Solvent Evaporation

Welch DryFast Collegiate Diaphragm Pump 2014

DryFast Collegiate Diaphragm Pump 2014 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details Chemical Resistant Oil-Free Tuneable Vacuum Welch DryFastTM PTFE Diaphragm Vacuum Pumps enable precise vacuum control for organic evaporations with exclusive Advanced Vapor Management (AVM). Oil-Free, portable, chemical resistant, 1 head diaphragm design simplifies maintenance. Choose from seven dry PTFE vacuum pump models with flows up to 70 L / min and adjustable vacuum down to 2 Torr. Economical DryFastTM vacuum pumps are perfect for tough lab applications. Model Number 2014 Applications Vacuum Filtration, SPE, Rotary Evaporations (volatile solvents <80oC B.P., volume <2 liters), pumping harsh vapors & gases, general laboratory vacuum Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 1.2(35) Free Air Displacement m3/hr (l/min.) @50Hz 1.75(29) Ultimate Pressure 40(53) Maximum Vacuum 28.3 Motor Horsepower (watts) 1/5(150) Adjustable Vac. / Gas Ballast Yes Tubing Needed 1/4(7) Intake Thread NPT M14(1/8) Overall Dimensions LxWxH in. (cm) 12x7.0x8.3 (30.5x 17.8x21.1) Ship Weight 19(8.6) Shipping Carton Dimensions LxWxH in. (cm) 21x14x15 (52x35x37) Adjustable Vacuum Knob

$1,602.00

24/29 Valve

24/29 Valve For 10L-50L Best Value Rotary Evaporators. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$35.00

Edwards E2M28 21 CFM Dual-Stage High Capacity Vacuum Pump

Edwards E2M28 21 CFM Dual-Stage High Capacity Vacuum Pump ***Note: This item Will Ship by Freight only*** The EM range of oil‑sealed rotary pumps – renowned for their high ultimate vacuum, rapid pumping speed, quiet operation and ability to handle vapor – have become the industry standard for laboratory and light industrial applications. The pump is a freestanding unit with the drive provided through a flexible coupling by either a single‑phase or three‑phase (four pole) air cooled motor.Each EM pump is supplied with 2 x 1 liter of Ultragrade 19 oil, O ring and centering ring, two Allen keys and spares seal for oil drain and filter plugs. For PFPE prepared FX pumps Fomblin® to be ordered separately. Technology The motor is totally enclosed and is cooled by the motor-cooling fan which directs air along the motor fins. The motors are fitted with a thermal overload device. When the motor is too hot, the thermal overload device switches off the pump. The thermal overload device has an automatic reset; when the motor cools down, the device resets and the motor will restart.An oil pressure system lubricates the pump shaft bearing surfaces and rotor sealing faces. The pump has an oil distribution valve which prevents discharge of oil to the pump interior after the pump stops. The pumping chambers are air-tight, so this arrangement also prevents suckback unless the gas ballast valve is open.You can inspect the level and condition of oil in the oil box reservoir through the oil sight-glass. An oil filler-plug is fitted to the top of the oil box. The pump has two oil drain-plugs to allow either gravity oil drain or pressure oil drain. Features and Benefits The pump is designed for reliable, long‑term operation. Thermal overload device prevents overheating (single phase only). The drive is provided through a flexible coupling by a single‑phase or three‑phase (four pole) motor. The motors are totally enclosed and are cooled by the motor cooling fan. Full height O ring sealed oil sight glass for easy checking of oil level and condition. Large sight glass and operating oil range. IE3 energy efficient 3 phase motor used with E2M28. Edwards E2M28 21 CFM Dual-Stage High Capacity Vacuum Pump. The EM range of oil-sealed rotary pumps - renowned for its high ultimate vacuum, rapid pumping speed, quiet operation and ability to handle vapour - has become the industry standard laboratory and light industrial applications. The E2M28 pump is a two-stage, direct drive, sliding vane pump. The pump is oil sealed and designed for reliable, long-term operation in both laboratory and industrial environments. The pump is a freestanding unit with the drive provided through a flexible coupling by either a single-phase or three-phase (four-pole) motor. Specifications Displacement 50Hz 32.2 m3h-1 / 19 ft3min-1 60Hz 38.9 m3h-1 / 22.3 ft3min-1 Speed (Pneurop 6602) 50Hz 27.5 m3h-1 / 16.2 ft3min-1 60Hz 33.0 m3h-1 / 19.5 ft3min-1 Ultimate vacuum (total pressure) without gas ballast 1 x 10-3 mbar / 7.5 x 10-4 Torr with gas ballast 1.5 x 10-2 mbar / 1.1 x 10-2 Torr with Fomblin® 1 x 10-2 mbar / 7.5 x 10-3 Torr Inlet connection NW25 flange Outlet connection** Nozzle 15 mm external Ø removable from 3/4 in BSP tapped hole Max allowed pressure at outlet 0.5 bar gauge / 7 psig Max water vapour pumping rate – GB II 220 gh-1 Max inlet pressure for water vapour 30 mbar / 23 Torr Max water vapour pumping rate 0.7 kg h-1 Operating temperature range 13 – 40 °C Nominal rotation speed 1440 / 1720 rpm Motor power 50 Hz 0.75 kW Motor power 60 Hz 0.90 kW Power Connector 1-ph* IEC EN60320 C19 Weight 44 kg / 97 lbs Noise 57 dB(A) @ 50 Hz Oil capacity - max 1.5 litre Oil capacity - min 1.2 litre Recommended oil (supplied) Ultragrade 19 * Pumps listed with IEC connector only ** The FX are supplied with NW25 outlet connection ** POWER CORD NOT INCLUDED. RECOMMEND FOR CUSTOMER TO WIRE PUMP TO OUTLET WITH EXACT LENGTH. DO NOT USE EXTENSIONS** **RECOMMEND FOR CUSTOMER TO HAVE ELECTRICIAN WIRE PUMP TO OUTLET WITH EXACT LENGTH** Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$8,653.00 - $10,402.00

Edwards RV8 6.9 CFM Dual-Stage Vacuum Pump

Edwards RV8 6.9 CFM Dual-Stage Vacuum Pump Edwards RV pumps have become the industry standard for scientific primary pumping applications. RV pumps are uniquely capable of delivering high or low throughputs with high ultimate vacuum. This, combined with ultra-low noise levels, makes them ideal for a wide range of applications including GCMS and other small bench top type applications.All pumps are approved to UL standards by an external test house. Edwards has a global network, providing world-wide support for product applications and service.Supplied with: 1 litre of Ultragrade 19 oil, inlet filter and O-ring. Fomblin must be purchased separately for PFPE RV pumps. Technology All our RV pumps are significantly quieter noise levels of 48 dBA 50Hz are typically half the noise of a conventional pump and have been achieved by extensive work on the drive train and motor. The pumps have the unique ability to deliver excellent ultimate vacuum in both high vacuum and high throughput modes with or without gas ballast. This gives the user an unrivalled opportunity to select the optimum pumping performance without compromising the application. In its high vacuum mode, the RV pump is ideal for analytical instruments, electron microscopes, physics research, backing turbo pumps, TV tube pumping and leak detection applications. Configure the same pump in the high throughput mode, and it becomes suitable for mass spectrometer inlet systems, distillation, laboratory furnaces, backing vapor pumps, solvent concentration, freeze drying and other drying applications. The simple to use mode selector and accessible, three-position gas ballast control allow the pump to be reconfigured at any time, even when the pump is running. Applications Analytical instruments Centrifuges, ultra-high speed Coating Degassing/curing - oil, epoxy resin Distillation/extraction/filtration Freeze drying Furnaces Gas bottle filling/emptying Gel drying Glove boxes, ovens Laboratory bench top vacuum Leak detectors, Helium Load locks and transfer chambers Refrigeration manufacture Research and development Rotary, centirfugal evaporators Scanning electron microscopes - SEM SEM/FIB (ion beam repair) Solvent recovery Surface science instruments Turbomolecuar backing pumps Specifications Model RV8 Vacuum pump type Dual stage rotary vane Power 110V 50/60Hz 1-PH 5A or 220V 50/60Hz 1-PH 2.1A Power connection US standard 3-prong plug (NEMA 5-15P) Motor power at 50Hz 450 watts Motor power at 60Hz 550 watts Peak pumping speed 6.9 CFM at 60Hz Ultimate vacuum without gas ballast 1.5 micron/millitorr Ultimate vacuum with gas ballast 60 micron/millitorr Unit dimensions (WxDxH) 18.5 x 6.2 x 8.9" Shipping dimensions (WxDxH) 31 x 11.5 x 19" Max water vapor inlet pressure 28.5 torr (38 mbar) Max allowed pressure at outlet 0.2 bar gauge/2.8 psig Operating temperature range 54°F to 104°F (12°C to 40°C) Oil capacity Minimum 0.48 quart (0.45 L), maximum 0.8 quart (0.75 L) Oil type Ultragrade 19 Nominal rotation speed at 50/60Hz 1500/1800 rpm Noise level 48 dB(A) Inlet connection NW25/KF25 Outlet connection NW25/KF25 Unit weight 57 Lbs Shipping weight 70 Lbs Users manual Click here to download Certification CE, UL

$4,637.00 - $5,042.00

5L ECO Nut and Washer Flask Set

Replacement nut and washer flask set for 5L Eco Rotary Evaporator

$45.00

PTFE Valve Core for 5/10/20L for Solvent Pro Rotary Evaporator

PTFE Valve Core for 5/10/20L for Rotary Evaporator This PTFE valve core is a direct replacement for Solvent Pro Series 5L, 10L, and 20L rotary evaporators. They are used on the injection valve, drain valve, and collection flask ancillary valves. The body and seal are made of PTFE making it chemical resistant. **Please confirm you have BVV Solvent Pro Series 5L, 10L, 20L rotary evaporator before purchasing this part. If you need help identifying which model you have, please call in.**

$75.00

Solvent Pro Series 18/35 Gasket

Solvent Pro Series 18/35 Gasket This is a replacement Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This gasket fits an 18mm(0.71") Inner Diameter and 35mm(1.38") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$13.00

5L BVV™ Rotary Evaporator Glass Axis

Glass axis for 5L BVV™ Rotary Evaporator *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$50.00

Welch 6.1 cfm Full Chemical-Resistant 8-Head Diaphragm Pump

Welch 6.1 cfm Full Chemical-Resistant 8-Head Diaphragm Pump The Welch 6.1CFM Full Chemical-Resistant 8-Head Diaphragm Pump is the ideal choice for 50L Rotary Evaporators and large oven systems. This high capacity, full chemical resistant pump gives users the ability to vac down large capacity spaces quickly, efficiently, and cleanly without worrying about contamination of pump oil. The inner diaphragm is lined with PTFE making it highly chemical resistant and long lasting. It is one of the quietest and cleanest running vacuum pumps on the market. Key Features: Fully Chemical-Resistant Oil-less diaphragm style vacuum pump High capacity vacuum capability Specifications: Electrical Requirements: 110v 60Hz single phase Pumping Rate: 6.1cfm / 174L/min Gasket Material: All-PTFE Ultimate Vacuum level: 6 torr / 8 mbar Maximum Vacuum: 29.9 inHg Inlet / Outlet: KF16 Flange Adjustable vac. / gas ballast: No Unit dimensions (LxWxH in): 21x10x12 in Shipping dimensions (LxWxH in): 28x15x20 in Shipping weight (lbs): 90 Technical Data Free Air Displacement @ 60 Hz, cfm (L/min) 6.1 (173) Ultimate Pressure, torr 6 Motor Power, HP (kW) at 60 Hz Motor Power, HP (kW) at 60 Hz Inlet (Exhaust) Connection Thread NPT NW16 - 1/4" NPT Tubing Needed, I.D. in. (mm) Hose Connector Available Weight, lbs (kg) 72.3 (32.8) Dimensions, LxWxH, in (mm) 21x11x12 (530x280x310) 115V Order Number 2064B-01 ***Note: Purchase of this pump is subject to End User Verification. A certification form must be filled out before completion of purchase.***

$5,864.00

5L Solvent Pro Rotary Evaporator Nut and Washer Flask Set

Replacement nut and washer flask set for 5L Solvent Pro Rotary Evaporator

$45.00

BVV™ Pro Series 14.1CFM Corrosion Resistant Two Stage Vacuum Pump

BVV™ Brand 14.1CFM Two Stage Pro Series This is the BVV™ Brand 14.1CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 14.1CFM will pull a vacuum down to 0.5 micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Compare to Cacejen or Xeno brand rotary vane vacuum pumps. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 115v 60Hz Pumping Rate: 14.1CFM Ultimate vacuum without gas ballast: 0.5 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2L/2.1 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Weight: 38KG / 84lbs Recommended oil: Ultragrade 19 CE Compliance: Yes Warranty 2 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$2,400.00

BVV™ Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump

BVV™ Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump This is the BVV™ Brand 21.2CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 21.2CFM will pull a vacuum down to 0.5mtorr micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 115v 60Hz Pumping Rate: 21.2CFM Ultimate vacuum without gas ballast: 0.5mtorr Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2.3L/2.4 quarts Working Temperature: 5C to 40C Unit Weight: 41KG / 90lbs Recommended oil: Ultragrade 19 CE Compliance: yes Warranty: 2 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$3,200.00

50L Solvent Pro Series Glass Axis

50L Solvent Pro Series Glass Axis. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$90.00

Solvent Pro Series 40/60 Clamp and Gasket Set

Solvent Pro Series 40/60 Clamp and Gasket Set This is a replacement Clamp and Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This Clamp and Gasket fit an 40mm(1.57") Inner Diameter and 60mm(2.36") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$35.00

35/15 Metal Flask Clamp for 2L and 5L Eco Rotary Evaporators

35/15 Metal Flask Clamp for 2L and 5L Eco Rotary Evaporators This is a replacement clamp for 2L and 5L Eco Rotary Evaporator receiving flask.

$14.00

MAXTRAP105 -105°C Vacuum Cold Trap, 120V

MAXTRAP105 -105°C Vacuum Cold Trap, 120V Cascade’s MAXTRAP105 is not an ordinary lab-grade cold trap. Cascade has integrated features necessary for time-sensitive, high-throughput, production-focused vacuum purging or drying applications. MAXTRAP105 Cold Trap Includes: Cascade’s COLDWELL 304 Stainless Steel Trap Insert (Patent pending baffle system) 3 Quart Capacity (2839 ml) Viton Gasket for Vacuum Integrity Labconco -105°C Refrigerated Base Green CFC / HFC Free Refrigerants Power Cord 3mm Neoprene Insulator Cap Requires 800ml (~ 3.5 cups) of a transfer fluid such as ethanol. Not Included. Cascade recommends: ethanol, glycol, cryo-cool fluids Quality Made in USA 1 Year Warranty Connection Lines and hardware: 4′ of 1″ Diameter Vacuum Tubing with KF-25 Flanges on each side. KF-25 clamps, centering rings for the connection tube MAXTRAP Tips: Safety At very cold temperatures, solvents and even oxygen can re-condense back into liquid. This is potentially explosive. Liquid oxygen is a light blue color and can condense into a cold trap if a pump has sucked air through the trap when the trap is very cold. Always follow your standard operating procedures and safety guidelines. Don’t Stop: Keep Processing while trap is being reclaimed, cleaned, refreshed Cold traps can become full or the captured material freezes and blocks flow. For high moisture, outgassing, 24 hour processing/vacuum purging consider adding a second, spare COLDWELL trap. The secondary COLDWELL can be dropped into place so processing continues while the full trap is cleaned, defrosted. Quick Start Up Tips: Remove shipping foam from reservoir bottom prior to use Fill reservoir with 800ml (+/-3.5 cups) ethanol to marked line Monitor ethanol levels inside reservoir Allow at least 30 mins for trap to cool Keep side vents clear. Allow at least 4″ for airflow Monitor interior of stainless trap for clogging Short tube – attach to vacuum pump Tall tube – attach to vacuum oven MAXTRAP105 Differences: The key to quality cold trap performance is: time, surface area, and temperature. Time: Most cold traps have very narrow inlets and outlets, slowing down your process. Not Cascade’s MAXTRAP105! Full KF25 inlet and outlet connections never reduce flow. Surface Area: Most cold traps have glass or a smaller surface area to collect the matter your vacuum pump would otherwise ingest. Cascade’s MAXTRAP105 surface area is a patent pending series of filter baffles inside the COLDWELL stainless trap. Specifications Coldwell Stainless Trap KF25 Inlet & Outlet 3 Quart Capacity (2839 mliters) Viton Gasket Neoprene Insulator Cap Labconco -105°C Mechanical Base 115V / 1ph / 3 AMP (60Hz) Cord Included CFC / HCFC Free Refrigerants Dimensions inches 24.1 W x 23.9 D x 12.6 H cm 34.3 x 59.7 x 30.5 *Requires approximately 800ml (~ 3.5 cups) of transfer fluid(ethanol, glycol, cryo-cool fluids) Connections 1 each 4′ KF-25 flanged vacuum rated line 1 each KF-25 Centering Ring 1 each KF-25 Clamp Weight COLDWELL Stainless Trap: 14 lbs Mechanical Base: 139 lbs Shipping Weight: 190 lbs Additional Resources: Download Specs Download Supplemental Manual NTRL Certifications -105C Refrigerated Base Safety Certification

$9,950.00

10L & 20L Injection Valve

10L & 20L Injection Valve *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement.

$45.00

NRE 10L 20L 50L Check Valve Gasket

Check valve to be placed between the condenser and receiving flask on BVV rotary evaporators. The outer diameter of the joint is 60mm.

$60.00

20L Solvent Pro Evaporating Flask

20L Solvent Pro Evaporating Flask Replacement Evaporating flask for 20L solvent pro rotary evaporators.

$720.00

Solvent Pro Series 18/35 Clamp and Gasket Set

Solvent Pro Series 18/35 Clamp and Gasket Set This is a replacement Clamp and Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This Clamp and Gasket fit an 18mm(0.71") Inner Diameter and 35mm(1.38") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$35.00

Vacuubrand MD 4C NT 2.2 CFM Chemistry Diaphragm Pump 110V

Vacuubrand MD 4C NT 2.2 CFM Chemistry Diaphragm Pump 110V MD 4C NT Technical Data Sheet.pdf These three-stage diaphragm pumps are an excellent solution for continuous, oil-free pumping of non-corrosive gases. They reach an excellent ultimate vacuum of 1 mbar. All parts in contact with pumped gases and vapors are made of aluminum, stainless steel and carefully selected plastics suitable for a wide range of applications with non-corrosive gases. The new NT-series provides whisper quiet and ultra-low vibration operation, high leak tightness and improved performance. The highly flexible fabric-reinforced double diaphragm made of FKM is ideal for extended operating life. These three-stage diaphragm pumps are an excellent choice for continuous, contamination-free evacuation and pumping of non-aggressive gases at demanding vacuum conditions. They are especially suitable for applications in physics and analytics. The low ultimate vacuum makes these an attractive alternative to rotary vane pumps in many applications. Typical uses are as backing pump for turbomolecular drag pumps, and for degassing of viscous media. Performance features: Outstanding chemical resistance and superior vapor tolerance Exceptionally high performance even at low vacuum Excellent ultimate vacuum even with gas ballast Whisper quiet and very low vibration Long diaphragm life, maintenance-free drive system Technical Data Max. pumping speed 50 Hz 3.8 m3/h Max. pumping speed 60 Hz 2.5 cfm Ultimate vacuum 1 mbar / 0.75 torr Number of heads 4 Number of stages 3 Lower ambient temperature (operation) 10 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 1.1 bar Anschluss saugseitig small flange KF DN 16 Outlet connection Silencer / G1/4" Rated motor power 0.25 kW Rated motor speed at 50/60 Hz 1500/1800 min-1 Protection class IP 40 Dimension L in mm 328 mm Dimension W in mm 239 mm Dimension H in mm 198 mm Weight 16.4 kg Noise level at 50 Hz, typ. 45 dBA Rated mains voltage range 1 230 V Mains frequency 1 50-60 Hz NRTL certification

$4,700.00

NRE 5L Evaporating Flask Gasket Set

NRE 5L Evaporating Flask Gasket Set This two part sealing kit will only fit the evaporating flask for the 5L Neocision rotary evaporator.

$145.00

NEOCISION Cold Trap - ETL Rated - (-80c)

NEOCISION Cold Trap - ETL Rated - (-80c) The BVV™ CT80 Cold Trap is used to condense vapors lost in vacuum applications before they reach the vacuum system. This prolongs the life of the vacuum system, reduces the need to change oil frequently, and efficiently traps vapors otherwise lost to evaporation such as terpenes. The CT80 model reaches a maximum temp of -80°c or -112F under vacuum and contains three traps for maximum efficiency and condensation of vapors. Place in-line between application and your vacuum system. Specifications: Temp Range: -112F to Ambient Internal Dimensions: 180mm Internal Diameter x 210mm Depth (Holds about 1.4 gallons) External Dimensions: 505 x 620 x 750mm Weight: 149lbs Stainless Steel Interior 3x Pyrex Glass Traps 110V Power Please Note: This device is designed for operation on its own independent circuit breaker. For best results, do not use this device on a breaker shared with other equipment. ***Notice to Customers: All units are inspected for broken glass or parts before the unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$6,400.00

NEOCISION Cold Trap with Pump - ETL Rated - (-40c)

NEOCISION Cold Trap with Pump - ETL Rated - (-40c) Looking for a cold trap and small application chiller? The BVV™ CT40 features a 2-in-1 use with a cold trap function and built in circulating system for small batch temperature control. Cold Trap Function Use the BVV™ CT40 to condense vapors down to -40°C before they reach your vacuum pump. This prolongs the life of the vacuum system, reduces the need to change oil frequently, and efficiently traps vapors otherwise lost to evaporation such as terpenes. Common applications include short path distillation, rotary evaporation, reactor setups, or any other application where volatile vapors can damage your vacuum pump. Chiller Function Use the BVV™ CT40 for small batch temperature control down to -40°C. Switch out the cold trap configuration with solid lid to turn your cold trap into a chiller. Common applications include condensing coils, small vessel setups, heat exchangers. Operating 2-in-1 Simultaneously Use the BVV™ CT40 as a cold trap and chiller. The unit can be used with the cold trap configuration and circulating function simultaneously. Commonly used as for chilling applications with no additional heat load. BVV™-CTC40-WP Power Requirement AC 110V +/- 10% / 60Hz Relative Humidity < 85% Cooling Capacity 400W Refrigerant R404A Cold Trap Capacity 3 x 300ml Cold Trap Barb Dia. 10mm Reservoir Capacity 6.8L External Dimensions 305 x 485 x 635mm Weight 149 lbs Call in to see how we can pair this unit with your setup Please Note: This device is designed for operation on its own independent circuit breaker. For best results, do not use this device on a breaker shared with other equipment. ***Notice to Customers: All units are inspected for broken glass or parts before the unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$3,100.00

Agilent IDP-15, 9 CFM, Dry Scroll Vacuum Pump

Agilent IDP-15, 9 CFM, Dry Scroll Vacuum Pump Overview The new Agilent IDP-15 dry scroll pump is designed for extremely quiet (<50dBA) and low vibration operation, delivering a peak pumping speed of 9 cfm at 60Hz.With a single-sided scroll design it offers fast, easy yearly maintenance and low cost of ownership. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. Specification Base pressure (50 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Base pressure (60 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Dimensions (WxHxL) 13.1 in x 14.3 in x 19.1 in Exhaust Connection NW16 Height 14.3 in Inlet Connection NW25 Input Voltage 220-230 VAC 100-115 Length 19.1 in Noise Level 50 dB(A) Pumping Speed (50 Hz) 12.8 m3/h 214 L/min 7.5 CFM Pumping Speed (60 Hz) 15.4 m3/h 256 L/min 9.1 CFM Width 13.1 in

$8,705.00 - $9,200.00

10L Solvent Pro Rotary Evaporator Nut and Washer Flask Set

Replacement nut and washer flask set for 10L Solvent Pro Rotary Evaporator

$60.00

Harvest Right Oil Free Pump

Harvest Right Oil Free Pump What is Included: One oil free pump. The oil free vacuum pump can be used with any size freeze dryer. They are quiet, fast, and easy to use. The Harvest Right oil free vacuum pumps do not require oil changes and do not require regular user maintenance. Overview The oil free vacuum pump can be used with any size freeze dryer. They are quiet, fast, and easy to use. The Harvest Right oil free vacuum pumps do not require oil changes and do not require regular user maintenance. Technical Specification CFM 7 Voltage Standard 110V. 60Hz Plug US 110V Intake Port 3/4 JIC flare Dimensions 19″ high x 10″ deep x 10″ wide Weight 42lbs

$1,695.00

Vacuubrand MZ 2C NT 1.4 CFM Chemistry Diaphragm Pump 110V

Vacuubrand MZ 2C NT 1.4 CFM Chemistry Diaphragm Pump 110V MZ 2C NT Technical Data Sheet.pdf Chemistry-design diaphragm pumps are an excellent solution for continuous, oil-free pumping of corrosive gases and vapors. The two-stage construction provides the advantageous combination of high pumping speed and low ultimate vacuum. All parts in contact with pumped media are made of chemically resistant fluoroplastics. Well-proven PTFE sandwich diaphragms increase reliability and extend operating life. The pump MZ 2C NT is equipped with a gas ballast valve for continuous condensate purge increasing the pumping capability of condensable vapors. This pump is our most popular chemistry diaphragm pump, and is the heart of a family of VACUUBRAND pumping systems. The NT-series features further improved performance data and superior vapor tolerance. Technical data Unit MZ 2C NT Number of heads / stages 2 / 2 Max. pumping speed at 50/60 Hz m3/h 2.0 / 2.3 Max. pumping speed at 50/60 Hz cfm 1.2 / 1.4 Ultimate vacuum (abs.) mbar/torr 7 / 5 Ultim. vac. (abs.) with gas ballast mbar/torr 12 / 9 Ambient temperature range (operation) °C 10 - 40 Ambient temperature range (storage) °C -10 - 60 Max. back pressure (abs.) bar 1.1 Inlet connection Hose nozzle DN 8-10 mm Outlet connection Hose nozzle DN 8-10 mm Rated motor power kW 0.18 Rated motor speed at 50/60 Hz min-1 1500/1800 Degree of protection IP 40 Dimensions (L x W x H) mm 243 x 243 x 198 Weight kg 11.1 Noise level at 50 Hz, typ. dBA 45 NRTL certification Canada and the USA ATEX conformity (only 230V) II 3/- G IIC T3 X Internal Atm. only Items supplied Pump completely mounted, ready for use, with manual. Accessories Rubber vacuum tubing DN 8 mm (20686001)

$2,930.00

250ml Bump Trap 24/40 Male to 24/40 Female

Bump traps are used on rotary evaporators between the evaporating flask and condensing column. They help prevent contamination in the collection vessel when “bumping” occurs. When “bumping” occurs substance in the evaporating flask shoots up and ends up in the collection flask, which is unwanted when operating. This bump trap features a 250ML round flask with upper 24/40 female ground joint and bottom 24/40 male ground joint. With the use of ground joints vacuum grease must be applied to assure a tight seal. Internally, there is a tube that extends and two openings on the sides. This is what stops the bumping from occurring. If any substance makes its way through the openings, it will get trapped in the flask. Vapor is still allowed to flow freely through the openings. Recommend using this bump trap on 2L rotary evaporators and other distillation setups it has an overall length of 9". Specifications Material Borosilicate Flask Size 250ml Top Connection 24/40 Female Ground Joint Bottom Connection 24/40 Male Ground Joint *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: Best Value Vacs is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$60.00

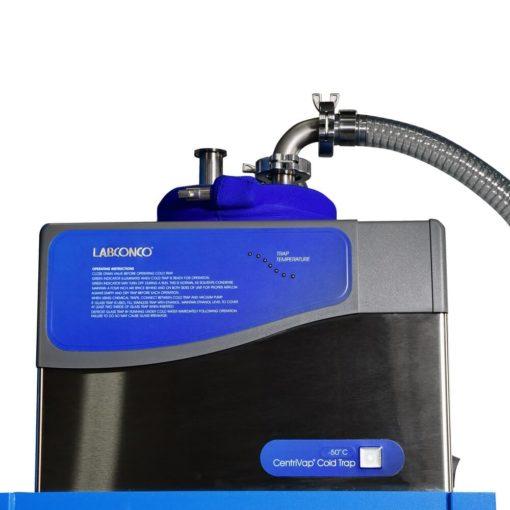

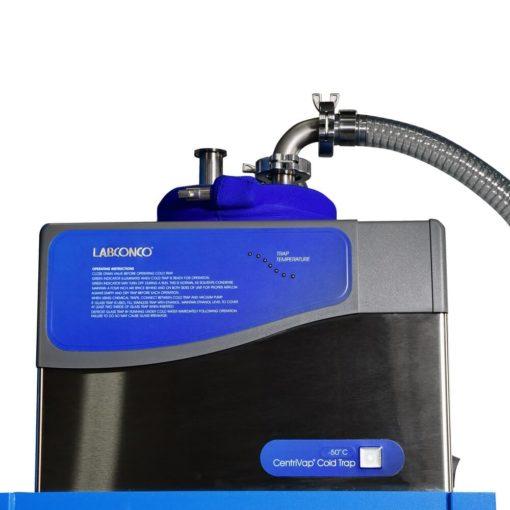

MAXTRAP50: -50°C Vacuum Cold Trap

MAXTRAP50: -50°C Vacuum Cold Trap There are numerous laboratory grade cold traps on the market and everyone agrees they are a best practice tool for preserving/extending vacuum pump life or the time between vacuum pump maintenance. Cascade’s MAXTRAP50 is not an ordinary lab-grade cold trap. Cascade has taken our extensive knowledge of vacuum best practices and integrated the features necessary for our customers with time-sensitive, high-throughput, production-focused vacuum purging or drying applications. Complete System Includes: Cascade’s COLDWELL 304 Stainless Steel Trap – patent pending baffle system. 3 Quart Capacity (2839 mliters) Viton Gasket Labconco -50°C Refrigerated Base Green CFC / HFC Free Refrigerants KF-25 Inlet/Outlet, 1 each 4′ Connection Line with KF-25 flanges, clamps, centering ring Power Cord 3mm Neoprene Insulator Cap Requires 800ml (~ 3.5 cups) of a transfer fluid such as ethanol. Not Included. Cascade recommends: ethanol, glycol, cryo-cool fluids Quality Made in USA 1 Year Warranty MAXTRAP Tips: Safety At very cold temperatures, solvents and even oxygen can re-condense back into liquid. This is potentially explosive. Liquid oxygen is a light blue color and can condense into a cold trap if a pump has sucked air through the trap when the trap is very cold. Always follow your standard operating procedures and safety guidelines. Don’t Stop: Keep Processing while trap is being reclaimed, cleaned, refreshed Cold traps can become full or the captured material freezes and blocks flow. For high moisture, outgassing, 24 hour processing/vacuum purging consider adding a second, spare COLDWELL trap. The secondary COLDWELL can be dropped into place so processing continues while the full trap is cleaned, defrosted. Quick Start Up Tips: Remove shipping foam from reservoir bottom prior to use Fill reservoir with 800ml (+/-3.5 cups) ethanol to marked line Monitor ethanol levels inside reservoir Allow at least 30 mins for trap to cool Keep side vents clear. Allow at least 4″ for airflow Monitor interior of stainless trap for clogging Short tube – attach to vacuum pump Tall tube – attach to vacuum oven MAXTRAP50 Differences: The key to quality cold trap performance is: time, surface area, and temperature. Time: Most cold traps have very narrow inlets and outlets, slowing down your process. Not Cascade’s MAXTRAP50! Full KF25 inlet and outlet connections never reduce flow. Surface Area: Most cold traps have glass or a smaller surface area to collect the matter your vacuum pump would otherwise ingest. Cascade’s MAXTRAP50 surface area is a patent pending series of filter baffles inside the COLDWELL stainless trap. Temperature: Cascade’s MAXTRAP50 features the mechanically refrigerated system built in the USA by Thermo Scientific – a leader in laboratory equipment. Specifications Coldwell Stainless Trap KF25 Inlet & Outlet 3 Quart Capacity (2839 mliters) Viton Gasket Neoprene Insulator Cap Labconco -50°C Mechanical Base 115V / 1ph / 3 AMP (60Hz) Cord Included CFC / HCFC Free Refrigerants Dimensions inches 13.5 W x 23.5 D x 12.0 H cm 34.3 x 59.7 x 30.5 *Requires approximately 800ml (~ 3.5 cups) of transfer fluid(ethanol, glycol, cryo-cool fluids) Connections 1 each 4′ KF-25 flanged vacuum rated line 1 each KF-25 Centering Ring 1 each KF-25 Clamp Weight COLDWELL Stainless Trap: 14 lbs Thermo Mechanical Base: 60 lbs Shipping Weight: 95 lbs Additional Resources: Download Specs Download Supplemental Manual NRTL Certifications

$7,049.00

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro8

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro8 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details The new CRVpro family of direct drive vacuum pumps offers increased reliability and longer service interval vs. other direct drive rotary vane vacuum pumps. The CRVpro family consumes up to 36% less oil than comparable pumps. Three features drive these benefits: Runs 10°C cooler than comparable pumps. Slows corrosion. Has a 40% larger oil capacity than comparable pumps. Dilutes aggressive chemicals. Has a chemical resistant coating in the oil case and pump module. Protects non-moving parts. The CRVpro family includes all the features you'd expect in a direct drive rotary vane pump: gas ballast, forced oil lubrication, anti-suckback mechanism and thermal overload protection. Suitable applications include freeze drying, degassing, vacuum ovens and concentrators. 3081-01 is wired for North American 115V, 60Hz operation. Includes North American line cord, vacuum inlet hose barb suitable for gum rubber hose from 5/8" to 3/4" ID, and a charge of oil. 3082-01 is wired for North American 230V, 60Hz operation. Includes 230V North American line cord, UK cord, and skuko cord, and a charge of oil. Direct drive pumps are not recommended for filtration, aspiration, drying electrophoresis gels, or other applications requiring sustained operation above 30 torr Specifications Application CRVpro8 Free Air Displacement @ 60 Hz, cfm (L/min) 5.6 (158) Free Air Displacement @ 50 Hz, m³/hr (L/min) 8 (133) Ultimate Pressure, torr (mbar) 5x10⁻⁴ (4x10⁻⁴) Noise Level, dBA 50 Motor Speed, RPM, @60Hz, @50Hz 1740 (1450) Motor Power, HP (kW) 0.4 (0.5) Oil Capacity, mL 1000 Connection Flanges NW 16 Inlet Hose Connection* 5/8" to 3/4" Weight, lbs (kg) 49.6 (22.5) Dimensions, LxWxH, in (mm) 18.2x6.1x9.1 (463x157x230)

$3,345.00

2L Electric Lift Glass Axis

Glass axis for 2L Best Value Electric Lift Rotary Evaporator. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$43.00

20L Solvent Pro Series Glass Axis

20L Solvent Pro Series Glass Axis. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$90.00

Welch DryFast Ultra Diaphragm Pump 2042

Welch DryFast Ultra Diaphragm Pump 2042 This item may carry up to a 5 day lead time. Product Details Chemical Resistant Oil-Free Tuneable Vacuum Welch DryFastTM PTFE Diaphragm Vacuum Pumps enable precise vacuum control for organic evaporations with exclusive Advanced Vapor Management (AVM). Oil-Free, portable, chemical resistant, 2 head diaphragm design simplifies maintenance. Choose from seven dry PTFE vacuum pump models with flows up to 70 L / min and adjustable vacuum down to 2 Torr. Economical DryFastTM vacuum pumps are perfect for tough lab applications. Specifications Model Number 2042 Application Rotary Evaporation/Distillation (lowvolatility solvents <160oC B.P., ~ 2 Liter), Centrifugal Concentrators, Vacuum ovens (mid- size), pumping harsh vapors & gases Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 1.2(35) Free Air Displacement m3/hr (l/min.) @50Hz 1.75(29) Ultimate Pressure 2(2.7) Maximum Vacuum 29.85 Motor Horsepower (watts) 1/5(150) Adjustable Vac. / Gas Ballast Yes Tubing Needed 1/4(7) Intake Thread NPT M14(1/8) Overall Dimensions LxWxH in. (cm) 13.8x6.8x8.8(35.2x7.2x22.3) Ship Weight 25(11.3) Shipping Carton Dimensions LxWxH in. (cm) 21x14x15 (52x35x37) Adjustable Vacuum Knob

$3,643.00

50L ECO Receiving Flask

Receiving flask for 50L Best Value Rotary Evaporator. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$395.00

BVV 6" Turnkey Falling Film Evaporator

BVV 6" Turnkey Falling Film Evaporator Cutsheet Is your lab floor filled with a fleet of rotary evaporators? Looking to increase solvent recovery throughput? Our new and compact 20GPH Falling Film Evaporator (FFE) has the capability to maximize throughput and replace up to five 50L Rotary Evaporators. The BVV™ 20GPH Falling Film Evaporator is designed to evaporate ethanol that has been diluted in crude oil during a filtration or extraction process. By reducing the vapor pressure inside the system and metering the injection valve, the user can set the heat exchangers to the appropriate temperatures to efficiently evaporate solvent from their crude oil. We paired our FFE with reliable equipment that will keep operations running. End users are required to plumb the process inlet and outlet connections for both heat exchangers. They are supplied with 1.5” sanitary tri-clamp connections. BVV™ can assist with necessary parts needed for a permanent or temporary installation. Temporary installations may be necessary if your lab has limited fume hoods or space which is shared with other processing equipment. Below you will find key features, additional equipment included with the system and the power requirements for each, and real-life efficiencies that were tested. Key Features: · Compact rack design for use in fume hoods (39”x30”x75.5”) · Vernier scale metering valve for controlled injection · Accurate heater and chiller temperature control · Deep vacuum for effective solvent removal · Discharge pumps to eliminate constant reservoir draining and down time · Chemical resistant vacuum pump · Adaptable discharge outlets to customer preference · Insulation to limit thermal loses and reduce condensation (Not Pictured) · Sanitary tri-clamp and compression fittings · Pre-heat injection coil · Injection distribution plate · Tube in shell heat exchanger for efficient evaporation and condensation · Packable vapor path for reduction of contaminants and cleaner separation · Water reservoir for priming the heating system and expansion during operation · The certified model is 22 State certified by PRV Engineers and includes an Infield Verification by PRV Engineers within the purchase price. States include but are not limited to: Alabama, Arizona, Arkansas, California, Colorado, Connecticut, Florida, Illinois, Kansas, Louisiana, Maine, Massachusetts, Missouri, Nevada, North Carolina, Oklahoma, Oregon, Texas, Vermont, Washington, West Virginia, and Wyoming Crude Discharge Pump Easily control discharge speed and collect your extract directly from the 3/8" tube via a collection vessel or swage on a fitting of your preference to pump collected extract to a secondary location. Eliminate constant reservoir draining and operate continuously. Metered Solvent Injection Effectively repeat efficiency and throughput with our vernier scale metering valve. Easy to dial in the desired efficiency and throughput desired by the user. Distribution Plate Directs the injected solvent to be evenly distributed across all tubes in the heat exchanger which maximizes the effective heating surface area. Solvent Discharge and Vacuum Pump The solvent discharge pump eliminates the need for a reservoir and allows you to pump recovered solvent to any desired secondary location. The vacuum pump manifold gives you easy vacuum control during the complete operation. POWER REQUIREMENTS The equipment listed below is included with the system. Check power requirements and amp draw prior to purchasing. Equipment Purpose Power Requirement Amp Draw Notes Hubbell Process Water Heater Heater for Heat Exchanger Column (Evaporation) 240V 3-Phase 87 36kW Heating Capacity Taco ECM High-Efficiency Circulator Water Circulator for Heater 115V 1-Phase 2.5 Max flow rate 52GPM 10hp Polyscience Chiller 230v Chiller for Heat Exchanger Column (Condensation) 230V 3-Phase 78 38.7kW Cooling Capacity 2GPM Ethanol Recovery Pump for Vacuum Pump for Ethanol Recovery Discharge 230V 1-Phase 2.4 2GPM Max Flow Rate, Vacuum Check Valve Beaker and Wrench Explosion Proof Oil Pump Pump for Oil Recovery Discharge 230V 1-Phase 1.1 90L/hr. Max Flow Rate, Vacuum Check Valve Welch BTpro100 Diaphragm Pump Vacuum Pump for System 115 1-Phase 3.4 3.5 CFM, 6 Torr Ultimate Vacuum Total Amp Draw 174.4 EFFICIENCY We are proud to present real data with running parameters and efficiencies that reflect the actual operation of our system. Below you will find the tested throughputs and efficiencies that our FFE is capable of handling. Throughput 11 GPH 18 GPH 20 GPH 22 GPH 24 GPH Efficiency 98% 97% 94% 90% 85% ** Efficiency calculated at 10:1 ratio (Ethanol : Crude Oil) with heater temperature of 160°F. Crude is fully dewaxed when going into the falling film evaporator. Solution starts at room temperature. Speeds may differ based on dilution ratio, crude quality, and running parameters. **

$72,000.00 - $75,200.00

Welch BTpro70

Welch BTpro70 ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Welch’s BTpro vacuum pump series has a flow and vacuum level to provide fast performance for your size of rotary evaporator, glass reactor, purge oven, or winterization filtration apparatus. These chemical duty PTFE diaphragm pumps are oil-free. The pumping action and deep vacuum comes from the movement of PTFE diaphragms within PTFE heads. All wetted services in the flow path are made of fluoroplastic making the BTpro pump highly chemically resistant. As a result, the BTpro vacuum pump series is near-zero maintenance. A cold trap placed in-line with BTpro pump is needed if terpenes are part of the flow path. The BTpro40 and BTpro70 models employ patented valve and diaphragm technology that generates a deep 15 Torr vacuum pressure with each PTFE head. In addition, both pump models have built-in tuneable vacuum to control evaporation rate. The tunable vacuum adjustment can also be used to stop accidental bumping/foaming. Model BTpro70 Free Air Displacement@60Hz,lpm(CFM) 70(2.5) Ultimate Vacuum Pressure, Torr 15 Maximum Vacuum, in. Hg 29.3 Horsepower, HP (watts) 1/5(150) Built-in adjustable vacuum Yes Gas Ballast - Head Material PTFE Diaphragm PTFE Inlet/outlet Connection 3/8” barb Agency (National Recognized Lab) CSA Weight, lbs (kg) 21.3(9.6) Overall Dimensions LxWxH in.(cm) 13.8x6.8x8.8 35x17x22 Shipping Weight, lbs(kg) 25 (11.3) Shipping Carton Dimensions LxWxH in.(cm) 21x14x15 (52x35x37)

$2,781.00

50L Solvent Pro Rotary Evaporator Auxiliary Condenser

50L Solvent Pro Rotary Evaporator Auxiliary Condenser Replacement Auxiliary Condenser for 50L Solvent Pro Rotary Evaporator

$300.00

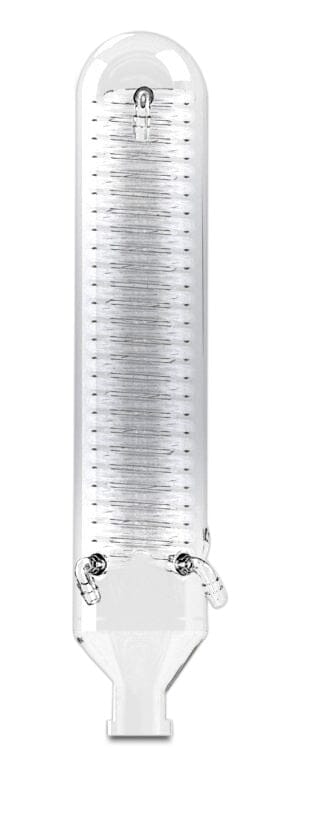

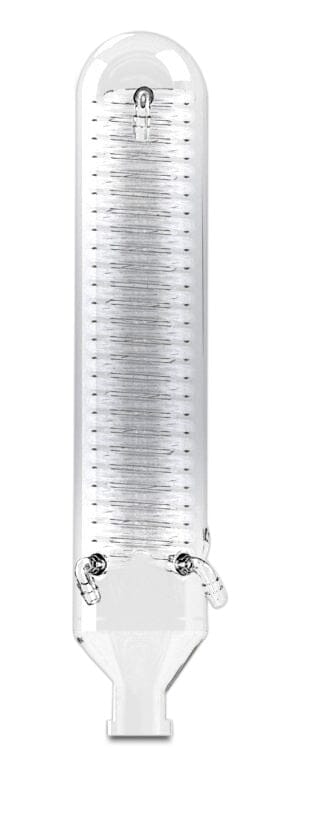

5L Solvent Pro Rotary Evaporator Main Condenser

5L Solvent Pro Rotary Evaporator Main Condenser 5L Solvent Pro Rotary Evaporator Main Condenser *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$300.00

Vacuubrand MD 1C Chemistry Diaphragm Pump

Vacuubrand MD 1C Chemistry Diaphragm Pump Chemistry diaphragm pump in action Three-stage chemistry-design diaphragm pumps are an excellent solution for continuous, oil-free pumping of corrosive gases and vapors and meet high requirements regarding ultimate vacuum. The three-stage construction provides the advantageous combination of high pumping speed and deep ultimate vacuum in a pump with a very small footprint. All parts in contact with pumped media are made of chemically resistant fluoroplastics. Well-proven PTFE sandwich diaphragms increase reliability and extend operating life. The MD 1C with gas ballast valve is optimally prepared for pumping easily condensable vapors (high boiling solvents). Three-stage chemistry diaphragm pumps are an excellent solution for applications involving corrosive gases and vapors at high vacuum requirements. Typical applications are vacuum generation at rotary evaporators, vacuum concentrators and many other laboratory applications. Due to their excellent ultimate vacuum they are the ideal solution for evaporation of high boiling solvents even with gas ballast. The MD 1C pump is the heart of a whole line of reliable chemistry pumping units. Performance features: outstanding chemical resistance and superior vapor tolerance exceptionally high performance even at low vacuum excellent ultimate vacuum even with gas ballast whisper quiet and ultra-low vibration proven long diaphragm life, maintenance-free drive system Technical Data Max. pumping speed 50 Hz 1.3 m3/h Max. pumping speed 60 Hz 0.88 cfm Ultimate vacuum 2 mbar / 1.5 torr Ultimate vacuum with gas ballast 4 mbar / 3 torr Number of heads 4 Number of stages 3 Lower ambient temperature (operation) 10 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 1.1 bar Anschluss saugseitig Hose nozzle DN 8-10 mm Outlet connection Hose nozzle DN 8 mm Rated motor power 0.08 kW Rated motor speed at 50/60 Hz 1500/1800 min-1 Protection class IP 40 Dimension L in mm 316 mm Dimension W in mm 143 mm Dimension H in mm 175 mm Weight 6.9 kg Noise level at 50 Hz, typ. 45 dBA Rated mains voltage range 1 200-230 V Mains frequency 1 50-60 Hz Brochure

$3,900.00

Solvent Pro Series 18/35 Clamp

Solvent Pro Series 18/35 Clamp This is a replacement clamp for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This clamp fits an 18mm(0.71") Inner Diameter and 35mm(1.38") Outer Diameter joint.

$15.00

10L & 20L Bump Trap

10L & 20L Bump Trap *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$240.00

Welch BTpro170

Welch BTpro170 ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Welch’s BTpro vacuum pump series has a flow and vacuum level to provide fast performance for your size of rotary evaporator, glass reactor, purge oven, or winterization filtration apparatus. These chemical duty PTFE diaphragm pumps are oil-free. The pumping action and deep vacuum comes from the movement of PTFE diaphragms within PTFE heads. All wetted services in the flow path are made of fluoroplastic making the BTpro pump highly chemically resistant. As a result, the BTpro vacuum pump series is near-zero maintenance. A cold trap placed in-line with BTpro pump is needed if terpenes are part of the flow path. Model BTpro170 2163 Free Air Displacement@60Hz,lpm(CFM) 170 (6.0) 170 (6.0) Ultimate Vacuum Pressure, Torr 6 6 Maximum Vacuum, in. Hg 29.7 29.7 Horsepower, HP (watts) 0.6(440) 0.6(440) Built-in adjustable vacuum - - Gas Ballast Yes Yes Head Material PTFE Coated Al Diaphragm PTFE PTFE Inlet/outlet Connection NW16 flange NW16 flange Agency (National Recognized Lab) cUL cUL Weight, lbs (kg) 72.3 (32.8) 72.3 (32.8) Overall DimensionsLxWxH in.(cm) 21x11x12(53x28x31) 21x11x12(53x28x31) Shipping Weight, lbs(kg) 88.2 (40.1) 88.2 (40.1) Shipping Carton Dimensions LxWxH in.(cm) 23.6x15.8x16.1 60x40x41 23.6x15.8x16.1 60x40x41

$4,349.00

ULVAC DA-40S 1.6 Cfm Oil-Free Diaphragm Pump

ULVAC DA-40S 1.6 Cfm Oil-Free Diaphragm Pump (Please note: This item has a minimum 6 week Lead Time) This Diaphragm Dry type pump creates vacuum by reciprocate movement of rubber diaphragms. The structure of this pump makes Oil-free environment and maintenance easy. Different pumping speed and two/single stages are optional depending on your required pressure and pumping volume. Applications: Vacuum chucks, wafer and tip handling devices. Vacuum tweezers, medical appliances. Printing equipment. Automatic packing machines. Optical appliances. Specifications Unit 50Hz - 60Hz Actual Pumping Speed L/min 40 - 46 Ultimate pressure Pa 19.9 x 10^3 Motor Single phase, 100V, 60W, 4P, Capacitor run Full load current A 1.6 Weight kg 7.2 Inlet, outlet pipe diameter mm O.D. dia.9 × I.D. dia.5 (Rc 1/4) Ambient temperature °C 7 – 40 Overall dimensions mm 128(W) × 242(L) × 178(H)

$1,190.00

BVV™ Pro Series 35.3CFM Corrosion Resistant Two Stage Vacuum Pump

BVV™ Pro Series 35.3CFM Corrosion Resistant Two Stage Vacuum Pump This is the BVV™ Brand 35.3CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 35.3CFM will pull a vacuum down to 0.5 micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with KF40 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Compare to Cacejen or Xeno brand rotary vane vacuum pumps. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 220/380VAC 3 Phase - Note this pump does not come with a plug and must be wired manually. Pumping Rate: 35.3CFM Ultimate vacuum without gas ballast: 0.5 micron Inlet/Outlet connection: KF40/NW40 Flange Oil Volume: 4.5L/4.76 quarts Working Temperature: 5C to 40C Unit Weight: 68KG / 150lbs Recommended oil: Ultragrade 19 CE Compliance: yes Warranty 2 year limited warranty Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$4,600.00

2L Electric Rotary Evaporator Retaining Nut

2L Electric Rotary Evaporator Retaining Nut Replacement retaining nut and washer for 2L electric rotary evaporators. The same nut is used on the flask and condenser side.

$55.00

10L Solvent Pro Rotary Evaporator Evaporating Flask

Replacement Evaporating flask for 10L solvent pro rotary evaporators.

$144.00

50L Solvent Pro Rotary Evaporator Bump Trap

50L Solvent Pro Rotary Evaporator Bump Trap Bump Trap to fit 30-50L Solvent Pro rotary evaporators. Connections: Bottom: 50mm ID 70mm OD Right side: 40mm ID 60mm OD Top/Left side: 17mm ID 35mm OD

$675.00

You have seen 96 out of 133 products