Non BVV product for sale

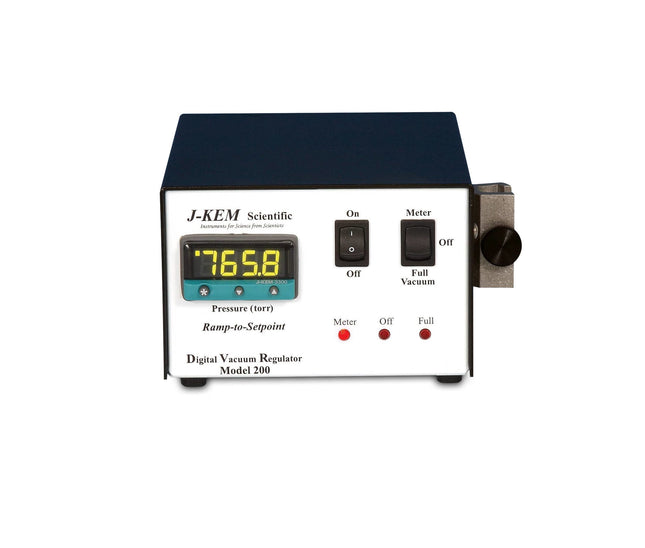

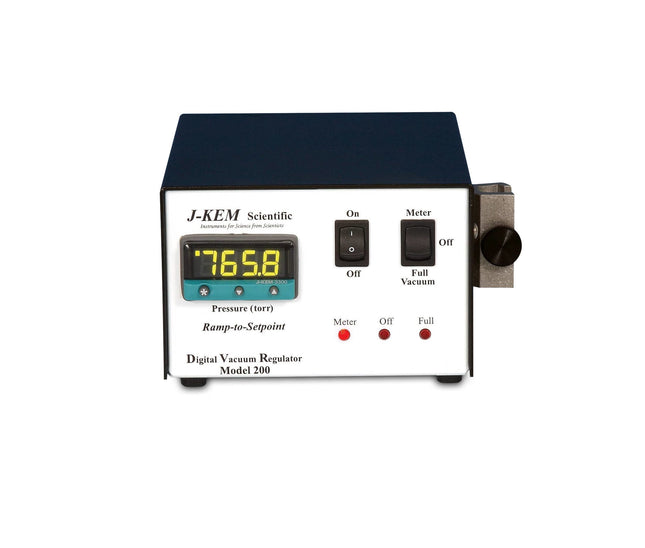

J-KEM DVR-200-EV Digital Vacuum Regulator

J-KEM DVR-200-EV Digital Vacuum Regulator The DVR-200-EV has the same stainless steel pressure transducer inside, but the vacuum valve is outside of the controller. The value of this design is that the vacuum valve can be cleaned or replaced much easier than the valve in the classic DVR-200. Some applications, like distillations or stripping large volumes of solvent, can leave residues inside the valve which causes it to fail. Replacing the vacuum valve is the most frequent repair that J-KEM performs on the DVR-200. Replacing the valve in the classic DVR-200 is difficult and must be returned to J-KEM for repair. With the EV version, the user can disassembled the valve and wash it out, or even replace it in under 5 minutes. For large distillations or botanical applications, J-KEM recommends the DVR-200-EV. No Mercury 100% digital pressure entry and control Wetted parts are 100% stainless steel and Teflon Vacuum ramping feature eliminates bumping Resists: All organic solvents Acids Bases Water Specifications: 100 watts. Vacuum fittings: 1/8″ NPTM. Warranty: Electronics 2 Years, Vacuum Valve 6 months (void if damaged by chemical buildup)

$1,665.00

Glass Vac 2 Gallon Aluminum Vacuum Chamber and Vacuum Pump Kit

Glass Vac 2 Gallon Aluminum Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Glass Vac 2 Gallon Aluminum Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 6.5" Tall x 10" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BVV chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. GlassVac chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$298.00 - $453.00

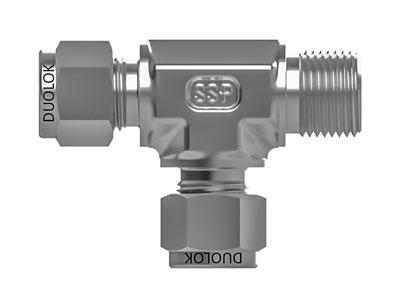

Union Cross

SSP - Union Cross SSP Instrumentation Duolok® tube fittings are designed, manufactured and quality controlled to be totally “interchangeable” with the Swagelok® brand of tube fittings. Component by component examination plainly shows the two brands as completely “componentintermixable.” The precision manufacturing of both products to stringent tolerances under rigid quality control procedures ensures the safety, performance, and reliability of service whenever Duolok® and Swagelok® component parts are mixed and used in accordance with published installation and service recommendations. Specifications Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Duolok Pressure Rating = Tubing Rating SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$20.00 - $27.00

Media Bros CRY™ MEDIUM FLOW

CRY™ MEDIUM FLOW (CRY-M™) FILTER MEDIA FOR BHO EXTRACTION (NON-REACTIVE) This medium flow non-reactive variant of CRY allows operators to increase operating pressures and surface area for a more fine-tuned process. PH 7 DESCRIPTION CRY™ Medium Flow (CRY-M™) is a finer version of CRY™ designed for systems operating at slightly higher PSIs that still need non-reactive high flow outputs and a little extra selectivity. It is not quite powder, but a much finer grain than CRY. The smaller granule size helps prevent channeling that can sometimes occur at higher PSIs. We recommend CRY-M™ for operators who want the same effect as CRY™ but are running at higher pressures or systems with size limitations. For extracts that require additional remediation beyond CRX-M™, CRY-M™ offers a superior polish, effectively addressing color, fats, and lipids. Opt for CRY-M when aiming for effortlessly reproducible results with older biomass. Suggested use: 150–250g per lb. of biomass Packaged in: 1.5 kg pouch, 5 gallon bucket, and 100 kg drum TECHNICAL SPECS Solvent Type Hydrocarbon Color Remediation Level Moderately Heavy/High Pesticide Remediation Level Medium Selectivity/Polarity Level Moderately Selective/Medium Polarity Heavy Metal Remediation Yes Moisture Remediation Level Moderate Fats/Lipids/Waxes Level Medium Crystal Growth Fast Depth Filtration No Flow Rate Moderate Flow pH Level Neutral (pH 7) Best For Slightly Aged Biomass, Medium Quality Suitable for Reruns Yes Distillation Clean-up Moderate Scrub SDS

$30.00 - $1,600.00

CHEMTEK W4 Pesticide Remediation Bleaching Clay

CHEMTEK W4 Pesticide Remediation Bleaching Clay W4 is an alkaline bleaching clay specialized for the removal of pesticides, chlorophyll, free fatty acids, and oxidized compounds. It removes pesticides through adsorption and hydrolysis. Pesticides undergo alkaline hydrolysis, in which a pH greater than 7 causes chemical degradation of certain pesticides in the presence of ions. W4 SDS W4 Technical Data Sheet

$50.00 - $2,250.00

The Press Club 4" x 7" ROSIN BAGS

4" x 7" ROSIN BAGS The Press Club brings science to the art of rosin pressing. We pride ourselves in making the toughest and strongest rosin bags on the market. After years of research and lab testing, all our rosin bags are now made with our proprietary pink stitch and come with a ZERO BLOWOUT GUARANTEE™. If you ever get one, we'll replace the bag. It's that simple. Available in 25, 37, 50, 75, 90, 120, 160 and 220 micron. 4” x 7” Inch 25-Pack Pre-Flipped Inside-Out 100% Food-Grade Nylon Solvent & Boil Resistant High Pressure Resistance (Over 20 Tons) High Heat Resistance (Up To 375° F) Reusable Over 5x (Simply Wash With Alcohol) Covered By The Press Club’s Zero Blowout Guarantee Satisfaction Guarantee & 365-Day Return Policy Made In USA General Micron Guideline: Dry Sift & Bubble (5, 10, 15, 25, 37, 50) | Flower (75, 90, 120, 160, 220)

$29.95

10 Gallon All-Mesh Bubble Wash Bags

10 Gallon All-Mesh Bubble Wash Bags The Press Club Wash Bags are the last set of bubble wash bags you'll ever own! Made from premium, food-grade material specifically for washing you can stop second guessing whether you have the right or best bags in the industry. All Press Club bubble wash bags are hand sewn with our proprietary pink stitching, making them 2x stronger than competitors. You can be confident The Press Club bags will perform the same no matter if it's your 1st or 1000th wash. The Press Club is so confident their bubble wash bags will stand the test of time, every bag comes with a Lifetime Warranty. If you have any manufacturer issues, they will be more than happy to replace the bag for you! KEY FEATURES Fits All Standard 10 Gallon Buckets Hand Sewn With Our Proprietary Pink Stitch w/ Food-Grade Materials Military-Grade Waterproof & No Flaking Bag Liner Premium Drawstring & Cord Locks To Secure Bags Lifetime Warranty On All Wash Bags Includes Meshed Carrying Case For 2-Way Drying & Storage Made In USA AVAILABLE MICRONS 220 Micron (Work Bag), 190 Micron, 160 Micron, 120 Micron, 90 Micron, 73 Micron, 45 Micron, 25 Micron

$44.95

True Terpenes Cherry Pie

True Terpenes Cherry Pie Fragrance: Sweet Dank Earthy Sour Effects: Happy Creative Uplifting A hybrid of Durban Poison and Granddaddy Purple, this earthy berry blend is sweet and sour. Within minutes, it gives feelings of happiness, creativity and is uplifting. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution. Cherry Pie-Specific Certificates: Product Specification Certificate of Analysis Safety Data Sheet Food Safety Company-Specific Certificates: ISO 9001:2015 GMP Certification FSSC 22000

$121.50 - $2,250.00

5L Neocision Short Path Distillation Turnkey Kit

5L Neocision Short Path Distillation Turnkey Kit This unit carries a 2 day lead time. The 5L Premium Distillation Turnkey Setup features our 5L Distillation Kit with P5 Distillation Head and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included is our Pro Series Corrosion Resistant Two Stage Vacuum Pump giving you extreme power and depth with a long lifespan, the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market, and a BVV 19L Heated Circulator for maximum condensation of vapors. You will also receive a Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The Premium Turnkey Kit Includes: 5L Neocision Kit with P5 Distillation Head KF-25 x 1/4" Barb Adapter Dewar Style Glass Cold Trap Bullseye Precision Vacuum Gauge BVV 19L MX Heated Circulator Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$10,500.00 - $14,750.00

Julabo C2 Thermal Bath Fluid - 10 Liters

Julabo C2 Thermal Bath Fluid JULABO Thermal bath fluids are ideally suited for all of your temperature control applications and guarantee safe and reliable operation. Choosing the proper bath fluid is critical for best results in temperature control. Viscosity, oxidation characteristics and heat transfer of Thermal fluids are specifically matched with each JULABO temperature control unit. C2 Thermal Bath Fluid Product Data Sheet C2 Thermal Bath Fluid SDS JULABO Thermal bath fluids have been carefully selected and are optimized for maximum performance with JULABO instruments. Benefits Low toxicity Low viscosity High stability Minimum odor Good heat conductivity Low corrosion tendency Wide temperature ranges Technical Data Order no. 10 liters 8891400 Working temperature (°C) -90...+60 Flash point (°C) > +75 Fire point (°C) > +430 Viscosity (kinematic at 20 °C in mm²/s) 2 Density (at 20 °C in g/cm³) 0.873 Pour point (°C) -120 Boiling point (°C) 229 Ignition temperature (°C) 430 Color clear

$1,668.00

ChemTek Small Fuge Bags - 50 Pack

ChemTek Small Fuge Bags - 50 Pack Centrifuge bags used for separations. Specifications: Size: 50-Pack Dimensions: H: 4” W: 2.5” Micron Size: 25 Microns Material: Food Grade Nylon

$28.00

Carbon Chemistry APG Granular (ZeoClear L)

Carbon Chemistry APG Granular (ZeoClear L) An acidic powder media designed for powerful polar adsorption and separation processes. This finely-milled activated alumina provides superior removal of basic compounds and color bodies, making it ideal for precise purification and filtration applications. Its optimized acidic surface chemistry enhances control in separations of basic compounds and targeted impurity removal. Download SDS

$40.00 - $7,200.00

3 Way Ball Valve - Fractional Tube Fitting

SSP - 3 Way Ball Valve - Fractional Tube Fitting SSP Instrumentation Flolok® manually operated three-way ball valves accept media through the bottom port and allow selection of flow through a selected port. Features: Directional handle indicates flow direction Panel Mountable 180-degree actuation Directional flow path Micro-finished ball provides positive seal Free-floating ball design provides compensation for seat wear for repetitive sealing Blow-out proof ball & stem Standard Product Testing - Every ball valve is assembled and tested @ 1000 psi (68.9 bar) with Nitrogen Specifications Body Material 316 Stainless Steel Pressure Rating @ 100F 3000 PSIG @37C 208 BAR @300F 2500 PSIG @148C 172 BAR Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Connection Type 2 Duolok Tube Fitting Connection Size 2 Specified by User Connection Type 3 Duolok Tube Fitting Connection Size 3 Specified by User Handle Type Nylon-Stainless Steel Insert Handle Color Black Packing Material PTFE SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$80.00 - $120.00

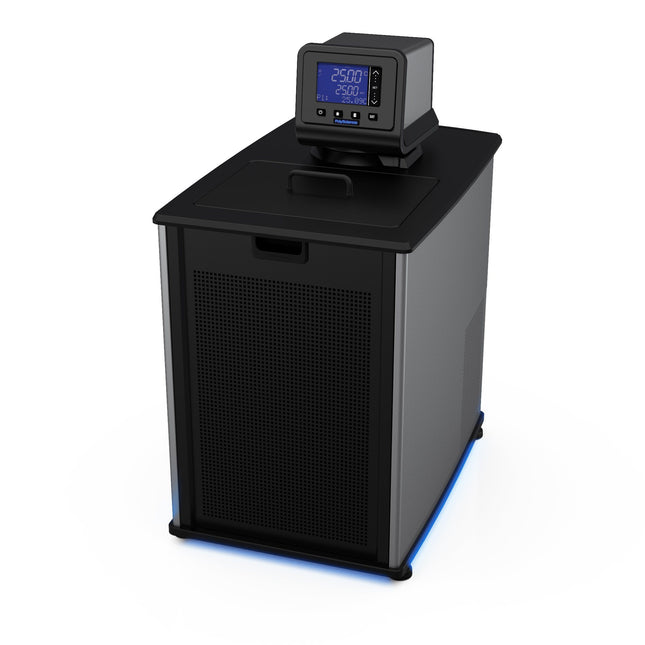

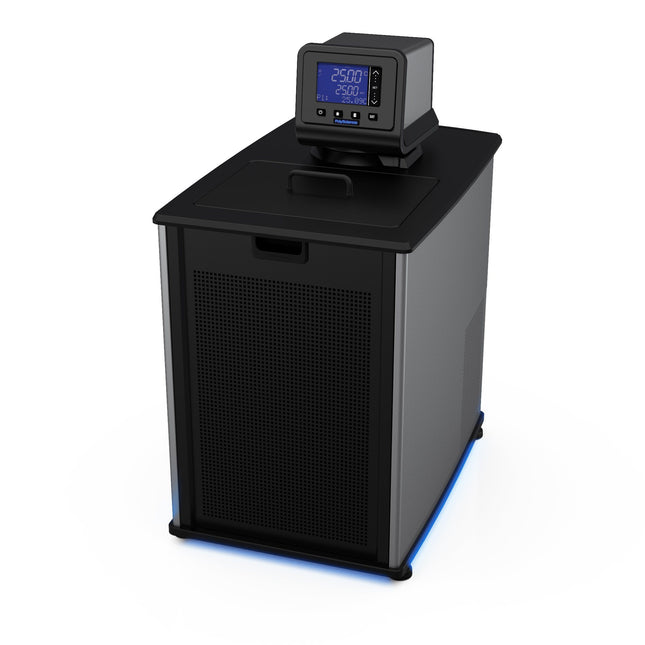

Polyscience 15 Liter Advanced Digital Refrigerated Circulator (-30°C/200°C)

Polyscience 15 Liter Advanced Digital Refrigerated Circulator (-30°C/200°C) ***Note: This item has a lead time of 2-3 weeks depending on stock availability.*** Description: -30, 15 L Ref. Circulator Controller Type: Advanced Digital Display: 3.75" Touch-Pad LCD Connectivity: Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe Languages Supported: 4: French, German, Spanish, English Swivel 180 Rotating Controller: Yes Working Temperature Range °C: -30° to 200° Temperature Stability °C: ±0.01° Fluid Optimization/Specific Heat Tuning: Automatic and/or user-adjustable Temperature Calibration Capability: 1-point Working Access (L x W x D) (cm): 21.2 x 27.6 x 14 cm Pump Type: Pressure/Suction External Temperature Control Capability: Yes Flammability Class (DIN 12876-1): III (FL) Specifications Working Temperature Range °F -22° to 392° Working Temperature Range °C -30° to 200° Nominal Cooling Capacity @ +20C (W) 915 Reservoir Capacity (gallons) 3.96 Reservoir Capacity (liters) 15 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 8.35 x 10.88 x 5.5 in Working Access (L x W x D) (cm) 21.2 x 27.6 x 14 cm Temperature Stability °F ±0.02° Temperature Stability °C ±0.01° Display 3.75" Touch-Pad LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure/Suction Pump Speed Variable Process Connections 1/4" (F) NPT External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes WhisperCool Environmental Control Technology Yes Cool Command Refrigeration Technology Yes Reservoir Drain Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 22.4 x 14.5 x 26.9 in Overall Dimensions (L x W x H) (cm) 56.9 x 36.8 x 68.3 cm Refrigerant R404A Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 118.0 Shipping Weight (kilograms) 53.5 60Hz Part Number AD15R-30-A11B Maximum Pressure (psi) 4.3 Maximum Pressure (bar) 0.30 Maximum Pressure Flow Rate (gpm) 5.30 Maximum Pressure Flow Rate (l/min) 20.1 Maximum Suction Flow Rate (gpm) 3.9 Maximum Suction Flow Rate (l/min) 14.7 Cooling Capacity @ -20°C (W) 165 Cooling Capacity @ 0°C (W) 505 Cooling Capacity @ +20°C (W) 915 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/13 Regulatory Approvals ETL Certifications: Regulatory Approvals: ETL Circulating Bath Operator's Manual

$6,350.00

Huber SilOil M40.165/220.10, Heat transfer fluid -40 to 220 °C

Huber SilOil M40.165/220.10, Heat transfer fluid -40 to 220 °C SilOil M40.165/220.10 is a low-viscosity silicone fluid which, as a result of its special property profile, is particularly suitable for use as a cold and heat transfer medium in cryostats, thermostats and heat transfer installations. SilOil M40.165/220.10 can be used in the range from -40 °C to 165 °C and to 220 °C in externally sealed systems (Unistats). It should be borne in mind that, at high temperatures, SilOil M40.165/220.10 can be chemically altered by oxidising media, such as air, or substances with a catalytic effect, such as acids, lyes and various metal compounds. An increase in viscosity, and possibly even gelling of the fluid owing to crosslinking reactions, must be expected in the presence of oxidising agents, while contact with products having a catalytic effect usually induces a process of depolymerisation, resulting in a drop in viscosity. Advantages: Virtually insolubile in water Non-corrosive Low setting points and vapour pressures High flash points Low toxicity No coking tendency under thermal stress High thermal stability Resistance to ageing Chlorine free Safety Data Sheet Heat transfer fluid M20.195/235.20 Working temperature °C -40 to165/220 open/closed systems: -40°C - 165°C Unistats (only closed): -40°C - 220°C Material: silicon oil Viscosity at 25°C: 10 mm²/s Colour colourless, clear Material incompatibility Silicone rubber

$895.00 - $1,600.00

V61 Series Vent Relief Valve

Features: Precise cracking pressure with high reliability Keep the sealing to 95-98% of Set Pressure at least Reliable Reseal performance Tamper proof design 316 Stainless Steel NBR Seal Material 1/4" MNPT Connection or 1/4" JIC Swivel Connection Pressure Range - 0.03 to 1.03 bar (0.5 to 15 PSI) Temperature Range: -195 to 204C (-45 to 400F) Design and Application: V61 Series Vent relief valves is designed to vent out the excess pressure from the line automatically to keep the required line pressure safely when the line pressure is exceeded over the limitation unusually. These valves can be used in the case that the working fluid is not harmful when vented out. The level of cracking pressure should be set by adjusting the force of the spring in the valve before this valve is installed in the system. Installation and Operation: This valve should be positioned perpendicularly to the direction of fluid flow in the line and that position should be considered and the vented fluid should be not directed to the personnel operating and the parts that has any influences on that. The line system should be run to check the performance of the valve after the personnel operating move to the safety zone. Because this valve is opened automatically when the excess of the required Line pressure.

$20.00

Eisco Labs Base Retort Stand Heavy Duty 8"x5"

Eisco Labs Base Retort Stand Heavy Duty 8"x5" HIGH QUALITY || Rectangular retort base made of chemical-resistant cast iron with a blue coating STABILITY || The 8" long by 5" wide base weighs 3lbs, providing superb stability for experiments & setups TAPPED HOLE FOR ROD || Base features a tapped hole for a 10mm x 1.5mm threaded rod (sold separately). Best used with Eisco Labs rod series: CH0657, CH0658, CH0659 GREAT FOR CLASSROOM &LABORATORIES || The durable and sturdy construction of this set...

$22.00 - $24.00

Edwards Oil Mist Exhaust Filter

Edwards EMF20 Oil Mist Exhaust Filter The Edwards EMF20 Oil Mist Filter is designed for use with the Edwards RV12 and E2M18 vacuum pumps, efficient at 99.999% DOP test and azide proof. The bottom white half of the body is semi-transparent allowing easy monitoring of oil levels. This oil mist filter is new in the box and ready for shipping and includes: NW25 Clamp Centering Ring O-Ring NW25 to 3/4 inch BSP Adaptor 1 year warranty

$552.00

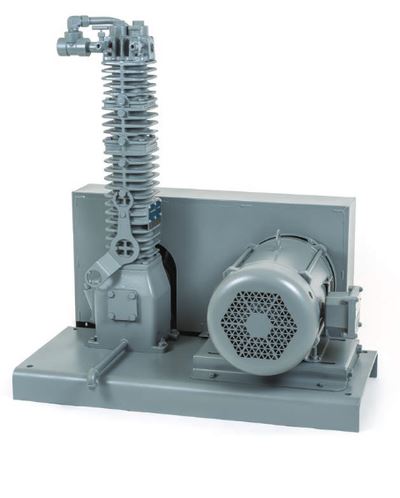

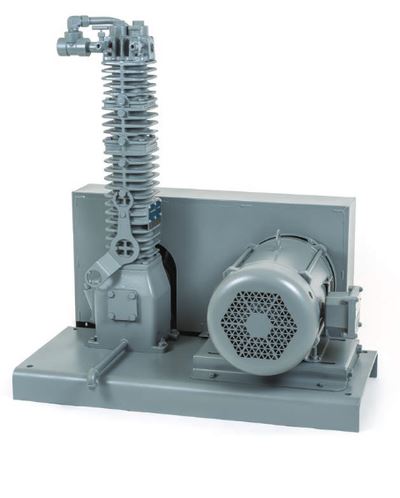

Corken T91-103 Oil-Free Gas Compressor

Corken Gas Compressor Corken's vertical industrial gas compressors offer piston displacement ranging from 2.8 to 117 CFM (4.76 to 198.8 m3/hr) while horizontal gas compressors offer piston displacement ranging from 7.6 to 414 CFM (12.9 to 704 m3/hr). Corken Recovery Pump T91 Corken is a leading manufacturer of industrial compressors designed for liquefied petroleum gas (LPG). The single stage T91 is oil-free and can recover your hydrocarbon gas faster than most recovery pumps on the market. Double Distance piece Triple Packing Oil wipe ring Adjustable packing Screw Features and Benefits: Oil-free gas compression: No product contamination Food grade material: PTFE trim and nickel coated parts Faster recovery time: Allows more production runs Zero psig evacuation pressure: Minimizes waste Self-lubricating PTFE piston rings: Low friction design provides many hours of trouble-free service Quiet operation: Suitable for indoor applications (approximately 85 dBa at three feet) Space saving: Air compressor is not required Adjustable packing screw: Extends life of the packing Cost effective: Does not require air compressor and pneumatic driver. Avoid possible air/propane cross contamination Motor: UL and CSA compliant and suitable for Class 1, Division 1, Group C & D application Operating Specifications Bore of cylinder inches (mm) 3.0 (76.2) Stroke inches (mm) 2.5 (63.5) Piston displacement cfm (m3/hr) Minimum @ 400 RPM 4.1 (7.0) Maximum working pressure psig (bar g) 335 (23.1) Maximum brake horsepower (kW) 7.5 (5.6) Maximum rod load lb (kg) 3,600 (1,632.9) Maximum outlet temperature °F (°C) 350 (177) General Performance Data for Vapor Recovery Compressor speed RPM 700 Vapor temperature °F 70 Final evac pressure psig 0 Maximum working pressure psig (bar g) 335 (23.1) Average recovery rate in lb/hr* Butane: 93Propane: 240 Power Requirements Phase 1Ø Voltage 115/230 VAC Motor Power 3 HP Motor Speed 1750 RPM Motor Frequency 60 Hz Data Sheet

$16,000.00

Mastercool Blue 60" HVAC Hose

This HVAC hose will fit 1/4" SAE or JIC fittings. One end of the hose has a fitting made to depress a Schrader valve within the male fitting, the other end of the hose is a standard connection.

$15.00

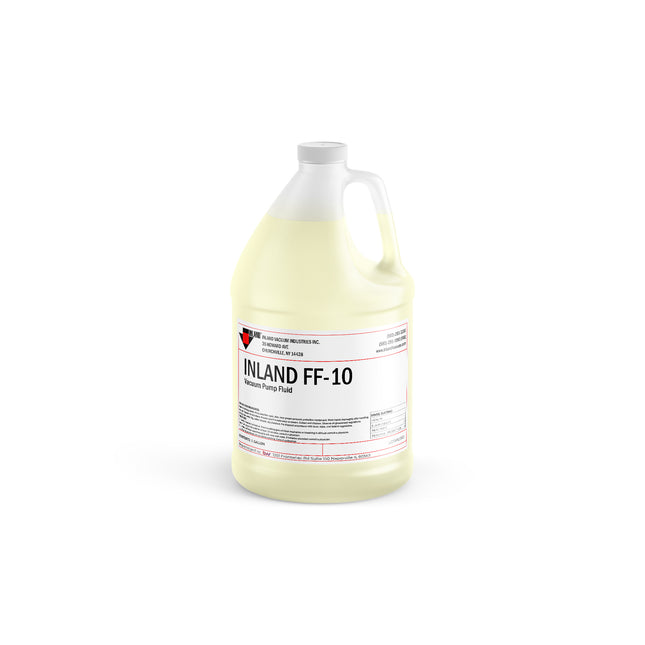

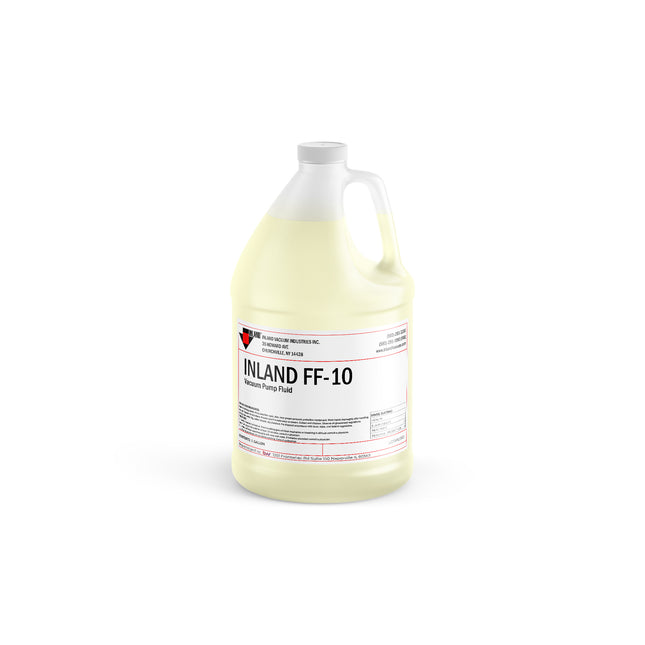

Inland FF-10 Flushing Fluid

Inland FF-10 Flushing Fluid Inland FF-10 is a solvent free hydrocarbon flushing fluid designed to be used as part of a preventive maintenance program. Periodic use of FF-10 will enable the user to remove contaminants and particulates from within all areas of the pump without the worry of contaminating the pump with an expensive solvent Specifications FF-10 Vapor Pressure at 25ºC (torr) 2x10-4 Viscosity at 40ºC (cSt) 28 Viscosity at 100ºC (cSt) 4.5 Flash Point (ºC) 199 Fire Point (ºC) 221 Density at 25ºC (g/ml) 0.85 Inland FF-10 Flushing Fluid Safety Data Sheet SDS

$14.00 - $1,020.00

True Terpenes Tropicana Cookies -Infused

True Terpenes Tropicana Cookies -Infused All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. (Please Note: This product has 1 week lead time) Tropicana Cookies Infused Strain Profile takes the uplifting and euphoric Tangie and GSC strains and boosts the good vibes with tropical cookie sweetness. Full Flavor. Full Effect. FRAGRANCE: Tropical and sweet EFFECT: Happy, uplifting and euphoric CERTIFICATES: COA | SDS | FOOD GRADE Storage Requirements Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. DilutionTerpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With CareCan cause skin irritation, do not ingest PRIOR to dilution. TRUE GRADE™ It is our promise to you. Our isolated terpenes are triple-distilled making them the cleanest terpenes in the world. Fresh out of the bottle, undiluted, every single one of our products bests the most rigorous consumer safety standards. GMP | ISO-9001:2015 | FSSC 22000 Blended in cGMP facilities adhering to the requirements for a Quality Management System (QMS) specified by ISO 9001:2015 and FSSC 22000 standards. Analyzed Tested and passed True Grade™ safety specifications for residual solvents, pesticides and heavy metals. Stability Tested Rigorously tested with mid-grade distillate against separation, cloudiness and unacceptable levels of color change. We Qualify True Terpenes implements supply-chain control for all raw materials and is proud to provide True Terpenes’ qualification documents such as certificates, licenses and registrations to be qualified as your supplier. Undiluted We do not add PG, VG, PEG, MCT or Vitamin E Acetate to any of our products. Food Grade Manufactured in cGMP facilities using food grade ingredients. UV Protected This product is packaged in a cobalt blue, UV deterrent and food grade bottle with tamper evident seal. Made in the USA Formulated, blended, manufactured and fulfilled in the United States. Refined Isolates This product contains ultra-pure, molecularly-refined terpene isolates. Only the best.

$135.00 - $2,250.00

Pipe Cross

SSP - Pipe Cross SSP Instrumentation TruFit® is manufactured from fully-traceable raw material to close tolerances and superior surface finishes. TruFit® provides optimal performance when installed in accordance with SSP’s recommendations and the design parameters appropriate for each type of connection – tapered thread, straight thread, and weld & braze. TruFit® components are cleaned in accordance with SSP documented work instructions using equipment calibrated to NIST standards with environmentally-safe and stable agents, ultrasonics, and heat/ temperature to remove all residual oil, grease, and loose particles. Stainless steel components are passivated to the requirements of MIL QQ-P-35 and ASTM A 967. ***Note: ALL NPT Threads REQUIRE the user to properly install the fitting by using a thread sealant to prevent leaks. Best Value Vacs recommends GAS PTFE Tape Specifications: Connection Type 1 Female NPT Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Working Pressure (PSIG) 1/4" - 7750 3/8" - 6800 NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$35.00$20.00

Pump Part - MVP - 60 PSI, 150 PSI, & Liquid - SS&S - Fluid Plate Kit

Pump Part - MVP - 60 PSI, 150 PSI, & Liquid - SS&S - Fluid Plate Kit All sales final

$230.00

6" ASME VIII Sanitary 316SS Clamp for High Pressure Connections

6" ASME VIII Sanitary 316SS Clamp for High Pressure Connections These heavy duty hygienic ASME VIII clamps are designed for pressure vessels, filter housings and other demanding/pressure intensive applications while operating under sterile conditiions. These clampos meet the requirements of ASME SEction VII Appendinx 24 of the pressure vessel code . All of these sanitary clamps are made from fully traceable 316 stainless steel. The ASME Code Sanitary Clamp is made specifically for the Pharmaceutical and Biotech Industries where joint cleanliness and efficiency are of paramount importance. These stainless steel sanitary fittings and clamps are made from investment castings to produce a high quality, precision fit assembly. The clamps are designed to provide quick access to the joint for cleaning and inspection without sacrificing safety. All sanitary clamps are CE compliant per the Pressure Equipment Directive 97/23/EC and the Machinery Directive 98/37/EC. DATASHEET - ASME Sanitary Clamp Fittings ASME Clamp Instructions

$695.00

HTP Square Press - 2 Ton

HTP Square Press - 2 Ton These high-quality presses are built from Aircraft Aluminum and stainless steel designed to be used in conjunction with a unique heating process. CAPACITY: 3” x 3” x 3” Thick PRESSURE: 2-Ton hydraulic jack SHAPE: Cube

$434.95$395.00

Chemglass Straight Connecting Adapter 24/40

Chemglass Straight Connecting Adapter 24/40 This Chemglass adapter allows you to connect 2 female jointed pieces together. ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.*** ***All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.

$58.00

LSD QTests

LSD QTests Know your dose with the LSD QTest The LSD QTest is the world’s first quantitative LSD test kit on the market. It can tell you how many micrograms are in each square of your blotter or each drop of liquid . . . before you ingest it. Use one drop of liquid or one half a hit of blotter, then compare the color of the detection vial to the enclosed color chart. It’s that simple. Instructions Note: A paper version of these instructions comes with your order. IMPORTANT INFORMATION! – READ THIS FIRST • Use this kit at room temperature. (If stored in a refrigerator, let it warm up for one hour first.) • Perform the test on a flat surface during the daytime. • Evaluate the result in daylight immediately after the 12-minute development time. (The color can change if you wait too long.) • Use a white, letter-sized sheet of paper as a background when evaluating the color. (See section four for evaluation details.) • Read all the instructions at least once through before beginning the test. 1. BACKGROUND INFORMATION This test kit can be used to detect the active ingredient LSD-25 (lysergic acid diethylamide) and its concentration in blotter, liquid, and sugar cubes. It does not work on gel tabs. The kit does not react to 1P-LSD, 1cP-LSD, ALD-52 or ETH-LAD When testing blotter, you should only test half of a dose. The end result will tell you how many micrograms of LSD are in the entire dose.* When testing liquid LSD, use only one drop. But remember, the end result tells you how much is in two drops.** When testing sugar cubes, you need to crush and mix up the sugar first. Weigh out and test one quarter (1/4th) of the sugar, then multiply the end result by two.*** IMPORTANT! – Always shake your vial of liquid LSD (and empty and refill the dropper a few times) before dosing out a drop. Liquid LSD tends to settle at the bottom of the vial. If you forget to shake it first, you could end up accidentally ingesting a dose ten or even twenty times larger than expected. Similarly, the liquid in a vial of LSD can evaporate over time, increasing its concentration. (The LSD doesn’t evaporate away. Only the liquid evaporates.) This is particularly true with alcohol solutions, and it can happen even when the lid is tightly closed. Make sure and take this into account. Older vials that have been sitting around for many months can become more potent over time. * Each perforated square in a given sheet of blotter will typically be the same dose. This is because the entire sheet was dipped into a tray of liquid LSD, and the LSD was absorbed evenly throughout the sheet. We designed the LSD QTest so that you only need to test half of a dose (half a square of blotter), and the result will tell you how much LSD is in each full dose (each full square of blotter) belonging to the same sheet. Keep in mind if you have individual squares of blotter that are not connected to each other (i.e., if the perforation was broken when you obtained them) then they may not come from the same sheet. Only connected squares can be assumed to come from the same sheet. ** When testing one drop of liquid LSD, the result tells you how much LSD is in two drops. So remember to divide the end result in half in order to determine how much LSD is in one drop. *** When a drop of liquid LSD is individually dropped onto an absorbent medium such as a sugar cube, it does not absorb evenly. This is why you need to homogenize it before you test it (by crushing and mixing thoroughly). Also, all that sugar won’t fit into the extraction vial, so just use a quarter of it. Then multiply the end result by two to determine the amount of LSD that was originally in the entire cube. 2. PREPARING FOR THE TEST Take out all the items from your kit. Along with these instructions, you should have: • protective gloves• glass vial with screw cap (the extraction vial)• dropper vial with green lid (detection reagent)• evaluation color chart 3. PERFORMING THE TEST 3.1 First put on the enclosed nitrile gloves and wear appropriate protective clothing and safety glasses. If you wear contact lenses, remove them. The liquids in the vials contain acids which may cause skin irritation or severe eye damage. In the event you come in contact with the liquid, remove the affected clothing immediately and rinse the affected skin area with water for several minutes. In case of eye contact, rinse the affected eye with running water for several minutes. (Keep pets, especially cats, away from the testing area.) If you are testing blotter, carefully cut it in half diagonally from one corner to the other using a fine pair of scissors. If you are testing a sugar cube, put it into a small zip lock baggie. Crush it up and shake it well, then pour all of it onto a milligram scale and weigh it. Write down the total weight. Now use the same scale and weigh out one quarter (1/4th) of the total for the test. 3.2 Open the glass vial and add the half piece of blotter (or the quarter amount of sugar). If you are testing liquid LSD, just add one drop. Put the lid back on the vial, close it tightly and shake it for about one or two minutes. For blotter, let the vial rest for five minutes and then repeat the process two more times to make sure all the LSD is extracted. During the five-minute resting periods, make sure the blotter is suspended in the liquid, not stuck to the side of the glass, or to the underside of the lid. Shaking three times with a five minute resting period in between is enough to extract all the LSD even from the thickest blotter. (For thinner blotter, you don’t really need to repeat this process three times, but we suggest it anyway just to make sure.) 3.3 Open the extraction vial again and place it in a safe position. Remove the green cap from the plastic dropper vial and carefully empty the entire contents into the glass vial by squeezing it with even pressure. Put the lids back onto both vials and close them tightly. 3.4 Gently invert the glass vial four or five times to mix the reagents together and then set the vial down. In the presence of LSD, the liquid will begin turning a blue color immediately. 3.5 Wait 12 minutes for the color to completely develop. The result can then be read and interpreted using the enclosed color chart. See the next section, “EVALUATING THE RESULT,” for details. IMPORTANT! – If you see blue spots or streaks on the blotter, this indicates that not all the LSD got extracted from the blotter. In this case the result will be inaccurate. (Your LSD is actually more potent than the result indicates.) This will only happen with thicker blotter if you did not carefully follow the instructions in section 3.2 above. 4. EVALUATING THE RESULT Follow the instructions above and wait 12 minutes before evaluating the result, but do not wait much longer than 12 minutes. Set a timer. By comparing the intensity or saturation of the liquid in the vial with the enclosed color chart, you can determine the result visually. In the presence of LSD-25, the detection reagent turns bluish over time. Daytime sunlight is best suited for optimal evaluation. If using artificial light, the influence of different color temperatures may slightly change the hue. You can still perform the evaluation, but you should take this into account (e.g. high blue content in energy-saving lamps, green discoloration when using LED light from cell phones, etc). SPECIFIC EVALUATION INSTRUCTIONS • Use a white, letter-sized sheet of paper as a background.• In daylight or under bright light, hold the glass vial next to the color chart about six to eight inches in front of the white sheet of paper and look through the glass vial head on. For best results, your eyes should be fairly close to the vial, but no closer than about six to eight inches.• Now compare the color of the liquid in the vial to the color chart. The corresponding concentration of LSD listed on the color chart is twice the amount of LSD that you tested. So if you tested half a square of blotter, the concentration listed indicates the amount of LSD present in the entire square.• If you tested one drop of liquid, the corresponding result indicates how much LSD is in two drops of the liquid. (So divide the result in half to calculate how much is in one drop.)• If you tested a quarter of a sugar cube, the result tells you how much LSD is in half the sugar cube. (So multiply the result by two to calculate how much LSD was in the entire, original cube.) 5. STORAGE AND SHELF LIFE Store the reagents in the refrigerator (35° – 46° F) and out of direct sunlight for a shelf life of at least 18 months. 6. WARNINGS • Keep the kit away from children and animals.• When performing the test, wear suitable protective gloves, clothing and face/eye protection. If you wear contact lenses, remove them before using the test kit.• The liquids contained in the dropper vial consist of various acids which may cause a corrosive/irritating effect on the skin or severe eye damage/irritation. Avoid contact with the skin, eyes, mouth or clothing.• Should contact with the above listed areas occur, remove the relevant clothing immediately. Instantly rinse the affected skin areas with water for several minutes. In case of contact with the eyes, immediately rinse them with water for several minutes using both hands to keep the upper and lower eyelids open.• Substances processed with the test kit are not to be consumed!• The solution in the extraction vial is flammable. It’s just a small amount, but please don’t smoke while performing the test. 7. DISCLAIMERS • QTests are only to be used for the detection and quantification of unknown substances.• The result may not be 100% accurate. Your sample could be adulterated with one or more unknown substances that cross-react with the reagents, affecting the quantitative result.• The result does not mean your sample is safe to consume. It could still contain unwanted substances and impurities that can be harmful or even deadly.• The LSD QTest is not a substitute for laboratory analysis.• miraculix and/or Qtests.org assume no responsibility for the use or misuse of the test kit or the results. 8. DISPOSAL OF MATERIALS Check your local regulations for proper disposal of acids.

$24.95

Welch 2019 Diaphragm Pump - vacuum filtration

Welch 2019 Diaphragm Pump - vacuum filtration ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details PTFE Contact Surfaces Light and Portable Economical Model 2019 diaphragm vacuum pump is durable and chemical resistant. Use Model 2019 for vacuum filtration, desiccation, degassing, and other mid-range vacuum applications. Recommended for operations utilizing organic / aqueous solvents and or light acid / base (e.g. acetic acid) solutions. Ideal for single funnel vacuum filtrations, SPE manifolds, or up to 6 holder manifold filtrations. Specifications Free Air Displacement, CFM (l/min) 1.3 (37) Ultimate Vacuum, torr (mbar) 150 (200) Max. Vacuum, in Hg 24 Tubing Needed, I.D. in. (mm) 1/4 (7) Weight, lbs 10.2 Overall Dimensions 8.8 x 5 x 8.8 MODEL 2019B-01 / 2019C‐02

$1,175.00

Vacuubrand MD 4C NT 2.2 CFM Chemistry Diaphragm Pump 110V

Vacuubrand MD 4C NT 2.2 CFM Chemistry Diaphragm Pump 110V MD 4C NT Technical Data Sheet.pdf These three-stage diaphragm pumps are an excellent solution for continuous, oil-free pumping of non-corrosive gases. They reach an excellent ultimate vacuum of 1 mbar. All parts in contact with pumped gases and vapors are made of aluminum, stainless steel and carefully selected plastics suitable for a wide range of applications with non-corrosive gases. The new NT-series provides whisper quiet and ultra-low vibration operation, high leak tightness and improved performance. The highly flexible fabric-reinforced double diaphragm made of FKM is ideal for extended operating life. These three-stage diaphragm pumps are an excellent choice for continuous, contamination-free evacuation and pumping of non-aggressive gases at demanding vacuum conditions. They are especially suitable for applications in physics and analytics. The low ultimate vacuum makes these an attractive alternative to rotary vane pumps in many applications. Typical uses are as backing pump for turbomolecular drag pumps, and for degassing of viscous media. Performance features: Outstanding chemical resistance and superior vapor tolerance Exceptionally high performance even at low vacuum Excellent ultimate vacuum even with gas ballast Whisper quiet and very low vibration Long diaphragm life, maintenance-free drive system Technical Data Max. pumping speed 50 Hz 3.8 m3/h Max. pumping speed 60 Hz 2.5 cfm Ultimate vacuum 1 mbar / 0.75 torr Number of heads 4 Number of stages 3 Lower ambient temperature (operation) 10 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 1.1 bar Anschluss saugseitig small flange KF DN 16 Outlet connection Silencer / G1/4" Rated motor power 0.25 kW Rated motor speed at 50/60 Hz 1500/1800 min-1 Protection class IP 40 Dimension L in mm 328 mm Dimension W in mm 239 mm Dimension H in mm 198 mm Weight 16.4 kg Noise level at 50 Hz, typ. 45 dBA Rated mains voltage range 1 230 V Mains frequency 1 50-60 Hz NRTL certification

$4,990.00

Polyscience 7 Liter Low Profile MX Refrigerated Circulator

Polyscience 7 Liter Low Profile MX Refrigerated Circulator Note: This item may carry up to a 4-6 week lead time. The Polyscience 7 Liter Low Profile MX Refrigerated Circulator is an more ergonomic version of the standard 7L Refrigerated Circulator. It is the ideal low temperature cooler for short path distillation and can also be used to heat jacketed bases and chill jacketed columns for small capacity extraction systems. Specification Description -20, 7 L Low Ref. Circulator Controller Type MX Display 3.75" Touch-Pad LCD Working Temperature Range °C -20° to 135° Temperature Stability °C ±0.07° Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Pump Type Pressure Flammability Class (DIN 12876-1) I (NFL) Working Temperature Range °F -4° to 275° Working Temperature Range °C -20° to 135° Nominal Cooling Capacity @ +20C (W) 200 Reservoir Capacity (gallons) 1.85 Reservoir Capacity (liters) 7 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 6.18 x 5.59 x 5 in Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Temperature Stability °F ±0.13° Temperature Stability °C ±0.07° Display 3.25" LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure Pump Speed One Process Connections 1/2" O.D. Barbed Tubes Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes Reservoir Drain Yes Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 23.2 x 16.2 x 17.3 in Overall Dimensions (L x W x H) (cm) 23.2 x 16.2 x 17.3 in Refrigerant R134a Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 84.0 Shipping Weight (kilograms) 38.1 Catalog Page Number 44-45 60 Hz Only Part Number MX7LR-20-A11B Maximum Pressure (psi) 2.3 Maximum Pressure (bar) 0.16 Maximum Pressure Flow Rate (gpm) 3.60 Maximum Pressure Flow Rate (l/min) 13.5 Cooling Capacity @ -20°C (W) 30 Cooling Capacity @ 0°C (W) 120 Cooling Capacity @ +20°C (W) 200 Cooling Capacity @ +100°C (W) 200 Included Hardware Fitting Kit for External Applications Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/12 Regulatory Approvals ETL Key Features: Large, universal icon and English display On-screen prompts Single-point calibration capability Certifications: Regulatory Approvals: ETL Operator's Manual

$4,200.00

10L Neocision Dual Head Short Path Distillation Turnkey System

10L Neocision Dual Head Short Path Distillation Turnkey System This unit carries a 2 day lead time. The 10L Neocision Distillation Turnkey Setup features our Dual 10L P5 Distillation Heads and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included is a KF-25 Vacuum Pump giving you extreme power and depth with a long lifespan, the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market, and a BVV 19L Heated Circulator for maximum condensation of vapors. You will also receive a Dual Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The Premium Turnkey Kit Includes: 10L Neocision Kit with Dual P5 Distillation Heads KF-25 2 Meter Bellows Dual Dewar Style Glass Cold Trap Bullseye Precision Vacuum Gauge BVV 19L Heated Circulator Your Choice Of KF-25 Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$13,250.00 - $17,750.00

Huber DW-Therm HT P20.340.32 Heat transfer fluid 20 to 340 °C

Huber DW-Therm HT 20 to 340 °C Heat transfer fluid Huber heat transfer fluids are recommended for many temperature control applications because they have the best possible thermodynamic and environmental characteristics. Safe reliable operation relies on compliance with safety standards to ensure optimal results. DW-Therm HT is a mixture of partially hydrogenated naphthalenes. It is especially suited for high temperature applications using hydraulically sealed thermostats. Please note: Valid only for Unistats Safety Data sheet Advantage: broad working range from 20 °C up to 340 °C (hydraulically sealed systems) Long lifetime at high temperatures under inert atmosphere: 3 -4 years Good thermal properties for heat transfer High thermo-oxiation stability Properties Working temperature°C 20 to 340 Flash Point °C 190 Flash Point °C approx. 218 Viscosity mm2/s (kinematic at 25 °C) 32 Density g/cm3,(at 20 °C) 1,043 Pour Point °C -30 Ignition temperature °C 385 Colour orange, clear Thermal expansion coefficient 10-5/K not specified Heat conductivity W/(m·K) at 30 °C 0,130 Material incompatibility not specified

$835.00 - $1,440.00

Extend Protection Plan

Extend Protection Plan

$0.09 - $49.99

Vacuubrand MZ 2C NT 1.4 CFM Chemistry Diaphragm Pump 110V

Vacuubrand MZ 2C NT 1.4 CFM Chemistry Diaphragm Pump 110V MZ 2C NT Technical Data Sheet.pdf Chemistry-design diaphragm pumps are an excellent solution for continuous, oil-free pumping of corrosive gases and vapors. The two-stage construction provides the advantageous combination of high pumping speed and low ultimate vacuum. All parts in contact with pumped media are made of chemically resistant fluoroplastics. Well-proven PTFE sandwich diaphragms increase reliability and extend operating life. The pump MZ 2C NT is equipped with a gas ballast valve for continuous condensate purge increasing the pumping capability of condensable vapors. This pump is our most popular chemistry diaphragm pump, and is the heart of a family of VACUUBRAND pumping systems. The NT-series features further improved performance data and superior vapor tolerance. Technical data Unit MZ 2C NT Number of heads / stages 2 / 2 Max. pumping speed at 50/60 Hz m3/h 2.0 / 2.3 Max. pumping speed at 50/60 Hz cfm 1.2 / 1.4 Ultimate vacuum (abs.) mbar/torr 7 / 5 Ultim. vac. (abs.) with gas ballast mbar/torr 12 / 9 Ambient temperature range (operation) °C 10 - 40 Ambient temperature range (storage) °C -10 - 60 Max. back pressure (abs.) bar 1.1 Inlet connection Hose nozzle DN 8-10 mm Outlet connection Hose nozzle DN 8-10 mm Rated motor power kW 0.18 Rated motor speed at 50/60 Hz min-1 1500/1800 Degree of protection IP 40 Dimensions (L x W x H) mm 243 x 243 x 198 Weight kg 11.1 Noise level at 50 Hz, typ. dBA 45 NRTL certification Canada and the USA ATEX conformity (only 230V) II 3/- G IIC T3 X Internal Atm. only Items supplied Pump completely mounted, ready for use, with manual. Accessories Rubber vacuum tubing DN 8 mm (20686001)

$2,930.00

Julabo Adapter M16x1 f to NPT 1/2″

Julabo Adapter M16x1 f to NPT 1/2″ 2 Adapters M16x1 f. to NPT 1/2″ m.

$210.00

J-KEM Model 250

J-KEM Model 250 The Model 250 has both heating and cooling outlets for maximum versatility. Two heating outlets supply 1800 watts of power for large equipment and heating mantles up to 22L. The third outlet (1800 watts), normally used for cooling, is programmable to supply power below, above, or at the set point. Contains J-KEM’s patented power control computer which provides 0.1° regulation of anything. Specifications: 120vac, 15 amps, 1800 wattsWarranty: 2 Years The temperature range desired determines the probe/thermocouple type: J [black] (0 – 800° C)K [yellow] (-50 – 1200° C)T [blue] (-200 – 250° C)RTD: (-200 – 400° C)

$1,233.00 - $1,427.00

Huber MinOil P20.190.40, Heat transfer fluid 20 to 190 °C

Huber MinOil P20.190.40, Heat transfer fluid 20 to 190 °C P20.190.40 is a high quality mineral oil based heat transfer fluid. It meets the technical safety requirements and tests according to DIN 4754 as well as the recommendations of VDI 3033 (Construction, operation and maintenance of heat transfer systems). Advantages: very good oxidation stability high thermal stability good viscosity-temperature characteristics low tendency to coke extended oil change interval Safety Data Sheet Properties Working temperature °C 20°C…190°C Flash Point °C 190 Fire Point °C not Specified Viscosity mm2/s (kinematic at 25 °C) 40 Density g/cm3 0,86 Pour Point °C > 300 Ignition temperature °C > 300 Color light yellow Thermal expansion coefficient 10-5/K not Specified Heat conductivity W/(m·K) at 25 °C 0,135 Material incompatibility Not Specified

$460.00 - $1,370.00

ChemTek Medium Fuge Bags - 50 Pack

ChemTek Medium Fuge Bags - 50 Pack Centrifuge bags used for separations Specifications: Size: 50-Pack Dimensions:H: 7” W: 5” Micron Size: 25 Micron Material: Food Grade Nylon

$30.00

CHEMTEK W5 Neutral Bleaching Clay

CHEMTEK W5 Neutral Bleaching Clay W5 is a neutral bleaching clay specialized for the removal of heavy metals. While most sorbents will remove heavy metals, the acids involved in the activation process could cause desorption. By neutralizing the clay processors can take advantage of the increased surface area without any risk of desorption. W5 SDS W5 Technical Data Sheet

$40.00 - $1,800.00

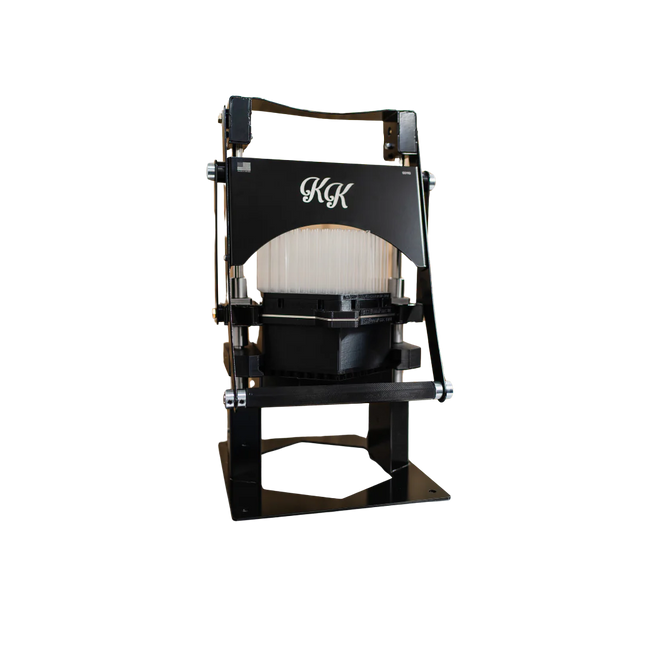

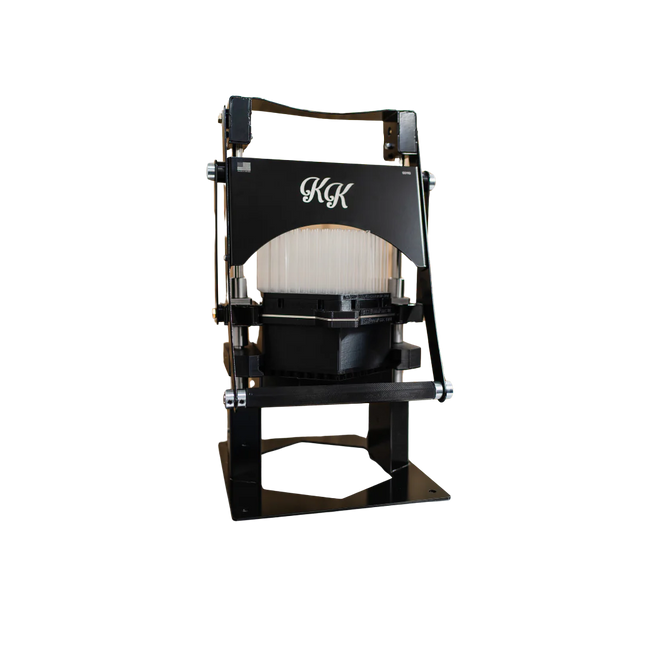

KING KONE CLOSER

KING KONE CLOSER Crown your pre-roll with a Dutch finish in just 4 easy steps. With this closer, you can produce up to 1,000 pre-rolls per hour from start to finish. Out of Stock: Due to high demand and the time required to craft this product, availability may take longer than our other items. At this time, we are not accepting pre-orders. We appreciate your patience as we work to fulfill all orders. Size: 109mm cone/King Size Cone Thank you for your understanding!

$1,799.00 - $2,000.00

Inland 70 Ultra Vacuum Pump Oil (Edwards Ultragrade 70)

Inland 70 Ultra Vacuum Pump Oil This is oil is a direct replacement for Edwards Ultragrade 70 oil. Specifications Inland 70 Ultra Vapor Pressure @25°C 1x10^-7 torr Viscosity @ 40°C 72 cSt Pour Point: -10°C Flash Point: 249°C Density: 0.86 g/ml Color: Clear Inland 70 Ultra Safety Data Sheet PDF

$17.00 - $1,856.50

Bullseye Precision Gauge with Agilent 536 KF25, NPT or KF16 Sensor | Vacuum Gauge for Processing

Bullseye Precision Gauge with Agilent 536 KF25, NPT or KF16 Sensor | Vacuum Gauge for Processing A rugged portable vacuum gauge for processing applications that pairs unparalleled vacuum measurement with the Agilent 536 sensor that has an integrated baffle which provides protection and helps reduce risk of sensor failure Numeric & Graphical Displays See vacuum readings in either numbers or easy-to-read graphs Has 12 measurement units for implementation in almost any vacuum application Torr, mbar, bar, kPa, inches of Hg, mm Hg, millitorr, microns, inches of water, PSI, Pa Calibrated & Precise Delivered pre-calibrated with Agilent/ Varian 536 thermocouple sensor under actual vacuum against the NIST standard. Note: NIST certification sent with the gauge is an available option here The 536 all stainless steel sensor with baffle has extended sensor life in the presence of condensable gases and improved performance at higher pressures Vacuum Interface: KF25 or NPT or KF16 Wetted materials: 304L Stainless steel, glass, Type P thermocouple Extended Battery Lifespan Portable | Solid state electronics built into a handheld gauge that operates using AA batteries that lasts up to 70 hours In-lab use | Power gauge using the integrated Micro-USB port for long-term use without the need to change batteries Ideal Vacuum Gauge for Processing Applications Laboratory, freeze drying, low pressure distillations, foreline monitoring, Schlenk lines performance, and transformer dry-out Or any application with higher levels of condensables where sensor failure is more likely Units Torr, mbar, kPa, millitorr, microns, Torr, mbar, bar, kPa, inches of Hg, mm Hg, millitorr, microns, inches of water, PSI, Pa 1E-4 – 1000 Torr Range with Accuracy .001 – 5 Torr Sensor Type Agilent 536-KF25 Dimensions 11 x 10 x 4 in Certifications CE, RoHS

$635.00 - $653.00

Edwards nXDS Series Dry Scroll Pumps Tip Seal Service Kit

Edwards nXDS Series Dry Scroll Pumps Tip Seal Service Kit The nXDS series is the next generation in completely oil free, dry scroll pumps nXDS improves on legacy XDS pumps by offering increased pumping speeds, combined with lower ultimate pressures, lower power consumption and lower noise. Gas ballast allows for pumping of condensable vapours including, water, solvents, dilute acids and bases. nXDS pumps also feature the latest in tip seal technology giving significantly longer life between tip seal changes. Integrated inverter drive with auto sensing voltage input delivers optimized pumping performance globally. nXDS pumps are designed to be completely field serviceable. Features: Lubricant-free within the vacuum envelope and hermetically sealed means totally clean and dry vacuum to prevent cross contamination No atmosphere to vacuum shaft seals means bearings are completely isolated, which prevents process attack and means the bearings run cooler and last longer Simple single sided scroll arrangement combined with an innovative motor and bearing design allows for easy field service with a minimum of special tooling for low cost of ownership and maximum up-time Improved motor and drive efficiencies for reduced power and cost of ownership Advanced interface provides a variety of traditional, analogue and digital control methods enabling remote control/monitoring via USB, RS232 or RS485 One year warranty, as well as technical

$626.00

True Terpenes Blue Cheese

True Terpenes Blue Cheese All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. (Please Note: This product has 2 week lead time) Fragrance: Cheese Funk Savory Effects: Soothing Couch-Lock Great for end of day discomforts! Blue Cheese is a heavy low with sweet scents of blueberry and savory notes of cheese. This distinct flavor provides soothing qualities and euphoria. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution.

$121.50 - $2,250.00

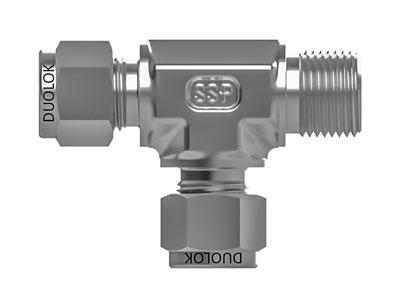

Male Run Tee

SSP - Male Run Tee SSP Instrumentation Duolok® tube fittings are designed, manufactured and quality controlled to be totally “interchangeable” with the Swagelok® brand of tube fittings. Component by component examination plainly shows the two brands as completely “componentintermixable.” The precision manufacturing of both products to stringent tolerances under rigid quality control procedures ensures the safety, performance, and reliability of service whenever Duolok® and Swagelok® component parts are mixed and used in accordance with published installation and service recommendations. Specifications Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Connection Type 2 Duolok Tube Fitting Connection Size 2 Specified by User Connection Type 3 Male NPT Connection Size 3 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Duolok Pressure Rating = Tubing Rating NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA! Dimensions A 1.98 in Bx 0.77 in By 0.92 in C 0.70 in D 0.60 in E 0.19 in F 0.56 in G 9/16 in H 9/16 in P 1/4 in T 1/4 in Ax 1.06 in B 1.69 in

$30.00$21.00

Huber SilOil M80.100/250.03, Heat transfer fluid -80 to 250°C

Huber SilOil M80.100/250.03, Heat transfer fluid -80 to 250°C SilOil M80.100/250.03 is a low-viscosity silicone fluid which, as a result of its special property profile, is particularly suitable for use as a cold and heat transfer medium in cryostats, thermostats and heat transfer installations. SilOil M80.100/250.03 can be used in the range from -80 °C to 100 °C (for open systems) and to 250 °C with externally sealed systems (Unistats). It should be borne in mind that, at high temperatures, SilOil M80.100/250.03 can be chemically altered by oxidizing media, such as air, or substances with a catalytic effect, such as acids, lyes and various metal compounds. An increase in viscosity, and possibly even gelling of the fluid owing to crosslinking reactions, must be expected in the presence of oxidising agents, while contact with products having a catalytic effect usually induces a process of depolymerization, resulting in a drop in viscosity Safety Data Sheet Advantage: virtually insoluble in water non-corrosive low setting points and vapor pressures high flash points low toxicity odorless no coking tendency under thermal stress high thermal stability resistance to ageing chlorine free Heat transfer fluid M80.100/250.03 Working temperature °C -80 to 100/250 open/closed systems: -80°C - 100°C Unistats (only closed): -80°C - 250°C Material: silicon oil Viscosity at 25°C: 7 mm²/s Color colorless, clear Material incompatibility Silicone rubber

$1,890.00 - $3,610.00

Agilent IDP-15, 9 CFM, Dry Scroll Vacuum Pump

Agilent IDP-15, 9 CFM, Dry Scroll Vacuum Pump Overview The new Agilent IDP-15 dry scroll pump is designed for extremely quiet (<50dBA) and low vibration operation, delivering a peak pumping speed of 9 cfm at 60Hz.With a single-sided scroll design it offers fast, easy yearly maintenance and low cost of ownership. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. Specification Base pressure (50 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Base pressure (60 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Dimensions (WxHxL) 13.1 in x 14.3 in x 19.1 in Exhaust Connection NW16 Height 14.3 in Inlet Connection NW25 Input Voltage 220-230 VAC 100-115 Length 19.1 in Noise Level 50 dB(A) Pumping Speed (50 Hz) 12.8 m3/h 214 L/min 7.5 CFM Pumping Speed (60 Hz) 15.4 m3/h 256 L/min 9.1 CFM Width 13.1 in

$9,503.00 - $10,028.00

You have seen 240 out of 657 products