BVV

-

Toluene Lab Grade 99.8% Purity

Toluene Lab Grade 99.8% Purity Toluene, also called methylbenzene is a colorless liquid with a flash point 40 °F. It is Less dense than water (7.2 lb / gal) and insoluble in water. Hence floats on water. This is an aromatic hydrocarbon that has a smell you would associate with paint thinners. It is a naturally occurring hydrocarbon found in crude oil. Toluene is volatile, flammable, and evaporates quickly. Toluene is the simplest member of the class toluenes consisting of a benzene core which bears a single methyl substituent. It is a non-polar solvent, Due to the presence of the methyl group, toluene is more reactive compared to benzene alone in the presence of electrophiles. Chemical Formula: C6H5CH3 Molecular Weight: 92.141 CAS Registry Number: 108-88-3 Appearance Colorless Liquid Odor: sweet, pungent, benzene-like Density 0.8623 g/ml Boiling Point: 110.60C/231.08F Solubility in water: 0.519 g/L (25 °C) GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H304, H315, H336, H361d, H373 GHS Precautionary Statements P210, P240, P301+P310, P302+P352, P308+P313, P314, P403+P233 UN Identification Number: 1294 Proper Shipping Name: Toluene Transport Hazard Class: 3 Packing Group: II DOT Placard: What is Toluene? Toluene is a colorless, volatile, and flammable liquid aromatic hydrocarbon. It has a benzene ring substituted with a methyl group (-CH3), making its chemical formula C6H5CH3. Toluene is also known by other names such as methylbenzene or phenylmethane. It has a sweet, pungent odor and is miscible with many organic solvents but only slightly soluble in water. How Is Toluene Produced? Toluene is primarily produced as a byproduct of the petroleum refining process, specifically during the catalytic reforming of naphtha fractions. The main steps involved in the production of toluene include: Naphtha Fractionation: The process begins with the distillation of crude oil to separate it into various fractions, including naphtha. Naphtha is a mixture of hydrocarbons with carbon chain lengths typically ranging from C5 to C12. Catalytic Reforming: The naphtha fraction undergoes catalytic reforming, which is a process that involves subjecting the hydrocarbons to high temperature and pressure in the presence of a catalyst. The catalyst, often composed of platinum or platinum-rhenium on an alumina support, promotes various reactions such as dehydrogenation, isomerization, and cyclization. Aromatic Hydrocarbon Formation: During catalytic reforming, some of the naphtha molecules undergo dehydrogenation and cyclization reactions, leading to the formation of aromatic hydrocarbons, including benzene, toluene, and xylene (BTX). Toluene is specifically formed through the methylation of benzene, where a methyl group (-CH3) is added to the benzene ring. Separation and Purification: After catalytic reforming, the product stream is subjected to fractionation to separate the various components, including toluene, from other hydrocarbons. Distillation and other separation techniques are used to isolate and purify toluene from the mixture. Further Processing: The purified toluene can undergo further processing, such as hydrogenation to produce other chemicals like benzene or mixed xylenes. Toluene itself is used as a feedstock in the production of chemicals such as benzene, toluene diisocyanate (TDI), and polyurethanes. Overall, the production of toluene is closely linked to the refining of crude oil, with catalytic reforming being the primary method for its synthesis from petroleum-derived feedstocks. Other sources of toluene include coal tar and certain biomass conversion processes, although these are less common compared to petroleum-based production. What is Toluene used for? Toluene is a versatile chemical compound with numerous industrial and commercial applications. Some of the common uses of toluene include: Solvent: Toluene is primarily used as a solvent in various industries, including paint manufacturing, coatings, adhesives, and printing. It effectively dissolves other substances, making it valuable in these applications. Fuel Additive: Toluene is used as an octane booster in gasoline, improving its performance and reducing knocking in internal combustion engines. It is sometimes added to racing fuels and aviation fuels for this purpose. Production of Chemicals: Toluene serves as a precursor in the production of various chemicals, including benzene, which is used in the manufacture of plastics, synthetic fibers, and rubber. It's also used in the synthesis of toluene diisocyanate (TDI), which is a precursor to polyurethane foams. Rubber and Tire Manufacturing: Toluene is used in the production of rubber and tires as a solvent and as a component of rubber adhesives. Ink Manufacturing: Toluene is used as a solvent in the formulation of printing inks for newspapers, magazines, and packaging materials. Cleaning Products: It's used in some cleaning products, such as degreasers and spot removers, due to its excellent solvent properties. Nail Polish and Nail Polish Removers: Toluene is used as a solvent in nail polish and nail polish removers to dissolve and suspend other ingredients. Dye Production: Toluene is used in the production of dyes and as a solvent in the dyeing process for textiles and leather. Medicinal Uses: In some cases, toluene is used in pharmaceutical manufacturing processes as a solvent or as a precursor to certain drugs. These are just a few examples of the diverse range of applications for toluene. Its versatility and effectiveness as a solvent make it an essential chemical in many industries. However, Is Toluene Dangerous? Toluene poses several potential dangers to human health and the environment, especially when handled improperly or in high concentrations. Some of the key dangers associated with toluene include: Health Effects: Toluene vapor can be harmful if inhaled in high concentrations over a prolonged period. Short-term exposure to high levels of toluene vapor can cause symptoms such as headaches, dizziness, nausea, fatigue, confusion, and irritation of the eyes, nose, and throat. Long-term exposure to toluene may lead to more serious health issues, including damage to the central nervous system, liver, kidneys, and respiratory system. Flammability: Toluene is highly flammable and can form explosive mixtures with air. It has a low flash point, which means it can ignite easily in the presence of a spark, flame, or heat source. Handling toluene near open flames, hot surfaces, or other ignition sources can result in fires or explosions. Environmental Hazards: Toluene can contaminate soil, water, and air if released into the environment. It is volatile and can evaporate quickly from spills or during use, leading to air pollution. Toluene is also persistent in the environment and can bioaccumulate in aquatic organisms, potentially causing harm to ecosystems. Occupational Hazards: Workers in industries where toluene is used, such as paint manufacturing, printing, and chemical production, may be at risk of exposure to high levels of toluene vapor. Proper safety measures, including ventilation, personal protective equipment, and training on safe handling practices, are essential to minimize occupational exposure and prevent health issues. Reproductive and Developmental Effects: There is evidence to suggest that exposure to toluene may have adverse effects on reproductive health and fetal development. Pregnant women exposed to high levels of toluene may be at increased risk of miscarriage, premature birth, or birth defects in their offspring. Addiction Potential: Toluene abuse, primarily through intentional inhalation of its vapors for recreational purposes (known as "huffing" or "sniffing"), poses significant health risks, including addiction, neurological damage, and sudden death due to cardiac arrest or asphyxiation. Given these dangers, it is important to handle toluene with care, follow safety guidelines and regulations, and take appropriate precautions to minimize exposure to protect both human health and the environment. What Gaskets are recommended for Toluene? Toluene is a chemical solvent that can have compatibility issues with certain gasket materials, especially over prolonged exposure or at elevated temperatures. Some gasket materials that are generally considered compatible with toluene include: PTFE (Polytetrafluoroethylene): PTFE gaskets, commonly known as Teflon gaskets, are highly resistant to a wide range of chemicals, including toluene. They offer excellent chemical resistance and can withstand high temperatures, making them suitable for many toluene applications. Viton (Fluoroelastomer): Viton gaskets are known for their excellent chemical resistance and can often withstand exposure to toluene. They are commonly used in applications requiring resistance to fuels, oils, and solvents. Fluorocarbon (FKM): FKM gaskets are known for their exceptional chemical resistance, high temperature stability, and resistance to oils and fuels. They are often used in applications where exposure to toluene and other aggressive chemicals is expected, such as in the automotive, aerospace, and chemical processing industries. Is Toluene Polar or Nonpolar? Toluene is considered to be a nonpolar molecule.The reason for this is its symmetrical molecular structure. Toluene consists of a benzene ring (which is a hexagonal ring of carbon atoms with alternating single and double bonds) with a methyl group (-CH3) attached. The bonds between carbon and hydrogen in the methyl group are nonpolar, and the carbon-carbon bonds in the benzene ring are relatively nonpolar due to the similar electronegativities of carbon and hydrogen.Because of this symmetrical arrangement and the similar electronegativities of the atoms involved, the overall distribution of charge in the molecule is relatively uniform, resulting in a nonpolar molecule. As a nonpolar solvent, toluene is often used to dissolve nonpolar substances and is immiscible with polar solvents such as water Toluene Lab Grade Safety Data Sheet (SDS)

$16.00 - $450.00

-

Tool-Less Adapter Assembly

Tool-Less Adapter Assembly This adapter fits on 30mm OD glass flanges. The other side is 1/2" MNPT to connect to various fittings for attaching hoses and like items.

$85.00

-

Tri Clamp / Tri Clover U-Bend

Tri Clamp / Tri Clover U-Bend Tri-Clamp / Tri Clover connection U-Bend made out of 304 sanitary stainless steel allows the user to make a 180 degree connection with their system and redirect flow as needed: Tri-Clamp / Tri-Clover Sizes Available: 1" (Fits 1.5" Tri-Clamp) 1.5" 2" 3" 4" 6"

$40.00 - $250.00

-

Tri-Clamp Ball Valve 316L SS

316L SS Tri-Clamp/Tri-Clover Ball Valve - Nitrogen Tested (Valve holds a 30 day limited warranty) The 316L Stainless Steel Tri-Clamp Sanitary connection ball valve allows the user to restrict flow on their extraction system and close off a connection to a spool to allow the material to soak for longer durations extracting more of the essential oils. This Ball Valve is 1/4 turn locking handle with the 3-piece PTFE encapsulated core that is rebuildable if needed. This ball valve is nitrogen tested for leaks at BVV™ to ensure the ball valve is safe to operate. Specifications Material: 316L Stainless Steel Handle Type: 1/4 Turn Locking Connection Type(s): Tri-Clamp Sizes Available: 1" (Fits 1.5" Tri-Clamp) 1.5" 2" Temperature Range: -20℃ To +150℃ Working Pressure: 1000 WOG BVV™ Tri Clamp Ball Valve - Data Sheet Note: the valve is warrantied for 30 days from defects in workmanship

$155.00 - $235.00

-

Tri-Clamp Direct Drive Mixers

Tri-Clamp Direct Drive Mixers 3/4 HP Air Direct Drive Tri-Clamp Mixer, (1) 4" PRL, 1" x 28" Exposed, Comp Mech Seal 3/4HP Shaft Length: 28" (From bottom of Tri-clamp) Air inlet port: 1/4" NPT Air adjustment valve to control speed Requires 30CFM @ 100 PSI air supply 3/4 HP Variable Speed Electric Direct Drive Tri-Clamp Mount Mixer 3/4 HP 115V Power supply Shaft Length: 28" (From bottom of Tri-clamp) 1 HP XP Direct Drive Tri-Clamp Mixer, Mech. Seal, (1) 5.5" HEI, 0.625" x 28" Exposed Shaft, VFD Motor: 1 HP, XPFC Inverter Duty, Class 1, Div 1, Group C&D; Class 2,Div 1, Group F&G, Temp Code T4, 10:1 Turndown, 208-230/460V,3Ph, 1760 RPM VFD Controler: 1HP Speed Controller with Digital RPM Readout in Outdoor Rated NEMA 4X Enclosure, 240V/1Ph (Mounted Outside of XP Area)w/ Local XP Control Package, 352 to 1760 RPM, Mounted to Motor ,Bare Wire Leads Mount: 3'' Sanitary Mount, 316SS Wetted faces Seal: 316 SS 60 Series 2-Piece Mechanical Inside Seal w/Viton ORings; Carbon-Graphite Rotary, Sintered Silicon Carbide Stationary, Hastelloy C-276 Springs, Dry Running, Sealed for Pressure/Vacuum Wetted Surface Finish: Mill Shaft: 0.625'' x 28'' Exposed Length, 316SS Bottom Impeller: 5.5'' High Efficiency Impeller, 3 Blades, Low Shear,316SS **On Site Wiring Required**

$4,200.00 - $7,400.00

-

Tri-Clamp Ferrule

Tri-Clamp/ Tri Clover Ferrule Tri-clamp ferrules are the bottom of our open blast systems. These ferrules allow the user to use a screened gasket at the end of an open blast spool while providing an open end. Specifications: Material: 304 Stainless Steel Connection Type: Tri-Clamp Standard: 3A Sizes Available: 1.5" 2" 3"

$5.00 - $7.00

-

Tri-Clamp Filter Plate

Stainless Steel Tri-Clamp/ Tri Clover Filter Plate Stainless steel filter plates offer the user a great solid platform to help with filtration during the extraction process and they come standard with a 100 mesh (150 Micron) pre-cut stainless steel mesh filter media and a solid filter plate ring (unless otherwise specified). These filter plates can be used simultaneously with ashless filter papers or any other filtration media like stainless steel ball bearings or steel wool to increase surface and filtration level to remove fats, lipids, waxes and any other unwanted material during the extraction process. For 6" sizes and above, a high pressure clamp is recommended for all filtering applications. *Note: Does not include Clamp or Gasket. **Note: 8" Sizes come with a compression ring instead of a solid filter plate ring. Sizes Available: 1.5" - Includes Solid Filter Plate Ring 2" - Includes Solid Filter Plate Ring 3" - Includes Solid Filter Plate Ring 4" - Includes Solid Filter Plate Ring 6" - Includes Solid Filter Plate Ring 8" - Includes Standard COMPRESSION Ring 10" - Includes Solid Filter Plate Ring 12" - Includes Solid Filter Plate Ring Specifications Material 304 Stainless Steel Standard 3A High Polish Connection Type(s) Tri-Clamp Hole Diameter 5.8mm Height 2" Mesh Specs 100 Mesh (150 Micron) - 304 Stainless Steel BVV™ Tri-Clamp Filter Plate - Drawing

$33.00 - $280.00

-

Tri-Clamp Neoprene Insulation Sleeve by BVV

BVV Neoprene Insulation Sleeve's Our Insulation sleeves are made from 3mm durable Neoprene Scuba Fabric and has a rated insulation value of R 1.5 These sleeves are 90% polyester and 10% spandex which makes all of these a snug fit around the spools. The material weighs in at 350 grams per square meter and has a smooth finish and a double stitched side seam. The sleeves can be easily cut with scissors and modified to add custom cutouts. The sleeves are also reversible and the inside color is black. Note: *Customers who order De-Wax or Fully Jacketed spool sleeves will not have pre-cut holes for the side ports. But fear not this material cuts very easily with sharp cutting tools, and you can easily add the small holes for these ports. BVV's Tested Temperatures: -80°C to 105°C (-112°F to 220°F) we have not tested beyond these temperature, it doesn't mean it not capable its just untested by BVV.

$8.00 - $57.81

-

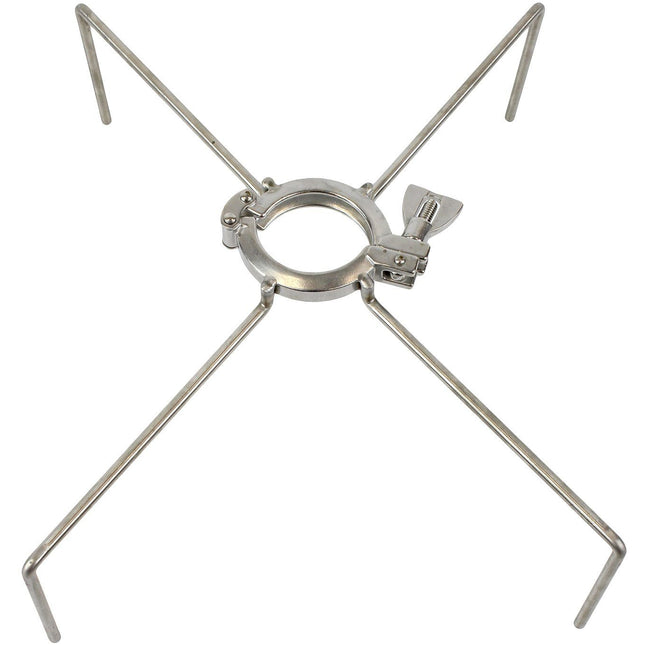

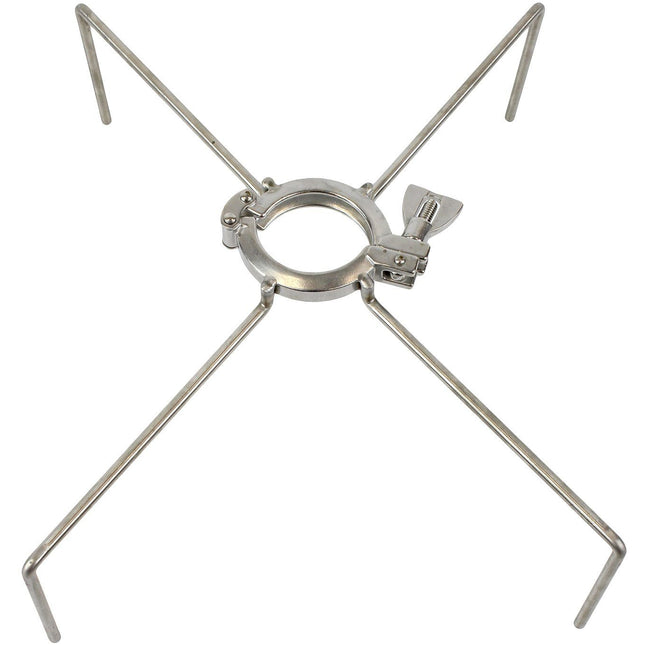

Tri-Clamp Quadpod

Tri-Clamp Quadpod Quadpods provide an excellent solution to holding any Tri-Clamp spool vertically. From closed columns to open blast extraction units, Quadpods are designed to fit over Pyrex dishes without getting in the way. This device has 4 legs, 4.5" in length, and extends 7" outward in each direction. Furthermore, each leg is welded to the clamp to provide a sturdy and durable platform. Sizes Available: 1.5" 2" 3" Specifications: Material 304 Stainless Steel Connection Type(s): Tri-Clamp

$36.00 - $45.00

-

Tri-Clamp Sight Glass - Long

Tri-Clamp Sight Glass - Long These tall sight glasses are a great additions closed-loop extraction system to view the liquefied solvent flowing through your system and see the color before the purging process is completed. The short sight glass also allows the user to add a viewing port to their system without adding a lot of additional height compared to a normal Tri-Clamp sight glass. Unlike many competitors, this sight glass is also nitrogen tested for leaks at 100 PSI before it is sent to the customer to ensure safe operation of their extraction system. ***Note: Does not include clamp or gasket. Specifications: Sight Glass Material: 304 Stainless Steel Glass Material: Borosilicate Gasket Material: Buna Connection Type: Tri-Clamp x Tri-Clamp Specifications for Caged Sight Glasses ONLY Product Temperature Spec (Min – Max) Max Pressure Rating Gasket Material Glass Material & Thickness SG150-C -20 - 100°C 230 PSI Butyronitrile Pyrex GlassØ45X7X100MM SG200-C -20 - 100°C 200 PSI Butyronitrile Pyrex GlassØ60X7X100MM SG300-C -20 - 100°C 180 PSI Butyronitrile Pyrex GlassØ85X8X80MM SG400-C -20 - 100°C 165 PSI Butyronitrile Pyrex GlassØ119X8X80 SG600-C -20 - 100°C 150 PSI Butyronitrile Pyrex GlassØ164X8X87

$79.00 - $350.00

-

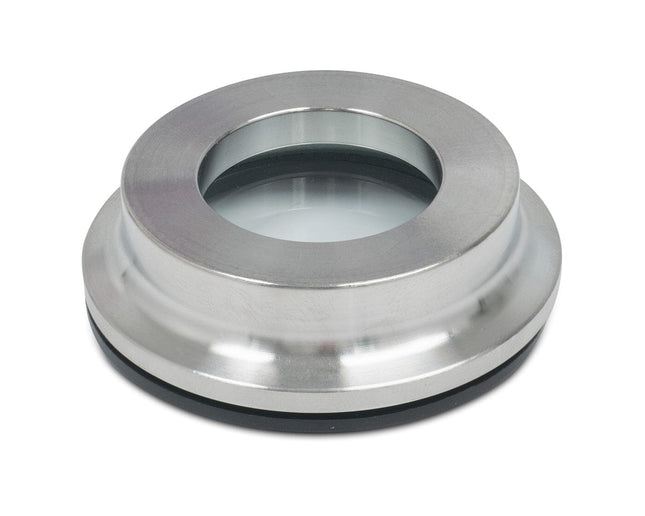

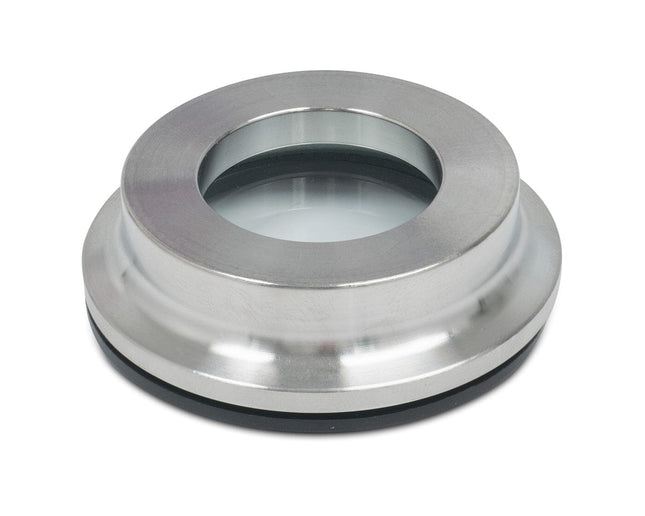

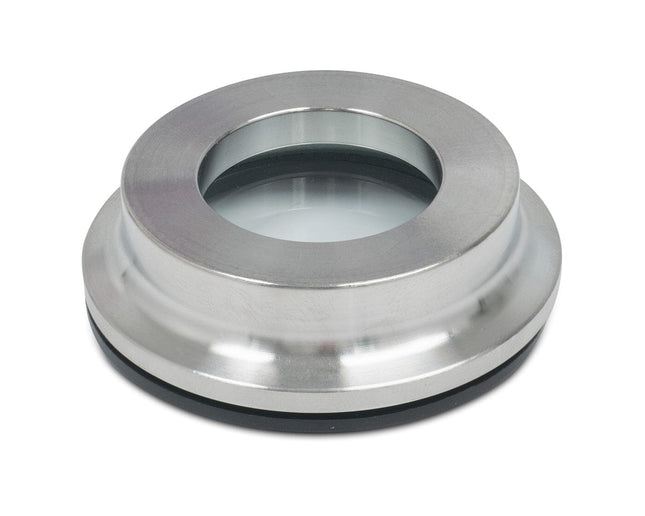

Tri-Clamp Sight Glass 250 PSI - Peer Reviewed Certified

Neocision Sight Glass Tempered Strengthened Soda Lime Glass The 3 piece Neocision certified sight glasses offer a greater chemical resistance, viewing area, and cleanability compared to a traditional sight glass such as polycarbonate or Metaglas sight glasses. These Tri-Clamp sight glasses consist of 3 pieces: the tempered glass disc, Viton x-profile gasket, and custom tri-clamp ferrule. When used in combination with high-pressure clamps the working PSI is rated at 250 PSI (3rd party tested). These glasses are also resistant to thermal shock, enduring extreme heating and cooling temperatures. A Viton Tri-Clamp gasket must be used to conform with the certification ratings, and and is included. ***Disclaimer: Please handle with care when installing on to a system and do not overtighten or the glass disc may chip if the clamp torque ratings are exceeded. Clamp Torque Specification Sheet Sizes Available: 1.5" Tri-Clamp 2" Tri-Clamp Ferrule Material 304 Stainless Steel Glass Material Tempered Soda Lime Gasket Material Viton(FKM) Connection Type(s) Tri-Clamp PSI Rating 250 PSI Negative Temperature Rating -40C BVV™ Neocision Sight Glass - Certified Data Sheet

$64.00 - $74.00

-

Tri-Clamp Single Hinge Clamp

Tri-clamp/ Tri Clover Single Hinge Clamp BVV™ recommends tightening all Standard Pressure Clamps (Non-High Pressure) to finger tight and then use either a screwdriver or wrench to tighten them approximately 2 full turns to achieve the torque specified on the data sheet. All tightening should be accordance with the data sheet. It is not recommended to overtighten the clamp and bottom it out as this will cause the gasket to be over-compressed and put too much tension on the clamp threads, which could cause it to fail. Overtightening can also cause stretching on the clamp reducing its operational effectiveness. Torque Specification Data Sheet Specifications: Mounting Type: Hinged (The 1.5" Clamp is Double Hinged) Material: 304 Stainless Steel Bolt Material: 304 Stainless Steel (3/8"-16 Bolt) Nut Material: Brass (5/8 Wrench Size w/ 3/8"-16 Thread Size) Connection Type: Tri-Clamp

$9.00 - $83.00

-

Tri-Clamp Spool with 2" Angled Ports

304 Stainless Steel Tri-Clamp Spools with 2" Angled Ports allow the user varying amounts of configuration and also the ability to put 2 sight glass end caps on the 2" Ports to allow the user to view the flow inside of a column or spool.Sizes Available: 4" Tri-Clamp x 6" Length x (2) 2" Angled Ports 6" Tri-Clamp x 6" Length x (2) 2" Angled Ports

$185.00 - $265.00

-

Tri-Clamp Spool x 3" Length x 1/4" MNPT

1.5" Tri-Clamp/ Tri Clover x 3" x 1/4" MNPT

$35.00

-

Tri-Clamp to 1" Barb

Tri-Clamp to 1" Barb / Tri Clover End Caps These tri-clamp end caps: Have a 1" Hose Barb connection Come in either 1.5", 2" tri-clamp sizes Are made of 304 stainless steel

$30.00

-

Tri-Clamp Topcap with Valve and 1/4" 37 Degree JIC Flare -40 to 230C

Tri-Clamp / Tri Clover Top cap with Valve and 1/4" 37 Degree JIC Flare (Nitrogen Tested) Pre-installed 1/4" 37 Degree JIC Flare and 304 stainless steel ball valve on a Tri-Clamp endcap. These endcaps and valves and nitrogen tested for leaks to ensure safe usage of any extraction system. Flare endcaps are useful when connecting PTFE lined stainless steel braided hoses to a system because the flared connection type requires NO PTFE tape to create a seal, unlike many threaded connections. Specifications: 304 Stainless Steel Tri-Clamp Endcap 304 Stainless Steel Heavy Duty Ball Valve -40 to 230C (1/4" MNPT/FNPT Connections) 304 Stainless Steel 1/4" 37 Degree JIC Flare Pre-Assembled and Nitrogen Tested for Leaks at Best Value Vacs Tri-Clamp Sizes Available: 1.5" 2" 3" 4" 6"

$48.00 - $85.00

-

Tri-Clamp Topcap with Valve and 1/4" Barb

Tri-Clamp/ Tri Clover Top cap with Valve and 1/4" Barb Pre-installed 1/4" hose barb (Fits 1/4" ID Hoses) and 304 stainless steel ball valve on a Tri-Clamp endcap. These endcaps and valves and nitrogen tested for leaks to ensure safe usage of any extraction system. Barb endcaps are useful when connecting flexible tubing to the barb connection to transfer fluids easily or even pull a vacuum on an extraction system instead of using flared connections. ***Note: Please check the pressure rating of the tubing that is going to be used beforehand. Specifications: 304 Stainless Steel Tri-Clamp Endcap 304 Stainless Steel Heavy Duty Ball Valve -40 to 230C (1/4" MNPT/FNPT Connections) 304 Stainless Steel Hose Barb (Fits 1/4" ID Hose) Pre-Assembled and Nitrogen Tested for Leaks at Best Value Vacs Tri-Clamp Sizes Available: 1.5" 2" 3" 4" 6"

$32.00 - $65.00

-

Tri-Clamp Welded Bottom Base

Welded Bottom Tri-Clamp/ Tri Clover Base These stainless steel welded bottom bases are the standard base for our extraction systems and provide the user with a heavy duty and high capacity way to collect and recovery their extracted material and solvent. Many people will have several of these welded bases set aside to quickly swap out their base on their extractor to reduce the time between system runs. Sizes Available: 4" x 4" 6" x 6" 8" x 12" 10" x 10" 12" x 12" Specifications: Material 304 Stainless Steel Standard 3A High Polish Connection Type(s): Tri-Clamp Welded Bottom Thickness 0.25" - 0.50" BVV™ Tri-Clamp Welded Bottom Base - Drawing

$60.00 - $246.00

-

Triclamp / Tri Clover Y

Specifications: 304 Grade Stainless Steel w/ High Polish interior Fits 1" or 1.5" Triclamp Unique Y Connection Disclaimer: All Stainless Steel Parts bought seperately to piece together a Closed Loop, Closed Column, or Open Blast Extractor DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested.User assumes all responsibility and risks of the system"

$38.00

-

Triclamp Spool x 3" Length x (2)1/4" Female NPT

Specifications: 304 Grade Stainless Steel w/ High Polish interior Fits 1.5" or 2" Triclamp / Tri Clover (2)1/4" Female NPT Port 3" Tall Disclaimer: All Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractor DO NOT come with a standard 1-year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested.User assumes all responsibility and risks of the system"

$39.00

-

Triclamp Spool x 3" Length x 1/4" Female NPT

Specifications: 304 Grade Stainless Steel w/ High Polish interior Fits 1.5" or 2" Triclamp 1/4" Female NPT Port 3" Tall Disclaimer: All Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractor DO NOT come with a standard 1-year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested.User assumes all responsibility and risks of the system" BVV™ Triclamp Spool x 3" Length x 1/4" Female NPT - Drawing

$35.00

-

Triclamp T

Sanitary Tri-Clamp Tee – 304 Stainless Steel (3A Certified) Upgrade your sanitary processing system with BVV’s high-quality Tri-Clamp Tees, precision-engineered from 304 stainless steel for superior corrosion resistance and long-lasting performance. Manufactured in accordance with 3A sanitary standards, these tees are ideal for use in food, beverage, pharmaceutical, and botanical extraction applications. ✅ 3-Way Tee Design for optimal flow distribution✅ High-Polish 304 Stainless Steel – Durable, hygienic, easy to clean✅ Available Sizes: 1.5", 2", and 6" Tri-Clamp connections✅ Compatible with standard Tri-Clamp fittings, gaskets, and clamps✅ Ideal for sanitary process piping, closed-loop extraction, and lab builds BVV’s Tri-Clamp fittings are trusted by industry professionals for their precision, quality, and performance. Whether you’re building out a new system or upgrading your existing setup, our Tri-Clamp Tees deliver reliability where it matters most.

$28.00 - $200.00

-

TRS21 & BVV Butane Recovery Pump Valve Rebuild Kit

This is the complete valve rebuild kit for the cylinder head on the BVV Recovery pumps or the TRS21. This is only for 2 pistons. So if you have the BVV 4 Cylinder pump you would need two kits. These gaskets are upgraded and are compatible with butane and propane gasses, all the O-ring seals in this kit are Viton

$80.00

-

TRS21 / BVV Upgraded Stainless Steel 2-Piece Piston and Rod Design for Hydrocarbon Extraction

BVV-1 Included in this kit: Complete connecting rod assemblies with 2-piece SS piston, piston seals, and viton o-rings. This upgrade kit can be used for the following recovery pumps: CPS TRS21 Anti-spark/explosion pump BVV 2 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified BVV 4 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified - Requires 2 kits because this unit has 4 cylinders. Looking to rebuild your TRS21 and want to upgrade to a more efficient and longer lasting piston/rod setup? This kit comes with a fully assembled connection rod and 2 piece piston. The piston is made out of SS making it a great choice for any application where bacterial growth must be eliminated. This design focuses on long life piston seal and wear band. This kit utilizes a Viton energized o-ring specifically designed for butane and or propane recovery used in the extraction process. By utilizing this kit the piston seal and wear band can be easily removed without having to disassemble the rod from crank. An inexpensive tool (*NOT INCLUDED* SKU: BVV-TL1) is required to rebuild the seals next time service is needed. The tool uses two posts to lock into the top of the piston and a 5/8” Hex heat to remove the top part of the piston. If you would like to purchase both the piston/rod assembly and tool it’s (SKU:BVV-K1). If the tool is not used the customer is responsible for all damage done to piston. After this has been done the wear ring can slide out and the piston seal can be replaced with a new one, the kit can be purchased for all future piston seal and wear band rebuilds (*NOT INCLUDED* SKU: BVV-3). Loctite 242 (*NOT INCLUDED) will also be required for proper installation. A test was performed between the OEM piston and seal design and the BVV. Results show that the BVV had a much less leak rate than the OEM design. After hours of use the leak rate of the OEM design was unable to recover the complete initial solvent batch. This affects the efficiency of the recovery process.

$185.00

-

TRS21 / BVV Upgraded Top Piston Assembly

BVV-3 Included in this kit: Top piston assembly with piston seal and piston wear band. This upgrade kit can be used for the following recovery pumps: CPS TRS21 Anti-spark/explosion pump BVV 2 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified BVV 4 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified - Requires 2 kits because this unit has 4 cylinders. BVV CMEP-OL Retro Fit Upgraded Head - Requires 2 kits because this unit has 4 cylinders. BVV 4 Cyl & 2 Cyl Pump Seal Rebuild Instructions If you have upgraded to the 2-piece SS piston design this kit is used to rebuild the piston seal and wear band. Piston tool (SKU: BVV-TL1) and Loctite 242 will be needed to properly install. If tool is not used the customer is responsible for any damage done to piston during assembly.

$110.00

-

TRS21 2 Piece Piston Tool

BVV-TL1 Included: 2-piece piston tool. This tool is specially used to rebuild BVV-1. It features two posts that lock into the top of the piston and a 5/8” hex head for easy installation. This tool is required to install top piston assembly without damaging the piston. If this tool is not used the customer is responsible for all damage done to piston.

$13.00

-

TRS21 Complete Connecting Rod Assembly Upgrade Kit

BVV-K1 Included in this kit: Complete connecting rod assemblies with 2-piece SS piston, piston seals, viton o-rings, and 2-piece piston tool. Looking to rebuild your TRS21 and want to upgrade to a more efficient and longer lasting piston/rod setup? This kit comes with a fully assembled connection rod and 2 piece piston. The piston is made out of SS making it a great choice for any application where bacterial growth must be eliminated. This design focuses on long life piston seal and wear band. This kit utilizes a Viton energized o-ring specifically designed for butane and or propane recovery used in the extraction process. By utilizing this kit the piston seal and wear band can be easily removed without having to disassemble the rod from crank. An inexpensive tool (*INCLUDED* SKU: BVV-TL1) is required to rebuild the seals next time service is needed. The tool uses two posts to lock into the top of the piston and a 5/8” Hex heat to remove the top part of the piston. After this has been done the wear ring can slide out and the piston seal can be replaced with a new one, the kit can be purchased for all future piston seal and wear band rebuilds (*NOT INCLUDED* SKU: BVV-3). Loctite 242 (*NOT INCLUDED*) will also be required for proper installation. A test was performed between the OEM piston and seal design and the BVV. Results show that the BVV had a much less leak rate than the OEM design. After hours of use the leak rate of the OEM design was unable to recover the complete initial solvent batch. This affects the efficiency of the recovery process.

$195.00

-

TRS21 Upgraded Compressor head SS ¼” SAE 45D IN and OUT fittings

BVV-9-1 Included in this kit: TRS21 compressor head SS ¼” SAE 45D IN and OUT fittings, Viton o-rings. Use these fittings to replace the OEM brass fittings on your TRS21. The SS fittings minimize and help eliminate bacterial growth in the recovery process.

$28.00

-

TRS21 Upgraded Cylinder Replacement Kit, w/Shims Fits BVV4CYL & BVV2CYL

BVV-6 Included in this kit: (2x) Anodized Aluminum Cylinders and Viton Gaskets, Plus 6 shims (2x .004" and 2x .002") use for top dead center adjustment of the cylinders to dial in the displacement (recommended displacement .008"). This upgrade kit can be used for the following recovery pumps: CPS TRS21 Anti-spark/explosion pump (including the SS model from BVV) BVV 2 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified BVV 4 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified - Requires 2 kits because this unit has 4 cylinders. BVV 4 Cyl & 2 Cyl Pump Seal Rebuild Instructions

$99.00

-

TRS21 Valve Head Complete Viton O-ring Kit

Replacement kit with Viton O-rings for the TRS21 head. Compatible for use with the Oil Extraction Market, Butane and Propane Extraction solvents.

$25.00

-

UL Listed BVV™ Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 21.2CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) This is the BVV™ Brand 21.2CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 21.2CFM will pull a vacuum down to 0.3 microns effortlessly. The pump is designed with corrosion resistance and long-term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 110v 60Hz 1100 Watts Pumping Rate: 21.2CFM Ultimate vacuum without gas ballast: 0.3 micron Ultimate vacuum with gas ballast: 6 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2L/2.1 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Dimensions: 21 x 7.5 x 12 Shipping Dimensions: 29.5 x 9.5 x 16.5 Unit Weight: 95lbs Shipping Weight: 105lbs Recommended oil: Ultragrade 19 Noise level: <58 dB CE Compliance: Yes Warranty: 1 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result in the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$3,500.00

-

UL Listed BVV™ Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 11.3CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) This is the BVV™ Brand 11.3CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 11.3CFM will pull a vacuum down to 0.3 microns effortlessly. The pump is designed with corrosion resistance and long-term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 110v 60Hz 750 Watts Pumping Rate: 11.3CFM Ultimate vacuum without gas ballast: 0.3 micron Ultimate vacuum with gas ballast: 6 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 1.5L/1.59 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Dimensions: 21 x 7.5 x 12 Shipping Dimensions: 29.5 x 9.5 x 16.5 Unit Weight: 66lbs Shipping Weight: 75lbs Recommended oil: Ultragrade 19 Noise level: <58 dB CE Compliance: Yes Warranty: 1 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result in the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$2,600.00

-

UL Listed BVV™ Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 5.6CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) Features Our Pro series are our most impressive line of rotary vane pumps available. Known for their high degree of efficiency and deep ultimate vacuum, all Pro models feature a dual-stage, chemical-resistant pump configuration designed to handle abusive, extended vacuum evacuations. Capable enough to comfortably handle laboratory and scientific applications, these pumps are also extremely simple in operation and require minimal maintenance. PTFE chemical resistant pump vanes provide superior corrosion resistance and reliability. Large oil reservoir and adjustable gas ballast standard on every model to increase pump oil lifetime. Internal check-valve included in every unit, prevents accidental pump oil backflow. Exhaust oil filter trap included. DEEP ultimate vacuum and KF25 inlet for optimal pumping speed. Lightweight, with noise-dampening rubber feet. Rugged, reliable, economical, and efficient pump designed for day in, day out use. Air cooled, thermally protected motors enclosed in a durable aluminum housing. Gas ballast valve for deeper vacuum. Steel inlet KF25 flange port with multiple intake size. Plastic handle, skid-resistant rubber base. 1 year limited warranty. Specification Electrical Voltage 120v Frequency 60 Hz Plug NEMA 5-15 US Standard Pump Flowrate 5.6 CFM Configuration 2 Stage Pump Ultimate Vacuum 0.3 Micron Ultimate Vacuum (with ballast) 6 Micron Oil Capacity 1000 ml Recommended Oil Ultragrade 19 Motor Power 1/2 hp Max Speed 1720 RPM Noise Level <56 dB Package Inlet / Exhaust KF25 / NW25 Weight 46 lbs Compliance CE Listed Ships With Exhaust Filter, Pump Oil, User Manual, Power Cable Warranty 1 year Components Pro Series Pump Components(Included exhaust filter not pictured) Performance Comparison Pump speed comparison for our Pro Series pumps. Downloads Maximum Attainable Vacuum at Altitude Reference Chart Vacuum Units Conversion Chart Additional Information How do Rotary Vane pumps work? Rotary vane pumps work by having a rotor with two adjusting vanes continuously rotating and exhausting air or any other molecules in the occupied space. The four stages which a rotary vane pump undergo are shown below Single Stage vs Two Stage Vacuum Pump: BVV™ Pro Series pumps are a dual-stage rotary vane pump style. Dual-stage pumps have two rotors and two sets of vanes that work together to fully pull a medium vacuum (1st stage) and then pull a better vacuum (2nd stage). These pumps will evacuate more quickly and can pull a deeper vacuum when compared to single-stage pumps. What is Gas Ballast and how does it work? During the pumping process the vacuum pump is trying to evacuate gas present in the occupied space, both non-condensable and condensable gases and vapors. Gas ballast helps increase the percentage of non-condensable vapors such that it will allow for the pump to efficiently exhaust all gases and vapors. This in turn will increase the overall efficiency and pumps life. When the pump is being used with non-condensable gases it's safe to keep the gas ballast valve closed. On the other hand, when there is a condensable gas or vapor present, the gas ballast should be opened appropriately. Gas ballast is used at the beginning of the pumping process when condensable gases are known to be present, then it's closed to finish pulling the deepest vacuum. For more info on rotary vane pumps please view our blog post: Rotary Vane Pumps and Gas Ballast Explained. Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$1,750.00

-

UL Listed Pro Series Vacuum Pump Complete Service Kit

Pro Series Vacuum Pump Complete Service Kit This is a compelete vacuum pump service kit for the BVV™ Pro Series 5.6, 11.3, 21.2CFM line of vacuum pumps and allows the user to completely rebuild their pump and keep it running like new.

$320.00 - $350.00

-

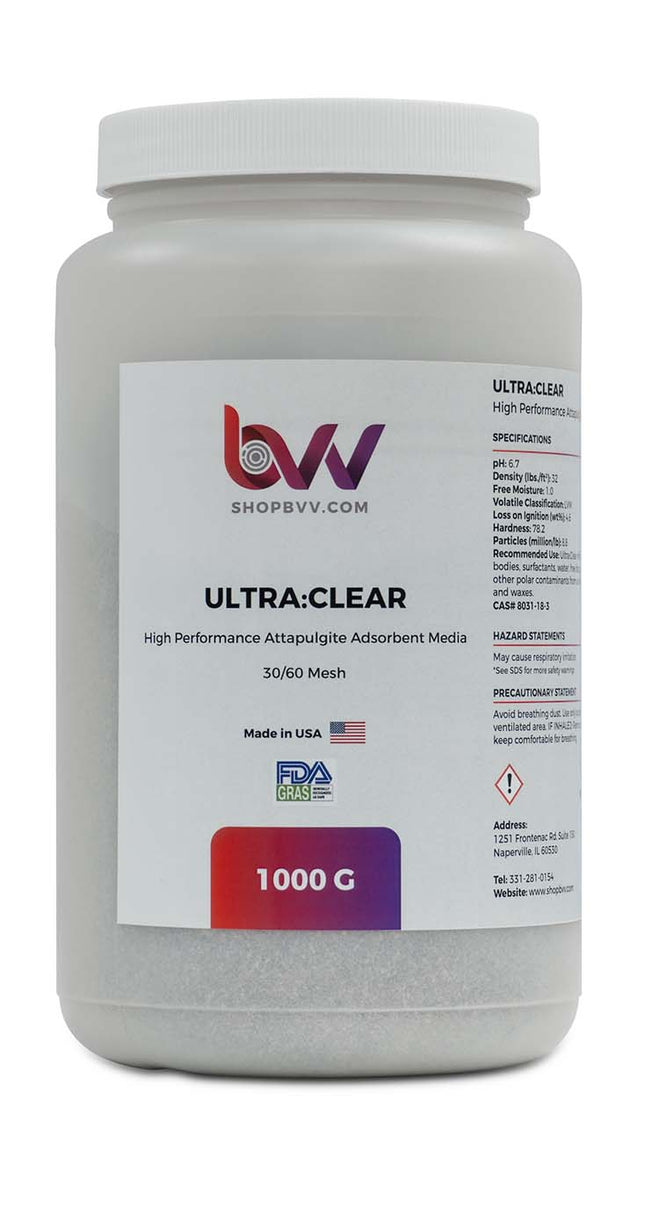

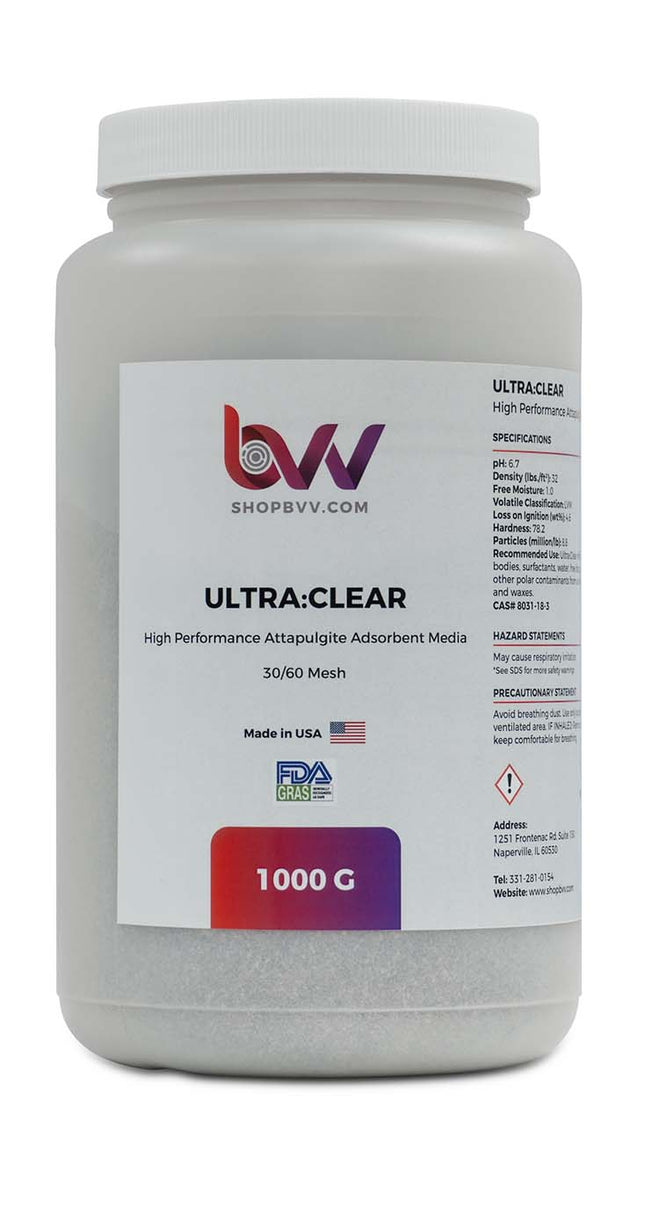

Ultra Clear - Granular High Performance Bentonite for Bleaching & Decolorizing Edible Oils *Compares to CRX™

Ultra:Clear® 30/60 Mesh, Compare to Media Bros CRX™ Made in USA, Food Grade Certified Ultra-Clear® effectively removes color bodies, surfactants, water, free fatty acids, organic oxides, and other polar contaminants from a wide range of oils, liquids, and waxes. This High-Flow media is amazing for color remediation CRC and has a 30/60 mesh granule size to get color remediation done quickly with low pressure drops. This media you will be sure to love. At BVV™ we recommend 100g per lb. of biomass. We also use this media with layering techniques & can be used with BVV™ Silica Gel and BVV™ Neutral Activated Alumina for a sugar in the oven finish! Save big on buying the 50lb Bag(s). Ultra:Clear is manufactured in 3 granule sizes, 8/16, 16/30 & 30/60 Mesh sizes. The smallest size granules are the 30/60 and will offer the greater surface area while retaining a High-Flow media for your extraction. See the technical data sheet for more information from the manufacturer. Ultra:Clear® Food Grade Certificate Ultra:Clear® Technical Data Sheet Ultra:Clear® Safety Data Sheet

$15.00 - $2,150.00

-

Ultra Clear L - Granular High Performance Bentonite for Bleaching & Decolorizing Edible Oils

Ultra:Clear® L 8/16 Mesh Made in USA, Food Grade Certified Ultra-Clear® L effectively removes color bodies, surfactants, water, free fatty acids, organic oxides, and other polar contaminants from a wide range of oils, liquids, and waxes. It is the Largest particle size in the Ultra-Clear product line. UltraClear® L is a unique, naturally occurring attapulgite that has been thermally processed to provide hard, durable granules that won’t swell or breakdown in the presence of water. All Ultra-Clear products are classified as processing aids andhave Generally Recognized As Safe (GRAS) status from theFood and Drug Administration (FDA). At BVV™ we recommend 200g per lb. of biomass. We also use this media with layering techniques & can be used with BVV™ Silica Gel and BVV™ Neutral Activated Alumina for a sugar in the oven finish! Ultra-Clear® is manufactured in 4 granule sizes, 8/16, 16/30, 30/60 & 60/90 mesh sizes. See the technical data sheet for more information from the manufacturer. Ultra:Clear® L Food Grade Certificate Ultra:Clear® L Technical Data Sheet Ultra:Clear® L Safety Data Sheet

$15.00 - $2,150.00

-

Ultra Clear M - Granular High Performance Bentonite for Bleaching & Decolorizing Edible Oils

Ultra:Clear® M 16/30 Mesh Made in USA, Food Grade Certified Ultra-Clear® M effectively removes color bodies, surfactants, water, free fatty acids, organic oxides, and other polar contaminants from a wide range of oils, liquids, and waxes. It is the Second Largest particle size in the Ultra-Clear product line. UltraClear® M is a unique, naturally occurring attapulgite that has been thermally processed to provide hard, durable granules that won’t swell or breakdown in the presence of water. All Ultra-Clear products are classified as processing aids andhave Generally Recognized As Safe (GRAS) status from theFood and Drug Administration (FDA). At BVV™ we recommend 150g per lb. of biomass. We also use this media with layering techniques & can be used with BVV™ Silica Gel and BVV™ Neutral Activated Alumina for a sugar in the oven finish! Ultra-Clear® is manufactured in 4 granule sizes, 8/16, 16/30, 30/60 & 60/90 mesh sizes. See the technical data sheet for more information from the manufacturer. Ultra:Clear® M Food Grade Certificate Ultra:Clear® M Technical Data Sheet Ultra:Clear® M Safety Data Sheet

$15.00 - $2,150.00

-

Ultra Clear S - Granular High Performance Bentonite for Bleaching & Decolorizing Edible Oils

Ultra:Clear® S 60/90 Mesh Made in USA, Food Grade Certified Ultra-Clear® S effectively removes color bodies, surfactants, water, free fatty acids, organic oxides, and other polar contaminants from a wide range of oils, liquids, and waxes. It is the Smallest particle size in the Ultra-Clear product line. UltraClear® S is a unique, naturally occurring attapulgite that has been thermally processed to provide hard, durable granules that won’t swell or breakdown in the presence of water. All Ultra-Clear products are classified as processing aids andhave Generally Recognized As Safe (GRAS) status from theFood and Drug Administration (FDA). At BVV™ we recommend 100g per lb. of biomass. We also use this media with layering techniques & can be used with BVV™ Silica Gel and BVV™ Neutral Activated Alumina for a sugar in the oven finish! Ultra-Clear® is manufactured in 4 granule sizes, 8/16, 16/30, 30/60 & 60/90 mesh sizes. Ultra-Clear® S is the smallest particle size and will offer the greatest surface area while remaining a High-Flow media for your extraction. See the technical data sheet for more information from the manufacturer. Ultra:Clear® S Food Grade Certificate Ultra:Clear® S Technical Data Sheet Ultra:Clear® S Safety Data Sheet

$18.00 - $2,200.00

-

Ultrasonic Cleaners

BVV™ Ultrasonic cleaners are the industry standard for lab and industrial grade applications and are made out of high quality stainless steel. Ultrasonic cleaning uses cavitation bubbles induced by high frequency pressure (sound) waves to agitate a liquid. The agitation produces high forces on contaminants adhering to substrates like metals, plastics, glass, rubber, and ceramics. This action also penetrates blind holes, cracks, and recesses. The intention is to thoroughly remove all traces of contamination tightly adhering or embedded onto solid surfaces. Water or solvents can be used, depending on the type of contamination and the workpiece. Contaminants can include dust, dirt, oil, pigments, rust, grease, algae, fungus, bacteria, lime scale, polishing compounds, flux agents, fingerprints, soot wax and mold release agents, biological soil like blood, and so on. Ultrasonic cleaning can be used for a wide range of workpiece shapes, sizes and materials, and may not require the part to be disassembled prior to cleaning. Specifications Model LS-30L IS-77L IS-264L Material Stainless Steel Stainless Steel Stainless Steel Reservoir Capacity 30L (7.9 gal) 77L (20.3 gal) 264L (70 gal) Exterior Dimensions 13" x 22" x 13-1/4" 23-1/2" x 31.5" x 32-1/8" 35" x 55-1/2" x 36" Weight 22lbs 130lbs 250lbs Reservoir Dimensions 11.5" x 19.5" x 7-3/4" 15-5/8" x 21.5" x 13-3/4" 23.5" x 31-3/8" x 21.5" Tray Dimensions 9-5/8" x 17.5" x 5" 18-7/8" x 14-1/8" x 7-1/2" 21-3/4" x 28.5" x 9-3/4" Ultra Sonic Power 600w 1200w 3000w Heating Power 500w 3000w 6000w Voltage 110v/60Hz 110v/60Hz 220v/60Hz 3 Phase Casters No (Rubber Feet) Yes (Locking) Yes (Locking)

$650.00 - $3,750.00

-

Universal Drum Wrench, Aluminum Alloy

This is an aluminum alloy universal drum wrench that is used on 3/4" and 2" drums and barrel bungs. This lightweight wrench can be used to open bungs and is capable of quarter turns in tighter spaces. Perfect for various facility and warehouse uses.

$19.00 $13.00

-

Universal Vacuum Chamber Gasket

Universal Vacuum Chamber Gasket Our patented gasket #9475627 This vacuum chamber gasket is made out of durable and heat resistant silicone. It features a large flange on a single side so the user can adapt one of our lids to varyingly sized vessels. Gasket Specifications: 10.75" - Can Fit lids 10.75" in Diameter and up to 3/4" in thickness 12.75" - Can Fit lids 12.75" in Diameter and up to 1" in thickness

$40.00 - $45.00

-

Upgrade Tool for TRS21 Suction Valve

Our specialized tool for use with rebuilding the head on TRS21, makes installation of new Suction Valve O-Rings much easier. Includes (5) Viton O-rings.

$18.00

-

Upgraded TRS21 Compressor Head

Upgraded TRS21 Compressor Head Complete, Stainless Fittings, Viton Upgrade your TRS21 by purchasing a new Compressor Head with Viton O-rings for butane and propane gas compatibly and stainless steel fittings to meet FDA guidelines on handling of consumable products. This head is assembled here in the USA and is a direct replacement for any TRS21 Compressor Head.

$180.00

-

V4D 4CFM Two Stage Vacuum Pump

BVV™ V4D 4CFM Two Stage Vacuum Pump This is the BVV™ V4D 4CFM Two Stage Vacuum Pump used in botanical extraction. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Feature Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer oil life Lightweight Rubber Feet for noise dampening Reliable, economical, and efficient Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports Pump Warranty Information Customers using solvents such as stabilization resin, rotaries (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$355.00

-

V7S 7CFM Single Stage Vacuum Pump

V7S 7CFM Single Stage Vacuum Pump This is the BVV™ V7S 7CFM Single Stage Vacuum Pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer Oil life Lightweight Rubber Feet for noise dampening Reliable, Economical and Efficient. Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$265.00

-

V9D 9CFM Two Stage Vacuum Pump

BVV™ V9D 9CFM Two Stage Vacuum Pump This is the BVV™ V9D 9CFM Two Stage Vacuum Pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer Oil life Lightweight Rubber Feet for noise dampening Reliable, Economical and Efficient. Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$445.00

-

Vacuum Chamber 50 Micron Air Filter

Vacuum Chamber 50 Micron Air Filter This vacuum chamber air filter is designed to be used with Best Value Vacs, SVac, and Glass Vac vacuum chambers. It easily threads into the Female NPT side of the valve manifold and protects the contents inside of the chamber from having dust be sucked back into the chamber when vacuum is released because it will filter the incoming air. Quality replacement parts & fittings for vacuum chambers.

$6.00

-

Vacuum Filter Trap

Vacuum Filter Trap This Vacuum Filter Trap is designed to remove potential contaminants from the vacuum line to prolong the lifetime of your pump. Packed with oil-free, stainless-steel SS304 wool and made with a glass jar, the filter trap may optionally be used as a low-cost cold trap. Welch Inlet / Exhaust Separator 1423B with stainless steel wool inside for even more filtration. We built out two separate fitting configurations for your convenience: just choose from the drop-down menu above! The trap ships default with two 3/8" Barbed fittings, but you may alternatively select our KF25 x 1/4" JIC fittings to receive your vacuum trap specially designed for use with our ovens! Simply clamp the trap directly onto your oven's KF25 vacuum port, then connect a 1/4" hose to your vacuum pump. Specifications: Inlet/Outlet: 3/8" FNPT (ships with adapters selected above) Jar: 230ml Glass -- Welch Inlet / Exhaust Separator 1423B Steel Wool: Oil-free SS304 Maximum Vacuum: <29"Hg Dimensions: 2.8" dia x 4.3" tall Please note this item does not include any vacuum tubing. To order, we recommend the 3/8" Gum Rubber Vacuum Tubing.

$360.00

You have seen 1056 out of 1084 products