BFCM-20

5L ECO Nut and Washer Flask Set

Replacement nut and washer flask set for 5L Eco Rotary Evaporator

$45.00

Solvent Pro Series 18/35 Gasket

Solvent Pro Series 18/35 Gasket This is a replacement Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This gasket fits an 18mm(0.71") Inner Diameter and 35mm(1.38") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$13.00

P2V4 Neocision Distillation Head - USA Made

P2V4 Neocision Distillation Head P2V4 Short Path Distillation Head includes 4 sets of Vigreux with 24/40 Joints and GL-14 Barb Connections. Key Features: MADE IN THE USA Designed for 1 & 2 Liter Flasks Set of 4 Vigreux to allow for better seperation of fractions without packing material Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$800.00

Dry Utility Vacuum/Pressure Gauge - Center Back Mount

Dry Utility Vacuum/Pressure Gauge - Center Back Mount 1/8" MNPT brass Connection

$12.00$7.00

Pipe Cap

SSP - Pipe Cap SSP Instrumentation TruFit® is manufactured from fully-traceable raw material to close tolerances and superior surface finishes. TruFit® provides optimal performance when installed in accordance with SSP’s recommendations and the design parameters appropriate for each type of connection – tapered thread, straight thread, and weld & braze. TruFit® components are cleaned in accordance with SSP documented work instructions using equipment calibrated to NIST standards with environmentally-safe and stable agents, ultrasonics, and heat/ temperature to remove all residual oil, grease, and loose particles. Stainless steel components are passivated to the requirements of MIL QQ-P-35 and ASTM A 967. ***Note: ALL NPT Threads REQUIRE the user to properly install the fitting by using a thread sealant to prevent leaks. Best Value Vacs recommends GAS PTFE Tape Specifications Connection Type 1 Female NPT Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Working Pressure (PSIG) 1/4" - 7750 3/8" - 6800 NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$5.00 - $6.00

Branch Tee

SSP - Branch Tee SSP Instrumentation TruFit® is manufactured from fully-traceable raw material to close tolerances and superior surface finishes. TruFit® provides optimal performance when installed in accordance with SSP’s recommendations and the design parameters appropriate for each type of connection – tapered thread, straight thread, and weld & braze. TruFit® components are cleaned in accordance with SSP documented work instructions using equipment calibrated to NIST standards with environmentally-safe and stable agents, ultrasonics, and heat/ temperature to remove all residual oil, grease, and loose particles. Stainless steel components are passivated to the requirements of MIL QQ-P-35 and ASTM A 967. ***Note: ALL NPT Threads REQUIRE the user to properly install the fitting by using a thread sealant to prevent leaks. BVV recommends GAS PTFE Tape Specifications Connection Type 1 Female NPT Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Working Pressure (PSIG) 1/4" - 7750 3/8" - 6800 NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA! Dimensions A 1.76 in E 0.28 in H 3/4 in P 1/4 in L 0.88 in S 1.09 in

$30.00

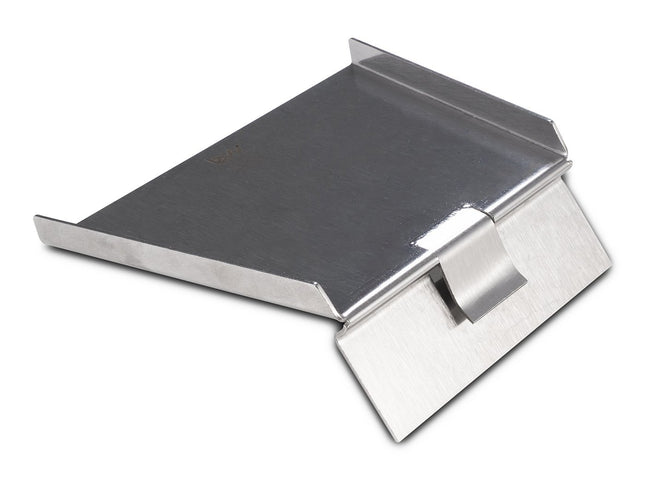

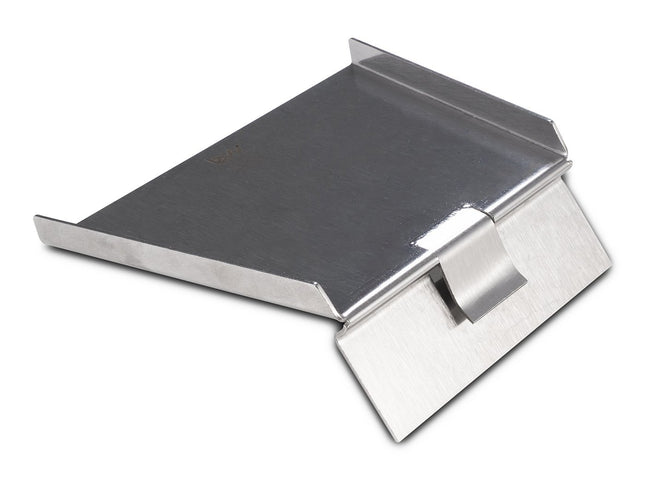

6" - 12" Dewax Dry Ice Funnel

This stainless steel funnel is meant to help get dry ice into 6" - 12" Dewaxing columns. It simply clips on the side of the dewaxer allowing an easier filling of the dry ice into the dewaxing column.

$65.00

PTFE Valve Core for 5/10/20L for Solvent Pro Rotary Evaporator

PTFE Valve Core for 5/10/20L for Rotary Evaporator This PTFE valve core is a direct replacement for Solvent Pro Series 5L, 10L, and 20L rotary evaporators. They are used on the injection valve, drain valve, and collection flask ancillary valves. The body and seal are made of PTFE making it chemical resistant. **Please confirm you have BVV Solvent Pro Series 5L, 10L, 20L rotary evaporator before purchasing this part. If you need help identifying which model you have, please call in.**

$75.00

Straight Inlet Adapter with Hose Barb

Straight Inlet Adapter with Hose Barb This straight inlet adapter allows the user to connect a male and female 24/40 jointed connection and attached a flexible hose for vacuum if needed. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$30.00

Economy Recirculating Heater Kit

Economy Recirculating Heater Kit The Economy Recirculating Heater Kit is designed to provide efficient heating and circulation at an affordable price. The kit includes a submersible water pump for fluid circulation, an LX or MX immersion heater, and all tubing and hose clamps needed to pair with your system. The tubing is 1/2" ID x 5/8" OD and the pump fitting is 1/2". The pump will circulate up to 594 GPH. Economy Recirculating Heater Kit Includes: Polyscience LX or MX Immersion Circulator EcoPlus Eco 633 Fixed Flow Submersible/Inline Pump 594 GPH 5 Gallon Aluminum Pot 10 Feet of 1/2" Silicone Tubing 10 Pack of Adjustable Stainless Steel Tubing Clamps

$1,700.00

Baffled Condenser - 6" x 36" with 1.5" Tri-Clamp Side Ports

Baffled Condenser - 6" x 36" with 1.5" Tri-Clamp Side Ports This 304 Stainless Steel Tri-Clamp condenser allows the user to condense hot vapors and solvent while running an extraction system or use it as a heat exchanger if needed. It features internal baffles in the system allowing for better overall heat exchange, 6" Tri-Clamp connections on each end and (2) 1.5" Tri-Clamp ports on the side to allow various connections the user may need. From end to end it is 36" in length. The inside diameter of the tubing measures 7.5mm.

$3,000.00

5L Short Path Distillation Kit with P5 Distillation Head

5L Short Path Distillation Kit with P5 Distillation Head This unit carries a 2 day lead time. The 5L Distillation Kit includes everything needed to perform distillation excluding the vacuum pump and chiller. This kit features our USA made P5 Distillation Head, as well as USA, made glass. This Kit is designed for high volume production with the highest quality components for precise, repeatable results time and again. This Kit Does NOT include a vacuum pump or chiller. Please see the below recommendations for both as well as recommended add-ons. Recommended Vacuum Pumps: Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (economy option) Recommended Chillers: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter Refrigerated Circulator (premium option with chilling capability) Recommended Add-Ons: Glass Dewar Style Cold Trap (recommended cold trap) Bullseye Precision Vacuum Gauge (premium vacuum gauge for measuing depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) J-KEM Digital Vapor Temp Monitor (digital vapor temp monitor with data-logging capabilites) Specifications: Boiling Flask Size: 5L Receiving Flask Size: 2x 500mL, 1000mL Batch Capacity approximate: 1000-2500 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Includes: Glass components: 5L Boiling Flask P5V6 Distillation Head Triple Neck Cow 2x 500mL Receiving Flask 1L Receiving Flask 120mm Glass Funnel Accessories: PTFE Magnetic Stir Bar Retriever 5 Pack of Metal Keck Clips Dow Corning High Vacuum Silicone Grease Tripod Stand 5L Digital Heating and Stirring Mantle 3-Finger Adjustable Clamp 0-77mm 6" x 6" Scissor Jack 500-1000mL Cork Stand 2x 24/40 ChemglassPTFE Thermometer Inlet Adapter 10ft of Gum Rubber Vacuum Hose 10ft of Silicone Chiller Hose 1/4" Vacuum Manifold Traceable Kangaroo Thermometer - Digital 10 Pack of Adjustable Stainless Steel Tubing Clamps Fiberglass Insulation Rope 10 Feet 1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen w/ 2x 1/4" Barb Adapters Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$2,200.00

BVV 280L Centrifuge Bags

This nylon bag is designed to fit in our BVV brand centrifuges to contain material and be easily swappable after runs to speed up processing times. These bags come with 2 zippers and come in 1, 10, 50, 100, and 200 micron filtration levels. For use with 280L Centrifuges Appx. Size : 39.25" Diameter x 14" Height Specifications SKU Appx. Diameter In. Appx. Height in. CFB-45L-XXX 17.5" 11.75" CFB-160L-XXX 32.25" 13" CFB-280L-XXX 39.25" 14" CFB-475L-XXX 47.25" 16.75"

$206.00 - $398.00

Dry Ice Condenser for 2L Electric Lift Rotary Evaporator

Dry Ice Condenser for 2L Best Value Electric Lift Rotary Evaporators. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$375.00

Glycerin Filled Vacuum Gauge with 1/4" NPT Back Mount -30inHg-0Psi

BVV -30inHg-0Psi BVV™ Glycerin filled vacuum gauge has a 1/4" MNPT brass connection with a readout of (-30) inHg - 0 PSI. The outer diameter of the gauge measures 2.25" We provide adapters to fit your setup in MNPT, FNPT, MJIC, FJIC, and standard compression tubing.

$18.00

BVV™ Extraction RACK # 5

BVV™ Extraction RACK # 5 (Assembled units come with a 30-day warranty) Note: The unit does not come assembled - select "pre-assembled" from the drop-down menu to have the unit assembled by BVV before shipping Pipe hangers are not included There is no warranty on unassembled units Shipping Notice: If the customer orders the rack as assembled, then the item will only ship via freight and there will be additional shipping charges. Extraction Rack 5 Technical Drawing BVV™ Extraction RACK # 5 is similar to Extraction Rack #3 but with thicker vertical support beams. This rack fits the following BVV™ Extraction Systems: 10LB Mercurius 30LB Closed Loop Extraction System Specifications (Does not include height with casters) Main Base Dimensions 39" X 30" Vertical Dimensions 39" X 48"

$1,620.00 - $1,845.00

BVV™ 8 Ton 304SS Puck Press

BVV™ 8 Ton 304SS Puck Press This BVV™ 8 Ton 304SS Puck Press allows users to compress material into an easily manageable puck. Specifications: 304 Stainless Steel Components (Excludes Jack) External Dimensions - 7-1/8" x 7-1/8" x 14" Internal Puck Mold Diameter - 3.75" Mold Height - 3-1/4" Weight - 34LBS

$315.00

5L Solvent Pro Rotary Evaporator Nut and Washer Flask Set

Replacement nut and washer flask set for 5L Solvent Pro Rotary Evaporator

$45.00

1L Standard Distillation Turnkey Setup

1L Standard Distillation Turnkey Setup The Standard Distillation Turnkey Setup includes all the components necessary to successfully perform distillation at an entry level price point. The Standard Turnkey Setup Includes: 1L Distillation Kit 1/4" Flare x 1/4" Barb Adapter BVV™ 5L Heated Circulator BVV™ V9D 9CFM Two Stage Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$2,100.00 - $2,350.00

7.5CF BVV™ Neocision ETL Lab Certified Vacuum Oven

7.5CF BVV™ Neocision Certified Lab Vacuum Oven, 5 Individually Heated Shelves, LED's - 3 Year Warranty Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! Introduction Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. Performance Capabilities At Best Value Vacs, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Uniformity: within 4% of the temperature setpoint. Heat-Up Time: 20 minutes. Ultimate Vacuum: <500 µmHg / mTorr / micron. Time to Vacuum: 10 minutes to 29"Hg using our VE Series 12cfm Dual Stage Vacuum Pump. Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. Technical Data Electrical Voltage 120V Frequency 60Hz Power 1960W Current 20A Plug IEC C13 (unit ships with detachable NEMA 5-20 cable) Internal Chamber Heating Individual direct-heat shelves Chamber Material Stainless Steel Dimensions (LxWxH) 22" x 23.25" x 25.25" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 5 Heated Shelves Shelf Dimensions (LxW) 21.5" x 21.5" Shelf Capacity 462 in2 Total Shelf Capacity 2311 in2 / 16.1 ft2 Safety Seal Silicone on Tempered Glass Window Dimensions (LxH) 20.25" x 23.75" Lights 4 strips of LEDs provide a clear, bright view of the interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 35" x 33" x 34.5" Weight 430 lbs Support Locking Casters Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connections Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose User Manual Included Vacuum Pump Sold Separately. Warranty 3 Years Capacity and Throughput Planning Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122 Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via UPS Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise UPS freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$8,100.00

Bore Through 1/2" Compression Fitting x 1/2" MJIC

Bore Through 1/2" Compression Fitting x 1/2" MJIC made out of 304 stainless steel.

$12.00

Upgraded TRS21 Compressor Head Complete, Stainless Fittings, Viton

Upgraded TRS21 Compressor Head Complete, Stainless Fittings, Viton Upgrade your TRS21 by purchasing a new Compressor Head with Viton O-rings for butane and propane gas compatibly and stainless steel fittings to meet FDA guidelines on handling of consumable products. This head is assembled here in the USA and is a direct replacement for any TRS21 Compressor Head.

$195.00

Best Value Vacs 1 Gallon Flat Stainless Steel Vacuum Chamber W/GLASS LID

1 Gallon Shatter Vac Flat Stainless Steel Vacuum Chamber W/ GLASS LID (Comes with 2 Year Limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 3" Tall x 10.25" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. DOES NOT APPLY TO GLASS LID VERSION ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$135.00

Glass Vac 1.5 Gallon TALL Stainless Steel Vacuum Chamber and Vacuum Pump Kit

Glass Vac 1.5 Gallon TALL Stainless Steel Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Glass Vac 1.5 Gallon TALL Stainless Steel Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 - 2B Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 8-5/8" Tall x 7-1/8" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result from the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$288.00 - $457.00

Duolok Male Elbow Tube Fitting

SSP - Duolok Male Elbow SSP Instrumentation Duolok® tube fittings are designed, manufactured and quality controlled to be totally “interchangeable” with the Swagelok® brand of tube fittings. Component by component examination plainly shows the two brands as completely “componentintermixable.” The precision manufacturing of both products to stringent tolerances under rigid quality control procedures ensures the safety, performance, and reliability of service whenever Duolok® and Swagelok® component parts are mixed and used in accordance with published installation and service recommendations. Specifications Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Connection Type 2 Male NPT Connection Size 2 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Duolok Pressure Rating = Tubing Rating NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA! Dimensions A 1.06 in Bx 0.77 in By 0.92 in C 0.70 in D 0.60 in E 0.19 in F 0.56 in G 9/16 in H 1/2 in P 1/4 in T 1/4 in

$15.00 - $48.00

BVV™ Pro Series 14.1CFM Corrosion Resistant Two Stage Vacuum Pump

BVV™ Brand 14.1CFM Two Stage Pro Series This is the BVV™ Brand 14.1CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 14.1CFM will pull a vacuum down to 0.5 micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Compare to Cacejen or Xeno brand rotary vane vacuum pumps. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 115v 60Hz Pumping Rate: 14.1CFM Ultimate vacuum without gas ballast: 0.5 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2L/2.1 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Weight: 38KG / 84lbs Recommended oil: Ultragrade 19 CE Compliance: Yes Warranty 2 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$2,400.00

Koby Adapter for BVV Pumps Series

Koby Adapter for BVV Pumps Series This fitting allows the user to connect a 1/4" NPT fitting to the exhaust for the desired application such as a carbon exhaust filter. It is made of steel and comes with a Viton O-ring.

$25.00

Glass Vac™ 16.75" Diameter LID

Glass Vac 16.75" Diameter LID Our patented gasket #9475627 Disclaimer: This item Includes Lid and Gasket Only This is a Replacement Lid for the following Vacuum Chambers: Glass Vac 15 Gallon Aluminum Vacuum Chamber

$213.00

EVO Mini Closed Loop Extractor

EVO Mini Closed Loop Extractor (System comes with 1 yr. limited warranty) The EVO Mini 90 gram closed-loop extractor was designed to provide the same versatility & capability of our EVO Extractor line, allowing both the use of adsorbent filtration and pre-chilling of solvent utilizing the inline Color remediation column and the Sleeved EVO recovery tank. The EVO Mini is the perfect small batch R&D system or top-of-the-line mini extractor. Perform small batch testing of new biomass or R&D new adsorbent filtration recipes without utilizing large volumes of biomass. The Evo Mini allows you to test with hot or cold solvent, try out different ratios of powders or granular medias, and test extract new biomass before running a larger extraction. The EVO Mini comes complete with a top fill injection manifold including a compound gauge, a stainless steel butterfly valve with a 1/4" MJIC connection that injects solvent directly into the 1.5"x 12" 90-gram material column which is enclosed by 2x 100 micron Buna-N mesh gaskets. Just below the 90-gram material column is the inline 1.5" x 3" color remediation column just below the material column with a 30-gram media capacity and a filter stack utilizing both a 5 micron & 1 micron sintered disk. Below the filter stack the EVO Mini drains into the collection base equipped with a compound gauge, a 4" Short sight glass, and a stainless steel butterfly valve with a 1/4" MJIC connector. The Collection base can accommodate up to 1.1lbs of butane perfect for a 5:1 solvent to biomass ratio. Which can be evaporated with ease when used in conjunction with the Mini Evo sleeved recovery tank filled with dry ice and a hot water bath. ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. KEY BENEFITS Meets or exceeds all industry listed standards Versatile in running butane, propane, and other blended solvents Perfect for R&D of media combinations or testing fresh biomass Inline color remediation Pre-chilling of solvent Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry-level extractor on a budget. This option comes equipped with single pin clamps rated to a service pressure of 300PSI for the 4" clamp and 500PSI for the 1.5" clamp at 70F. Elite: The Elite series is the premium version of the EVO Mini that comes equipped with High-pressure clamps rated to a service pressure of 800PSI for the 4" clamp and 1500PSI for the 1.5" clamp at 70F. *All configurations are pressure tested for 24 hours before shipment using nitrogen at 100PSI. Although many of the components of the EVO Mini are rated to withstand well above 100PSI during extraction we do not recommend pressurizing any system past 100PSI. During normal operation of the EVO Mini pressures typically don't exceed 50PSI* Explorer Elite Single Pin Clamps High-Pressure Clamps Unit Includes: Injection manifold complete with a compound gauge, 1/4" butterfly valve, and a 1/4" MJIC Connection. 1.5"x12" 90 gram material column. 1.5"x6" adsorbent filtration column with 30g gram media capacity. Adsorbent filtration filter stack including 5 micron and 1 micron sintered disks. 4" collection base with splatter platter & short sight glass complete with a compound gauge, and a 1/4" butterfly valve with a 1/4" MJIC Connection. 4"x8" Sleeved EVO Recovery tank with compound gauge, polycarbonate sight glass, and a 1/4" butterfly valve, and a 1/4" MJIC Connection. (1) 1/4" 48" FJIC Stainless Steel Injection hose (1) 1/4" 24" FJIC Stainless Steel Recovery Hose Specifications: 1.5"x 12" 304 Stainless Steel Material Column- 90 gram capacity 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple 37-degree FJIC port connections 304 Stainless collection base Tri-Clamps at all interfaces make for a high pressure/standard pressure, easy-clean unit BUNA-N Gaskets are designed for Oil Processing Temp range -40-200F, and have superior solvent resistance Construction: All components are made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$800.00 - $860.00

Tri-Clamp Spool with 2" Angled Ports

304 Stainless Steel Tri-Clamp Spools with 2" Angled Ports allow the user varying amounts of configuration and also the ability to put 2 sight glass end caps on the 2" Ports to allow the user to view the flow inside of a column or spool.Sizes Available: 4" Tri-Clamp x 6" Length x (2) 2" Angled Ports 6" Tri-Clamp x 6" Length x (2) 2" Angled Ports

$160.00 - $225.00

Best Value Vacs 2 Gallon Aluminum Vacuum Chamber W/GLASS LID

2 Gallon Vacuum & Degassing Chamber W/GLASS LID (Comes with 2 yr Limited Warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 6.5" Tall x 10" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micron Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$124.00

USP / Food Grade 190 Proof Ethanol 95% AVB

USP / Food Grade 190 Proof Ethanol 95% AVB | Grain Derived Alcohol EXCISE TAX INCLUDED IN PRICING. HAZMAT ITEMS ARE NON-REFUNDABLE. ALL SALES ARE FINAL BVV™ Food / USP Ethanol 190 Proof, This product is the highest purity possible for extraction grade ethanol on the market, at 95% pure. Provides unmatched purity while performing extractions for crude oil or even cleaning equipment. 190 Proof Ethanol is a great choice when processing oil for short path distillation processes because it can be immediately winterized, filtered, and then rotary evaporated to recover the ethanol for later usage. NOTE : *USP and Kosher certified 190 proof available upon request. Lot numbers for certificates of analysis can be found via the BVV COA lookup up page. (click here) *Disclaimer(s): Spigots/Faucets are only compatible with 5 & 15 Gallon Plastic Jugs and must be purchased separately (Recommended Dispensing Spigot) Trigger Sprayer is only compatible with 1QT and 1 Gallon sizes A copy of your unexpired DRIVERS LICENSE, STATE ID CARD, or US PASSPORT and your completed and signed END-USER STATEMENT must be received before we ship out your order. End Users Agreement Technical Data: Chemical Formula: C2H6O Molecular Weight: 46.069 CAS Registry Number: 64-17-5 Appearance Colorless Liquid Odor: wine-like, pungent Density 0.78945 g/cm3 @ 20 °C Boiling Point: 78.23C/172.81F Solubility in water: Miscible GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H319, H360D GHS Precautionary Statements P210, P233, P240, P241, P242, P305+P351+P338 UN Identification Number: 1170 Proper Shipping Name: Ethanol Solution Transport Hazard Class: 3 Packing Group: II DOT Placard: Federal & State Law Requirements You must be the age of 21 or over to purchase this ethanol product. All Alcohol and Tobacco Tax Trade Bureau (TTB), federal, state and local laws must be complied with, and you may be required to provide BVV™ with your state or federal license even when purchasing products that require a federal excise tax payment. (Note: Container style and color may vary)

$26.00 - $5,940.00

50L Solvent Pro Series Glass Axis

50L Solvent Pro Series Glass Axis. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$90.00

Solvent Pro Series 40/60 Clamp and Gasket Set

Solvent Pro Series 40/60 Clamp and Gasket Set This is a replacement Clamp and Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This Clamp and Gasket fit an 40mm(1.57") Inner Diameter and 60mm(2.36") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$35.00

BVV™ Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump

BVV™ Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump This is the BVV™ Brand 21.2CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 21.2CFM will pull a vacuum down to 0.5mtorr micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 115v 60Hz Pumping Rate: 21.2CFM Ultimate vacuum without gas ballast: 0.5mtorr Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2.3L/2.4 quarts Working Temperature: 5C to 40C Unit Weight: 41KG / 90lbs Recommended oil: Ultragrade 19 CE Compliance: yes Warranty: 2 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$3,200.00

1" ID Braided Clear PVC Hose NSF-51 Certified

1" ID Braided Clear PVC Hose NSF-51 Certified Crystal clear Phthalate, BPA Free PVC compound, formulated with ingredients in compliance with applicable ratings: NSF-51 Certified USP Class VI Rated Compound, FDA Ingredients, Self-Extinguishing and Reinforced with braided polyester yarn. Key Features: Constructed with Phthalate Free compounds. NSF-51 certified material. Crystal clear - allows visual confirmation of product flow. Longitudinally reinforced to reduce elongation under pressure. Light weight. Self-extinguishing. Non-marking. Silicone-free. Non-conductive. One-piece lengths. Resistant to chemicals (see chemical-resistance chart). Compound hardness 80A Phthalate Free! Common Applications: Food & beverage. Agriculture Drain Line Hose/Tubing Bundling Industrial Air and Water Hose Light Vacuum Liquid and Powder Transfer Medical and Pharmaceutical Sight Gauge Water Lines Specifications Series 1600 Sized Code 16 Service Temperature Range 25 to 150°F (-5 to 65°C) Nominal ID 1" (25.4mm) Nominal OD 1.375" (34.9mm) Max Working Pressure @ 70°F (20°C) 125 Psi Standard Length Coils 100ft Approx. Wt. per Pkg. 28lb Packaging Coils Material PVC Min. Bend Radius @ 70°F 1" Type Reinforced Water Supply and Food Grade Hose Reinforcement Material Braided Polyester Color Crystal Clear Weight per Foot 0.28lbs/ft

$14.50 - $290.00

Teleflex USA High Pressure Smooth Bore PTFE Braided Stainless Steel Hose

Teleflex Lightweight high-pressure hose is specially constructed for applications requiring strength, reliability and long-term performance along with low profile and flexibility. Added to this is the wide temperature range in which these hoses operate. These advantages combine to make Teleflex hose the choice for hot oils, phosphate esters, industrial gases and chemicals and many more. This hose is constructed of a smooth innertube of PTFE impregnated with carbon black to provide conductivity for status dissipations. The outer braids unique bunch braid design made with 300 series stainless steel. Properties of PTFE Tensile Strength @ 73F 1500-3000lb./sq. in. Elongation @ 73F 100-200% Stiffness @ 73F 60,000 lb./sq. in. Impact Strength, Izod 70F 2.0 ft. - lb./in. 73F 3.5 ft. - lb./in. 170F 6.0 ft. - lb./in Hardness Durometer D55-D70 Compressive Stress at 1% Deformation @ 73F 600 lb./sq. in. @ 1% Offset @ 73F 1000 lb./sq. in Deformation Under Load @ 122°F 1200 lb./sq. in., 24 hrs. 4-8% 2000 lb./sq. in., 24 hrs. 25% Heat-Distortion Temperature, 66 lb./sq. in. 250°F Coefficient of Linear Thermal Expansion Per °F, 77-140°F 5.5x10-5 Thermal Conductivity, 0.18 in. 1.7 B.T.U./hr./sq.ft./°F/in. Specific Heat 0.25 B.T.U./lb./°F Water Absorption 0.0° Flammability Nonflammable Specific Gravity 2.1-2.3 Useful Conversions 1 p.s.i. = 0.0689 bar 1 Atms = 14.70 p.s.i. 1 bar = 14.5035 p.s.i. 1 Atms = 29.92 in. mercury 1 p.s.i. = 0.0703 Kg/sq.cm 1 m. = 3.281 ft. 1 Kg/sq.cm = 14.22 p.s.i. 1 ft. = 0.3048 m.

$60.00 - $79.00

Best Value Vacs 3 Gallon Aluminum Vacuum Chamber W/GLASS LID

Best Value Vacs 3 Gallon Aluminum Vacuum Chamber W/GLASS LID Comes with 2 yr Limited Warranty This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. *Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 9" Tall x 10" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC HosePlatinum Cured Silicone PadBlack 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. DOES NOT APPLY TO GLASS LID VERSION ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$135.00

Best Value Vacs 3 Gallon Stainless Steel Vacuum Chamber W/GLASS LID

3 Gallon Stainless Steel Vacuum & Degassing Chamber W/GLASS LID (Comes with 2 Year Limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent-pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User-friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 10-7/8" Tall x 9" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic-based monomers or polymers.The lid may only be cleaned with soapy water. DOES NOT APPLY TO GLASS LID VERSION ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic-based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™, etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$152.00

LusterMax ALPHA

LusterMax ALPHA alpha by LusterMax is an activated bentonite clay with modified characteristics best suited for botanical extraction being made into the wide variety of end product types, This takes a balance of strength and aversion for precious aromatic and flavor producing compounds. Developed by an experienced extraction technician, LusterMax qualities stem from its attention to 4 variable characteristics that make up how well and absorbent media works. Mineral Composition: What is the bentonite clay composed of. Particle Size Range: What are the particle sizes and how well do they let liquid flow through. Degree Of Activation: How much surface area is unlocked via activation Post Activation pH: What is the measured pH and how this affects crystallization speed. LusterMax products are designed by extractors to be simple and of omni-use. Meaning you can ditch your complicated 4-part blend and use LusterMax to achieve the same quality results with the occasional Silica Gel additive for extremely degraded biomass. No media option on the market exists that offers this level of strength and aversion for terpenes at the price point that allows manufacturers to fully utilize the refinement of adsorbent media like LusterMax. See our Neutral version of this exact media for lighter remediation usage that is still magnitudes stronger then any other neutral clay on the market. Also our own Silica additive Si Strength+ is available to pair with your order of a bentonite clay. Now available! We are happy to introduce the LusterMax Protocol, which is a 32 page training manual of how to implement CRC in your lab or optimize your existing process to be more precise, have less variations, and keep it cleaner. SDS File

$36.00 - $288.00

10L & 20L Injection Valve

10L & 20L Injection Valve *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement.

$45.00

Jacketed Sucker Pot with Ring Stand

Jacketed Sucker Pot with Ring Stand This jacketed sucker pot works perfectly as a collection base for extracted oil and easy discharge or as a storage vessel for distillate dispensing. Both of these applications are made easier with the use of a heater running through the jacket. Connections: -Top: 6" Tri-Clamp -Bottom: 1/4" FNPT -Jacket: 1/4" FNPT (2x ports)

$600.00

SSP 1/2" Compression Fitting Parts

SSP 1/2" Compression Fitting Parts ISSD8N: Duolok Tube Fittings, 1/2 in. Nut ISSD8FF: SSP® Duolok® Front Ferrule, FF Series, Nominal Size: 1/2 in, 316 Stainless Steel ISSD8BF: SSP® Duolok® Back Ferrule, BF Series, Nominal Size: 1/2 in, 1/2 in ID, 316 Stainless Steel

$3.00 - $9.00

Magnetic PTFE Stirring Bar - L Style - 70mm

Magnetic PTFE Stir Bar - L Style - 70mm Reduce stir bar jumping with the contoured shape of this L Style Magnetic PTFE Stir Bar. Ideal for round-bottom flask stirring applications. This 70mm L Style Magnetic Stir bar is great for round-bottom flasks above 5 liters in capacity. With its PTFE coating this Magnetic Stir Bar carries excellent solvent and temperature compatibility for a variety of applications. Specifications: L Style 70mm Length Material: High-temperature PTFE

$25.00

Hemispherical Reducer with Filter Plate V3

Hemispherical Reducer with Filter Plate V3 This hemispherical reducer has a built-in filter plate that is welded flush with the top of the reducer. This unique design allows the user to save even more space by combining a filter plate and hemispherical reducer. Made out of 304 stainless steel the filter plate is welded into the hemispherical reducer and has Tri-Clamp connections on both ends.

$70.00 - $360.00

35/15 Metal Flask Clamp for 2L and 5L Eco Rotary Evaporators

35/15 Metal Flask Clamp for 2L and 5L Eco Rotary Evaporators This is a replacement clamp for 2L and 5L Eco Rotary Evaporator receiving flask.

$14.00

5L Neocision Short Path Distillation Turnkey Kit

5L Neocision Short Path Distillation Turnkey Kit This unit carries a 2 day lead time. The 5L Premium Distillation Turnkey Setup features our 5L Distillation Kit with P5 Distillation Head and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included is our Pro Series Corrosion Resistant Two Stage Vacuum Pump giving you extreme power and depth with a long lifespan, the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market, and a BVV 19L Heated Circulator for maximum condensation of vapors. You will also receive a Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The Premium Turnkey Kit Includes: 5L Neocision Kit with P5 Distillation Head KF-25 x 1/4" Barb Adapter Dewar Style Glass Cold Trap Bullseye Precision Vacuum Gauge BVV 19L MX Heated Circulator Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$10,500.00 - $14,750.00

Replacement O-ring for Chemglass 1/4" Thermometer Adapters

Black circular replacement op-ring for chemglass 1/4" thermometer adapters.

$1.25

You have seen 816 out of 1031 products