BVV

-

Molecular Sieve Filter Drier W/ Heating Jacket

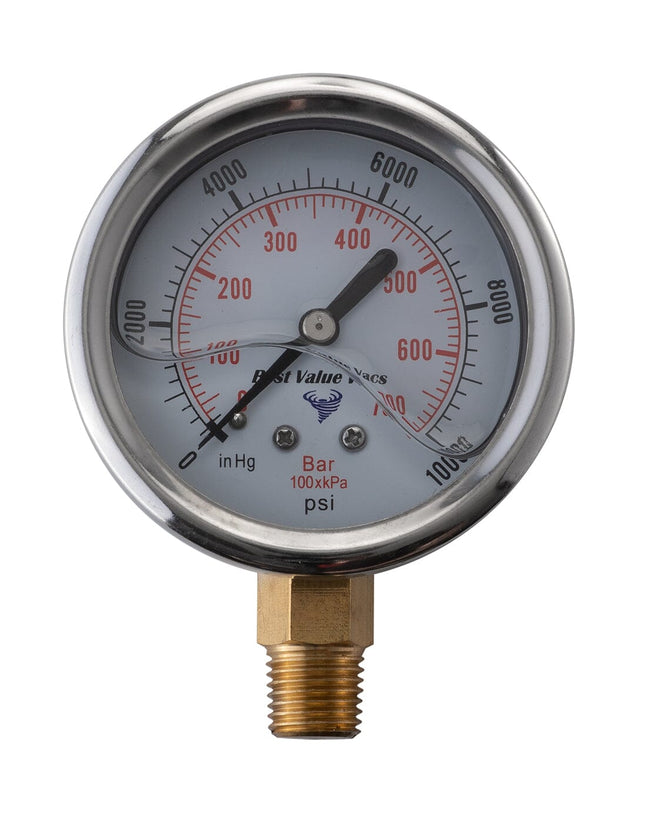

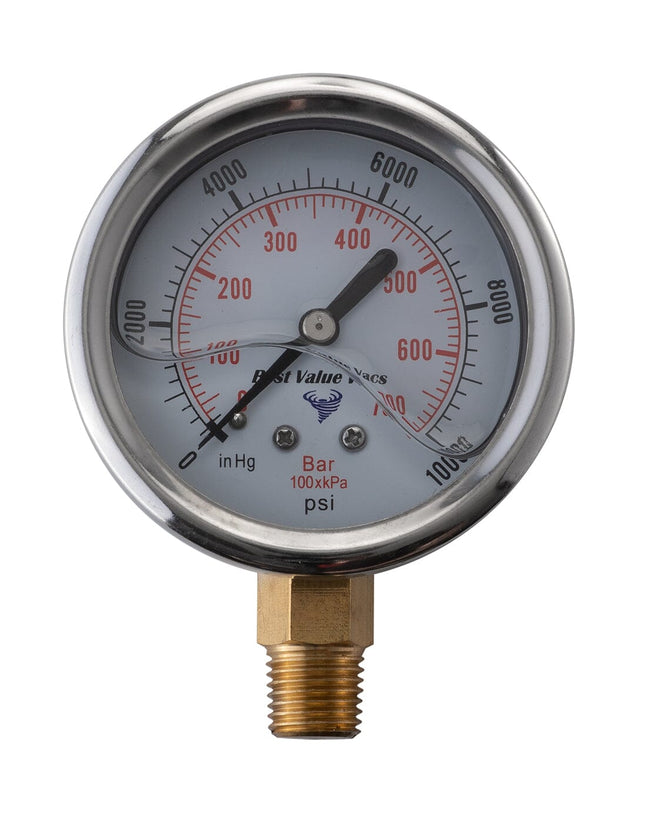

Molecular Sieve Filter Drier with Heating Jacket A Molecular Sieve Filter Drier is intended to capture moisture and contaminants in the solvent by filter it out while the solvent passes through the Filter Drier. This Filter Drier is made out of 304 Stainless Steel parts and includes High Pressure Clamps, 2x 3" 2500 Mesh (5 Micron) Gaskets to prevent any Sieve dust contaminating the solvent, a digital heating jacket, and 13X Molecular Sieve. The end connections are 37° Flared Connection with a compound gauge that reads (-30)-0-(150Psi). Specifications Material: 304 Stainless Steel Spool Size: 3" Triclamp x 12" Length End Connections: 1/4", 3/8", or 1/2" 37° JIC Flares Molecular Sieve: 13X Clamps: High Pressure Gaskets: 2x 3" 2500 Mesh (5 Micron) Compound Gauge: (-30-0-(150 Psi) Includes: Digital Heating Jacket Size Recommendations: 2LB - Will fit our Molecular Sieve Filter Drier 4LB - Will fit our XL Molecular Sieve Filter Drier 6LB - Will fit our 30LB Extractor

$370.00 - $380.00

-

Monster Pro II Butane Torch TWIN FLAME!

The Monster Pro strikes back with a twin-flame sequel. Our much-loved torch returns, now with a dual burner for an even fiercer blaze. When it comes to heat, two heads are better than one - don't miss this sizzling encore. Automatic Ignition, Easy to use, Adjustable Flame, Lightweight, & Quick Refill!

$21.00

-

Ms Cream 8g Food Grade Nitrous Oxide Charger 99.5% Pure Triple Filtered

Ms. Cream 8g Nitrous Oxide Cream Chargers 99.5% Purity - Food Grade Made in Europe, Triple Filtered Mr. Cream® is a true culinary gas. Trusted for it high purity and known for not adding any strange or unknown flavors to your cream that other lesser quality import gasses my leave behind. The blue body painted charger goes back to the 1930's the original brand that made its place in kitchens across the world. 8g Charger - 4.04 Gas Liters of N2O (Do not heat over 120F) SUPERIOR GAS QUALITY - Each cream whipper is filled with the purest, and highest quality E942 food grade gas. That is why you will not have a hard time making chocolate or vanilla, mint, or Bailey's flavored cream whipper. Cocktail foams, airy sauce, mousse, and hot or cold foam can be made easily, too. FOOD-GRADE & LONG SHELF LIFE - Ms Cream chargers are made with food-grade compliance and production standards. Each cream charger has a long shelf life of 5 years so you can use them over a period of time. ANTI-LEAKAGE DESIGN - Ms Cream charger canister conforms with Manufacturing International Standards such as ISO 9001, and ISO 9002. Any cream dispenser can be used with this cylinder. UNIVERSAL COMPATIBILITY - Compatible with all professional whipped cream makers in the market. From now on, you can easily finish making whipped cream in a few seconds and without leaving odors or contaminants in the dispenser. RECYCLEABLE CONTAINER - Recycle empty cartridge with other metal recycling. The cartridge is considered empty if the top is punctured and a hole is present. What Is Nitrous Oxide? Nitrous Oxide is a chemical compound with the formula N2O. It is a colorless, non-flammable gas with a slightly sweet odor and taste. Nitrous oxide is often used for various purposes due to its unique properties and effects. What is Nitrous Oxide Used For? Nitrous oxide (N2O) is most commonly used in the culinary world for various purposes, primarily for creating foams, whipped creams, and infusions. Outside the culinary world nitrous oxide is also commonly utilized as a propellant, a cryogenic refrigerant, and as a performance-enhancing additive for internal combustion engines. Here's how nitrous oxide is most commonly used in culinary applications: Whipped Cream: Nitrous oxide is perhaps most well-known in the culinary field for its use in making whipped cream. In this application, heavy cream and sweeteners are combined in a whipped cream dispenser or siphon, and nitrous oxide cartridges are used to pressurize the dispenser. When the cream is released from the dispenser, the sudden release of pressure causes the nitrous oxide to expand and whip the cream into a light and fluffy texture. This method allows for the creation of stable whipped cream that retains its texture for an extended period. Foams: Chefs use nitrous oxide to create foams from various liquids, such as fruit juices, sauces, and purees. To make a foam, the desired liquid is mixed with a gelling agent, strained, and loaded into a whipped cream dispenser along with nitrous oxide. When dispensed, the nitrous oxide aerates the liquid, resulting in a light and airy foam that can be used as a garnish or flavor enhancer. Infusions: Nitrous oxide can be used to infuse liquids with the flavors of herbs, spices, fruits, or other aromatic ingredients. For example, herbs like basil or spices like cinnamon can be placed in a whipped cream dispenser along with a liquid (e.g., oil or alcohol) and nitrous oxide. The pressurized nitrous oxide infuses the liquid with the flavors and aromas of the added ingredients quickly. Cocktails: Some bartenders use nitrous oxide to create foam or froth on cocktails, adding a unique visual and textural element to drinks. This technique is especially popular in molecular mixology. Sauces and Dressings: Nitrous oxide can be used to create light and airy sauces or dressings. By adding nitrous oxide to a mixture of liquids and ingredients, chefs can achieve a desired texture and consistency. Desserts: Nitrous oxide can be used to create innovative desserts, such as foamy fruit purees, mousse-like textures, and light, airy soufflés. It's essential to use food-grade nitrous oxide and follow proper safety precautions when using it in culinary applications. The use of nitrous oxide cartridges and whipped cream dispensers is common in professional kitchens and home cooking to achieve these culinary effects. What Are The Hazards Of Nitrous Oxide? Nitrous oxide (N2O), while commonly used in various applications can pose certain hazards if not used properly. Here are some potential hazards associated with nitrous oxide: Asphyxiation: The most significant hazard of nitrous oxide in culinary use is the risk of asphyxiation. Nitrous oxide can displace oxygen in an enclosed space, leading to oxygen deprivation if inhaled in high concentrations. This can result in dizziness, loss of consciousness, and even death. Frostbite: Nitrous oxide is stored as a compressed liquid and is extremely cold when released. Contact with liquid nitrous oxide can cause frostbite or cold burns to the skin. Care should be taken when handling nitrous oxide cartridges or dispensers. Is Nitrous Oxide Flammable? Nitrous oxide (N2O) is not flammable in the typical sense because it does not support combustion. However, it can contribute to the combustion of other substances. Here's a more detailed explanation: Non-Flammable: Nitrous oxide itself does not burn or catch fire. It is an oxidizer, meaning it can support the combustion of other substances by providing oxygen. When nitrous oxide is used in applications like rocket propulsion or automotive nitrous systems, it does not ignite by itself. Enhancing Combustion: Nitrous oxide is sometimes used in combination with fuel in internal combustion engines to increase power output. In this context, it is often referred to as "nitrous" or "NOS." When nitrous oxide is injected into the engine's intake, it provides additional oxygen, allowing more fuel to burn, resulting in increased engine power. However, it's important to note that this process is controlled and safe when used as intended in automotive applications. Safety Precautions: While nitrous oxide is generally considered safe when used according to manufacturer guidelines, improper handling or misuse can be hazardous. Nitrous oxide should not be exposed to open flames, sparks, or high temperatures, as it can decompose at elevated temperatures and pressure, potentially leading to the release of oxygen and nitrogen gases. In summary, nitrous oxide is not flammable by itself, but it can enhance the combustion of other materials when used in controlled and purposeful applications. When using nitrous oxide, it's essential to follow safety guidelines and avoid exposing it to conditions that could lead to its decomposition or unintended ignition. How Do I Use Nitrous Oxide Safely? Using nitrous oxide (N2O) safely is crucial to prevent accidents and health risks. Here are some general guidelines for using nitrous oxide safely: Follow Manufacturer's Instructions: Always follow the manufacturer's instructions for any equipment or cartridges containing nitrous oxide. Different devices or cartridges may have specific usage guidelines. Ventilation: Ensure that you use nitrous oxide in a well-ventilated area. Adequate ventilation helps disperse any gas leaks and prevents the buildup of nitrous oxide in confined spaces, reducing the risk of asphyxiation. Avoid Direct Inhalation: Never inhale nitrous oxide directly from cartridges, whipped cream dispensers, or any other source. Inhaling nitrous oxide for recreational purposes can be dangerous and is not recommended. Protective Gear: When handling nitrous oxide cartridges or equipment, especially if they contain liquid nitrous oxide, wear appropriate protective gear, such as gloves and safety glasses, to prevent frostbite or cold burns. Store Safely: Store nitrous oxide cartridges and equipment in a cool, dry place away from direct sunlight and heat sources. Keep them out of the reach of children and unauthorized individuals. No Smoking: Avoid smoking or open flames near nitrous oxide, while nitrous oxide is not flammable, it will support combustion to the same extent as oxygen. Training and Education: Ensure that individuals using nitrous oxide equipment are trained in its safe handling and usage. Leak Detection: Regularly check for leaks in nitrous oxide equipment and connections. Use a leak detection solution (soapy water) to identify leaks by observing bubbles at the connections. Proper Disposal: Dispose of used nitrous oxide cartridges and equipment according to local regulations and guidelines. Do not puncture or incinerate cartridges. Emergency Preparedness: Be prepared for emergencies by having safety equipment, such as fire extinguishers and first-aid kits, readily available in areas where nitrous oxide is used or stored. Follow Legal Regulations: Abide by local laws and regulations regarding the sale, purchase, and use of nitrous oxide. In some areas, nitrous oxide may be subject to restrictions due to its potential for misuse. Always exercise caution and prioritize safety when using nitrous oxide, whether it's for culinary, automotive, medical, or other legitimate purposes. If you have specific concerns or questions about the safe use of nitrous oxide in a particular context, consult with experts or regulatory authorities in your area. Chemical Formula: N2O Molecular Weight: 44.013 g/mol CAS Registry Number: 10024-97-2 Appearance Colorless Odor: Characteristic Density 0.115 lb/ft3 Boiling Point: -88.5C (-127.3F) Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H270, H280, H281, H336 GHS Precautionary Statements P220, P244, P261, P271, P282, P304+P340, P319, P336+P317, P370+P376, P403, P403+P233, P405, P410+P403, P501 UN Identification Number: 1070 Proper Shipping Name: Nitrous Oxide Transport Hazard Class: 2.2, 5.1 Packing Group: None DOT Placard: Nitrous Oxide Safety Data Sheet (SDS)

$9.60 - $19.16

-

Mushroom Grow / Spawn Bag Sealable Large 8" X 5" X 19" - 0.5 Micron Filter 3 Mil Polypropylene Autoclavable

Mushroom Grow / Spawn Bag 0.5 Micron Filter | 3mil Polypropylene | Autoclavable 8" X 5" X 19" (20cmx12cmx50cm) Our mycology bags are 8" wide, have a 5" gusset, and are 19" long. They are made of strong and durable polypropylene (3mil heavy duty). The bags are sealable with an impulse sealer. The bags are autoclavable and have a 0.5micron respiratory membrane filter. The breathable filter is a 1.5" diameter and is a microporous barrier which allows the passage of air but not contaminates. These bags are suitable for making sterile grain or sterile substrate. Suitable for Autoclave temperatures up to 250°F (121°C)

$0.20 - $10.00

-

Mushroom Grow / Spawn Bag Sealable w/ Injection Port Large 8" X 5" X 19" " - 0.5 Micron Filter 3 Mil Polypropylene Autoclavable

Mushroom Grow / Spawn Bag 0.5 Micron Filter | 3mil Polypropylene | Autoclavable | with Injection Port 8" X 5" X 19" (20cmx12cmx50cm) Our mycology bags are 8" wide, have a 5" gusset, and are 19" long. They are made of strong and durable polypropylene (3mil heavy duty). The bags are sealable with an impulse sealer. The bags are autoclavable and have a 0.5micron respiratory membrane filter. The breathable filter is a 1.5" diameter and is a microporous barrier which allows the passage of air but not contaminates. These bags are suitable for making sterile grain or sterile substrate. Suitable for Autoclave temperatures up to 250°F (121°C)

$0.50 - $25.00

-

MVP-6CFM 1PH Wired - Used

USED-MVP-6CFM 1PH Wired The Master Vapor Pump Model MVP-6CFM is a certified gas recovery pump designed to operate at 60 PSI. This pump is designed specifically for LP-Gas vapor recovery and is ideal for butane or butane / propane mixtures. Disclaimer: This item has been USED for about 400-500 hours of runtime in the BVV R&D lab. It may contain traces of CBD or solvent used in our lab. This specific pump includes a C1D1 receptacle and switch that is already installed. You will need a sealed wire with NEMA 5-20 male plug. For our recommended item click HERE Engineering Specifications: Recover LP-Gas vapor at OVER 6 CFM (cubic feet per minute) Recover butane at up to 1 LB/MIN (pounds per minute) Recover and recondense butane at OVER 12 GPH (gallons per hour) Electric motor: explosion proof for C1D1 hazardous areas; rated Class I Gr C & D, Class II Gr F&G Electric motor: 1 HP, 1800 RPM, 60 HZ Pump speed: 190 CPM (cycles per minute) at 60 HZ Size: 17.0” x 19.9” base x 46” tall Weight: 182.5 lb (82.8 kg) Downloads Product Manual Technical Data Sheet Features and Benefits Sheet

$6,700.00 $4,000.00

-

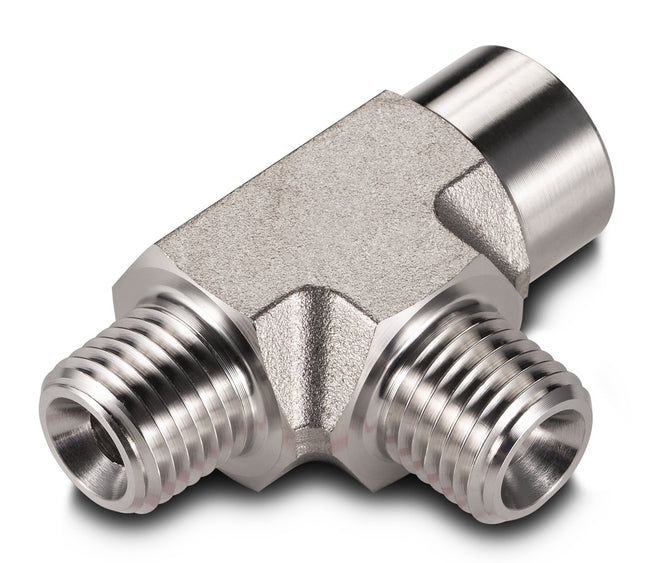

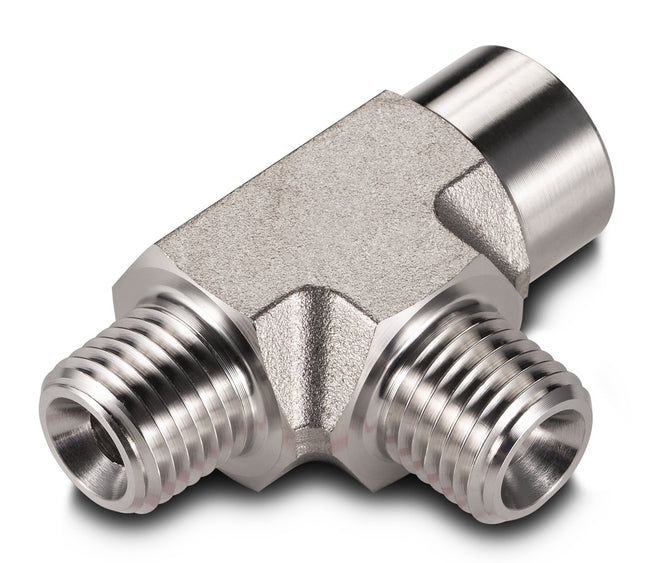

MxMxF Street Tee

BVV™ MxMxF Street Tee BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are NPT threads (National Pipe Taper) and will compress against other Female/Male NPT threads creating a tighter and tighter connection. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. **NOTE: Pre-Taped option comes from BVV Pre-taped with Yellow UL Listed Gas PTFE Tape on the Male NPT threads ONLY for a +0.50c charge per male npt end. (JIC Threads DO NOT need to be taped.) MxMxF Street Tees are the reverse version of a normal street tee and have 2 Male NPT Connectors and 1 Female NPT Connector. This street tee can reduce the amount of pipe nipples or hex nipples a system configuration has and reduces the amount of possible leak points on the system.BVV™ MxMxF Street Tee - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4"-18 FNPT 3/8"-18 FNPT 1/4"-18 MNPT 3/8"-18 MNPT Sizes Available: 1/4" 3/8"

$20.00

-

N-Heptane 99.3% Lab Grade

ULTRA High Purity Lab Grade N-Heptane 99.3% Purity (Note: Container style and color may vary) BVV™ ULTRA High Purity Lab Grade N-Heptane is a perfect solution for cleaning up and clarifying the extracted material and removing the green colored plant material and some waxes out of the product to produce a cleaner end result when distilling extracts. Heptane can be used the same as hexane or as a solvent, but has a higher boiling point when needing to remove residuals from extracted material. Chemical Formula: C7H16 Molecular Weight: 100.205 g·mol−1 CAS Registry Number: 142-82-5 Appearance Colorless Liquid Odor: Petrolic Density 0.6795 g cm−3 Boiling Point: 98.38 °C /209.08 °F Solubility in water: 0.0003% (20 °C GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H304, H315, H336, H410 GHS Precautionary Statements P210, P261, P273, P301+P310, P331 UN Identification Number: 1206 Proper Shipping Name: Heptanes Transport Hazard Class: 3 Packing Group: II DOT Placard: N-Heptane Safety Data Sheet (SDS) N-Heptane Certificate of Analysis (COA)

$20.00 - $850.00

-

N-Hexane 99.5% Lab Grade

BVV™ Ultra High Purity Lab Grade N-Hexane (Note: Container style and color may vary) BVV™ Ultra High Purity Lab Grade N-Hexane is a perfect solution for cleaning up and clarifying the extracted material and removing the green colored plant material and some waxes out of the product to produce a cleaner end result when distilling extracts. Chemical Formula: C6H14 Molecular Weight: 86.178 g·mol−1 CAS Registry Number: 110-54-3 Appearance Colorless Liquid Odor: Petrolic Density 0.6606 g mL−1 Boiling Point: 68.5 °C / 155.2 °F Solubility in water: 9.5 mg L−1 GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H302, H305, H315, H336, H361fd, H373, H411 GHS Precautionary Statements P201, P202, P210, P233, P235, P240, P241, P242, P243, P260, P264, P271, P273, P280, P281, P301+P330+P331, P302+P352, P303+P361+P353, P304+P340, P308+P313, P310, P312, P314, P332+P313, P363, P370+P378, P391, P403+P233, P405, P501 UN Identification Number: 1208 Proper Shipping Name: Hexanes Transport Hazard Class: 3 Packing Group: II DOT Placard: n-Hexane Safety Data Sheet (SDS)

$29.00 - $925.00

-

N-Pentane 99% Lab Grade

BVV™ High Purity Lab Grade N-Pentane 99% (Note: Container style and color may vary) BVV™ High Purity Lab Grade n-Pentane 99% is a hydrocarbon that has properties that are similar to butanes and hexanes. Pentane is a non-polar solvent and refrigerant. Pentane is used for the extraction and eluting of distillates, concentrates, volatiles, and essential oils from plant materials. Pentane can be used with hydrocarbon extraction systems that extract herbal oils, botanical compounds and oils from plants. It is a colorless liquid and has a petroleum-like odor. Chemical Formula: C5H12 Molecular Weight: 72.151 g·mol−1 CAS Registry Number: 109-66-0 Appearance Colorless Liquid Odor: Gasoline-like Density 0.6262 g/mL (20 °C) Boiling Point: 35.9°C /96.5 °F Solubility in water: 40 mg/L (20 °C) GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H304, H336, H411 GHS Precautionary Statements P210, P261, P273, P301+P310, P331 UN Identification Number: 1265 Proper Shipping Name: Pentanes Transport Hazard Class: 3 Packing Group: II DOT Placard: What Is N-Pentane? N-Pentane, also known as normal pentane, is a straight-chain alkane hydrocarbon with the molecular formula C5H12. It is one of the isomers of pentane, a hydrocarbon that consists of five carbon atoms bonded together in a linear, unbranched chain. n-Pentane is called "normal" because its carbon atoms are arranged in a continuous, straight chain, without any branching. What Are The Properties Of N-Pentane? Here are some of the key properties of n-pentane: Physical State: At room temperature and standard atmospheric pressure, n-pentane is a colorless, clear, and highly flammable liquid. Odor: It has a gasoline-like or organic solvent-like odor. Boiling Point: The boiling point of n-pentane is approximately 36.1 degrees Celsius (97 degrees Fahrenheit). This relatively low boiling point makes it useful in various applications. Density: The density of n-pentane at room temperature is about 0.626 grams per milliliter (g/mL). It is less dense than water, which has a density of 1 g/mL. Solubility: n-Pentane is sparingly soluble in water, which means it does not readily mix with water. This is because it is a nonpolar compound, and water is a polar solvent. However, it is highly soluble in nonpolar solvents and organic compounds. Flammability: n-Pentane is highly flammable and poses a fire hazard. It has a low flash point and can easily ignite when exposed to an open flame or heat source. Vapor Pressure: It has a relatively high vapor pressure at room temperature, meaning it readily evaporates into the air. Chemical Structure: As a straight-chain alkane, n-pentane consists of five carbon atoms bonded together in a linear fashion, with 12 hydrogen atoms bonded to these carbons. Molar Mass: The molar mass of n-pentane is approximately 72.15 grams per mole (g/mol). Reactivity: n-Pentane is relatively unreactive under normal conditions and does not readily undergo chemical reactions with common reagents. Uses: It is used as a laboratory solvent, industrial solvent, component in fuel blends, foam blowing agent, and as a chemical reagent in various applications. Safety Precautions: Due to its high flammability, proper safety precautions should be taken when handling n-pentane. It should be stored away from open flames, sparks, and heat sources. Environmental Impact: Like other hydrocarbons, the combustion of n-pentane releases carbon dioxide and other greenhouse gases into the atmosphere, contributing to climate change. n-Pentane is commonly employed in laboratory and industrial settings as a solvent, and its physical and chemical properties make it suitable for various applications. However, its flammability requires careful handling and storage to prevent accidents. What Is The Difference between N-Pentane and ISO-Pentane? n-Pentane and isopentane are two different structural isomers of pentane, each with distinct molecular arrangements. Here are the key differences between n-pentane and isopentane: Structural Arrangement: n-Pentane (Normal Pentane): n-Pentane has a linear, straight-chain structure with five carbon atoms connected in a continuous, unbranched chain. It is sometimes referred to as "normal" pentane due to its unbranched structure. Isopentane (2-Methylbutane): Isopentane has a branched-chain structure with one methyl (CH3) group branching off from the second carbon atom (C2) of the main carbon chain. This branching gives it its common name, "isopentane." Physical Properties: n-Pentane: n-Pentane is a clear, colorless liquid at room temperature and atmospheric pressure. It has a higher boiling point than isopentane and is less volatile. Isopentane: Isopentane is also a clear, colorless liquid at room temperature, but it has a lower boiling point compared to n-pentane. It is more volatile and evaporates more easily. Boiling Points: n-Pentane: The boiling point of n-pentane is approximately 36.1 degrees Celsius (97 degrees Fahrenheit). Isopentane: The boiling point of isopentane is lower, at approximately -11.7 degrees Celsius (11 degrees Fahrenheit). This lower boiling point makes it more suitable for certain applications. Applications: n-Pentane: n-Pentane is used as a laboratory solvent, in the formulation of industrial solvents, and as a component in gasoline and other fuels. Its relatively higher boiling point makes it less volatile and suitable for some applications where slow evaporation is desired. Isopentane: Isopentane is commonly used as a refrigerant and as a component in aerosol propellants, blowing agents for foam production, and as a solvent. Its lower boiling point and greater volatility make it useful in these applications. In summary, n-pentane and isopentane differ in their molecular structures, physical properties, boiling points, and applications. The choice between the two depends on the specific requirements of a given application, with n-pentane being less volatile and isopentane being more volatile. What Is The Structure Of N-Pentane? Pentane is an alkane with the chemical formula C5H12. It is a colorless, flammable liquid that is commonly used as a solvent and a fuel. The structure of pentane is a straight chain of five carbon atoms, with each carbon atom bonded to four hydrogen atoms. The carbon atoms in pentane are arranged in a tetrahedral geometry, with each carbon atom forming four bonds with other atoms. The hydrogen atoms are bonded to the carbon atoms in a single bond. What Is Pentane Used For? Pentane, both in its various isomeric forms (n-pentane and isopentane), has several industrial and commercial applications due to its properties as a hydrocarbon solvent and fuel component. Here are some common uses of pentane: Solvent: Pentane is used as a nonpolar solvent in various laboratory and industrial applications. It is particularly useful for dissolving oils, fats, waxes, and some organic compounds. Its low boiling point and relatively low toxicity make it suitable for these purposes. Foam Blowing Agent: Isopentane (also known as 2-methylbutane) is often used as a blowing agent in the production of polyurethane foams. When mixed with other chemicals, isopentane vaporizes and creates bubbles within the foam, leading to its expansion and formation. Fuel Component: Pentane, primarily in the form of isopentane, is used as a component in gasoline and other fuel blends. It enhances the octane rating of gasoline and helps reduce engine knocking, improving engine performance. Chemical Reagent: Pentane can serve as a chemical reagent in organic synthesis and research. It may be used as a reactant in some chemical reactions or as a medium for certain processes. Extraction: In laboratories, pentane is utilized for liquid-liquid extractions to separate compounds from mixtures based on differences in solubility. It is a common choice for extracting natural products and essential oils. Cleaning Agent: Pentane is employed for cleaning and degreasing purposes in industrial settings. It can effectively remove residues, contaminants, and oils from various surfaces and equipment. Refrigeration: Pentane has been used as a refrigerant in some applications, particularly in the form of isopentane. However, due to environmental concerns and regulations related to ozone depletion, its use as a refrigerant has diminished. Analytical Chemistry: In gas chromatography (GC), pentane is sometimes used as a carrier gas to transport samples through the GC column for analysis. Adhesives and Sealants: Some adhesive and sealant formulations may contain pentane as a solvent or propellant. Aerosol Propellants: Pentane, particularly isopentane, has been used as a propellant in aerosol spray products. Energy Production: In certain regions, pentane may be used as a fuel for heating and electricity generation, although this application is less common. It's important to note that while pentane has various industrial and commercial uses, safety precautions should be taken when handling it due to its flammable nature. Proper storage, ventilation, and safety measures are essential to minimize the risk of accidents. Additionally, environmental regulations and concerns have led to the exploration of alternative substances in some applications where pentane was traditionally used as a refrigerant or propellant. How Is Pentane Produced? Pentane is typically produced from petroleum through refining processes. It is a natural component of crude oil, and the separation and purification of pentane from crude oil involve various refining techniques. Here's an overview of how pentane is produced: Fractional Distillation: Crude oil is first subjected to fractional distillation in an oil refinery. This process separates the crude oil into different fractions based on their boiling points. Pentane, along with other hydrocarbons of similar boiling points, is separated from the crude oil in this initial distillation step. Fraction Separation: The fraction obtained in the distillation containing pentane and similar hydrocarbons is further separated in subsequent distillation columns. These columns are designed to separate hydrocarbons with similar boiling points, and pentane is separated from other hydrocarbons through a series of distillation steps. Purification: After the initial separation, the pentane fraction may still contain impurities and other hydrocarbons. To obtain high-purity pentane, additional purification steps are often employed. One common method is solvent extraction, where selective solvents are used to remove impurities. Adsorption and molecular sieves may also be used for purification. Final Processing: The purified pentane may undergo additional processing steps to meet specific product specifications or requirements. For example, it may be dried to remove any remaining water content. Packaging and Distribution: Once purified and processed, pentane is typically packaged into containers suitable for transportation and distribution. It may be distributed to various industries where it is used for its specific applications. Overall, the production of pentane is part of the larger petroleum refining process, and its availability depends on the composition of the crude oil and the specific refining techniques employed by the refinery. What Are The Hazards Of Pentane? Pentane, like other hydrocarbon compounds, poses certain hazards, especially when handled and used in industrial or laboratory settings. It's essential to be aware of these hazards and take appropriate safety precautions when working with pentane. Here are some of the hazards associated with pentane: Flammable: Pentane is highly flammable and can form explosive mixtures with air when its vapor concentration is within a specific range (approximately 1.5% to 7.8% by volume). This means that even a small spark or open flame can ignite pentane vapors, leading to fires or explosions. Health Hazards: Inhalation of pentane vapor can cause respiratory irritation, dizziness, headache, nausea, and, in severe cases, central nervous system depression. Prolonged exposure to pentane may lead to adverse health effects, including drowsiness, unconsciousness, and even asphyxiation. Irritant: Pentane can be a skin and eye irritant. Contact with the skin may cause irritation, redness, and dermatitis, particularly with prolonged or repeated exposure. Eye contact with pentane can result in irritation, redness, and discomfort. Environmental Impact: Pentane is a volatile organic compound (VOC) that can contribute to air pollution. When released into the atmosphere, it can react with other pollutants and contribute to the formation of ground-level ozone, which is harmful to human health and the environment. Asphyxiation Hazard: Pentane vapors can displace oxygen in poorly ventilated areas, creating an oxygen-deficient atmosphere. This can lead to asphyxiation if pentane is released in a confined space without proper ventilation. To use pentane safely, consider the following precautions: Work in well-ventilated areas or use exhaust systems to prevent the buildup of pentane vapors. Avoid open flames, sparks, and hot surfaces when working with pentane, and ensure that electrical equipment and wiring are explosion-proof in areas where pentane is used. Store pentane in approved containers away from heat, ignition sources, and incompatible materials. Use appropriate personal protective equipment (PPE), including safety goggles, gloves, and lab coats, when handling pentane. Have emergency response measures in place, including fire extinguishers and eyewash stations, when working with pentane. Follow safety data sheet (SDS) guidelines and procedures provided by the manufacturer or supplier of pentane. Educate and train personnel on the safe handling and storage of pentane. It's crucial to have a thorough understanding of the potential hazards associated with pentane and to implement appropriate safety measures to mitigate these risks. Always follow safety guidelines and regulations specific to your workplace or laboratory when working with pentane or any other hazardous chemicals. How Do I Use Pentane Safely? Using pentane safely is essential due to its flammable nature and associated hazards. Whether you're working with pentane in a laboratory, industrial setting, or any other environment, following proper safety procedures is crucial. Here are some steps to use pentane safely: Work in a Well-Ventilated Area: Always work in a properly ventilated area. Ensure that fumes and vapors can be effectively removed to prevent the buildup of pentane in the air. No Open Flames or Sparks: Avoid working near open flames, sparks, or other potential ignition sources. Pentane is highly flammable and can ignite easily. Use Appropriate Containers: Store pentane in approved containers designed for flammable liquids. These containers are typically designed to prevent leaks and resist fire. Keep Away from Heat Sources: Store pentane away from heat sources, including direct sunlight, radiators, and hot surfaces. Static Electricity: Ground yourself and any equipment that could generate static electricity. This helps prevent static sparks that could ignite pentane vapors. Wear Protective Gear: Use appropriate personal protective equipment (PPE), including safety goggles, gloves, and lab coats, to protect your eyes, skin, and clothing from contact with pentane. No Smoking or Eating: Do not smoke or eat while working with pentane. Keep food and beverages away from the work area. Emergency Equipment: Have safety equipment on hand, such as fire extinguishers, eyewash stations, and safety showers, in case of accidents or emergencies. Avoid Confined Spaces: Do not use pentane in confined spaces without proper ventilation. Pentane vapors can displace oxygen, leading to an oxygen-deficient atmosphere. Secure Containers: Ensure that containers are tightly sealed when not in use. Prevent spills and leaks. Safety Data Sheet (SDS): Familiarize yourself with the safety data sheet (SDS) provided by the manufacturer or supplier of pentane. SDS contains important information about the chemical's properties, hazards, and safe handling procedures. Training and Education: Train all personnel working with pentane on its safe handling, storage, and disposal. Ensure that they understand the hazards and know how to respond to emergencies. Labeling and Signage: Clearly label containers of pentane with appropriate warnings and hazard symbols. Use warning signs in areas where pentane is stored or used. Emergency Response: Develop and communicate emergency response plans, including evacuation procedures and fire safety protocols. Conduct regular drills to ensure that personnel are prepared. Proper Disposal: Dispose of pentane and any contaminated materials according to local, state, and federal regulations. Do not pour pentane down drains or dispose of it improperly. Regular Inspections: Periodically inspect equipment, storage areas, and containers for signs of damage or deterioration. Replace damaged equipment or containers promptly. By following these safety guidelines and practices, you can minimize the risks associated with pentane use and create a safer working environment. Always prioritize safety and be prepared to respond to potential emergencies involving pentane or other flammable chemicals. N-Pentane Safety Data Sheet (SDS) N-Pentane Certificate of Analysis (COA)

$37.00 - $1,000.00

-

NEO 1.4CFM Diaphragm Pump ETL Rated

The BVV V series pumps are Ani-corrosion PTFE diaphragm vacuum pumps. The two head design operates as a two-stage pump to achieve a lower degree of vacuum. They are ideal for pumping corrosive gases and organic solvents. These pumps do not need any pump oil or other lubricants, which means less maintenance and smaller chance for cross contamination. The BVV V-40 is ETL listed to be used in laboratories and comes with a 2 year manufacturer warranty on all non consumable pieces. Model V-40 Power 110V 60Hz, 240 W Ultimate Vacuum 6 torr (8mbar) Maximum Operating Pressure 1 bar Maximum Flow 40 L/min Ambient Temperature 5 - 40°C Pump Head Material PTFE Composite Valve Material FFPM Noise <70db Dimensions 315x165x210mm Weight 10.4 kg For replacement diaphragms, click HERE

$1,675.00

-

Neo Diaphragm Replacement Membrane

These replacement diaphragms are used in the BVV V-40 diaphragm vacuum pumps. The V-40 has two diaphragms and will need one two pack to do a rebuild on it.

$80.00 - $160.00

-

NEO Oven Needle Valve

NEO Oven Needle Valve Replacement Needle valve for vacuum shut off for NEOCISION vacuum ovens

$60.00

-

NEO Oven PID

NEO Oven PID Specifications NEO PID Temp Range: 0-225°F Temp Accuracy: +/- 1° Built-In Calibration: Yes Temp Display Unit: C or F Timer Range: 0-999 Electrical Requirements: 110v @ 60Hz Compatible Ovens: 09NEO / 19NEO / 32NEO / 75NEO Shipping Dimensions: 5 x 5 x 5 - 1lbs SKU: NEOPID

$220.00

-

Neo Vacuum Oven Valve Knob

Replacement Valve Knob for BVV Neocision Vacuum Ovens.

$15.00

-

Neocision 5L - Rotary Evaporator Replacement parts

5L - Rotary Evaporator Replacement parts These replacement parts are specifically for 5L Neocision rotary evaporators. Clamps and gaskets can be found here: Clamps Gaskets

$14.00 - $190.00

-

NEOCISION Cold Trap - ETL Rated - (-80c)

NEOCISION Cold Trap - ETL Rated - (-80c) The BVV™ CT80 Cold Trap is used to condense vapors lost in vacuum applications before they reach the vacuum system. This prolongs the life of the vacuum system, reduces the need to change oil frequently, and efficiently traps vapors otherwise lost to evaporation such as terpenes. The CT80 model reaches a maximum temp of -80°c or -112F under vacuum and contains three traps for maximum efficiency and condensation of vapors. Place in-line between application and your vacuum system. Specifications: Temp Range: -112F to Ambient Internal Dimensions: 180mm Internal Diameter x 210mm Depth (Holds about 1.4 gallons) External Dimensions: 505 x 620 x 750mm Weight: 149lbs Stainless Steel Interior 3x Pyrex Glass Traps 110V Power Please Note: This device is designed for operation on its own independent circuit breaker. For best results, do not use this device on a breaker shared with other equipment. ***Notice to Customers: All units are inspected for broken glass or parts before the unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$5,500.00 $4,500.00

-

NEOCISION Cold Trap with Pump - ETL Rated - (-40c)

NEOCISION Cold Trap with Pump - ETL Rated - (-40c) Looking for a cold trap and small application chiller? The BVV™ CT40 features a 2-in-1 use with a cold trap function and built in circulating system for small batch temperature control. Cold Trap Function Use the BVV™ CT40 to condense vapors down to -40°C before they reach your vacuum pump. This prolongs the life of the vacuum system, reduces the need to change oil frequently, and efficiently traps vapors otherwise lost to evaporation such as terpenes. Common applications include short path distillation, rotary evaporation, reactor setups, or any other application where volatile vapors can damage your vacuum pump. Chiller Function Use the BVV™ CT40 for small batch temperature control down to -40°C. Switch out the cold trap configuration with solid lid to turn your cold trap into a chiller. Common applications include condensing coils, small vessel setups, heat exchangers. Operating 2-in-1 Simultaneously Use the BVV™ CT40 as a cold trap and chiller. The unit can be used with the cold trap configuration and circulating function simultaneously. Commonly used as for chilling applications with no additional heat load. BVV™-CTC40-WP Power Requirement AC 110V +/- 10% / 60Hz Relative Humidity < 85% Cooling Capacity 400W Refrigerant R404A Cold Trap Capacity 3 x 300ml Cold Trap Barb Dia. 10mm Reservoir Capacity 6.8L External Dimensions 305 x 485 x 635mm Weight 149 lbs Call in to see how we can pair this unit with your setup Please Note: This device is designed for operation on its own independent circuit breaker. For best results, do not use this device on a breaker shared with other equipment. ***Notice to Customers: All units are inspected for broken glass or parts before the unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$2,900.00

-

Neocision Elite 750W LED Grow Light

Neocision Elite 750 LED Grow Light Neocision Elite 750 led grow light fixtures feature a 21% blue spectra and 44% red spectra with a peak at 660nm for your flowering plants. This unique spectra mix creates stronger plants for nutrient uptake with maximized red for increased photosynthesis. Ideal for hanging over benches. Features: PPE 2.88 Micromoles / J 2146 PPF per Fixture Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Folding Design for Fast and Easy Installation 7 Year Limited Warranty

$452.00 $350.00

-

Neocision Rotary Evaporator 10-50L Glass Parts

Neocision Rotary Evaporator 10-50L Glass Parts Replacement parts for Neocision Rotary Evaporators, be sure to choose the correct sized part for you model of rotary evaporator. (Parts may also fit Eco Rotary Evaporators manufactured after 2019) All Joint dimensions given in millimeters. Specifications NRE-10L • Main Condenser Connection sizes: Bottom Joint - 60ID / 80OD Coil Connection Ports - GL18 (x2) Vacuum Port - GL18 NRE-10L • Auxiliary Condenser Connection sizes: Top Joint - 60ID / 80OD Bottom Joint - 40ID / 60OD Coil Connection Ports - GL18 (x2) NRE-10L • Receiving Flask Connection sizes: Top Joint (Aux) - 40ID / 60OD Top Valve Joints - 30ID / 50OD Drain Valve Joint - 30ID / 50OD NRE-10L • Evaporating Flask Main Joint - 100ID / 125OD NRE-20L • Main Condenser Connection sizes: Bottom Joint - 60ID / 80OD Coil Connection Ports - GL18 (x2) Vacuum Port - GL18 NRE-20L • Auxiliary Condenser Connection sizes: Top Joint - 60ID / 80OD Bottom Joint - 40ID / 60OD Coil Connection Ports - GL18 (x2) NRE-20L • Receiving Flask Connection sizes: Top Joint (Aux) - 40ID / 60OD Top Valve Joints - 30ID / 50OD Drain Valve Joint - 30ID / 50OD NRE-20L • Evaporating Flask Main Joint - 100ID / 125OD NRE-50L • Main Condenser Connection sizes: Bottom Joint - 60ID / 80OD Coil Connection Ports - GL18 (x2) Vacuum Port - GL18 NRE-50L • Auxiliary Condenser Connection sizes: Top Joint - 60ID / 80OD Bottom Joint - 40ID / 60OD Coil Connection Ports - GL18 (x2) NRE-50L • Receiving Flask Connection sizes: Top Joint (Aux) - 40ID / 60OD Top Valve Joints - 30ID / 50OD Drain Valve Joint - 30ID / 50OD NRE-50L • Evaporating Flask Main Joint - 100ID / 125OD NRE-10/20/50L • Glass Axis Top Joint - 50ID / 70OD NRE-10/20/50L • Drain Valve Joint Size - 30ID / 50OD NRE-10/20/50L • Injection Valve Joint Size - 30ID / 50OD Barb Size - 12mm NRE-10/20/50L • Bump Trap Connection Sizes: Top Joint (Injection) - 30ID / 50OD Side Joint (Aux) - 40ID / 60OD Bottom Joint (Body) 50ID / 70OD NRE-10/20/50L • Valve Joint Size - 30ID / 50OD Barb Size - 12mm *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement.

$20.00 - $961.00

-

Neocision Rotary Evaporator 10-50L Parts

Neocision Rotary Evaporator 10-50L Parts Miscellaneous replacement parts (non-glass) for 10-50L Neocision Rotary Evaporators, including fixtures for holding glass pieces. Some parts may be universal.

$5.00 - $340.00

-

Neocision Rotary Evaporator Clamps

Neocision Rotary Evaporator Clamps These clamps are measured by the outer diameter of the glass flange in which it is sealing. NRE-10/20/50L • 80MM Clamp General Uses: Main Condenser to Auxiliary Condenser NRE-10/20/50L • 60MM Clamp General Uses: Auxiliary Condenser to Bump Trap Auxiliary Condenser to Collection Flask Injection Valve to Bump Trap NRE-5/10/20/50L • 40MM Clamp General Uses: Collection Flask to Valves Injection Valve to Bump Trap NRE- 5L • 30MM Clamp General Uses: Collection Flask to Valves (5L only)

$25.00 - $37.00

-

Neocision Rotary Evaporator Gaskets

Neocision Rotary Evaporator Gaskets Part General Use Main Seal Evaporating Flask to Main body 60/80 Gasket Main Condenser to Auxiliary Condenser (10-50L) 50/70 Gasket Bump Trap to main body (10-50L) 40/60 Gasket Bump Trap to Auxiliary Condenser (10-50L) 30/50 Gasket Collection Flask to Valves (10-50L) 25/49 Gasket Collection Flask to Valves (5L Only)

$20.00 - $125.00

-

Neocision Spectra Elite LED Grow Light - DLC Listed

Neocision Spectra Elite LED Grow Light ELITE Neocision Spectra Elite fixtures feature 20.6% blue spectra and 45.1% red spectra witha peak at 660nm for your flowering plants. This unique spectra mix creates stronger plants for nutrient uptake with maximized red for increased photosynthesis. Get increased yields, quality bud formation and high rates of cannabinoid production levels. Neocision Specta Elite Cutsheet DLC Qualified Product List Performance, Specs and Ranking FEATURES: Efficacy up to 2.85 Micromoles / J Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Folding Design for Fast and Easy Installation Leading 660nm LED Count – 150 660nm diodes Per Fixture 7 Year Limited Warranty on Fixture 8 Year Limited Warranty on Driver Looking for bulk purchases? We offer volume discounts and other value-adding services with our partners at RSX Enterprises. Call (331-281-0154) and speak with a rep for more information. SPECTRUM AND EFFICACY PPF Efficacy: 2.85 at 240 VAC Photon Flux (µmol/s) (400-700nm): 1939 Photon Flux Blue (µmol/s) (400-500nm): 400 Photon Flux Green (µmol/s) (500-600nm): 666 Photon Flux Red (µmol/s) (600-700nm): 874 Total Blue/Red - Energy Bands: 1274 % Blue: 20.64% % Green: 34.34% % Red: 45.06% POWER Power Consumption: 680W AC Driver: Sosen Power Factor: >0.95 Surge Protection: 6 KV 208V: 3.44A 240V: 2.98A 277V3: 2.58A DIMENSIONS Fixture Size (driver mounted on the fixture): (L) 43.9” x (W) 43.9” x (H) 4.1” Fixture Size (without driver): (L) 43.9” x (W) 43.9” x (H) 1.6” Power Supply Dimension: (L)23” X (W) 6.5” X (H) 3” Driver Net Weight: 10.1 lb. Fixture Net Weight: 20.4 lb. OTHER Mounting Height >6” above canopy Beam Angle 120 Degree Input Voltage 200 - 277 VAC Manual Dimming Knob Yes Built In Control Ports Yes Power Cord Length (Extensions available) AWG 18, 6 Foot Standard Plug 240 VAC - NEMA 6-15P Substitute Plugs (Upon request at order) 277 VAC, Pigtails Adjustable Height Hanging Kit Included Yes Fixture Warranty 7 Years Limited Driver Warranty 8 Years Limited ETL Safety Certified Conforms to UL 1598:2018 Ed.4Certified to CSA C22.2#250.0:2018 Ed.4*ETL Safety Certified No. 5020070 DLC Listed Yes

$550.00 $400.00

-

Neocision Spectra Explorer LED Grow Light

Neocision Spectra Explorer LED Grow Light Explorer Our Explorer grow light fixture is designed for a full grow cycle with maximized red for increased photosynthesis. Ideal for 2’ x 4’ tent environments for increased consistency and yield. Neocision Spectra Explorer Cutsheet Performance, Specs, Ranking FEATURES: Efficacy up to 2.56 Micromoles / J @120 VAC Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Fast and Easy Installation 7 Year Limited Warranty on Fixture 8 Year Limited Warranty on Driver Looking for bulk purchases? We offer volume discounts and other value adding services with our partners at RSX Enterprises. Call (331-281-0154) and speak with a rep for more information. SPECTRUM AND EFFICACY PPF Efficacy: 2.56 at 120VAC Photon Flux (µmol/s) (400-700nm): 870 Photon Flux Blue (µmol/s) (400-500nm): 161 Photon Flux Green (µmol/s) (500-600nm): 355 Photon Flux Red (µmol/s) (600-700nm): 355 Total Blue/Red - Energy Bands: 516 % Blue: 18.51% % Green: 40.76% % Red: 40.73% POWER Power Consumption: 340W AC Driver: Sosen Power Factor: >0.95 Surge Protection: 6 KV 120V: 2.90 A 208V: 1.75 A 240V: 1.51 A 277V: 1.31 A DIMENSIONS Fixture Size (driver mounted on the fixture): (L) 43.7” x (W) 22” x (H) 4.1” Fixture Size (without driver): (L) 43.7” x (W) 22” x (H) 1.6” Power Supply Dimension: (L)18.7” X (W) 4.4” X (H) 2.4” Driver Net Weight: 6 lb. Fixture Net Weight: 6 lb. OTHER Mounting Height >6” above canopy Beam Angle 120 Degree Input Voltage 100 - 277 VAC Manual Dimming Knob Yes Built In Control Ports Yes Standard Power Cord (Extensions available) AWG 18, 6 Foot Standard Plug 120 VAC - NEMA 5-15P Substitute Plugs (Upon request at order for bulk purchases) 240 VAC, 277 VAC, Pigtails Adjustable Height Hanging Kit Included Yes Fixture Warranty 7 Years Limited Driver Warranty 8 Years Limited ETL Safety Certified Conforms to UL 1598:2018 Ed.4Certified to CSA C22.2#250.0:2018 Ed.4*ETL Safety Certified No. 5020070

$375.00 $210.00

-

Neocision Spectra Pro LED Grow Light - DLC Listed

Neocision Spectra Pro LED Grow Light PRO Neocision Spectra Pro fixtures feature 18.5% blue spectra and 40.7% red spectra with a peak at 660nm for your flowering plants. This unique spectra mix creates stronger plants for nutrient uptake with maximized red for increased photosynthesis. Get increased yields, quality bud formation and high rates of cannabinoid production levels. Neocision Spectra Pro Cutsheet DLC Qualified Product List Performance, Specs and Ranking FEATURES: Efficacy up to 2.58 Micromoles / J @ 120 VAC Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Folding Design for Fast and Easy Installation 7 Year Limited Warranty on Fixture 8 Year Limited Warranty on Driver Looking for bulk purchases? We offer volume discounts and other value adding services with our partners at RSX Enterprises. Call (331-281-0154) and speak with a rep for more information. SPECTRUM AND EFFICACY PPF Efficacy: 2.58 at 120 VAC Photon Flux (µmol/s) (400-700nm): 1751 Photon Flux Blue (µmol/s) (400-500nm): 324 Photon Flux Green (µmol/s) (500-600nm): 714 Photon Flux Red (µmol/s) (600-700nm): 713 Total Blue/Red - Energy Bands: 1037 % Blue: 18.51% % Green: 40.76% % Red: 40.73% POWER Power Consumption: 680W AC Driver: Sosen Power Factor: >0.95 Surge Protection: 6 KV 120V: 5.72 A 208V: 3.44 A 240V: 2.98 A 277V: 2.58 A DIMENSIONS Fixture Size (driver mounted on the fixture): (L) 43.9” x (W) 43.9” x (H) 4.1” Fixture Size (without driver): (L) 43.9” x (W) 43.9” x (H) 1.6” Power Supply Dimension: (L)23” X (W) 6.5” X (H) 3” Driver Net Weight: 10.1 lb. Fixture Net Weight: 13.8 lb. OTHER Mounting Height >6” above canopy Beam Angle 110 Degree Input Voltage 100 - 277 VAC Manual Dimming Knob Yes Built In Control Ports Yes Power Cord Length (Extensions available) AWG 16, 6 Foot Standard Plug 120 VAC - NEMA 5-15P Substitute Plugs (Upon request at order for bulk purchases) 240 VAC, 277 VAC, Pigtails Adjustable Height Hanging Kit Included Yes Fixture Warranty 7 Years Limited Driver Warranty 8 Years Limited ETL Safety Certified Conforms to UL 1598:2018 Ed. 4Certified to CSA C22.2#250.0:2018 Ed.4*ETL Safety Certified No. 5020070 DLC Listed Yes

$550.00 $390.00

-

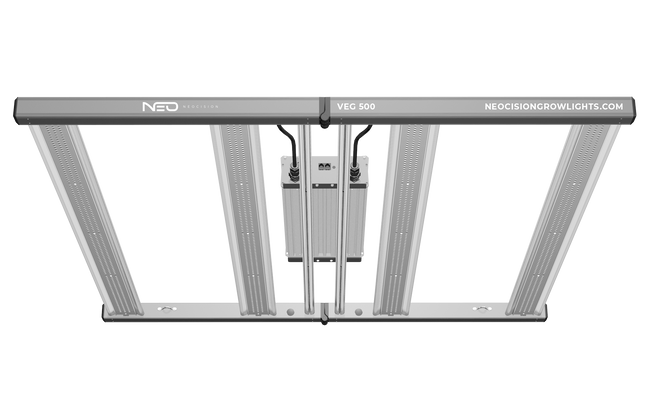

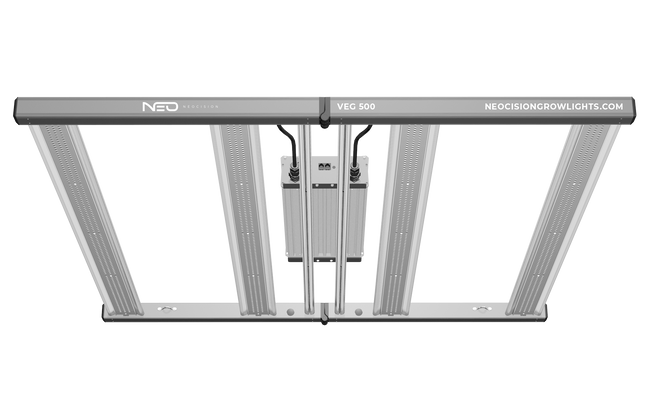

Neocision Spectra Veg 500W LED Grow Light

Neocision Veg 500 LED Grow Light Neocision Veg 500 LED grow light fixtures are designed for commercial growers seeking enhanced yield and canopy coverage as compared to 600W metal halide or 630W ceramic metal halide lights. Increasing PPFD can help you accelerate growth for your mother plants before and after you take cuttings. Features: Tested efficacy of 2.62 μmols/J at 240 VAC Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Folding Design for Fast and Easy Installation 5 Year Limited Warranty

$228.00

-

Neocision Spectra Veg LED Grow Light - DLC Listed

Neocision Spectra Veg LED Grow Light VEGETATIVE Our Vegetative Spectrum 5000k grow light fixture is designed to produce a healthy and more flavorful, aromatic yield. Experience a new level of cultivation. Neocision Spectra Veg Cutsheet DLC Qualified Product List Performance, Specs, Ranking FEATURES: Efficacy up to 2.51 Micromoles / J @120 VAC Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Fast and Easy Installation 7 Year Limited Warranty on Fixture 8 Year Limited Warranty on Driver Looking for bulk purchases? We offer volume discounts and other value-adding services with our partners at RSX Enterprises. Call (331-281-0154) and speak with a rep for more information. SPECTRUM AND EFFICACY PPF Efficacy: 2.5~2.60 at 120VAC - 240VAC Photon Flux (µmol/s) (400-700nm): 853 Photon Flux Blue (µmol/s) (400-500nm): 221 Photon Flux Green (µmol/s) (500-600nm): 390 Photon Flux Red (µmol/s) (600-700nm): 242 Total Blue/Red - Energy Bands: 463 % Blue: 25.94% % Green: 45.70% % Red: 28.53% POWER Power Consumption: 340W AC Driver: Sosen Power Factor: >0.95 Surge Protection: 6 KV 120V: 2.90 A 208V: 1.75 A 240V: 1.51 A 277V: 1.31 A DIMENSIONS Fixture Size (driver mounted on the fixture): (L) 43.9” x (W) 22” x (H) 4.1” Fixture Size (without driver): (L) 43.9” x (W) 22” x (H) 1.6” Power Supply Dimension: (L)16.9” X (W) 6.5” X (H) 3” Driver Net Weight: 6 lb. Fixture Net Weight: 6 lb. OTHER Mounting Height >6” above canopy Beam Angle 110 Degree Input Voltage 100 - 277 VAC Manual Dimming Knob Yes Built In Control Ports Yes Standard Power Cord (Extensions available) AWG 18, 6 Foot Standard Plug 240 VAC - NEMA 6-15P Substitute Plugs (Upon request at order) 120 VAC, 277 VAC, Pigtails Adjustable Height Hanging Kit Included Yes Fixture Warranty 7 Years Limited Driver Warranty 8 Years Limited ETL Safety Certified Conforms to UL 1598:2018 Ed.4Certified to CSA C22.2#250.0:2018 Ed.4*ETL Safety Certified No. 5020070 DLC Listed Yes

$325.00 $204.00

-

Neocision Ultra-Low Chest Style Freezer with Touch Screen LCD (-86°C) 16.2 Cubic Feet - ETL Rated

Neocision ULTRA-Low Chest Style Freezer with Touch Screen LCD (-86°C) 16.2 Cubic Feet - ETL Rated The brand new Neocision ETL Rated 16.2 cubic foot -86°C Ultra-Low Chest Freezer is a lab grade freezer at an affordable price with great temperature stability. This unit will run productively and adequately while brandishing a sleek design that will fit any lab or office setting. Every unit accompanies various safety and protection features taking into consideration user and item safety. These highlights incorporate high and low-temperature alerts. These units are appropriate for emergency clinics, creature cultivation, pharmaceutical organizations, and research foundations. They are intended to store pharmaceuticals, medication, immunizations, natural materials, testing reagents, research facility materials and can likewise be utilized to pre-chill solvents or winterize material. Key Features: ETL Rated Durable Powder Coated Exterior Touch Screen LCD with Datalogging Capabilities Stainless Steel Interior CFC-Refrigerant Free Power Failure and Over Temp Alarm High and Low Temp Alarms Large Digital Display Heavy Duty Rolling Casters (3) 1" ID Ports for putting lines through the freezer Backup battery Included. Specifications Model Number NEO-86C162 Voltage 115V / 60Hz / 13A Wattage 1560w Capacity 16.2cu ft. / 458L / 121G Temperature Range -40°C to -86°C Exterior Dimensions 79-3/4" x 36" x 40" Interior Dimensions 51-1/2" x 23" x 25" Weight 529lbs Certification ETL Rated

$6,750.00 $4,900.00

-

Neocision ULTRA-Low Upright Style Freezer with Touch Screen LCD (-86°C) 17.3 Cubic Feet - ETL Rated

Neocision ULTRA-Low Upright Style Freezer with Touch Screen LCD (-86°C) 17.3 Cubic Feet - ETL Rated The BVV™ Neocision Freezers offer optimal temperature control conditions to use in laboratories and medical facilities. The freezers have a quiet operating noise of less than 53 decibels. This freezer has a user friendly touch screen that can be used to monitor many different aspects of the internal systems. The screen will display any errors such as temperature faults or power faults. There is a backup battery that will keep the screen operational though a facility power outage, and it will display the internal temperatures. This information can help the user input dry ice or liquid nitrogen to assist in cooling sensitive materials through a prolonged power outage. The internal chamber has 4 sections that can be used individually or the shelves can be removed or adjusted to fit larger items. Features: Backup Battery Data Logging Gasket Heating Locking Handle Vent Port Interior Chamber Probe High Condenser Temperature Alarm Power Failure Alarm Temperature Sensor Failure Alarm Low Battery Alarm High/Low Temperature Alarm Door Alarm Specifications: Model NEO-86L490 Temperature Range (°C) -50 ~ -86 Temperature Uniformity (°C) ≤6 Cooldown time (hours) ≤6 Capacity (ft^3) 17.3 Exterior Dimensions (LxWxH) (in) 35.8 x 36.5 x 78.3 Interior Dimensions (LxWxH) (in) 23.1 x 25 x 51.5 Door Opening (LxH) (in) 23.1 x 51.5 Insulation thickness (in) 5 Interior Material Stainless Steel Door Sections 4 Shelves 3 Levels 4 Refrigerant Type Non HCFC Voltage 110V AC Power 1500 W Weight (lbs) 732

$7,000.00 $4,500.00

-

Neocision Vacuum Oven Shelves

Neocision Vacuum Oven Shelves These are stainless steel oven shelves for our Neocision Vacuum Ovens and fit either a 0.9CF or a 1.9CF Neocision Oven. Specifications: 0.9CF - 11" (279mm) x 11.2" (285mm) x 1/8" Thickness 1.9CF - 14" (356mm) x 15.75" (400mm) x 1/8" Thickness

$35.00 - $45.00

-

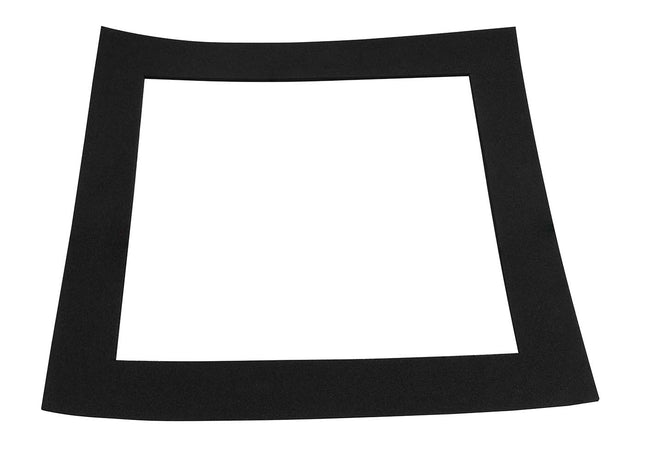

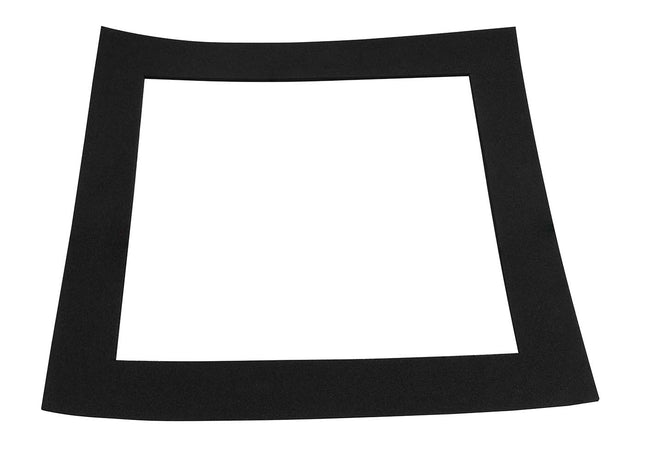

Neoprene Gasket for Cubes

NEOPRENE GASKET FOR CUBES Replacement Neoprene gasket for acrylic vacuum chambers. The existing gasket will have to be completely removed in order to get the new one to seal. It is recommended to use a cleaning solution such as CitraKlean.

$39.00

-

Neutral Activated Alumina Chromatographic Grade (50-200um) *Compare to Alumicel™N

Neutral Activated Alumina pH: 6.8 | 50-200 Micron Made in USA *Compare to Alumicel™ N This activated alumina is a neutral pH adsorbent used to remove excess moisture from your extraction and CRC process. The addition of this media is used as the last layer in the typical BVV™ CRC setups. This grabs any excess moisture from the previous CRC layers and the Biomass. The activated alumina will produce a sugary finish almost immediately after you start your purge. This rapid crystallization is because the process has stripped out additional phospholipoids and fats. This produces an overall extract that is less prone to oxidation and has a longer shelf life. Chromatographic Grade Manufactured in the USA since 1937 Manufactured to the highest quality standards ISO 9001:2015 BVV™ Neutral Activated Alumina Technical Data Sheet BVV™ Neutral Activated Alumina Safety Data Sheet BVV™ Neutral Activated Alumina Quality Certificate

$54.00 - $9,500.00

-

Nickel Plated Brass 1/4" NPT Female to 1/4" Barb Fitting

Nickel Plated Brass 1/4" NPT Female to 1/4" Barb Fitting allows the user to adapt a male NPT thread to a 1/4" Hose barb for flexible tubing. Note: This connection requires PTFE tape on the threaded side to create a leak free seal.

$3.50

-

Nitric Acid 64.6% Lab Grade

Nitric Acid 64.6% Laboratory / Technical Grade *Excellent for gold refining Nitric Acid 64.6% (41° Baumé) (HNO3) is a highly corrosive mineral acid widely used in various industrial application. It is a clear to pale yellow in color and is a strong oxidizing agent known for its corrosive properties. It is commonly used in chemical manufacturing, metal processing, and as a laboratory reagent. Nitric Acid plays a key role in refining gold, particularly in methods like aqua regia refining and in parting processes. Urban mining and pcb board gold recovery commonly uses nitric acid to dissolve gold. *Ships in Level 4 Fluorinated Polyethylene Bottles, 55g ships in HDPE blue drum. Aqua Regia Gold Refining Process (Most Common Use)Aqua regia is a mixture of nitric acid (HNO₃) and hydrochloric acid (HCl) in a 1:3 ratio. This combination dissolves gold, which neither acid can do alone. Step-by-step Overview:Preparation of Aqua Regia: Mix 1 part nitric acid with 3 parts hydrochloric acid. Dissolution: Add impure gold to the aqua regia. Nitric acid oxidizes the gold to gold ions (Au³⁺). Hydrochloric acid provides chloride ions (Cl⁻) to form chloroauric acid (HAuCl₄), which is soluble. Filtration: Filter the solution to remove impurities and undissolved metals. Precipitation: Add a reducing agent like sodium metabisulfite (Na₂S₂O₅) to the solution. This causes pure gold to precipitate out of solution as fine particles. Washing & Melting: Wash the gold powder, dry it, and melt it to form pure gold bars or granules. Chemical Formula: HNO3 Molecular Weight: 63.013 CAS Registry Number: 7697-37-2 Appearance Colorless to faint yellow Odor: Acrid Density > 1.4078@ 25 °C Boiling Point: 248 'F 67.2% HNO3 Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H272, H314, H330 GHS Precautionary Statements P210, P220, P260, P264, P271, P280, P284, P301+P330+P331, P302+P361+P354, P304+P340, P305+P354+P338, P316, P320, P321, P363, P370+P378, P403+P233, P405, and P501 UN Identification Number: 2031 Proper Shipping Name: Nitric Acid Transport Hazard Class: 5.1, 8 Packing Group: II DOT Placard: Nitric Acid 64% Lab/Tech Grade Safety Data Sheet (SDS) Nitric Acid 64% Lab/Tech Grade Certificate of Analysis (COA)

$28.00 - $850.00

-

Nitrogen Hydrogen 95% N2 and 5% H

Nitrogen Hydrogen 95% N2 and 5% H 99.5% Purity, Filled, Compressed Gas Made in Italy This 3"x12" compressed gas tank is filled with a high purity blend of nitrogen and hydrogen. 95% Nitrogen and 5% Hydrogen. The gas can be removed using our regulator or valve dispenser that attaches to the top of the tank. This tank will produce a continuous ~56 Seconds of Nitrogen Hydrogen @ 80PSI. *Note Tank Pressure is 1624 PSI *At end of use, completely empty the tank for recycling. Tank Volume of Gas Product SKU: 130g / 103 Liters / 27 Gallons NITROHYDRO-130G Regulator/Dispenser Details (not included with tank only purchase) Regulator - Adjustable via. needle valve, regulated to 29 PSI. Made in Italy. Thread: M11x1 (tank connection). Output: 1/4" JIC to connect to any of our 1/4" extractor hoses or vacuum hoses. Gauges read in BAR. M11 Valve Dispenser Kit - Includes adjustable pushpin style valve dispenser. Output: 1/4" JIC Flare, NO GAUGE. Connects to any 1/4" JIC Hose.

$38.00 - $133.00

-

Nitrogen Pressure Filter

Nitrogen Pressure Filter Is vacuum filtration bottlenecking your processing? Filter faster with BVV's Nitrogen assisted pressure filters. Designed for versatility our prebuilt pressure filters come complete with our 1 micron Dutch Weave Sintered disk for ultra-fine filtration. Process continuous or batch-style solutions in half the time compared to most vacuum filtration applications. Specifications 6"x12" or 12"x12" filtration body 1um Dutch Weave Sintered disc Filter Plate Retention Ring Fast Flow Filter paper Included Solvent dispersal plate 2X Borosilicate Sight Glasses 1X 125 PSI ASME Safety Valves 1X -30hg-250PSI Compound Pressure Gauges 1X 1/2" JIC Lid Valve 2X 1/4" JIC Lid Valves 1X JIC Drain Valve (6NPS: 1/4" 12NPS: 1/2" JIC) Maximum Pressure Rating: 125PSI

$1,400.00 - $2,650.00

-

Nitrogen Tank for Extraction 99.5% Pure

Nitrogen Beverage Grade 99.5% Pure Made in Italy This modest but mighty nitrogen tank is a great to pair with any 2lb or smaller extraction system. For those customers that need nitrogen to push their solvent through color remediation columns (CRC) or for those super cold dewax extractions that need the extra push to get the remaining solvent out of the cold columns. This tank will produce a continuous ~66.5 Seconds of Nitrogen @ 80PSI. Directions: (*Hose not Included with regulator) Connect a stainless steel braided 1/4" JIC hose (or vacuum hose BVV-HVAC) to your extractor, placed at the valve where you need your extra pressure push. Using the needle valve you can open the regulator and the nitrogen will flow. Pressurize 15-30PSI. *Note Nitrogen Tank Pressure is 1580 PSI *At end of use, completely empty the tank for recycling. Tank Volume of Nitrogen Coverage Product Sku: 130g / 103 Liters / 3.67 Cubic Feet See Use Chart Below... NITROGEN-130G Regulator/Dispenser Details (not included with tank only purchase) Nitrogen Regulator - Adjustable via. needle valve, regulated to 80 PSI. Made in Italy. Thread: M11x1 (tank connection). Output: 1/4" JIC to connect to any of our 1/4" extractor hoses or vacuum hoses. Gauges read in BAR. M11 Valve Dispenser Kit - Includes adjustable pushpin style valve dispenser. Output: 1/4" JIC Flare, NO GAUGE. Connects to any 1/4" JIC Hose. How long will it last?: A 1lb column of biomass (3"x24") is equal to ~2.7 liters empty. That's about 38 column volumes. Assuming you only used 4 column volumes per extraction you would get ~10 extractions from one tank. Column Size Column Volume # Runs/Tank 1.5x12 (70g biomass column) 0.34 Liters ~75 2x12 (120g biomass column) 0.6 Liters ~54 3x24 (1lb biomass column) 2.7 Liters ~12 4x24 (2lb biomass column) 4.9 Liters ~6 *Use calculated @ 4 column volumes per run What Is Nitrogen Gas? Nitrogen gas is a chemical element and a diatomic molecule with the chemical formula N2. It is a colorless, odorless, and tasteless gas that makes up about 78% of Earth's atmosphere by volume. Nitrogen gas is an essential component of the air we breathe and plays a crucial role in various natural processes and industrial applications. In its gaseous form, nitrogen is composed of two nitrogen atoms tightly bonded together by a strong triple bond. Due to its stable molecular structure, nitrogen gas is relatively inert and does not readily react with other substances under normal conditions. What Is Nitrogen Gas Used For? Nitrogen gas has a wide range of applications across various industries and scientific fields due to its inert nature, abundance, and unique properties. Some of the key uses of nitrogen gas include: Food Preservation: Nitrogen gas is used to create controlled atmospheres in food packaging to extend the shelf life of perishable products. It helps prevent the growth of spoilage microorganisms and maintains the freshness of packaged foods. Laboratory Applications: Nitrogen gas is used in laboratories as a carrier gas for chromatography, as a purge gas to remove oxygen and moisture from sensitive reactions, and for preserving and storing samples. Welding and Metalworking: Nitrogen gas is employed as a shield gas during welding and metalworking processes to prevent oxidation and maintain the integrity of metal surfaces. Electronics Manufacturing: In electronics manufacturing, nitrogen gas is used to create inert environments that prevent oxidation and improve the quality of soldering and component assembly. Cryogenic Applications: Nitrogen gas, when cooled to extremely low temperatures, becomes liquid nitrogen. It is used in cryopreservation of biological samples, freezing and storing biological materials, and in various cryogenic cooling applications. Fire Suppression: Nitrogen gas is utilized as a fire suppressant in certain situations to reduce the concentration of oxygen, effectively suppressing fires and preventing explosions. Oil and Gas Industry: In the oil and gas industry, nitrogen gas is used for pressure testing pipelines, purging equipment, and enhancing oil recovery. Medical and Healthcare: Nitrogen gas is used in medical applications, such as cryotherapy for skin treatments, freezing of warts and lesions, and providing a dry environment for sensitive medical instruments. tAerospace and Aviation: Nitrogen gas is used to pressurize aircraft tires and hydraulic systems, preventing moisture and oxidation-related issues. Fertilizer Production: Nitrogen gas is a key component in the production of ammonia-based fertilizers, which are essential for promoting plant growth in agriculture. Diving Industry: In underwater diving, nitrogen gas is used in breathing gases such as air and nitrox. Pneumatic Systems: Nitrogen gas is used in pneumatic systems for inflating tires, powering tools, and operating machinery. Food and Beverage Industry: Nitrogen gas is used to dispense draft beer, wine, coffee, and other beverages, creating a foamy head and enhancing the presentation. How Can I Pressure Test My Extractor With Nitrogen? Pressure testing your extractor with nitrogen involves using nitrogen gas to check for leaks, verify the integrity of the equipment, and ensure its safety before performing actual extraction processes. Here's a step-by-step guide on how to pressure test your extractor using nitrogen gas: Materials Needed: Nitrogen gas cylinder with appropriate regulator Pressure gauge PTFE tape (thread seal tape) Bubble solution or soapy water Safety goggles and gloves Wrench or spanner Steps: Preparation: Ensure that the extractor is clean and free from any residual materials. Check all fittings, connections, valves, and joints for signs of damage, wear, or corrosion. Replace any damaged components. Make sure the extractor is properly assembled and closed, including any access ports or lids. Safety Precautions: Wear appropriate safety goggles and gloves to protect your eyes and hands. Work in a well-ventilated area to prevent the buildup of nitrogen gas. Regulator Setup: Attach the nitrogen gas cylinder to the regulator and secure it tightly using a wrench. Set the desired pressure on the regulator according to the recommended pressure for your extractor and testing requirements. Sealing Threads: Apply PTFE tape to the threads of the fittings and connections. This helps create a better seal and prevents leaks. Connect Nitrogen Gas: Connect the regulator outlet to the appropriate inlet or access port on the extractor using a compatible hose or tubing. Pressure Testing: Slowly open the nitrogen gas cylinder valve to allow gas to flow into the extractor. Monitor the pressure gauge and allow the pressure to build up to the desired test pressure. Once the desired pressure is reached, close the cylinder valve to stop the flow of nitrogen gas. Leak Detection: If pressure is not maintained apply a bubble solution or soapy water to all the fittings, joints, and connections. Inspect the extractor for any bubbles forming, indicating potential leaks. Pay close attention to areas where bubbles appear, and tighten or adjust fittings after depressurizing the system as needed to eliminate leaks. Release Pressure: Slowly release the pressure from the extractor by gradually opening the cylinder valve. Once the pressure is completely released, disconnect the nitrogen gas source. Final Inspection: Reapply the bubble solution or soapy water to the connections that were adjusted. Verify that no bubbles form, indicating that leaks have been successfully resolved. Documentation: Keep a record of the pressure test results, including the test pressure and any adjustments made. Repeat if Necessary: If any leaks were detected and resolved, repeat the pressure test to ensure all leaks have been eliminated. Pressure testing your extractor with nitrogen gas helps ensure the safety and integrity of the equipment, minimizing the risk of leaks during actual extraction processes. Always follow proper safety guidelines and manufacturer recommendations when working with nitrogen gas and pressure testing equipment. How Do I Perform A Nitrogen Assisted Extraction? Using nitrogen to inject butane into a closed-loop extraction system requires careful consideration and adherence to safety protocols. Nitrogen gas can be used to pressure test the extraction system, assist in transferring butane throughout the system, and assist in the process of adsorbent filtration/color remediation. Here's a step-by-step guide on how to use nitrogen to inject butane into your closed-loop extraction setup: Materials Needed: Closed-loop extraction system with Pressure Relief Valve Nitrogen gas cylinder with appropriate regulator Pressure gauge Nitrogen-compatible hose or tubing Butane tank Butane-compatible hose or tubing Safety goggles and gloves Wrench or spanner Steps: Safety Precautions: Wear appropriate safety goggles and gloves to protect your eyes and hands. Work in a C1D1 environment to prevent the buildup of flammable gases. Preparation: Ensure that the closed-loop extraction system is clean, properly assembled, and free from any residual materials. Regulator Setup: Attach the nitrogen gas cylinder to the regulator and secure it tightly using a wrench. Set the desired pressure on the regulator based on the recommended pressure for your closed-loop system and extraction process We recommend utilizing 25-50 PSI to perform solvent transfer throughout the system. Nitrogen Line Connection: Connect the regulator outlet to the nitrogen-compatible hose or tubing. Connect the other end of the hose to the vapor port or accessory port to the recovery cylinder of your closed-loop system. Butane Line Connection: Connect the recovery cylinder to the closed-loop system using a butane-compatible hose or tubing. Ensure that the recovery cylinder is securely connected to the system, properly sealed, and grounded. Pressurizing the System: Slowly open the nitrogen gas cylinder valve to allow nitrogen gas to flow into pressurize the recovery cylinder. Monitor the pressure gauge and pressurize the recovery cylinder to the desired pressure for injecting butane. Nitrogen gas is used to create pressure that forces the butane into the system. Injecting Butane: Open the valve on the recovery tank to allow the butane to flow into the material column of the closed-loop system. The pressurized nitrogen gas assists in transferring the butane through the system and into the collection base of the system. Monitoring and Safety: Carefully monitor the pressure levels on both the nitrogen gas cylinder and the recovery cylinder. Venting: Once the injection and extraction processes are complete, close the valves on both the nitrogen gas cylinder and the recovery tank. Prior to applying heat to your collection base and starting your solvent recovery procedure first slowly vent the nitrogen from the collection base directly into the ventilation system of your C1D1 Booth. Monitor the pressure gauge and sight glass of the collection base closely. Slowly and incrementally vent the nitrogen from the system until the solution begins to boil this is an indication that the nitrogen filling the headspace of the collection base has been removed and the butane is filling the remaining headspace. Additionally, if the pressure starts to increase after an incremental venting procedure that is a good indication that the nitrogen has been released from the system and the butane is building pressure within the system. If the tank PSI remains the same after a venting procedure then nitrogen is most likely still within the system. Recovery: Once the nitrogen has been successfully removed from the collection base proceed to vent the nitrogen from the empty recovery cylinder and pull the recovery cylinder and the associated lines under vacuum. With the nitrogen now removed from both the collection base and recovery cylinder you can now proceed with your recovery procedure Disconnect the nitrogen gas line and the butane line from the closed-loop system. Properly store the nitrogen gas cylinder and the recovery tank according to safety guidelines. Using nitrogen to inject butane into a closed-loop extraction system requires a solid understanding of the equipment, processes, and safety procedures involved. Always refer to your closed-loop system's manufacturer guidelines and follow best practices for safe operation. How Much Nitrogen Pressure Do I Need For Adsorbent Filtration/ Color Remediation? The nitrogen pressure required for adsorbent filtration and color remediation can vary depending on the specific equipment, setup, and the type of media you are using. It's essential to follow the manufacturer's recommendations for your particular closed-loop extraction system and adsorbent filtration equipment. In general, nitrogen gas can be used to apply pressure to assist in pushing the solvent through the adsorbent media, enhancing the filtration and color remediation process. The pressure you need may vary based on factors such as the viscosity of the solvent, the flow rate, the type of adsorbent media, and the desired results. It's recommended to start with a moderate nitrogen pressure and gradually increase it while monitoring the flow rate and effectiveness of the process. Generally, pressures in the range of 20 to 50 psi (pounds per square inch) are commonly used for adsorbent filtration and color remediation. However, this pressure range can be adjusted based on your specific equipment and requirements. Keep in mind that using too high of a pressure can potentially cause channeling, uneven flow, and limited retention through the adsorbent media, affecting the quality of the filtration process. It's essential to strike a balance between achieving effective filtration and avoiding excessive pressure that could lead to inefficient results or potential safety risks. It's best to perform small-scale tests before scaling up to ensure optimal results and start off slowly when using nitrogen pressure for adsorbent filtration and color remediation. Chemical Formula: N2 Molecular Weight: 28.014 g/mol CAS Registry Number: 7727-37-9 Appearance Colorless Odor: Odorless Density 0.072 lb/ft3 Boiling Point: -196C (-320.8F) Solubility in water: N/A GHS Pictograms: GHS Signal Word: Warning GHS Hazard Statements: H280, H281 GHS Precautionary Statements P282, P336+P317, P403, and P410+P403 UN Identification Number: 1066 Proper Shipping Name: Nitrogen, Compressed Transport Hazard Class: 2.2 Packing Group: None DOT Placard: Nitrogen Safety Data Sheet (SDS)

$38.00 - $133.00

-

Nitrous Oxide Tank Pressure Regulator made by Best Whip