All products

SC Filtration - Agitatore Mesh Bag Sieve Bucket Vibrating Ring

SC Filtration - Agitatore Mesh Bag Sieve Bucket Vibrating Ring Vibrating ring for agitation of loose mesh sieves or screen bags installed over a bucket. Looking for an inexpensive yet effective way to automate your sieving? Look no further. Our stainless steel ring with an incorporated vibrator attaches to a bucket over your mesh bags. It will agitate your mesh screen bags more efficiently than handshaking, achieving better separation. Sort trichomes and other solids more efficiently than shaking by hand alone, with the use of this cost-effective mechanical vibrator. 5 Gallon Size: Fits Bucket Size: 5 GallonsRing Internal Diameter: 305 mm (12.0 Inches)Weight: 3.9 Pounds Specifications: Ring Material: 316L Stainless SteelGasket: FDA Compliant 21 CFR 177.2600, USP Class VIVoltage: 115 Volts, 60 Hz, 1-PhaseAmps: 0.48Standards: UL Recognized/CSA CertifiedForce: 8 Foot PoundsIncludes 9ft long 3 conductor cord set with In-Line On/Off Switch Warranty: 90 Days from the date of purchase. Notice: This item is not meant to replace a rotary vibrating sieve. For best results, bags should be stretched as tight as possible. Though it can be used on metal containers of the correct diameter, the transfer of energy may not be sufficient for your application.

$399.00

SC Filtration - FDA cGMP Filter Press 1 Cubic Foot

SC Filtration - FDA cGMP Filter Press 1 Cubic Foot Filter presses have become a crucial piece of equipment in many industries, providing a fast and efficient way to filter various solutions. They are used in the food, pharmaceutical, chemical, and mining industries, among others, to remove solids, separate liquids, and clarify solutions. In the botanical industry, filter presses are commonly used for the removal of lipids and polishing of oleoresin. With their ability to handle a variety of solutions, filter presses have become a versatile tool for any operation that requires filtration. Introducing our FDA cGMP-compliant filter press - the fastest and most convenient way to filter your solution. Our filter press is designed to remove lipids and polish up any oleoresin dissolved in a solvent, making it an essential step in your MIPs lab. Our filter presses are FDA-compliant and capable of filtering solvents at -40 Celsius, ensuring safe and efficient operation. Our unit is recommended for each batch every +/-2 hours and is capable of filtering 22 liters of lipids (fats, waxes), 44 liters of crude (@50% lipids), and 446 liters (118 gallons) of 10:1 mixture (solvent/crude). The recessed plate filter press allows you to customize the number of filter plates and filtration capacity of the unit, making it easy to expand your equipment as your operation grows. Our filter press features durable, specialty polypropylene filter plates and leak-free EDPM-gasketed polypropylene filter cloth. It also comes equipped with a manual hydraulic closure using vegetable oil fluid, a 304 stainless steel sanitary tri-clamp type feed manifold with an SS connection plate, and various manifold options, including precoat manifold, center feed, and air blowdown. Our filter press also features a 1" FDA-compliant 316SS dual diaphragm pump with Santoprene diaphragms, making it easy to regulate the speed of operation, and comes with an air bleed system that eliminates waste from soaked filter aides such as DE, clay, or carbon, ensuring quick and easy cleanup. In addition, our filter press is versatile and can filter solids (Carbon, clay, silica, plant particles), remove lipids, and clarify. It's fast filtering and filters under pressure for higher speeds without the danger of boiling solvent under a vacuum. Our filter press is made in the USA and includes everything you need to get started, including operating instructions and support. We also stock all consumables at reasonable prices, including plates sold separately to expand to 2 cu. ft., a CGR tool kit for cloth maintenance, Viton plate gaskets for cold temperature operations, a pre-coat tank stainless steel, a cake hopper on casters for cake disposal, and an air hydraulics upgrade from manual closure to pneumatic. Our filter press is the perfect solution for your filtration needs. Safe and easy to use, quick and easy to clean, it provides time, labor, and solvent savings, while ensuring fast and efficient filtering. FDA cGMP Winterization Process Capacity Example: 22 liters of lipids (fats, waxes) 44 liters of crude (@50% lipids) 446 liters (118 Gallons) of 10:1 Mixture (Solvent/Crude) Specifications: Plate Size: 470 x 470 mm Capacity: 1 cu. ft. Expandable to 2 cu. ft. (plates sold separately) Reduceable to 0.5 cu. ft. (backer plate sold separately) Filter Surface area: 24 sq. ft. (also expandable to 44 sq. ft.) Feed Pressure: 100 PSI Dimensions: 76”L x 29”W x 46”H Filter Plates: Durable, specialty polypropylene for low-temperature operation, EDPM gasketed. Filter Cloth: Leak Free, EDPM Gasketed Polypropylene Hydraulics Closure: Manual Hydraulic, Vegetable Oil Fluid Feed Manifold: 304 Stainless Steel Sanitary Tri-Clamp Type with SS connection plate. Manifold Options Included: Precoat Manifold Center Feed. Air Blowdown. Feed Pump*: 1” FDA Compliant 316SS Dual Diaphragm pump with Santoprene diaphragms. Area Classification: Class 1 Division 1 and 2 Compliant (C1D1 and C1D2) Benefits of this system: FDA cGMP Compliant Operate safely at -40 Celsius Labor savings. Solvent savings. Time savings. Safe and easy to use. Quick and easy to clean. We stock all consumables at reasonable prices. The multi-function unit can filter solids (Carbon, clay, silica, plant particles), remove lipids, and clarify. Fast filtering. Filters under pressure for higher speeds without danger of boiling solvent under vacuum. Made in the USA Basic Pricing: A) FDA cGMP 1 Cubic Foot Filter Press $28,000.00 B) Add extra plates to covert to 2 Cubic Feet $2,020.00 C) Add CGR Tool Kit for cloth maintenance $495.00 D) Add Viton Plate Gaskets for cold temperature operations. $550.00 E) Add Pre-Coat Tank Stainless Steel $7,320.00 F) Cake Hopper on Caster for Cake Disposal $2,450.00 G) Air Hydraulics: Upgrade from manual closure to Pneumatic $2,590.00 *Various pump materials are available. We manufacture our equipment in the USA by skilled craftsmen using American-made components. Manufacturing times vary. Shipping will be invoiced separately.

$28,000.00 - $38,440.00

SC Filtration - FDA cGMP Filter Press 0.3 Cubic Feet

SC Filtration - FDA cGMP Filter Press 0.3 Cubic Feet Filter presses have become a crucial piece of equipment in many industries, providing a fast and efficient way to filter various solutions. They are used in the food, pharmaceutical, chemical, and mining industries, among others, to remove solids, separate liquids, and clarify solutions. In the botanical industry, filter presses are commonly used for the removal of lipids and polishing of oleoresin. With their ability to handle a variety of solutions, filter presses have become a versatile tool for any operation that requires filtration. FDA cGMP (Current Good Manufacturing Practices) filter press for lipids removal and for polishing up any Oleoresin dissolved in a solvent. We only sell FDA Compliant filter presses capable of filtering solvents at -40 Celsius. There is no faster or more convenient way to filter your solution than a filter press. We recommend this unit per batch every +/-2 Hours: 6.5 liters of lipids (fats, waxes) 13 liters of crude (@50% lipids) 130 liters (34 Gallons) of 10:1 Mixture (Solvent/Crude) Specifications: Plate Size: 320 x 320 mm Capacity: 0.3 cu. ft. Filter Surface area: 8 sq. ft. Feed Pressure: 100 PSI Dimensions: 68”L x 34”W x 42”H Filter Plates: Durable, specialty polypropylene for low-temperature operation, EDPM gasketed. Filter Cloth: Leak Free, EDPM Gasketed Polypropylene Hydraulics Closure: Manual Hydraulic, Vegetable Oil Fluid Feed Manifold: 304 Stainless Steel Sanitary Tri-Clamp Type with SS connection plate. Manifold Options Included: Precoat Manifold Center Feed. Air Blowdown. Feed Pump*: 1” FDA Compliant 316SS Dual Diaphragm pump with Santoprene diaphragms. Area Classification: Class 1 Division 1 and 2 Compliant (C1D1 and C1D2) Benefits of this system: FDA cGMP Compliant Operate safely at -40 Celsius Labor savings. Solvent savings. Time savings. Safe and easy to use. Quick and easy to clean. We stock all consumables at reasonable prices. Multi-function unit can filter solids (Carbon, clay, silica, plant particles), remove lipids, and clarify. Fast filtering. Filters under pressure for higher speeds without danger of boiling solvent under vacuum. Made in the USA Add-On: A) Add CGR Tool Kit for cloth maintenance $495.00 B) Add Viton Plate Gaskets for cold temperature operations. C) Add Pre-Coat Tank $2,266.00 Startup, Support, Training per Day $1,950.00 plus travel expenses *Various pump materials are available. This machine is the critical step missing in your MIPs lab between your initial extraction (Ethanol, CO2, BHO) and your solvent recovery system. No more filtering by hand. Oleoresin must be dissolved in a solvent like ethanol, isopropanol, and methanol. We do not recommend pentane or hexane. The recessed plate filter press allows you to customize the number of filter plates and thus the filtration capacity of the unit. This versatility allows you to expand your equipment as your operation grows, but also to reduce the capacity when you need to process a small batch. We design our press with an air bleed system, so you can clear out all your solution from the press and filtration media so there is no waste from soaked filter aides such as DE, clay, or carbon or lots of solution in your pipes and plates. You must have a tank or barrel where your solution is stored, preferably agitated. The included pump will suck the solution from wherever you are storing it and run it through the filtration plates. We can provide an agitation tank for you if one is not available. Further clarification and decontamination are achieved by using a silica-based filter aide such as DE or Perlite to produce a tincture that is as clear as possible which has been scrubbed of dirt and debris, mold, and bacteria, most color from chlorophyll and other contaminants, heavy metals from fertilizers, and some chemicals from pesticides. It includes everything needed to get you going (you must supply compressed air), operating instructions, and support. All valves and plumbing are included, and we use sanitary Tri-Clamp fittings so this unit is easy to disassemble and clean. We know how nasty and sticky oleoresins are so this machine breaks down quickly so you can clean in compliance with FDA guidelines. The unit includes a diaphragm pump with Santoprene diaphragms inert to your solution and tough enough to last for months of service. The diaphragms will work hot or cold and can take large particles without getting clogged or damaged. Diaphragm pumps are easy to use and easy to regulate the speed they operate at, are easy to clean and disassemble, and are easy to repair with easy-to-source replacement parts. Air powers these pumps, thus eliminating the risk of an explosion caused by sparks in an electric motor. This unit uses one simple pump to power the filter press, send the solution to heating, centrifuge, or recirculate your tincture as it agitates in a tank with additives. Our pump does not have to be primed, so it can suck the solution and pump it to the press at high pressures. From the press, the filtered solution flows in a closed system to your next process such as solvent recovery. This unit will save you money the day you set it up. Labor savings alone pay for this machine. Because the unit is a closed-loop system, you will not lose solvent to evaporation during filtration. We manufacture our equipment in the USA by skilled craftsmen using American-made components. Manufacturing times vary. Shipping will be invoiced separately.

$23,075.00 - $25,341.00

SC Filtration - FDA cGMP Filter Press 5 Cubic Foot

SC Filtration - FDA cGMP Filter Press 5 Cubic Foot Filter presses have become a crucial piece of equipment in many industries, providing a fast and efficient way to filter various solutions. They are used in the food, pharmaceutical, chemical, and mining industries, among others, to remove solids, separate liquids, and clarify solutions. In the botanical industry, filter presses are commonly used for the removal of lipids and polishing of oleoresin. With their ability to handle a variety of solutions, filter presses have become a versatile tool for any operation that requires filtration. FDA cGMP (Current Good Manufacturing Practices) filter press for lipids removal and for polishing up any Oleoresin dissolved in a solvent. We only sell FDA Compliant filter presses capable of filtering solvents at -40 Celsius. There is no faster or more convenient way to filter your solution than a filter press. We recommend this unit per batch every +/-2 Hours: 116 liters of lipids (fats, waxes) 232 liters of crude (@50% lipids) 2,322 liters (614 Gallons) of 10:1 Mixture (Solvent/Crude) Specifications: Plate Size: 630 x 630 mm Capacity: 5 cu. ft. Expandable to 10 cu. ft. (plates sold separately) Reduceable to 2 cu. ft. (backer plate sold separately) Filter Surface area: 102 sq. ft. (also expandable to 204 sq. ft.) Feed Pressure: 100 PSI Dimensions: 141”L x 36”W x 52”H Filter Plates: Durable, specialty polypropylene for low-temperature operation, EDPM gasketed. Filter Cloth: Leak Free, EDPM Gasketed Polypropylene Hydraulics Closure: Air Operated Automatic, Vegetable Oil Fluid Feed Manifold: 304 Stainless Steel Sanitary Tri-Clamp Type with SS connection plate. Manifold Options Included: Precoat Manifold Center Feed. Air Blowdown. Feed Pump*: 1.5” FDA Compliant 316SS Dual Diaphragm pump with Santoprene diaphragms. Area Classification: Class 1 Division 1 and 2 Compliant (C1D1 and C1D2) Benefits of this system: FDA cGMP Compliant Operate safely at -40 Celsius Labor savings. Solvent savings. Time savings. Safe and easy to use. Quick and easy to clean. We stock all consumables at reasonable prices. Multi-function unit can filter solids (Carbon, clay, silica, plant particles), remove lipids, and clarify. Fast filtering. Filters under pressure for higher speeds without danger of boiling solvent under vacuum. Made in the USA Basic Pricing: A) FDA cGMP 5 Cubic Foot Filter Press $44,030.00 B) Add extra plates to covert to 10 Cubic Feet $6,120.00 C) Add Dumpster Bins for waste removal to $2,450.00 (2 Required) D) Add CGR Tool Kit for cloth maintenance $495.00 E) Add Viton Plate Gaskets for cold temperature operations. $1,430.00 (5 CuFt) F) Add Pre-Coat Tank Stainless Steel $8,750.00 G) Add Pre-Coat Tank PE (No pipes) $4,785.00 Startup, Support, Training per Day $1,950.00 plus travel expenses *Various pump materials are available. This machine is the critical step missing in your MIPs lab between your initial extraction (Ethanol, CO2, BHO) and your solvent recovery system. No more filtering by hand. Oleoresin must be dissolved in a solvent like ethanol, isopropanol, and methanol. We do not recommend pentane or hexane. The recessed plate filter press allows you to customize the number of filter plates and thus the filtration capacity of the unit. This versatility allows you to expand your equipment as your operation grows, but also to reduce the capacity when you need to process a small batch. We design our press with an air bleed system, so you can clear out all your solution from the press and filtration media so there is no waste from soaked filter aides such as DE, clay or carbon or lots of solution in your pipes and plates. You must have a tank or barrel where your solution is stored, preferably agitated. The included pump will suck the solution from wherever you are storing it and run it through the filtration plates. We can provide an agitation tank for you if one is not available. Further clarification and decontamination are achieved by using a silica-based filter aide such as DE or Perlite to produce a tincture that is as clear as possible which has been scrubbed of dirt and debris, mold, and bacteria, most color from chlorophyll and other contaminants, heavy metals from fertilizers, and some chemicals from pesticides. It includes everything needed to get you going (you must supply compressed air), operating instructions, and support. All valves and plumbing are included, and we use sanitary Tri-Clamp fittings so this unit is easy to disassemble and clean. We know how nasty and sticky oleoresins are so this machine breaks down quickly so you can clean in compliance with FDA guidelines. This unit will save you money the day you set it up. Labor savings alone pay for this machine. Because the unit is a closed-loop system, you will not lose solvent to evaporation during filtration. We manufacture our equipment in the USA by skilled craftsmen using American-made components. Manufacturing times vary. Shipping will be invoiced separately.

$28,000.00 - $42,180.00

SC Filtration - Solventless Mesclatore - Ice Water Extraction

SC Filtration - Solventless Mesclatore - Ice Water Extraction Our solventless solution is the perfect addition to any industrial lab looking to automate and expand their production capabilities. With swappable trolleys and a computer-controlled system that allows for customizable programs, you can easily adjust the level of agitation to suit your specific needs. Whether you're working with loose biomass or bagged material, our system is designed to gently extract trichomes from flowers and produce high-quality solventless ice water extracts. Our trolley system is mounted on casters and made with German polypropylene materials, making it easy to move around your lab and simple to clean and disassemble. It also features a removable lid and low-shear impeller to ensure efficient and gentle extraction. Plus, with an insulated design and no chiller required, you'll save on labor and ice usage. In addition to these features, our solventless solution also comes equipped with a trichome AODD transfer pump, motorized lift, and fast bagged clean-out system. The large filtering reservoir and programmable touchscreen controller make it easy to transfer and drain your extracts using either gravity or a pump. And with FDA food-grade polypropylene construction, you can be confident in the safety and quality of your end product. Made in Italy, this is the most cost-effective solution for medium and craft labs looking to increase their solventless extract production. Tank not included. Insulated trolleys are sold separately. Where it excels: Agitation of biomass to gently remove trichomes from flowers. Loose biomass or bagged. Perfect for medium and craft labs. Features: Insulated Trolley (Sold Separately) Removable Lid Low shear impeller Mounted on casters German Polypropylene Materials Trichome AODD Transfer Pump (Included) Motorized Lift Fast Bagged Clean-out System Advantages: Labor savings - one operator needed Easy to clean and disassemble Insulated – Low Ice Usage No Chiller Required Built with FDA Food Grade Polypropylene Large filtering reservoir Programmable Touch Screen Controller Gravity or Pump Drain/Transfer Made in Italy Optional Features: Additional Trichome Pumps Additional Trolleys Chiller & Heat Exchanger Trichome Filtration Ultrasonic Transducer Specifications: Model: SS 800 Tank Diameter: 32" Capacity: 100 Gallons Dimensions mm (LxWxH): 1630 x 1210 x 2340mm Weight: Kg. 350 Recommended Compressor: 5HP 17.9 CFM @ 100 PSI Compressed Air Pressure: From 25 to 100 PSI Compressed Air Pressure Consumption: 5.6-42.3 CFM Noise Level: 70 dB Electrical: 230V 60Hz 1 Phase Operating Temperature: 0 F to 160F Maximum Flow Rate: 29 GPM Fresh Frozen Wet Capacity per batch 20,000 Grams Ultrasonic Transducer not included. Trolley not included. Soaker lid not included.

$34,000.00

SC Filtration - Magna Agitatore Pro - Vibrating Screen System

SC Filtration - Magna Agitatore Pro - Vibrating Screen System Have a solventless extraction machine but no reliable sieve solution? Look no further than our Rotary Vibrating Screen system. Our sieve will help you optimize your trichome sieving needs and allow continuous extraction, improving quality and efficiency. Our sieving solution can be integrated into any extraction system, not just the Mesclatore.As always, our systems are easy to use, inexpensive to operate, and the least capital-intensive solutions at scale. Sieving System Only. Agitator not included.Where it excels: Screening Botanical Trichomes or any particle. Features: Multideck sieves. Screen sizes are customizable. Filter Trolley with Integrated Pump Hash Pump Advantages: Allows continuous operation, and eliminates the need to stop to filter. Improves product quality by preventing damage in agitation. Labor savings - one operator needed Easy to clean and disassemble Sort 5 particle sizes Large filtering capacity Optional Features: Electro Polished to ASTM B912 Mobile Trolley for Pump Pulsation Damper for Pump System Includes: Circular Vibrating Sieve Device 400mm Filter Trolley with integrated pump Trichome Pump 44 GPM Sanitary Pipes Not Included but Required: Air Compressor Flexible hoses to your process Connections to third party equipment Specifications: Sieve Diameter: 550mm Wetted Parts: 316L Not Wetted Parts: Painted Surface Finish: Mirror Polish <0.2 Ra Micron Casters + Silentblock Feet Quick Release Clamps 5 Separations (Mesh Sizes as per Customer) On/Off Switch 230/480V 3 Phase CE Certified (UL, CSA Available)(Monophase Available)

$31,700.00 - $38,075.00

SC Filtration - Magna Agitatore Standard - Vibrating Screen System

SC Filtration - Magna Agitatore Standard - Vibrating Screen System Have a solventless extraction machine but no reliable sieve solution? Look no further than our Rotary Vibrating Screen system. Our sieve will help you optimize your trichome sieving needs and allow continuous extraction, improving quality and efficiency. Our sieving solution can be integrated into any extraction system, not just the Mesclatore.As always, our systems are easy to use, inexpensive to operate, and the least capital-intensive solutions at scale. Sieving System Only. Agitator not included.Where it excels: Screening Botanical Trichomes or any particle. Features: Multideck sieves. Screen sizes are customizable. Filter Trolley with Integrated Pump Hash Pump Advantages: Allows continuous operation, and eliminates the need to stop to filter. Improves product quality by preventing damage in agitation. Labor savings - one operator needed Easy to clean and disassemble Sort 5 particle sizes Large filtering capacity Optional Features: Electro Polished to ASTM B912 Mobile Trolley for Pump Pulsation Damper for Pump System Includes: Circular Vibrating Sieve Device 400mm Filter Trolley with integrated pump Trichome Pump 44 GPM Sanitary Pipes Not Included but Required: Air Compressor Flexible hoses to your process Connections to third party equipment Specifications: Sieve Diameter: 550mm Wetted Parts: 304 AISI Not Wetted Parts: Painted Surface Finish: Mirror Polish <0.2 Ra Micron Silentblock Feet Standard Clamps 5 Separations (Mesh Sizes as per Customer) On/Off Switch 230/480V 3 Phase CE Certified (UL, CSA Available)(Monophase Available)

$25,550.00 - $31,925.00

SC Filtration Magna Agitatore Mini - Vibrating Screen System

SC Filtration Magna Agitatore Mini - Vibrating Screen System Have a solventless extraction machine but no reliable sieve solution? Look no further than our Rotary Vibrating Screen system. Our sieve will help you optimize your trichome sieving needs and allow continuous extraction, improving quality and efficiency. Our sieving solution can be integrated into any extraction system, not just the Mesclatore.As always, our systems are easy to use, inexpensive to operate, and the least capital-intensive solutions at scale. Sieving System Only. Agitator not included.Where it excels: Screening Botanical Trichomes or any particle. Features: Multideck sieves. Screen sizes are customizable. Filter Trolley with Integrated Pump Hash Pump Advantages: Allows continuous operation, and eliminates the need to stop to filter. Improves product quality by preventing damage in agitation. Labor savings - one operator needed Easy to clean and disassemble Sort 2 particle sizes Large filtering capacity Optional Features: Electro Polished to ASTM B912 Mobile Trolley for Pump Pulsation Damper for Pump System Includes: Circular Vibrating Sieve Device 400mm Filter Trolley with integrated pump Trichome Pump 44 GPM Sanitary Pipes Not Included but Required: Air Compressor Flexible hoses to your process Connections to third party equipment Specifications: Sieve Diameter: 550mm Wetted Parts: 304 AISI Not Wetted Parts: Painted Surface Finish: Mirror Polish <0.2 Ra Micron Casters for mobility Quick Release Clamps 2 Separations (Mesh Sizes as per Customer) On/Off Switch 230/480V 3 Phase CE Certified (UL, CSA Available)(Monophase Available)

$17,600.00 - $21,975.00

SC Filtration Depuratore Botanico R&D- Membrane Nano Filtration Solvent Recovery & Winterization System OSN

SC Filtration Depuratore Botanico R&D- Membrane Nano Filtration Solvent Recovery & Winterization System OSN Nano-filtration membrane system for non-thermal solvent recovery, winterization, color remediation, terpene isolation, and hundreds of other applications including the botanical industry. R&D Sized version for method development and membrane testing. Expect 1-2 liters of permeate per hour. 1/8th the size of a 2540 membrane which scales linearly. By testing your process with this system you can correctly extrapolate what size system is required for a full production version. Applications: Non-Thermal Solvent Recovery Winterization: Remove Lipids & Waxes Remove Gums and Phospholipids Remove Water Soluble compounds Remove Sugars Color Remediation Terpene Isolation Sugar Removal Features: 1812 Membrane Size, One housing. Maximum Flow Rate: 600 L/Hour Minimum Volume: 1 Liter Pressures up to 6.5MPa. Circulation Tank: 10 Liters All stainless steel construction. Integrated cleaning tank. Non Explosion Proof Design USA-made pump. Specification: Power: 110 Volts, 60 Hz 1.5KW

$17,000.00 - $22,000.00

CDA 12A w/ Toluene High Purity Extraction Solvent

CDA 12A w/ Toluene HAZMAT ITEMS ARE NON-REFUNDABLE. ALL SALES ARE FINAL (Note: Container style and color may vary) BVV's Ultra High Purity Toluene Denatured Ethanol (CDA 12A) is distinguished by its exceptional purity, Our CDA 12A formulation combines 95% Food Grade/USP/ACS 200 Proof Ethanol, derived from corn, with ~5% high-purity Toluene. Adhering to stringent industry standards, ensuring it meets the precise requirements of our customers, our Ultra High Purity Toluene Denatured Ethanol excels across diverse applications widely adopted as an effective botanical extraction solvent. Being that our Ultra High Purity Denatured Ethanol is made unfit for consumption when denatured with Toluene it is not subject to the Federal Excise Tax on alcohol saving you a huge cost without compromising on it suitability for top-tier extractions. Primarily utilized as pure ethanol in extraction processes, this solvent is favored for its cost-effectiveness and extraction efficiency. Reduce manufacturing costs and increase extraction efficiency with BVV's Ultra High Purity Toluene Denatured Ethanol. Disclaimer: Prices may vary due to market value and for orders of 4 totes or more and a tanker there could be up to a 2 week lead time. Call in for more accurate lead times. Spigots/Faucets are only compatible with 5 Gallon Plastic Jugs and must be purchased separately Trigger Sprayer is only compatible with 1QT and 1 Gallon sizes Key Features: Significantly Reduced Cost due to the absence of Federal Tax Produces Exceptional Quality Extractions Leaves No Residuals or Tastes Evaporates Completely in a Rotary Evaporator Specifications Vapor Pressure: 40.9mmHg at 20°C UN Numbe 1170 Density: 0.7905g/cm³ Specific Gravity 0.7905 Flash Point: 13.9°C (57°F) Boiling Point: 78.5°C (173°F) Melting Point: -90.0°C (-130°F) Chemical Formula: Ethanol C2H6ON-Heptane C7H16 CAS#(s) Ethanol 64-17-5N-Heptane142-82-5 Chemical Formula: Ethanol C2H6ON-Heptane C7H16 Molecular Weight: 72.1057 CAS Registry Number: Ethanol 64-17-5N-Heptane142-82-5 Appearance Colorless Liquid Odor: Mint or acetone-like Density 0.7905g/cm³ Boiling Point: 78.5c/173.3F Solubility in water: Miscible GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H319 GHS Precautionary Statements P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P370+P378, P403+P233, P403+P235, P405, P501 UN Identification Number: 1987 Proper Shipping Name: Alcohols Transport Hazard Class: 3 Packing Group: I DOT Placard: What is Denatured Ethanol? Denatured ethanol, also known as denatured alcohol, is ethanol (ethyl alcohol) that has been rendered unfit for human consumption by the addition of denaturants. Denaturants are typically chemicals that make the ethanol taste bad or have toxic effects, and they are added to discourage people from drinking the substance. The denaturation process is done to avoid the high taxes and regulations associated with beverage alcohol, as denatured ethanol is intended for industrial, pharmaceutical, or cosmetic uses rather than for consumption. Common denaturants include heptane, methanol, isopropyl alcohol, acetone, and other chemicals. Denatured ethanol is widely used in various industries, such as in the production of paints, solvents, cleaning products, and as a fuel for alcohol burners. Why is Ethanol Denatured? Ethanol is denatured, or rendered undrinkable, for several reasons: Tax Purposes: Denaturing ethanol allows for the imposition of lower taxes on industrial or non-beverage alcohol compared to potable alcohol. Governments often place higher excise taxes on alcohol intended for human consumption. Regulatory Compliance: Denaturing ethanol is a regulatory requirement to discourage the illegal diversion of tax-free industrial alcohol for beverage use. The addition of denaturants makes it unpalatable and unsafe for consumption. Public Safety: Making ethanol undrinkable helps prevent accidental or intentional ingestion of industrial alcohol, which can be toxic. Denaturing agents are chosen to deter people from attempting to use denatured alcohol as a substitute for beverage alcohol. Industrial Use: Denatured ethanol is widely used in various industries, including pharmaceuticals, cosmetics, and manufacturing. It serves as a solvent, fuel, or raw material in these applications. Common denaturants include substances like heptane, methanol, isopropanol, and various chemicals that make the alcohol unsuitable for human consumption while maintaining its usability in industrial processes. The specific denaturing formulations, such as CDA 12-A mentioned earlier, are defined by regulatory agencies to ensure compliance with safety and tax regulations. What is denatured ethanol used for? Denatured ethanol is used for various industrial and commercial purposes where the alcohol is needed for its properties but should not be consumed. Here are some common applications: Industrial Solvent: Denatured ethanol is widely used as a solvent in industries such as pharmaceuticals, cosmetics, and manufacturing. It is effective in dissolving a variety of substances. Cleaning Agent: Due to its solvent properties, denatured ethanol is used as a cleaning agent for surfaces, equipment, and machinery in industrial and commercial settings. Fuel Additive: Denatured ethanol is sometimes used as a fuel additive, especially in the blending of gasoline. It can improve combustion efficiency and reduce emissions. Paint and Coating Industry: It is used as a solvent in the formulation of paints, varnishes, and coatings. Pharmaceuticals: Denatured ethanol is used in the pharmaceutical industry for various purposes, including the extraction of medicinal compounds. Laboratory Use: In laboratories, denatured ethanol is often used for tasks like sterilization and as a solvent for experiments. Inks and Dyes: It is employed in the production of inks and dyes due to its ability to dissolve pigments. Adhesives and Sealants: Denatured ethanol is used in the formulation of adhesives and sealants. Window Cleaning: It is used in commercial window cleaning solutions. Automotive Industry: In the automotive industry, denatured ethanol is used for cleaning and degreasing. What can be used to denature ethanol? Here are examples of common Completely Denatured Alcohol (CDA) formulations used to denature ethanol: CDA 12-A To every 100 gallons of alcohol, add either: Five gallons of n-heptane or 5 gallons of toluene. CDA-19 To every 100 gallons of ethyl alcohol (not less than 160 proof), add: 4.0 gallons of either methyl isobutyl ketone, mixed isomers of nitro propane, or methyln-butyl ketone 1.0 gallon of either kerosene, deodorized kerosene, gasoline, unleaded gasoline, rubber hydrocarbon solvent, or heptane. CDA-20 To every 100 gallons of ethyl alcohol (not less than 195 proof), add a total of: 2.0 gallons of either unleaded gasoline, rubber hydrocarbon solvent, kerosene, or deodorized kerosene, or any combination of these. What does CDA mean? Completely Denatured Alcohol (CDA) is a type of denatured alcohol that has been rendered unfit for human consumption by the addition of denaturing agents. Denatured alcohol is ethanol (ethyl alcohol) that has been intentionally adulterated to make it toxic, foul-tasting, or otherwise undrinkable. This denaturing process is done to exempt the alcohol from excise duty and other taxes, as it's not intended for use in beverages. The denaturing agents used in CDA can vary, but they often include chemicals such as methanol, isopropanol, or other substances that make the alcohol unpalatable and potentially harmful if ingested. The specific formulation of denatured alcohol may be regulated by government authorities to ensure it meets safety standards and legal requirements. CDA is commonly used in industrial applications, as a solvent, fuel, or as a cleaning agent. It's important to note that due to the addition of denaturing agents, CDA should not be used for purposes that involve contact with the human body or ingestion. Safety precautions, including proper ventilation, should be followed when working with denatured alcohol. What is CDA 12A? CDA 12-A is a formulation specified by the Alcohol and Tobacco Tax and Trade Bureau (TTB) for Completely Denatured Alcohol (CDA). The formula is defined under §21.26 as Formula No. 12-A. The composition of CDA 12-A is as follows: For every 100 gallons of alcohol, add either: 5 gallons of n-heptane or 5 gallons of toluene. This denaturing process renders the ethanol unfit for consumption while meeting regulatory requirements for various industrial applications. CDA formulations, including CDA 12-A, are used to denature ethanol for purposes such as industrial solvents, cleaning agents, and manufacturing processes. Can you remove heptane from CDA 12A? When n-Heptane is added to ethanol it creates an azeotrope between the ethanol and n-heptane. An azeotrope is defined as a mixture of two liquids that have a constant boiling point and composition through distillation. This azeotrope results in the ethanol and n-heptane evaporating at the same temperature, making it extremely difficult to separate the two through distillation. While these azeotropic solvents are still easily recovered from a botanical extract at a relatively low boiling point around 78C/173F using a rotary evaporator or falling film evaporator, it is near impossible to separate the two via distillation. What is an Azeotrope? An azeotrope is a mixture characterized by having identical concentrations in both its vapor and liquid phases. This stands in contrast to ideal solutions, where one component is usually more volatile than the other, allowing for separation through distillation. When an azeotrope forms, the concentrations in both phases remain the same, hindering separation through traditional distillation methods. Azeotropes consist of a blend of at least two different liquids, and this mixture can exhibit either a higher or lower boiling point than either of its individual components. Azeotropes become relevant when certain liquid fractions resist alteration through distillation processes. In typical mixtures, components can be extracted using Fractional Distillation, a process involving repeated distillation stages. The more volatile component vaporizes and is collected separately, while the less volatile component remains in the distillation container, resulting in two distinct, pure solutions.

$24.00 - $2,050.00

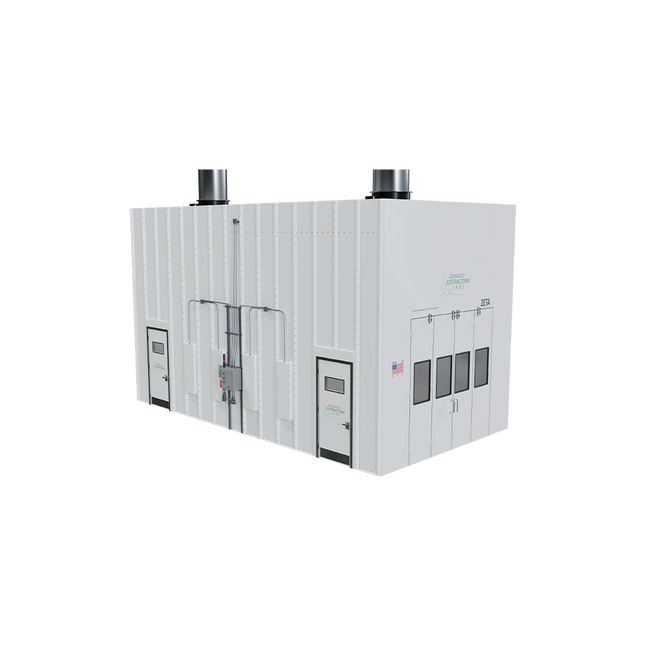

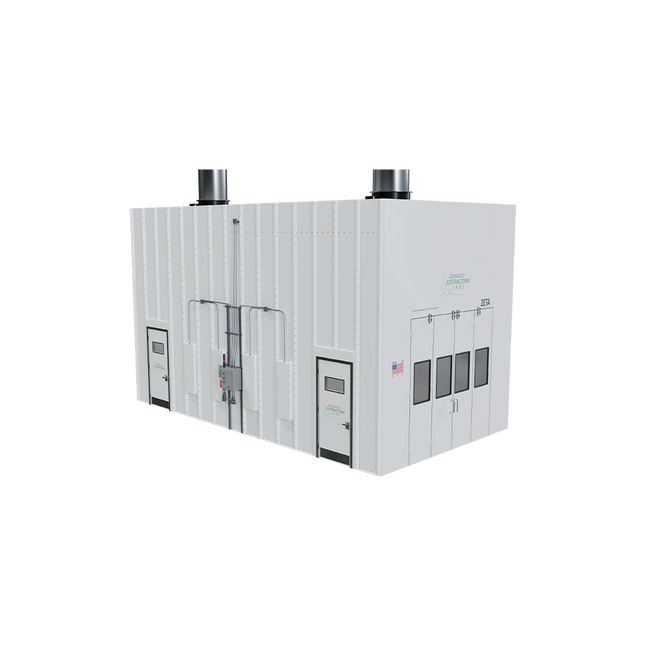

Advanced Extraction Labs ZETA Extra Large Series C1D1 Indoor Booth

Advanced Extraction Labs ZETA Extra Large Series C1D1 Indoor Booth Zeta Labs Indoor Booth Series Zeta advanced extraction labs are the largest size and are made to handle large extraction environments. Regarding big XL labs and extraction systems, the Zeta Series lab is up to the task. These units can be as large as you can imagine and come in many configurations. Like our other modular units, these units are expandable and can be made larger anytime. These labs come fully equipped and can be used for CBD, THC, and various other extraction types. ***Note: C1D2 option, Duct Package, Mechanical Installation, Fire suppression, and Electrical Installation available upon request.

$188,922.00 - $214,728.00

Advanced Extraction Labs EXXA Series C1D1 Indoor Booth

Advanced Extraction Labs EXXA Series C1D1 Indoor Booth Exxa Series Exxa Series is the perfect choice for labs with a high output. This Advanced Extraction Labs unit is made with accessibility and safety in mind. Our large front doors are ideal for moving equipment in and out of the c1d1 extraction booth. This lab is compatible with all extraction types and can be made into a dual-zone environment. This lab has all safety and gas detection systems and can be made in multiple configurations to best suit your needs. One of our larger extraction booths, our Exxa series is a C1D1 Extraction lab and can be used for CBD, THC, and various other extraction types. These labs are modular and can be expanded. ***Note: C1D2 option, Duct Package, Mechanical Installation, Fire suppression, and Electrical Installation available upon request.

$95,203.75 - $163,411.25

Advanced Extraction Labs DYS Economy Series C1D1 Indoor Booth

Advanced Extraction Labs DYS Economy Series C1D1 Indoor Booth DYS Series DYS Series advanced extraction labs are our most economical model, and they are made without compromising product quality. These C1D1 booth Labs come fully equipped with all necessary gas detection and safety features, high-efficiency filtration, and a variety of sizes. ***Note: C1D2 option, Duct Package, Mechanical Installation, Fire suppression, and Electrical Installation available upon request.

$38,340.00 - $62,250.00

Advanced Extraction Labs Mega Deluxe Series C1D1 Indoor Booth

Advanced Extraction Labs Mega Deluxe Series C1D1 Indoor Booth Mega Deluxe Series The Mega Deluxe series extraction lab is made for medium to large extraction environments. These labs are modular and can be disassembled and reassembled with ease. They are fully equipped and come with an optional permit package, too. ***Note: C1D2 option, Duct Package, Mechanical Installation, Fire suppression, and Electrical Installation available upon request.

$65,000.00 - $83,160.00

Advanced Extraction Labs Mega Economy Series C1D1 Indoor booth

Advanced Extraction Labs Mega Economy Series C1D1 Indoor booth Mega Economy Series The Mega Economy series advanced extraction labs are the only choice for an affordable, functional lab. This unit is turnkey and ready to go, equipped with everything you need, from safety features to gas detection. Labs can be configured to meet your needs! This booth is legitimate if you're just starting out in the Extraction business with C1D1. All the trimmings you're going to need at a one-time cost. You buy it; you start using it. We're experts at setting these up to meet your requirements. Call us, and we'll walk you through this from start to finish. ***Note: C1D2 option, Duct Package, Mechanical Installation, Fire suppression, and Electrical Installation available upon request.

$44,732.50 - $70,000.00

Advanced Extraction Labs Micro Series C1D1 Indoor Booth

Advanced Extraction Labs Micro Series C1D1 Indoor Booth Micro Series This advanced extraction labs is designed for small to medium-level extraction production businesses, the walk-in style for C1D1 indoor baths or C1D2 environments, for those using ethanol, post-extraction process, and various solvents. ***Note: C1D2 option, Duct Package, Mechanical Installation, Fire suppression, and Electrical Installation available upon request.

$33,562.50 - $42,940.80

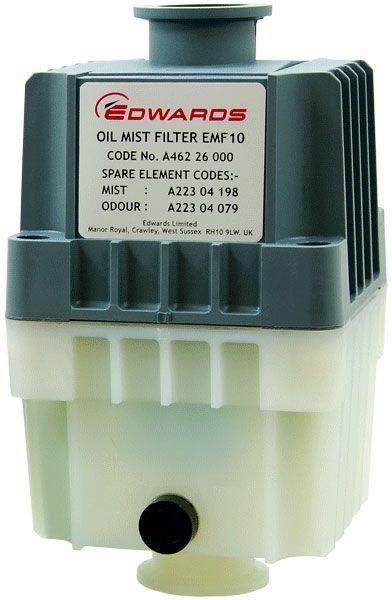

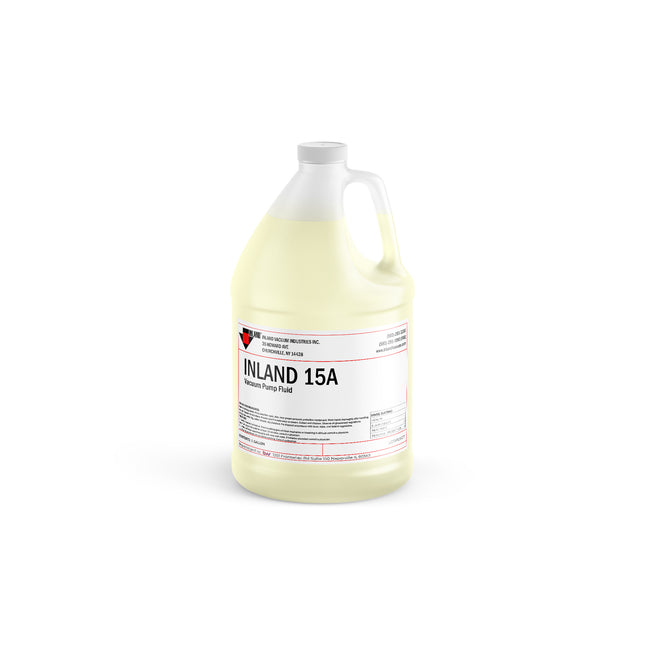

Inland 15A Vacuum Pump Oil

Inland 15A Vacuum Pump Oil Inland 15A Vacuum Pump Oil Safety Data Sheet SDS

$24.00 - $1,750.00

Inland 56 Vacuum Pump Oil (LVO 200)

Inland 56 Vacuum Pump Oil The Inland 56 is an equivalent to the Leybold LVO 200 oil. This oil can be used in pumps specifically designed for pumps that use the Leybold LVO 200 oil. Inland 56 Vacuum Pump Oil Safety Data Sheet SDS

$30.00 - $4,700.00

1/2" ID Blue Tubing 100'

Blue TubingUse our sturdy blue tubing, which is FDA-approved and BPA-free, for your irrigation systems and tanks, and to complete your own hydroponic systems. The material is Polyurethane which is easy to cut to size, but will remain strong and reliable. Keep a roll on hand for instant access to repairs. Extremely resistant to weathering, tearing, impact, radiation, and abrasion Transparent, flexible, resilient, tough Free of DEHP, phthalates, BPA and conflict minerals RoHS compliant Can be heat sealed, coiled, fabricated, or bonded Inside Diameter Outside Diameter .5" .64" 30 PSI max operating pressure at 70 degrees. *FDA approved and Food safe

$132.67

Gaia Green Power Bloom

Gaia Green Power BloomPower Bloom is a high phosphate fertilizer specifically formulated to support prolific flowering and fruiting. As a result, Power Bloom is our best fertilizer for root development and for all flowering and fruiting plants.Benefits: This complex, multi-ingredient blend contains high phosphorus and potassium levels suitable for a wide range of flowering and fruiting crops. Embodies the Gaia Green ethos of improving soil quality to support resilient plant growth and abundant, long-lasting blooms. Easy-to-use and long-lasting, this formulation combines ingredients with variable nutrient release rates to support high-yields. Available in granulated and non-granulated. Note: Granulated version is not approved for use in organic agriculture.

$10.51 - $94.07

55 gal Drum with Pre-Drilled Locking Lid

This high quality 55-gallon drum is black in color and comes with a pre-drilled solid cover and bolt ring closure. It is perfect for use as a reservoir for larger hydroponic systems. The pre-drilled holes can be used for the grommets and barbed fittings necessary to outfit the drum with tubing for filling and draining. A larger hole can also be cut in the cover to act as a port for adding nutrients, checking pH, etc. Features 55 gallon nominal capacity 57 gallon actual capacity 2.2 mm minimum wall thickness Weight: 25 3/4 lbs Height: 36 1/2" Top diameter: 23" Bottom diameter: 22 1/4" Food grade Made of high molecular weight HDPE

$163.99

Active Air CO2 System with Timer, 0.2-2 cu ft per hour

Deliver growth-boosting CO2 with our user-friendly, easy to operate system. With its programmable timer, it will automatically maintain ideal CO2 levels for optimum growth. For small to medium size areas, select the COSYS; for larger than 10' x 10' areas, select the COSYS20. To use Hydrofarm's CO2 Flow Rate Calculator, click HERE NOTE: Current COSYS & COSYS20 now come equipped with a black rubber O-ring that has replaced the white plastic washer.

$105.68

20' Mini 3P(M) to Mini 3P(F) WT data link cable, IP65, RF

20' Mini 3P(M) to Mini 3P(F) WT data link cable, IP65, RF. Intended to connect Autopilot PX2 controller to the first PHOTOBIO CX fixture. Does not interconnect PHOTOBIO CX fixtures

$13.62

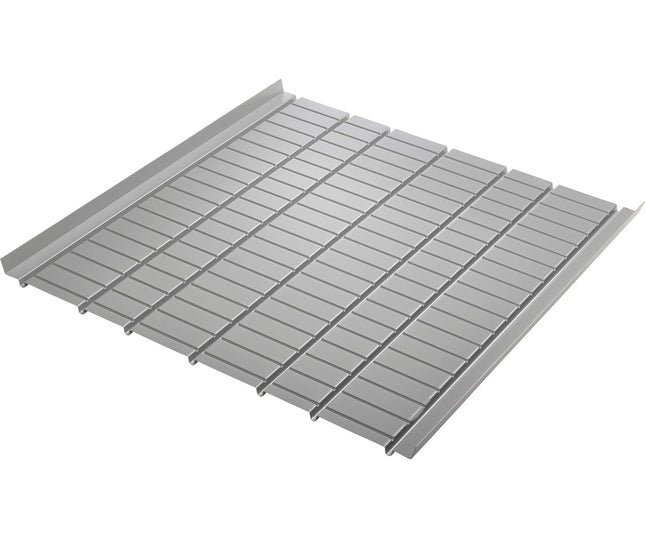

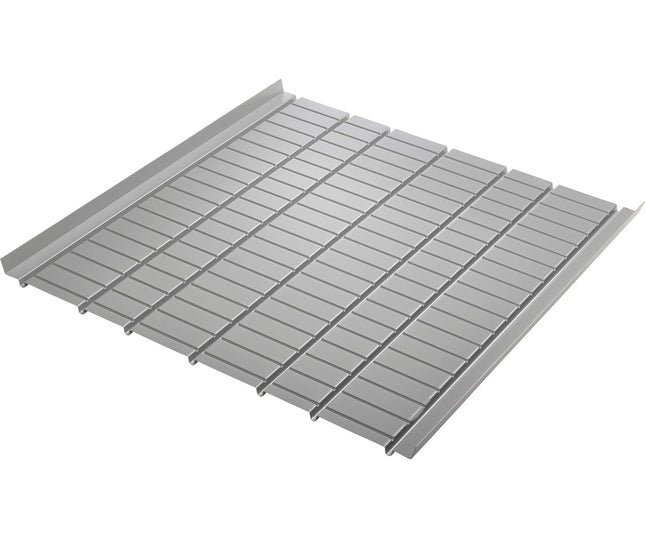

Active Aqua 2.0 Infinity Tray, 4' x 4' (Division Tray)

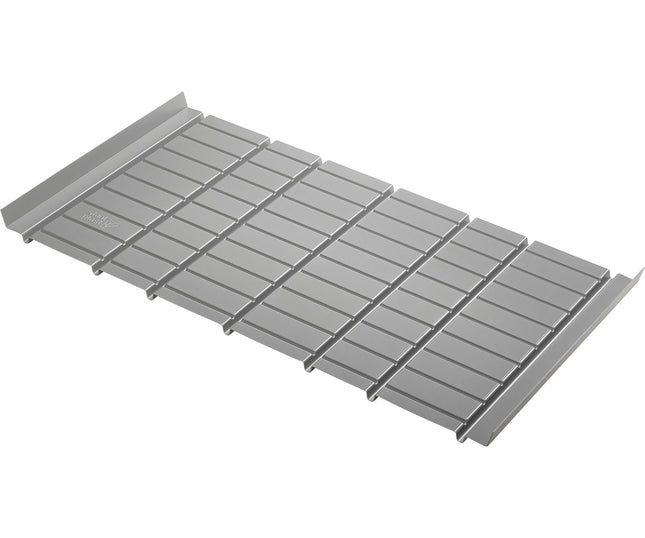

Active Aqua introduces the new and improved 2.0 Infinity Trays by Staal Plast — an array of premium UV-stable High Impact Polystyrene (HIPS) expandable trays that work with standard 4' wide and 5’ wide benches. Designed for commercial installations. After many years of continuous use, the trays are still 100% recyclable. The 2.0 Infinity Trays consists of End Trays, Middle Trays, and Division Trays which interlock to form 1 continuous grow tray maximizing your square footage. Each 2.0 Infinity Tray setup MUST include the following, in consecutive order: (1) End Tray w/Drain, (up to 7) Middle Trays, (1) Division Tray, and (1) End Tray. (1) End Tray w/Drain -6.5’ length (1-7) Middle Tray - 6.5' length (1) Division Tray - 4' or 2' length (1) End Tray - 6.5' length Staal Plast Polystyrene glue (STP3010 sold separately) is used to seal the trays together at each joint. *Download the 2.0 Infinity Tray Installation Guide for more details. Tray Info: Proudly made in the USA Low profile at 2.5-inch height Polystyrene glue seals trays together permanently at each joint, (STP3010 sold separately) No arch lip allows you to maximize your inner tray space Maximum tray length of 65' Division Trays can be cut to size (top of block only) to customize tray length Recyclable—made from UV-stable High Impact Polystyrene Shallow grooves for easy cleaning Recommended Use: Active Aqua IZON Rolling Bench Systems Active Aqua 4x8 Rolling Bench (AARBK48) IGE Benches Standard 4’ & 5’ wide benches

$108.52

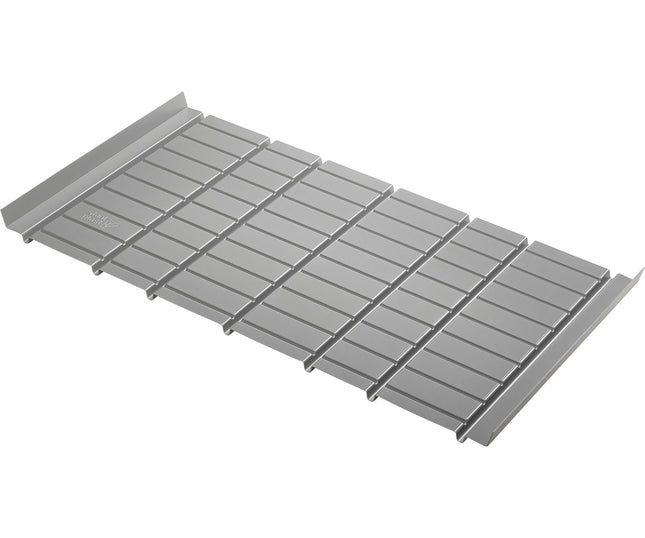

Active Aqua 2.0 Infinity Tray, 4' x 2' (Division Tray)

Active Aqua introduces the new and improved 2.0 Infinity Trays by Staal Plast — an array of premium UV-stable High Impact Polystyrene (HIPS) expandable trays that work with standard 4' wide and 5’ wide benches. Designed for commercial installations. After many years of continuous use, the trays are still 100% recyclable. The 2.0 Infinity Trays consists of End Trays, Middle Trays, and Division Trays which interlock to form 1 continuous grow tray maximizing your square footage. Each 2.0 Infinity Tray setup MUST include the following, in consecutive order: (1) End Tray w/Drain, (up to 7) Middle Trays, (1) Division Tray, and (1) End Tray. (1) End Tray w/Drain -6.5’ length (1-7) Middle Tray - 6.5' length (1) Division Tray - 4' or 2' length (1) End Tray - 6.5' length Staal Plast Polystyrene glue (STP3010 sold separately) is used to seal the trays together at each joint. *Download the 2.0 Infinity Tray Installation Guide for more details. Tray Info: Proudly made in the USA Low profile at 2.5-inch height Polystyrene glue seals trays together permanently at each joint, (STP3010 sold separately) No arch lip allows you to maximize your inner tray space Maximum tray length of 65' Division Trays can be cut to size (top of block only) to customize tray length Recyclable—made from UV-stable High Impact Polystyrene Shallow grooves for easy cleaning Recommended Use: Active Aqua IZON Rolling Bench Systems Active Aqua 4x8 Rolling Bench (AARBK48) IGE Benches Standard 4’ & 5’ wide benches

$72.39

Cutting Edge Solutions Louder Powder Grow A (15-0-0)

Cutting Edge Solutions – Mineral Family: Louder PowderLOUDER POWDER™GROW AThe Louder Powder Grow A is a granular nutrient blend formulated with calcium, magnesium, and nitrogen for the vegetative stage. The high quality chelates and precision blending of these nutrients make them readily available to the plant, and easily solubilized in water. In GROW A the calcium strengthens cell walls, the magnesium promotes synthesis of chlorophyll, and the nitrogen promotes vegetative plant growth. GROW A is compatible with all irrigation platforms including: Drip irrigation direct from reservoir mix. Recirculating hydroponic systems. Flood & Drain Recirculating Deep Water Culture Aeroponic NFT Injection from stock tank concentrate. Siphon Electric Diaphragm Pneumatic Hand mix tanks for traditional wand feeding. NOTE: For injection and reservoir mixes GROW A should always be mixed first.

$43.97 - $267.09

1" 304SS Butterfly Valve with 90 Spout

1" 304SS Butterfly Valve with 90 Spout 1" Triclamp butterfly valve with 90-degree spout. can be used as either a shutoff service, or for coarse flow discharge in several applications Trigger handle butterfly valves provide speed control through resistance and they offer more control than a 3-position pull handle butterfly valve. Material: 304 Stainless Steel Tri Clamp Size: 1 inch

$100.00

Barista Pro Stainless Steel Cream Whipper 1 liter & 1 Pint

The Barista Pro Stainless Steel whipped cream dispenser was meticulously crafted to cater to the needs of both baristas and devoted coffee connoisseurs. Made entirely from 304 grade stainless steel, including the head, this product offers the convenience of dishwasher safety. The stainless steel construction makes this whipper heavy duty around the kitchen. Efficient Operation: Utilizing 8gm and/or 16gm nitrous oxide chargers, it assures a sleek and speedy whipping encounter (16gm chargers require adaptor). Long-lasting Freshness: Store your whipped cream in the refrigerator, and it'll stay fresh and luscious for up to 14 days.

$55.00 - $65.00

White Kitchen Whip Aluminum Dispenser 1 Pint & 1 Liter

Crafted from stunning aluminum, our half-pint and 1 liter cream whipper by BestWhip ensures top-notch quality for those who seek to prepare smaller quantities of whipped cream. Don't be fooled by its size; this compact dispenser is a powerhouse in the kitchen, delivering flawless whipped cream consistently. Professional Grade: Engineered to meet the standards of culinary experts. Elegant Design: The plastic head complements the beautiful aluminum construction, adding an aesthetic appeal to your kitchen tools. Efficient Operation: Utilizing 8gm nitrous oxide chargers, it guarantees a smooth and quick whipping experience. Perfect Capacity: Holds 1 quart of liquid, making it suitable for intimate gatherings or individual servings. Long-lasting Freshness: Store your whipped cream in the refrigerator, and it'll stay fresh and luscious for up to 14 days.

$29.95 - $39.95

Model 200 | Laboratory-Grade Vacuum Gauge | Accuracy 0.001 to 6 Torr

Model 200 | Laboratory-Grade Vacuum Gauge | Accuracy 0.001 to 6 Tor DigiVac Model 200 is a laboratory-grade vacuum gauge. The industry’s best value for a rugged digital vacuum gauge for measuring through 6 decades of rough vacuum. Giving wide range accuracy. Laboratory-Grade Vacuum Gauge: The DigiVac Model 200 is housed in a laboratory grade case consisting of vinyl clad metal on an extruded aluminum base ensuring maximum durability This DigVac gauge comes with everything to measure vacuum: Display gauge, cables, power and Agilent 531 thermocouple sensor with NPT Every DigiVac Vacuum gauge is pre-tested and calibrated under actual vacuum against a NIST-standard Highly impact-resistant because of no moving parts requiring infrequent calibration Applications: laboratory, coating, metalizing, distillation, refrigeration, schlenk line vacuum measurement The Model 200 is also available with the DigiVac Thermocouple Plus sensor, which is electrically equivalent to the Agilent 531 at a more economical price point Upgrade to the Agilent 536 sensor series | a thermocouple gauge tube with integrated baffle. Made from welded 304 steel with equivalent accuracy of the 531 sensor but has an additional baffle that protects the thermocouple technology to greatly extend the sensor’s life when exposed to condensable gases This DigiVac gauge measures vacuum in Torr. Technical Specifications Total Range .001-760 Torr Range with Accuracy .001-6 Torr 0 – 0.009 Torr +/-0.002 Torr0.010 – 2.00 Torr +/-15% of reading2.0 – 5.0 Torr +/- 1 Torr5 – 760 Torr – Continuous and monotonic Sensor Type Agilent 531, Agilent 536, Thermocouple Plus Dimensions 1.5” h x 4.25” w x 5.5” d

$549.61 - $748.00

Bullseye Precision Gauge with Bluetooth | Wireless Vacuum Gauge NPT, KF25

Bullseye Precision Gauge with Bluetooth | Wireless Vacuum Gauge NPT, KF25 The DigiVac Bullseye Precision Gauge with Bluetooth is the world’s first wireless vacuum gauge featuring one-of-a-kind patented vacuum graphing and DigiVac’s ‘Vacuum Gauge’ app Versatile wireless vacuum gauge that you can monitor right from your phone or tablet (Apple ios and android) Enables remote monitoring and troubleshooting Set low and high alarm from your phone Email vacuum data to document leaks, baseline pressure or pump-downs Use battery power or standard microB-USB power Choose standard Thermocouple Plus sensor or the Upgraded Agilent 531 NPT sensor (this sensor configuration is CE and RoHs compliant), or the Agilent 536 NPT sensor which includes an integrated baffle to extend the life of the sensor by helping to protect it from contamination Portable and Precise Rugged thermocouple vacuum gauge ideal for understanding: Leaks, Pump Downs, Out-gassing or Stable Systems Includes a powerful magnet and kickstand to enable hands-free operation Long battery life and versatility with 12 different measuring units (micron, Torr, Inches of Hg, kPa, Inches of H20, millitorr, mbar, Pa, PSIA, mm of Hg, bar, and mm of H2O) Calibrated under actual vacuum against a NIST standard. Graphing and Analysis Patented vacuum graphing displays vacuum and time data Visual graphing right on the display that identifies current system status Vacuum Analytics to quickly identify vacuum pressure trends Graphical display for quick determination of vacuum level Bluetooth Bullseye Gauge Applications Vacuum pump testing Baseline vacuum pump performance Transformer dry-out Schlenk line monitoring Botanical oil processing Distillations Vacuum Process Monitoring Technical Specifications Units Torr, mbar, bar, kPa, inHg, mm Hg, millitorr, microns, inches of water, PSI, Pa Control Range 1E-4 – 1000 Torr Range with Accuracy .001-5 Torr Sensor Type Agilent 531 (NPT), Agilent 536 (NPT, KF15, or KF16), VGT500 Dimensions 6.2”H x 3.7”W x 1.3”D Certifications ROHS and CE

$735.00 - $845.62

Bullseye Precision Gauge-531 | with upgraded Agilent 531 Sensor

Bullseye Precision Gauge-531 | with upgraded Agilent 531 Sensor The Bullseye Precision Gauge-531 is the Bullseye Vacuum Gauge that you trust with the upgraded Agilent 531 sensor The Bullseye Precision Gauge-531 is a rugged and portable vacuum gauge, which features visual graphing to pinpoint problems in real time (leak, pump, outgas, stable). Includes a powerful magnet and kickstand to enable hands-free operation. Benefits of Choosing the Upgraded Agilent 531 sensor option: All metal, sturdy, structure Used in applications requiring higher levels of accuracy Vacuum Interface: 1/8″ NPT but can be easily adapted to KF Total Range: of 1 millitorr to 760 Torr (continuous and monotonic from atmosphere down to 6 Torr) Range with Accuracy: 10 millitorr (.001 Torr) to 6 Torr (1 x 10-3 mbar to to 7.99 mbar) 15% accuracy Electrically identical to Agilent 536 sensors Bullseye Precision Gauge-531 Features Portable and Precise Rugged thermocouple vacuum gauge ideal for understanding: Leaks, Pump Downs, Out-gassing or Stable Systems Includes a powerful magnet and kickstand to enable hands-free operation Long battery life and versatility with 12 different measuring units (micron, Torr, Inches of Hg, kPa, Inches of H20, millitorr, mbar, Pa, PSIA, mm of Hg, bar, and mm of H2O) Calibrated under actual vacuum against a NIST standard. Graphing and Analysis Patented vacuum graphing displays vacuum and time data Visual graphing right on the display that identifies current system status Vacuum Analytics to quickly identify vacuum pressure trends Graphical display for quick determination of vacuum level Bullseye Precision Gauge-531 Applications Vacuum pump testing Baseline vacuum pump performance Transformer dry-out Schlenk line monitoring Botanical oil processing Distillations Vacuum Process Monitorin Technical Specifications Units Torr, mbar, bar, kPa, inHg, mm Hg, millitorr, microns, inches of water, PSI, Pa 1E-4 – 1000 Torr Range with Accuracy .001-5 Torr Sensor Type Agilent 531 NPT Dimensions 6.2”H x 3.7”W x 1.3”D Certifications ROHS and CE

$640.62

Bullseye Precision Gauge with Agilent 536 KF25, NPT or KF16 Sensor | Vacuum Gauge for Processing

Bullseye Precision Gauge with Agilent 536 KF25, NPT or KF16 Sensor | Vacuum Gauge for Processin A rugged portable vacuum gauge for processing applications that pairs unparalleled vacuum measurement with the Agilent 536 sensor that has an integrated baffle which provides protection and helps reduce risk of sensor failure Numeric & Graphical Displays See vacuum readings in either numbers or easy-to-read graphs Has 12 measurement units for implementation in almost any vacuum application Torr, mbar, bar, kPa, inches of Hg, mm Hg, millitorr, microns, inches of water, PSI, Pa Calibrated & Precise Delivered pre-calibrated with Agilent/ Varian 536 thermocouple sensor under actual vacuum against the NIST standard. Note: NIST certification sent with the gauge is an available option here The 536 all stainless steel sensor with baffle has extended sensor life in the presence of condensable gases and improved performance at higher pressures Vacuum Interface: KF25 or NPT or KF16 Wetted materials: 304L Stainless steel, glass, Type P thermocouple Extended Battery Lifespan Portable | Solid state electronics built into a handheld gauge that operates using AA batteries that lasts up to 70 hours In-lab use | Power gauge using the integrated Micro-USB port for long-term use without the need to change batteries Ideal Vacuum Gauge for Processing Applications Laboratory, freeze drying, low pressure distillations, foreline monitoring, Schlenk lines performance, and transformer dry-out Or any application with higher levels of condensables where sensor failure is more likely Units Torr, mbar, kPa, millitorr, microns, Torr, mbar, bar, kPa, inches of Hg, mm Hg, millitorr, microns, inches of water, PSI, Pa 1E-4 – 1000 Torr Range with Accuracy .001 – 5 Torr Sensor Type Agilent 536-KF25 Dimensions 11 x 10 x 4 in Certifications CE, RoHS

$618.75 - $653.00

Lab Armor Peltier Bead Bath

Lab Armor Peltier Bead Bath Lab Armor revolutionizes the scientific bath industry with the Peltier Bead Bath! Utilizing Peltier Thermoelectric Cooler-Heater (TEC-H) technology, the Peltier Bead Bath is an all-in-one unit that efficiently controls the temperature in chilled and heated applications. The air jacketed design is exclusive to the Lab Armor Peltier Bead Bath, and it is the only bead bath on the market with both cooling and heating capabilities. The Peltier Bead Bath works with Beads to deliver exceptional temperature uniformity! The Lab Armor Peltier Bath securely holds lab vessels of various sizes in place. Samples may be conveniently transported using the removable Lab Armor Peltier Bead Baskets. The Bead Bath helps prevent the risk of sample contamination by removing water from many laboratory processes. These design features allow the Peltier Bead Bath to perform the role of multiple appliances, reducing benchtop space requirements.

$3,934.32 - $6,206.61

Lab Armor BEAD BATH

BEAD BATH Unique DESIGN Lab Armor Bead Baths were specifically designed to work with Lab Armor Beads to optimize their performance. Uniform Temperatures With Bead Bath designed expressly for beads, temperatures are consistent and uniform everywhere in the bath. Thermal uniformity is +/-1.0 at 37ºC. Always On The bath always stays on, so you don’t have to plan around warmup times. You don’t need to worry about refilling or low water burnout because there is no water to evaporate. Lab Armor Bead Baths are up to 50% more energy efficient than a standard lab water bath. Stays Clean Lab Armor reduces the risk of contamination. Contaminated samples and reagents result in distorted data and unpredictable outcomes. Stays Organized Unlike water baths that require racks, floats, and bottleneck weights, Bead Bath naturally holds things in place without accessories. So no more floating accidents.

$1,428.95 - $2,813.02

Lab Armor Beads

Lab Armor Beads Modern Upgrade Lab Armor Beads are dry metallic beads that replace water/ice/oil/sand in baths, giving old equipment a cool, shiny, state-of-the-art upgrade. Stays clean Lab Armor eliminates water bath contamination, harmful germicides, and unpleasant maintenance. Beads are dry and naturally more resistant to microbial growth than water, and therefore, are less likely to harbor and contribute to transmitting microorganisms in the laboratory. Saves time & Money Lab Armor Beads will help you save time and money. No more hassling with emptying, cleaning, and refilling water baths. Always On The bath stays on so there is no need to plan around warm-up times. Lab Armor Beads eliminate the worry about low water burnout because there is no water to evaporate. Other benefits of using Lab Armor Beads: Cleaner working environment. Greater organization capabilities as samples are held in place. Environmentally friendly. Temperature range -80°C to 180°C. High thermal conductivity. Non-toxic, non-vaporizing, antimicrobial No daily requirement for biocides, germicides, and other cleaners. No gray water. Smooth rounded shape allows fluidity and will conform to many sizes and shapes of vessels. No Racks, floats or weights required to hold items in place. Recyclable.* Weight 4 Lbs. (1.81 kg) per Liter.

$214.49 - $857.93

Quick Sift - Commercial Sifting Machine - Automatic Sifter

Quick Sift - Commercial Sifting Machine - Automatic Sifter Sifting your plant material is an excellent way to remove stems automatically. This commercial sifting machine was explicitly designed with processors in mind - the stainless steel construction and screens ensure you can easily clean our sifter, and the screen sizes are fine-tuned for the most common sifting needs. The commercial grade sifter offers a larger diameter, coming in at 16 inches, compared to the 13.74 inches of the original starter sifter - this means you'll be able to sift more plants in one sitting! Once you've ground your plant material, you only need to pour it into the sifter and switch it on. You can now walk away and wait for your plants to be automatically sifted - no more standing around doing manual sifting. Sifting your biomass will not only ensure no stems make it into your final product but will also ensure nothing else makes it into your product, like large leaves, gravel, or any other foreign matter. Additionally, consistent grinding will make your product burn more evenly and pack more evenly in any cone-filling machine. Plant Material Specific Sifter The commercial sifter was explicitly designed for plant material processors. From its stainless steel construction to multiple screen sizes, our team of Experts is confident this sifter or our other larger sizes will be the perfect addition to your product production process. We offer multiple screen sizes, allowing you to customize the particle size for the plant material in your product. Depending on the strain or weight of the product you are making, you may want to experiment with various screen sizes. Multiple Screen Sizes When it comes to sifting your plant material, you will want to have an ideal particle size for your plant material in mind. If you are still determining what size screen you need, our team of Experts is here to help! Depending on your strain and grinder, your ground biomass will have a different consistency. Additionally, depending on the size of the cone you are using and your desired fill weight, the particle size of your plant material will play a significant role. For example, a smaller particle size will allow you to pack more plant material into a small cone, but a particle size that is too small may lead to a poor, uneven burn. Machine Starter Kits The QuickSift Pro pairs perfectly with our industrial plant material grinder and cone-filling machines. Although our industrial grinder will grind stems to a small enough size, some brands want to sift all the stems out. The larger grind screen can be used to ensure stems stay big enough to be sifted completely out and then the rest of the material is ground. Processors have great success sifting their plant material post harvest, due to the larger amount of stems and leaves. Specifications PURPOSE: Sifting Ground plant materialCONSTRUCTION: Stainless SteelSCREEN DIAMETER: 16 inchesMACHINE TYPE: SifterPOWER REQUIREMENT: 120vRATED VOLTAGE: 110VRATED FREQUENCY: 60HzRATED POWER: 50W

$1,649.00

Quick Sift Mini - Sifting Machine - Automatic Sifter

Quick Sift Mini - Sifting Machine - Automatic Sifter Sifting your plant material is a great way to remove stems automatically, and if you are producing a premium product, it is always best to sift out any stems! Our QuickSift was explicitly designed with plant material processors in mind - the stainless steel construction and screens ensure you can easily clean our sifter and the screen sizes are fine tuned for the most common sifting needs. Once you've ground your plant material, you only need to pour it into the sifter and switch it on. You can now walk away and wait for your plant material to be automatically sifted - no more standing around doing manual sifting. Sifting your plant material properly will not only ensure no stems make it into your product but will also ensure nothing else makes it into your products, like large leaves, gravel, or any other foreign matter. The Consistent grind will make your products burn more evenly and pack more evenly in any cone-filling machine. Plant Material Specific Sifter Our QuickSift was explicitly designed for plant material processors. From its stainless steel construction to multiple screen sizes, our team of Experts is confident this sifter or our other larger sizes will be the perfect addition to your product production process. We offer multiple screen sizes, allowing you to customize the particle size for the plant material in your product. Depending on the strain or weight of the product you are making, you may want to experiment with various screen sizes. Multiple Screen Sizes When it comes to sifting your plant material, you will want to have an ideal particle size for your plant material in mind. If you are still determining what size screen you need, our team of Experts is here to help! Depending on your strain and grinder, your ground plant material will have a different consistency. Additionally, depending on the size of the cone you are using and your desired fill weight, the particle size of your plant material will play a significant role. For example, a smaller particle size will allow you to pack more plant material into a small cone, but a particle size that is too small may lead to a poor, uneven burn. Machine Starter Kits Our QuickSift pairs perfectly with our industrial plant material grinder and cone-filling machines. Although our industrial grinder will grind stems to a small enough size, some brands want to sift all the stems out. The larger grind screen can ensure stems stay big enough to be sifted entirely out and the rest of the material is ground. Processors have great success sifting their post-harvest due to the larger amount of stems and leaves.

$699.00

Cascade CVO-10 Vacuum Oven

Cascade CVO-10 Vacuum Oven High production, large vacuum drying system for vacuum purging production quantities, the Cascade CVO-10 is our largest 10 cubic foot vacuum oven. Model CVO-10 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, and slurries – especially temperature sensitive material. This vacuum oven liberates solvents, water, and other unwanted compounds in large batch production environments. Note that this is a 220V vacuum oven. The Cascade Difference Vacuum ovens have been around for decades. Basic vacuum ovens are mass-produced and sold by many large-scale laboratory equipment distributors. But there are key differences between and other inexpensive, often imported vacuum ovens. Exceptional Temperature Control & StabilityThe CVO-10 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-10 eliminate hot and cold spots, making accurate use of every inch of shelf space. Independent Overtemp Failsafe ProtectionThe CVO-10 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 392°F or 200°C. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. Digital Vacuum GaugeThe digital vacuum gauge installed on the CVO-10 is selectable between inches of mercury (“Hg) or torr, mtorr. Equipped for Inert Gas Backfill. Built-In Safety ReliefIntroduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the ¼” rear vent barb. The maximum backfill pressure is 15PSI. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection PortsFor faster evaporation, purging or drying the CVO-10 includes MAX EVAP connection kit. The MAX EVAP connection kit secures to the oven’s rear 1” dia KF-25 port located on the back center of the chamber. The MAX EVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthrus, or monitoring sensors inside the vacuum chamber during processing. Ergonomically Designed, Easy Quarter-Turn ValvesFor anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vent valve. Your wrists will thank you! Faster Venting With Large ½” Diameter Vent LinesFor large capacity production environments, time is money. The CVO-10 vacuum oven has larger than industry standard vent lines. ½” diameter vent lines means operators spend less time venting the oven. Features CVO-10 PRO Package Includes: Cascade Sciences CVO-10 Vacuum Oven Heavy-Duty Industrial Mobile Cart 9x Total Shelves – 28”W x 24”D MAXEVAP KF-25 Connection for faster purge Agilent IDP15 Oil-Free Vacuum Pump, 9cfm Features: NRTL Certified by TUV 9 sliding, removable shelves that pull out and stay in place for easy load/unload Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Easy mobility as oven sits on heavy duty industrial cart. Pump sits underneath at base of cart Silicone Door Gasket Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reads in inches of mercury or torr Smooth, quarter-turn vent valve Oven to pump connection: Rear KF-25 line, valve 220V / 1ph / 10AMPS plugs into NEMA 16-5R outlet Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Ergonomic. Turn vacuum pump on/off from oven control panel Fast Venting with larger ½” diameter vent line. Allows for nitrogen or other inert gas connection Touch Panel LED control screen with user settable features (torr, mtorr, Hg, Fahrenheit, Celsius) Walls lined with heat conductive copper for improved temp transfer. Known antimicrobial properties can prevent bacteria buildup Specifications VOLUME:9.3 Cubic Ft. (263 Liters) SHELVES:9 total (max), removableFull-extension, stay in placeIntegrated copper strips optimize temp transferSurface area: 28″W x 24″DWeight Capacity Per Shelf: 50 lb / 22.7 kgApprox 930 cubic inches of volume OVEN INTERIOR:28”W x 24”D x 24”H711mm x 609mm x 609mm OVEN EXTERIOR:(not including rack)42” W x 40” D x 67.4”H1067mm x 1021mm x 1712mm WEIGHT:Shipping: 775 lb/ 352 kgNet Weight: 663.0 lb/ 301 kg TEMPERATURE RANGE:Ambient +26° to 302°F / Ambient +14.4°C to 150°C TEMPERATURE UNIFORMITY:@ 105°F +/- 0.2°F – ±2.0°F@ 200°F +/-0.4°F – ±5.5°F@ 300°F +/- 0.2°F – ±8.0°F @40°C +/- 2°C – ±1.0°C@90°C +/- 3°C – ±3.0°C@150°C +/- 4.5°C – ±4.5°C TEMPERATURE STABILITY:@ 105°F +/- 0.2°F – ±0.2°F@ 200°F +/-0.4°F – ±0.4°F@ 302°F +/- 0.2°F – ±0.2°F @40°C +/- 0.1°C – ±0.1°C@93.3°C +/- 0.2°C – ±0.2°C@150°C +/- 0.1°C – ±0.1°C HEAT UP TIME FROM AMBIENT:@ 105°F / 40.5°C – 42 min@ 200°F / 93.3°C – 94 min@ 302°F / 150°C – 175 min COOL DOWN TIMES:@ 105°F / 40.5°C – 330 min@ 200°F / 93.3°C – 94 min@ 302°F / 150°C – 420 min *Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product. VACUUM VALVE:Side Mounted Round VENT VALVE:¼ Turn Lever½” diameter line GLASS WINDOW:Tempered NGI-US to ANSI Z97.1.2007Interior lighting VACUUM GAUGE:Reads in inches mercury or torr(Selectable) CONTROLLER:Touch ScreenAccurate Within 1°FIndependent Overtemp Failsafe PORTS (REAR):Vacuum = KF-25 PortVent = 1/2” Barb INERT GAS INTRODUCTION:Yes. Via 1/2” Vent Barb15 psi max inlet pressure POWER:220V – 240V / 1ph / 10A 50/60HzCord IncludedNEMA 6-15R Power Outlet(System will run on 208V)Oven BTU Rating at 250ºF: 6980 BTUs/hr at full capacity

$24,997.00 - $31,799.00

Cascade CVO-2 Vacuum Oven