1% Sale Products

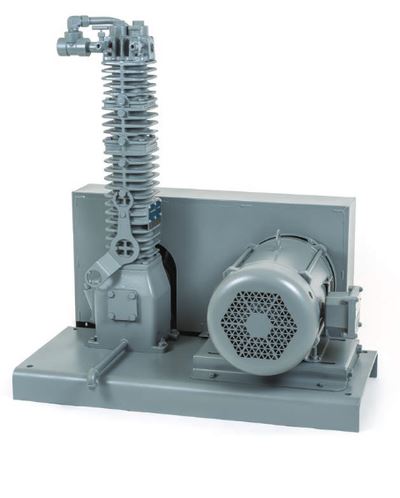

Corken T91-103 Oil-Free Gas Compressor

Corken Gas Compressor Corken's vertical industrial gas compressors offer piston displacement ranging from 2.8 to 117 CFM (4.76 to 198.8 m3/hr) while horizontal gas compressors offer piston displacement ranging from 7.6 to 414 CFM (12.9 to 704 m3/hr). Corken Recovery Pump T91 Corken is a leading manufacturer of industrial compressors designed for liquefied petroleum gas (LPG). The single stage T91 is oil-free and can recover your hydrocarbon gas faster than most recovery pumps on the market. Double Distance piece Triple Packing Oil wipe ring Adjustable packing Screw Features and Benefits: Oil-free gas compression: No product contamination Food grade material: PTFE trim and nickel coated parts Faster recovery time: Allows more production runs Zero psig evacuation pressure: Minimizes waste Self-lubricating PTFE piston rings: Low friction design provides many hours of trouble-free service Quiet operation: Suitable for indoor applications (approximately 85 dBa at three feet) Space saving: Air compressor is not required Adjustable packing screw: Extends life of the packing Cost effective: Does not require air compressor and pneumatic driver. Avoid possible air/propane cross contamination Motor: UL and CSA compliant and suitable for Class 1, Division 1, Group C & D application Operating Specifications Bore of cylinder inches (mm) 3.0 (76.2) Stroke inches (mm) 2.5 (63.5) Piston displacement cfm (m3/hr) Minimum @ 400 RPM 4.1 (7.0) Maximum working pressure psig (bar g) 335 (23.1) Maximum brake horsepower (kW) 7.5 (5.6) Maximum rod load lb (kg) 3,600 (1,632.9) Maximum outlet temperature °F (°C) 350 (177) General Performance Data for Vapor Recovery Compressor speed RPM 700 Vapor temperature °F 70 Final evac pressure psig 0 Maximum working pressure psig (bar g) 335 (23.1) Average recovery rate in lb/hr* Butane: 93Propane: 240 Power Requirements Phase 1Ø Voltage 115/230 VAC Motor Power 3 HP Motor Speed 1750 RPM Motor Frequency 60 Hz Data Sheet

$16,000.00

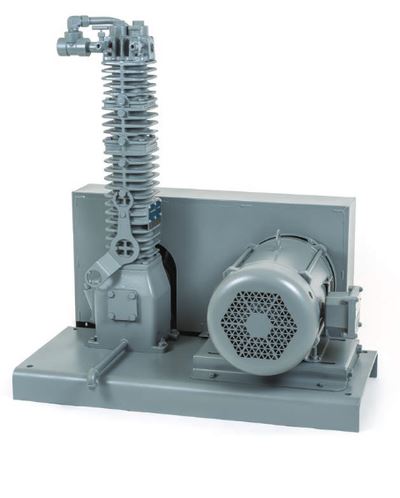

Corken T291-103 Botanical Oil Extraction Compressor

Corken T291 Botanical Oil Extraction Compressor Botanical Oil Extraction Using a Reciprocating Compressor/Vapor Recovery PumpAs a leading manufacturer of industrial pump and gas compression solutions for the LPG, petrochemical, chemical, and gas processing industries, Corken specializes in liquefied gas transfer and vapor recovery.One of Corken’s more recent vapor recovery applications involves botanical oil extraction. Plant compounds/substances have provided nutritional and medicinal benefits since the beginning of time. As scientists learned more about the healing properties of various plant materials, they began using botanical oil extraction to separate the desired components on a large scale.More recently, botanical extraction is a growing opportunity. Desirable compounds and terpenes are separated from the rest of the plant using hydrocarbon extraction. Other forms of extraction include ethanol and carbon dioxide (CO2); however, hydrocarbon is a more widely used since it’s more efficient and cost effective. Regulatory ComplianceGood Manufacturing Practice (GMP), European Union ATEX Directive, European Union Machinery Directive, ISO 9001 Standard on Quality Management Systems, and ISO 14001 Standard on Environmental Management Systems. Technical Literature: Application Bulletin Technical Specifications Service Bulletin Hydrocarbon Extraction Has Four Primary Steps: Step One (Washing): A cold solvent made of propane or butane-washes over the plant material (biomass) at a low temperature and pressure. This process removes the desired material and terpenes from the biomass and dissolves them into the liquid solvent. Step Two (Removing the Impurities): This step removes any waxes and lipids left in the solution. Unlike ethanol extraction that requires a day-long winterization process, hydrocarbon extraction has fewer waxes and lipids so the removal process is easier and does not take as much time. In most closed loop systems, a de-waxing column filters out any of the remaining waxes and lipids. Step Three (Collection): The filtered solvent solution is collected into a new or separate container and the hydrocarbon solvent (propane, butane, or propane butane mix) is purged. Corken’s gas compressors (also known as recovery pump) remove the vapor formed by the solvent solution within the collection tank and returns it to the supply tank so it can be re-circulated. Step Four (Purification): Depending on the desired final state of the product, a purification process may be necessary. Various methods such as a vacuum purge, centrifugal, and co-solvent separation are used to further refine the product. Botancial Oil Extraction Using a Reciprocating Compressor/Vapor Recovery Pump The Corken T-Style reciprocating gas compressor is oil free so there is no contamination of the process gas stream. A T-Style compressor has three sets of packing between the crankcase and compression chamber. Listed below are some of the features and benefits: PTFE trim and nickel coated parts: Compatible with food grade materials Faster recovery time: Allows more production runs Zero psig evacuation pressure: Minimizes waste Self-lubricating PTFE piston rings: Low friction design provides many hours of trouble-free service Quiet operation: Suitable for indoor applications (approximately 85 dBa at three feet)Air compressor is not required: Space saving Adjustable packing screw: Extends life of the packing Cost effective: Does not require air compressor and pneumatic driver. Avoid possible air/propane cross contamination Motor: UL and CSA compliant and suitable for Class 1, Division 1, Group C & D application Optional purge kit available (Compatible with the 07-01-06 U.S. Environmental Protection Agency Regulations 40 CFR CH Section 264.1053) Power Requirements Phase 3Ø Voltage 230/460 VAC Motor Power 10 HP Motor Speed 1800 RPM Motor Frequency 60 Hz

$30,500.00

Corken T-491 Oil-Free Gas Compressor

Corken T-491 Corken hydrocarbon gas compressor are used to handle butane, propane and isobutane. Benefits of Corken's Gas Compressor: Cost effective: Motor driven unit does not require a pneumatic driver/air compressor Fast recovery time: High Capacity design shortens recovery time and increases production. Low evacuation pressure: 0 psig or lower evacuation pressure Space Saving: Eliminates the need for a separate air compressor, Oil-free Compression: No contamination of gas products Food Grade material: PTFE trim nickel coating for gas wetter parts. Quiet: Noise rating of approximately 85dBa os beneficial to an enclosed explosion proof processing area. T-491 OUTLINE Drawing T-491 SPECIFICATION D / T Model

$45,000.00