Shop BVV

Welch ProBoost Air-Cooled Diffusion Pump

Welch ProBoost Air-Cooled Diffusion Pump Product Details Use Welch ProBoost in conjunction with a backing pump like the CRVpro to get deeper vacuum and higher flow. High Vacuum to 10⁻⁵ torr Use with high vacuum and Schlenk lines Employs air cooled diffusion pump Easy Attachment to backing pump Welch ProBoost is an air cooled gas jet pump (commonly called a diffusion pump). The gas jet is formed by directing boiling silicone vapors through a hollow cone. There are no internal moving parts. The pumping action commences when the vacuum pressure in the still (i.e. wiped film) goes below 0.2 torr (200 millitorr). On an empty, leak free still, ProBoost backed by a rotary vane pump lowers the vacuum pressure to 0.00002 torr (20x lower in pressure than a 2-stage rotary vane vacuum pump can do alone). ProBoost backed by a rotary vane vacuum pump will lower vacuum pressure to below 0.0001 torr in high vacuum and Schlenk lines. This high vacuum is invaluable to improve the results from reactions using air-sensitive compounds such as organometallics, metal amides, and hydrides. ProBoost has a built-in control board for fan and heater. When you turn on ProBoost, the fan and heater both turn on. When you turn off ProBoost, the heater turns off immediately and the fan runs for another 20 minutes to cool the pump. Specifications Maximum Pumping Speed, Air 80 l/sec Ultimate Vacuum Pressure 0.00002 torr Minimum Back Pump FAD at 60 Hz 2.8 CFM Maximum Discharge Pressure 0.2 torr Ambient Environmental Temp 10–30°C Heat-up time 7 minutes Inlet Connection NW50 Discharge Connection NW25 Silicone Oil Capacity Approximately 30 ml Cool Down Time 20 minutes Pump Dimensions, L x W x H 5.5 x 5.4 x 7.5 in Weight 5.6 lbs (2.5 kg) Download Manual

$3,099.00

Welch Premium Oil - Direct Drive Vacuum Pumps, Liter

Welch Premium Oil - Direct Drive Vacuum Pumps, Liter Description: Welch Premium Oil - Direct Drive Vacuum Pumps derived from hydrotreated base, made for high performance in vacuum pump operation at elevated temperatures. Welch Premium vacuum pump oil resists breakdown in the high RPM operation environment of direct drive pumps. Enables direct drive pumps to maintain the highest vacuum performance over time. Low vapor pressure Excellent resistance to heat Designed for direct drive vacuum pumps

$55.00

ULVAC DA-40S 1.6 Cfm Oil-Free Diaphragm Pump

ULVAC DA-40S 1.6 Cfm Oil-Free Diaphragm Pump (Please note: This item has a minimum 6 week Lead Time) This Diaphragm Dry type pump creates vacuum by reciprocate movement of rubber diaphragms. The structure of this pump makes Oil-free environment and maintenance easy. Different pumping speed and two/single stages are optional depending on your required pressure and pumping volume. Applications: Vacuum chucks, wafer and tip handling devices. Vacuum tweezers, medical appliances. Printing equipment. Automatic packing machines. Optical appliances. Specifications Unit 50Hz - 60Hz Actual Pumping Speed L/min 40 - 46 Ultimate pressure Pa 19.9 x 10^3 Motor Single phase, 100V, 60W, 4P, Capacitor run Full load current A 1.6 Weight kg 7.2 Inlet, outlet pipe diameter mm O.D. dia.9 × I.D. dia.5 (Rc 1/4) Ambient temperature °C 7 – 40 Overall dimensions mm 128(W) × 242(L) × 178(H)

$1,190.00

BVV Vacuum Jacket Assembly

This vacuum jacket assembly is pre-assembled to fit on BVV Jacketed Stainless Steel tanks to allow users to create a vacuum jacket around the tank increasing the insulation of the stainless steel LP tank. This assembly comes with pre-taped 1/2" MNPT fitting on the main assembly with a compound gauge and 1/4" 37 JIC flare and BVV butterfly valve. It also comes with a 1/2" MNPT plug for the other port on the tank.

$68.00

Female Run Tee

SSP Instrumentation Duolok® tube fittings are designed, manufactured and quality controlled to be totally “interchangeable” with the Swagelok® brand of tube fittings. Component by component examination plainly shows the two brands as completely “componentintermixable.” The precision manufacturing of both products to stringent tolerances under rigid quality control procedures ensures the safety, performance and reliability of service whenever Duolok® and Swagelok® component parts are mixed and used in accordance with published installation and service recommendations. Specifications Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Connection Type 2 Duolok Tube Fitting Connection Size 2 Specified by User Connection Type 3 Female NPT Connection Size 3 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Duolok Pressure Rating = Tubing Rating NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$24.00 - $29.00

J-KEM® Temperature Controller Model 260/Timer Complete

J-KEM® Temperature Controller Model 260/Timer Complete Designed for processes requiring an extra measure of safety. The Model 260/Timer disconnects outlet power if the process temperature exceeds the set point by a user-specified amount, or following recovery from a power failure. Power remains off until the controller is manually reset. Over temperature is signaled by both an indicator lamp and an audible alarm. Contains a 100-hour digital timer to turn heating OFF (or ON) when the time expires. The Model 260 has two power outlets (1800 watts) for large equipment or heating mantles up to 22L. Contains J-KEM’s patented power control computer which provides 0.1° regulation of anything. SPECIFICATIONS: Power: 15 amps @ 120 VAC, 1800 Watts Weight: 6 Lbs Dimensions: 9.25 × 7.75 × 3.5 in .

$1,295.00 - $1,465.00

20L Neocision Dual Head Short Path Distillation Kit

20L Neocision Dual Head Short Path Distillation Kit This unit carries a 2 day lead time. (Note: This kit does NOT include the stainless steel table.) The 20L Neocision Distillation Kit Setup features our Dual P10V6 Distillation Heads and USA made glass. Every component in this distillation kit is made for precision, throughput, and repeatable results. You will also receive Dual Dewar Style Ribbed Glass Cold Traps to keep all volatiles and solvents out of your vacuum system. This kit gives you the essentials of a short path distillation system and allows you to add a pump and temperature control system of your choosing. The 20L Neo Kit Includes: 20L Neocision Kit with glassware, labware, and Dual P10V6 Distillation Heads. KF-25 Bellow Y Manifold Dual Ribbed Dewar Style Glass Cold Trap Non-Mercury Glass Thermometers 20L Digital Heating and Stirring Mantle Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in the boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$6,800.00 - $7,000.00

1LB EVO Closed Loop Extraction Kit

1LB Evo Closed Loop Extraction Kit (System comes with 1 yr. limited warranty) The EVO series of 1LB closed-loop extractors was designed with the evolution of stand-up extractors in mind. The aim of the EVO series of extractors is to provide unparalleled utility and ease of use within a traditional stand-up design. The EVO series was designed to tackle the two most common plights with stand-up extractors, difficulty in extract harvesting, and integration of adsorbent filtration. The Evo series accomplishes both through the use of its elevated extract pour spout and its optional inline color remediation column. Beyond the elevated pour spout and optional inline color remediation column. The EVO series aims to provide unbridled safety and solvent recovery speed through the integration of ASME pressure relief valves on both the material column and collection base standard and full bore 1/2" recovery lines found on the professional, elite, and active explorer models. The 1lb EVO Closed Loop Extraction kit comes complete with a top fill injection manifold including a compound gauge, a 125 psi ASME pressure relief valve, and two full bore ball valves complete with 2x 1/4" Male JIC connections on the explorer and both 1/4" & 1/2" Male JIC connections on the professional and elite models. Just below the injection manifold, all 1lb EVO models have a solvent dispersion plate that evenly disperses solvent into the 3"x 24" 1lb material column which is enclosed by 2x 100 micron Buna-N mesh gaskets. Both the Professional and Elite models come complete with an inline 3" x 6" color remediation column just below the material column with a 300-gram media capacity and a filter stack utilizing both a 5 micron & 1 micron sintered disk. Professional and Elite models also include 25-micron filter paper and a 500-gram sample of Pure-Flo B80 Below the 1lb material column and optional inline color remediation column the 1lb Evo includes the jacketed and elevated pour spout collection base that allows for easy extract harvesting and speedy solvent recovery. The elevated base can accommodate up to a 5:1 solvent to biomass ratio and accept a standard round pyrex dish or a small parchment paper boat below the pour spout. Upon completion of the run, extract removal is made easy by simply draining the extract from the elevated extract pour spout. Both the professional, elite, and active explorer models have increased solvent recovery capability from the jacketed collection base through full bore 1/2" recovery MJIC connections and stainless steel recover hoses. Beyond the larger recovery lines and inline color remediation column the 1lb EVO Elite options come paired with our ETL listed 5 liters Neocision heated circulator and the sleeved EVO recovery tank that allows for the pre-chilling of solvent and speedy solvent recovery, reaching sub 20 minute recovery times on high heat. All varients of the EVO Extraction Kits come equipped with a 1.9CFT vacuum oven, a 7CFM single-stage vacuum pump, a 5' HVAC hose, and an 8"x8" silicone pad. The Explorer & Professional models come with the ECO model vacuum ovens and the Elite versions equipped with the ETL list Neocision 1.9CFT vacuum oven. All EVO closed-loop extraction kits come available with an active recovery option including: BVV 2 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified BVV Large Condensing Coil 1/2" x 24" SS JIC Braided Hose (2) 1/2" x 48" SS JIC Braided Hose (2) 1/2" x 60" SS JIC Braided Hose Molecular Sieve Filter Drier BVV 5' HVAC Hose BVV Vacuum Tee ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. KEY BENEFITS Meets or exceeds all industry listed standards Versatile in running butane, propane, and other blended solvents Perfect for mid to large-scale extraction/production facilities Faster run times and less degradation in the process Easy extract harvesting using the elevated pour spout Inline color remediation Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry-level extractor on a budget. Comes with the jacketed and elevated collection base and 1/4" Male JIC connections on the injection manifold and collection base. The explorer options include a 1.9CFT ECO Vacuum Oven, a 5' HVAC hose, and a 7CFM single-stage vacuum pump. This model does not include the inline color remediation column or 1/2" Male JIC recovery/ injection connections. The Explorer model is forward compatible and can be easily upgraded to include 1/2" lines and the inline color remediation column. *This model does not come with a heated circulator* Professional: This model includes all the features of the explore model with the increased functionality of an inline color remediation column Just under the material column that comes with 25micron filter paper and a 500-gram sample of b80, an upgraded stainless steel recovery tank, and a full bore 1/2" Male JIC connection included on the injection manifold and collection base. The Professional extraction kit options include a 1.9CFT ECO Vacuum Oven, a 5' HVAC hose, and a 7CFM single-stage vacuum pump.*This model does not come with a heated circulator* Elite: The Elite series is the premium version of the Professional. It features the same 1/2" Male JIC, and inline color remediation column upgrades. But also includes the EVO recovery tank and 5 liter ETL listed Neocision heated circulator that allows for pre-chilling and speedy recovery of solvent. The Elite options include a 1.9CFT ETL Listed Neocision Vacuum Oven, a 5' HVAC hose, and a 7CFM single-stage vacuum pump. Passive: Passive recovery is the standard option on the extraction kit with the explorer model coming with 1/4" recovery lines and the professional and elite models coming equipped with 1/2" recovery lines. Active: The Active Recovery Upgrade Kit will increase recovery times by condensing the vapor a lot faster than just a hot/cold differential. All active models come equipped with 1/2" recovery lines and the inclusion of our BVV 2 Cylinder Butane recovery pump, BVV Large Condensing Coil, Molecular Sieve Filter Drier, and all the associated hosing to perform active recovery. Explorer Professional Elite Jacketed & Elevated pour spout collection base Jacketed & Elevated pour spout collection base Inline Color remediation column 25-micron filter paper 500 gram B80 sample 1/2" recovery lines 30# Stainless steel Recovery Tank Jacketed & Elevated pour spout collection base Inline Color remediation column 25-micron filter paper 500 gram B80 sample 1/2" recovery & Injection lines EVO Recovery Tank 5 liter ETL listed Neocision heated circulator with insulated hoses Unit Includes: Full bore injection Manifold complete with a compound gauge,125 PSI ASME pressure relief valve, and 2x 1/4" MJIC connections (1x1/2" MJIC connection on professional & elite models) 3"x24" 1lb Material column with solvent dispersal plate. 3"x6" Color remediation column 300g gram media capacity complete with a filter stack including 5 micron and 1 micron sintered disks (Professional & Elite model) 25-micron ashless filter paper (Professional & Elite) Jacketed & elevated collection base with extract pour spout 6" hemispherical collection base lid complete with borosilicate sight glasses, a compound gauge, 125 PSI ASME pressure relief valve, and full bore ball valves with MJIC Connections. 30# LP storage and recovery tank (Explorer) 30# stainless steel LP tank (Professional) & EVO Recovery tank (Elite) (1) 1/4" 72" FJIC Stainless Steel Injection hose (Explorer & Professional) 1/2" 96" FJIC Stainless Steel Injection Hose (Elite) (1) 1/4" 60" FJIC Stainless Steel Recovery Hose (Explorer) 1/2" 60" FJIC Stainless Steel Recovery Hose (Professional & Elite) High-pressure clamps Specifications: 3"x 24" 304 Stainless Steel Material Column-1lb capacity (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple 37 degree FJIC port connections 304 Stainless jacketed & elevated collection base Tri-Clamps at all interfaces make for a high pressure/standard pressure, easy-clean unit BUNA-N Gaskets are designed for Oil Processing Temp range -40-200F, and have superior solvent resistance Construction: All components are made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$4,275.00 - $10,979.00

Master Vapor MVP Liquid Recovery Pump

Master Vapor MVP Liquid Recovery Pump THE NEW LIQUID Pumps solvent in liquid state Hydrocarbon and ethanol compatible C1D1 and 3rd party Certified Drastically increases evaporation byexpanding surface area andcreating turbulence Electric Driven FDA Food Grade Compliant MADE IN THE USA Engineering Specifications: Maximum pumping outlet pressure - 70 PSI Center Section CO2 charge range 5 to 80 PSI(10-15psi over inlet pressure recommended) CO2 Inlet Size: 1 /4 in. npt(f) Maximum Pump Speed 135 cpm (cycle per minute) Process Inlet and Outlet Size: 1 in. npt Electric Motor: Explosion proof for C101 Hazardous areas Motor Specifications: 2HP, 3,600 rpm, 60Hz Size: 18.3” x 15.4” base x 42.3” tall Weight: 173.2 lb All sales final Technical Data sheet US Metric Maximum Pumping outlet Pressure 70 PSI 0.48 MPa, 4.8 bar Center section CO2 Change range 6 to 80 PSI 0.03-0.55 MPa 0.3-5.5 bar Equipment Withstand Pressure 350 PSI 2.41 MPa, 24.1 bar Maximum CO2 Consumption <0.2 scfh <0.006 cubic meters/hour CO2 inlet size 1/4 in. npt(f) Maximum Pump Speed 135 cpm Process intel and outlet size 1 in. npt Model MVP Liquid, 3 ph, Inverter Rated Power 2 HP 1.5kW Speed 3600 rp, (60 Hz) Gear Ratio 25.85 Voltage 1-phase 208-230/460V Maximum Amperaage Load 5.2 A (230V / 2.6 A (460V) Model MVP Liquid 1PH Power 2 HP 1.5kW Speed 3600 rpm (60 Hz) Gear Ratio 25.85 Maximum Amperaage Load 5.2 A (115V / 10 A (230V) Noise Data Sound Power (measured per ISO-9614-2 88.5 dBa Sound Pressure {Tested 3.28ft (1m) From Equipment} 80.5dBa Materials Process Pressure Section and Reed Valves Stainless Steel Diaphragms Standard: FKM Fluoroelastomer Optional:PTFE Process Vapor Temperature Range FKM: -40 to 275 °F (-40 to 135 C)PTFE: +40 to 220 °F 9+4 to 104 C

$13,700.00 - $14,250.00

Best Value Vacs 1.5 Gallon Tall Stainless Steel Vacuum Chamber - W/GLASS LID

Best Value Vacs 1.5 Gallon Tall Stainless Steel Vacuum Chamber - W/GLASS LID This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User-friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 - 2B Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 8-5/8" Tall x 7-1/8" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. DOES NOT APPLY TO GLASS LID VERSION ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$115.00

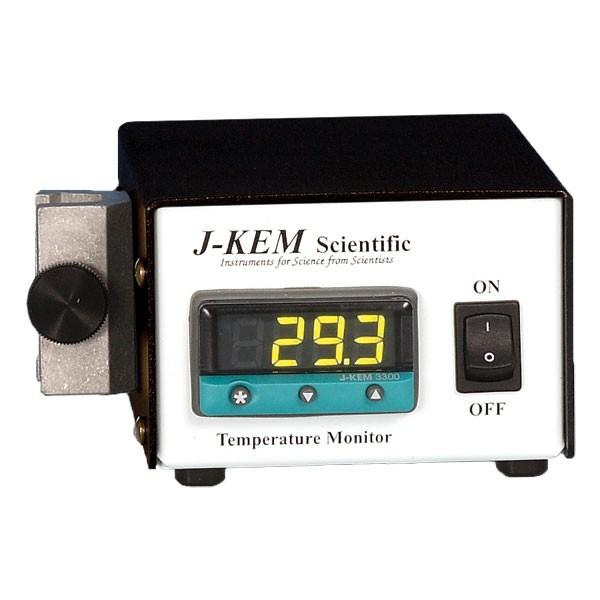

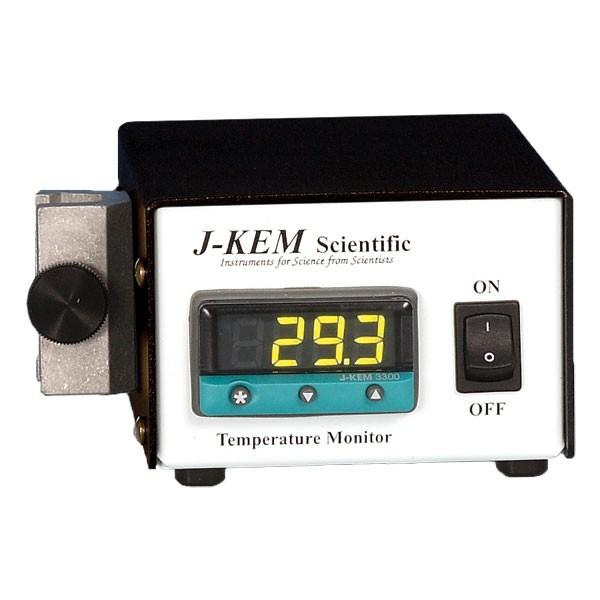

J-KEM Digital Temperature Monitor

J-KEM Digital Temperature Monitor Monitors and displays the temperature of an attached piece of equipment on a bright LED display. Built-in USB and free KEM-Net software provide remote temperature monitoring and data logging to a GLP/GMP compliant file. Audible alarm. Specifications: 120 or 230Vac, 50 watts.Warranty: 2 Years The temperature range desired determines the probe/thermocouple type: J [black] (0 – 800° C) K [yellow] (-50 – 1200° C) T [blue] (-200 – 250° C)

$576.00

J-KEM® Temperature Controller Model 210

J-KEM® Temperature Controller Model 210 J-KEM’s most compact, research-grade controller, yet packed with 1200 watts of power. Sufficient for heating mantles up to 5L in size and most laboratory ovens, hot plates, reaction blocks and other heaters. Contains J-KEM’s patented power control computer which provides 0.1° regulation of anything Specifications: 120vac, 10 amps, 1200 watts.Warranty: 2 Years The temperature range desired determines the probe/thermocouple type: J [black] (0 – 800° C) K [yellow] (-50 – 1200° C) T [blue] (-200 – 250° C) RTD: (-200 – 400° C) Specifications: 120vac, 10 amps, 1200 watts Weight: 5 Lbs Dimensions: 7.4 x 5.2 x 3.25 in

$949.00 - $1,130.00

Summit Research #45 1000ml CT-1 Flask

Summit Research #45 1000ml CT-1 Flask #45 1000ml CT-1 Flask. 100% Threaded Schott glass. Made in the USA Rodaviss kit not included. Shipping not included for this item. *Summit recommends all users of any and all glassware to operate inside a ventilated fume hood with sufficient blast shields to prevent injury in case of fatigued glass failure. *Summit is not responsible or liable for the result of any failures from use, and/or loss of subsequent hardware contamination/failure with or without the result of material loss or damaged caused to surroundings. By purchasing our premiere lines of laboratory glassware the user is responsible to operate in the recommended environment safely. We recommend all users to operate in a legal and licensed facility where safety is the number 1 goal.

$95.00

So-Low -80°C Ultra-Low Upright Freezer - 30 Cubic Ft.

So-Low -80°C Ultra-Low Upright Freezer - 30 Cubic Ft. Please note: This Product may carry up to an 8 week lead time! So-Low Ultra-Low Upright Freezers are second to none in low temp applications to suit any laboratory or application needs. These Ultra-Low Temp freezers feature digital temperature control with 2 temperature displays. One shows the set temperature and the other shows the actual temperature in the freezer. The So-Low U80-30 features a battery operated alarm system that will emit an audible and visual signal when there is a mechanical or electrical failure. The alarm has an over and under temperature setting, alarm silencing switch, and battery test switch. Product Specifications Temperature Control Digital Control with two temperature displays. One display shows the set temperature, the other shows the actual temperature in the freezer. Alarm System Battery operated alarm system will emit an audible and visual signal when there is a mechanical or electrical failure. The alarm has an over and under temperature setting, alarm silencing switch, and battery test switch. Dimensions: Exterior: 60.5" x 37" x 79.5" Interior: 42" x 25" x 51.25" Capacity 30 Cubic Ft. / 877 Liters Temperature Range -40°C to -80°C / -40°F to -112°F Shelving 4 Fixed Shelves (5 Compartments) Inventory Rack Capacity 35 Remote Alarm Relay A relay for a remote alarm hook-up is also provided. Refrigeration System So-Low cascade type. Two hermetic compressors. CFC & HCFC free refrigerants. Construction Chamber is 14-ga. zinc coated galvanized steel. Exterior is 16-ga. steel. Powder coated cool gray finish. Voltages Available 115/60/1 - 220/50/1 Technical Support Supplied by Nation-Wide-Network of service companies. ETL Electrical Approval Specification Data Sheet Diagram Data Sheet

$15,300.00 - $17,380.00

So-Low -80°C Ultra-Low Upright Freezer - 28 Cubic Ft.

So-Low -80°C Ultra-Low Upright Freezer - 28 Cubic Ft. Please note: This product may carry up to an 8 week lead time So-Low Ultra-Low Upright Freezers are second to none in low temp applications to suit any laboratory or application needs. These Ultra-Low Temp freezers feature digital temperature control with 2 temperature displays. One shows the set temperature and the other shows the actual temperature in the freezer. The So-Low U80-28 features a battery operated alarm system that will emit an audible and visual signal when there is a mechanical or electrical failure. The alarm has an over and under temperature setting, alarm silencing switch, and battery test switch. Product Specifications Temperature Control Digital Control with two temperature displays. One display shows the set temperature, the other shows the actual temperature in the freezer. Alarm System Battery operated alarm system will emit an audible and visual signal when there is a mechanical or electrical failure. The alarm has an over and under temperature setting, alarm silencing switch, and batter test switch. Dimensions: Exterior: 54" x 37" x 79.5" Interior: 38" x 25" x 51.25" Capacity 28 Cubic Ft. / 792 Liters Temperature Range -40°C to -80°C / -40°F to -112°F Shelving 4 Adjustable Shelves (5 Compartments) Inventory Rack Capacity 30 Remote Alarm Relay A relay for a remote alarm hook-up is also provided. Refrigeration System So-Low cascade type. Two hermetic compressors. CFC & HCFC free refrigerants. Construction Chamber is 14-ga. zinc coated galvanized steel. Exterior is 16-ga. steel. Powder coated cool gray finish. Voltages Available 115/60/1 - 220/50/1 Technical Support Supplied by Nation-Wide-Network of service companies. ETL Electrical Approval Specification Data Sheet Diagram Data Sheet

$14,800.00 - $16,830.00

So-Low -85°C Ultra-Low Chest Freezer - 17 Cubic Ft.

So-Low -85°C Ultra-Low Chest Freezer - 17 Cubic Ft. Please note: This Product may carry up to an 8 week lead time! So-Low Ultra-Low Chest Freezers are second to none in low temp applications to suit any laboratory or application needs. These Ultra-Low Temp freezers feature digital temperature control with 2 temperature displays. One shows the set temperature and the other shows the actual temperature in the freezer. The So-Low C85-17 features a battery operated alarm system that will emit an audible and visual signal when there is a mechanical or electrical failure. The alarm has an over and under temperature setting, alarm silencing switch, and battery test switch. Product Specifications Temperature Control Digital Control with two temperatures display. One Display shows the set temperature, the other shows the actual temperature Alarm System Battery operated alarm system will emit an audible and visual signal when there is a mechanical or electrical failure. The alarm has an over and under temperature setting, alarm silencing switch, and battery test switch. Dimensions: Exterior: 81.25" x 33.5" x 48.5" Interior: 69" x 20" x 21" Capacity 17 Cubic Ft. / 480 Liters Temperature Range -40°C to -85°C / -40°F to -121°F Shelving N/A Inventory Rack Capacity 36 Remote Alarm Relay A relay for a remote alarm hook-up is also provided. Refrigeration System So-Low cascade type. Two hermetic compressors. CFC & HCFC free refrigerants. Construction Chamber is 14-ga. zinc coated galvanized steel. Exterior is 16-ga. steel. Powder coated cool gray finish. Voltages Available 115/60/1 - 220/50/1 Technical Support Supplied by Nation-Wide-Network of service companies. ETL Electrical Approval Specification Data Sheet Diagram Data Sheet

$10,995.00 - $12,644.50

So-Low -85°C Ultra-Low Chest Freezer - 3 Cubic Ft.

So-Low -85°C Ultra-Low Chest Freezer - 3 Cubic Ft. Please note: This Product may carry up to an 8 week lead time! So-Low Ultra-Low Chest Freezers are second to none in low temp applications to suit any laboratory or application needs. These Ultra-Low Temp freezers feature digital temperature control with 2 temperature displays. One shows the set temperature and the other shows the actual temperature in the freezer. The So-Low C85-3 features a battery operated alarm system that will emit an audible and visual signal when there is a mechanical or electrical failure. The alarm has an over and under temperature setting, alarm silencing switch, and battery test switch. Specification Data Sheet Diagram Data Sheet Specification Manufacturer So-Low Temperature Range -40°C to -85°C / -40°F to -121°F Capacity 3 Cubic Ft. / 83 Liters Dimensions: Exterior: 34.5" x 25.25" x 48" Interior: 24" x 12" x 18" Refrigeration System So-Low cascade type. Two hermetic compressors. CFC & HCFC free refrigerants. Construction Chamber is 14-ga. zinc coated galvanized steel. Exterior is 16-ga. steel. Powder coated cool gray finish.

$6,300.00 - $7,480.00

Cascade CDO-5 Dry & Decarb Oven, 5 cu ft, 2 Mesh Bags

Cascade CDO-5 Dry & Decarb Oven, 5 cu ft, 2 Mesh Bags This item carries up to a 2 week lead time. Cascade’s CDO-5 is purpose-built for bench-top, R&D drying and decarboxylation of material with additional features: Built-in Humidity Sensor assists in monitoring dryness Adjustable stainless steel shelves – 2 each NRTL Certification 2 each FDA temp rated fine micron mesh bags for ground material – Mesh bags are required to prevent oven contamination and ground material loss. This powerful benchtop forced air laboratory oven uses heated air to remove unwanted compounds from products that are not temperature sensitive. Our ovens feature horizontal airflow that enables more consistent distribution of air. They are designed to have uniform temperatures and airflow across the shelf space from right to left. The CDO-5 includes a built-in humidity sensor and fine micron mesh bags for drying or decarboxylating powders or ground material. Ideal Uses: R&D, laboratory scale forced-air convection drying Decarboxylation processes Drying organic material. Drier material will yield better results than processing wet material. Removing as much moisture as possible pre-processing will save time in in the post process of vacuum purge and winterization. Lab glassware dryer Model CDO-5 Features Horizontal Airflow. The airflow moves uniformity across the shelf space from right to left Digital set-point control, timer and overtemp failsafe protection Humidity sensor displays relative humidity levels during process Stainless steel interior / Food lab-grade construction 1 Year Warranty Includes 2 stainless steel shelves, height adjustable with mounting clips Includes 2 temp rated mesh bags for easy loading & uniform drying of messy powders, ground up or turbulent materials Triple wall construction the CDO-5 meets CE, UL and TUV requirements to keep work-spaces cool Quality made in Oregon USA 120V / 1ph / 14FLA NEMA 5-15P Plug Supplied (220V 1 PH Version available) The Cascade Difference Basic forced-air lab ovens are mass-produced and sold by many large scale laboratory equipment distributors. But there are key differences between Cascade and other less costly, often imported lab ovens: Independent Overtemp Failsafe Protection The Cascade Sciences CDO-5 is equipped with a heating cutoff system that will automatically stop power to the heaters when the overtemp setting is tripped. This protection system will provide peace of mind for overnight or unattended drying processing. NRTL Certification No Extra cost. The CDO-5 Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities. CAN/CSA-C22.2 No. 61010-1:2012 +UPD No. 1:2015-07 + UPD No. 2:2016-04 CAN/CSA-C22.2 No. 61010-2-010:2015 UL 61010-1:2012-05 UL 61010-2-010:2015 EN 61010-1:2010 EN 61010-2-010:2014 Rigorous Quality Assurance in an ISO Certified, USA Manufacturing Facility Cascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment: Electrical & mechanical safety is thoroughly tested in compliance with TUV requirements Functional testing verifies user settable items consistent with most lab protocols/usage models Temperature verification includes calibration & temp chamber uniformity following ASTM standards Units are cleaned and packed in ISTA tested, certified packaging materials Specifications Capacity Volume 4.9 Cubic Ft. / 138 Cubic Liters Interior Dimensions 21” x 19.44” x 20.75”534mm x 494mm x 527mm Exterior Dimensions 34.1” x 28.1” x 38.75”866mm x 711mm x 984mm Temperature Temperature Range +2°C (36°F) above room temp to 180°C (350°F) Temp Stability +/-0.4 °F Temp Uniformity @ 40°C (100°F): +/- .5°C (1°F)@ 115°C (240°F): +/- 1°C (1.5°F)@ 150°C (305°F): +/- 2°C (3°F) Heat up / Stabilization Time from 25°C (77°F) to 115°C (240°F) 40 minutes Air Statistics Airflow Exchanges 220 per hour @ 80°C (176°F) Linear Shelf Space Airflow 145 Feet Per Min (44 Liters Per Min) Air Intake Adjustable side vents. Air Exhaust Adjustable. Top 2.75: Dia Exhaust Airflow @ 80°C (176°F) 18.5 Feet Per Min (523.9 Liters Per Min) Shelving 18.5 Feet Per Min (523.9 Liters Per Min) Fits 5 maximum Surface Area (W x D): 20.75″ x 19″ Weight Capacity: 50lbs Bags Comes with 2 Temp Rated Mesh Bags, fits four max Material Polypropylene (PP) Melt Temperature 161°C (363°F) Softening Point 152°C (305°F) Heat Deflection Temperature 90°C (194°F) Glass Transition Temperature 0°C (32°F) * Mesh bags are REQUIRED to prevent oven contamination and ground material loss. * Polypropylene products produced for some filtration applications are made from resin that complies with FDA regulations for food contact. The regulation compliance is product number dependent / specific. * Impact at cold temperatures is likely to cause strand cracking or breakage Certifications ISO 9001NRTL TUV #U8 170464972 077CAN/CSA-C22.2 No. 61010-1:2012+ UPD No. 1:2015-07 + UPD No. 2:2016-04CAN/CSA-C22.2 No. 61010-2-010:2015UL 61010-1:2012/R:2016-04UL 61010-2-010:2015EN 61010-1:2010EN 61010-2-010:2014 Warranty 1 Year

$7,607.00

30L Glass Axis

30L Glass Axis Oil Filled Vacuum/Pressure Gauge - Bottom Mount *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$140.00

2L BVV™ Rotary Evaporator Turnkey Setup

2L BVV™ Rotary Evaporator Turnkey Setup 2L Electric Lift Rotary Evaporator turnkey setup includes all the necessary components to successfully perform solvent recovery via rotary evaporation. A cold trap should always be used inline between your vacuum system and application to protect the pump from volatile vapors. 2L Rotary Evaporator Turnkey Setup includes: 2L Electric Lift Rotary Evaporator 90-day limited warranty (excludes glassware, consumables & moving parts) BVV NEO 1.4 CFM Diaphragm Pump ETL Rated OR. 3.5CFM Dry Floating Scroll Vacuum Pump Polyscience LS -20C to 40C 1/2HP Chiller w/ Turbine Pump OR BVV NEOCISION 20L Chiller (-40C) - ETL Rated 10ft of Vacuum Tubing 20ft of Chiller Tubing 10 Pack of Adjustable stainless steel hose clamps 3/8" Vacuum Manifold Optional add-on : BVV™ CT40 -40°F 300ml x 3 Cold Trap, BVV™ CT80 -112°F 300ml x 3 Cold Trap Optional add-on: J-KEM DVR-200 Digital Vacuum Regulator Optional add-on: Heat Transfer Fluid -- NuTherm PF-50 or Dynalene HC-50 Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to the condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of the condenser, chiller input to bottom of the condenser). Connect vacuum pump to cold trap and connect cold trap to the vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller, and cold trap have reached desired temperatures, turn on the rotovap motor and set the speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once the vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow the solution to enter the evaporating flask. At this point, you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$7,000.00 - $13,500.00

20L Neocision ETL Lab Certified Rotary Evaporator Turnkey System

20L Neocision ETL Lab Certified Rotary Evaporator Turnkey System 20L NEO Rotary Evaporator Turnkey System setup includes all the necessary components to successfully perform solvent recovery via rotary evaporation. A cold trap should always be used inline between your vacuum system and application to protect the pump from volatile vapors. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram 20L NEO Rotary Evaporator Turnkey System setup includes: 20L Neocision ETL Lab Certified Rotary Evaporator Polyscience 6160T 1HP Chiller 3/8" Gum Rubber - 100ft 3/8" Silicone Tubing - 25ft Welch BTpro100 Diaphragm Pump Adjustable Stainless Steel Hose Clamps Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$14,750.00 - $17,305.00

10L Premium Short Path Distillation Kit with P10 Distillation Head

10L Short Path Distillation Kit with P10 Distillation Head This unit carries a 2 day lead time. (Note: Stainless Steel Table NOT Included.) The 10L Short Path Distillation Kit features our USA made P10 Distillation Head. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Kangaroo digital thermometer which is very rugged and reliable. You will also receive a Ribbed Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Kit gives you the basic necessities of a short path distillation system and allows you to add on a temperature control system and vacuum pump to fit your needs. The 10L Neo Kit Includes: 10L Short Path Distillation Kit including glassware, labware, and P10 Distillation Head. 10L Digital Heating and Stirring Mantle. Valved Vacuum Adapter. Ribbed Dewar Style Glass Cold Trap. Kangaroo Digital Thermometer. Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$4,100.00

Press Club’s 100% Aluminum Pre-Press Mold

PRE-PRESS MOLD The Press Club 100% aluminum pre-press molds help you quickly condense your start material before pressing. Pre-press molds will not only save you time but will help you achieve more uniform results and increase yields. 1.5" x 2.5" This 1.5" x 2.5" pollen press creates a circular puck (approximately the size of a quarter) that fits perfectly inside a bag. Made in the USA. 2" x 4" This 2" x 4" pre-press mold creates a rectangular slab that that fits perfectly inside a 2" x 4" bag or larger. Made in the USA. 2" x 9" This 2" x 9" pre-press mold creates a rectangular slab that that fits perfectly inside a 2" x 9" bag or larger. Made in the USA. 2.5" x 2.5" This 2.5" x 2.5" mold creates a square slab that fits perfectly inside a 2.5" x 4.5" rosin bag. Made in the USA. 2.5" x 4.5" This 2.5" x 4.5" pre-press mold creates a rectangular slab that that fits perfectly inside a 2.5" x 4.5" bag or larger. Made in the USA. 2.5" x 9" This 2.5" x 9" pre-press mold creates a rectangular slab that that fits perfectly inside a 2.5" x 9" bag or larger. Made in the USA. 3" x 5" This 3" x 5" mold creates a rectangular slab that fits perfectly inside a 3" x 6" filter bag. Made in the USA. 4" x 7" This 4" x 7" pre-press mold creates a rectangular slab that that fits perfectly inside a 4" x 7" bag or larger. Made in the USA.

$59.95 - $169.95

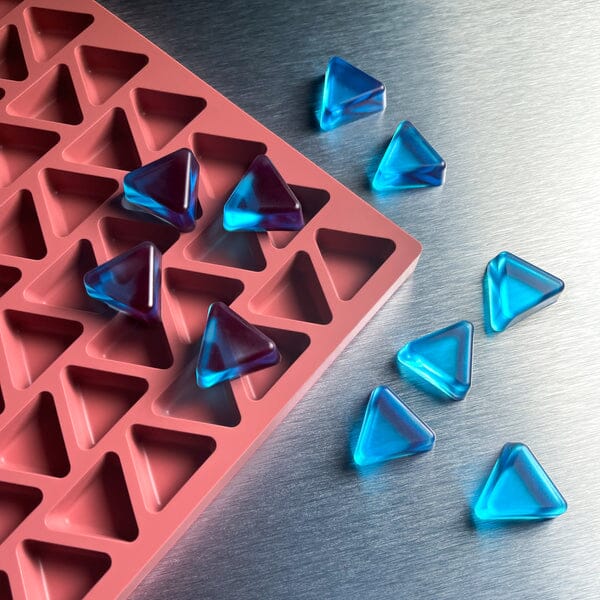

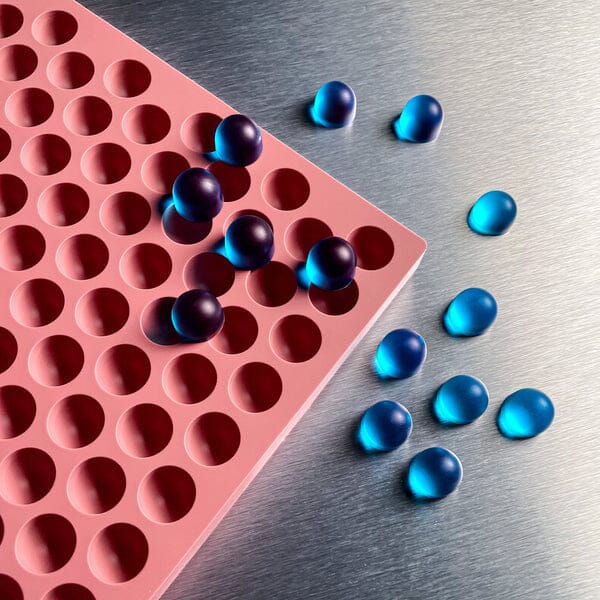

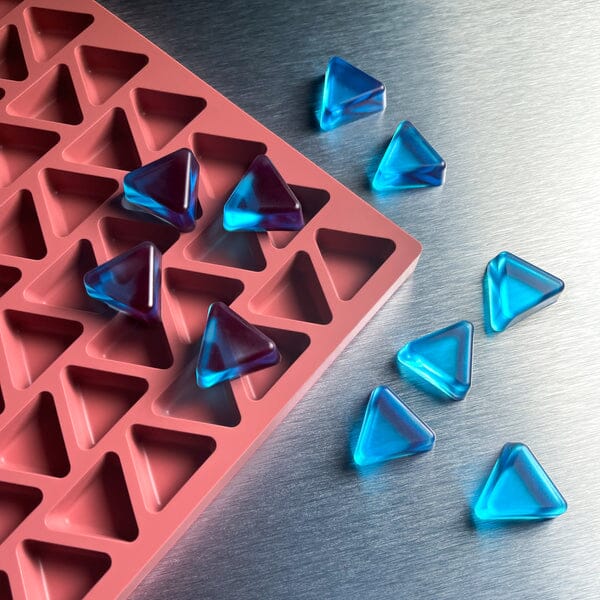

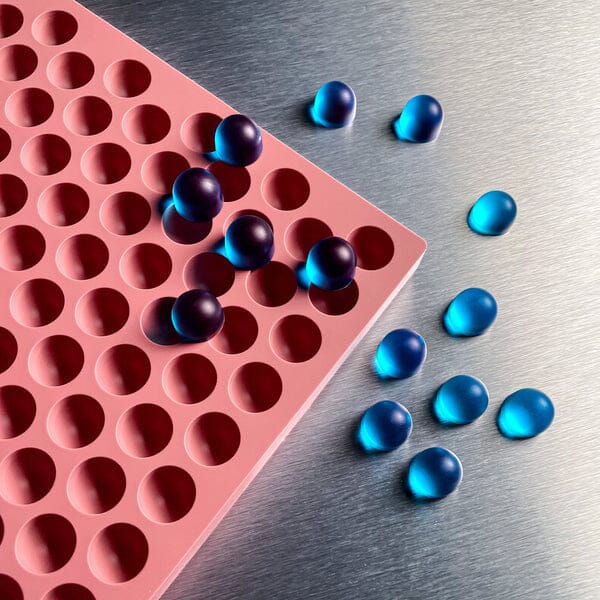

Dark City Molds Triangle Gummy Molds

Dark City Molds Triangle Gummy Molds Sizes Available 2.66mL Triangle 2.8mL Tetrahedron 4.1mL 8 Triangle Mold Properties 100% FDA Approved Food-Contact Safe Platinum Silicone Temperature Resistant - Freezer, Dishwasher & Oven Safe Half Sheet Molds Are Optimized to Fit 2 Molds Per 18” x 26” Full Size Baking Sheet Strategically Designed Geometry Optimized For Rapid Extraction Proprietary Natural Slip Finish For Oil Free Workflow Precision Diamond Tooled Masters For Superior Detail & Finish Guaranteed Highest Resolution Designs On The Market Rapid Demolding Rates - Extract up to 1000+ Gummies Per Minute Perfect for Gummies, Hard Candies, Caramels, Chews, Chocolates, and More 6-10 Year Expected Lifetime with Proper Care & Use OUR PROMISE Every mold that leaves our facility is covered by DCM’s 18 Month Gold Standard Warranty. If you experience any issues within that period, we'll immediately exchange the mold in question. No hassle. No fuss. Highest quality platinum silicone molds in the world. Whether you’re manufacturing gummies, hard candies, caramels, chews, or other confections, our diamond tooled molds will provide superior finish and detail to ensure maximal aesthetic clarity and operational efficiency for your manufacturing workflow. We’re proud to offer best-in-industry performance with our Rose Pro Series™ silicones as well as the most competitive price points on translucent platinum molds currently available. *Assumes a 1ml : 1.4g recipe ratio. Since weight is a metric of a recipe's specific density, we cannot exactly determine the weight of your specific recipe. Please consult the designated volume (ml) specification above to calculate a more exact weight (g) reading. All Dark City Gold Standard SOPs yield a 1ml : 1.4g ratio. Mold Specifications Sizes Avaliable (Volume) Shape Pieces Per Mold Weight Material Options Mold Dimensions Compatibility Square Molds 2.5mL Square 134 3.5g Rose Pro Series, Translucent 280mm x 392mm Hand Fill, Flood & Scrape, Universal Depositor 2.85mL Square 234 3.5g Rose Pro Series, Translucent 290mm x 390mm Hand Fill, Flood & Scrape, Universal Depositor 3.57mL Square 120 5g Rose Pro Series, Translucent 276mm x 387mm Hand Fill, Flood & Scrape, Universal Depositor 4mL Square 192 5.6g Rose Pro Series, Translucent 290mm x 390mm Hand Fill, Flood & Scrape, Universal Depositor 6mL Square 165 8.4g Rose Pro Series, Translucent 391.6mm x 286.5mm Hand Fill, Flood & Scrape, Universal Depositor Cube Molds 1mL Cube 609 1.5g Rose Pro Series, Translucent 286mm x 398mm Hand Fill, Flood & Scrape, Universal Depositor 1.6mL Cube 275 2.2g Rose Pro Series, Translucent 289mm x 384mm Hand Fill, Flood & Scrape, Universal Depositor 2.2mL Cube 209 3g Rose Pro Series, Translucent 289mm x 365mm Hand Fill, Flood & Scrape, Universal Depositor, Baker Perkins ServoForm Mini 3.4mL Cube 280 4.8g Rose Pro Series, Translucent 275.9mm x 394.7mm Hand Fill, Flood & Scrape, Universal Depositor Triangle Molds 2.66mL Triangle 210 3.7g Rose Pro Series, Translucent 280mm x 379.7mm Hand Fill, Flood & Scrape, Universal Depositor 2.8mL Tetrahedron 95 3.9g Rose Pro Series, Translucent 135mm x 374mm Hand Fill, Flood & Scrape, Universal Depositor 4.1mL Triangle 160 5.7g Rose Pro Series, Translucent 285mm x 384mm Hand Fill, Flood & Scrape, Universal Depositor Multidose Molds 2.25mL Cube 144 3.2g Rose Pro Series, Translucent 254mm x 355mm Hand Fill, Flood & Scrape, Universal Depositor 3.3mL Rhombus 209 4.6g(each segment: 2.3g*) Rose Pro Series, Translucent 284mm x 375.4mm Hand Fill, Flood & Scrape, Universal Depositor 4mL Square 165 5.5g Rose Pro Series, Translucent 289mm x 380mm Hand Fill, Flood & Scrape, Universal Depositor 12.5mL Rectangle 60 17.5g Rose Pro Series, Translucent 279.3mm x 385.2mm Hand Fill, Flood & Scrape, Universal Depositor 23.5mL Square Rope 20 32g (each segment: 3.2g*) Rose Pro Series, Translucent 258mm x 385mm Hand Fill, Flood & Scrape, Universal Depositor 42.4mL Rectangle 18 59.4g Rose Pro Series, Translucent 240.9mm x 381.3mm Hand Fill, Flood & Scrape, Universal Depositor Cube Molds 1mL Cube 609 15.g Rose Pro Series, Translucent 286mm x 398mm Hand Fill, Flood & Scrape, Universal Depositor 1.6mL Cube 275 2.2g Rose Pro Series, Translucent 289mm x 384mm Hand Fill, Flood & Scrape, Universal Depositor 2.2mL Cube 209 3g Rose Pro Series, Translucent 289mm x 365mm Hand Fill, Flood & Scrape, Universal Depositor 3.4mL Cube 280 4.8g Rose Pro Series, Translucent 275.9mm x 394.7mm Hand Fill, Flood & Scrape, Universal Depositor Coin Mold 2.5mL Coin 120 3.5g Rose Pro Series, Translucent 276mm x 387mm Hand Fill, Flood & Scrape, Universal Depositor 2.17mL Coin 176 3g Rose Pro Series, Translucent 289mm x 374mm Hand Fill, Flood & Scrape, Universal Depositor 2.5mL Coin 120 3.5g Rose Pro Series, Translucent 276mm x 387mm Hand Fill, Flood & Scrape, Universal Depositor 3.26mL Coin 165 4.6g Rose Pro Series, Translucent 289mm x 385mm Hand Fill, Flood & Scrape, Universal Depositor 7.1mL Puck 88 9.9g Rose Pro Series, Translucent 283.2mm x 390.2mm Hand Fill, Flood & Scrape, Universal Depositor 7.1mL (Bit) Coin 88 9.9g Rose Pro Series, Translucent 280.2mm x 386.1mm Hand Fill, Flood & Scrape, Universal Depositor 34.3mL Coin 35 48g Rose Pro Series, Translucent 268.1mm x 371.7mm Hand Fill, Flood & Scrape, Universal Depositor 45.2mL Coin 20 63.3g Rose Pro Series, Translucent 293.0mm x 365.3mm Hand Fill, Flood & Scrape, Universal Depositor Gum Drop 1.3mL Gum Drop 388 1.82g Rose Pro Series, Translucent 286mm x 390mm Hand Fill, Flood & Scrape, Universal Depositor 2.15mL Gum Drop 176 3g Rose Pro Series, Translucent 289mm x 392mm Hand Fill, Flood & Scrape, Universal Depositor 3.6mL Gum Drop 140 5g Rose Pro Series, Translucent 259mm x 363.6mm Hand Fill, Flood & Scrape, Universal Depositor

$150.00 - $250.00

1/4" Fractional Tube Fitting Hose

1/4" Fractional Tube Fitting Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have a tube stub on each end that fits a standard compression fitting. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Specifications: Connection Type(s): 1/4" Tube Stub Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -94°F to 500°F (-70°C - 260°C) Pressure Rating 2100 PSI Chemical Resistance Excellent Max Bend Radius 3"

$47.95 - $70.00

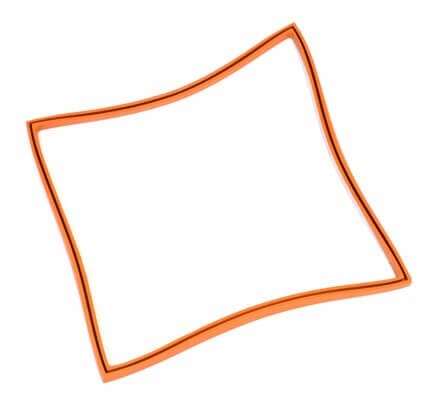

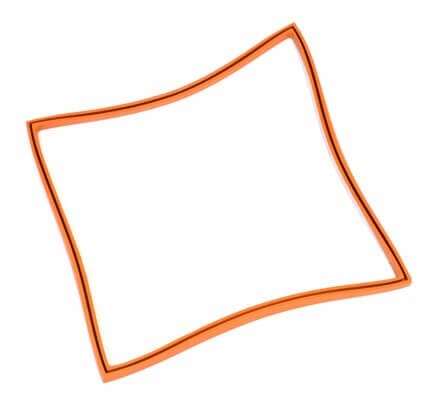

Silicone Door Gasket, 24in x 28in

Silicone Door Gasket, 24in x 28in These 24″ x 28″ ORANGE colored door gaskets fit all Cascade CSO-10 vacuum ovens. They are made of cured silicone and are the highest temperature rated (230°C or 446°F) gaskets available for the CSO-10 vacuum oven.

$218.00

WELCH Self-Cleaning Vacuum System 2025

WELCH Self-Cleaning Vacuum System 2025 Product Details Automatic Self-cleaning purge maintains efficiency, extends diaphragm life Free air displacement: 35 L/min (1.2 CFM) Incremental ballast switch enables fast response to bumping / foaming Complete oil-free dry vacuum systems for rotary evaporators and concentrators. Corrosion-resistant PTFE diaphragm vacuum pump systems enable superior control and efficiency for each evaporation. Provides controlled solvent stripping in flasks up to 5 L. Use 9 torr Model 2025 for solvents with atmospheric B.P. <120o C. Includes analog gauge and vacuum regulation. Inlet and exhaust separators protect pump and lab atmosphere. Specification Model Number 2025 Applications Controlled vacuum for Rotary evaporators, Centrifugal concentrators, and other evaporative processes. Type Laboratory Vacuum Pump Free Air Displacement m3/hr (l/min.) @50Hz 1.2(34) Ultimate Pressure 1.7(28) Max Pressure PSIG (pascal) 29.5 Adjustable Vac. / Gas Ballast 1/5 Tubing Needed Yes Intake Thread NPT 1/4 Overall Dimensions LxWxH in. (cm) 13.6x12x11.3 (34.5x30.5x28.7) Ship Weight 36(16.3) Intake Catch Jar Yes Exhaust Catch Jar Yes

$3,725.00 - $3,742.00

Compression TEE 1/2" Compression x 3/4" Compression x 1/2" FNPT

Compression TEE 1/2" Compression x 3/4" Compression x 1/2" FNPT made out of 304 stainless steel

$40.00

5L Rotary Evaporator 2L Evaporating Flask (2L Flask that is swap able with the RT5L-V2)

This 2L evaporating flask is made out of borosilicate and designed to fit BVV 5L rotary evaporators. Overall length is about 10-3/4".

$105.00

12" Tri-Clamp Dewaxer Columns

12" Tri-Clamp/ Tri Clover Dewaxing Columns This is a 12" Tri-Clamp BVV™ Tri-Clamp Dewaxing Spool. It is intended to have dry ice put into the sleeve to chill the material inside the column. **Note: When selecting a Pipe Hanger choose the size that correlates to the Sleeve OD NOT Spool OD Sizes Available: 12" x 12" Tri-Clamp Dewaxer Column Specifications: Tri-Clamp Size 3" Material 304 Stainless Steel Standard 3A High Polish Sleeve OD 14.000" Spool ID 11.732" Spool OD 12" Flange OD 12.57" Bead Center 12.17" Drain Port 1/4"-18 FNPT (Drain Plug Included) OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested.

$345.00

Gas Plug Clear Mix #02

Gas Plug Clear Mix #02 This special Ethanol Blend is a mixture of minerals that electromagnetically affixes themselves to plant compounds and pigment, removing the bad stuff from extracted oil, and purifying your oil Gas Plug Clear Mix #02 SDS CONTAINS: CARBON, SILICA, MAGNESIUM. * DISCLAIMER * You should only lose yield from your oil in correspondence to the amount of residual plant compound removed. If you lose more than 20% yield from gold oil, you have done it wrong. It is not uncommon to have a 50-60% cannabinoid crude oil that loses 30-40% yield under refinement. The amount of yield loss should be proportionate to the overall potency.

$30.00 - $200.00

5L Neocision Short Path Distillation Kit

5L Neocision Short Path Distillation Kit This unit carries a 2 day lead time. The 5L Neocision Short Path Distillation Kit features our 5L Distillation Kit with P5 Distillation Head and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. You will also receive a Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. The Premium Turnkey Kit Includes: 5L Neocision Kit with P5 Distillation Head KF-25 x 1/4" Barb Adapter Dewar Style Glass Cold Trap Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$6,950.00

Cascade CVO-10 Vacuum Oven