BVV

-

Sodium Chloride (Salt) USP, Kosher Certified, Fine Grain

Our USP Sodium Chloride is a purified salt which meets United States Pharmacopeia standards. Morton is the only US supplier with multiple USP Sodium Chloride producing plants. The crystals are fine grain in form. Our USP Sodium Chloride complies with United States Pharmacopeia, Food Chemicals Codex, and federal cGMP standards. It is annually certified as Kosher. AdditivesThis Brand of USP Sodium Chloride contains no additives. Sodium Chloride Product Data Sheet (PDS) Sodium Chloride Certificate of Analysis (COA) Sodium Chloride Safety Data Sheet (SDS)

$8.00 - $60.00

-

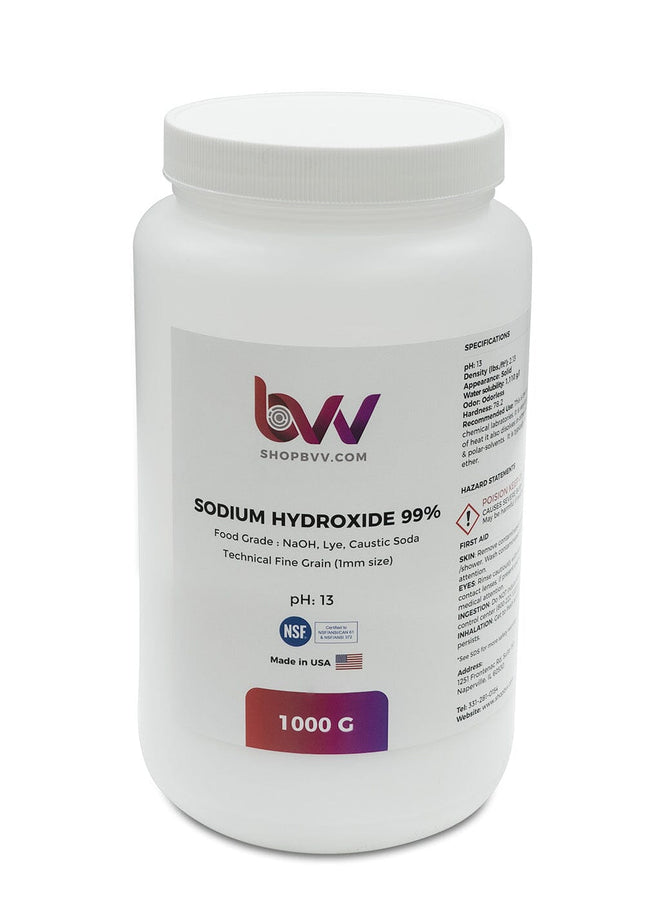

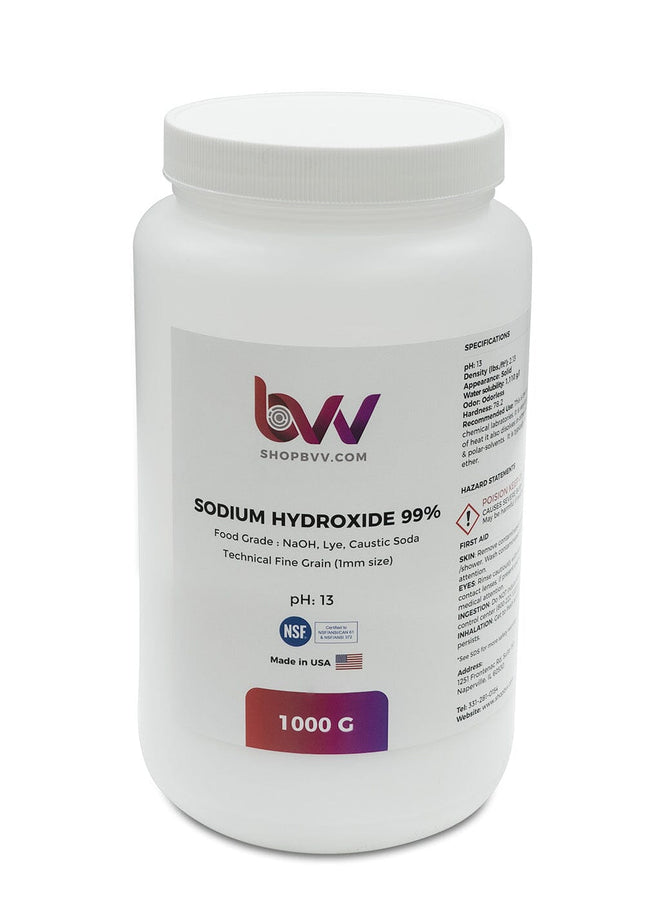

Sodium Hydroxide 99% (Food Safe)

High Purity Sodium Hydroxide 99% NSF Certified (Food Safe Chemical) Sodium Hydroxide is a highly versatile compound that finds extensive use in various applications, including acid-base extractions. As a strong base, Sodium Hydroxide is used to adjust the pH of aqueous solutions, making it an ideal choice for separating acidic and basic compounds during extraction. Also known as caustic soda, Sodium Hydroxide is a highly alkaline compound that is used in a wide range of applications beyond extraction including manufacturing, cleaning, and water treatment. At BVV, we pride ourselves on offering only the highest-quality chemicals and compounds, including Sodium Hydroxide. Our Sodium Hydroxide is a premium-grade product that is manufactured to the highest standards, ensuring exceptional quality and performance for your pH adjustment needs. Our Sodium Hydroxide is NSF certified as a food safe chemical, which means it can be used in a variety of applications including drinking water and is evaluated safe for consumption.Our product is available in a range of sizes and quantities to suit your needs, and our team is always on hand to provide expert advice and support. High Purity Sodium Hydroxide Safety Data Sheet SDS High Purity Sodium Hydroxide Certificate of Analysis COA Chemical Formula: NaOH Molecular Weight: 39.9971 g/mol CAS Registry Number: 1310-73-2 Appearance White, hard (when pure), opaque crystals Odor: Odorless Density 2.13 g/cm3 Boiling Point: 1388°C / 2530°F Solubility in water: 418 g/L (0 °C)1000 g/L (25 °C)3370 g/L (100 °C) GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H290, H302, H314 GHS Precautionary Statements P280, P305+P351+P338, P310 UN Identification Number: 1823 Proper Shipping Name: Sodium Hydroxide, solid Transport Hazard Class: 8 Packing Group: II DOT Placard: What Is Sodium Hydroxide? Sodium hydroxide, commonly known as lye or caustic soda, is a highly versatile and strong alkaline compound. It is represented by the chemical formula NaOH and consists of one sodium (Na+) ion, one hydrogen (H+) ion, and one hydroxide (OH-) ion. Sodium hydroxide is a white, odorless solid at room temperature and is highly soluble in water, producing a highly alkaline solution. It is widely used in various industries and applications, including manufacturing, chemical processes, cleaning agents, soap production, food processing, and more. What Is Sodium Hydroxide Used For? Sodium hydroxide (NaOH), commonly known as caustic soda or lye, has a wide range of industrial, commercial, and household uses due to its strong alkaline properties. Some of the common uses of sodium hydroxide include: Chemical Manufacturing: Sodium hydroxide is a key component in the production of various chemicals, including detergents, soaps, textiles, paper, and synthetic materials. Soap and Detergent Production: It is used in the saponification process to make soap and is also a crucial ingredient in many household and industrial cleaning products. Food Processing: Sodium hydroxide is used to process and refine certain foods, such as in the preparation of olives, cocoa, and chocolate. It is also used for peeling fruits and vegetables. Water Treatment: In water treatment, sodium hydroxide is used to adjust pH levels, remove acidity, and precipitate metals from wastewater. Petroleum Industry: It is used in refining petroleum products, including the removal of impurities from crude oil. Aluminum Production: Sodium hydroxide is employed in the extraction of alumina from bauxite ore and as an electrolyte in the aluminum extraction process. Pulp and Paper Industry: It is used in the pulping and bleaching processes of paper manufacturing. Textile Industry: Sodium hydroxide is utilized to process and dye textiles and fabrics. Pharmaceuticals: It is used in the manufacture of certain drugs and pharmaceutical products. Biodiesel Production: Sodium hydroxide is used as a catalyst in the transesterification process to produce biodiesel from vegetable oils or animal fats. Hydrogen Production: Sodium hydroxide is used to produce hydrogen gas through the electrolysis of water. Cleaning and Degreasing: It is used as a strong cleaning agent for surfaces, equipment, and industrial machinery due to its ability to dissolve oils, fats, and grease. Drain Cleaning: Sodium hydroxide-based drain cleaners are used to unclog and clean drains. pH Adjustment: In laboratories and industrial processes, sodium hydroxide is used to adjust the pH of solutions. It's important to note that sodium hydroxide is a highly caustic and reactive substance, and its use should be handled with care and appropriate safety measures. Is Sodium Hydroxide Lye? Yes, sodium hydroxide is commonly known as lye. Lye is a strong alkaline substance that is often used in various industrial, commercial, and household applications, as mentioned earlier. It is important to handle sodium hydroxide with caution, as it can cause severe burns and irritation if it comes into contact with skin or eyes. Proper safety measures should be taken when working with sodium hydroxide or lye. Are Sodium Hydroxide and Caustic Soda The Same Thing? Yes, sodium hydroxide and caustic soda are the same thing. Caustic soda is a common name for sodium hydroxide, which is a strong alkaline chemical compound. Both terms refer to the same chemical substance with the chemical formula NaOH. It is used in various industrial, commercial, and household applications, including cleaning, manufacturing, and chemical processes. What Is Sodium Hydroxide Structure? Sodium hydroxide (NaOH) has a simple molecular structure consisting of one sodium (Na) atom, one oxygen (O) atom, and one hydrogen (H) atom. The structure of sodium hydroxide can be visualized as follows: In this structure, the sodium atom (Na) is bonded to the oxygen atom (O) through an ionic bond, and the oxygen atom is bonded to the hydrogen atom (H) through a covalent bond. The hydroxide ion (OH-) is formed by the combination of the oxygen and hydrogen atoms, and it is the key component that gives sodium hydroxide its strong alkaline properties. What Is The pH of Sodium Hydroxide? The pH of sodium hydroxide (NaOH) is very high and strongly alkaline. Sodium hydroxide is a strong base and is commonly used to raise the pH of solutions. In its pure form, sodium hydroxide has a pH of approximately 14, which is the highest value on the pH scale. When dissolved in water, it dissociates into hydroxide ions (OH-) and sodium ions (Na+), resulting in a highly alkaline solution with a pH greater than 14. The exact pH of a sodium hydroxide solution will depend on its concentration and the amount dissolved in the solventWhat Are The Hazards of Sodium Hydroxide? Is Sodium Hydroxide A Weak or Strong Base? Sodium hydroxide (NaOH) is considered a strong base. It is highly soluble in water and dissociates completely into sodium ions (Na+) and hydroxide ions (OH-) when dissolved. This complete dissociation results in a high concentration of hydroxide ions in the solution, making sodium hydroxide a strong and effective source of hydroxide ions for chemical reactions. Strong bases like sodium hydroxide have a high tendency to accept protons (H+) from other substances, leading to the characteristic properties of strong bases, such as high alkalinity and the ability to neutralize acids.What Is Sodium Hydroxide? What Are The Hazards of Sodium Hydroxide? Sodium hydroxide (NaOH) is a caustic and highly reactive compound, and its use should be handled with care due to the following hazards: Corrosive to Skin and Tissues: Sodium hydroxide is highly corrosive and can cause severe burns upon contact with the skin, eyes, and mucous membranes. It can damage and destroy living tissue upon contact, leading to chemical burns and tissue damage. Inhalation Hazard: Inhaling sodium hydroxide dust, fumes, or mists can irritate the respiratory tract and cause coughing, shortness of breath, and lung irritation. Prolonged exposure to airborne sodium hydroxide particles can lead to more serious respiratory effects. Eye Irritation: Contact with sodium hydroxide can cause irritation, redness, and damage to the eyes. Severe exposure can lead to permanent eye damage or blindness if not promptly treated. Reactivity: Sodium hydroxide is highly reactive and can react violently with certain substances, especially acids. Mixing sodium hydroxide with acids can result in rapid heat generation, spattering, and potentially explosive reactions. Environmental Impact: Sodium hydroxide is harmful to aquatic life and can lead to water pollution if released into the environment. It is important to properly dispose of sodium hydroxide-containing solutions and prevent their release into water systems. Corrosion of Materials: Sodium hydroxide can corrode metals and other materials, causing structural damage and weakening of containers, pipes, and equipment. Toxicity: Ingesting sodium hydroxide can cause severe internal burns, damage to the digestive system, and even death. Ingestion can lead to life-threatening medical emergencies and requires immediate medical attention. To mitigate these hazards, it is essential to handle sodium hydroxide with proper protective equipment, such as gloves, goggles, and lab coats, in a well-ventilated area. Proper storage, labeling, and disposal procedures should also be followed to prevent accidents and environmental contamination. How Do I Use Sodium Hydroxide Safely? Sodium hydroxide, also known as caustic soda or lye, is a highly caustic and potentially dangerous chemical. It's essential to handle and use it safely to prevent accidents or injuries. Here are guidelines for safely using sodium hydroxide: Protective Equipment: Wear appropriate personal protective equipment (PPE), including chemical-resistant gloves, safety goggles or a full-face shield, a lab coat or chemical-resistant apron, and closed-toe shoes with chemical-resistant soles. Work in a Controlled Environment: Work in a well-ventilated area, such as a fume hood, to minimize exposure to fumes. Adequate ventilation helps disperse any fumes produced during handling. Avoid Skin Contact: In case of skin contact, immediately flush the affected area with plenty of water for at least 15 minutes. Remove contaminated clothing and seek medical attention if irritation or burns occur. Prevent Eye Contact: Wear chemical-resistant safety goggles or a full-face shield to protect your eyes from splashes. If sodium hydroxide comes into contact with your eyes, rinse them immediately with water for at least 15 minutes and seek medical attention. Use Appropriate Containers: Use containers made of materials that are compatible with sodium hydroxide, such as glass or certain types of plastic. Avoid using aluminum or reactive metals. Dilution Procedure: When diluting sodium hydroxide in water, always add the chemical to the water, not the other way around. Stir gently while adding to prevent splashing. Label Containers: Properly label containers holding sodium hydroxide solutions with appropriate hazard warnings and information. Handling Crystals or Pellets: Handle sodium hydroxide crystals or pellets with dry hands or appropriate gloves to avoid skin contact. Always use tools (e.g., scoops or spatulas) to handle solid sodium hydroxide. Do Not Inhale Fumes: Avoid inhaling sodium hydroxide fumes. Work in a well-ventilated area, and if working with large quantities or generating fumes, use a fume hood or wear a chemical-resistant mask with appropriate filters. Emergency Equipment: Have access to emergency equipment, such as eye wash stations and safety showers, in case of accidental exposure. Know the location of fire extinguishers and fire alarm systems. Spill Response: In case of a sodium hydroxide spill, follow your organization's spill response procedures. Typically, this involves containing the spill, neutralizing with an acid if appropriate, and safely cleaning it up. Storage: Store sodium hydroxide in a cool, dry, well-ventilated area, away from incompatible substances (e.g., acids, organic materials). Keep containers tightly closed when not in use. Dispose of Waste Properly: Dispose of sodium hydroxide waste in accordance with local, state, and federal regulations. It is considered hazardous waste and should be handled and disposed of as such. Training and Knowledge: Ensure that personnel working with sodium hydroxide are adequately trained in its safe handling, storage, and disposal. Training should include hazard recognition, first aid procedures, and emergency response protocols. First Aid: Familiarize yourself with the appropriate first aid measures for sodium hydroxide exposure, including how to treat skin contact, eye exposure, and ingestion. Medical Monitoring: If workers are regularly exposed to sodium hydroxide, consider implementing a medical monitoring program to track their health and detect early signs of exposure-related issues. Always follow the safety guidelines and procedures established by your organization or regulatory authorities when working with sodium hydroxide. Remember that sodium hydroxide is a highly caustic substance, and improper handling can result in severe burns or other injuries. Prioritize safety and take appropriate precautions to protect yourself and others from potential hazards associated with sodium hydroxide.

$12.00 - $1,200.00

-

Sodium Metabisulfite NSF-Certified

Sodium Metabisulfite has many major and niche uses. It is widely used for preserving food and beverages, and as a laboratory reagent. It is a white crystalline powder. Our Sodium Metabisulfite is NSF® Certified. NSF-certified means a product was independently verified for safety, sanitation, and quality by NSF. NSF certification is recognized by health departments, government agencies, and industry associations. Sodium Metabisulfite NSF Certified - Certificate of Analysis (COA) Sodium Metabisulfite NSF Certified - Safety Data Sheet (SDS)

$16.00 - $61.00

-

Solid Cap, PTFE Seal, GL-14 Thread

Cap is made from PBT (thermoplastic polyester) and will withstand temperatures from -45 to 200º C. The seal is PTFE

$8.00

-

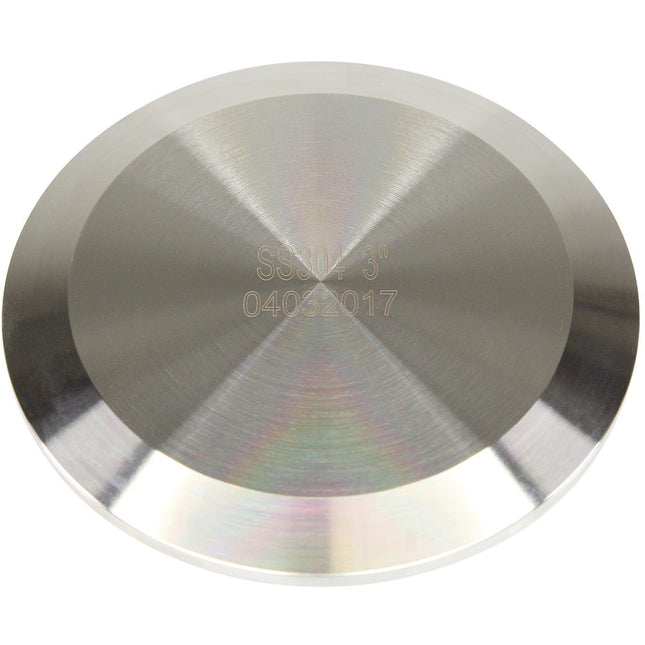

Solid Tri-Clamp End Caps

Solid Tri-Clamp/ Tri Clover End Caps Best Value Vacs Brand Solid Tri-Clamp End Caps provide the user with the option to cap off a spool or lid or for custom fabrication. Specifications: Material: 304 Stainless Steel Connection Type: Tri-Clamp Standard: 3A Sizes Available: 1.5" 2" 3" 4" 6" BVV™ Solid Tri-Clamp End Caps - Drawing BVV™ Solid Tri-Clamp End Caps - End Cap Chart

$12.00 - $59.00

-

Solvent Pro 18/35 Collection Flask Valve

Solvent Pro 18/35 Collection Flask Valve This is a replacement collection flask valve for Solvent Pro series rotary evaporators. It features a PTFE threaded valve with Viton O-rings for a precision leak-proof vacuum seal. The flange has an ID of 18mm and an OD of 35mm with a 3/8" hose barb for 3/8" ID hoses.

$60.00

-

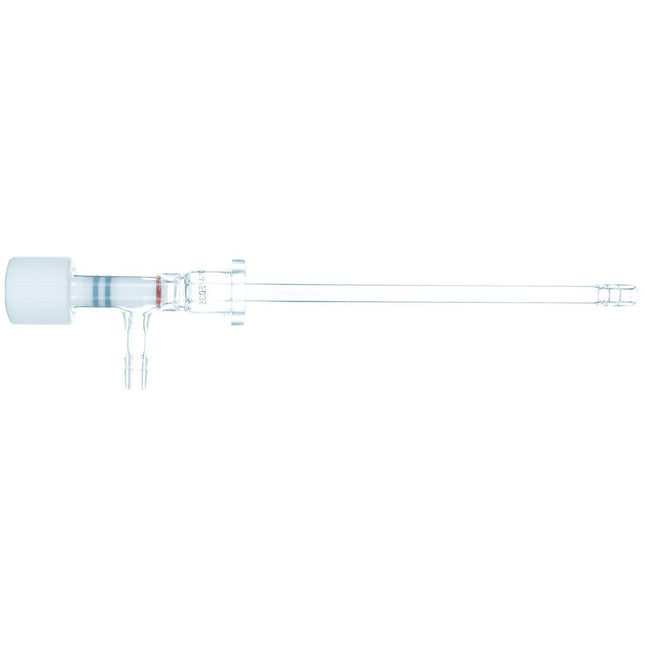

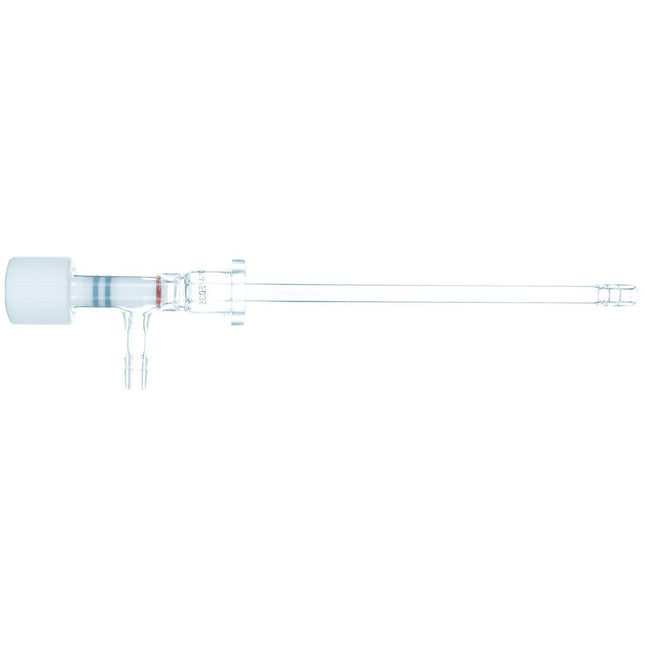

Solvent Pro Injection Valve

Solvent Pro Injection Valve Replacement Injection Valve for Solvent Pro series rotary evaporators with an 18mm ID and 35mm OD flange and a PTFE thread valve with Viton O-ring to provide a leak-proof precision vacuum seal. This valve also has a 3/8" barbed connection with a stem to allow for a PTFE tubing (not included) to inject directly into the rotary flask.

$85.00

-

$10.00

-

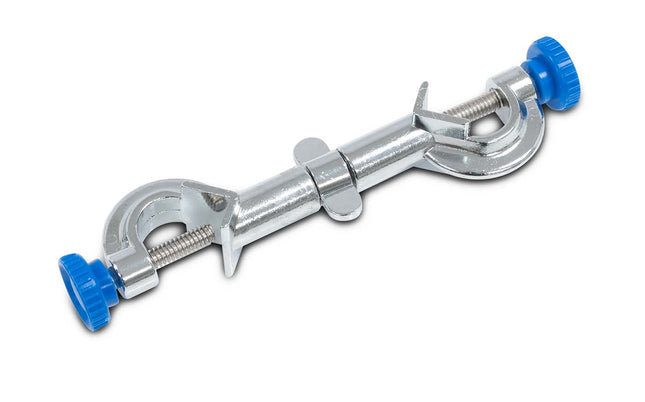

Solvent Pro Series 18/35 Clamp

Solvent Pro Series 18/35 Clamp This is a replacement clamp for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This clamp fits an 18mm(0.71") Inner Diameter and 35mm(1.38") Outer Diameter joint.

$15.00

-

Solvent Pro Series 18/35 Gasket

Solvent Pro Series 18/35 Gasket This is a replacement Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This gasket fits an 18mm(0.71") Inner Diameter and 35mm(1.38") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$13.00

-

Solvent Pro Series 40/60 Clamp

Solvent Pro Series 40/60 Clamp This is a replacement clamp for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This clamp fits an 40mm(1.57") Inner Diameter and 60mm(2.36") Outer Diameter joint.

$15.00

-

Solvent Pro Series 40/60 Clamp and Gasket Set

Solvent Pro Series 40/60 Clamp and Gasket Set This is a replacement Clamp and Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This Clamp and Gasket fit an 40mm(1.57") Inner Diameter and 60mm(2.36") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$35.00

-

Solvent Pro Series 40/60 Gasket

Solvent Pro Series 40/60 Gasket This is a replacement Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This gasket fits an 40mm(1.57") Inner Diameter and 60mm(2.36") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$20.00

-

Solvent Pro Series 60/80 Gasket

Solvent Pro Series 60/80 Gasket This is a replacement Gasket for 10, 30, and 50L Solvent Pro Rotary Evaporators. This gasket fits an 60mm(2.36") Inner Diameter and 80mm(3.15") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$21.00

-

Solvent Recovery Kit - 2 Gallon (Compares to ExtractCraft Source Turbo)

Solvent Recovery Kit - 2 Gallon The BVV Solvent Recovery Kit makes it easy for anyone to recover and reuse their extraction solvent. The kit uses a vacuum pump to lower the boiling point of the solvent, then will use a cooling source such as ice or dry ice to turn the vaporized solvent back into liquid form. This kit has a few different seals, be sure that all materials are compatible with your solvent. These materials include: Viton (FKM) Silicone EPDM / Butyl Please verify before using that all these materials are compatible with your solvent. For an easy resistance chart please visit the Cole Parmer link below: https://www.coleparmer.com/chemical-resistance What's included: No Pump BVV-2G Condensing Coil Hosing Glass Vacuum Chamber Lids/hardware Receiving Vessel Chamber Air Inlet Filter Evaporating Vessel Induction Heating Plate With Pump BVV-2G-V40 Condensing Coil Hosing Glass Vacuum Chamber Lids/hardware Receiving Vessel Chamber Air Inlet Filter Evaporating Vessel Induction Heating Plate Chemically Resistant Vacuum Pump No Evap/ Pump BVV-2G-NEV Condensing Coil Hosing Glass Vacuum Chamber Lids/hardware Receiving Vessel Chamber Air Inlet Filter Evaporating Vessel LID with Universal Gasket *NOTE: This option will fit any pot with an outer diameter of 6.5" - 10.5" Not included in the kit, you will need: Ice Tray Ice Bucket Ice or dry ice A 5 gallon bucket and disposable aluminum catering tray will suffice, however a container with a drain plug or valve would be ideal to easily drain the water produced throughout the process. This kit requires a vacuum pump to operate, we would recommend a chemically resistant diaphragm vacuum pump. We include a 1/4" JIC and 1/4" barb connection to connect to your vacuum pump. The included hosing is 1/4" ID Tygon tubing to easily attach to a barbed vacuum pump. Running the Unit Caution: Unit uses flammable solvents. Use caution while operating unit. ALWAYS OPERATE IN EXTREMELY WELL VENTILATED AREAS Place your solution into the Evaporating Vessel. This can be done by: removing the lid and pouring the solution into the vessel Using the vacuum pump to suck the liquid mixture through the Liquid Inlet Port. Using this method, you can use a Micro-Cap filter in-line to remove solid particulate. Close the Liquid Inlet Port valve and Air Inlet valve Add ice to the bucket and tray. A drain valve built in to the ice bucket and tray would help to drain water later in the test. Open the Vacuum Pump valve and turn on the Vacuum Pump Turn on the Heat Plate. An induction heating plate is recommended Replace ice as needed throughout the run When recovery is completed, close the Vacuum Pump valve and turn off the Vacuum Pump. Open the Air Inlet valve and release the vacuum pressure from the chamber. Use the included micron filter to prevent contaminants from entering the vessel. Turn off the Heat Plate and allow the solute in the Evaporating Vessel to come down to a safe temperature. Removing the solute is easiest when it is still warm. Remove the solvent from the Receiving Vessel. Once the kit is cooled down, use clean ethanol to wipe down the sealing surfaces for the next run. For a more detailed operating procedure please be sure to check out this website: HOME EXTRACTION BY ICHIBANCRAFTER : https://extractcrafter.com/2022/05/10/diy-vacuum-still-part-2-putting-together-and-operation/

$642.00 - $2,485.00

-

Soya Peptone Powder for Mushrooms Mycology

Soya Peptone Powder Bacteriological GradeBest for Vigorous Mycelia Growth Soya peptone is a protein hydrolysate derived from soybeans, used as a rich nutrient source in microbiological culture media and fermentation media to promote the rapid growth of microorganisms, particularly fastidious ones. It serves as a source of nitrogen and other essential nutrients, is available in powder form STORAGE: Cool dry conditions, sealed original package Mix: Mix: 1 gram per. 500ml pH: 6.41 ODOR: Soy bean protein smell. SOLUBILITY: Soluble in water. TOTAL NITROGEN: 10.45% W/W TOTAL ALPHA AMINO NITROGEN: 3.09% W/W TOTAL PLATE COUNT: 1098 CFU/gm YEAST AND MOLDS:: 200CFU/gm E.COLI: NEGATIVE SALMONELLA: NEGATIVE STA{HYLOCOCCUS AUREUS: NEGATIVE PSEUDOMONAS AERUGINOSA: NEGATIVE SHELFLIFE: 4 years. CAS# 91079-46-8 Directions for Use: 1. Mix 1g of soya peptone powder per 500ml of liquid culture or agar recipe for vigorous mycelia growth. 2. Boil and stir until powder is fully dissolved. Sterilize the mixture for 45min @15psi 250°F (121°C) in a pressure cooker or autoclave.

$12.00 - $53.00

-

Splatter Platters

Splatter Platters Splatter platters are a huge step up from normal Tri-Clamp/ Tri Clover bases used on extractors because they provide the user a more effective way of pouring and scraping the extracted material out of the base. These splatter platters are much lighter and easier to deal with during the post-extraction process. Sizes Available: 4" 6" 8" 10" 12" Specifications: Material 304 Stainless Steel Standard 3A High Polish Connection Type(s): Tri-Clamp Height 2" BVV™ Splatter Platters - Drawing

$58.00 - $155.00

-

SSP - Union Elbow - 1/2" Tube x 3/8"

Stainless Steel SSP -Union Elbow 1/2" x 3/8" Duolok

$55.00

-

Stacking Filter Plate Ring Kit

Stacking Filter Plate Ring KIT This Stacking Filter Plate and Ring Kit allows the user to stack multiple levels of filtration while having the rigidity of a solid filter plate. These components are made out of 304 polished stainless steel and will fit inside of the corresponding Tri-Clamp/ Tri Clover parts. The stainless steel rings are solid and measure 8mm in thickness and the filter plates measure about 3mm in thickness with 6mm holes. This Kit Includes: 1x Filter Plate 2x Drop-in Retaining Rings Sizes Available: 1.5" 2" 3" 4" 6" 8" 10" 12" Specifications Material 304 Stainless Steel Ring Thickness 8mm Plate Thickness 3mm Plate Hole Size 6mm

$30.00 - $145.00

-

Stainless Steel 1/4" Hose Barb x 1/4" 37 Degree Flare

Stainless Steel 1/4" Hose Barb x 1/4" 37° Flare

$7.00

-

Stainless Steel 24/40 x 1.5" Tri-Clamp Adapter

Stainless Steel 24/40 x 1.5" Tri-Clamp/ Tri Clover Adapter This Custom Built 304 Stainless Steel Adapter allows the user to adapt to a 24/40 ground glass joint to a 1.5" Tri-Clamp fitting to allow the user to connect the glass joint to a Tri-Clamp system.

$50.00

-

Stainless Steel Butane/Propane Tank Fitting CGA 510

Stainless Steel Butane/Propane Tank Fitting CGA 510 Custom Stainless Steel CGA 510 Butane and Propane Tank Fitting with Viton O-Ring. Specifications: CGA 510 Thread with Viton O-ring seal and either 1/4" MNPT or 1/4", 3/8", 1/2" Flare Material: Stainless Steel

$22.00 - $95.00

-

Stainless Steel Condensing Coils

BVV SS304 Condensing Coils are used in solvent injection kits such as the one show in the video below. They are used to condense ethanol or other hydrocarbons to decrease run times and allow for a pre-chilling of the solvent to be used in the extraction processes. ** For dry ice applications please make sure condensing coil is free of any water/moisture as it will freeze and restrict/block flow when submerged in dry ice. To clear the condensing coil blow pressurized air through one of the ports and drain it into a bucket ** Specifications Small Large X-Large Material 304 Stainless Steel Coil Diameter 6" 9.5" 9.5" Coil Height 5.9" 9.75" 9.75" Coil Length 11' 30' 30' ID 1/4" 1/4" 1/2" Bare Ports 1/4" NPT 1/2" NPT Available Connections: Valves BVV 316SS Full Bore Valves Flares 1/4" - 1/2" 37 Degree JIC Hose Barbs 1/4" - 1/2" Hose Barbs

$125.00 - $465.00

-

Stainless Steel Drum Lid Exhaust 2" Teardrop Flanged Vent Damper Smoke Stack for BBQ Smoker

304 grade stainless steel vent damper for a drum smoker lid. The vent tube has a 2" ID. Height is 4"

$56.00

-

Stainless Steel Extractor Packing Rod for Material *Fits Tri Clamp spools

Stainless Steel Packing Rod for Material Tubes Stainless Steel Extractor Packing Rods for Material Columns are a great addition to any extraction system because they allow the user to compact the plant material tightly into the column allow for more material per extraction and faster overall processing time. These rods come with a plate that matches the size of the inner diameter of the tri-clamp column utilizing a gasket for a tight fit. The rod is able to be extended with extra 24" sections that can also be purchased separately. Specifications: Plate and Rod Material: 304 Stainless Steel Gasket Flange Material: Viton

$55.00 - $380.00

-

Stainless Steel Female Elbow

BVV™ Female Elbow BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are NPT threads (National Pipe Taper) and will compress against other Female/Male NPT threads creating a tighter and tighter connection. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. Three sizes available: 1/4, 3/8, and 1/2 inch. BVV™ SS Female Elbow - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4"-18 FNPT 3/8"-18 FNPT 1/2"-14 FNPT Sizes Available: 1/4" 3/8" 1/2"

$12.00 - $33.00

-

Stainless Steel Filters - 25 Micron (25μm) - 5ct - Cut to Size

25μm Stainless Steel Filter Tube 5Pk 1" Diameter x 9" Length

$15.00

-

Stainless Steel Hang-On Bracket for BVV™ Extraction Racks

Stainless Steel Hang-On Bracket for BVV™ Extraction Racks This heavy duty Stainless steel Hang-On bracket is designed for easy removal of material columns. They are made out of 1/4" thick stainless steel and can fit on either a 1.5" extraction rack bar if needed and include (2) Flathead Hex screws and Nylon lock nuts. (8020 bolts are sold separately.)

$25.00

-

Stainless Steel Injection Coil - Tall

Stainless Steel Injection Coil - Tall The BVV Stainless Steel Injection Coil- Tall allows the user to chill solvent with dry ice and does not have 90 degree bends to slow down the speed of the fluid passing through the coil. The extended top allows the user to completely submerge the coil while preventing the dry ice and alcohol slurry from splashing out of the pot. This coil comes standard with 1/2" NPT ports that will not restrict flow of solvent through the coil. Specifications: Weight: 26LB Chamber OD: 10" Depth: 16" Connection Sizes: Bare 1/2" FNPT ports w/ Drain Plug, JIC or Barb fittings available Material: 304 Stainless Steel

$275.00 - $280.00

-

Stainless Steel KF-25 x Glass Jointed Adapter

Stainless Steel KF-25 x Glass Jointed Adapter This Custom Built 304 Stainless Steel Adapter allows the user to adapt to a KF-25 high vacuum fitting to a 24/40 or 34/45 ground glass joint fitting to allow the user to connect a KF flanged laboratory grade vacuum pump.

$55.00 - $60.00

-

Stainless Steel Laboratory Scissor Jacks

Stainless Steel Scissor Jacks Adjustable height laboratory scissor jack. The platform is 4"/6"/8" & the durable 304 stainless steel heavy-duty lab lifts with very little effort necessary! Specifications: 304 Stainless Steel Platform size: 4" x 4" / 6" x 6" / 8" x 8"

$29.00 - $49.00

-

Stainless Steel LP Tank - Includes Gas and Liquid Fill/Drain Ports

Stainless Steel LP Tank - Includes Gas and Liquid Fill/Drain Ports Stainless Steel LP tanks offer a superior way to decrease contamination of solvent and feature a tri-clamp lid with a high-pressure clamp. This allows easy access to the inside of the tank, making cleanout simple, unlike a normal carbon steel LP tanks. Tanks feature a safety collar to prevent damage to the valves, as well as a welded ring on the bottom to prevent damage to the tank body and allow better circulation of fluid around the entire tank. Lids come configured with 2 valves and compound gauge and polycarbonate sight glass on the larger #50 and #100 tanks. These tanks come with BVV 1/4" FNPT valves and 1/4" 37 Degree JIC Flares with one port being connected to a dip tube. ***Note: Tank comes empty and does not include solvent. Butane Capacity Calculation: All solvent tanks sold by Best Value Vacs have their capacity determined by this calculation and are based on industry-standard nomenclature of the water weight tank # system because the specific gravity of water is 1.000 and the DOT 80% fill guideline. Example: 100# Tank = ~100lbs of water weight, Halfton Tank = 1000lbs of water weight. Specifications Tank # Water Weight in Lbs Specific Gravity of Butane 0.601 80% Fill Guideline 0.800 (Tank #) * (Specific Gravity of Butane) * ( 80% Fill Guildine) Sizes Available: 30# 50# - 1.5" Tri-Clamp ferrule with sight glass 100# - 1.5" Tri-Clamp ferrule with sight glass Specifications Tank/Component Material 304 Stainless Steel Gasket Material BUNA-N Sight Glass Material (50# and 100# Only) Polycarbonate Standard 3A High Polish Connection Type(s) 1/4" (7/16-20) x 37° JIC Lid Connection Type(s): Tri-Clamp 1/4"-20 FNPT Butane Capacity: 30# 14.424 50# 24.040 100# 48.080 ***Disclaimer: These are not DOT rated tanks and are not recommended for transportation when filled.

$475.00 - $830.00

-

Stainless Steel Packing Plate

Stainless Steel Packing Plate Replacements for Packing Plate Stainless Steel Rods

$20.00 - $160.00

-

Stainless Steel Tri-Clamp Hopper

The Triclamp / Tri Clover hopper can be attached to a material column to assist in packing the column with material. The Hopper has no tri clamp ferrule on the larger end and is made out of sanitary 304 stainless steel.

$155.00 - $185.00

-

Stainless Steel Tri-Clamp x Female Joint Adapter

This unique adapter allows the user to adapt a Tri-Clamp fitting to a male ground joint glass fitting and it is made out of 304 stainless steel.

$38.00

-

Stainless Tri-Clamp Weldless Bulkhead

Stainless Tri-Clamp Weldless Bulkhead This tri clamp bulkhead or panel mount can be mounted through a vessel wall such as vacuum chamber or tank. It has a silicone or buna-n tri clamp gasket that is placed on the outside of the chamber or vessel. It is capable of holding vacuum, and can also withstand positive pressure 8-10 psi is expected but depending on the installation geometries and material you can expect some higher pressures than that. It will be able to hold vacuum, but not high positive pressure. For best vacuum results, vacuum greases is recommended on the sealing surface of the panel/lid or vessel wall. Max wall thickness: .875" Hole Size: TCPM150- 1.3-1.4" TCPM200- 1.9-2.0" Thread Size: TCPM150- 1" NPS TCPM200- 1.5" NPS

$33.00 - $36.00

-

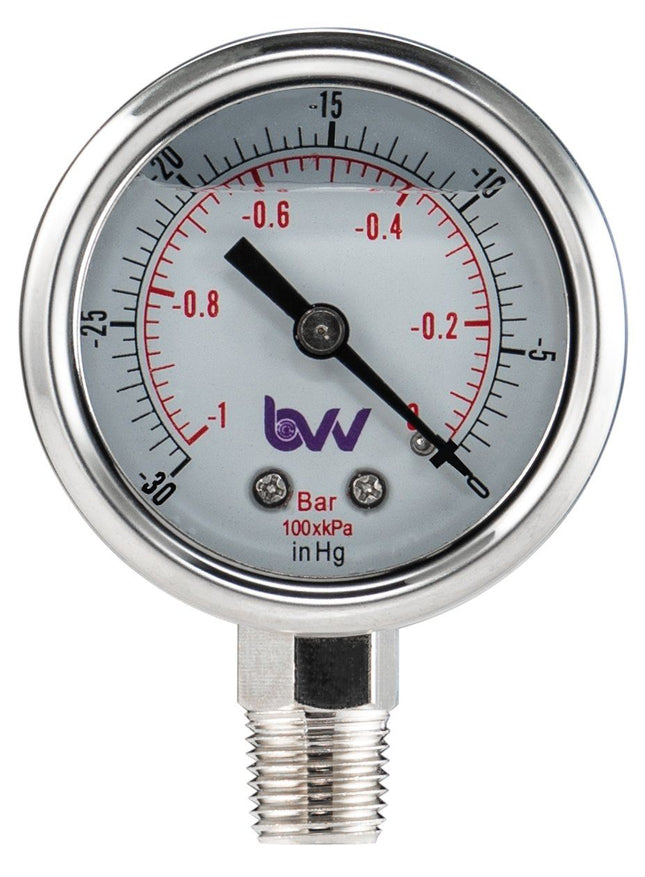

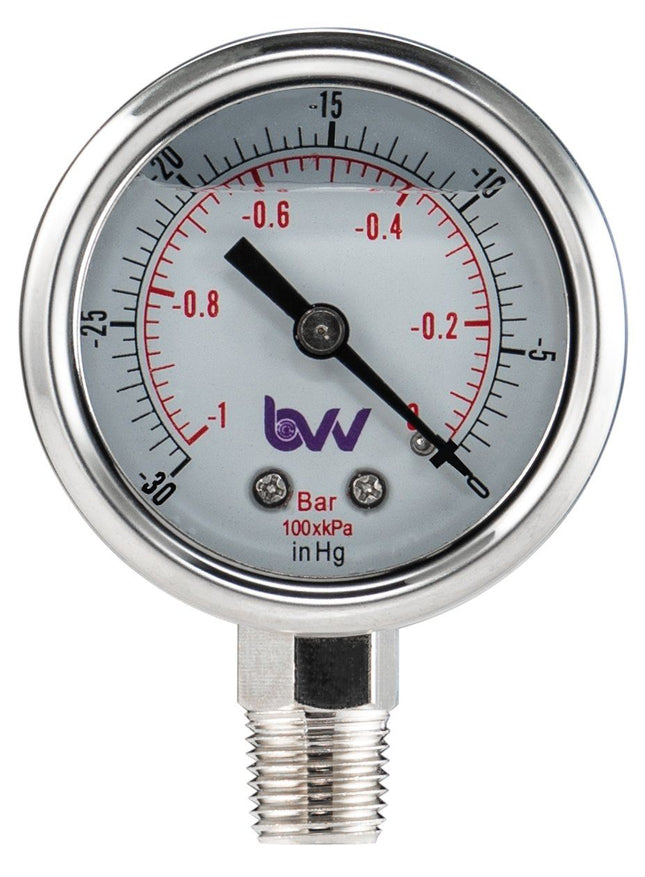

Standard Glycerine Filled Vacuum Gauge 1/4" NPT BASE

Standard Glycerine Filled Vacuum Gauge 0-(-30) in Hg with a 1/4" Stainless Steel NPT BASE

$26.00

-

Steam Distillation Kit

Steam Distillation Steam distillation is the separation of organic compounds at low temperatures by boiling water. It is widely used for essential oils and terpenes because it does not degrade the organic material as a traditional fractional distillation does. Alternatively, steam distillation can extract a diverse array of immiscible substances. You can use steam distillation for “steam stripping” in petroleum refineries and separate commercially important organic compounds, including fatty acids. Our system is composed of a 6-piece glass distillation set up paired with a separatory funnel. Simply fill the boiling flask with water and the material flask with your organic material, then use the heating mantle to boil the water and pass the steam through the material flask. There is a port above the material flask on the U-Tube to insert a thermometer to more closely monitor the process. The steam passing around the material will lower the boiling point on the surface of the plant material and cause the terpenes to boil off at low temperatures. After moving through the U-Tube the steam and terpenes will condense in the graham condenser and drain into the flask below. After filling the flask, simply swap it and drain the contents into the separatory funnel to remove all water. Steam Distillation is beneficial due to the lower boiling point being able to reduce the decomposition of temperature-sensitive compounds. Here’s a look at the key benefits of steam distillation. Key Benefits of Steam Distillation: Streamlined method produces organic solvent-free products Possesses large capacity for processing at the industrial scale Requires no subsequent separation steps Requires less fuel for the steam boiler for extraction of oils Due to its wide application and inexpensive equipment, steam distillation can be a cost-effective investment Kit Includes: 2L Analog Mantle 2L Boiling Flask 2L Material Flask U-Tube 24/40 Thermometer Adapter 24/40 Male Stopper Graham Condenser 500ml Flask 500ml Separatory Funnel BVV™ Lab Stand Three Finger Clamp Boss Head Please Note: for any replacement parts, please contact us. 2L Dual Neck Flask (SKU: STEAM-01-2000ml) 2L Material Flask (SKU: STEAM-02) U-Tube (SKU: STEAM-03) Graham Condenser (SKU: STEAM-04)

$495.00

-

Straight GL-14 Barb

Straight GL14 Barb Straight GL14 Barb connection Specifications: 8MM GL14 Female Connection Straight Style

$8.00

-

Straight Inlet Adapter with Hose Barb

Straight Inlet Adapter with Hose Barb This straight inlet adapter allows the user to connect a male and female 24/40 jointed connection and attached a flexible hose for vacuum if needed. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$30.00

-

Street Elbow

BVV Street Elbow BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are NPT threads (National Pipe Taper) and will compress against other Female/Male NPT threads creating a tighter and tighter connection. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. **NOTE: Pre-Taped option comes from BVV Pre-taped with Yellow UL Listed Gas PTFE Tape on the Male NPT threads ONLY for a +0.50c charge per male npt end. (JIC Threads DO NOT need to be taped.) Street Elbows are unique because they offer the 90 Degree transition, but they also offer a Male NPT connection along with a Female NPT connection and because of this they can reduce the amount of fittings used in a system which in turn will reduce leak points in the system overall.BVV™ Street Elbow - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4"-18 FNPT 1/4"-18 MNPT 3/8"-18 FNPT 3/8"-18 MNPT Sizes Available: 1/4" 3/8" FNPT x 1/4" MNPT 3/8"

$10.00 - $38.00

-

$14.00 $10.00

-

Superfine Agar Powder for Mushrooms Mycology Petri Dishes

Superfine Agar Powder Bacteriological, Food Grade, USP-NF Our Agar Powder is extracted from Red Seaweed. Our agar is a complex polysaccharide and is a top choice for mycology cultures. This superfine agar dissolves quickly and has a high gel strength making it an excellent choice for a variety of applications an petri dishes. Gel Strength (1.5%) : 1020 gm/cm² Gel Temperature: 38-40°C (100-104°F) CAS# 9002-18-0 Gluten Free Allergen Free Vegan & Vegetarian approved Non-GMO Shelf Life: 2 years pH: 5.5-8.5 Superfine Agar Powder Certificate of Analysis Directions for Use: Mix 10g of superfine agar powder per 500ml of distilled water. Boil and stir until powder is fully dissolved. Sterilize the mixture for 45min @15psi 250°F (121°C) in a pressure cooker or autoclave. Allow mixture to cool to approximately 140°F (60°C) *To avoid excessive condensation. Fill dishes with 15ml of mixture, approximately ~30-35 dishes.

$21.00 - $150.00

-

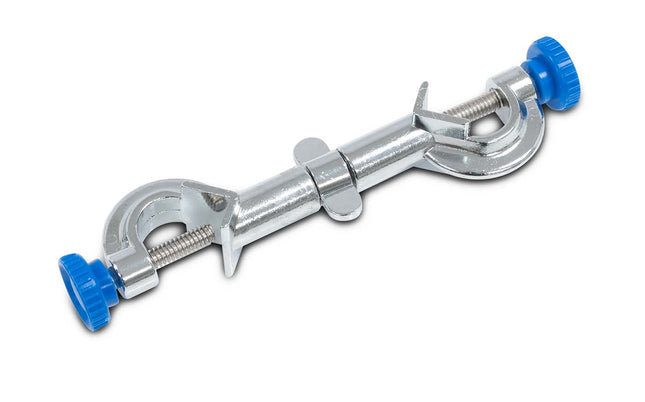

Swivel Bosshead

This swivel boss head is made out of die-cast alloy is nickel plated and will fit rod diameters up to 16mm. The boss head can be adjusted and locked to any angle (360°). It is also designed to carry heavy loads and prevent torque damage. Note:Clamps and rods are NOT included.

$11.00

-

Syloid® XDP 3150 Silica : Turn Distillate to Powder (FDA Approved Ingredient)

Syloid® XDP 3150 Silica Solid Carrier for lipid- based drug delivery systems Convert your Distillate to a Powdered Ingredient! SYLOID® XDP is engineered for transforming liquids to free-flowing solids particularly oily actives and lipid-based systems. SYLOID XDP silica provides the most complete release of loaded oils. We use this Patented silica for a variety of infusions, and to build repeatable recipes. Simply mix by hand slowly or with a machine mixer 1:1 (distillate to SYLOID). SYLOID® XDP give you the ability to create large powdered ingredient batches that can be used later. The best part is that your ratio of distillate equals the SYLOID. This makes batching and recipes easy to replicate and you don't have to be an expert at infusing. Recommended Use: Capsules, Chewable Tables, Gummy Products, Chocolates, Drinks BVV Recommends Ratio of 1:1 Weight (Distillate to SYLOID) Oil-Liquisolid Formulations Maximum daily intake: 5.4 grams/day The daily intake calculations are for adults of average 132 lbs. Benefits: FDA Approved Inactive Ingredient Stays in Suspension for edibles, delivering an equal dose into each serving! Optimum Bioavailability Complete release of your Active Ingredients! Pharmaceutical product for Infusion products Mixing by hand for small batches, or kitchen planetary mixer SLOWLY Water Based Drink Notes Does not stay suspended evenly in drinks, shaking before drinking required. Distillate can Release in hot drinks above 170F. (this does not apply to edible recipes) SYLOID® XDP Technical Data Sheet SYLOID® XDP Standard Operating Procedures - Liquid Loading Syloid® XDP is a high purity silica gel that consists of over 99% SiO2, and it meets ICH guidelines on elemental impurities, the test requirements of U.S. Pharmacopoeia-National Formulary for Silicon Dioxide and European Pharmacopoeia for Silica, Colloidal Hydrated. This product is labeled CAS # 7631-86-9 amorphous silica gel or silicon dioxide. An approved FDA Database inactive Ingredient, approved for drug products.

$127.00 - $3,800.00

-

Synder NFG Membrane (600-800Da MWCO)

Synder NFG Membrane With a pore size ranging between 0.1-10nm,Synder Filtration's nanofiltration membranes enable the passage of water and certain salts through the membrane while effectively retaining multivalent ions, low molecular weight molecules, sugars, proteins, and various organic compounds. A result of extensive research and development, Synder's NFS, NFX, NFW, and NFG nanofiltration membrane products have demonstrated exceptional resistance to fouling, a high level of selectivity, and the physical durability necessary for diverse industrial separation processes. Specifically, NFS, NFX, and NFW exhibit outstanding rejection of MgSO4 and lactose, while NFG is designed to partially remove monosaccharides from oligosaccharides. These nanofiltration membranes, as a whole, have the capacity to significantly reduce levels of hardness, nitrates, sulfates, tannins, turbidity, color, total dissolved solids (TDS), and moderate levels of salt from feed water streams. The proven performance of Synder's nanofiltration membranes makes them well-suited for a broad spectrum of industrial applications including the desolvation of ethanol from botanical extract solutions. BVV utilizes 4X NFS 2540 Membranes inside our Nanofiltration Skid to recovery ethanol at 30 Gallons per hour. Specifications Polymer: Proprietary PA TFC Approx. Molecular Weight Cutoff: 600-800 DA Typical Operating Flux 55-60 GFD Average Lactose Rejection: 60% Average MgSO4 Rejection: 50% Average NaCl Rejection: 10% Maximum Operating Pessure <95F/35C: 600PSI/41.4 Bar Maximum Operating Pressure >95F/35C: 435PSI/30 Bar Maximum Pressure Drop per Element: 15PSI/1.0 Bar Maximum Pressure Drop per hosing: 60PSI/4.1 Bar Maximum continuous Operation Temperature: 122F/50C Maximum CIP Temperature: 104F/40C Maximum Temperature Operating pH Range: 4-9 Ambient Temperature Operating pH Range: 4-10 Maximum Temperature Cleaning pH Range: 3-10 Ambient Temperature Cleaning pH Range: 3-10.5

$577.50 - $1,277.50

-

Synder NFS Membrane (200-300Da MWCO)

Synder NFS Membrane With a pore size ranging between 0.1-10nm, Synder Filtration's nanofiltration membranes enable the passage of water and certain salts through the membrane while effectively retaining multivalent ions, low molecular weight molecules, sugars, proteins, and various organic compounds. A result of extensive research and development, Synder's NFS, NFX, NFW, and NFG nanofiltration membrane products have demonstrated exceptional resistance to fouling, a high level of selectivity, and the physical durability necessary for diverse industrial separation processes. Specifically, NFS, NFX, and NFW exhibit outstanding rejection of MgSO4 and lactose, while NFG is designed to partially remove monosaccharides from oligosaccharides. These nanofiltration membranes, as a whole, have the capacity to significantly reduce levels of hardness, nitrates, sulfates, tannins, turbidity, color, total dissolved solids (TDS), and moderate levels of salt from feed water streams. The proven performance of Synder's nanofiltration membranes makes them well-suited for a broad spectrum of industrial applications including the desolvation of ethanol from botanical extract solutions. BVV utilizes 4X NFS 2540 Membranes inside our Nanofiltration Skid to recovery ethanol at 30 Gallons per hour. Specifications Polymer: Proprietary PA TFC Approx. Molecular Weight Cutoff: 100-250 DA Typical Operating Flux 30-40 GFD Average Lactose Rejection: 99.5% Average MgSO4 Rejection: 99.5% Average NaCl Rejection: 50% Maximum Operating Pressure <95F/35C: 600PSI/41.4 Bar Maximum Operating Pressure >95F/35C: 435PSI/30 Bar Maximum Pressure Drop per Element: 15PSI/1.0 Bar Maximum Pressure Drop per hosing: 60PSI/4.1 Bar Maximum continuous Operation Temperature: 122F/50C Maximum CIP Temperature: 104F/40C Maximum Temperature Operating pH Range: 3-9.5 Ambient Temperature Operating pH Range: 3-10.5 Maximum Temperature Cleaning pH Range: 2-11 Ambient Temperature Cleaning pH Range: 2-11

$978.00 - $1,245.00

-

Synder NFX Membrane (150-300Da MWCO)

Synder NFS Membrane With a pore size ranging between 0.1-10nm, Synder Filtration's nanofiltration membranes enable the passage of water and certain salts through the membrane while effectively retaining multivalent ions, low molecular weight molecules, sugars, proteins, and various organic compounds. A result of extensive research and development, Synder's NFS, NFX, NFW, and NFG nanofiltration membrane products have demonstrated exceptional resistance to fouling, a high level of selectivity, and the physical durability necessary for diverse industrial separation processes. Specifically, NFS, NFX, and NFW exhibit outstanding rejection of MgSO4 and lactose, while NFG is designed to partially remove monosaccharides from oligosaccharides. These nanofiltration membranes, as a whole, have the capacity to significantly reduce levels of hardness, nitrates, sulfates, tannins, turbidity, color, total dissolved solids (TDS), and moderate levels of salt from feed water streams. The proven performance of Synder's nanofiltration membranes makes them well-suited for a broad spectrum of industrial applications including the desolvation of ethanol from botanical extract solutions. BVV utilizes 4X NFS 2540 Membranes inside our Nanofiltration Skid to recovery ethanol at 30 Gallons per hour. Specifications Polymer: Proprietary PA TFC Approx. Molecular Weight Cutoff: 200-300 DA Typical Operating Flux 30-40 GFD Average Lactose Rejection: 99.7% Average MgSO4 Rejection: 99.5% Average NaCl Rejection: 50-55% Maximum Operating Pressure <95F/35C: 600PSI/41.4 Bar Maximum Operating Pressure >95F/35C: 435PSI/30 Bar Maximum Pressure Drop per Element: 15PSI/1.0 Bar Maximum Pressure Drop per hosing: 60PSI/4.1 Bar Maximum continuous Operation Temperature: 122F/50C Maximum CIP Temperature: 104F/40C Maximum Temperature Operating pH Range: 3-9.5 Ambient Temperature Operating pH Range: 3-10.5 Maximum Temperature Cleaning pH Range: 2-11 Ambient Temperature Cleaning pH Range: 2-11

$577.50 - $3,829.00

You have seen 960 out of 1084 products