BVV

-

Hydrogen Peroxide 50% Food Grade

50% Food Grade Hydrogen Peroxide Our Food-grade 50% peroxide tests at ~50.4%. This the strongest peroxide we offer, next to our 35% Food Grade Peroxide, Our Food Grade 50% hydrogen peroxide is formulated with a special stabilizer package (organophosphonate) that replaces transition metals stabilizers typically found in hydrogen peroxide solutions. Our Peroxide is NSF® Certified. NSF-certified means a product was independently verified for safety, sanitation, and quality by NSF. NSF certification is recognized by health departments, government agencies, and industry associations. *Certified under ANSI/NSF Standard 60 Drinking Water Additives-Health Effects. Dosage levels shall be in accordance with NSF requirements. 55 Gallon Drum weights 548lbs, 270 Gallon Tote weighs 2500lbs. hydrogen peroxide usually loses less than 1% of its initial concentration in one year (0.5% for a 50% solution). 50% Hydrogen Peroxide NSF Food Grade Certificate of Analysis 50% Hydrogen Peroxide NSF Food Grade Safety Data Sheet Chemical Formula: H2O2 Molecular Weight: 34.015 g/mol CAS Registry Number: 7722-84-1 Appearance Colorless Liquid Odor: None Density 1.196 g/cm3 @ 20 °C (68 °F) Boiling Point: 114 °C (237 °F) Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H272, H302 + H332, H314, H335 GHS Precautionary Statements P210, P220, P260, P261, P264, P270, P271, P280, P283, P301+P317, P301+P330+P331, P302+P361+P354, P304+P340, P305+P354+P338, P306+P360, P316, P317, P321, P330, P363, P370+P378, P371+P380+P375, P405, P420, and P501 UN Identification Number: 2014 Proper Shipping Name: 50% Hydrogen Peroxide, Aqueous Solution Transport Hazard Class: 5.1, 8 Packing Group: II DOT Placard:

$260.00 - $645.00

-

Hydrogen Peroxide 50% NSF Tech

50% Technical Grade Hydrogen Peroxide Our Technical-grade 50% peroxide tests at ~50.4%. Is the strongest proxied we offer, next to our 35% Technical Peroxide, Our Technical Grade 50% hydrogen peroxide is formulated with a special stabilizer (organophosphonate) package that replaces transition metals stabilizers typically found in hydrogen peroxide solutions. Our Peroxide is NSF® Certified. NSF-certified means a product was independently verified for safety, sanitation, and quality by NSF. NSF certification is recognized by health departments, government agencies, and industry associations. *Certified under ANSI/NSF Standard 60 Drinking Water Additives-Health Effects. Dosage levels shall be in accordance with NSF requirements. 55 Gallon Drum weights 548lbs, 270 Gallon Tote weighs 2500lbs. hydrogen peroxide usually loses less than 1% of its initial concentration in one year (0.5% for a 50% solution). 50% Hydrogen Peroxide NSF Technical Grade Certificate of Analysis 50% Hydrogen Peroxide NSF Technical Grade Safety Data Sheet Chemical Formula: H2O2 Molecular Weight: 34.015 g/mol CAS Registry Number: 7722-84-1 Appearance Colorless Liquid Odor: None Density 1.196 g/cm3 @ 20 °C (68 °F) Boiling Point: 114 °C (237 °F) Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H272, H302 + H332, H314, H335 GHS Precautionary Statements P210, P220, P260, P261, P264, P270, P271, P280, P283, P301+P317, P301+P330+P331, P302+P361+P354, P304+P340, P305+P354+P338, P306+P360, P316, P317, P321, P330, P363, P370+P378, P371+P380+P375, P405, P420, and P501 UN Identification Number: 2014 Proper Shipping Name: 50% Hydrogen Peroxide, Aqueous Solution Transport Hazard Class: 5.1, 8 Packing Group: II DOT Placard:

$240.00 - $540.00

-

Ice Water Extraction Kit

BVV's Ice Water Extraction Kit Designed with our solventless extractors in mind BVV's Ice Water Extraction Kit was engineered for durability and ease of use. Comprised of our sanitary grade seamless 55-gallon 304 stainless steel washing vessels. Our easy drain barrels come complete with 4X 1.5" Triclamp drains mounted as low as possible for effortless draining of its 55-gallon volume capacity. Perfect for medium to large-scale ice water extraction labs this kit comes complete with industry-leading Boldtbags Lock-top Full mesh stacker grading bags and a 20lb capacity Large BoldtBags Open Top Washing Bag for unbridled durability and ease of use. The ice Water Extraction Kit comes with your choice of either a low shear Multi-stage pump ideal for gravity draining or a hash-safe pneumatically driven diaphragm pump. Processing Power Material Capacity Per Batch: 20-30LB Water Capacity: 55 Gallons Cycle Time: 60-90 Minutes Daily Extraction Capacity: Up to 60 lb, per 8-hour shift Specifications 2X 23"x36" 55-gallon Stainless Steel Washing Vessel 4X 1.5" Tri-clamp ports 4X BoldtBags Lock-top Full mesh stacker grading bags (190um(Green),160um(Red),90um(Black),45um(White)) 1X Large Boltd Open Top Wash Bag (20lb Capacity) 1X Food grade PTFE mixing paddle 1X 27 GPM Low shear Multistage pump or 16 GPM hash-safe pneumatically driven diaphragm pump. 1X 25Ft 1" Clear Braided PVC Hose 1X 1.5" Tri-clamp Thermometer (0-220F/0-100C) 4X Polycarbonate Sight glasses 2X 1.5" Tri-Clamp Butterfly valves with 1" barbed fittings Performance Seamless sanitary construction Low-mounted drain ports for complete draining Tri-Clamp Thermometer for water temperature measurement Polycarbonate sight glasses for visual monitoring of the process Open Top Wash Bag for easy loading & unloading Low-shear force Multistage pump for gentle water transfer or a hash safe pneumatically driven diaphragm pump

$5,750.00 - $7,400.00

-

Ignition Resistant Axial Fans

Our Ignition Resistant Axial fan with 30' of ducting provides the user with much-needed air circulation within a room to move flammable gases and any other air contaminants to an area with open air. This axial fan features superior design and durable construction, ensuring long-lasting capabilities with proper maintenance. Many of these gases are heavier than air so it is best to keep the fan ground level to provide the best room circulation possible. The body is made of carbon steel and the impeller is made of aluminum. This combination provides a spark-free environment should the impeller make contact with the body. Warning: Do not run the fan daisy-chained, it will cause disruption with air circulation and may cause the fan to back up air into the room. ***Note: Do not run fans daisy-chained it will cause disruption with air circulation and may cause the fan to back up air into the room. Specifications Impeller Size: 8" 12" 16" Actual Size LxWxH: 14x9x14 15x13x18 18x17x22 Voltage: 110v/60Hz (USA Plug) RPM: 2800 2800 3300 Watts: 180w 500w 1100w Airflow CFM: 880 2300 4200 Noise: 61(AdB) 69dB(A) 79dB(A)

$52.00 - $200.00

-

Indicating Molecular Sieve Beads Type 4A

Indicating Molecular Sieve Beads TYPE 4A (Blue) Description: 4A Blue Indicating Molecular Sieve is a porous, high capacity alkali metal aluminosilicate compound. Like non-indicating 4A molecular sieve, our blue indicating 4A molecular sieve has 4 Angstrom-sized pore openings that allow to adsorb all molecules adsorbed by 3A, molecular sieve, plus larger molecules like aromatic and branched-chain hydrocarbons. Handling & Storage Recommendations: Store in a dry location to prevent unintentional water adsorption. Reseal packages after opening to prevent contamination and unintentional water adsorption. We recommend that you rotate stock so the oldest material is used first. Please read the safety data sheet to ensure proper handling and always wear personal protection equipment when handling molecular sieve. Molecular Sieve 4A Indicating Technical Data Sheet Molecular Sieve 4A Indicating Technical Data Sheet

$16.00 - $975.00

-

Industrial Vibrating Sifter - 16.25 x 6" (Compare to Custom Cones)

Automatic Vibrating Sifter - Industrial 16.25 x 6" This item Ships Freight - 88 lbs. Sifting your plant material is a great way to remove stems automatically, and if you are producing a premium pre-roll product, it is always best to sift out any stems! Our Large Automatic Vibrating Sifter was explicitly designed with plant processors in mind - the stainless steel construction and screens ensure you can easily clean our sifter, and the screen sizes are fine-tuned for the most common sifting needs. Once you've ground your plant material, you only need to pour your flower into the sifter and switch it on. You can now walk away and wait for your flower to be automatically sifted - no more standing around doing manual sifting. Sifting your plant material will not only ensure no stems make it into your pre-rolls but will also ensure nothing else makes it into your pre-rolls, like large leaves, gravel, or any other foreign matter. The consistent grind will make your pre-rolls burn more evenly and pack more evenly in any cone-filling machine. Package Dimensions - 19"x21"x35"

$1,500.00

-

Inline Candy Desiccant Dryer

The inline candy desiccant dryer is a necessary accessory to any one using a vacuum oven for candy drying. The column will need to be filled by the user with silica gel and has fine mesh stainless filters on each end to hold in the beads. We recommend connecting the vacuum inlet from the pump to the top of the column to prevent any water accumulation in the beads from reaching the pump via gravity. The bottom of the column will connect to the oven itself. The column holds 1.5lb of silica gel desiccant. Its water holding capacity is 36%. Since 1lb of candy can hold as much as 40-60g of water, a 1lb column of desiccant will have the capacity to handle approximately 4.5-5lb of fresh candy drying before it needs to be reactivated. Silica gel can be reactivated by placing in an oven on a sheet pan for 0.5-2.0 hours at 200-250F or microwave for 10 minutes on defrost. BVV Hook Up Guide - Quick Assembly PDF Size Variants Standard Size 2" Outside Diameter x 24" Tall Column (Holds 1.5lbs Silica) XL Size Column 3" Outside Diameter x 36" Tall Column (Hold 6.5lbs Silica) Extension Kit for the Standard Column 2" Outside Diameter x 24" Tall (Holds1.5lbs Silica) *Silica Gel: Source from amazon (USE Clear silica gel) https://www.amazon.com/Dry-Quart-White-Silica-Desiccant/dp/B014VM4AZI/ref=sr_1_3?crid=N1FARCPRUFPT&keywords=silica+gel+clear&qid=1678139406&sprefix=silica+gel+cle%2Caps%2C100&sr=8-3

$29.50 - $390.00

-

Inline CRC

Inline CRC Kit BVV's Inline CRC Kit can be utilized to adapt any 1.5", 2", 3", 4", or 6" diameter material column for inline adsorbent filtration. This kit includes a corresponding sized media column and a filter stack including a 5 micron & 1 micron Dutch Weave Sintered Filter Disc. This Inline color remediation kit is meant to be plumbed between your existing extractors material column and the existing hemispherical reducer of any closed loop hydrocarbon extractor.Assembly starts with placing the 1 micron sintered disk and gasket between the extracts hemispherical reducer and the included filter plate securing both with one of the included high-pressure clamps. Next, take the 5-micron sintered disk and the included ashless filter paper and rip around the circumference of the sintered disk, placing both atop the filter plate placing the sintered disc gasket and media column spool over top before securing both with the remaining high-pressure clamp. Since the spool secures the filter paper in place a filter plate ring is not required. Media can then be layered into the media column by weight before placing the loaded material column above the adsorbent filtration column and assembling the remainder of the extractor. For optimum filtering results utilize the following layer recipe from top to bottom: 30-50g per lb of biomass Silica 60A 75-100g per lb of biomass Bentonite Clay 30-50g per lb of biomass Neutral Activated Alumina This Kit includes: Media column Tri-clamp Spool V3 Filter Plate 5 Micron Sintered Disk 1 Micron Sintered Disk 2X Buna-N Sintered Disc Gaskets 2X High-pressure Clamps Fast Flow Ashless Filter Paper (100qty) *This video provides a visual assembly of the 3" Inline CRC which is applicable across all sizes*

$175.00 - $491.00

-

Inline Strainer 304 Stainless Steel

Inline Strainer 304 Stainless Steel Inline Tri-Clamp strainers are used when filtering solids from liquids in fluid processing systems. The inside of the strainer is perforated with 2mm holes to collect larger solids when filtering and comes with (1) 3" Single pin clamp and (1) 3" silicone Tri-Clamp gasket. It is recommended that a strainer be placed after a pump, as the suction could damage the strainer core. Specifications Material 304 Stainless Steel Connection Type 1.5" Tri-Clamp Secondary Mesh Perforated Stainless Steel with 2mm Holes

$165.00

-

Insulated Heavy Duty 1/8" Wall Silicone Tubing For Flow - 6 Feet

Insulated Heavy Duty 1/8" Wall Silicone Tubing For Flow - 6 Feet (**Note: This tubing is only for flow and is NOT vacuum rated) The most outstanding properties of SILCON tubing are its flexibility and resistance to temperature extremes. These, plus its good electrical properties and ability to self-extinguish, make SILCON tubing an excellent choice for appliances and computers Peroxide-cured SILCON contains no sulfur or other acid-producing chemicals, thereby eliminating the possibility of staining, corroding, or deteriorating materials it contacts. It is extremely resistant to ozone and U.V. over long time periods. Care is recommended in the selection of fittings and clamps for SILCON as sharply barbed fittings or unlined metal clamps could tear into the tubing wall and possibly cause a failure. SILCON may be low-pressure steam sterilized in-line or autoclaved at up to 250°F in a normal autoclaving cycle. However, if exposed to repeated steam sterilization or long-term high temperature or pressure, silicone will eventually relax and become gummy. It should then be replaced. Insulation Compliance: ASTM C 534, Type I – Grade 1 ASTM D 1056, 2C1 ASTM E 84, UL723 ASTM G21/C1338 CAN/ULC S102 ➀ City of New York Approval MEA 107-89M MIL-P-15280J, FORM T ➁ NFPA 90A, 90B UL 181 UL 94 5V-A, V-0, File E55798 Insulation Approvals, Certifications, Compliances: 3rd party certified by FM Approvals through 1-1/2" wall thickness per FM 4924 GREENGUARD® Children & Schools Indoor Air Quality certified. Manufactured without CFCs, HFCs, HCFCs, PBDEs, or Formaldehyde. Made with EPA registered Microban® antimicrobial product protection. All Armacell facilities in North America are ISO 9001:2008 certified. Plenum Rated Conforms to ASHRAE 90.1 Energy Standards Conforms to building codes: International Mechanical Code, IMC, International Energy Conservation Code, IECC, International Residential Code, IRC, Title 24California Building Energy Efficiency Standards. Please call or email Best Value Vacs to request different sizes and thickness (1/16" to 3/4"ID) - Colors for industrial applications are available through minimum order. Key Features: Made from FDA-sanctioned ingredients Insulation R-Value of 3.3 Able to resist extreme temperature variation: -100°F to 500°F Translucent natural color for visual contact with the flow resilient, stretchable, and resistance to compression set Odorless, tasteless and inert Good electrical and weatherability properties - resists U.V., ozone, gases, and moisture Certified by the National Sanitation Foundation (NSF-51) for food equipment materials MADE IN THE U.S.A. Specifications/Physical Properties Hardness, Shor A +/-5 50 Tensile Strength, PSI 1100 Elongation at Break % 375 Brittle Temperature °F -100 Max Operating Temperature °F 500 Max Operating Temperature for NSF °F 350 Comp. Set 22 Hrs. at 177°F, % 35 Tear Resistance (PPI minimum) 100 Tubing Specifications Chart ID (IN.) OD (IN.) STANDARD LENGTH WORKING PSI @ 70°F BURST PSI @ 70°F LBS PER 100FT 1/16 1/8 100 10 30 0.50 1/16 3/16 100 20 60 1.34 3/32 5/32 100 10 30 0.66 3/32 7/32 100 15 45 1.58 1/8 3/16 100 10 30 0.88 1/8 1/4 100 20 60 2.00 1/8 5/16 100 25 75 3.32 1/8 3/8 100 28 84 4.92 5/32 9/32 100 20 60 2.14 5/32 11/32 100 20 60 3.64 3/16 1/4 100 5 15 1.22 3/16 5/16 100 20 60 2.64 3/16 3/8 100 20 60 4.12 3/16 7/16 100 15 45 6.14 1/4 5/16 100 10 30 1.50 1/4 3/8 100 5 15 3.34 1/4 7/16 100 20 60 5.12 1/4 1/2 100 15 45 7.50 5/16 7/16 100 10 30 3.66 5/16 1/2 100 10 30 6.30 3/8 1/2 100 10 30 4.32 3/8 9/16 100 10 30 7.15 3/8 5/8 100 10 30 10.16 3/8 3/4 100 15 45 16.72 7/16 5/8 100 10 30 7.70 1/2 5/8 100 5 15 5.84 1/2 11/16 100 5 15 9.50 1/2 3/4 100 10 30 13.12 1/2 7/8 100 10 30 15.00 5/8 3/4 100 5 15 6.86 5/8 13/16 100 5 15 11.34 5/8 7/8 100 5 15 13.38 5/8 1 100 10 30 22.86 3/4 1 50 5 15 17.64 3/4 1-1/8 50 10 30 26.56

$70.00

-

Insulation Jackets for Centrifuges

Insulation Jackets for Centrifuges ***Disclaimer: Fiberglass may be present on the exterior of the jacket and users should use PPE when handling the jacket. These insulated jackets are specifically designed to fit BVV brand Centrifuges and allow the user to better control and keep a more stable temperature when running the system. The jackets are made out of flame retarded material and are insulated with fiberglass.

$450.00 - $1,150.00

-

Isopropyl Alcohol 70% Tech Grade

Isopropyl Alcohol 70% Technical Grade Isopropyl alcohol is a fast-evaporating solvent and industrial cleaning agent, intended for industrial or professional use only. It can be used as a solvent for gums, shellac, and essential oils. Can be used as a fuel additive. Isopropyl Alcohol (liquid) - 70% Purity / 30% De-Ionized Water Shelf Life - 5 years Chemical Formula: C3H8O Molecular Weight: 60.096 g/mol CAS Registry Number: 67-63-0 Appearance Colorless Liquid Odor: Pungent Alcoholic odor Density 0.858 g/cm3 @ 20 - 25 °C (68 - 77 °F) Boiling Point: 80.9 - 83.2 °C (177.6 - 181.8 °F) Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H319, H336 GHS Precautionary Statements P210, P233, P240, P241, P242, P243, P261, P264+P265, P271, P280, P303+P361+P353, P304+P340, P305+P351+P338, P319, P337+P317, P370+P378, P403+P233, P403+P235, P405, and P501 UN Identification Number: 1219 Proper Shipping Name: Isopropanol Transport Hazard Class: 3 Packing Group: II DOT Placard: Isopropyl Alcohol 70% Tech Safety Data Sheet (SDS) Isopropyl Alcohol 70% Tech Certificate of Analysis (COA)

$14.00 - $2,350.00

-

Isopropyl Alcohol 70% USP

Isopropyl Alcohol 70% USP Isopropyl alcohol is a fast-evaporating solvent and industrial cleaning agent, intended for industrial or professional use only. It can be used as a solvent for gums, shellac, and essential oils. Can be used as a fuel additive. Isopropyl Alcohol (liquid) - 70% Purity / 30% De-Ionized Water Shelf Life - 5 years *Disclaimer: 1 Quart Bottles are exempt from additional Hazmat shipping charges and can ship immediately, Less paperwork for shipping is required for shipping only 1 single bottle per order. Chemical Formula: C3H8O Molecular Weight: 60.096 g/mol CAS Registry Number: 67-63-0 Appearance Colorless Liquid Odor: Pungent Alcoholic odor Density 0.786 g/cm3 (20 °C) Boiling Point: 82.6 °C /180.7 °F Solubility in water: miscible GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H302, H319, H336 GHS Precautionary Statements P210, P261, P305+P351+P338 UN Identification Number: 1219 Proper Shipping Name: Isopropanol Transport Hazard Class: 3 Packing Group: II DOT Placard: Isopropyl Alcohol 70% Safety Data Sheet (SDS) Isopropyl Alcohol 70% Certificate of Analysis (COA)

$16.00 - $2,450.00

-

Isopropyl Alcohol 99% Tech Grade

Isopropyl Alcohol IPA 99% Isopropyl alcohol, also known as 2-propanol or rubbing alcohol, is one of the most common alcohol solutions. The exact mechanism behind isopropanol’s disinfectant is not certain, however, it’s believed to kill cells through the process of denaturing cell proteins and DNA, dissolving cell lipoprotein membranes, and obstructing cellular metabolism. Isopropanol has a range of applications and uses across multiple industries, from medicine to cosmetics, and we explore this below. Cleaning Agent for Extraction, Laboratory, and Medical Industries In addition, 99% pure isopropyl alcohol serves as a cleaning agent for the laboratory, medical, and extraction industries. Mixed with water, this solution can be used as a rubbing-alcohol antiseptic. Quality solvents are vital for cleaning delicate electronics, extraction equipment, and other sensitive items. It also makes a perfect solution for surface disinfectant. 99% IPA evaporates cleanly and minimizes residual substances. Cleaning Agent for Home Care A truly versatile solution used in a variety of applications, isopropyl can also serve as a home cleaning remedy. For example, many window and toilet bowl cleaners contain isopropyl alcohol. rubbing alcohol can dissolve icky residues such as chewing gum, sap, hairspray, and other difficult compounds from hands, surfaces, and more. Other ways isopropyl can be used: Cleaning makeup brushes Cleaning blinds Cleaning sinks and chrome Deodorizing shoes Disinfecting computer mouse and keyboard Disinfecting mobile phone Dissolving windshield frost Getting rid of fruit flies Cleaning jewelry Creating homemade sanitizer Preventing ring around the collar Cleaning stainless steel Other Things to Note Spigots/Faucets are only compatible with 5 Gallon Jugs and must be purchased separately Isopropyl alcohol is a fast-evaporating solvent and industrial cleaning agent, intended for industrial or professional use only. It can be used as a solvent for gums, shellac, and essential oils. Can be used as a fuel additive. Isopropyl Alcohol (liquid) - 99.8% Purity Shelf Life - 5 years Specific Gravity - 0.79 Vapor Pressure - 1psi @ 20°C Flash Point - 12°C *Disclaimer: 1 Quart Bottles are exempt from additional Hazmat shipping charges and can ship immediately, Less paperwork for shipping is required for shipping only 1 single bottle per order. Chemical Formula: C3H8O Molecular Weight: 60.096 g/mol CAS Registry Number: 67-63-0 Appearance Colorless Liquid Odor: Pungent Alcoholic odor Density 0.786 g/cm3 (20 °C) Boiling Point: 82.6 °C /180.7 °F Solubility in water: miscible GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H302, H319, H336 GHS Precautionary Statements P210, P261, P305+P351+P338 UN Identification Number: 1219 Proper Shipping Name: Isopropanol Transport Hazard Class: 3 Packing Group: II DOT Placard: Isopropyl Alcohol Safety Data Sheet (SDS) Isopropyl Alcohol Certificate of Analysis (COA)

$17.00 - $2,850.00

-

Isopropyl Alcohol 99% USP

Isopropyl Alcohol 99% USP Isopropyl alcohol, also known as 2-propanol or rubbing alcohol, is one of the most common alcohol solutions. The exact mechanism behind isopropanol’s disinfectant is not certain, however, it’s believed to kill cells through the process of denaturing cell proteins and DNA, dissolving cell lipoprotein membranes, and obstructing cellular metabolism. Isopropanol has a range of applications and uses across multiple industries, from medicine to cosmetics, and we explore this below. Cleaning Agent for Extraction, Laboratory, and Medical Industries In addition, 99% pure isopropyl alcohol serves as a cleaning agent for the laboratory, medical, and extraction industries. Mixed with water, this solution can be used as a rubbing-alcohol antiseptic. Quality solvents are vital for cleaning delicate electronics, extraction equipment, and other sensitive items. It also makes a perfect solution for surface disinfectant. 99% IPA evaporates cleanly and minimizes residual substances. Cleaning Agent for Home Care A truly versatile solution used in a variety of applications, isopropyl can also serve as a home cleaning remedy. For example, many window and toilet bowl cleaners contain isopropyl alcohol. rubbing alcohol can dissolve icky residues such as chewing gum, sap, hairspray, and other difficult compounds from hands, surfaces, and more. Other ways isopropyl can be used: Cleaning makeup brushes Cleaning blinds Cleaning sinks and chrome Deodorizing shoes Disinfecting computer mouse and keyboard Disinfecting mobile phone Dissolving windshield frost Getting rid of fruit flies Cleaning jewelry Creating homemade sanitizer Preventing ring around the collar Cleaning stainless steel Other Things to Note Spigots/Faucets are only compatible with 5 Gallon Jugs and must be purchased separately Isopropyl alcohol is a fast-evaporating solvent and industrial cleaning agent, intended for industrial or professional use only. It can be used as a solvent for gums, shellac, and essential oils. Can be used as a fuel additive. Isopropyl Alcohol (liquid) - 99.8% Purity Shelf Life - 5 years Specific Gravity - 0.79 Vapor Pressure - 1psi @ 20°C Flash Point - 12°C Boiling Point - 82°C *Disclaimer: 1 Quart Bottles are exempt from additional Hazmat shipping charges and can ship immediately, Less paperwork for shipping is required for shipping only 1 single bottle per order. Chemical Formula: C3H8O Molecular Weight: 60.096 g/mol CAS Registry Number: 67-63-0 Appearance Colorless Liquid Odor: Pungent Alcoholic odor Density 0.786 g/cm3 (20 °C) Boiling Point: 82.6 °C /180.7 °F Solubility in water: miscible GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H302, H319, H336 GHS Precautionary Statements P210, P261, P305+P351+P338 UN Identification Number: 1219 Proper Shipping Name: Isopropanol Transport Hazard Class: 3 Packing Group: II DOT Placard: Isopropyl Alcohol Safety Data Sheet (SDS) Isopropyl Alcohol Certificate of Analysis (COA)

$18.00 - $3,175.00

-

J636T Hubbell Process Water Heater 240V 3P with Pump

Hubbell Process Water Heater 240V 3P Process Water Heater 6 Gallon Stainless Steel ASME Vessel 36 kW, 240 volt, 3 phase Complete with electrical operating controls including the following: magnetic contactor, immersion elements, digital temperature controller with safety hi-temperature cut out, low water cut out, and an ASME rated combination temperature and pressure relief valve. Unit is factory assembled, insulated, jacketed, wired, and tested. Unit is ready for electrical and plumbing service connections. This kit includes a stainless steel pump to continuously circulate water through a closed loop system, an expansion chamber may be needed. Professional installation of water lines by a certified plumber is recommended. Water Heater Features Industrial Grade Construction Stainless steel pressure vessel provides maximum service life ASME Section VIII stamped vessel ensures high quality construction Heavy duty construction withstands demanding industrial use Packaged with all electrical operating controls for efficient installation Small reserve capacity lowers peak power demand and reduces operating costs in systems with ON / OFF cyclical demand Hubbell V636T Heater Specs Model J636T Voltage 240V Current Draw (A) 87 Heating Wattage (kW) 36 Storage Capacity (Gal) 6 Inlet / Outlet Connections 3/4" MNPT Circulation Pump Specs Model AHWS-25-60-180 Material Stainless Steel Power 40 W Max Head (Ft.) 18 Max Flow (GPM) 15.8 Max Water Temp (°C) 110 Voltage 220VAC / 1ph Current Draw (A) .2 Max Ambient Temp (°C) 40

$6,600.00

-

Jacketed Collection Column (6in Tri clamps)

This column can be used as a collection or solvent vessel for a larger rack mounted extractor. The top and bottom tri clamp size are 6" to allow for a higher pressure rating on the entire vessel. The jacket of the vessel is baffled and has 1/2" NPT ports to run fluid through for good temperature control. This column is intended to hold 55lbs of hydrocarbon solvent, it can be rack mounted with 12" pipe hangers. Max Pressure: 300psi @70°F (dependent on clamp used) Material: 304 Stainless Steel Capacity: 55 Liters Height: 48"

$1,800.00

-

Jacketed Collection Spool

8"x 52" Jacketed Collection Spool This spool is 8" in diameter x 52" in length with 4" Tri-Clamp ports on either end. The top has 1/4" and 1/2" NPT ports to add a gauge and pressure relief directly to the vessel. The spool has a closed jacket with 1/2" NPT ports that make this spool ideal to use as a collection tank on a rack-mounted system.

$1,100.00 $700.00

-

Jacketed Hemispherical Reducer Stand

Jacketed Hemispherical Tri-Clamp Reducer with Welded Ring Stand Jacketed Hemispherical Tri-Clamp Reducer with Welded Ring Stand allows the user to create a larger drain/filtering system allowing more weight to be supported with the ring stand. These reducers have (2) 1/2" FNPT connection jacket ports with Tri-Clamp connection on the top and a 1/4" FNPT drain port on the bottom. The outer jacket allows the user to recover faster or keep materials at a specific temperature for more accurate processes. Specifications: Material: 304 Stainless Steel High Polish Interior Standard: 3A Connection Types: Tri-Clamp x (2) 1/2" FNPT x 1/4" FNPT

$150.00 - $300.00

-

Jacketed Hemispherical Reducers with 1/2" FNPT Drain Port

Jacketed Hemispherical Reducers Jacketed Hemispherical Reducers allow the user to circulate water around the bowl and keep extracted material liquefied for easier flow through the bottom port. These jacketed reducers have 1/2" FNPT ports on either side and a 1/2" FNPT port through the bottom of the dish. These reducers are made out of 304 stainless steel with a high polish interior. Specifications Material 304 Stainless Steel Connection Type(s): Tri-Clamp 1/2" FNPT Sizes Available: 6" 10" 12"

$255.00 - $320.00

-

Jacketed Hemispherical Reducers with 2" Tri-Clamp Drain Port

Jacketed Hemispherical Reducers with 2" Tri-Clamp Drain Port Jacketed Hemispherical Reducers allow the user to circulate water around the bowl and keep extracted material liquefied for easier flow through the bottom port. These jacketed reducers have 1/2" FNPT ports on either side for circulation and a 2" Tri-Clamp port through the bottom of the dish. These reducers are made out of 304 stainless steel with a high polish interior. Specifications Material 304 Stainless Steel Connection Type(s): 12" Tri-Clamp 2" Tri-Clamp (2) 1/2" FNPT

$340.00

-

Jacketed Reactor with Motor and Collection Vessel

Jacketed Reactor with Motor and Collection Vessel This jacketed reactor kit includes your choice of a C1D1 motor, standard motor, or non-electric air powered motor (air compressor required). If using an electric motor it will require wiring to the included speed controller. Using the jacketed reactor to heat your solution, use your reactor to mix your solution during the heating process. The condenser and collection vessel allow you to recover residual solvents up to 100L. The collection vessel includes a dip tube to empty the vessel and a 1/4" JIC flare to input pressure into the base to assist in emptying the tank through the dip tube. This system does NOT include a heater or chiller, please inquire with your account representative for recommendations based on your application! Jacket connections are 1/2" hose barbs. Mixer Type Pneumatic Electric C1D1 Electric Horsepower 3/4 HP 3/4 HP 1 HP Power Air Compressor 120V 220V 1ph Reactor Size 150L Collection Size 50L / 100L Jacket Connections 1/2" Hose Barb

$7,022.00 - $13,690.00

-

Jacketed Splatter Platters

Jacketed Splatter Platters Fully Jacketed splatter platters are a huge step up from normal splatter platters by providing the user a more efficient recovery of their solvent without having to move or lift the extractor into a hot water bath. These jacketed splatter platters allow the circulation of water through the outer jacket through 2x 1/2" FNPT offset ports on each side of the splatter platter. ***Note: Edges of Jacket may be rounded instead of flat. Sizes Available: 6" 8" 10" 12" Specifications: Material 304 Stainless Steel Standard 3A High Polish Connection Type(s): Tri-Clamp 1/2"-14 FNPT BVV™ Jacketed Splatter Platters - Drawing

$150.00 - $230.00

-

Jacketed Stainless Steel LP Tank with Internal Condensing Coil and Dip Tube

Jacketed Stainless Steel LP Tank with Internal Condensing Coil and Dip Tube (This item will ship via Freight ONLY) Jacketed Stainless Steel LP tanks offer a superior way to decrease contamination of solvent and feature a tri-clamp lid with a high-pressure clamp. This allows easy access to the inside of the tank, making clean out simple, unlike a normal carbon steel LP tanks. These tanks feature an exterior jacket to allow the user to circulate fluid around the outside of the tank while having an internal condensing coil on the inside of the tank to help condense hot vapors. Lids come configured with 3 valves, compound gauge and hose barbs for the internal condensing coils to help condense hot solvent vapor when the recovery stage of the extraction process is started. These tanks come with 1/4" FNPT valves and 1/4" 37 Degree JIC Flares with one port being connected to a dip tube. To avoid contamination of your solvent, the Jacketed Stainless Steel LP Tank is a simple and professional option to reduce cleaning time. Our tri-clamp lid with a high-pressure clamp makes it easy to open up the system and fully clean it out in between uses. The exterior jacket circulates fluid around the outside of the tank which the internal condensing coil condenses hot vapors. These tanks come with 1/4" FNPT valves and 1/4" (or 3/8") 37 Degree JIC Flares with one port being connected to a dip tube. If you are not using the jacket to circulate a chilling fluid, the jacket should be evacuated of all air and closed off. This is also known as a vacuum jacket, it will help to keep the fluid inside the tank at the set temperature and not transfer any temperature with the atmosphere around it. *Tank does not come with solvent Butane Capacity Calculation: All solvent tanks sold by Best Value Vacs have their capacity determined by this calculation and are based on industry standard nomenclature of the water weight tank # system because the specific gravity of water is 1.000 and the DOT 80% fill guideline. Example: 100# Tank = ~100lbs of water weight, Halfton Tank = 1000lbs of water weight. Tank # Water Weight in Lbs Specific Gravity of Butane 0.601 80% Fill Guideline 0.800 (Tank #) * (Specific Gravity of Butane) * ( 80% Fill Guideline) Sizes Available: 25# 50# 100# Specifications Tank/Component Material 304 Stainless Steel Gasket Material BUNA-N Standard 3A High Polish Connection Type(s) 1/4" (7/16-20) x 37° JIC Hose Barb Lid Connection Type(s): Tri-Clamp 1/4"-20 FNPT Hose Barb Butane Capacity: 25# 12.424 50# 24.040 100# 48.080 ***Disclaimer: These are not DOT rated tanks and are not recommended for transportation when filled.

$850.00 - $1,450.00

-

Jacketed Sucker Pot

Jacketed Sucker Pot This jacketed sucker pot works perfectly as a collection base for extracted oil and easy discharge or as a storage vessel for distillate dispensing. Both of these applications are made easier with the use of a heater running through the jacket. This pot can be mounted to an extraction rack with the use of 8" pipe hangers. Connections: Top: 6" Tri-Clamp Bottom: 1/2" FNPT Jacket: 1/4" FNPT (2x ports)

$300.00

-

Jacketed Sucker Pot with Ring Stand

Jacketed Sucker Pot with Ring Stand This jacketed sucker pot works perfectly as a collection base for extracted oil and easy discharge or as a storage vessel for distillate dispensing. Both of these applications are made easier with the use of a heater running through the jacket. Connections: -Top: 6" Tri-Clamp -Bottom: 1/4" FNPT -Jacket: 1/4" FNPT (2x ports)

$500.00

-

KF Clamps

KF Clamps Clamp for standard High Vacuum flanges. Size Available: KF-16 KF-25 KF-40 KF-50

$18.50

-

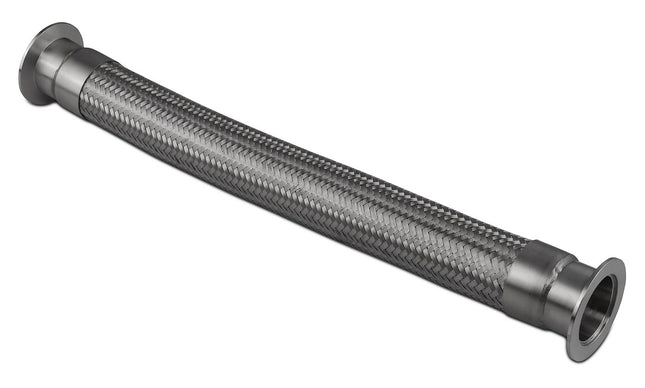

KF Connection Braided Stainless Steel Bellow Hose

KF Connection Braided Stainless Steel Bellow Hose This KF or (NW) bellow hose is made out of 304-grade stainless steel with braided exterior which allows a high vacuum to be obtained with a large flow diameter for vapors. These bellow hoses are flexible and allow the user to connect a KF flanged vacuum pump to a KF flanged vacuum oven or any other application using adapters. Sizes Available: KF-16 KF-40 KF-50 Lengths Available: 20" 40"

$60.00 - $165.00

-

KF Flange x FNPT Adapter

KF Flange x FNPT Adapter KF- or NW Vacuum fittings are designed for Ultra-High-Vacuum applications and are made out of 304 stainless steel. These fittings require a special gasket with metal centering ring to not allow over compression of the gasket. These fittings have female NPT threads that come in a variety of sizes, Female NPT threading which require thread sealant if they are installed to another NPT adapted fitting.

$22.00 - $37.00

-

KF Flange x Tri-Clamp End Cap Adapter

KF Flange x Tri-Clamp End Cap Adapter These 304 stainless steel adapters allow you to adapt from a KF (NW) type flange to a Tri-Clamp sanitary flange. This part can be used for vacuum lines or even adapting to a distillation setup.

$42.00

-

KF Hand Needle Valve - Nitrogen Tested

KF Hand Needle Valve This 90 degree valve has a KF (NW) High Vacuum Flange to adapt to any other KF type pump or manifold if needed. Sizes available include KF16, KF25, KF40, and KF50. It is made out of 304 stainless steel with Viton seals. This valve is not meant for precise flow control.

$225.00

-

KF High Vacuum Stainless Steel Flange x Female Joint Adapter

This unique adapter allows the user to adapt a KF25 or KF40 High Vacuum Flange fitting to a male ground joint glass fitting and it is made out of 304 stainless steel.

$38.00

-

KF O-ring

KF O-ring O-ring features a depth stop for clamping with Viton O-ring also fits the following high vacuum connections. NW16 NW25 NW40 NW50

$7.50 - $18.00

-

KF Sight Glass

These 4 piece sight glasses can hold high vacuum levels on a system with KF connections. The housing is made of 304 stainless steel with a viton x-profile seal. The glass is tempered, impact resistant glass that increases the longevity of the sight glass. The connection sizes available are: KF25 (NW25) KF40 (NW40) KF50 (NW50) *Light assembly may be required with a 5/64" Allen wrench. Before assembly, a light application of vacuum grease on the gasket is recommended.

$74.00 - $112.00

-

KF Solid End Caps

KF Solid End Caps This is a solid KF Endcap to cap of any size port when needed Size Available: NW16 NW25 NW40 NW50

$12.00 - $15.00

-

KF Stainless Steel Bellow Hose

KF Stainless Steel Bellow Hose This KF or NW flange bellow hose is made out of 304-grade stainless steel which allows a high vacuum to be obtained with a large flow diameter for vapors. These bellow hoses are flexible and allow the user to connect a KF flanged vacuum pump to a KF flanged vacuum oven or any other application using adapters like our KF x NPT or KF x Tri-Clamp Fittings.

$70.00 - $175.00

-

KF Vacuum Flange Reducer Adapter

This 304 Stainless Steel KF Vacuum Flange Reducer / Adapter is designed to convert K16 to KF25 or KF25 to K40 and vise versa.

$38.00

-

KF-25 5 Way Manifold

This is a KF-25 5 Way manifold for the splitting of vacuum applications especially vacuum ovens connected to a single Vacuum Pump in an array. The material is 304 Stainless Steel with a 10^-7 torr @ 72F Vacuum Rating. (Note: Does not include KF-25 Clamp or O-ring these items are sold separately.)

$59.00

-

KF-25 90 Degree Stainless Steel Elbow

KF-25 90 Degree Stainless Steel Elbow This 90-degree elbow has KF-25 connections on the end and is made out of high polish 304-grade stainless steel.

$28.00

-

KF-25 Bellow Fitting Hose - KIT

KF-25 Bellow Fitting Hose Kit This KF25 or (NW25) bellow hose is made out of 304-grade stainless steel which allows a high vacuum to be obtained with a large flow diameter for vapors. These bellow hoses are flexible and allow the user to connect a KF25 flanged vacuum pump to a KF25 flanged vacuum oven or any other application using adapters like our KF25 x NPT or KF25 x Tri-Clamp/ Tri Clover Fittings. This kit also has 2 KF25 clamps and gaskets. What's Included? (1) KF25 Flexible 304 Stainless Steel Bellow Hose (2) KF25 Centering Gaskets with Viton O-ring (2) KF25 Aluminum Clamps Bellow Hose Sizes Available: 1 Meter(s) (3.28 Feet) 2 Meter(s) (6.56 Feet)

$162.00 - $197.00

-

KF-25 Cross - 4 Way Splitting of Vacuum Applications

This is a KF-25 Cross for 4 Way splitting of Vacuum Applications especially vacuum ovens connected to a single Vacuum Pump in an array. The material is 304 Stainless Steel with a 10^-7 torr @ 72F Vacuum Rating. Does not include KF-25 Clamp or O-ring these items are sold separately.

$56.00

-

KF-25 Flange Kit

Complete KF-25 Flange Kit The Complete Kit for KF-25 Vacuum Fittings. Connect your flange to a pipe with this complete kit from BVV™. It includes Clamp, O-ring, and Flange

$35.00

-

KF-25 Ground Joint PTFE Adapter

KF-25 Ground Joint PTFE Adapter This adapter will fit any standard 24/40 or 34/45 ground glass joints and adapt to a KF25 flange. This adapter is best used to hook up a glass system to a steel vacuum hose such a KF25 bellows. The Joint has an o-ring for better sealing, but vacuum grease is still recommended for the best connection.

$42.00

-

KF-25 Stainless Steel 90 Degree Manifold

KF-25 Stainless Steel 90 Degree Manifold This 90 degree stainless steel KF-25 manifold has 2 1/4" FNPT ports and measures 10" x 7".

$65.00 $30.00

-

KF-25 Stainless Steel 90 Degree Manifold - Long

KF-25 Stainless Steel 90 Degree Manifold - Long This 90 degree stainless steel KF-25 manifold has 2 1/4" FNPT ports and measures 10" x 36".

$80.00 $40.00

-

KF-25 Stainless Steel Ball Valve (Nitrogen Tested)

KF-25 (NW25) Stainless Steel Ball Valve This ball valve has a KF25 (NW25) High Vacuum Flange to adapt to any other KF25 pump or manifold if needed and is made out of 304 stainless steel with a PTFE seat and seals. BVV™ Tri Clamp Ball Valve - Data Sheet

$120.00

-

KF-25 Stainless Steel Spools

KF-25 Stainless Steel Spools This spool has KF-25 connections on the end and is made out of high polish 304-grade stainless steel.

$17.00 - $28.00

-

KF-25 Tee

This is a KF-25 Flanged Tee for High Vacuum Applications. The Material is 304SS and it has a maximum vacuum rating of 10^-7 torr @ 72F.

$45.00

You have seen 720 out of 1084 products