Christmas/New Year- 10

TRS21 Upgraded Compressor head SS ¼” SAE 45D IN and OUT fittings

BVV-9-1 Included in this kit: TRS21 compressor head SS ¼” SAE 45D IN and OUT fittings, Viton o-rings. Use these fittings to replace the OEM brass fittings on your TRS21. The SS fittings minimize and help eliminate bacterial growth in the recovery process.

$28.00

Graco Pneumatic Diaphragm Pump for Ethanol

Graco Pneumatic Diaphragm Pump for Ethanol This air driven diaphragm pump is designed to be used with ethanol filtration, pumping processes, and BVV Centrifuges. It's unique rugged design can withstand temperatures from -40C to -80C. The inner diaphragms are made out of PTFE and the main body of the pump is made out of 316 Stainless Steel. The pre-built version comes with a 0-160 psi pressure gauge, mini ball valve, and 1.5" Tri-Clamp connections for the inlet and outlet ports. Specifications -40C -80C Power Source Air Operated 100PSI 28CFM Certification Required No Certifications ATEX Fluid Section Material Stainless Steel Pump Inlet/Outlet 716-3/4 Inc, 16gpm (19mm, 61lpm) Center Section Polypropylene Standard Air Vale (NPT) Porting SST Standard Porting (NPT) Seats 316 SST Balls PTFE Diaphragms PTFE PTFE Overmolded Manifold O-rings PTFE Max Operating Temp. 220°F (105°C)

$2,580.00 - $3,595.00

UL Listed BVV™ Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 21.2CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) This is the BVV™ Brand 21.2CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 21.2CFM will pull a vacuum down to 0.3 microns effortlessly. The pump is designed with corrosion resistance and long-term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 110v 60Hz 1100 Watts Pumping Rate: 21.2CFM Ultimate vacuum without gas ballast: 0.3 micron Ultimate vacuum with gas ballast: 6 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2L/2.1 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Dimensions: 21 x 7.5 x 12 Shipping Dimensions: 29.5 x 9.5 x 16.5 Unit Weight: 95lbs Shipping Weight: 105lbs Recommended oil: Ultragrade 19 Noise level: <58 dB CE Compliance: Yes Warranty: 1 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result in the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$3,500.00

KF Hand Needle Valve - Nitrogen Tested

KF Hand Needle Valve This 90 degree valve has a KF (NW) High Vacuum Flange to adapt to any other KF type pump or manifold if needed. Sizes available include KF16, KF25, KF40, and KF50. It is made out of 304 stainless steel with Viton seals. This valve is not meant for precise flow control.

$225.00

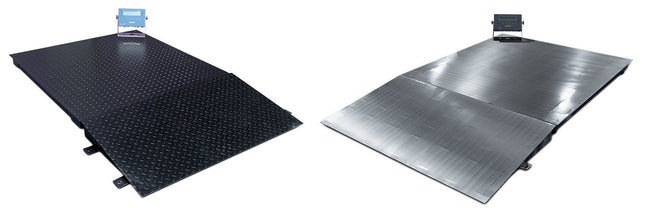

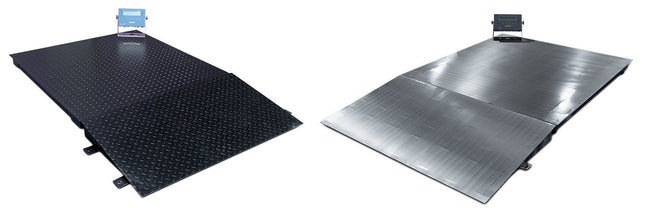

Explosion Proof Platform Scales - 3000KG

These Explosion proof platform scales come with a ramp and can handle a maximum load of 3000KG. Scale measurement: 1200MM X 1200MM (47.24" x 47.24") Scale height: 110mm (4.33") Scale weight: 83KG (182.984LBS) Note: This scale only measures in KG

$2,250.00

Master Vapor MVP Recovery Pump - 60 PSI

Master Vapor MVP Recovery Pump - 60 PSI The Master Vapor Pump Model MVP-6CFM is a certified gas recovery pump designed to operate at 60 PSI. This pump is designed specifically for LP-Gas vapor recovery and is ideal for butane or butane / propane mixtures. Engineering Specifications: Recover LP-Gas vapor at OVER 6 CFM (cubic feet per minute) Recover butane at up to 1 LB/MIN (pounds per minute) Recover and recondense butane at OVER 12 GPH (gallons per hour) Electric motor: explosion proof for C1D1 hazardous areas; rated Class I Gr C & D, Class II Gr F&G Electric motor: 1 HP, 1800 RPM, 60 HZ Pump speed: 190 CPM (cycles per minute) at 60 HZ Size: 17.0” x 19.9” base x 46” tall Weight: 182.5 lb (82.8 kg) Motor Option: Model MVP-6CFM-1PH: Single-phase: 115/208-230V, 13.4/6.7 FLA (full load amps) Model MVP-6CFM-3PH: Three-phase: 208-230/460V, 3.3/1.65 FLA, Inverter-rated Documentation: Product Manual Technical Data Sheet Features and Benefits Sheet

$9,570.00

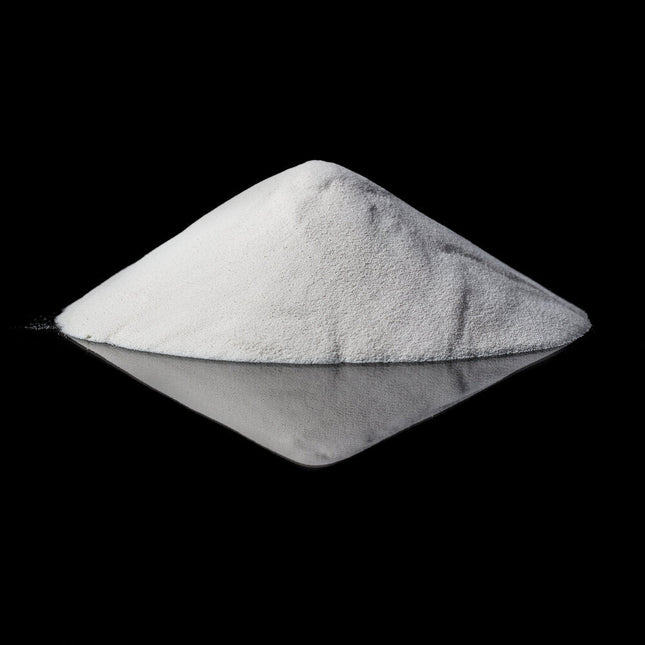

CHEMTEK W3 Acid Activated Bleaching Clay

CHEMTEK W3 Acid Activated Bleaching Clay W3 is a highly active adsorptive clay designed for difficult to bleach oils. It has a high cation exchange capacity paired with high moisture content making it ideal for adsorption of impurities such as chlorophyll, carotenes, heavy metals, phospholipids, soaps, and other impurities. W3 SDS W3 Technical Data Sheet

$50.00 - $2,250.00

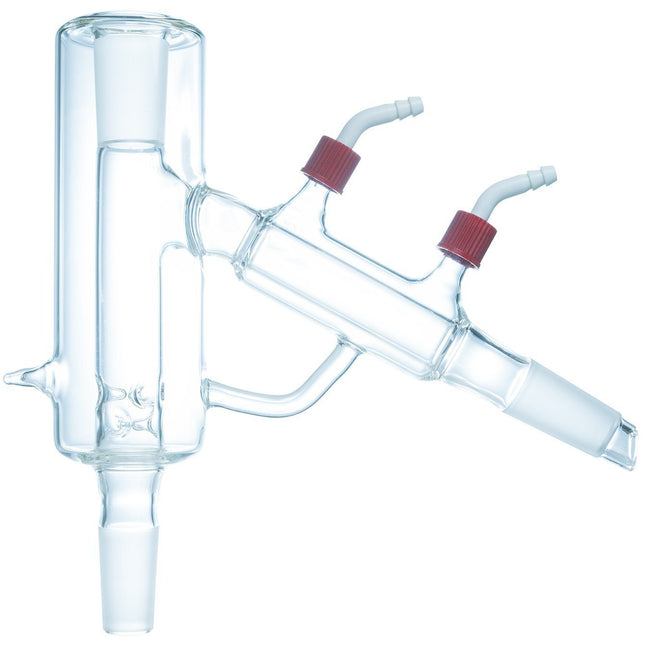

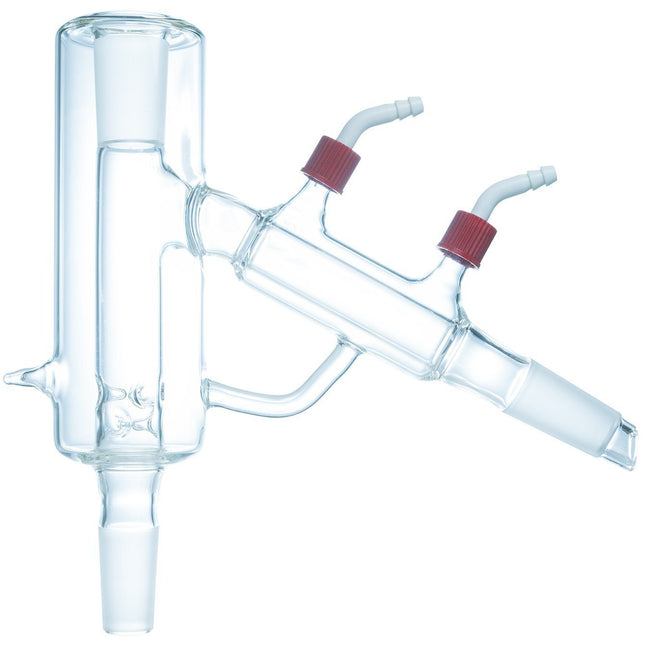

P2 Distillation Head - USA Made

P2 Distillation Head P2 Packable Distillation Head with 24/40 Joints. Includes GL-14 Barb Connections. Recommended packing media: Raschig Rings, Porcelain Berl Saddles, Glass Beads, Pro-Pak, or Stainless Steel Wool. Key Features: MADE IN THE USA Designed for 1 & 2 Liter Flasks Single set of lowered vigreaux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$600.00

1.5 Gallon Tall Stainless Steel - POT ONLY

1.5 Gallon Tall Stainless Steel - POT ONLY This is a replacement part for the following Vacuum Chambers: Best Value Vacs 1.5 Gallon Tall Stainless Steel Vacuum and Degassing Chamber SVac 1.5 Gallon Tall Stainless Steel Vacuum Chamber Dimensions: 8-5/8" Tall x 7-1/8" Diameter Material: 304 - 2B Stainless Steel

$52.00

Habonim Cryogenic Ball Valve

Habonim Cryogenic Ball Valve BVV™ Habonim Cryogenic Ball Valve - Data Sheet General Specifications Body Material CF8M Seat Material TFM Ball Material 316 SS Pressure Class 800 Temperature Range -60°C to 200°C

$150.00 - $500.00

UL Listed BVV™ Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 11.3CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) This is the BVV™ Brand 11.3CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 11.3CFM will pull a vacuum down to 0.3 microns effortlessly. The pump is designed with corrosion resistance and long-term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 110v 60Hz 750 Watts Pumping Rate: 11.3CFM Ultimate vacuum without gas ballast: 0.3 micron Ultimate vacuum with gas ballast: 6 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 1.5L/1.59 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Dimensions: 21 x 7.5 x 12 Shipping Dimensions: 29.5 x 9.5 x 16.5 Unit Weight: 66lbs Shipping Weight: 75lbs Recommended oil: Ultragrade 19 Noise level: <58 dB CE Compliance: Yes Warranty: 1 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result in the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$2,600.00

3 Gallon Tall Stainless Steel - POT ONLY

3 Gallon Tall Stainless Steel - POT ONLY This is a replacement part for the following Vacuum Chambers: Best Value Vacs 3 Gallon Stainless Steel Vacuum and Degassing Chamber SVac 3 Gallon Stainless Vacuum Chamber Dimensions: 10-7/8" Tall x 9" Diameter Material: 304 Stainless Steel

$86.00

W2 Heat Activated Natural Bleaching Clay

CHEMTEK W2 Heat Activated Natural Bleaching Clay W2 is a natural bleaching clay offering mild yet efficient results. It is heat activated to increase its adsorptive power without the use of any acids. The lack of acid prevents terpene isomerization and keeps the terpene profile the same while also slowing the oxidation rate of the oil thus increasing its shelf life. W2 is heavier in bulk density giving it lower oil retention. W2 SDS W2 Technical Data Sheet

$50.00 - $2,250.00

Digital Vacuum Chamber Gauge Upgrade *Wireless

Digital Vacuum Chamber Gauge Upgrade *Wireless After many requests, we have combined our infamous vacuum tight bulkhead with the power of a wireless vacuum gauge that can be a simple upgrade to ANY of our vacuum chamber products or resin traps. For those seeking truly accurate readings at any altitude and wireless monitoring this is the ultimate gauge for any vacuum system!. *To install: All that is required is a 1/2" wrench to remove the original and replace the digital one. The VGW-mini Wireless micron vacuum gauge measures vacuum via just one service port and with no loss of refrigerant. Its compact, robust and smart design support HVAC technicians with numerous intelligent features like the graphic display of measurement data in the Elitech Tools App. Its smart Bluetooth integration allows for data to be stored and evaluated reliably and efficiently, thus saving precious time and resources. Product Features High Accuracy The digital vacuum gauge achieves precise deep vacuum measurements down to single digit resolutions and provides notifications when the evacuation target is met. Smart APP Control Control your micron tester remotely and navigate through all measurement data via Smartphone or Tablet. Quickly and conveniently document your job, finalize your report and export - directly from the job site. Intelligent Judgement of H2O Status The vacuum meter automatically judges physical state of H2O by comparing ambient temperature and water saturation temperature corresponding to the vacuum in the system. Large, Easy-to-Read Display Continual digital readout of evacuation process can be viewed easily on the large, full-view LCD screen. Rechargeable Lithium Battery Built-in rechargeable lithium battery can work up to 20 hours per single full charge, saving troubles of frequent battery change. Product Specifications Measuring Range: 0-19000 micron Operating Temperature: -4℉~140℉ (-20°C~60°C) Interface: 1/4 SAE Accuracy: 1~10,000 microns: ±10% of readings ±10 microns10,000~19,000 microns: ±20% of readings Resolution: 0-400 1 Micron400-3000 10 Micron3000-10000 100 Micron10000-19000 250 Micron Vacuum Units microns, mTorr, in/hg, Pa, Torr, KPa, mbar and psia Battery rechargeable lithium battery (1,000mAh) Overload 27.5 bar Certification CE

$178.00

Mineral Oil 7 White NF (USP/NF)

BVV Mineral Oil 7 White NF (USP/NF) Food Grade White mineral oil can be used for many applications. Industrial, cosmetics, and food processing. Our Mineral Oil can be used in direct skin and food contact. Our oil is colorless, odorless and tasteless . This mineral oil can act as a non-conductive coolant, thermal fluid, lubricant, release agent, binder, defoamer, protective coating or float, sealing and polishing agent, dust control agent, and more. It has applications in three main areas: The industrial sector Cosmetics Food processing While those three sectors use this element most widely, it has a variety of other applications. White mineral oil is a standard household item, but has also found uses in some niche markets. The substance is versatile and has many properties making it useful in a range of applications. Food Grade Certified to FDA 21 CFR 172.878 BVV Mineral Oil 7 White NF - COA BVV Mineral Oil 7 White NF - Spec Sheet BVV Mineral Oil 7 White NF - SDS What is a food grade mineral oil? To use mineral oil in food preparation, it must be classified as a food-grade mineral oil. This is vital for health and safety as well as legal compliance. The Food and Drug Administration (FDA) has established standards any 'food-grade' substance must meet for both direct additions to foods and uses that may result in incidental contact with food. The requirements for purity, amount used, and processes vary based on how one uses mineral oil. The United States Pharmacopoeia (USP) and the National Formulary (NF) first created guidelines for the use of mineral oil in manufacturing. The FDA requires that food-grade mineral oil meet USP XX test requirements for readily carbonizable substances, which USP released in 1980, and USP XVII test requirements for sulfur compounds. It also needs to meet the specifications in Volume 45 of the Journal of the Association of Official Analytical Chemists. Mineral oil used as a lubricant for food-processing machinery must be registered with NSF International, an independent global food safety organization, as lubricants for incidental food contact to be used in food-processing plants under the jurisdiction of the U.S. Department of Agriculture (USDA). Other organizations oversee mineral oil use in other industries. For example, the Association of American Feed Control Officials (AAFCO) governs its use as a dust control agent for animal feeds. This classification is different, however, from food-grade mineral oil. Mineral oil used in the production of pharmaceuticals must be considered pharmaceutical-grade. The cosmetics and medical industry use highly refined mineral oil to avoid irritating the skin, eyes, and other body parts. Mineral oil chemical formula Mineral oils coming from crude petroleum oils vary in their make-up and contain complex structures. They include mixtures of straight and branched-chain paraffinic, naphthenic, and aromatic hydrocarbons. Alkanes, which are acyclic saturated hydrocarbons, are a significant component. They are made up of hydrogen and carbon atoms in a tree structure where all the carbon-to-carbon bonds are single. Mineral oil typically contains between 15 and 40 hydrocarbons. Mineral oil attributes Understanding the physical and chemical properties of mineral oil will help you to determine how best to use it in your industrial, food-processing, or other processes. These attributes may differ depending on the type of mineral used, how you use it, and whether any other substances get added to the oil. Mineral oil is a clear, colorless, and odorless liquid. This lack of strong physical qualities helps make it valuable in a variety of applications. Manufacturers can add it to products without changing their color, scent, flavor, or other crucial aspects. Mineral oil is also generally regarded as safe for human consumption, but in limited amounts. These features enable its use in the food processing and pharmaceutical sectors. Refined mineral oil does not clog pores, which allows for its use in cosmetics. Mineral oil has a density of 0.85 grams per milliliter (g/ml), and its specific gravity is 0.845 - 0.905. Its kinematic viscosity is greater than or equal to 38.1 millimeters squared per second (mm2/s). It is insoluble in water. The substance has an initial boiling point of 424.4 degrees Fahrenheit (°F) and a boiling range that extends up to 1189.4 °F. Its flash point is 275.00 °F closed cup and 380.00 °F open cup. It has an auto-ignition temperature of 500 °F, and its heat of combustion is 31.5 kilojoules per gram (kJ/g). As mentioned above, mineral oil has an NFPA flammability rating of one, a health rating of zero, and a reactivity rating of zero, meaning it is not a high fire risk. One of the most beneficial attributes of white mineral oil is its lubrication capabilities. This is the primary reason it has so many industrial, mechanical, food-processing, and medical applications. This property plays a crucial role in many manufacturing and food production processes. Its ability to transfer heat and its non-conductivity enable mineral oil's use as a coolant in a various electronic and mechanical equipment, as well as in industrial processes. Its resistance to water and other liquids, as well as insolubility in water, allow mineral oil to function as a sealant and binder in a variety of products. Safety Mineral oil is not regarded as an especially dangerous substance, but like all chemicals, users should handle it with appropriate care and precautions. A Material Safety Data Sheets (MSDS) for mineral oil may include the following information: Eyes: Mineral oil may cause eye irritation if it comes into contact with them. Flush eyes for several minutes and seek medical attention. Skin: It may cause skin irritation if prolonged contact with skin occurs. Remove contaminated clothing and wash affected areas or shower. Get medical attention if irritation persists. Inhalation: Inhaling mineral oil mist may irritate the respiratory tract and lungs. If this occurs, move to fresh air. Get medical attention if irritation persists. Ingestion: Ingestion can cause gastrointestinal irritation and result in nausea, vomiting, and diarrhea. If conscious, rinse mouth and drink water. Do not induce vomiting. If irritation persists, get medical attention. Mineral oil is combustible but has a low flammability rating. Having a National Fire Protection Association (NFPA) rating of one, means mineral oil must be preheated to ignite. Mineral oil has an instability rating of zero, which means it is stable even under fire conditions, and a health rating of zero, meaning it does not create any additional hazards beyond normal combustibility. You can extinguish a mineral oil fire using water fog, foam, dry chemical powder, or carbon dioxide (CO2) but should not use a water jet as this can spread the fire.If you encounter a spill of mineral oil, keep unnecessary personnel away, wear protective equipment, and absorb the spill with an absorbent material before cleaning the affected surface to remove any residue. Applications for mineral oil Mineral oil is inert, which makes it easy to use. Both consumers and businesses in a range of industries use mineral oil for a variety of applications. The three sectors named above primarily use mineral oil, but it appears across a wide range of industries and applications. Here are some of the most common uses in the industrial, personal care, and food production sectors. Use in cosmetics You can find mineral oil in many different cosmetics products including baby lotions, ointment, make-up remover, sunscreens, hair conditioner, and even tissues. Mineral oil is an ideal base material for many of these products because it is inert, colorless, and odorless. Mineral oils may appear in cosmetics as liquid oils or solid waxes. Some kinds of mineral oils are comedogenic, meaning they clog pores. Because of this, the mineral oil used in skincare and cosmetic products is noncomedogenic and does not clog pores. In fact, cosmetics companies often describe mineral oil as having moisturizing, protective, and cleansing properties for the skin. Additionally, these oils are used to give cosmetic products film-forming and water-repellent features as well as increased firmness. Use in food processing The food processing and preparation industries frequently use mineral oil. Sometimes, manufacturers add mineral oil directly to food. At other times, mineral oil assists in the production process but is not added to food directly. As mentioned earlier, all mineral oil that may come into contact with food must achieve classification as food-grade, and it must be used in accordance with all relevant laws and regulations. Food producers use mineral oil as a: Binder, release agent, or lubricant in bakery products, dehydrated foods, egg white solids, and in tablets or capsules for adding nutrients, flavoring, spices, or for use as a dietary supplement Release agent, sealing agent, and polishing agent in confectioners Protective coating on raw fruits and vegetables Defoamer in vinegar and beet sugar production Dough divider Dust control agent for grains. Binder, release agent, and lubricant in the manufacturing of yeast Mineral oil plays a role in some of the non-food products used to prepare, serve, and eat food. In these situations, the oil should also be food-grade. When applied to cookware, bakeware, and cooking utensils, mineral oil prevents food from sticking to them. People rub it onto the surface of wooden cutting boards, bowls, and utensils to prevent them from absorbing water, which can damage them. Mineral oil also prevents wood-based cooking tools from absorbing food liquids and odors, which makes cleaning easier. It acts as a lubricant for food processing equipment as well. Industrial, mechanical, and electrical uses Mineral oil serves to assist with various industrial, mechanical, and electrical purposes. It is an effective lubricant for industrial equipment and often functions as a processing aid. It is an element that helps make up various substances used in industrial processes, such as lubricants, greases, dyes, polymers, and surface treatment products. Mineral oil also acts as a thermal fluid or non-conductive coolant in various electric components. In refrigerators and oil-based electric heaters, mineral oil is used as a cooling liquid. In switchgear, it serves as an insulator and a coolant to diffuse switching arcs. In the production of plastics, mineral oil is used to control the melt flow rate of finished polymer and act as a release agent. Automotive equipment frequently uses mineral oil, primarily as a component in hydraulic liquids in automotive suspension, as well as in lubricants in brake fluids and motor oil.

$15.00 - $4,900.00

Certified 45L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller - 15LB Max Capacity

Certified 45L Ethanol Wash/Dry Centrifuge with Explosion Proof Motor and Controller Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift to lift it. It will also ship via freight only. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 1500 RPM with Gradual Speed Stepping 566 Separation Factor Multiple Connection Ports/Sizes High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation *BVV Centrifuges are now available certified by PRV Engineers. Field visits/verification letters are an additional $4,000 + travel expenses.* Specifications Capacity 45L Drum Dimensions 17.7" (450mm) Diameter x 11-7/8" (300mm) Deep Max Capacity 15lbs (6.8Kg) Speed 1500 rpm Separation Factor 566 Electrical 240V 1Ø (10.58A) Weight 794lbs (360Kg) Exterior Dimensions 50" x 27.6" x 28.7" (1280mm x 700mm x 730mm) Viewport Diameter 5.5" Connection Size(s): 2" Tri-Clamp Drain Port 1" Tri-clamp Side Port X 2 1" Tri-Clamp Top Port 1.5" Tri-Clamp Top Port 1/4" FNPT Top Port KF25 Top Port

$19,500.00 - $23,500.00

20L Neocision Dual Short Path Distillation Turnkey System

20L Neocision Dual Short Path Distillation Turnkey System This unit carries a 2 day lead time. (Note: This kit does NOT include the stainless steel table.) The 20L Neocision Distillation Turnkey Setup features our Dual USA made P10V6 Distillation Heads. Every component in this distillation kit is made for precision, throughput, and repeatable results. You will also receive Dual Dewar Style Ribbed Glass Cold Traps to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The 20L Neo Kit Includes: 20L Neocision Kit with glassware, labware, and Dual P10V6 Distillation Heads. BVV 15 Liter Advanced Digital Heated Circulator Choice of Vacuum Pump KF-25 Bellow Y Manifold Dual Ribbed Dewar Style Glass Cold Trap Non-Mercury Glass Thermometers 20L Digital Heating and Stirring Mantle Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in the boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$13,000.00 - $17,000.00

Welch DryFast Collegiate Diaphragm Pump 2014

DryFast Collegiate Diaphragm Pump 2014 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details Chemical Resistant Oil-Free Tuneable Vacuum Welch DryFastTM PTFE Diaphragm Vacuum Pumps enable precise vacuum control for organic evaporations with exclusive Advanced Vapor Management (AVM). Oil-Free, portable, chemical resistant, 1 head diaphragm design simplifies maintenance. Choose from seven dry PTFE vacuum pump models with flows up to 70 L / min and adjustable vacuum down to 2 Torr. Economical DryFastTM vacuum pumps are perfect for tough lab applications. Model Number 2014 Applications Vacuum Filtration, SPE, Rotary Evaporations (volatile solvents <80oC B.P., volume <2 liters), pumping harsh vapors & gases, general laboratory vacuum Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 1.2(35) Free Air Displacement m3/hr (l/min.) @50Hz 1.75(29) Ultimate Pressure 40(53) Maximum Vacuum 28.3 Motor Horsepower (watts) 1/5(150) Adjustable Vac. / Gas Ballast Yes Tubing Needed 1/4(7) Intake Thread NPT M14(1/8) Overall Dimensions LxWxH in. (cm) 12x7.0x8.3 (30.5x 17.8x21.1) Ship Weight 19(8.6) Shipping Carton Dimensions LxWxH in. (cm) 21x14x15 (52x35x37) Adjustable Vacuum Knob

$1,990.00

Edwards E2M28 21 CFM Dual-Stage High Capacity Vacuum Pump

Edwards E2M28 21 CFM Dual-Stage High Capacity Vacuum Pump ***Note: This item Will Ship by Freight only*** The EM range of oil‑sealed rotary pumps – renowned for their high ultimate vacuum, rapid pumping speed, quiet operation and ability to handle vapor – have become the industry standard for laboratory and light industrial applications. The pump is a freestanding unit with the drive provided through a flexible coupling by either a single‑phase or three‑phase (four pole) air cooled motor.Each EM pump is supplied with 2 x 1 liter of Ultragrade 19 oil, O ring and centering ring, two Allen keys and spares seal for oil drain and filter plugs. For PFPE prepared FX pumps Fomblin® to be ordered separately. Technology The motor is totally enclosed and is cooled by the motor-cooling fan which directs air along the motor fins. The motors are fitted with a thermal overload device. When the motor is too hot, the thermal overload device switches off the pump. The thermal overload device has an automatic reset; when the motor cools down, the device resets and the motor will restart.An oil pressure system lubricates the pump shaft bearing surfaces and rotor sealing faces. The pump has an oil distribution valve which prevents discharge of oil to the pump interior after the pump stops. The pumping chambers are air-tight, so this arrangement also prevents suckback unless the gas ballast valve is open.You can inspect the level and condition of oil in the oil box reservoir through the oil sight-glass. An oil filler-plug is fitted to the top of the oil box. The pump has two oil drain-plugs to allow either gravity oil drain or pressure oil drain. Features and Benefits The pump is designed for reliable, long‑term operation. Thermal overload device prevents overheating (single phase only). The drive is provided through a flexible coupling by a single‑phase or three‑phase (four pole) motor. The motors are totally enclosed and are cooled by the motor cooling fan. Full height O ring sealed oil sight glass for easy checking of oil level and condition. Large sight glass and operating oil range. IE3 energy efficient 3 phase motor used with E2M28. Edwards E2M28 21 CFM Dual-Stage High Capacity Vacuum Pump. The EM range of oil-sealed rotary pumps - renowned for its high ultimate vacuum, rapid pumping speed, quiet operation and ability to handle vapour - has become the industry standard laboratory and light industrial applications. The E2M28 pump is a two-stage, direct drive, sliding vane pump. The pump is oil sealed and designed for reliable, long-term operation in both laboratory and industrial environments. The pump is a freestanding unit with the drive provided through a flexible coupling by either a single-phase or three-phase (four-pole) motor. Specifications Displacement 50Hz 32.2 m3h-1 / 19 ft3min-1 60Hz 38.9 m3h-1 / 22.3 ft3min-1 Speed (Pneurop 6602) 50Hz 27.5 m3h-1 / 16.2 ft3min-1 60Hz 33.0 m3h-1 / 19.5 ft3min-1 Ultimate vacuum (total pressure) without gas ballast 1 x 10-3 mbar / 7.5 x 10-4 Torr with gas ballast 1.5 x 10-2 mbar / 1.1 x 10-2 Torr with Fomblin® 1 x 10-2 mbar / 7.5 x 10-3 Torr Inlet connection NW25 flange Outlet connection** Nozzle 15 mm external Ø removable from 3/4 in BSP tapped hole Max allowed pressure at outlet 0.5 bar gauge / 7 psig Max water vapour pumping rate – GB II 220 gh-1 Max inlet pressure for water vapour 30 mbar / 23 Torr Max water vapour pumping rate 0.7 kg h-1 Operating temperature range 13 – 40 °C Nominal rotation speed 1440 / 1720 rpm Motor power 50 Hz 0.75 kW Motor power 60 Hz 0.90 kW Power Connector 1-ph* IEC EN60320 C19 Weight 44 kg / 97 lbs Noise 57 dB(A) @ 50 Hz Oil capacity - max 1.5 litre Oil capacity - min 1.2 litre Recommended oil (supplied) Ultragrade 19 * Pumps listed with IEC connector only ** The FX are supplied with NW25 outlet connection ** POWER CORD NOT INCLUDED. RECOMMEND FOR CUSTOMER TO WIRE PUMP TO OUTLET WITH EXACT LENGTH. DO NOT USE EXTENSIONS** **RECOMMEND FOR CUSTOMER TO HAVE ELECTRICIAN WIRE PUMP TO OUTLET WITH EXACT LENGTH** Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$7,000.00$6,200.00

Welch 6.1 cfm Full Chemical-Resistant 8-Head Diaphragm Pump

Welch 6.1 cfm Full Chemical-Resistant 8-Head Diaphragm Pump The Welch 6.1CFM Full Chemical-Resistant 8-Head Diaphragm Pump is the ideal choice for 50L Rotary Evaporators and large oven systems. This high capacity, full chemical resistant pump gives users the ability to vac down large capacity spaces quickly, efficiently, and cleanly without worrying about contamination of pump oil. The inner diaphragm is lined with PTFE making it highly chemical resistant and long lasting. It is one of the quietest and cleanest running vacuum pumps on the market. Key Features: Fully Chemical-Resistant Oil-less diaphragm style vacuum pump High capacity vacuum capability Specifications: Electrical Requirements: 110v 60Hz single phase Pumping Rate: 6.1cfm / 174L/min Gasket Material: All-PTFE Ultimate Vacuum level: 6 torr / 8 mbar Maximum Vacuum: 29.9 inHg Inlet / Outlet: KF16 Flange Adjustable vac. / gas ballast: No Unit dimensions (LxWxH in): 21x10x12 in Shipping dimensions (LxWxH in): 28x15x20 in Shipping weight (lbs): 90 Technical Data Free Air Displacement @ 60 Hz, cfm (L/min) 6.1 (173) Ultimate Pressure, torr 6 Motor Power, HP (kW) at 60 Hz Motor Power, HP (kW) at 60 Hz Inlet (Exhaust) Connection Thread NPT NW16 - 1/4" NPT Tubing Needed, I.D. in. (mm) Hose Connector Available Weight, lbs (kg) 72.3 (32.8) Dimensions, LxWxH, in (mm) 21x11x12 (530x280x310) 115V Order Number 2064B-01 ***Note: Purchase of this pump is subject to End User Verification. A certification form must be filled out before completion of purchase.***

$7,300.00

P10V6 Neocision Distillation Head - USA Made

P10V6 Distillation Head P10V6 Distillation Head has 6 sets of vigreux in the distillation column with 45/50 lower joint, 24/40 Thermometer Joint, and a 34/45 side joint and includes GL-14 barb connections. MADE IN THE USA Designed for 10 Liter Flasks Set of 6 vigreux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$600.00

1 Gallon Flat Stainless Steel - POT ONLY

1 Gallon Flat Stainless Steel - POT ONLY This is a replacement part for the following Vacuum Chambers: Best Value Vacs 1 Gallon Flat Stainless Steel Vacuum and Degassing Chamber SVac 1 Gallon Flat Stainless Steel Vacuum Chamber Dimensions: 3" Tall x 10.25" Diameter Material: 304 Stainless Steel

$32.00

7 Gallon Aluminum - POT ONLY

7 Gallon Aluminum - POT ONLY This is a replacement part for the following Vacuum Chambers: Best Value Vacs 7 Gallon Aluminum Vacuum and Degassing Chamber Dimensions: 8" Tall x 16" Diameter Material: 3004 Aluminum

$108.00

Wireless Digital Vacuum Gauge 1~19,000 Microns

VGW-mini Wireless micron vacuum gauge measures vacuum via just one service port and with no loss of refrigerant. Its compact, robust and smart design support HVAC technicians with numerous intelligent features like the graphic display of measurement data in the Elitech Tools App. Its smart Bluetooth integration allows for data to be stored and evaluated reliably and efficiently, thus saving precious time and resources. Product Features High Accuracy The digital vacuum gauge achieves precise deep vacuum measurements down to single digit resolutions and provides notifications when the evacuation target is met. Smart APP Control Control your micron tester remotely and navigate through all measurement data via Smartphone or Tablet. Quickly and conveniently document your job, finalize your report and export - directly from the job site. Intelligent Judgement of H2O Status The vacuum meter automatically judges physical state of H2O by comparing ambient temperature and water saturation temperature corresponding to the vacuum in the system. Large, Easy-to-Read Display Continual digital readout of evacuation process can be viewed easily on the large, full-view LCD screen. Rechargeable Lithium Battery Built-in rechargeable lithium battery can work up to 20 hours per single full charge, saving troubles of frequent battery change. Product Specifications Measuring Range: 0-19000 micron Operating Temperature: -4℉~140℉ (-20°C~60°C) Interface: 1/4 SAE Accuracy: 1~10,000 microns: ±10% of readings ±10 microns10,000~19,000 microns: ±20% of readings Resolution: 0-400 1 Micron400-3000 10 Micron3000-10000 100 Micron10000-19000 250 Micron Vacuum Units microns, mTorr, in/hg, Pa, Torr, KPa, mbar and psia Battery rechargeable lithium battery (1,000mAh) Overload 27.5 bar Certification CE

$170.00

CHEMTEK Alumina 150

Alumina 150 is a neutral pH adsorbent used to remove moisture, free fatty acids, and phospholipids to speed up crystallization and to improve the end products’ oxidative stability. Alumina 150 SDS

$30.00 - $1,000.00

P5 Distillation Head - USA Made

P5 Distillation Head P5 Packable Distillation Head with 34/45 lower joint and 24/40 upper and side joints. Includes GL-14 Barb Connections. Recommended packing media: Raschig Rings, Porcelain Berl Saddles, Glass Beads, Pro-Pak, or Stainless Steel Wool. Key Features: MADE IN THE USA Designed for 5 Liter Flasks Single set of lowered vigreaux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$550.00$400.00

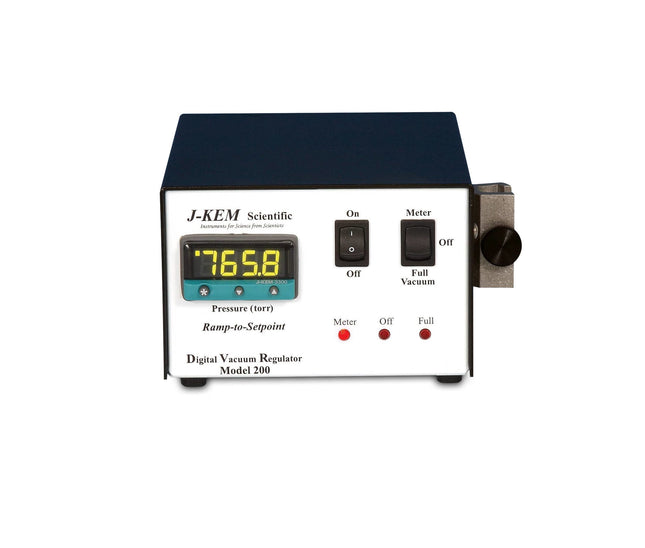

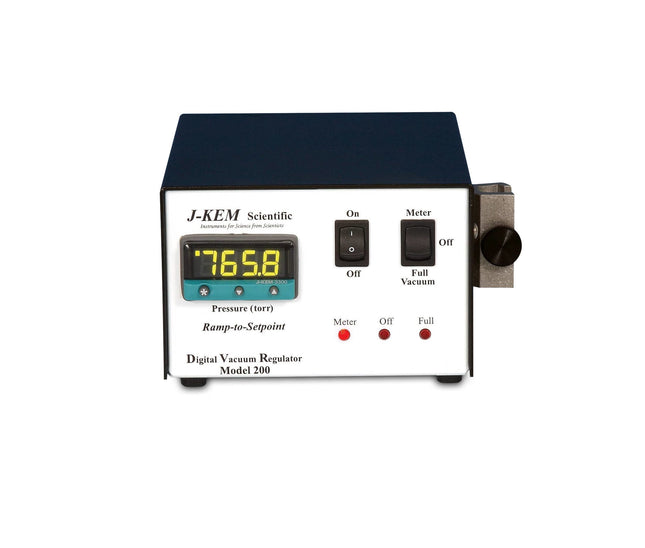

J-KEM DVR-200-EV Digital Vacuum Regulator

J-KEM DVR-200-EV Digital Vacuum Regulator The DVR-200-EV has the same stainless steel pressure transducer inside, but the vacuum valve is outside of the controller. The value of this design is that the vacuum valve can be cleaned or replaced much easier than the valve in the classic DVR-200. Some applications, like distillations or stripping large volumes of solvent, can leave residues inside the valve which causes it to fail. Replacing the vacuum valve is the most frequent repair that J-KEM performs on the DVR-200. Replacing the valve in the classic DVR-200 is difficult and must be returned to J-KEM for repair. With the EV version, the user can disassembled the valve and wash it out, or even replace it in under 5 minutes. For large distillations or botanical applications, J-KEM recommends the DVR-200-EV. No Mercury 100% digital pressure entry and control Wetted parts are 100% stainless steel and Teflon Vacuum ramping feature eliminates bumping Resists: All organic solvents Acids Bases Water Specifications: 100 watts. Vacuum fittings: 1/8″ NPTM. Warranty: Electronics 2 Years, Vacuum Valve 6 months (void if damaged by chemical buildup)

$1,665.00

Dk-Lok V63 Series 1/4" 10-250PSI Adjustable Pressure Relief Valve 316SS

V63 Series 1/4" 10-250PSI Adjustable Pressure Relief Valve 316SS DK-LOK® V63/66 series proportional relief valves provide a wide range of set pressures in order to protect your systems against over pressurization resulting in damage to system components. These proportional relief valves open in direct relation to how quickly the system inlet pressure overcomes the set pressure of the spring. They close in direct relation to how quickly the system inlet pressure drops below the spring set pressure. We offer a variety of connection configurations and seal materials to match your system requirements. DK-LOK V63/66 Series Pressure Relief Valve Data Sheet

$230.00

Half Ton - High Purity USA 70/30% N-Butane/Propane Blend - 99.5% Guaranteed

Half Ton - High Purity USA 70/30% N-Butane/Propane Blend - 99.5% Guaranteed DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Freight ONLY. This tank requires a CGA 510 fitting - Sold Separately BVV™ always recommends distillation of every solvent before use. *Actual liquid weight is 483LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Permitted Sales Include the Following: Medical Collectives or Cooperatives operating under CA Health & Safety Code Section 11362.775 Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale High purity 70/30% N-Butane/Propane is USA sourced, and guaranteed to be 99.5% pure. This instrument grade solvent helps to produce a higher quality extract by reducing mystery oils and contaminants. Solvent comes in a DOT refillable LP tank with liquid withdrawal valve (Diptube). This product is clean, colorless and odorless. *Actual liquid weight is 483LB Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via UPS Ground/Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers. Chemical Formula: C₄H₁₀ + C3H8 Molecular Weight: 58.12 g/mol & 44.10 g/mol CAS Registry Number: 106-97-8 & 74-98-6 Appearance Colorless Odor: Faint Petroleum Density N/A Boiling Point: N/A Solubility in water: Low Solubility GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220, H280 GHS Precautionary Statements P210, P377, P381, P403, P410+P403 UN Identification Number: 1965 Proper Shipping Name: Hydrocarbon Gas Mixture, (Butane/Propane) liquefied, n.o.s. Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Dual Blend Certificate of Analysis (COA) Dual Blend Safety Data Sheet (SDS)

$2,400.00

Stainless Steel Laboratory Scissor Jacks

Stainless Steel Scissor Jacks Adjustable height laboratory scissor jack. The platform is 4"/6"/8" & the durable 304 stainless steel heavy-duty lab lifts with very little effort necessary! Specifications: 304 Stainless Steel Platform size: 4" x 4" / 6" x 6" / 8" x 8"

$29.00 - $49.00

3 Way Ball Valve - Fractional Tube Fitting

SSP - 3 Way Ball Valve - Fractional Tube Fitting SSP Instrumentation Flolok® manually operated three-way ball valves accept media through the bottom port and allow selection of flow through a selected port. Features: Directional handle indicates flow direction Panel Mountable 180-degree actuation Directional flow path Micro-finished ball provides positive seal Free-floating ball design provides compensation for seat wear for repetitive sealing Blow-out proof ball & stem Standard Product Testing - Every ball valve is assembled and tested @ 1000 psi (68.9 bar) with Nitrogen Specifications Body Material 316 Stainless Steel Pressure Rating @ 100F 3000 PSIG @37C 208 BAR @300F 2500 PSIG @148C 172 BAR Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Connection Type 2 Duolok Tube Fitting Connection Size 2 Specified by User Connection Type 3 Duolok Tube Fitting Connection Size 3 Specified by User Handle Type Nylon-Stainless Steel Insert Handle Color Black Packing Material PTFE SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$80.00 - $120.00

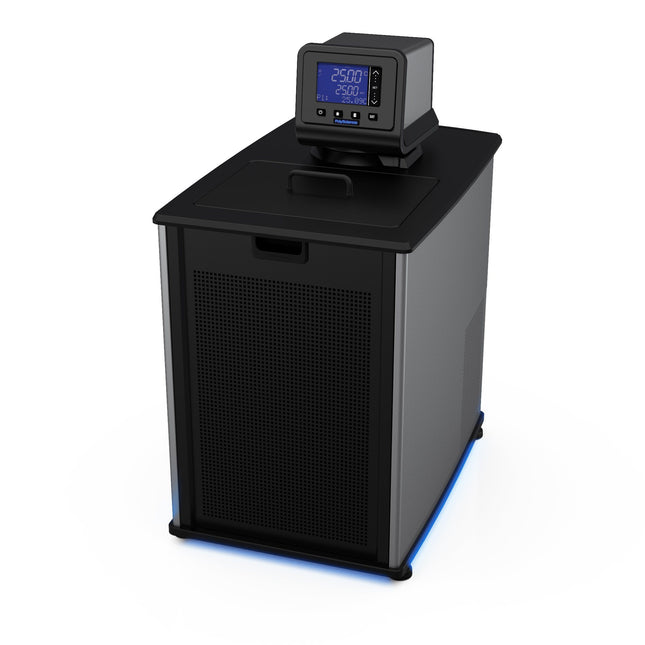

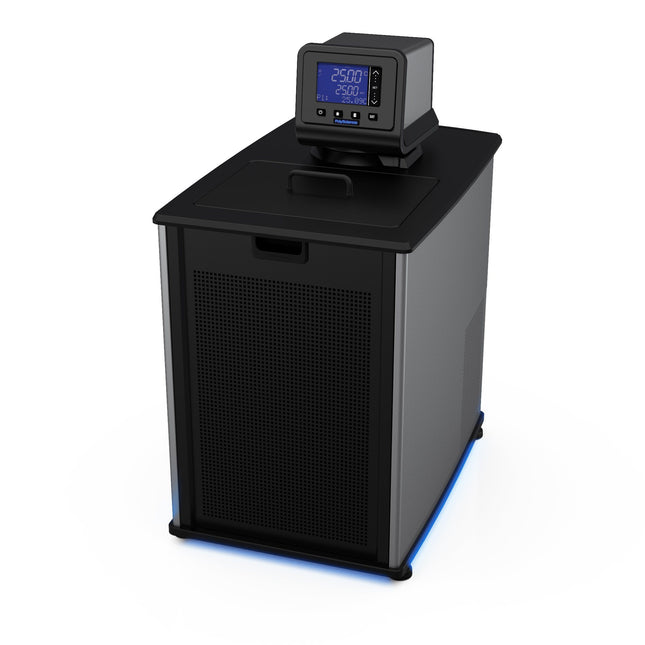

Polyscience 15 Liter Advanced Digital Refrigerated Circulator (-30°C/200°C)

Polyscience 15 Liter Advanced Digital Refrigerated Circulator (-30°C/200°C) ***Note: This item has a lead time of 2-3 weeks depending on stock availability.*** Description: -30, 15 L Ref. Circulator Controller Type: Advanced Digital Display: 3.75" Touch-Pad LCD Connectivity: Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe Languages Supported: 4: French, German, Spanish, English Swivel 180 Rotating Controller: Yes Working Temperature Range °C: -30° to 200° Temperature Stability °C: ±0.01° Fluid Optimization/Specific Heat Tuning: Automatic and/or user-adjustable Temperature Calibration Capability: 1-point Working Access (L x W x D) (cm): 21.2 x 27.6 x 14 cm Pump Type: Pressure/Suction External Temperature Control Capability: Yes Flammability Class (DIN 12876-1): III (FL) Specifications Working Temperature Range °F -22° to 392° Working Temperature Range °C -30° to 200° Nominal Cooling Capacity @ +20C (W) 915 Reservoir Capacity (gallons) 3.96 Reservoir Capacity (liters) 15 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 8.35 x 10.88 x 5.5 in Working Access (L x W x D) (cm) 21.2 x 27.6 x 14 cm Temperature Stability °F ±0.02° Temperature Stability °C ±0.01° Display 3.75" Touch-Pad LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure/Suction Pump Speed Variable Process Connections 1/4" (F) NPT External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes WhisperCool Environmental Control Technology Yes Cool Command Refrigeration Technology Yes Reservoir Drain Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 22.4 x 14.5 x 26.9 in Overall Dimensions (L x W x H) (cm) 56.9 x 36.8 x 68.3 cm Refrigerant R404A Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 118.0 Shipping Weight (kilograms) 53.5 60Hz Part Number AD15R-30-A11B Maximum Pressure (psi) 4.3 Maximum Pressure (bar) 0.30 Maximum Pressure Flow Rate (gpm) 5.30 Maximum Pressure Flow Rate (l/min) 20.1 Maximum Suction Flow Rate (gpm) 3.9 Maximum Suction Flow Rate (l/min) 14.7 Cooling Capacity @ -20°C (W) 165 Cooling Capacity @ 0°C (W) 505 Cooling Capacity @ +20°C (W) 915 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/13 Regulatory Approvals ETL Certifications: Regulatory Approvals: ETL Circulating Bath Operator's Manual

$6,350.00

CHEMTEK W4 Pesticide Remediation Bleaching Clay

CHEMTEK W4 Pesticide Remediation Bleaching Clay W4 is an alkaline bleaching clay specialized for the removal of pesticides, chlorophyll, free fatty acids, and oxidized compounds. It removes pesticides through adsorption and hydrolysis. Pesticides undergo alkaline hydrolysis, in which a pH greater than 7 causes chemical degradation of certain pesticides in the presence of ions. W4 SDS W4 Technical Data Sheet

$50.00 - $2,250.00

10L Neocision Dual Head Short Path Distillation Turnkey System

10L Neocision Dual Head Short Path Distillation Turnkey System This unit carries a 2 day lead time. The 10L Neocision Distillation Turnkey Setup features our Dual 10L P5 Distillation Heads and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included is a KF-25 Vacuum Pump giving you extreme power and depth with a long lifespan, the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market, and a BVV 19L Heated Circulator for maximum condensation of vapors. You will also receive a Dual Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The Premium Turnkey Kit Includes: 10L Neocision Kit with Dual P5 Distillation Heads KF-25 2 Meter Bellows Dual Dewar Style Glass Cold Trap Bullseye Precision Vacuum Gauge BVV 19L Heated Circulator Your Choice Of KF-25 Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$13,250.00 - $17,750.00

Edwards Oil Mist Exhaust Filter

Edwards EMF20 Oil Mist Exhaust Filter The Edwards EMF20 Oil Mist Filter is designed for use with the Edwards RV12 and E2M18 vacuum pumps, efficient at 99.999% DOP test and azide proof. The bottom white half of the body is semi-transparent allowing easy monitoring of oil levels. This oil mist filter is new in the box and ready for shipping and includes: NW25 Clamp Centering Ring O-Ring NW25 to 3/4 inch BSP Adaptor 1 year warranty

$552.00

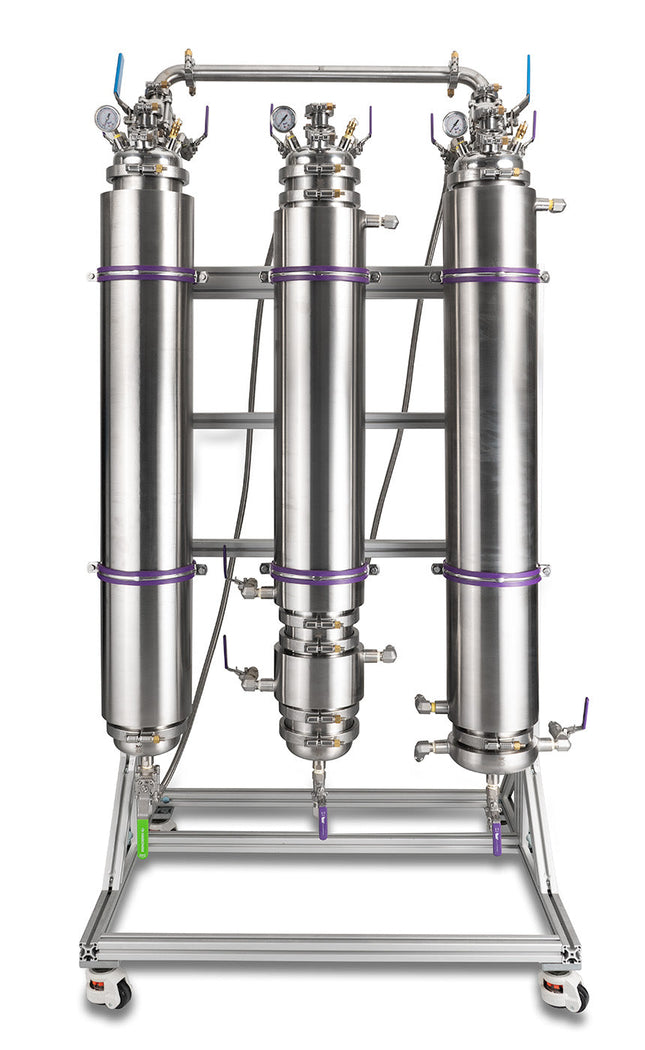

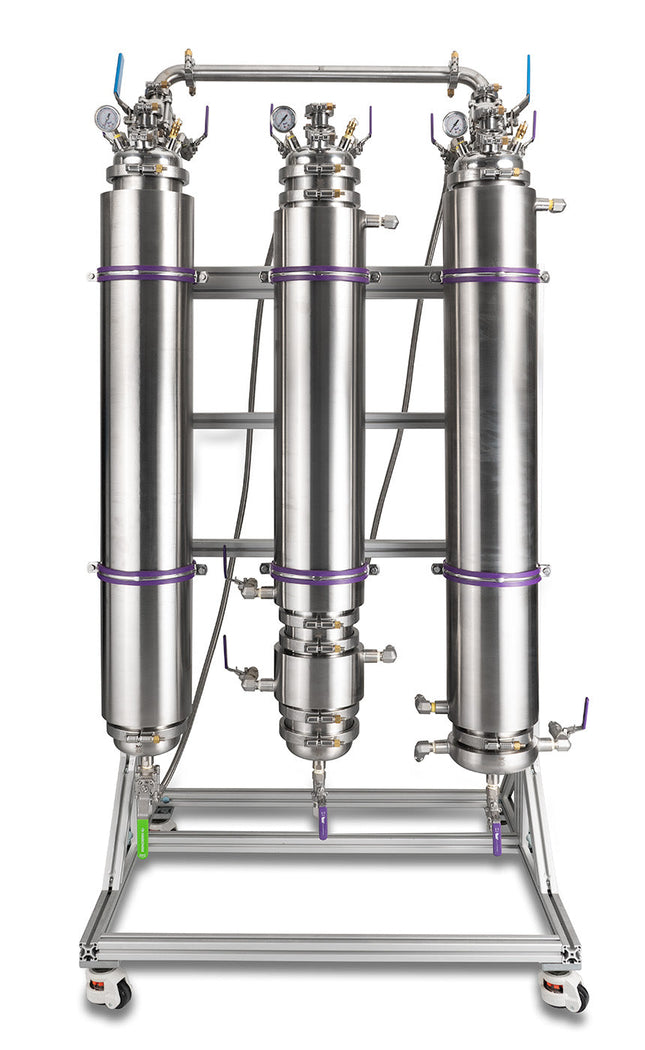

5LB EVO Certified Closed Loop Extractor *49 State Certified

5LB Evo Certified Closed Loop Extractor Equipped with the latest in modern extraction technology the 5lb EVO produces extracts of the highest purity in the shortest time possible through its inline solvent chilling and adsorbent filtration capabilities using its unrestricted passive recovery speeds when paired with our 11KW Express Extraction Heater. Peer reviewed and 3P certified the 5lb EVO meets or exceeds Class 1 Division 1, NFPA 58, and ASME standards. With the ability to process 40+ pounds of biomass material every 8 hours the 5lb Evo provides precision performance without the price. Processing Power Capacity Per Batch: 5LB Cycle Time: 30-45 Minutes Capacity: Up to 40 lb, per 8-hour shift Extracts: isolate/sauce, distillate, vape pens, shatter, and wax/sugar 5LB EVO Certified Closed Loop Technical Data Sheet Specifications 6"x36" 5lb Material Column 6"x6" Adsorbent Filtration Column 1-5um Sintered disk filtration 1.5"x24" Inline molecular sieve column 7X 1.5" Certified Borosilicate Sight Glasses 3X 250 PSI ASME Safety Valves 3X -30hg-250PSI Compound Pressure Gauges 1.5" Full Bore Recovery Lines 1/2" JIC process Flow lines Footprint (DxWxH) 30"x40"x79" Weight: 400 lb Maximum Pressure Rating: 250PSI Compliance Class 1, Division 1 Compliant Designed to ASME standrds NFPA 58 LPG compliant 3P Certifed 49 State compliant: AL, AR, AZ, CA, CO, CT, DE, DC, FL, GA, HI, IA, ID, IL, IN, KS, KY, LA, ME, MD, MA, MI, MN, MS, MO, MT, NE, NV, NH,NM, NY, NC, ND, OH, OK, OR, PA, RI, SC, SD, TN, TX, UT, VA, VT, WA, WV, WY, WI Performance Jacketed or sleeved solvent column for prechilling of solvent & unbridled passive recovery Material Column solvent dispersal plate for complete biomass saturation 1500g Adsorbent filtration column complete with a 1-5um Sintered disk filter stack Independently Jacketed Material column, adsorbent filtration column, & collection column for complete process temperature control 1.5" full bore recovery lines for unrestricted solvent recovery Integrated -1.5"x24" Inline molecular sieve column for preserving solvent's effectiveness Easy to use extract pour spout for streamlined extract harvesting

$10,250.00 - $10,650.00

50L Neocision ETL Lab Certified Rotary Evaporator Turnkey System

50L Neocision ETL Lab Certified Rotary Evaporator Turnkey System 50L NEO Rotary Evaporator Turnkey System setup includes all the necessary components to successfully perform solvent recovery via rotary evaporation. A cold trap should always be used inline between your vacuum system and application to protect the pump from volatile vapors. 10-50L NEO and ECO Rotary Evaporator Diagram 50L NEO Rotary Evaporator Turnkey System setup includes: 50L Neocision ETL Lab Certified Rotary Evaporator Polyscience DuraChill 1.5HP Chiller w/ Turbine Pump 3/8" Gum Rubber - 100ft 3/8" Silicone Tubing - 25ft Welch BTpro100 Diaphragm Pump Adjustable Stainless Steel Hose Clamps This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently.

$21,200.00 - $24,250.00

Half Ton - High Purity USA 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend - 99.5% Guaranteed

Half Ton - High Purity USA 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend - 99.5% Guaranteed DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Freight ONLY. This tank requires a CGA 510 fitting - Sold Separately BVV™ always recommends distillation of every solvent before use. *Actual liquid weight is 482LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Permitted Sales Include the Following: Medical Collectives or Cooperatives operating under CA Health & Safety Code Section 11362.775 Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale High purity 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend is USA sourced, and guaranteed to be 99.5% pure. This instrument grade solvent helps to produce a higher quality extract by reducing mystery oils and contaminants. Solvent comes in a DOT refillable LP tank with liquid withdrawal valve (Diptube). This product is clean, colorless and odorless. *Actual liquid weight is 482LB Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via UPS Ground/Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers. Chemical Formula: C₄H₁₀ + C3H8 Molecular Weight: 58.12 g/mol & 44.10 g/mol CAS Registry Number: 106-97-8 & 74-98-6 & 75-28-5 Appearance Colorless Odor: Faint Petroleum Density N/A Boiling Point: N/A Solubility in water: Low Solubility GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220, H280 GHS Precautionary Statements P210, P377, P381, P403, P410+P403 UN Identification Number: 1965 Proper Shipping Name: Hydrocarbon Gas Mixture, liquefied, n.o.s. Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Tri-Blend Certificate of Conformance (COC) and Certificates of Analysis (COA's) Tri-Blend Safety Data Sheet (SDS)

$2,400.00

6" ASME VIII Sanitary 316SS Clamp for High Pressure Connections

6" ASME VIII Sanitary 316SS Clamp for High Pressure Connections These heavy duty hygienic ASME VIII clamps are designed for pressure vessels, filter housings and other demanding/pressure intensive applications while operating under sterile conditiions. These clampos meet the requirements of ASME SEction VII Appendinx 24 of the pressure vessel code . All of these sanitary clamps are made from fully traceable 316 stainless steel. The ASME Code Sanitary Clamp is made specifically for the Pharmaceutical and Biotech Industries where joint cleanliness and efficiency are of paramount importance. These stainless steel sanitary fittings and clamps are made from investment castings to produce a high quality, precision fit assembly. The clamps are designed to provide quick access to the joint for cleaning and inspection without sacrificing safety. All sanitary clamps are CE compliant per the Pressure Equipment Directive 97/23/EC and the Machinery Directive 98/37/EC. DATASHEET - ASME Sanitary Clamp Fittings ASME Clamp Instructions

$695.00

CHEMTEK W5 Neutral Bleaching Clay

CHEMTEK W5 Neutral Bleaching Clay W5 is a neutral bleaching clay specialized for the removal of heavy metals. While most sorbents will remove heavy metals, the acids involved in the activation process could cause desorption. By neutralizing the clay processors can take advantage of the increased surface area without any risk of desorption. W5 SDS W5 Technical Data Sheet

$40.00 - $1,800.00

5L Neocision ETL Lab Certified Rotary Evaporator Turnkey System

5L Neocision ETL Lab Certified Rotary Evaporator Turnkey System The 5L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 5L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. 5L NEO Rotary Evaporator Turnkey System setup includes: 5L Neocision ETL Lab Certified Rotary Evaporator Polyscience LS -20C to 40C 1/2HP Chiller w/ Turbine Pump 1/4" Gum Rubber - 100ft 1/4" Silicone Tubing - 25ft Welch BTpro70 Adjustable Stainless Steel Hose Clamps Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware. Specifications: Model 5L Solvent Pro Series Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 110V 50/60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 20-130 RPM Set Temperature RT+5 - 99C Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 5L (5000ml) Receiving Flask Capacity 5L (5000ml) Condenser Style Main + Auxiliary Vertical Double Helix Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 1800w Dimensions 45 x 32 x 15in Weight 155 lbs Vacuum Connection 14mm / .55 in. Barb Condenser Connection 18mm / .70 in. Barb Warranty 1 Year excluding glass parts Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$10,250.00 - $12,250.00

1/2" x 0.035 wall 316SS Hard Line Tubing 5FT

1/2" 316SS Hard Line Tubing 5FT Stainless Steel 316 Hard line tubing for compression fitting connections and systems. Specifications Length 5' Material 316 Stainless Steel ASTM A-269 Max Allowed Working Pressure (PSIG) 1/2" x .035 2339

$110.00

ASME-Code Fast-Acting Pressure-Relief Valve for Air, Test Ring, Brass Seal, 1/4 NPT, 3-1/8" High

ASME-Code Fast-Acting Pressure-Relief Valve for Air, Test Ring, Brass Seal, 1/4 NPT, 3-1/8" High Valve Function Pressure Relief For Use With Air, Inert Gas Activation Pressure Driven Inlet Pipe Size 1/4 Connection Type Pipe Pipe Connection Type Threaded Connection NPT Male Location Bottom Maximum Pressure 300 psi Relief Port Connection Type Vent Relief Port Location Side Set Pressure Configuration Nonadjustable Temperature Range -40° to 400° F Valve Shape 90° Elbow Valve Body Shape Straight Overall Height 3 1/8" Material Body Brass Seal Brass Test Mechanism Ring Valve Type Pop Safety Specifications Met ASME BPVC.VIII RoHS RoHS 3 (2015/863/EU) compliant with exemption 6(c) - Lead in copper alloy REACH REACH (EC 1907/2006) (07/08/2021, 219 SVHC) Compliant DFARS Specialty Metals COTS-Exempt Country of Origin United States USMCA Qualifying No Schedule B 848140.0000 ECCN EAR99 To protect against damage in air lines, air receivers, compressor tanks, and other air-powered equipment, these valves spring fully open at the set pressure and remain open until the system pressure is restored below the set pressure. All meet ASME Code Section VIII for use with air and inert gas pressure vessels. They have a vented relief port to exhaust discharge directly.

$55.00

CHEMTEK D-Wax