BVV (Ok to Discount)

10L Premium Short Path Distillation Kit with P10 Distillation Head

10L Short Path Distillation Kit with P10 Distillation Head This unit carries a 2 day lead time. (Note: Stainless Steel Table NOT Included.) The 10L Short Path Distillation Kit features our USA made P10 Distillation Head. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Kangaroo digital thermometer which is very rugged and reliable. You will also receive a Ribbed Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Kit gives you the basic necessities of a short path distillation system and allows you to add on a temperature control system and vacuum pump to fit your needs. The 10L Neo Kit Includes: 10L Short Path Distillation Kit including glassware, labware, and P10 Distillation Head. 10L Digital Heating and Stirring Mantle. Valved Vacuum Adapter. Ribbed Dewar Style Glass Cold Trap. Kangaroo Digital Thermometer. Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$4,100.00

BVV™ Vacuum Oven Vent Outlet Hole and Cap

Replacement outlet hole and cap for eco and neo oven vacuum release knobs. Note the vent release may require the fitting to be greased to hold vacuum.

$10.00

2L BVV™ Rotary Evaporator Turnkey Setup

2L BVV™ Rotary Evaporator Turnkey Setup 2L Electric Lift Rotary Evaporator turnkey setup includes all the necessary components to successfully perform solvent recovery via rotary evaporation. A cold trap should always be used inline between your vacuum system and application to protect the pump from volatile vapors. 2L Rotary Evaporator Turnkey Setup includes: 2L Electric Lift Rotary Evaporator 90-day limited warranty (excludes glassware, consumables & moving parts) BVV NEO 1.4 CFM Diaphragm Pump ETL Rated OR. 3.5CFM Dry Floating Scroll Vacuum Pump Polyscience LS -20C to 40C 1/2HP Chiller w/ Turbine Pump OR BVV NEOCISION 20L Chiller (-40C) - ETL Rated 10ft of Vacuum Tubing 20ft of Chiller Tubing 10 Pack of Adjustable stainless steel hose clamps 3/8" Vacuum Manifold Optional add-on : BVV™ CT40 -40°F 300ml x 3 Cold Trap, BVV™ CT80 -112°F 300ml x 3 Cold Trap Optional add-on: J-KEM DVR-200 Digital Vacuum Regulator Optional add-on: Heat Transfer Fluid -- NuTherm PF-50 or Dynalene HC-50 Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to the condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of the condenser, chiller input to bottom of the condenser). Connect vacuum pump to cold trap and connect cold trap to the vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller, and cold trap have reached desired temperatures, turn on the rotovap motor and set the speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once the vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow the solution to enter the evaporating flask. At this point, you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$7,000.00 - $13,500.00

Polyethylene Glycol 400 - PEG 400

Polyethylene Glycol 400 Polyethylene glycol 400 has an average molecular weight of 400. It is a clear, viscous liquid at room temperature. APPLICATIONS • Chemical Intermediate• Plasticizer• In cosmetics for preparation of ointments and lotions.• As a mold release agent and lubricant for both natural and synthetic products. Physical Properties Flash point, PMCC, °F 390 Flash point, PMCC, °C 199 Refractive index, 25°C 1.463 Density, g/ml, 20°C (68°F) 1.1254 Weight, lbs/US gal, 20°C (68°F) 9.39 Freezing Range, °F 39-46 Freezing Range, °C 4-8 Viscosity, kinematic cSt at 25°C (77°F) 84 cSt at 98.9°C (210°F) 7.3 Chemical Properties Molecular Weight (range) 380-420 Average number of EO units 8.7 Water Solubility Soluble Potassium acetate, wt% 0.02-0.2 pH, 5% aqueous solution 4.5-7.0 Water, wt% 0.5 max. Color, Pt-Co 50 max. Hydroxyl number, mg KOH/g 267-295 Appearance, 20°C Clear The expiration date is 3 years from the date of manufacture and when the glycol is kept below 100F and out of direct sunlight.

$30.00 - $5,400.00

5LB TFX Closed Loop Extractor

5LB TFX Closed Loop Extractor Are you ready to embark on an exciting journey into the world of extraction? Look no further than the TFX – your ultimate entryway into the realm of closed-loop extraction. The TFX not only offers exceptional performance straight out of the box at an affordable price but also serves as a dynamic foundation for future upgrades and enhancements, allowing you to elevate your extraction prowess over time. Whether you're just starting your extraction venture or seeking to amplify your capabilities, the TFX provides a sturdy base that can be tailored to meet your evolving requirements. With its adaptable design and compatibility with various upgrades, the TFX empowers you to experiment with novel processing techniques and adapt to the ever-changing demands of the industry. Initiate your journey with the TFX and unlock boundless possibilities for innovation and expansion in the extraction domain. Introducing the TFX closed-loop extractor – the evolution of the popular Apollo extractor. The TFX heralds a new era of safety, user-friendliness, and performance. Building upon the achievements of its predecessor, the TFX takes operator safety to new heights, featuring enhanced safety mechanisms such as High-pressure Clamps and pressure relief valves as standard features. Harvesting extracts is made effortless with splatter platter bases, ensuring a cleaner and more seamless process. The optimized design of the TFX translates to heightened ease of use, safety, and performance, resulting in top-tier extracts. The TFX stands as the cornerstone of many extractors' journeys, providing a reliable, efficient, and future-proof solution to meet your evolving demands. The TFX closed-loop extractor comes in three model variants, tailored to different extraction needs. The V1 Explorer is the ideal choice for those mindful of their budget, offering an affordable entry point into the extraction world. Equipped with features like a DOT-Approved carbon steel recovery tank, 1/4" JIC Recovery lines, and polycarbonate sight glasses, it establishes the groundwork for seamless future upgrades. For those seeking a professional setup from the outset, the V2 Professional model is the prime selection. It boasts an upgraded stainless steel recovery tank with 1/2" JIC Recovery lines for optimal solvent recovery. Enhanced borosilicate sight glasses provide improved visibility during the extraction process. For the ultimate extraction experience, the V3 Elite model is your answer. It encompasses all the upgrades of the professional variant, along with additional features such as a solvent dispersal plate for uniform biomass saturation and a jacketed splatter platter compatible with a heated circulator, enhancing solvent recovery efficiency. The TFX closed-loop extractor empowers you to choose the model that suits your budget and needs perfectly. Whether you're taking your first steps or aiming for professional-grade capabilities, the TFX series lays the groundwork for your extraction journey. Regardless of your choice – Explorer, Professional, or Elite – the TFX closed-loop extractor offers endless modification possibilities to amplify your capabilities and remain ahead of industry trends. Tailored for quick wash extraction procedures, the TFX guarantees outstanding purity and yield. For those inclined towards soaking procedures, a simple addition of our 316L SS Tri-Clamp Ball Valve beneath the material column transforms the TFX. For utmost purity, pair your TFX with an Inline CRC (Color Remediation Column) to achieve the highest quality and purest extracts. Planning to work with fresh frozen material? Swap out the standard 4"x 24" spools for Sleeved Spools to preserve the biomass's flavor during extraction. To attain unparalleled clarity in your extracts, reduce wax content by integrating an injection coil into your setup. To enhance solvent recovery efficiency and minimize loss, consider adding our BVV 2 Cylinder Active Closed Loop Recovery kit to your TFX closed-loop extractor. This kit optimizes solvent recovery, ultimately saving you valuable time and resources. With the TFX closed-loop extractor and its range of modification options, you have the freedom to tailor your extraction setup to match your distinct requirements. Stay at the forefront of the industry and unlock the full potential of your extraction process with the versatile TFX closed-loop extractor. As a prominent manufacturer of extraction equipment, we prioritize precision and safety in the extraction process. The TFX embodies these principles, offering a state-of-the-art solution for extraction professionals. Engineered from high-quality stainless steel, the TFX guarantees exceptional durability and corrosion resistance, providing you with a dependable and enduring extraction solution. Its innovative design integrates advanced safety features such as high-pressure clamps, pressure relief valves, and sight glasses, ensuring operator well-being and operational control. Its superior design promotes efficient solvent flow and comprehensive material saturation, resulting in high-quality, potent extracts that meet your specific requirements. When it comes to introductory closed-loop extractors, the TFX sets a new benchmark with its exceptional performance, safety features, and reliability. With our product, you can streamline your extraction operations, amplify productivity, and craft premium extracts that surpass industry standards. At BVV, we take pride in offering top-tier extraction equipment tailored to your unique needs. Our team of experts is devoted to providing unparalleled customer support, assisting you every step of the way, from your initial purchase to setup and beyond. Elevate your butane extraction experience with the TFX – the definitive top-fill closed-loop extractor. Reach out to us today to initiate your extraction journey and propel your business to new heights. Specifications 2X 4"x24" 1LB Material Column 12"x12" Collection Base Body 12" Collection Base Splatter Platter 100um Nitrile BUNA-N Mesh Gaskets 1.5" Polycarbonate or Borosilicate Sight Glasses 125 PSI ASME Safety Valves -30hg-250PSI Compound Pressure Gauge 1/4" or 1/2" Full Bore Recovery Lines 1/4" JIC process Flow lines Explorer Professional Elite DOT Carbon Steel Solvent Tank Polycarbonate Sight Glasses 1/4" JIC Recovery Lines Stainless Steel Solvent Tank Borosilicate Sight Glasses 1/2" JIC Recovery Lines Stainless Steel Solvent Tank Borosilicate Sight Glasses 1/2" JIC Recovery Lines Solvent Dispersal Plate Jacketed Splatter Platter ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$1,400.00 - $2,150.00

Kuritech 3/4 ID PVC Reinforced Braided Hose

Kuritech 3/4 ID PVC Reinforced Braided Hose 3/4" Flexible hose that is ideal for heat transfer applications utilizing mixtures of water and propylene glycol. Specifications: Max Pressure: 150 PSI @ 20° Working Temperature: -4°C - 65°C

$12.50 - $250.00

ECO Replacement 50L Main Condenser (V1)

ECO Replacement 50L Main Condenser (V1) Replacement main condenser for ECO rotary evaporators made before 2019. 60/80 Lower Flange 40/60 Top Flange 1/2" Barb connections for cooling coil

$895.00

Block Manifold with 8 - 1/2" FNPT ports

Block Manifold with 8 - 1/2" FNPT ports This Manifold has 8x 1/2" FNPT ports that are commonly used for connecting multiple columns or different tanks to one input of vacuum and/or nitrogen. It has six ports on top and one on each end. The manifold has two 5/16 holes that can be used to easily mount on one of our extruded aluminum rack systems.

$300.00

5L ECO V2 Bump Trap

5L ECO V2 Bump Trap This replacement bump trap fits 5L BVV rotary evaporators with manual lift baths. It has connections for the injection valve, condenser, receiving flask, and motor. Connections & Sizes: Injection Valve: 19/26 Ground Joint Condenser: 40/38 Ground Joint Receiving Flask: 35mm Ball Socket Motor: ID34/ED50 Flange

$190.00

5L Rotary Evaporator 2L Evaporating Flask (2L Flask that is swap able with the RT5L-V2)

This 2L evaporating flask is made out of borosilicate and designed to fit BVV 5L rotary evaporators. Overall length is about 10-3/4".

$105.00

30L ECO Rotary Evaporator Nut and Washer Flask Set

30L ECO Rotary Evaporator Nut and Washer Flask Set This nut and washer set will fit 30L BVV ECO rotary evaporators produced before 2019.

$65.00

12" Tri-Clamp Dewaxer Columns

12" Tri-Clamp/ Tri Clover Dewaxing Columns This is a 12" Tri-Clamp BVV™ Tri-Clamp Dewaxing Spool. It is intended to have dry ice put into the sleeve to chill the material inside the column. **Note: When selecting a Pipe Hanger choose the size that correlates to the Sleeve OD NOT Spool OD Sizes Available: 12" x 12" Tri-Clamp Dewaxer Column Specifications: Tri-Clamp Size 3" Material 304 Stainless Steel Standard 3A High Polish Sleeve OD 14.000" Spool ID 11.732" Spool OD 12" Flange OD 12.57" Bead Center 12.17" Drain Port 1/4"-18 FNPT (Drain Plug Included) OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested.

$345.00

300L ASME Single Jacket Solvent Tank 350psi Max - Bare

300L ASME Single Jacket Solvent Tank 350psi Max - Bare This is a custom manufactured made ASME Certified 300L Jacketed Solvent Tank with ASME Stamp and made out of 304 Stainless Steel. This base is designed to be configured to any application and can even be used as a solvent tank. This tank comes bare with no fittings and will hold 300LBS of liquid butane and is able to have fluid circulated around the outer jacket to increase recovery speeds in the extraction system. This unit also has welded lift points on the top of the tank. **This Item will ship Via FREIGHT ONLY. Specifications Material 304 Stainless Steel Certification: ASME MAWP @ 100°C / 212°F: Inside 350 PSI / 2.42 MPa Jacket 150 PSI / 1.1 MPa MDMT -40°C / -40°F MIN TEMP -20°F at 350PSI Butane Capacity 300LBS Connection Sizes: (3) 6" Tri-Clamp (2) 2" Tri-Clamp (2) 1/2" FNPT Weight 750LBS Outer Dimensions: 64" Tall 32" W x 32" L

$9,750.00

Cryogenic 45L Centrifuge Extractor Kit

Cryogenic 45L Centrifuge Extractor Kit EXPECT 3-WEEK LEADTIME Cryogenic 45L Centrifuge Extractor Kit Overview: The BVV Cryogenic 45L Centrifuge Extractor Kit is a modular closed loop alcohol extraction system with low temperature extraction in mind. It features low temperature rated (-60°C) components including PTFE envelope gaskets, pneumatic diaphragm pumps and cryogenic rated ball valves for longevity. The centrifuge controller and motor are EX rated and come with supporting documents making it easier to get approved for operation. Load centrifuge bags with 8-15lb (10lb avg.) biomass and line them up for an efficient extraction process. This system makes repeatability easier by letting the operator control extraction parameters including soak/agitation time, spin dry time, target alcohol temperature, and different pore material bags and filtration socks in our Pressure Filtration System (PFS). The system also allows operators to re-direct the first wash back to the holding vessel to re-chill if needed and go for a second extraction. This allows full use of alcohol’s extraction ability and minimize time spent recovering solvent in a rotary evaporator or falling film. Users will have to dial in their parameters and washes based on biomass potency. Low temperature extraction leads to less refinement after the extraction process. Inline PFS allows for fine particulate refinement down to 1µm. Higher potency will require further post processing for the removal of unwanted compounds. NOTE: CHILLER AND AIR COMPRESSOR NOT INCLUDED IN THE KIT. CALL IN FOR RECOMMENDED CHILLER AND AIR COMPRESSOR. Insulation: Insulation package is included with the order but does not come installed upon arrival. Insulation included are straight tubing, tees, and elbows. BVV can install insulation as an add on prior to shipping the system out. This will also include color coordinated zip ties that help assembly process. Assembly diagrams will also be included with the system. Installation requires taping seams cutting tubing to length, and zip tying tees and elbows. Holding vessel and centrifuge are vacuum insulated via the jacket. Supporting documents included: Standard Operating Procedure for CF45L-CRYO-01 Centrifuge Wiring Instructions CF45L-CRYO-01 Manual CF45L-CRYO-01 Assembly Diagram Centrifuge Controller EX Certificate Centrifuge Motor EX Certificate Pneumatic Pump specification sheet with operating pressure/flow chart CALL IN TO SCHEDULE A FULL PRESENTATION WITH ONE OF THE CRYOGENIC 45L CENTRIFUGE EXTRACT KIT. QUESTIONS CAN BE ANSWERED BY OUR ENGINEERING TEAM. Specifications Centrifuge Controller Power Requirements 220v 1PH 60Hz, 20A Circuit Liquid Transfer Pumps Pneumatic (Compressor Required) Drum Volume 45L Drum Dimensions 17.7" (450mm) Diameter x 11-7/8" (300mm) Deep Centrifuge Bags Included 1 of Ea: 1, 10, 50, 100, 200 Micron Max Biomass Capacity 15lbs (6.8Kg), Recommended 10lbs Solvent Capacity per Run 17 Gallons Centrifuge Speed 1500 RPM Centrifuge Weight 794lbs (360Kg) Overall System Dimensions 12'6" x 13'8" x 71" (3810mm x 4166mm x 1804mm) **with chiller next to system System Temperature Rating -60C (-76F) Material in Contact with Solvent and Extract PTFE envelope, Silicone, 304SS, BIIR(butyl) *FDA & USDA compliant Footprint: NOTE: CHILLER INCLUDED IN EXTRACTION SPACE WILL NEED TO BE APPROVED FOR USE IN C1D2 SPACE. AIR COMPRESSOR FOR PNEUMATIC PUMPS NOT INCLUDED IN DIAGRAM.

$51,000.00

20L Solvent Pro Rotary Evaporator Main Condenser

20L Solvent Pro Rotary Evaporator Main Condenser 20L Solvent Pro Rotary Evaporator Main Condenser *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. *Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$400.00

10-20L Solvent Pro Rotary Evaporator Bump Trap

10-20L Solvent Pro Rotary Evaporator Bump Trap 10-20L Solvent Pro Rotary Evaporator Bump Trap *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement.

$180.00

3 Gallon Aluminum SIDEMOUNT - POT ONLY

3 Gallon Aluminum SIDEMOUNT - POT ONLY ***Note: 'with Hardware' Option only includes the side-mount manifold with gauge pre-installed. (Does Not Include Lid or Gasket) This is a replacement part for the following Vacuum Chambers: Best Value Vacs 3 Gallon Aluminum Side Mount Vacuum and Degassing Chamber Glass Vac 3 Gallon Aluminum Vacuum Chamber Dimensions: 9" Tall x 10" Diameter Hole Size: 21/64 Material: 3004 Aluminum

$40.00 - $50.00

2 Gallon Aluminum SIDEMOUNT - POT ONLY

2 Gallon Aluminum - POT ONLY ***Note: 'with Hardware' Option only includes the side-mount manifold with gauge pre-installed. (Does Not Include Lid or Gasket) This is a replacement part for the following Vacuum Chambers: SVac 2 Gallon Aluminum Vacuum Chamber Best Value Vacs 2 Gallon Aluminum Side Mount Vacuum and Degassing Chamber Dimensions: 6.5" Tall x 10" Diameter Hole Size: 21/64 Material: 3004 Aluminum

$33.00 - $41.00

High Pressure Heated Stainless Steel Hose, 4FT JIC Fittings, up to 450°F

This item is sold with or without a PID controller. The hose is heated and insulated. The hose temperature is controlled by an Digital PID. The hose and PID controller are made in the USA, and of the best quality. The hose uses Platinum Thermocouples for durability and accuracy, for many many years of service. Hose Temperature Rating: 50°F - 450°F Controller Temperature Range: 50°F -450°F 120 VAC w/ 6ft cord The overall length of the hose is 4ft The hose is Made in the USA. HOSE ID - 0.187" (1/4"Style) HOSE ID - 0.312" (3/8"Style) HOSE ID - 0.406" (1/2"Style) Each side of the heated hose assembly is a JIC 37° Fitting

$600.00 - $1,405.00

BVV Replacement Centrifuge EX Motors

BVV replacement centrifuge EX motors for BVV 45L and 475L centrifuges.

$550.00 - $1,450.00

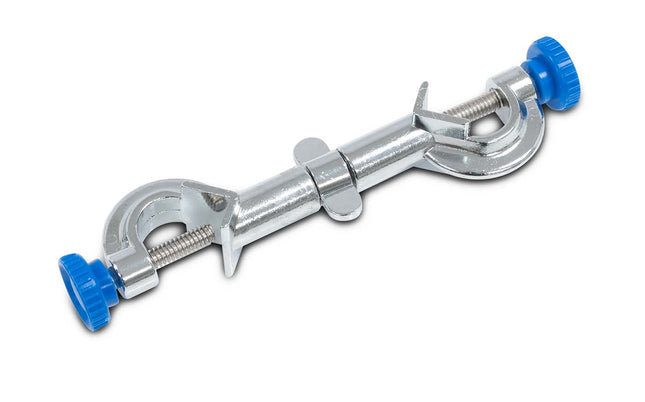

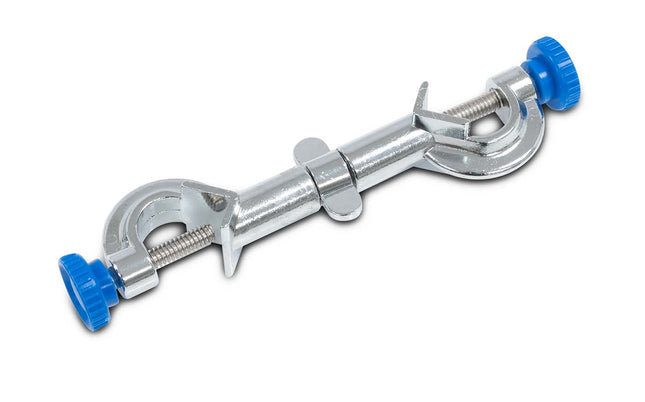

Swivel Bosshead

This swivel boss head is made out of die-cast alloy is nickel plated and will fit rod diameters up to 16mm. The boss head can be adjusted and locked to any angle (360°). It is also designed to carry heavy loads and prevent torque damage. Note:Clamps and rods are NOT included.

$14.00

Siemens Touch Screen Controller with Explosion Proof Housing for Centrifuges

Siemens Touch Screen Controller with Explosion Proof Housing for Centrifuges Disclaimer: When bought separately and NOT with our Centrifuge this item will have no warranty and all sales are final. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Controller: This centrifuge is controlled by a Siemens Smart Line PLC. This PLC is pre-programmed to have both a soaking cycle, shown as AGITATION TIME on the screen, and a spin drying cycle, made of 4 separate specifications. SPIN TIME 1 through 4 allow the user to choose four different speeds and however long they wish to be at each speed. All four parameters labeled as SPIN TIME combine to make one spin cycle when the Spin button is pressed. To change a parameter, simply tap on the number to be changed and type in the desired value when prompted on screen. Any number displayed within a white box can be adjusted. SPEED SET: This number represents the RPM as a percentage of the machine max speed. In this case the max speed is 1500RPM. SET: This column will dictate how long the centrifuge spins for a cycle or at a specified speed within the cycle. For the Agitation Time, the Set value will control the total length of the agitation cycle. The FWD/REV TIME will control how long the basket will spin in one direction before reversing to cause agitation. The “current” value will only count up while at the set speed for the agitation cycle. CURRENT: The “current” column will give a readout of how long the basket has been spinning at the set speed. This value will not increase while the centrifuge is increasing speed between SPIN TIME values. When running the agitation cycle, it will be complete when the count of seconds in the CURRENT reaches the value in the SET column. The centrifuge will stop automatically. For the spin cycle, the centrifuge will go through all 4 set SPIN TIME values, the CURRENT column will only begin to count when the centrifuge is at the set speed. The cycle time will not account for time taken to get up to speed. Temperature: Shows a live readout of the temperature inside the centrifuge.Inlet Valve and Drain Valve: These are two pre-programmed buttons that can be used with electronic valves. This unit does not come standard with these valves, but leaves the option open for them to be added. Electrical Power Size Specification 45L Input: 240V 1ΦOutput: 240V 3Φ 4kW 160L Input: 240V 1ΦOutput: 460V 3Φ 7kW 280L Input: 240V 1ΦOutput: 460V 3Φ 11kW 475L Input: 240V 3ΦOutput: 460V 3Φ 11kW

$6,000.00 - $7,230.00

PTFE WFE Wipers - 3 Pack

PTFE WFE Wipers These wipers are designed for wiped film evaporators spinning counterclockwise. Pack of 3 Dimensions: 15.375L x .38W x .42D

$350.00

Weld On Flanged Sight Glass : 400psi Rated

Weld On Flanged Sight Glass : 400psi Rated These sight glasses are made of AISI 304 Stainless Steel and must be welded to the vessel that they are being used on. These flanged sight glasses are capable of holding up to 400 PSI. The sight windows options are 1.5" and 2", dimensions as follow: 1.5" Height- 2" Diameter- 4.72" Bolt Circle- 3.6" 2" Height- 2" Diameter- 5.51" Bolt Circle- 4.17"

$80.00$60.00

NRE 5L Main Condenser

NRE 5L Main Condenser This condenser directly connects to our 5L Neocision ETL Lab Certified Rotary Evaporator (SKU: NRE-5L). NOTE: Condenser does not come with GL caps and barbs or gaskets. Specifications Connection Type and Size To Bump Trap Flange ID32/OD50 (mm) To Collection Flask Flange ID22/OD37.5 (mm) Condenser Input/Output GL14 Vacuum GL14

$390.00

NEO Oven Needle Valve

NEO Oven Needle Valve Replacement Needle valve for vacuum shut off for NEOCISION vacuum ovens

$35.00

2L Full Bore Short Path Distillation Turnkey Kit with P2 Distillation Head

2L Full Bore Short Path Distillation Turnkey Kit with P2 Distillation Head This unit carries a 2-day lead time The 2L Full Bore Short Path Distillation Turnkey Kit with P2 Distillation Head is a great setup for smaller scale processors that want a budget friendly system without sacrificing quality on the main components that make a short path great. We understand that as an operator our customers want to be able to start their system and operate in ideal conditions run after run. That is why we paired a full-bore setup with a 14.1CFM pump that will assure the lowest vacuum depth will be pulled every time. Main components such as the distillation head, vacuum valve adapter, and cold trap are all American blown glass. These components allow us to present this system that will repeat in performance time after time. For a in depth analysis of this system please view the following videos. Here you will see the system setup, component explanation, and even see it perform in a first and second distillation pass. These runs were all performed in our lab and the data was used to help fine tune the system. The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Video 1 - Setup and Component Explanation Video 2 - Setup Addendum Video 3 - Fist pass Distillation Video 4 - Second Pass Distillation The 2L Full Bore Short Path Distillation Turnkey Kit with P2 Distillation Head Includes: 1 First Pass Distillation Operating Procedure 1 P2 Distillation Kit 1 2L Double Neck Boiling Flask 1 Full Bore Vacuum Valve Adapter 1 BVV MP7H Heater 1 2L Heating Mantle 1 Ribbed Glass Cold Trap 1 Bullseye Precision Vacuum Gauge 1 BVV Pro Series 14.1CFM Rotary Vane Pump (Comes filled with oil. Recommend purchasing additional Ultra 19 Vacuum Pump Oil. SKU: INLAND19-ULTRS-1G) 1 Oil Mist Filter Trap for Rotary Vane Pump 1 24/40 250ml Single Neck Round Bottom Flask 3 24/40 500ml Single Neck Round Bottom Flask 1 24/40 Glass Funnel 1 Vacuum Manifold for Rotary Vane Pump 1 1 Meter Bellow Hose 1 PTFE Magnetic Stirring Bar Retriever 1 24/40 Metal Keck Clip 6 24/40 Plastic Keck Clips 3 250-500ml Cork Stands 2 Chain Clamps 1 Boss Head with 3 Finger Clamp 1 BVV Lab Stand 10 Fiber Glass Insulation Rope 1 Dow Corning High Vacuum Grease 1 10/30 Non-Mercury Glass Thermometers 1 24/40 – 10/30 Glass Adapter Bushing 1 24/40 – 1/8” Thermometer Adapter 1 24/40 Straight Adapter 2 6”x6” Scissor Jack 3 36” Threaded Lab Stand Rod 2 Gl14 – 8mm Barb 6 ¼” Silicone Tubing 2 PTFE Magnetic Stirring Bar 4 Hose Clamp with Butterfly Key ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$7,500.00

Throttle Valves for Pneumatic Presses

Throttle Valves for Pneumatic Presses Throttle Valve used to control the speed of your pneumatic press. Replace the fitting on the output side of your regulator. Thread Size: 1/2" NPT, Quick Connect Air Hose Size: 12mm

$20.00

5L Solvent Pro Rotary Evaporator Bump Trap

5L Solvent Pro Rotary Evaporator Bump Trap Replacement Bump Trap for 5L Solvent Pro Rotary Evaporator

$400.00

10L Solvent Pro Rotary Evaporator Main Condenser

10L Solvent Pro Rotary Evaporator Main Condenser 10L Solvent Pro Rotary Evaporator Main Condenser *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement.

$350.00

1.5 Gallon Tall Stainless Steel SIDEMOUNT - POT ONLY

1.5 Gallon Tall Stainless Steel SIDEMOUNT - POT ONLY ***Note: 'with Hardware' Option only includes the side-mount manifold with gauge pre-installed. (Does Not Include Lid or Gasket) This is a replacement part for the following Vacuum Chambers: Glass Vac 1.5 Gallon Tall Stainless Steel Vacuum Chamber Dimensions: 8-5/8"" Tall x 7-1/8"" Diameter Hole Size: 21/64 Material: 304 - 2B Stainless Steel

$58.00 - $70.00

50L Auxiliary Condenser

Auxiliary condenser for 50L Best Value Rotary Evaporator. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$370.00

CDA 12A w/ Toluene High Purity Extraction Solvent

CDA 12A w/ Toluene HAZMAT ITEMS ARE NON-REFUNDABLE. ALL SALES ARE FINAL (Note: Container style and color may vary) BVV's Ultra High Purity Toluene Denatured Ethanol (CDA 12A) is distinguished by its exceptional purity, Our CDA 12A formulation combines 95% Food Grade/USP/ACS 200 Proof Ethanol, derived from corn, with ~5% high-purity Toluene. Adhering to stringent industry standards, ensuring it meets the precise requirements of our customers, our Ultra High Purity Toluene Denatured Ethanol excels across diverse applications widely adopted as an effective botanical extraction solvent. Being that our Ultra High Purity Denatured Ethanol is made unfit for consumption when denatured with Toluene it is not subject to the Federal Excise Tax on alcohol saving you a huge cost without compromising on it suitability for top-tier extractions. Primarily utilized as pure ethanol in extraction processes, this solvent is favored for its cost-effectiveness and extraction efficiency. Reduce manufacturing costs and increase extraction efficiency with BVV's Ultra High Purity Toluene Denatured Ethanol. Disclaimer: Prices may vary due to market value and for orders of 4 totes or more and a tanker there could be up to a 2 week lead time. Call in for more accurate lead times. Spigots/Faucets are only compatible with 5 Gallon Plastic Jugs and must be purchased separately Trigger Sprayer is only compatible with 1QT and 1 Gallon sizes Key Features: Significantly Reduced Cost due to the absence of Federal Tax Produces Exceptional Quality Extractions Leaves No Residuals or Tastes Evaporates Completely in a Rotary Evaporator Specifications Vapor Pressure: 40.9mmHg at 20°C UN Numbe 1170 Density: 0.7905g/cm³ Specific Gravity 0.7905 Flash Point: 13.9°C (57°F) Boiling Point: 78.5°C (173°F) Melting Point: -90.0°C (-130°F) Chemical Formula: Ethanol C2H6ON-Heptane C7H16 CAS#(s) Ethanol 64-17-5N-Heptane142-82-5 Chemical Formula: Ethanol C2H6ON-Heptane C7H16 Molecular Weight: 72.1057 CAS Registry Number: Ethanol 64-17-5N-Heptane142-82-5 Appearance Colorless Liquid Odor: Mint or acetone-like Density 0.7905g/cm³ Boiling Point: 78.5c/173.3F Solubility in water: Miscible GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H319 GHS Precautionary Statements P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P370+P378, P403+P233, P403+P235, P405, P501 UN Identification Number: 1987 Proper Shipping Name: Alcohols Transport Hazard Class: 3 Packing Group: I DOT Placard: What is Denatured Ethanol? Denatured ethanol, also known as denatured alcohol, is ethanol (ethyl alcohol) that has been rendered unfit for human consumption by the addition of denaturants. Denaturants are typically chemicals that make the ethanol taste bad or have toxic effects, and they are added to discourage people from drinking the substance. The denaturation process is done to avoid the high taxes and regulations associated with beverage alcohol, as denatured ethanol is intended for industrial, pharmaceutical, or cosmetic uses rather than for consumption. Common denaturants include heptane, methanol, isopropyl alcohol, acetone, and other chemicals. Denatured ethanol is widely used in various industries, such as in the production of paints, solvents, cleaning products, and as a fuel for alcohol burners. Why is Ethanol Denatured? Ethanol is denatured, or rendered undrinkable, for several reasons: Tax Purposes: Denaturing ethanol allows for the imposition of lower taxes on industrial or non-beverage alcohol compared to potable alcohol. Governments often place higher excise taxes on alcohol intended for human consumption. Regulatory Compliance: Denaturing ethanol is a regulatory requirement to discourage the illegal diversion of tax-free industrial alcohol for beverage use. The addition of denaturants makes it unpalatable and unsafe for consumption. Public Safety: Making ethanol undrinkable helps prevent accidental or intentional ingestion of industrial alcohol, which can be toxic. Denaturing agents are chosen to deter people from attempting to use denatured alcohol as a substitute for beverage alcohol. Industrial Use: Denatured ethanol is widely used in various industries, including pharmaceuticals, cosmetics, and manufacturing. It serves as a solvent, fuel, or raw material in these applications. Common denaturants include substances like heptane, methanol, isopropanol, and various chemicals that make the alcohol unsuitable for human consumption while maintaining its usability in industrial processes. The specific denaturing formulations, such as CDA 12-A mentioned earlier, are defined by regulatory agencies to ensure compliance with safety and tax regulations. What is denatured ethanol used for? Denatured ethanol is used for various industrial and commercial purposes where the alcohol is needed for its properties but should not be consumed. Here are some common applications: Industrial Solvent: Denatured ethanol is widely used as a solvent in industries such as pharmaceuticals, cosmetics, and manufacturing. It is effective in dissolving a variety of substances. Cleaning Agent: Due to its solvent properties, denatured ethanol is used as a cleaning agent for surfaces, equipment, and machinery in industrial and commercial settings. Fuel Additive: Denatured ethanol is sometimes used as a fuel additive, especially in the blending of gasoline. It can improve combustion efficiency and reduce emissions. Paint and Coating Industry: It is used as a solvent in the formulation of paints, varnishes, and coatings. Pharmaceuticals: Denatured ethanol is used in the pharmaceutical industry for various purposes, including the extraction of medicinal compounds. Laboratory Use: In laboratories, denatured ethanol is often used for tasks like sterilization and as a solvent for experiments. Inks and Dyes: It is employed in the production of inks and dyes due to its ability to dissolve pigments. Adhesives and Sealants: Denatured ethanol is used in the formulation of adhesives and sealants. Window Cleaning: It is used in commercial window cleaning solutions. Automotive Industry: In the automotive industry, denatured ethanol is used for cleaning and degreasing. What can be used to denature ethanol? Here are examples of common Completely Denatured Alcohol (CDA) formulations used to denature ethanol: CDA 12-A To every 100 gallons of alcohol, add either: Five gallons of n-heptane or 5 gallons of toluene. CDA-19 To every 100 gallons of ethyl alcohol (not less than 160 proof), add: 4.0 gallons of either methyl isobutyl ketone, mixed isomers of nitro propane, or methyln-butyl ketone 1.0 gallon of either kerosene, deodorized kerosene, gasoline, unleaded gasoline, rubber hydrocarbon solvent, or heptane. CDA-20 To every 100 gallons of ethyl alcohol (not less than 195 proof), add a total of: 2.0 gallons of either unleaded gasoline, rubber hydrocarbon solvent, kerosene, or deodorized kerosene, or any combination of these. What does CDA mean? Completely Denatured Alcohol (CDA) is a type of denatured alcohol that has been rendered unfit for human consumption by the addition of denaturing agents. Denatured alcohol is ethanol (ethyl alcohol) that has been intentionally adulterated to make it toxic, foul-tasting, or otherwise undrinkable. This denaturing process is done to exempt the alcohol from excise duty and other taxes, as it's not intended for use in beverages. The denaturing agents used in CDA can vary, but they often include chemicals such as methanol, isopropanol, or other substances that make the alcohol unpalatable and potentially harmful if ingested. The specific formulation of denatured alcohol may be regulated by government authorities to ensure it meets safety standards and legal requirements. CDA is commonly used in industrial applications, as a solvent, fuel, or as a cleaning agent. It's important to note that due to the addition of denaturing agents, CDA should not be used for purposes that involve contact with the human body or ingestion. Safety precautions, including proper ventilation, should be followed when working with denatured alcohol. What is CDA 12A? CDA 12-A is a formulation specified by the Alcohol and Tobacco Tax and Trade Bureau (TTB) for Completely Denatured Alcohol (CDA). The formula is defined under §21.26 as Formula No. 12-A. The composition of CDA 12-A is as follows: For every 100 gallons of alcohol, add either: 5 gallons of n-heptane or 5 gallons of toluene. This denaturing process renders the ethanol unfit for consumption while meeting regulatory requirements for various industrial applications. CDA formulations, including CDA 12-A, are used to denature ethanol for purposes such as industrial solvents, cleaning agents, and manufacturing processes. Can you remove heptane from CDA 12A? When n-Heptane is added to ethanol it creates an azeotrope between the ethanol and n-heptane. An azeotrope is defined as a mixture of two liquids that have a constant boiling point and composition through distillation. This azeotrope results in the ethanol and n-heptane evaporating at the same temperature, making it extremely difficult to separate the two through distillation. While these azeotropic solvents are still easily recovered from a botanical extract at a relatively low boiling point around 78C/173F using a rotary evaporator or falling film evaporator, it is near impossible to separate the two via distillation. What is an Azeotrope? An azeotrope is a mixture characterized by having identical concentrations in both its vapor and liquid phases. This stands in contrast to ideal solutions, where one component is usually more volatile than the other, allowing for separation through distillation. When an azeotrope forms, the concentrations in both phases remain the same, hindering separation through traditional distillation methods. Azeotropes consist of a blend of at least two different liquids, and this mixture can exhibit either a higher or lower boiling point than either of its individual components. Azeotropes become relevant when certain liquid fractions resist alteration through distillation processes. In typical mixtures, components can be extracted using Fractional Distillation, a process involving repeated distillation stages. The more volatile component vaporizes and is collected separately, while the less volatile component remains in the distillation container, resulting in two distinct, pure solutions.

$24.00 - $2,050.00

BVV 6" Falling Film Evaporator

BVV 6" Falling Film Evaporator Cutsheet Is your lab floor filled with a fleet of rotary evaporators? Looking to increase solvent recovery throughput? Our new and compact 20GPH Falling Film Evaporator (FFE) has the capability to maximize throughput and replace up to five 50L Rotary Evaporators. The BVV™ 20GPH Falling Film Evaporator is designed to evaporate ethanol that has been diluted in crude oil during a filtration or extraction process. By reducing the vapor pressure inside the system and metering the injection valve, the user can set the heat exchangers to the appropriate temperatures to efficiently evaporate solvent from their crude oil. We paired our FFE with reliable equipment that will keep operations running. End users are required to plumb the process inlet and outlet connections for both heat exchangers. They are supplied with 1.5” sanitary tri-clamp connections. BVV™ can assist with necessary parts needed for a permanent or temporary installation. Temporary installations may be necessary if your lab has limited fume hoods or space which is shared with other processing equipment. Below you will find key features, additional equipment included with the system and the power requirements for each, and real-life efficiencies that were tested. Key Features: · Compact rack design for use in fume hoods (39”x30”x75.5”) · Vernier scale metering valve for controlled injection · Accurate heater and chiller temperature control · Deep vacuum for effective solvent removal · Discharge pumps to eliminate constant reservoir draining and down time · Chemical resistant vacuum pump · Adaptable discharge outlets to customer preference · Insulation to limit thermal loses and reduce condensation (Not Pictured) · Sanitary tri-clamp and compression fittings · Pre-heat injection coil · Injection distribution plate · Tube in shell heat exchanger for efficient evaporation and condensation · Packable vapor path for reduction of contaminants and cleaner separation · Water reservoir for priming the heating system and expansion during operation Crude Discharge Pump Easily control discharge speed and collect your extract directly from the 3/8" tube via a collection vessel or swage on a fitting of your preference to pump collected extract to a secondary location. Eliminate constant reservoir draining and operate continuously. Metered Solvent Injection Effectively repeat efficiency and throughput with our vernier scale metering valve. Easy to dial in the desired efficiency and throughput desired by the user. Distribution Plate Directs the injected solvent to be evenly distributed across all tubes in the heat exchanger which maximizes the effective heating surface area. Solvent Discharge and Vacuum Pump The solvent discharge pump eliminates the need for a reservoir and allows you to pump recovered solvent to any desired secondary location. The vacuum pump manifold gives you easy vacuum control during the complete operation. POWER REQUIREMENTS The equipment listed below is included with the system. Check power requirements and amp draw prior to purchasing. Equipment Purpose Power Requirement Amp Draw Notes 2GPM Ethanol Recovery Pump for Vacuum Pump for Ethanol Recovery Discharge 230V 1-Phase 2.4 2GPM Max Flow Rate, Vacuum Check Valve Beaker and Wrench Explosion Proof Oil Pump Pump for Oil Recovery Discharge 230V 1-Phase 1.1 90L/hr. Max Flow Rate, Vacuum Check Valve Welch BTpro100 Diaphragm Pump Vacuum Pump for System 115 1-Phase 3.4 3.5 CFM, 6 Torr Ultimate Vacuum Total Amp Draw 6.9 EFFICIENCY We are proud to present real data with running parameters and efficiencies that reflect the actual operation of our system. Below you will find the tested throughputs and efficiencies that our FFE is capable of handling. Throughput 11 GPH 18 GPH 20 GPH 22 GPH 24 GPH Efficiency 98% 97% 94% 90% 85% ** Efficiency calculated at 10:1 ratio (Ethanol : Crude Oil) with heater temperature of 160°F. Crude is fully dewaxed when going into the falling film evaporator. Solution starts at room temperature. Speeds may differ based on dilution ratio, crude quality, and running parameters. **

$35,000.00

FYRA for End of Primary Drying Detection | Vacuum Drying Monitoring | for Lyophilization| CE, UL, CSA

FYRA for End of Primary Drying Detection. This bundle is set up to allow for vacuum drying applications like freeze-drying and vacuum ovens to help determine the end of drying. Will help you detect when most of the water or residual solvent from a product has been removed or the end of primary drying has been reached in a vacuum drying application. Background on How this FYRA End of Primary Drying package works: When a freeze dryer is equipped with both a thermal and direct measurement, these sensors can be utilized to indicate the end of primary drying (Source). Step One: Clean process documentation | Get a baseline Characterize the convection-enhanced Pirani and the capacitance manometer (in this case the DCP Quantum) against each other in a dry, empty and refrigerated system. The freeze dryer is turned on, as per the manufacturer’s operator manual, with nothing on the shelf. The shelf temperature can be left at room temperature, and if so the cold trap, the condenser, and the vacuum pump should be on and running for a period of time The vacuum oven or freeze dryer is allowed a period of time to become stable in this condition and the Pirani and capacitance manometers are read. The difference in their pressure readings in a dry, empty and refrigerated freeze dryer will be relatively small (mT to 10’s of mT) when the system is working properly. DigiVac will NOT calibrate these two gauges against each other. There may always be slight differences in their readings due to their difference in design. The difference in pressure (ΔP) between these two gauges, when dry, empty, and refrigerated, indicates how close they come together when there is little to no water vapor in the gas mix over the product. Step 2: Drying with Product The intent of primary drying is to maximize the sublimation rate within the product. As such the gases in the chamber have a high water vapor content. The Pirani sensor will read a higher pressure than the capacitance manometer. As freeze drying progresses the amount of ice converting to vapor through the sublimation process will decrease as the product becomes lyophilized from the top through the bottom of the product. Eventually, the Pirani and capacitance manometers will approach the ΔP that was established in a dry, empty and refrigerated system. Approaching this ΔP value indicates that the end of primary drying has occurred. The DigiVac FYRA controller has a rich remote command-line interface which enables the user a high degree of remote control and monitoring from any computer when communicating through the USB port. Calibrated—Every FYRA is calibrated and pretested under actual vacuum against a NIST standard (Need NIST traceable documentation? Add this option to your order) Applications—Ideal for End of Drying Detection, Freeze Drying Primary Drying Monitoring, and Vacuum Oven Drying Monitoring and Detection DCP Quantum DuoSense Measurement Range: .05 mT to 1000 Torr 275 Convection-enhanced Pirani Measurement Range: 0.1mT to 1000 Torr FYRA Bleed Vacuum Controller Components: FYRA controller Convection-enhance Pirani KF25 gauge sensor | Lesker 275, driver card, and Pirani sensor cable Quantum DCP Gauge and driver card | DuoSENS Capacitive Piezo Vacuum Sensor 0.01 to 1000 Torr, Gas Independent 3 Simple Steps for Vacuum Process Set-up with FYRA Vacuum Controller: Plumb the vacuum gauge(s) and valve into your vessel Connect the sensor, power, and I/O cables into FRYA Measure and control vacuum

$3,456.00

Chemglass Adapter, Bushing

Chemglass Adapter, Bushing Chemglass Bushing style adapter having a lower standard taper inner joint and outer joint ground in the bore of the adapter. Adapters having a 10/18 or 10/30 outer member in the bore are used to insert thermometers into apparatus. __________________________________________________________________________________________ ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.*** ***All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces

$47.00$32.00

20L Solvent Pro Rotary Evaporator Auxiliary Condenser

20L Solvent Pro Rotary Evaporator Auxiliary Condenser Replacement Auxiliary Condenser for 20L Solvent Pro Rotary Evaporator

$360.00

10L Solvent Pro Rotary Evaporator Auxiliary Condenser

10L Solvent Pro Rotary Evaporator Auxiliary Condenser Replacement Auxiliary Condenser for 10L Solvent Pro Rotary Evaporator

$284.00

10L ECO Main Condenser

10L ECO Main Condenser This condenser is made to fit BVV rotary evaporators manufactured before 2019. The bottom port is a 60/80 joint to attach to the auxiliary condenser, and the top port is a 40/60 joint to connect to a vacuum connection.

$550.00

5L ECO V2 Rotary Evaporator Motor

5L ECO V2 Rotary Evaporator Motor This replacement motor fits on 5L rotary evaporators with manual lift baths. The controller connection must have the same 5 pin configuration as the plug shown in the pictures.

$450.00

2 Liter BVV 3 - Neck Decarb Flask Kit

BVV 3 - Neck Decarb Flask Kit This 3 neck flask will fit in a 2L heating mantle. The flask can be used under vacuum but is ideal for use as a decarboxylation flask before running a short path setup. The lid has 3x 24/40 tapered glass joints.

$220.00$175.00

$600.00

Room Temperature 45L Centrifuge Extractor Kit

Cryogenic 45L Centrifuge Extractor Kit EXPECT 3-WEEK LEADTIME Cryogenic 45L Centrifuge Extractor Kit Overview: The BVV Cryogenic 45L Centrifuge Extractor Kit is a modular closed loop alcohol extraction system with low temperature extraction in mind. It features low temperature rated (-60°C) components including PTFE envelope gaskets, pneumatic diaphragm pumps and cryogenic rated ball valves for longevity. The centrifuge controller and motor are EX rated and come with supporting documents making it easier to get approved for operation. Load centrifuge bags with 8-15lb (10lb avg.) biomass and line them up for an efficient extraction process. This system makes repeatability easier by letting the operator control extraction parameters including soak/agitation time, spin dry time, target alcohol temperature, and different pore material bags and filtration socks in our Pressure Filtration System (PFS). The system also allows operators to re-direct the first wash back to the holding vessel to re-chill if needed and go for a second extraction. This allows full use of alcohol’s extraction ability and minimize time spent recovering solvent in a rotary evaporator or falling film. Users will have to dial in their parameters and washes based on biomass potency. Low temperature extraction leads to less refinement after the extraction process. Inline PFS allows for fine particulate refinement down to 1µm. Higher potency will require further post processing for the removal of unwanted compounds. NOTE: CHILLER AND AIR COMPRESSOR NOT INCLUDED IN THE KIT. CALL IN FOR RECOMMENDED CHILLER AND AIR COMPRESSOR. Insulation: Insulation package is included with the order but does not come installed upon arrival. Insulation included are straight tubing, tees, and elbows. BVV can install insulation as an add on prior to shipping the system out. This will also include color coordinated zip ties that help assembly process. Assembly diagrams will also be included with the system. Installation requires taping seams cutting tubing to length, and zip tying tees and elbows. Holding vessel and centrifuge are vacuum insulated via the jacket. Supporting documents included: Standard Operating Procedure for CF45L-CRYO-01 Centrifuge Wiring Instructions CF45L-CRYO-01 Manual CF45L-CRYO-01 Assembly Diagram Centrifuge Controller EX Certificate Centrifuge Motor EX Certificate Pneumatic Pump specification sheet with operating pressure/flow chart CALL IN TO SCHEDULE A FULL PRESENTATION WITH ONE OF THE CRYOGENIC 45L CENTRIFUGE EXTRACT KIT. QUESTIONS CAN BE ANSWERED BY OUR ENGINEERING TEAM. Specifications Centrifuge Controller Power Requirements 220v 1PH 60Hz, 20A Circuit Liquid Transfer Pumps Pneumatic (Compressor Required) Drum Volume 45L Drum Dimensions 17.7" (450mm) Diameter x 11-7/8" (300mm) Deep Centrifuge Bags Included 1 of Ea: 1, 10, 50, 100, 200 Micron Max Biomass Capacity 15lbs (6.8Kg), Recommended 10lbs Solvent Capacity per Run 17 Gallons Centrifuge Speed 1500 RPM Centrifuge Weight 794lbs (360Kg) Overall System Dimensions 12'6" x 13'8" x 71" (3810mm x 4166mm x 1804mm) **with chiller next to system System Temperature Rating -60C (-76F) Material in Contact with Solvent and Extract PTFE envelope, Silicone, 304SS, BIIR(butyl) *FDA & USDA compliant Footprint: NOTE: CHILLER INCLUDED IN EXTRACTION SPACE WILL NEED TO BE APPROVED FOR USE IN C1D2 SPACE. AIR COMPRESSOR FOR PNEUMATIC PUMPS NOT INCLUDED IN DIAGRAM.

$29,500.00

Enclosed Motor Switch Hazardous-Location - UL Listed / CSA Certified for MVP Recovery Pumps

Enclosed Motor Switch Hazardous-Location - UL Listed / CSA Certified for MVP Recovery Pumps This motor switch is designed for hazardous environments where ignitable gas and dust may be present. They're rated NEMA 7 and 9 for hazardous locations. Use them to turn motors on and off, or with other circuits such as lighting and electric heat circuits. They do not provide overload protection. This item also includes a 1" Male x 3/4" Female NPSM bushing and 1/2" Pipe nipple for steel conduit. Specifications Switch Type Motor Control Reversing Capability Nonreversing Number of Circuits Controlled 2 Electrical Phase (hp) Single (3 hp @ 240 V AC) Switch Starting Position 2 Off (Normally Open) Switch Action Stays Switched (Maintained) Industry Designation DPST-NO Switching: Current 30 A Voltage 600V AC Housing: Material Painted Aluminum Color Gray Height 6.5" Width 3" Depth 4.3" Number of Mounting Holes 2 Mounting Hole Diameter 0.31" Mounting Fasteners Included No Wire Connection Type Screw Terminals Environment Hazardous Location Environment Rating NEMA 7, NEMA 9 Specifications Met UL Listed, CSA Certified RoHS Not Compliant REACH Not Compliant DFARS Specialty Metals COTS-Exempt Country of Origin Mexico

$400.00

Pre-Built 150L 304SS Jacketed Collection and Storage Vessel with 12" Tri-Clamp Port and Locking Casters

150L 304SS Jacketed Collection and Storage Vessel (Pre-Built 150L 304SS Jacketed Collection and Storage Vessel with 12" Tri-Clamp Port and Locking Casters) This massive 304 Stainless Steel Jacketed vessel can hold up to 150L of water (~40 gallons) and has a 12" Tri-Clamp port on the top and a 6" Tri-Clamp port on the bottom of the vessel. The outer jacket has 2x 1/2" FNPT ports to allow the circulation of heat transfer fluids and can also be used a vacuum jacket and can hold 21.5L or 5.68 gallons of fluid in the outer jacket. This unit also features 4 stainless steel legs with locking casters to allow the vessel to be moved around easily. Specifications Material 304 Stainless Steel Connection Type(s): 12" Tri-Clamp Top Ports 6" Tri-Clamp Bottom Port (2) 1/2" FNPT Ports ***Note: This item will ship via freight ONLY.

$3,500.00

P10 BVV™ Distillation Head - USA Made

P10 BVV™ Distillation Head P10 Distillation Head has 2 sets of vigreux in the distillation column with 45/50 lower joint, 24/40 Thermometer Joint, and 34/45 side joint and includes GL-14 barb connections. MADE IN THE USA Designed for 10 Liter Flasks Set of 2 vigreux to allow for more packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$800.00

20L Main Condenser

20L Main Condenser Big port- 60/79 Small port- 41/59

$500.00

You have seen 815 out of 815 products