery power or standard microB-USB power Choose standard Thermocouple Plus sensor or the Upgraded Agilent 531 NPT sensor (this sensor configuration is CE and RoHs compliant), or the Agilent 536 NPT sensor which includes an integrated baffle to extend the life of the sensor by helping to protect it from contamination Portable and Precise Rugged thermocouple vacuum gauge ideal for understanding: Leaks, Pump Downs, Out-gassing or Stable Systems Includes a powerful magnet and kickstand to enable hands-free operation Long battery life and versatility with 12 different measuring units (micron, Torr, Inches of Hg, kPa, Inches of H20, millitorr, mbar, Pa, PSIA, mm of Hg, bar, and mm of H2O) Calibrated under actual vacuum against a NIST standard. Graphing and Analysis Patented vacuum graphing displays vacuum and time data Visual graphing right on the display that identifies current system status Vacuum Analytics to quickly identify vacuum pressure trends Graphical display for quick determination of vacuum level Bluetooth Bullseye Gauge Applications Vacuum pump testing Baseline vacuum pump performance Transformer dry-out Schlenk line monitoring Botanical oil processing Distillations Vacuum Process Monitoring Technical Specifications Units Torr, mbar, bar, kPa, inHg, mm Hg, millitorr, microns, inches of water, PSI, Pa Control Range 1E-4 – 1000 Torr Range with Accuracy .001-5 Torr Sensor Type Agilent 531 (NPT), Agilent 536 (NPT, KF15, or KF16), VGT500 Dimensions 6.2”H x 3.7”W x 1.3”D Certifications ROHS and CE

$735.00 - $845.62

Bullseye Precision Gauge-531 | with upgraded Agilent 531 Sensor

Bullseye Precision Gauge-531 | with upgraded Agilent 531 Sensor The Bullseye Precision Gauge-531 is the Bullseye Vacuum Gauge that you trust with the upgraded Agilent 531 sensor The Bullseye Precision Gauge-531 is a rugged and portable vacuum gauge, which features visual graphing to pinpoint problems in real time (leak, pump, outgas, stable). Includes a powerful magnet and kickstand to enable hands-free operation. Benefits of Choosing the Upgraded Agilent 531 sensor option: All metal, sturdy, structure Used in applications requiring higher levels of accuracy Vacuum Interface: 1/8″ NPT but can be easily adapted to KF Total Range: of 1 millitorr to 760 Torr (continuous and monotonic from atmosphere down to 6 Torr) Range with Accuracy: 10 millitorr (.001 Torr) to 6 Torr (1 x 10-3 mbar to to 7.99 mbar) 15% accuracy Electrically identical to Agilent 536 sensors Bullseye Precision Gauge-531 Features Portable and Precise Rugged thermocouple vacuum gauge ideal for understanding: Leaks, Pump Downs, Out-gassing or Stable Systems Includes a powerful magnet and kickstand to enable hands-free operation Long battery life and versatility with 12 different measuring units (micron, Torr, Inches of Hg, kPa, Inches of H20, millitorr, mbar, Pa, PSIA, mm of Hg, bar, and mm of H2O) Calibrated under actual vacuum against a NIST standard. Graphing and Analysis Patented vacuum graphing displays vacuum and time data Visual graphing right on the display that identifies current system status Vacuum Analytics to quickly identify vacuum pressure trends Graphical display for quick determination of vacuum level Bullseye Precision Gauge-531 Applications Vacuum pump testing Baseline vacuum pump performance Transformer dry-out Schlenk line monitoring Botanical oil processing Distillations Vacuum Process Monitorin Technical Specifications Units Torr, mbar, bar, kPa, inHg, mm Hg, millitorr, microns, inches of water, PSI, Pa 1E-4 – 1000 Torr Range with Accuracy .001-5 Torr Sensor Type Agilent 531 NPT Dimensions 6.2”H x 3.7”W x 1.3”D Certifications ROHS and CE

$640.62

Bullseye Precision Gauge with Agilent 536 KF25, NPT or KF16 Sensor | Vacuum Gauge for Processing

Bullseye Precision Gauge with Agilent 536 KF25, NPT or KF16 Sensor | Vacuum Gauge for Processin A rugged portable vacuum gauge for processing applications that pairs unparalleled vacuum measurement with the Agilent 536 sensor that has an integrated baffle which provides protection and helps reduce risk of sensor failure Numeric & Graphical Displays See vacuum readings in either numbers or easy-to-read graphs Has 12 measurement units for implementation in almost any vacuum application Torr, mbar, bar, kPa, inches of Hg, mm Hg, millitorr, microns, inches of water, PSI, Pa Calibrated & Precise Delivered pre-calibrated with Agilent/ Varian 536 thermocouple sensor under actual vacuum against the NIST standard. Note: NIST certification sent with the gauge is an available option here The 536 all stainless steel sensor with baffle has extended sensor life in the presence of condensable gases and improved performance at higher pressures Vacuum Interface: KF25 or NPT or KF16 Wetted materials: 304L Stainless steel, glass, Type P thermocouple Extended Battery Lifespan Portable | Solid state electronics built into a handheld gauge that operates using AA batteries that lasts up to 70 hours In-lab use | Power gauge using the integrated Micro-USB port for long-term use without the need to change batteries Ideal Vacuum Gauge for Processing Applications Laboratory, freeze drying, low pressure distillations, foreline monitoring, Schlenk lines performance, and transformer dry-out Or any application with higher levels of condensables where sensor failure is more likely Units Torr, mbar, kPa, millitorr, microns, Torr, mbar, bar, kPa, inches of Hg, mm Hg, millitorr, microns, inches of water, PSI, Pa 1E-4 – 1000 Torr Range with Accuracy .001 – 5 Torr Sensor Type Agilent 536-KF25 Dimensions 11 x 10 x 4 in Certifications CE, RoHS

$618.75 - $653.00

Lab Armor Peltier Bead Bath

Lab Armor Peltier Bead Bath Lab Armor revolutionizes the scientific bath industry with the Peltier Bead Bath! Utilizing Peltier Thermoelectric Cooler-Heater (TEC-H) technology, the Peltier Bead Bath is an all-in-one unit that efficiently controls the temperature in chilled and heated applications. The air jacketed design is exclusive to the Lab Armor Peltier Bead Bath, and it is the only bead bath on the market with both cooling and heating capabilities. The Peltier Bead Bath works with Beads to deliver exceptional temperature uniformity! The Lab Armor Peltier Bath securely holds lab vessels of various sizes in place. Samples may be conveniently transported using the removable Lab Armor Peltier Bead Baskets. The Bead Bath helps prevent the risk of sample contamination by removing water from many laboratory processes. These design features allow the Peltier Bead Bath to perform the role of multiple appliances, reducing benchtop space requirements.

$3,934.32 - $6,206.61

Lab Armor BEAD BATH

BEAD BATH Unique DESIGN Lab Armor Bead Baths were specifically designed to work with Lab Armor Beads to optimize their performance. Uniform Temperatures With Bead Bath designed expressly for beads, temperatures are consistent and uniform everywhere in the bath. Thermal uniformity is +/-1.0 at 37ºC. Always On The bath always stays on, so you don’t have to plan around warmup times. You don’t need to worry about refilling or low water burnout because there is no water to evaporate. Lab Armor Bead Baths are up to 50% more energy efficient than a standard lab water bath. Stays Clean Lab Armor reduces the risk of contamination. Contaminated samples and reagents result in distorted data and unpredictable outcomes. Stays Organized Unlike water baths that require racks, floats, and bottleneck weights, Bead Bath naturally holds things in place without accessories. So no more floating accidents.

$1,428.95 - $2,813.02

Lab Armor Beads

Lab Armor Beads Modern Upgrade Lab Armor Beads are dry metallic beads that replace water/ice/oil/sand in baths, giving old equipment a cool, shiny, state-of-the-art upgrade. Stays clean Lab Armor eliminates water bath contamination, harmful germicides, and unpleasant maintenance. Beads are dry and naturally more resistant to microbial growth than water, and therefore, are less likely to harbor and contribute to transmitting microorganisms in the laboratory. Saves time & Money Lab Armor Beads will help you save time and money. No more hassling with emptying, cleaning, and refilling water baths. Always On The bath stays on so there is no need to plan around warm-up times. Lab Armor Beads eliminate the worry about low water burnout because there is no water to evaporate. Other benefits of using Lab Armor Beads: Cleaner working environment. Greater organization capabilities as samples are held in place. Environmentally friendly. Temperature range -80°C to 180°C. High thermal conductivity. Non-toxic, non-vaporizing, antimicrobial No daily requirement for biocides, germicides, and other cleaners. No gray water. Smooth rounded shape allows fluidity and will conform to many sizes and shapes of vessels. No Racks, floats or weights required to hold items in place. Recyclable.* Weight 4 Lbs. (1.81 kg) per Liter.

$214.49 - $857.93

Quick Sift - Commercial Sifting Machine - Automatic Sifter

Quick Sift - Commercial Sifting Machine - Automatic Sifter Sifting your plant material is an excellent way to remove stems automatically. This commercial sifting machine was explicitly designed with processors in mind - the stainless steel construction and screens ensure you can easily clean our sifter, and the screen sizes are fine-tuned for the most common sifting needs. The commercial grade sifter offers a larger diameter, coming in at 16 inches, compared to the 13.74 inches of the original starter sifter - this means you'll be able to sift more plants in one sitting! Once you've ground your plant material, you only need to pour it into the sifter and switch it on. You can now walk away and wait for your plants to be automatically sifted - no more standing around doing manual sifting. Sifting your biomass will not only ensure no stems make it into your final product but will also ensure nothing else makes it into your product, like large leaves, gravel, or any other foreign matter. Additionally, consistent grinding will make your product burn more evenly and pack more evenly in any cone-filling machine. Plant Material Specific Sifter The commercial sifter was explicitly designed for plant material processors. From its stainless steel construction to multiple screen sizes, our team of Experts is confident this sifter or our other larger sizes will be the perfect addition to your product production process. We offer multiple screen sizes, allowing you to customize the particle size for the plant material in your product. Depending on the strain or weight of the product you are making, you may want to experiment with various screen sizes. Multiple Screen Sizes When it comes to sifting your plant material, you will want to have an ideal particle size for your plant material in mind. If you are still determining what size screen you need, our team of Experts is here to help! Depending on your strain and grinder, your ground biomass will have a different consistency. Additionally, depending on the size of the cone you are using and your desired fill weight, the particle size of your plant material will play a significant role. For example, a smaller particle size will allow you to pack more plant material into a small cone, but a particle size that is too small may lead to a poor, uneven burn. Machine Starter Kits The QuickSift Pro pairs perfectly with our industrial plant material grinder and cone-filling machines. Although our industrial grinder will grind stems to a small enough size, some brands want to sift all the stems out. The larger grind screen can be used to ensure stems stay big enough to be sifted completely out and then the rest of the material is ground. Processors have great success sifting their plant material post harvest, due to the larger amount of stems and leaves. Specifications PURPOSE: Sifting Ground plant materialCONSTRUCTION: Stainless SteelSCREEN DIAMETER: 16 inchesMACHINE TYPE: SifterPOWER REQUIREMENT: 120vRATED VOLTAGE: 110VRATED FREQUENCY: 60HzRATED POWER: 50W

$1,649.00

Quick Sift Mini - Sifting Machine - Automatic Sifter

Quick Sift Mini - Sifting Machine - Automatic Sifter Sifting your plant material is a great way to remove stems automatically, and if you are producing a premium product, it is always best to sift out any stems! Our QuickSift was explicitly designed with plant material processors in mind - the stainless steel construction and screens ensure you can easily clean our sifter and the screen sizes are fine tuned for the most common sifting needs. Once you've ground your plant material, you only need to pour it into the sifter and switch it on. You can now walk away and wait for your plant material to be automatically sifted - no more standing around doing manual sifting. Sifting your plant material properly will not only ensure no stems make it into your product but will also ensure nothing else makes it into your products, like large leaves, gravel, or any other foreign matter. The Consistent grind will make your products burn more evenly and pack more evenly in any cone-filling machine. Plant Material Specific Sifter Our QuickSift was explicitly designed for plant material processors. From its stainless steel construction to multiple screen sizes, our team of Experts is confident this sifter or our other larger sizes will be the perfect addition to your product production process. We offer multiple screen sizes, allowing you to customize the particle size for the plant material in your product. Depending on the strain or weight of the product you are making, you may want to experiment with various screen sizes. Multiple Screen Sizes When it comes to sifting your plant material, you will want to have an ideal particle size for your plant material in mind. If you are still determining what size screen you need, our team of Experts is here to help! Depending on your strain and grinder, your ground plant material will have a different consistency. Additionally, depending on the size of the cone you are using and your desired fill weight, the particle size of your plant material will play a significant role. For example, a smaller particle size will allow you to pack more plant material into a small cone, but a particle size that is too small may lead to a poor, uneven burn. Machine Starter Kits Our QuickSift pairs perfectly with our industrial plant material grinder and cone-filling machines. Although our industrial grinder will grind stems to a small enough size, some brands want to sift all the stems out. The larger grind screen can ensure stems stay big enough to be sifted entirely out and the rest of the material is ground. Processors have great success sifting their post-harvest due to the larger amount of stems and leaves.

$699.00

Cascade CVO-10 Vacuum Oven

Cascade CVO-10 Vacuum Oven High production, large vacuum drying system for vacuum purging production quantities, the Cascade CVO-10 is our largest 10 cubic foot vacuum oven. Model CVO-10 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, and slurries – especially temperature sensitive material. This vacuum oven liberates solvents, water, and other unwanted compounds in large batch production environments. Note that this is a 220V vacuum oven. The Cascade Difference Vacuum ovens have been around for decades. Basic vacuum ovens are mass-produced and sold by many large-scale laboratory equipment distributors. But there are key differences between and other inexpensive, often imported vacuum ovens. Exceptional Temperature Control & StabilityThe CVO-10 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-10 eliminate hot and cold spots, making accurate use of every inch of shelf space. Independent Overtemp Failsafe ProtectionThe CVO-10 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 392°F or 200°C. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. Digital Vacuum GaugeThe digital vacuum gauge installed on the CVO-10 is selectable between inches of mercury (“Hg) or torr, mtorr. Equipped for Inert Gas Backfill. Built-In Safety ReliefIntroduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the ¼” rear vent barb. The maximum backfill pressure is 15PSI. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection PortsFor faster evaporation, purging or drying the CVO-10 includes MAX EVAP connection kit. The MAX EVAP connection kit secures to the oven’s rear 1” dia KF-25 port located on the back center of the chamber. The MAX EVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthrus, or monitoring sensors inside the vacuum chamber during processing. Ergonomically Designed, Easy Quarter-Turn ValvesFor anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vent valve. Your wrists will thank you! Faster Venting With Large ½” Diameter Vent LinesFor large capacity production environments, time is money. The CVO-10 vacuum oven has larger than industry standard vent lines. ½” diameter vent lines means operators spend less time venting the oven. Features CVO-10 PRO Package Includes: Cascade Sciences CVO-10 Vacuum Oven Heavy-Duty Industrial Mobile Cart 9x Total Shelves – 28”W x 24”D MAXEVAP KF-25 Connection for faster purge Agilent IDP15 Oil-Free Vacuum Pump, 9cfm Features: NRTL Certified by TUV 9 sliding, removable shelves that pull out and stay in place for easy load/unload Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Easy mobility as oven sits on heavy duty industrial cart. Pump sits underneath at base of cart Silicone Door Gasket Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reads in inches of mercury or torr Smooth, quarter-turn vent valve Oven to pump connection: Rear KF-25 line, valve 220V / 1ph / 10AMPS plugs into NEMA 16-5R outlet Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Ergonomic. Turn vacuum pump on/off from oven control panel Fast Venting with larger ½” diameter vent line. Allows for nitrogen or other inert gas connection Touch Panel LED control screen with user settable features (torr, mtorr, Hg, Fahrenheit, Celsius) Walls lined with heat conductive copper for improved temp transfer. Known antimicrobial properties can prevent bacteria buildup Specifications VOLUME:9.3 Cubic Ft. (263 Liters) SHELVES:9 total (max), removableFull-extension, stay in placeIntegrated copper strips optimize temp transferSurface area: 28″W x 24″DWeight Capacity Per Shelf: 50 lb / 22.7 kgApprox 930 cubic inches of volume OVEN INTERIOR:28”W x 24”D x 24”H711mm x 609mm x 609mm OVEN EXTERIOR:(not including rack)42” W x 40” D x 67.4”H1067mm x 1021mm x 1712mm WEIGHT:Shipping: 775 lb/ 352 kgNet Weight: 663.0 lb/ 301 kg TEMPERATURE RANGE:Ambient +26° to 302°F / Ambient +14.4°C to 150°C TEMPERATURE UNIFORMITY:@ 105°F +/- 0.2°F – ±2.0°F@ 200°F +/-0.4°F – ±5.5°F@ 300°F +/- 0.2°F – ±8.0°F @40°C +/- 2°C – ±1.0°C@90°C +/- 3°C – ±3.0°C@150°C +/- 4.5°C – ±4.5°C TEMPERATURE STABILITY:@ 105°F +/- 0.2°F – ±0.2°F@ 200°F +/-0.4°F – ±0.4°F@ 302°F +/- 0.2°F – ±0.2°F @40°C +/- 0.1°C – ±0.1°C@93.3°C +/- 0.2°C – ±0.2°C@150°C +/- 0.1°C – ±0.1°C HEAT UP TIME FROM AMBIENT:@ 105°F / 40.5°C – 42 min@ 200°F / 93.3°C – 94 min@ 302°F / 150°C – 175 min COOL DOWN TIMES:@ 105°F / 40.5°C – 330 min@ 200°F / 93.3°C – 94 min@ 302°F / 150°C – 420 min *Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product. VACUUM VALVE:Side Mounted Round VENT VALVE:¼ Turn Lever½” diameter line GLASS WINDOW:Tempered NGI-US to ANSI Z97.1.2007Interior lighting VACUUM GAUGE:Reads in inches mercury or torr(Selectable) CONTROLLER:Touch ScreenAccurate Within 1°FIndependent Overtemp Failsafe PORTS (REAR):Vacuum = KF-25 PortVent = 1/2” Barb INERT GAS INTRODUCTION:Yes. Via 1/2” Vent Barb15 psi max inlet pressure POWER:220V – 240V / 1ph / 10A 50/60HzCord IncludedNEMA 6-15R Power Outlet(System will run on 208V)Oven BTU Rating at 250ºF: 6980 BTUs/hr at full capacity

$24,997.00 - $31,799.00

Cascade CVO-2 Vacuum Oven

Cascade CVO-2 Vacuum Oven Model CVO-2 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, slurries, or any temperature sensitive material. This vacuum oven liberates solvents, water, and other unwanted compounds in small batch, R&D and lab environments. NRTL Certified. Operating Range: Ambient +10ºC to 150°C (Ambient +18°F to 300°F) Benchtop Size: 1.47 Cubic Ft (47.2L) 12″W x 20″D x 12″H Exceptional Temperature Control & Stability The CVO-2 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-2 eliminate hot and cold spots, making accurate use of every inch of shelf space. Independent Over-temp Failsafe Protection The CVO-2 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 200°C or 392°F. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. Digital Vacuum Gauge The digital vacuum gauge installed on the CVO-2 is factory default set to read in inches of mercury (“Hg) with a scale of 0 – 29.9”Hg. Change the unit of vacuum measurement to read in a wide variety of units from mmHg, bar psi, kPa, cm2, mmH20. Zero out the vacuum gauge to calibrate for just above sea level adjustments. Equipped for Inert Gas Backfill. Built-In Safety Relief Introduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the 1/4″ rear vent barb. The maximum backfill pressure is 15psi at the inlet. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection Ports The CVO-2 ovens offer two different vacuum oven connection points. The standard connection is a 3/8″ dia barb located at the rear of the oven. It is connected to the vacuum valve level on the front control panel. For even faster evaporation, purging or drying consider upgrading to the MAXEVAP connection kit. The MAXEVAP connection kit secures to the oven’s rear 1″ dia KF-25 port located on the back center of the chamber. The MAXEVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthroughs, or monitoring sensors inside the vacuum chamber during processing. Stackable Shelf Design For Maximum Temperature Conduction Under vacuum, there is no air inside a vacuum oven. Temperatures are achieved by a process of conduction and radiation to move temperatures into the product inside the oven. stackable shelf design makes the most of this opportunity by making the chamber longer and narrower, rather than square and supplies stackable shelves in multiple height configurations to allow for the fastest, most uniform transfer of heat. Ergonomically Designed, Easy Quarter-Turn Valves For anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vacuum/vent valves. Your wrists will thank you! Door Gasket Options – Ideal For Your Process Vacuum ovens come standard with a High Temp Silicone Door Gasket. We also offer a Solvent resistant BUNA gasket as well. Ask us about the variety of door gaskets we can supply based on your application: Silicone, BUNA, Viton, Fluorosilicone. Gaskets will eventually wear out. It’s ideal to keep a few spares on hand. Features CVO-2 STANDARD Package Includes: Cascade Sciences CVO-2 (120V) Vacuum Oven Vacuum Oven to Pump Connection Kit Agilent IDP3 Oil-Free Vacuum Pump, 2.1 cfm Features: NRTL Certified by TUV 5 shelves (11.5″W x 19″D) in a flexible configuration. Stack-able and removable Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reports in wide variety of measurement units Simple, set-point control Smooth, quarter-turn vacuum and vent valves Rear KF-25 port allows for rapid MAXEVAP purging or running feedthroughs inside oven for monitoring 120V (220V available) Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Adjustable leveling feet ensure oven sits solid and level in the workspace CVO-2 Connections 3/8″ Barb for Vacuum Pump 1/4″ Barb for Venting (N2 Connection OK) KF-25 Port for feedthroughs or MAXEVAP Connection Kit Specifications Capacity Volume:1.67 Cu Ft (47.2 L) Exterior:20.5″W x 28.8″D x 24.9″H (521mm x 732mm x 633mm) Interior:12.0″W x 20.0″D x 12.0″H (304mm x 508mm x 304mm) Temperature Temperature Range:Ambient +10ºC to 150°C (Ambient +18°F to 300°F) Temperature Uniformity:@ 105°F ±2.5°F@ 200°F ±7.5°F@ 300°F ±16.0°F@ 40°C ±1.4°C@ 90°C ±4.2°C@ 150°C ±8.9°C Temperature Stability:@ 105°F ±0.3°F@ 200°F ±0.3°F@ 300°F ±0.3°F @ 40°C ±0.2°C@ 90°C ±0.2°C@ 150°C ± 0.2°C Heat Up Times:To 105°F 60 minutesTo 200°F 126 minutesTo 300°F 180 minutes To 40°C 60 minutesTo 90°C 126 minutesTo 150°C 180 minutes *Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product and variable ambient conditions. Vacuum Vacuum Valve:1/4 Turn Lever Vent Valve:1/4 Turn Lever Vacuum Gauge:Digital 0 to 29.9″Hg Temperature Controller:Digital Set PointAccurate Within .5ºC (1°F)Independent Overtemp Failsafe Ports (Rear) Vacuum:3/8″ Barb Vent:1/4″ Barb Auxiliary:KF-25 Port Inert Gas Introduction:Use 1/4″ Vent Barb15 psi max inlet pressure Power Options CVO-2 (120V Standard)110V – 120V / 1ph / 8A 50/60Hz (Cord Included)NEMA 5-15R Power OutletFull Power 2456 BTU/hr CVO-2-2 (220V)220 – 240V / 1ph / 4A 50/60 Hz (Cord Included)NEMA 6-15R Power Outlet Shelving Includes 5 aluminum, stackable, removable 1″ High = 1 each2″ High = 2 each3″ high = 2 each Surface Area:11.5″W x 19″D Weight Capacity:50 lbs (22.7 kgs)*Flexible configuration, 4 shelves max Door Interior Lighting:LED Strips (Rated to 150°C) Glass Window:Tempered NGI-US to ANSI Z97.1.2007 Gasket Type:12″ x 12″ High Temp Silicone Standard Gasket Rated to: 230°C (446°F) Gasket Options:Solvent Resistent BUNA Option rated to 105°C (221°F)Viton Option rated to 205°C (401°F) Weight Unit Weight:179 lb (81.2 kg) Shipping Weight:218 lb (99 kg) Shipping Dimensions:33″L x 33″W x 47″D (Class 85) CV0-2 Vacuum Oven Accessories: CVO-2 2″ ShelfCVO-2 3″ ShelfCVO-2 PTFE Sheets

$6,889.00 - $10,499.00

CRVpro30

Welch CRVpro30 Two-Stage Rotary Vane Pumps •Consumes up to 36% less oil than comparable pumps. •Runs 10°C cooler than comparable pumps. Slows corrosion. •Has a 40% larger oil capacity than comparable pumps. Dilutes aggressive chemicals. •Has a chemical resistant coating in the oil case and pump module. Protects non-moving parts. •Available in 115V/60Hz. •Free air displacement @60Hz: 22.1 cfm (627 L/min) •Ultimate pressure: 3x10-3 mbar (2x10-3 Torr). CRVpro vacuum pumps are two-stage direct-driven vacuum pumps. They are nine models of CRVpro available with free air displacement from 1.8 cfm to 52.5 cfm. Ultimate pressure to 2x10⁻³ torr. Three models of pumps with explosion proof motors, with free air displacements from 2.8 to 12.8 cfm, are available by clicking on the "Explosion Proof" tab below. The benefits of CRVpro pumps are: reduced risk of chemical attacks and oil breakdown by diluting chemical vapors with a larger oil chamber slowing down corrosion by cool running operation provides a measure of protection from sublimed chemical vapors with coating on pump module and oil case. These benefits lead to extended service interval. Depending on model, motor options include 1 Ph TEFC, 3 Ph TEFC, and 1 Ph ex proof motors. Welch vacuum pump oil is specifically formulated for the unique needs of vacuum pumps. Use of non-Welch vacuum pump oil voids any performance claims and product warranties. •In Duoseal belt driven rotary vane pumps, use Welch Duoseal or Welch Gold Oil •In CRVpro rotary vane pumps use Welch premium or Welch gold oil •In Chemstar belt driven rotary vane pumps use Welch gold oil CRVpro vacuum pumps can be used for freeze drying, vacuum ovens, concentrators, glove boxes, schlenk lines, HVAC/refrigeration service, coaters, backing diffusion pumps and turbo molecular pumps, short path, wiped film, metallurgy/vacuum furnaces, lamp manufacture, space simulation, degassing, vessel/chamber evacuation. CRVpro vacuum pumps prepared with perfluoropolyether (PFPE) for oxygen service are available. Contact your local Welch sales representative for details on PFPE prepared pumps and for selecting correct vacuum pump for your application. Weight 99 Ultimate Pressure 3 x10⁻³ Dimensions (mm) 683x384x389 Free Air Desplacement 22.1 (627)

$7,738.00

Edwards EMF10/20 Vacuum Pump Exhaust Filter Mist/Odour Elements

Edwards EMF10/20 Vacuum Pump Exhaust Filter Mist/Odour Elements One replacement oil mist element and one replacement odour removal element for Edwards EMF10 dual-stage vacuum pump exhaust filters. (2 replacement filter elements only, EMF10 filter and accessories NOT included)

$207.00 - $220.00

Edwards EMF20 Dual-Stage Exhaust Mist/Odour Filter

Edwards EMF20 Dual-Stage Exhaust Mist/Odour Filter Mist filters capture oil mist from the outlet of pumps, which would otherwise be ejected into the atmosphere. This may happen when you use gas ballast or when you pump high gas throughputs. You can also return oil trapped in the mist filter back to the pump, although you must ensure that the process gases will not contaminate the pump or pump oil. The EMF20 mist filter is suitable for use with RV12 and E2M18 pumps. The EMF20 mist filter can be used with an E2M28 on low pressure applications; contact Edwards. They are very efficient at 99.999% DOP test and are also azide proof. The white bottom half of the body is semi-transparent, allowing the oil level to be monitored. The EMF filters have a unique odor element which neutralizes the smell of oil mist. Supplied with NW25 clamp, centering ring and O ring, NW25 to 3/4 inch BSP adaptor.

$482.00

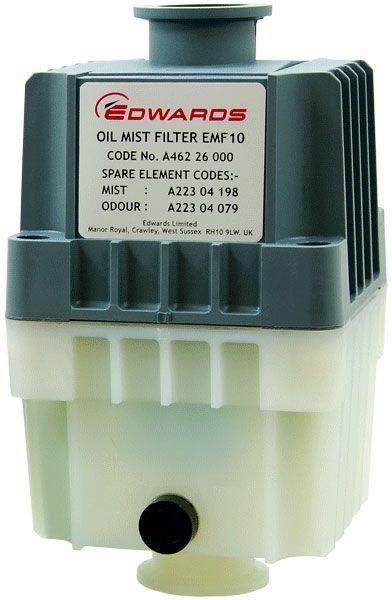

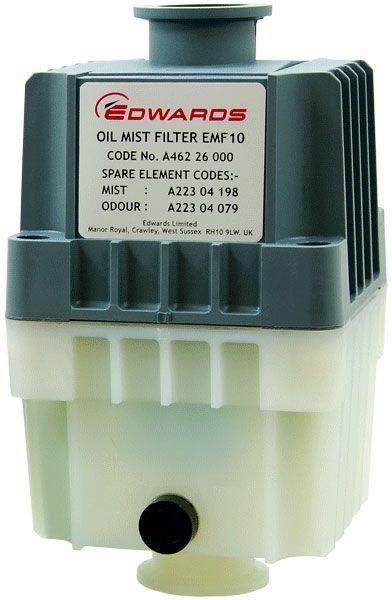

Edwards EMF10 Dual-Stage Exhaust Mist/Odour Filter

Edwards EMF10 Dual-Stage Exhaust Mist/Odour Filter OverviewMist filters capture oil mist from the outlet of pumps, which would otherwise be ejected into the atmosphere. This may happen when you use gas ballast or when you pump high gas throughputs. You can also return oil trapped in the mist filter back to the pump, although you must ensure that the process gases will not contaminate the pump or pump oil. The EMF10 mist filter is suitable for use with RV3, RV5 and RV8 pumps. They are very efficient at 99.999% DOP test and are also azide proof. The white bottom half of the body is semi-transparent, allowing the oil level to be monitored. The EMF filters have a unique odor element which neutralizes the smell of oil mist. Supplied with NW25 clamp, centering ring and O ring, NW25 to 3/4 inch BSP adaptor.Dimensions Height: 6.72" Width: 3.81"

$405.00 - $612.00

Edwards XDS46iC 35cfm Chemical-Resistant Scroll Pump W/ Silencer

Edwards XDS46iC 35cfm Chemical-Resistant Scroll Pump W/ Silencer XDS scroll pumps have become industry standard when dry pumping is essential, proving to be a robust and clean vacuum pump solution in a range of applications and processes.The XDS46i shares many of the same features of the XDS35i but with a peak speed of 40 m3h-1. The pump has been optimised for maximum pumping speed at inlet pressures between 1 mbar and 10 mbar, making it ideally suited for LCMS and ICPMS applications requiring higher pumping speeds. The C variant has been modified so that it is more suitable for use on vapour handling processes and may be used in some applications using corrosive substances. The C version is fitted with Chemraz internal valve pads and stainless steel exhaust port. Applications Automotive; brake line and air conditioning evacuation Backing turbomolecular pumps Chemical applications including gel dryers and solvent recovery Coating systems High energy physics Mass spectrometry Features and benefits Lubricant-free within the vacuum envelope and hermetically sealed means a totally clean and dry vacuum to prevent cross contamination. No atmosphere to vacuum shaft seals means bearings are completely isolated, this prevents process attack and enable the bearings to run cooler and last longer. No oil to change eliminating cost of contaminated oil disposal. Simple single sided scroll design allows maintenance to be done in minutes for low cost of ownership and maximum uptime. Inverter drive for consistent pumping speeds worldwide. Specifications Power 100-120V or 200-230V switchable Displacement 50 or 60HzPeak pumping speed 50 or 60Hz 60 m3h-1 / 35 ft3min-140 m3h-1 / 23.5 ft3min-1 Ultimate vacuum (Total pressure) 5 x 10-2 mbar / 4 x 10-2 Torr Max continuous inlet pressure 40 mbar / 30 Torr Max continuous outlet pressure 0.2 bar gauge / 2.9 psig Max allowed inlet and GB pressure 0.5 bar gauge / 7 psig Motor power 0.52kW Power connector IEC EN60320 C19 Nominal rotation speed 1750 rpm Weight 48 kg / 105 lb Inlet / exhaust flange NW40 / NW25 Noise and vibration level 55.4 dB (A), <4.5mms -1 (rms) Leak tightness (static) <1 x 10-6 mbar ls-1 Operating temperature range 10 to 40 °C / 50 to 104 °F Compliance UL, CE, ATEX

$18,708.00

Edwards XDS35iC 25cfm Chemical-Resistant Scroll Pump W/ Silencer

Edwards XDS35iC 25cfm Chemical-Resistant Scroll Pump W/ Silencer Dry Scroll Pumps Dry scroll vacuum pumps are positive displacement pumps that use two spiral-shaped scrolls, one fixed and one orbiting, to trap and compress gas molecules. They are oil-free, low maintenance pumps that are commonly used for clean vacuum applications. Since they do not rely on oil for sealing and lubrication, they eliminate the risk of oil contamination and leakage, making them an environmentally-friendly choice. We in Edwards are driving scroll technologies to its best and we are committed to offer the most sustainable solution now and in the future. XDSi Scroll Pumps XDS dry scroll pumps have become industry standard when dry pumping is essential, proving to be a robust and clean vacuum pump solution in a range of applications and processes. XDS35i The XDS35i family of scroll pumps offers proven dry, clean vacuum solutions for a wide range of applications, with smart drive technology to look after the pump and provide worldwide performance. Now, a combination of the double start scroll form technology and by-pass valves have enabled Edwards to offer the XDS35i Enhanced range of pumps to complement our original family. XDS35i - 100-120/200-230V 50/60Hz 1Ph The XDS35i is our standard product variant which can be operated in a wide range of applications. Features and Benefits Bearing shield - ensures separation between process gases and bearing lubrication to ensure a clean vacuum and no possibility of contamination to lubrication from process gases, which prolongs bearing life. Smart motor drive - means consistent performance globally, pump overload protection and remote start/stop capability. High flow gas ballast feature - allows pumping of vapours including water vapour at up to 240 gh-1. Simple single-sided scroll design - allows maintenance to be done in minutes for low cost of ownership and maximum up-time. Take another step - the Enhanced versions offer up to 20% lower peak power requirements during initial pump down which means it has the ability to pump down large volume chambers with no loss of performance and has up to 25% more pumping speed at these roughing pressures which helps on higher frequency cycling applications as well. Specifications Specifications Power 100-120V or 200-230V switchable Displacement / peak pumping speed (50/60Hz) 43 m3h-1 / 25 ft3min-135 m3h-1 / 21 ft3min-1 Ultimate vacuum (Total pressure)Max continuous inlet pressure 1 x 10-2 mbar / 8 x 10-3Torr35 mbar / 23 Torr Max water vapour pumping rate - GB I / GBII 70 gh-1 / 240 gh-1 Max continuous outlet pressure 0.2 bar gauge / 2.9 psig Max allowed inlet and GB pressure 0.5 bar gauge / 7 psig Motor power / speed 0.52kW / 1750 rpm Power connector IEC EN60320 C19 Weight 48 kg / 105 lb Inlet flange / Exhaust flange NW40 / NW25 Noise and vibration 57 dB (A), <4.5mms -1 (rms) Leak tightness (static) <1 x 10-6 mbar ls-1 Operating temperature range 10 to 40 °C / 50 to 104 °F Compliance CE, UL, CSA, ATEX

$17,264.00

Edwards NXDS20iC 16.5 Cfm Chemical-Resistant Dry Scroll Pump

Edwards NXDS20iC 16.5 Cfm Chemical-Resistant Dry Scroll Pump Dry Scroll Pumps Dry scroll vacuum pumps are positive displacement pumps that use two spiral-shaped scrolls, one fixed and one orbiting, to trap and compress gas molecules. They are oil-free, low maintenance pumps that are commonly used for clean vacuum applications. Since they do not rely on oil for sealing and lubrication, they eliminate the risk of oil contamination and leakage, making them an environmentally-friendly choice. We in Edwards are driving scroll technologies to its best and we are committed to offer the most sustainable solution now and in the future. nXDSi Scroll Pumps Edwards nXDS is the great new shape of dry vacuum pumping. The nXDS has taken scroll vacuum technology to the next level. Improved performance, exceptional pumping capability, quiet operation and extended service intervals make nXDS the ultimate dry choice. The range covers pumping speeds from 6 to 20 m3/h. nXDS20i The nXDS20i is our highest peak pumping speed offering in the nXDS range. Standard variant suitable for a large variety of applications; R-variant with blanked gas ballast and C-variant being corrosion resistant. nXDS20iC - 100-127/200-240V 1Ph 50/60Hz The nXDS20iC has been modified so that it is more suitable for use on vapour handling processes and may be used in some applications involving corrosive substances. This chemically resistant version is fitted with Chemraz® internal valve pads and stainless steel fittings. Features and Benefits Quiet operation - Better working environment Hermetically sealed for a lubricant-free vacuum environment - Contamination free process and no oil to dispose of Low power consumption - Low cost of ownership Intelligent and easy to use controls - Flexibility of operation Superior vapour handling - Wider range of applications Long service intervals - Maximised up-time

$14,472.00

Edwards NXDS10iC 7.5 Cfm Chemical-Resistant Dry Scroll Pump

Edwards NXDS10iC 7.5 Cfm Chemical-Resistant Dry Scroll Pump Dry Scroll Pumps Dry scroll vacuum pumps are positive displacement pumps that use two spiral-shaped scrolls, one fixed and one orbiting, to trap and compress gas molecules. They are oil-free, low maintenance pumps that are commonly used for clean vacuum applications. Since they do not rely on oil for sealing and lubrication, they eliminate the risk of oil contamination and leakage, making them an environmentally-friendly choice. We in Edwards are driving scroll technologies to its best and we are committed to offer the most sustainable solution now and in the future. nXDSi Scroll Pumps Edwards nXDS is the great new shape of dry vacuum pumping. The nXDS has taken scroll vacuum technology to the next level. Improved performance, exceptional pumping capability, quiet operation and extended service intervals make nXDS the ultimate dry choice. The range covers pumping speeds from 6 to 20 m3/h. nXDS10i The nXDS10i same as the nXDS15i are our key products offering a small dry pump solution for most Scientific Applications. Standard variant suitable for a large variety of applications; R-variant with blanked gas ballast and C-variant being corrosion resistant. nXDS10iR - 100-127/200-240V 1Ph 50/60Hz The nXDS10iR has the gas ballast blanked off so it cannot be accidently opened. These variants are available for specialist applications such as gas recirculation, rare gas pumping and recovery or other applications where the dilution of the pumped gas is undesirable, or where sealing is integral to minimising potential gas loss. Features and Benefits Quiet operation - Better working environment Hermetically sealed for a lubricant-free vacuum environment - Contamination free process and no oil to dispose of Low power consumption - Low cost of ownership Intelligent and easy to use controls - Flexibility of operation Superior vapour handling - Wider range of applications Long service intervals - Maximised up-time Specifications Technical Data Power requirements 100-127V~10A or 200-240V~6A, 50/60 Hz, 280 watts Nominal rotational speed 1800 rpm Displacement 12.7 m3h-1/ 7.5 ft3min-1 Peak pumping speed 11.4 m3h-1/ 6.7 ft3min-1 Ultimate vacuum (total pressure) 0.007 mbar / 0.005 Torr / 5 micron Minimum standby rotational speed 1200 rpm Speed control resolution (% of full speed) 1% Maximum inlet pressure for water vapour 35 mbar Maximum water vapour pumping rate 145 gh-1 Maximum continuous inlet pressure 200 mbar Power connector 1-ph IEC EN60320 C13 Recommended fuse 10A, 250Vac rms Unit/shipping weight 57 Lb / 60 Lb Unit/shipping dimensions 16.5x10x12" / 20.5x13x14" (DxWxH) Inlet flange NW25 (KF25) Exhaust flange NW25 (KF25) Noise level 52 dB(A) Vibration at inlet flange < 4.5 mms-1 (rms) Leak tightness (static) < 1x10-6mbar ls-1 Operating temperature range 10 to 40 C / 41 to 104 F Edwards part number A73602983 Certification CE, UL

$10,445.00

Edwards NXDS6iC 4.0 Cfm Chemical-Resistant Dry Scroll Pump

dwards NXDS6iC 4.0 Cfm Chemical-Resistant Dry Scroll Pump Dry Scroll Pumps Dry scroll vacuum pumps are positive displacement pumps that use two spiral-shaped scrolls, one fixed and one orbiting, to trap and compress gas molecules. They are oil-free, low maintenance pumps that are commonly used for clean vacuum applications. Since they do not rely on oil for sealing and lubrication, they eliminate the risk of oil contamination and leakage, making them an environmentally-friendly choice. We in Edwards are driving scroll technologies to its best and we are committed to offer the most sustainable solution now and in the future. nXDSi Scroll Pumps Edwards nXDS is the great new shape of dry vacuum pumping. The nXDS has taken scroll vacuum technology to the next level. Improved performance, exceptional pumping capability, quiet operation and extended service intervals make nXDS the ultimate dry choice. The range covers pumping speeds from 6 to 20 m3/h. nXDS6i The nXDS6i is our entry performance model in the nXDS range. Standard variant suitable for a large variety of applications; R-variant with blanked gas ballast and C-variant being corrosion resistant. nXDS6iC - 100-127/200-240V 1Ph 50/60Hz The nXDS6iC has been modified so that it is more suitable for use on vapour handling processes and may be used in some applications involving corrosive substances. This chemically resistant version is fitted with Chemraz® internal valve pads and stainless steel fittings. Features and Benefits Quiet operation - Better working environment Hermetically sealed for a lubricant-free vacuum environment - Contamination free process and no oil to dispose of Low power consumption - Low cost of ownership Intelligent and easy to use controls - Flexibility of operation Superior vapour handling - Wider range of applications Long service intervals - Maximised up-time Specifications Connection Vacuum Inlet Flange DN 25 ISO-KF (NW25) Connection vacuum outlet flange DN 25 ISO-KF (NW25) Cooling Method Air Cooling (forced - fan) Pressure Ultimate 2.901 x 10 -4 Supply Voltage 1Ph 100-127/200-240V 50/60Hz Specifications Technical Data Power requirements 100-127V~10A or 200-240V~6A, 50/60 Hz, 260 watts Nominal rotational speed 1800 rpm Displacement 6.8 m3h-1/ 4.0 ft3min-1 Peak pumping speed 6.2 m3h-1/ 3.6 ft3min-1 Ultimate vacuum (total pressure) 0.020 mbar / 0.015 Torr / 15 micron Minimum standby rotational speed 1200 rpm Speed control resolution (% of full speed) 1% Maximum inlet pressure for water vapour 35 mbar Maximum water vapour pumping rate 110 gh-1 Maximum continuous inlet pressure 200 mbar Power connector 1-ph IEC EN60320 C13 Recommended fuse 10A, 250Vac rms Unit/shipping weight 58 Lb / 63 Lb Unit/shipping dimensions 16.5x10x12" / 20.5x13x14" (DxWxH) Inlet flange NW25 (KF25) Exhaust flange NW25 (KF25) Noise level 52 dB(A) Vibration at inlet flange < 4.5 mms-1 (rms) Leak tightness (static) < 1x10-6mbar ls-1 Operating temperature range 10 to 40 C / 41 to 104 F Edwards part number A73502983 Certification CE, UL, CSA

$8,491.00

Edwards E2M80 57 CFM Dual-Stage High Capacity Vacuum Pump

Edwards E2M80 57 CFM Dual-Stage High Capacity Vacuum Pump Brand new Edwards E2M80 high capacity vacuum pump with one year manufacturer warranty from Edwards. https://shop.edwardsvacuum.com/products/a36504940/view.aspx Overview Edwards E2M series two stage oil sealed rotary vane vacuum pumps are renowned for their high ultimate vacuum, rapid pumping speeds, quiet operation and ability to handle water vapour. These direct drive rotary vane pumps are inherently compact and vibration free, and with their finger-proof fan and coupling housings they offer excellent operator protection.A comprehensive range of accessories is available to allow use on a wide variety of vacuum applications.Supplied with Ultragrade 70 Oil. Fomblin must be purchased separately for PFPE prepared pumps E2MFX. Technology Reliable system protection devices: Every pump has protection devices to prevent oil and air suck-back into the vacuum system if the pump stops while under vacuum. A variety of protection devices are used, depending on the pump size and cost, but emphasis is always placed on reliability and simplicity. When you use gas ballast on some of the pumps, you must use a solenoid operated gas ballast control valve to prevent air suck-back.Positive Pressure Oil Lubrication: The EM pumps incorporate a well proven positive pressure oil lubrication system which as been developed by Edwards to ensure correct lubrication in all duty modes and particularly to prevent oil starvation with high gas loads.An integral oil pump ensures that a more than adequate oil flow is pumped throughout the stator/rotor assembly at all times. This oil lubrication system means that the level of oil in the reservoir is less critical than with other pump designs. All pumps can operate with oil levels as low as 50-70 of the maximum. A full length, easily visible oil level sight glass allows you to conveniently monitor the oil level.Gas Ballast Facility: The EM pumps have a gas ballast valve. The valve is used to introduce a suitable gas into the stator during the compression stage: this prevents condensation of vapors inside the pump, dilutes and ejects corrosive gases and purges the oil of gases and vapors. Therefore, the use of gas ballast reduces oil degradation and pump corrosion.Low Noise Levels: The EM pumps maintain Edwardss reputation for quiet operation pumps with a typical noise level of 70 dB(A).Pumping Systems: The EM pumps, with suitable accessories, can partner a variety of other types of pump in vacuum systems for industry and for research. A special feature of the E2M80 is the central vacuum inlet which enables you to fit a mechanical booster pump with a minimum overhang, to create compact combination pumping systems.Easy Maintenance: The advanced lubrication system allows the EM pumps to work with wide oil level tolerances, which reduce the need to top-up the oil.All EM pumps are constructed with internal dowels, which reduce the need for skilled setting of tolerances, when the pump is dismantled. The pumps are designed so that all key components are easily accessible. The exhaust valve seals and oil distributor seals are exposed after the top cover is removed. The shaft seal can be replaced quickly without stripping down the pump. Applications Vacuum metallurgy processes Thin film coating technologies Pharmaceutical freeze drying Refrigeration and air conditioning system evacuation, drying, and backfilling Transformer and cable drying and impregnation, insulating oil treatment plant Lamp manufacture Cryogenic vessel evacuation Vacuum drying and distillation in chemical industries Semiconductor device manufacture Backing pump for high vacuum applications

$18,244.00

Edwards PFPE E2M28 FX 22 CFM Dual-Stage Vacuum Pump

Edwards PFPE E2M28 FX 22 CFM Dual-Stage Vacuum Pump Brand new Edwards E2M28 FX high capacity vacuum pump with one year manufacturer warranty from Edwards. E2M28 replaces the discontinued E2M30, click links below for more details. Free KF25 flexible stainless steel bellow (3.3 ft), clamps and centering rings set ($219 value) included. Technical support and one year warranty, covered by Edwards. https://shop.edwardsvacuum.com/products/a37325984/view.aspx Requires three of the Edwards FOMBLIN Y VAC 06/06 1KG PEPE oil (Not included. P/N h21301019) https://shop.edwardsvacuum.com/products/h21301019/view.aspx Edwards ITC20K inlet chemical trap recommended (Not included. P/N A44410000) https://shop.edwardsvacuum.com/products/a44410000/view.aspx Overview The EM range of oil‑sealed rotary pumps – renowned for their high ultimate vacuum, rapid pumping speed, quiet operation and ability to handle vapour – have become the industry standard for laboratory and light industrial applications. The pump is a freestanding unit with the drive provided through a flexible coupling by either a single‑phase or three‑phase (four pole) air cooled motor. Each EM pump is supplied with 2 x 1 litre of Ultragrade 19 oil, O ring and centering ring, two Allen keys and spares seal for oil drain and filter plugs. For PFPE prepared FX pumps Fomblin® to be ordered separately. Technology The motor is totally enclosed and is cooled by the motor-cooling fan which directs air along the motor fins. The motors are fitted with a thermal overload device. When the motor is too hot, the thermal overload device switches off the pump. The thermal overload device has an automatic reset; when the motor cools down, the device resets and the motor will restart. An oil pressure system lubricates the pump shaft bearing surfaces and rotor sealing faces. The pump has an oil distribution valve which prevents discharge of oil to the pump interior (suckback) after the pump stops. The pumping chambers are air-tight, so this arrangement prevents oil suckback unless the gas ballast valve is open. You can inspect the level and condition of oil in the oil box reservoir through the oil sight-glass. An oil filler-plug is fitted to the top of the oil box. The pump has two oil drain-plugs to allow either gravity oil drain or pressure oil drain. Features The pump is designed for reliable, long-term operation. Thermal overload device prevents overheating (single phase only). The drive is provided through a flexible coupling by a single-phase or three-phase (four pole) motor. The motors are totally enclosed and are cooled by the motor-cooling fan. Full height O ring sealed oil sight glass for easy checking of oil level and condition. Large sight glass and operating oil range. IE3 energy efficient 3 phase motor used with E2M28. Applications Analytical instruments - LCMS Automotive Beam lines and high energy physics Centrifuges, ultra-high speed Coating Cryogenics Degassing/curing - oil, epoxy resin Distillation/extraction/filtration Freeze drying Furnaces Gas bottle filling/emptying Gel drying Glove boxes, ovens Laboratory bench top vacuum Lasers, gas recovery and re-circulation Leak detectors, Helium Load locks and transfer chambers Refrigeration manufacture Rotary, centrifugal evaporators Solvent recovery Surface science instruments Turbomolecular backing pumps

$10,414.00

Edwards PFPE RV3 2.6 CFM Dual-Stage KF25 Vacuum Pump

Edwards PFPE RV3 2.6 CFM Dual-Stage KF25 Vacuum Pump Free KF25 flexible stainless steel bellow (3.3 ft), clamps and centering rings set ($219 value) included for immediately use (mist filter NOT included). Technical support and one year warranty covered by Edwards. https://shop.edwardsvacuum.com/products/a65209903/view.aspx Requires two of the Edwards FOMBLIN Y VAC 06/06 1KG PEPE oil (Not included. P/N h21301019) https://shop.edwardsvacuum.com/products/h21301019/view.aspx Edwards ITC20K inlet chemical trap recommended (Not included. P/N A44410000) https://shop.edwardsvacuum.com/products/a44410000/view.aspx Overview The Edwards RV series of small oil sealed rotary vane pumps deliver excellent ultimate vacuum pressure, high pumping speeds and superior vapour handling capabilities with quiet operation. With 400,000 units produced, these pumps offer proven performance that sets the industry standard for R&D and scientific pumping applications. Fomblin® must be purchased separately for PFPE RV pumps. Technology All our RV pumps are quiet. Noise levels of 48 dBA 50Hz have been achieved by extensive work on the pump design, drive train and motor.The pumps have the unique ability to deliver excellent ultimate vacuum in both high vacuum and high throughput modes with or without gas ballast. This gives the user an unrivalled opportunity to select the optimum pumping performance without compromising the application.The simple to use mode selector and accessible, three-position gas ballast control allow the pump to be reconfigured at any time, even when the pump is running.In high vacuum mode, the RV pump is ideal for analytical instruments, electron microscopes, physics research, backing turbo pumps and leak detection applications. Configure the same pump in the high throughput mode, and it becomes suitable for distillation, laboratory furnaces, backing vapor pumps, solvent concentration, freeze drying and other drying applications. Features High reliability – generous lubrication of moving parts. Safe process and systems – fast acting inlet valve for best in class anti‑suck back protection. Configured to meet your vacuum needs – mode selector and three position gas ballast No unplanned downtime – designed for easy maintenance. Better work environment – quiet running and intrusive frequencies minimised. Three position gas ballast allows either 60 g/hr or a class leading 220 g/hr (290 g/hr on RV12) of water vapour to be handled. Universal motor to cover the widest possible voltage and frequency range from a single variant. Smooth controlled inlet valve opening by oil pressure to eliminate pressure surges. Rapid closing inlet valve within 0.4 seconds of pump stopping. Applications Analytical instruments Centrifuges, ultra-high speed Coating Degassing/curing - oil, epoxy resin Distillation/extraction/filtration Freeze drying Furnaces Gas bottle filling/emptying Gel drying Glove boxes, ovens Laboratory bench top vacuum Leak detectors, Helium Load locks and transfer chambers Refrigeration manufacture Research and development Rotary, centirfugal evaporators Scanning electron microscopes - SEM SEM/FIB (ion beam repair) Solvent recovery Surface science instruments Turbomolecuar backing pumps

$5,131.00 - $7,026.00

Edwards RV3 2.6 CFM Dual-Stage KF25 Vacuum Pump

Edwards RV3 2.6 CFM Dual-Stage KF25 Vacuum Pump Free KF25 flexible stainless steel bellow (3.3 ft), clamps and centering rings set ($219 value) included for immediately use (mist filter NOT included). Technical support and one year warranty covered by Edwards. https://shop.edwardsvacuum.com/products/a65201903/view.aspx Overview The Edwards RV series of small oil sealed rotary vane pumps deliver excellent ultimate vacuum pressure, high pumping speeds and superior vapour handling capabilities with quiet operation. With 400,000 units produced, these pumps offer proven performance that sets the industry standard for R&D and scientific pumping applications. Technology All our RV pumps are quiet. Noise levels of 48 dBA 50Hz have been achieved by extensive work on the pump design, drive train and motor.The pumps have the unique ability to deliver excellent ultimate vacuum in both high vacuum and high throughput modes with or without gas ballast. This gives the user an unrivalled opportunity to select the optimum pumping performance without compromising the application.The simple to use mode selector and accessible, three-position gas ballast control allow the pump to be reconfigured at any time, even when the pump is running.In high vacuum mode, the RV pump is ideal for analytical instruments, electron microscopes, physics research, backing turbo pumps and leak detection applications. Configure the same pump in the high throughput mode, and it becomes suitable for distillation, laboratory furnaces, backing vapor pumps, solvent concentration, freeze drying and other drying applications. Features High reliability – generous lubrication of moving parts. Safe process and systems – fast acting inlet valve for best in class anti‑suck back protection. Configured to meet your vacuum needs – mode selector and three position gas ballast No unplanned downtime – designed for easy maintenance. Better work environment – quiet running and intrusive frequencies minimised. Three position gas ballast allows either 60 g/hr or a class leading 220 g/hr (290 g/hr on RV12) of water vapour to be handled. Universal motor to cover the widest possible voltage and frequency range from a single variant. Smooth controlled inlet valve opening by oil pressure to eliminate pressure surges. Rapid closing inlet valve within 0.4 seconds of pump stopping. Applications Analytical instruments Centrifuges, ultra-high speed Coating Degassing/curing - oil, epoxy resin Distillation/extraction/filtration Freeze drying Furnaces Gas bottle filling/emptying Gel drying Glove boxes, ovens Laboratory bench top vacuum Leak detectors, Helium Load locks and transfer chambers Refrigeration manufacture Research and development Rotary, centirfugal evaporators Scanning electron microscopes - SEM SEM/FIB (ion beam repair) Solvent recovery Surface science instruments Turbomolecuar backing pumps

$3,836.00 - $4,241.00

Dual Diaphragm Rebuild Kit For ULVAC UDP 6 Cfm Pumps

Dual Diaphragm Rebuild Kit For ULVAC UDP 6 Cfm Pumps Overview Dual-diaphragm rebuild kit for UDP6 6 CFM chemical duty diaphragm pumps. Standard package Part description Quantity Part image Diaphragm 2 pc Pump Head Cover Gasket 2 pc Valve 4 pc O-Ring N-15 4 pc O-Ring P-18 2 pc Bill of Material 1 pc

$880.00

Dual Diaphragm Rebuild Kit For ULVAC DTC-41 1.6 Cfm Pumps

Dual Diaphragm Rebuild Kit For ULVAC DTC-41 1.6 Cfm Pumps Overview Dual-diaphragm rebuild kit for DTC-41 1.6 CFM dual-stage chemical duty diaphragm pumps. Standard package Part description Quantity Part image Diaphragm NT 2 pc Suction/discharge Valve A 3 pc Suction/discharge Valve B 2 pc O-Ring (S-28) 4 pc O-Ring (P-10A) 2 pc O-Ring (AS568-110) 4 pc Bill of Material 1 pc

$420.00

ULVAC UDP-6 6 Cfm Full Chemical-Resistant 2-Head Diaphragm Pump

ULVAC UDP-6 6 Cfm Full Chemical-Resistant 2-Head Diaphragm Pump Overview Ai exclusive, compact, lightweight, manufactured and imported directly from Japan, ULVAC UDP-6 is a high capacity full chemical-resistant 2-head pump that creates deep vacuum by reciprocate movement of rubber diaphragms. These pumps are oil-free, which means less maintenance and no more frequent and costly oil change, or cross contamination. Applications TUV certified to UL and CSA standards Moisture & solvent evaporation Vacuum chucks, wafer and tip handling devices Vacuum tweezers, medical appliances Printing equipment Automatic packing machines Optical appliances Semiconductor industry Specifications Model ULVAC UDP-6 (DA-170DA/B) Electrical requirements 110V 50/60Hz or 220V 50/60Hz single phase 400 watts, 5.6 amp rated current Pumping rate 6 cfm Ultimate vacuum level 6 torr Inlet/Outlet KF25 flange Adjustable vac./gas ballast No Unit/shipping dimensions (LxWxH) 16 x 7 x 13" / 18 x 11 x 14.5" Noise level 68 dBA at Atmosphere pressure 62 dBA at ultimate pressure Unit/shipping weight 58 Lb / 63 Lb Working environment 32°F to 104°F (0°C to 40°C) Compliance TUV certified to UL and CSA standards

$3,990.00 - $4,870.00

ULVAC DA-241 9.2 Cfm Oil-Free Diaphragm Pump

ULVAC DA-241 9.2 Cfm Oil-Free Diaphragm Pump Overview Manufactured and imported directly from Japan, ULVAC DA series diaphragm pumps creates vacuum by reciprocate movement of rubber diaphragms. Various pumping speed and two/single stages are selectable depends on your required pressure and pumping volume. These pumps are oil-free, which means less maintenance and no more frequent and costly oil change, or cross contamination. Ai is now the official dealer of ULVAC vacuum pumps. These pumps are made in Japan with one year warranty and technical support from ULVAC. Applications Alcohol evaporation Vacuum chucks, wafer and tip handling devices Vacuum tweezers, medical appliances Printing equipment Automatic packing machines Optical appliances Semiconductor industry Free three feet 3/8" white premium food grade silicone vacuum tubing ($19.99 value) included. Specifications Model ULVAC DA-241 Electrical requirements 110V 50/60Hz or 220V 50/60Hz single phase, 400 watts Full load current 6.0 amps Pumping rate 9.2 cfm Ultimate vacuum level 120 torr Inlet/Outlet 5/8" hose barb Adjustable vac./gas ballast No Unit/shipping dimensions (LxWxH) 8 x 16 x 11" / 18/11/14.5" Unit/shipping weight 58 Lb / 63 Lb Working environment 32°F to 104°F (0°C to 40°C) Noise level 70 dBA at near Atmospheric pressure 65 dBA at ultimate pressure Certification CE, TUV

$3,490.00 - $3,539.00

Agilent IDP-3 Dry Scroll Vacuum Pump With Inlet Isolation Valve

Agilent IDP-3 Dry Scroll Vacuum Pump With Inlet Isolation Valve A Overview The Agilent IDP-3 dry scroll pump is an innovative, compact, high-performance, oil-free vacuum pump that is suitable for a wide variety of applications. It is the smallest scroll pump made for general vacuum applications, which makes it easy to integrate into OEM systems, and it weighs only 21 pounds (9.5 kg). Yet with a pumping speed of 2.1 cfm (60 L/min) and a very low base pressure of 250 milliTorr, it is the highest-performing dry pump in its class. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. The IDP-10 uses an inverter driven motor, which provides uniform vacuum performance at all global frequencies and input voltages. Its uniform global performance and compact size make it an ideal choice for analytical instruments and industrial OEMs. Specifications Base pressure (50 Hz) - Torr & mbar 2.5 x 10-1 Torr 3.3 x 10-1 mbar Base pressure (60 Hz) - Torr & mbar 2.5 x 10-1 Torr 3.3 x 10-1 mbar Dimensions (WxHxL) 5.5 in x 7.13 in x 14.09 in Exhaust Connection ¼ inch female NPT (10 mm hose barb provided) Height 7.13 in Inlet Connection NW16 Input Voltage 1Ø, 115 V. 60 Hz Length 14.09 in Noise Level 55 dB(A) Pumping Speed (50 Hz) 1.8 CFM 3 m3/h 50 L/min Pumping Speed (60 Hz) 2.1 CFM 3.6 m3/h 60 L/min UNSPSC Code 40151502 Width 5.5 in

$4,331.00

ULVAC DTC-41 230V 1.6 Cfm 2-Stage Chemical-Duty Diaphragm Pump TUV

ULVAC DTC-41 230V 1.6 Cfm 2-Stage Chemical-Duty Diaphragm Pump TUV Manufactured and imported directly from Japan, ULVAC DTC series diaphragm pumps feature integral forced-air cooling. They have two-stage PTFE diaphragms that are ideal for pumping corrosive gases and organic solvents. These pumps are oil-free, portable, and chemical-resistant, which means less maintenance and no more frequent and costly oil change, or cross contamination. Ai is now the official dealer of ULVAC vacuum pumps. These pumps are made in Japan with one year warranty and technical support from ULVAC. Features: TUV certified to UL and CSA standards Only PTFE components are exposed to vacuum, ideal for pumping corrosive gases and organic solvents Integral forced-air cooling Very compact and portable Designed to back most hybrid turbo pumps Applications: Rotary evaporator Evaporating system Vacuum concentrator Vacuum filtration Vacuum drying systems Medical/pharmaceutical equipments Centrifuge Laser-gas circulation Free three feet 3/8" white premium food grade silicone vacuum tubing ($19.99 value) included. Model ULVAC DTC-41 Part number 1042840 Electrical requirements 115V 60Hz or 230V 50/60Hz, single phase 0.13HP, 100 watts Full load current 1.1 amps Pumping rate 1.62 cfm (6 minutes to pump down a 0.9 cu ft oven) Gasket material All-PTFE Ultimate vacuum level 7.5 torr / 10 mbar Inlet/Outlet 3/8" hose barb Adjustable vac./gas ballast No Pump dimensions (LxWxH) 13 x 5.5 x 8.5 inches Shipping dimensions (LxWxH) 15 x 9 x 10 inches Pump weight 23 Lb Shipping weight 26 Lb Noise 53 dB(A) Working environment 32°F to 104°F (0°C to 40°C) Compliance TUV certified to UL and CSA standards

$1,990.00 - $2,410.00

Tip Seal Kit For Agilent IDP3, IDP7, IDP10 Or IDP15

Tip Seal Kit For Agilent IDP3, IDP7, IDP10 Or IDP15 Agilent tip seal replacement kit for IDP-3, IDP-7, IDP-10 or IDP-15 dry scroll pumps.

$287.00 - $510.00

Agilent Diffusion Pump Oil

Agilent Diffusion Pump Oil Agilent diffusion pump oil, recommended for Agilent AX-65 diffusion pump (do NOT fill more than 30mL oil at a time).

$288.00 - $2,005.00

Agilent PCG-750 Pirani Capacitance Diaphragm High Vacuum Gauge (Gauge Only)

Agilent PCG-750 Pirani Capacitance Diaphragm High Vacuum Gauge (Gauge Only) User Manual

$891.00 - $1,116.00

KING SHRED

KING SHRED This is a one of a kind grinder that guarantees a consistent grind every run! Many people who use other grinders face an issue of pulverizing their product leaving dust, chunks, and clusters: making it unpleasant to roll with. This machine has been designed to eliminate all of those unwanted outcomes and ensures the desired consistent and fluffy grind. It contains a motorized hopper that has the ability to work through a pound of material in 1.5 minutes. Its easy to clean and maintain, and there's no doubt that it will increase the efficacy and quality of your production. Dimesions:16 x 12 x 13.75 inches Warranty: One year

$2,500.00$2,450.00

Agilent AX-65 Air-Cooled Diffusion Pump

Agilent AX-65 Air-Cooled Diffusion Pump The Agilent AX-65 diffusion pump is a high-performance, air-cooled pump designed with bench-top analytical instruments in mind. Its vertical finned boiler and high power provide stable pumping and high helium pumping speed. This pump can be ordered with a cold cap or a dense baffle. The pump includes a fluid-level sight glass that indicates the fluid level at all times. Features High performance specifications means higher, cleaner vacuum levels Fluid-level sight glass provides quick indication of pump fluid status at all times The wide range of available pump configuration and flange combinations optimizes pump performance and fit for your application Compact design makes integration into space-limited equipment easy Full thermal protection guards against all over-temperature conditions “Pump-ready” thermal switch sends a signal when pump is operational Finned, vertical boiler promotes stable pumping, especially of light gases Three-stage fractionating jet with ejector stage purifies pumping fluid, giving higher forepressure tolerance Do NOT fill more than 30mL diffusion pump oil at a time

$2,383.00

Agilent TwisTorr 74 FS Turbo Pump Package

Agilent TwisTorr 74 FS Turbo Pump Package The Agilent TwisTorr 74 FS is a small, 70 L/s turbo pump for research and development, UHV systems, nuclear research, and electron microscopy. It delivers high vacuum performance thanks to the synergy between turbo technology and innovative TwisTorr drag stages.Its floating suspension enables low vibration and noise level, making it compatible with sensitive instrumentation and work environments. Unique cantilever suspension ensures no magnetic interferences with your application and no hydrocarbon contamination. Features High compression ratios for light gases and hydrocarbon free design, enabling low base pressure Remote controller allows operation from 100 m away High foreline tolerance allows smaller foreline pumps, reducing cost and footprint Low vibration and noise levels - 41 dB(A), for a comfortable working environment and operation in sensitive experiments Maintenance-free bearings for zero operating cost Compact size and installation in any position allows easy integration Gauge reading capability for system pressure monitoring Ready for wireless control via Vacuum Link app for pump operation on the go Radiation and magnetic field-proof design with no embedded electronics allows operation in demanding magnetic field and radiation environments Low electromagnetic emission guarantees no interference with application process

$11,282.74

Agilent IDP-15 Dry Scroll Vacuum Pump With Inlet Isolation Valve

Agilent IDP-15 Dry Scroll Vacuum Pump With Inlet Isolation Valve The new Agilent IDP-15 dry scroll pump is designed for extremely quiet (<50dBA) and low vibration operation, delivering a peak pumping speed of 9 cfm at 60Hz.With a single-sided scroll design it offers fast, easy yearly maintenance and low cost of ownership. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. Specifications Base pressure (50 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Base pressure (60 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Dimensions (WxHxL) 13.1 in x 14.3 in x 19.1 in Exhaust Connection NW16 Height 14.3 in Inlet Connection NW25 Input Voltage 220-230 VAC 100-115 Length 19.1 in Noise Level 50 dB(A) Pumping Speed (50 Hz) 12.8 m3/h 214 L/min 7.5 CFM Pumping Speed (60 Hz) 15.4 m3/h 256 L/min 9.1 CFM Width 13.1 in

$9,409.00 - $9,904.00

Agilent IDP-7 Dry Scroll Vacuum Pump With Inlet Isolation Valve

Agilent IDP-7 Dry Scroll Vacuum Pump With Inlet Isolation Valve Overview The new Agilent IDP-7 dry scroll pump is a compact, high performance, oil-free vacuum pump, delivering large pumping speed capacity and simple maintenance. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. Specifications Base pressure (50 Hz) - Torr & mbar 3.0 x 10-2 Torr 4.0 x 10-2 mbar Base pressure (60 Hz) - Torr & mbar 2.0 x 10-2 Torr 2.6 x 10-2 mbar Dimensions (WxHxL) 10.24 in x 10 in x 16.54 in Exhaust Connection NW16 Height 10 in Inlet Connection NW25 Input Voltage 200-240 VAC 100-120 Length 16.54 in Noise Level 52 dB(A) Pumping Speed (50 Hz) 120 L/min 4.2 CFM 7.2 m3/h Pumping Speed (60 Hz) 152 L/min 5.4 CFM 9.1 m3/hr Width 10.24 in

$6,826.00 - $7,181.00

Agilent IDP-3 2.1 Cfm Oil-Free Compact Dry Scroll Pump - 110V

Agilent IDP-3 2.1 Cfm Oil-Free Compact Dry Scroll Pump - 110V Overview The Agilent IDP-3 dry scroll pump is an innovative, compact, high-performance, oil-free vacuum pump that is suitable for a wide variety of applications. It is the smallest scroll pump made for general vacuum applications, which makes it easy to integrate into OEM systems, and it weighs only 21 pounds (9.5 kg). Yet with a pumping speed of 2.1 cfm (60 L/min) and a very low base pressure of 250 milliTorr, it is the highest-performing dry pump in its class. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. The IDP-10 uses an inverter driven motor, which provides uniform vacuum performance at all global frequencies and input voltages. Its uniform global performance and compact size make it an ideal choice for analytical instruments and industrial OEMs.

$3,609.00 - $3,896.00

Refurbished Vacuubrand PC 3001 Vario SELECT

Refurbished Vacuubrand VARIO® chemistry pumping unit PC 3001 VARIOpro The PC 3001 VARIO select pumping unit precisely controls the vacuum level in order to achieve unparalleled process control. This pump is suitable for even high boiling point solvents. The integrated VACUU·SELECT controller provides an easy-to-use, application based interface that covers all common lab applications. The VACUU·SELECT controller has you covered. Use manual set-point-control for simple processes, run fully automated distillations, or create your own application with simple drag-and-drop editing. For solvent evaporation, the VACUU·SELECT controller detects solvent boiling and automatically adjusts the pump's motor speed to maintain process control. The VARIO motor speed control also makes the pump whisper quiet and provides for exceptionally long maintenance intervals. The inlet separator, made of glass with a robust protective coating, prevents particles and liquid droplets from entering the pump, preventing damage and extending pump life. And the exhaust vapor condenser allows for nearly complete recovery of solvents when used with a chilled water line or recirculating chiller for economical recycling and environmental protection. Performance features simplify lab work with the VACUU·SELECT vacuum controller with graphic user interface and predefined applications automatic boiling point detection and continuous optimization of vacuum levels for quick process times compact and powerful; superior performance even with continuous condensate purge whisper quiet and ultra low vibration eco-friendly: extremely low power consumption and efficient solvent recovery. Oil-free! CE Approval Safety Information Manual Controller Manual Manual interfaces Technical data Unit PC 3001 VARIO select Vacuum controller VACUU·SELECT Number of heads / stages 4 / 3 Max. pumping speed m3/h 2.0 Max. pumping speed cfm 1.2 Ultimate vacuum (abs.) mbar/torr 2.0 / 1.5 Ultim. vac. (abs.) with gas ballast mbar/torr 4 / 3 Ambient temperature range (operation) °C 10 - 40 Ambient temperature range (storage) °C -10 - 60 Max. back pressure (abs.) bar 1.1 Inlet connection Hose nozzle DN 6-10 mm Outlet connection Hose nozzle DN 8-10 mm Coolant connection 2 x hose nozzle DN 6-8 mm Rated motor power kW 0.16 Motor speed range min-1 200 - 3000 Protection class IP 20 Dimensions (L x W x H) mm 303 x 306 x 400 Weight kg 8.2 Noise level at 50 Hz, typ. dBA 42 ATEX conformity (only 230V) II 3/- G IIC T3 X Internal Atm. only Items supplied Pumping unit completely mounted, ready for use, with manual. Accessories Rubber vacuum tubing DN 6 mm (20686000) Rubber vacuum tubing DN 8 mm (20686001) Coolant valve VKW-B (20674220) Vent valve VB M-B (20674217) Liquid level sensor (20699908) VACUU·BUS® Y-Adapter mit Kabel 2m (20683240)

$7,275.00$4,500.00

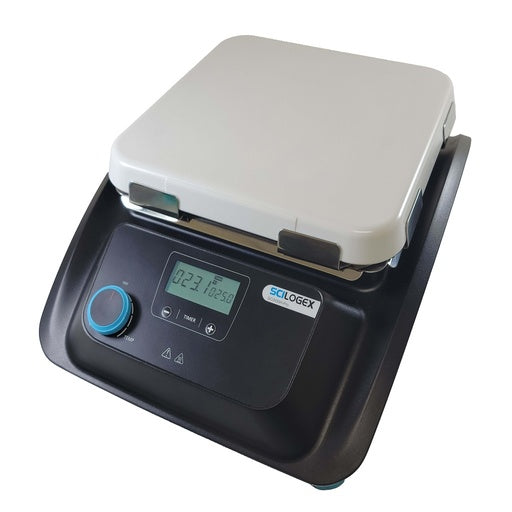

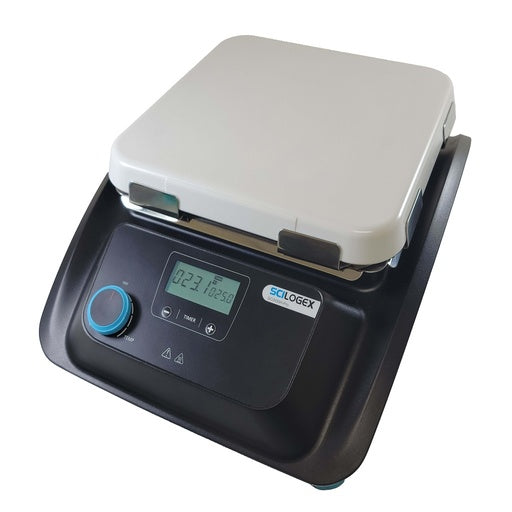

SCILOGEX SCI500H-Pro LCD Digital 10 x 10 Magnetic Hotplate, ceramic-glass plate, 110V, 50/60Hz US Plug