EVERY PRODUCT BUT HYDRO FOR WHOLESALE STORE

Huber SilOil M20.195/235.20, Heat transfer fluid -20 to 235 °C

Huber SilOil M20.195/235.20, Heat transfer fluid -20 to 235 °C SilOil M20.195/235.20 is a low-viscosity silicone fluid which, as a result of its special property profile, is particularly suitable for use as a cold and heat transfer medium in cryostats, thermostats and heat transfer installations. SilOil M20.195/235.20 can be used in the range from -20 °C to 195 °C (for open systems) and to 235 °C in externally sealed systems (Unistats). It should be borne in mind that, at high temperatures, SilOil M20.195/235.20 can be chemically altered by oxidising media, such as air, or substances with a catalytic effect, such as acids, lyes and various metal compounds. An increase in viscosity, and possibly even gelling of the fluid owing to crosslinking reactions, must be expected in the presence of oxidising agents, while contact with products having a catalytic effect usually induces a process of depolymerisation, resulting in a drop in viscosity. Advantages: Virtually insolubile in water Non-corrosive Low setting points and vapour pressures high flash points low toxicity odourless no coking tendency under thermal stress high thermal stability resistance to ageing Safety Data Sheet Heat transfer fluid M20.195/235.20 Working temperature °C -20 to 195/235 open/closed systems: -20°C…195°C Unistats (only closed): -20°C…235°C Material: silicon oil Viscosity at 25°C: 20 mm²/s Colour colourless, clear Material incompatibility Silicone rubber

$895.00 - $1,600.00

20L BVV™ Double Jacketed Glass Reactor

The BVV™ Double Jacketed Glass Reactors are ideal for reaction applications involving extreme temperatures. They include an inner jacket for cooling or heating and an outer jacket for vacuum insulation. The outer jacket also alleviates moisture buildup so you can always see exactly what's happening inside the system. Jacketed Reaction vessels are used for synthetic reaction of different types of materials in a controlled temperature and vacuum environment. Reaction Vessels can be used as an all in one tool for extraction, refinement, distillation, and homogenization. Consisting of an inner vessel with either one or two jackets, a reactor uses temperature differentials created by a chiller to change it's internal environment. Reaction vessels also operate under vacuum making them ideal for any atmospheric sensitive applications. They can be made out of glass or stainless steel and range in volume from 1L to 100L+. To run a reaction vessel most efficiently, you will need a chiller capable of bringing the internal temperature of the vessel to an extreme low, a chemical resistant vacuum pump, and a cold trap to catch any vapors that might pass through the condenser during operation. BVV™ Jacketed Reaction vessels are simple, cost-effective, and durable machines that allow you to process material quickly and efficiently. BVV 20L and 50L Glass Reactor Diagram Specifications: Glass Material: GG-17 High Borosilicate Glass Internal Volume: 20L 6.75L Jacket Capacity Shelf Material: Aluminum Alloy Homogenizer Power: 110V/60Hz Homogenizer Speed: 0-400 RPM Digital Homogenizer Control Digital temperature probe readout included Double Jacket 3/4" Jacket Connections 1/4" and 3/8" Vacuum Connections Length: 20 in. Width: 30 in. Height: 76 in. Does not include: Chiller, Vacuum System, Cold Trap Requires Assembly *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. ***Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS!*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$4,500.00 - $4,900.00

CMEP-OL Fan Bearing

CMEP-OL Fan Bearing This is a replacement bearing for the fan of the CMEP-OL and is fully encased and require no lubrication.

$35.00

Pipe Cap

SSP - Pipe Cap SSP Instrumentation TruFit® is manufactured from fully-traceable raw material to close tolerances and superior surface finishes. TruFit® provides optimal performance when installed in accordance with SSP’s recommendations and the design parameters appropriate for each type of connection – tapered thread, straight thread, and weld & braze. TruFit® components are cleaned in accordance with SSP documented work instructions using equipment calibrated to NIST standards with environmentally-safe and stable agents, ultrasonics, and heat/ temperature to remove all residual oil, grease, and loose particles. Stainless steel components are passivated to the requirements of MIL QQ-P-35 and ASTM A 967. ***Note: ALL NPT Threads REQUIRE the user to properly install the fitting by using a thread sealant to prevent leaks. Best Value Vacs recommends GAS PTFE Tape Specifications Connection Type 1 Female NPT Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Working Pressure (PSIG) 1/4" - 7750 3/8" - 6800 NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$5.00 - $6.00

Stainless Steel Laboratory Scissor Jacks

Stainless Steel Scissor Jacks Adjustable height laboratory scissor jack. The platform is 4"/6"/8" & the durable 304 stainless steel heavy-duty lab lifts with very little effort necessary! Specifications: 304 Stainless Steel Platform size: 4" x 4" / 6" x 6" / 8" x 8"

$29.00 - $49.00

280L Centrifuge Bags

This nylon bag is designed to fit in our BVV brand centrifuges to contain material and be easily swappable after runs to speed up processing times. These bags come with 2 zippers and come in 1, 10, 50, 100, and 200 micron filtration levels. For use with 280L Centrifuges Appx. Size : 39.25" Diameter x 14" Height Specifications SKU Appx. Diameter In. Appx. Height in. CFB-45L-XXX 17.5" 11.75" CFB-160L-XXX 32.25" 13" CFB-280L-XXX 39.25" 14" CFB-475L-XXX 47.25" 16.75"

$160.00 - $416.00

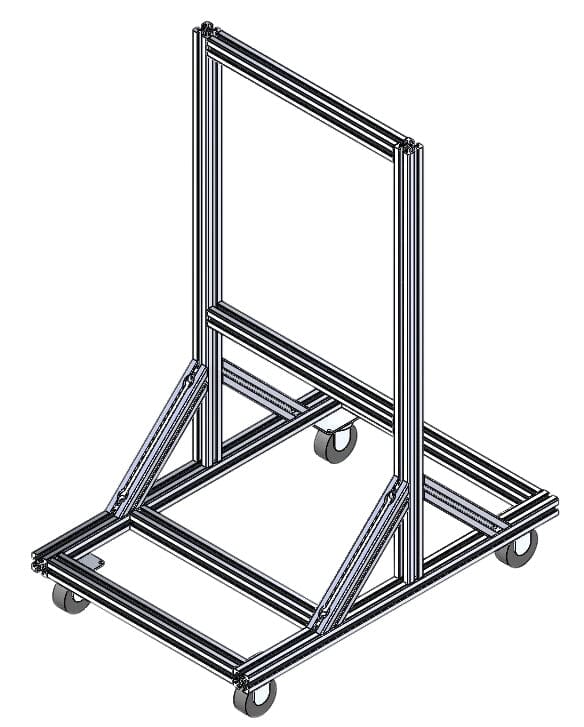

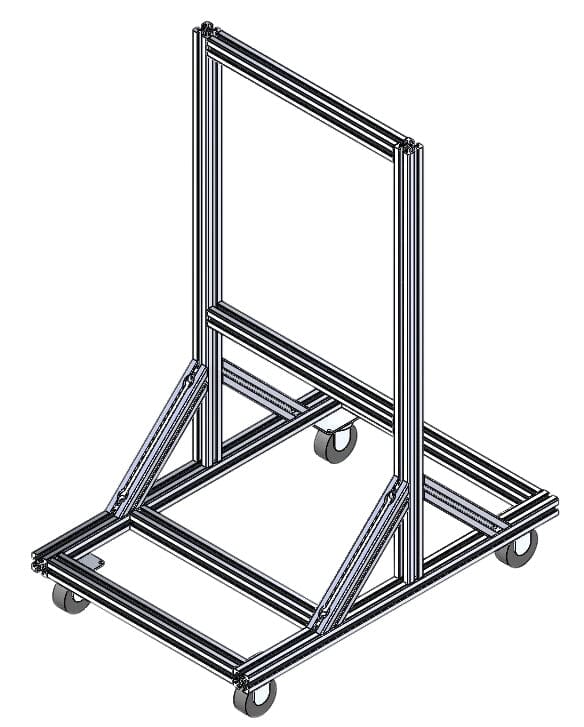

Extraction RACK # 6

Extraction RACK # 6 (Assembled units come with a 30-day warranty) Note: The unit does not come assembled - select "pre-assembled" from the drop-down menu to have the unit assembled by BVV before shipping Pipe hangers are not included There is no warranty on unassembled units Shipping Notice: If the customer orders the rack as assembled, then the item will only ship via freight and there will be additional shipping charges. Extraction Rack 6 Technical Drawing This rack fits the following BVV™ Extraction Systems: 8.5LB Athena 1LB Icarus 5LB Icarus XL Refinement Filter Stackable Diamond Miner Specifications (Does not include height with casters) Main Base Dimensions 21" X 30" Vertical Dimensions 21" X 36"

$580.00 - $780.00

4.8CF CSA Certified Lab Grade Forced Air Convection Drying Oven – 12 Shelves Standard

4.8CF BVV™ CSA Certified Lab Grade Forced Air Convection Drying Oven – 12 Shelves Standard DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! The 4.8CF CSA Certified Laboratory Grade Drying Oven is our newest addition to the Best Value Vacs line of Laboratory-grade processing equipment. Offering a leading ±1⁰F temperature stability, over 98% heat uniformity, and no overshoot, technicians can now process material with ease and confidence. We regulate heat using a modern, high-precision PID controller with a large, bright display and touchscreen buttons. The interior is a high-polish stainless steel, presenting a clean and easy to maintain surface. Our drying oven comes fully-stocked as a standard- offering ten spacious, wire frame shelves you can easily insert, remove, and clean. With a clear, no-overshoot advantage, there’s simply no better choice for your precision processing needs. Key Oven Features: Long-lifetime convection fan gently circulates air for optimal heat distribution Stainless steel interior for a sanitary, easy-to-clean look 12 spacious, wire racks are easy to insert and remove Level-adjusting caster wheels for mobility and stability Overload circuit breaker for electrical protection Large, tough, stainless steel door handle feels solid and works great Temperature overshoot protection enabled Digital timer allows users precise control of heating cycle Simple and powerful user interface presented in a large, bright, clear display Specifications Electrical 120 VAC / 60Hz / 2050W / USA Plug Internal Chamber Material: Polished Stainless Steel Dimensions (LxWxH): 21.65" x 17.72" x 21.65" Temperature Control LED PID Controller Temperature Range: RT+18F - 572F Temperature Stability: +/- 1F Temp Resolution: +/-0.1F Heat Uniformity: 98% Shelves Up to 12 Removeable Shelves Door Dual Layer Observation Window made from Tempered Glass Replaceable Gasket Material: Silicone Weight & Dimensions Outside Dimensions (LxWxH): 33.07" x 22.83" x 28.74" Weight: 149.91lbs Compliance CSA Certified *ISO 9001:2005 Note: This item is a freight ship item and will ship Via UPS Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise UPS freight Cannot Contact you for a delivery setup window.

$2,550.00

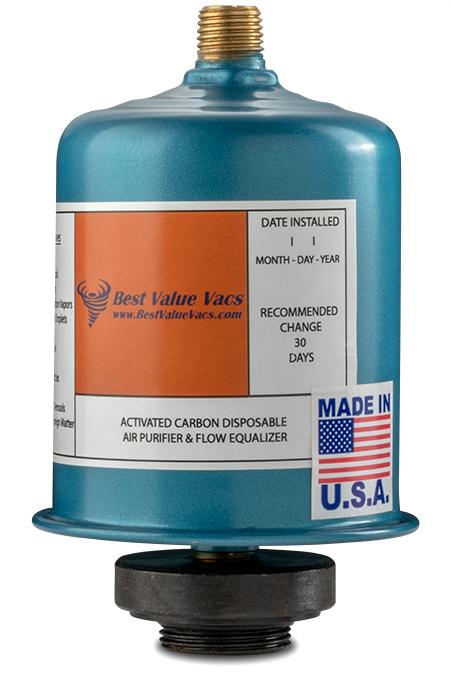

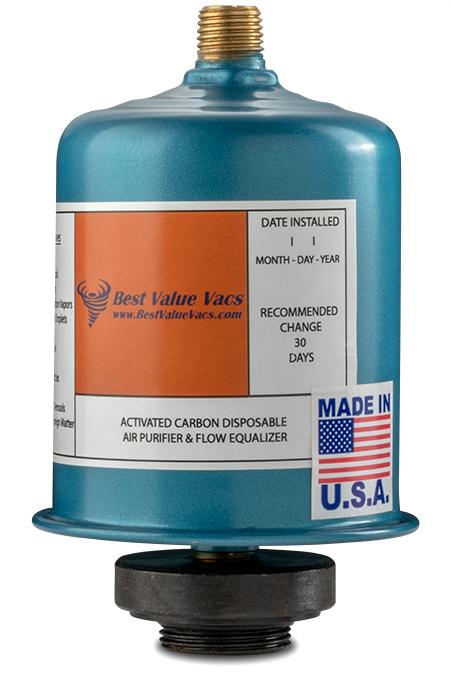

Purple BVV Vacuum Pump Activated Carbon Exhaust Filter

Carbon Exhaust Filter for BVV Vacuum Pumps Replaces Koby Junior (US Patent# 3169112A) BVV Vacuum Pump Activated Carbon Filter for use with Purple BVV vacuum pumps. Pump Models Include: BVV4D, BVVSF6S, BVVSF6D, BVV7S, BVV9D, BVVSF12D This filter will adsorb contaminants such as oil aerosols, oil vapors, certain other hydrocarbon vapors, and trace moisture. They also trap all foreign solid particles and bacteria down to 0.5 microns in size. Key Features: Purifies Exhaust Gases from Vacuum Pumps Up to 19 CFM 0.5 Micron Filtration levels. Helps Maintain Safe Working Environment Adsorbs Organic Vapors and Small Particles High-Efficiency Filtration Minimal Pressure Drop Maintenance Free - Completely Disposable Pressure Safe to 90 PSI M30 x 1.0 - Brass Pump Connection Filter connections 1/4" NPT Pipe Fitting Connections Removes the following contaminants: Oil Mist Oil Aerosols Oil Vapors Hydrocarbon Vapors Moisture Droplets Dust Pipe Scale Rust Fine Particles Odors Organic Aerosols Other Foreign Matter Lifespan:720 hrs. of continuous operation. (Then replacement is recommended) **NOTE PUMP NOT INCLUDED

$115.00

20 Gallon All-Mesh Bubble Wash Bags

20 Gallon All-Mesh Bubble Wash Bags The Press Club Wash Bags are the last set of bubble wash bags you'll ever own! Made from premium, food-grade material specifically for washing you can stop second guessing whether you have the right or best bags in the industry. All The Press Club bubble wash bags are hand sewn with our proprietary pink stitching, making them 2x stronger than competitors. You can be confident The Press Club bags will perform the same no matter if it's your 1st or 1000th wash. We're so confident our bubble wash bags will stand the test of time, every bag comes with a Lifetime Warranty. If you have any manufacturer issues, they will be more than happy to replace the bag for you! KEY FEATURES Fits All Standard 20 Gallon Buckets Hand Sewn With Our Proprietary Pink Stitch w/ Food-Grade Materials Military-Grade Waterproof & No Flaking Bag Liner Premium Drawstring & Cord Locks To Secure Bags Lifetime Warranty On All Wash Bags Includes Meshed Carrying Case For 2-Way Drying & Storage Made In USA AVAILABLE MICRONS 220 Micron (Work Bag), 190 Micron, 160 Micron, 120 Micron, 90 Micron, 73 Micron, 45 Micron, 25 Micron

$49.95

SSP 1/2" Compression Fitting Parts

SSP 1/2" Compression Fitting Parts ISSD8N: Duolok Tube Fittings, 1/2 in. Nut ISSD8FF: SSP® Duolok® Front Ferrule, FF Series, Nominal Size: 1/2 in, 316 Stainless Steel ISSD8BF: SSP® Duolok® Back Ferrule, BF Series, Nominal Size: 1/2 in, 1/2 in ID, 316 Stainless Steel

$3.00 - $8.00

Huber SilOil M60.115/200.05, Heat transfer fluid -60 to 200 °C

Huber SilOil M60.115/200.05, Heat transfer fluid -60 to 200 °C SilOil M60.115/200.05 is a low-viscosity silicone fluid which, as a result of its special property profile, is particularly suitable for use as a cold and heat transfer medium in cryostats, thermostats and heat transfer installations. SilOil M60.115/200.05 can be used in the range from -60 °C to 115 °C (for open systems) and to 200 °C in externally sealed systems (Unistats). It should be borne in mind that, at high temperatures, SilOil M60.115/200.05 can be chemically altered by oxidising media, such as air, or substances with a catalytic effect, such as acids, lyes and various metal compounds. An increase in viscosity, and possibly even gelling of the fluid owing to crosslinking reactions, must be expected in the presence of oxidising agents, while contact with products having a catalytic effect usually induces a process of depolymerisation, resulting in a drop in viscosity Advantages: virtually insolubile in water non-corrosive low setting points and vapour pressures high flash points low toxicit odourless no coking tendency under thermal stress high thermal stability resistance to ageing chlorine free Safety Data Sheet Heat transfer fluid M60.115/200.05 Working temperature °C 60 to 115/200 open/closed systems: -60°C…115°C Unistats (only closed): -60°C…200°C Material: silicon oil Viscosity at 25°C: 5 mm²/s Colour colourless, clear Material incompatibility Silicone rubber

$895.00 - $1,600.00

Certified 45L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller - 15LB Max Capacity

Certified 45L Ethanol Wash/Dry Centrifuge with Explosion Proof Motor and Controller Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift to lift it. It will also ship via freight only. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 1500 RPM with Gradual Speed Stepping 566 Separation Factor Multiple Connection Ports/Sizes High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation *BVV Centrifuges are now available certified by PRV Engineers. Field visits/verification letters are an additional $4,000 + travel expenses.* Specifications Capacity 45L Drum Dimensions 17.7" (450mm) Diameter x 11-7/8" (300mm) Deep Max Capacity 15lbs (6.8Kg) Speed 1500 rpm Separation Factor 566 Electrical 240V 1Ø (10.58A) Weight 794lbs (360Kg) Exterior Dimensions 50" x 27.6" x 28.7" (1280mm x 700mm x 730mm) Viewport Diameter 5.5" Connection Size(s): 2" Tri-Clamp Drain Port 1" Tri-clamp Side Port X 2 1" Tri-Clamp Top Port 1.5" Tri-Clamp Top Port 1/4" FNPT Top Port KF25 Top Port

$19,500.00 - $23,500.00

Chromatography Column Kit

Chromatography Column Kit Chromatography Column Kit This 3”x24” chromatography column features an internal volume of 2.7L. It’s commonly used for removing pesticides, separating components, and cleaning different chemical compounds. Additional consumables or accessories will be needed depending on application. Capacity can be increased with an additional reservoir adapted to the top 45/50 Rodaviss joint. Rodaviss joints are great for disconnecting any stubborn joints. Light grease is still recommended when assembling joints. This kit features: Casted base with 36” rod stand Support ring Chain clamp Needle control valve 3”x24” column with 2.7L capacity 45/50 Rodaviss joint Sintered disk Stop cock For additional information or questions regarding this kit, accessories, and consumables contact our customer support line. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$485.00

HTP The Monster Press - 8 Ton

HTP The Monster Press - 8 Ton If you have a large amount of plant material and are looking for a quality press then the Monster Press is for you! These high-quality presses are built from Aircraft Aluminum and stainless steel designed to be used in conjunction with a unique heating process.The Monster Press exerts 8 Tons of pressure to output a maximum shape of 5”x 7” x 3” thick.High Tech Pipes make quality presses that are manufactured in the U.S.A. using American materials and labor. Each Press is assembled and individually inspected before shipping. Our Presses are designed to be heated to the ideal temperature which is an important aspect of the Pressing process. We design and build our products to stand the test of time and to become a permanent piece of equipment for the end user. We use aircraft aluminum which maintains heat as opposed to other Presses on the market which use steel that either quickly loses heat or heats up too fast thus destroying the material that is being pressed. Each Press comes with full step by step instructions and a video is available as well.

$934.95$895.00

6" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves

6" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 6" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 3 BVV 316SS Full Bore Valves with (2)1/4" and (1)3/8" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have 3 1.5" Tri-Clamp ports with the middle port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" and 3/8" 37° JIC Flares -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" and (1) 3/8" 37° JIC Tri-Clamp Size(s) (3) 1.5" Ports x 6" Tri-Clamp Nitrogen Tested Yes

$310.00

6" x 4" x 3" x (2) 1/4" FNPT Tri-Clamp Skylight

Specifications: 304 Grade Stainless Steel Reducer 'Skylight' w/ High Polish interior 6" Triclamp x 4" Triclamp x 3" Triclamp (Can be used as viewport to see inside) x (2)1/4" FNPT 7" Tall

$140.00

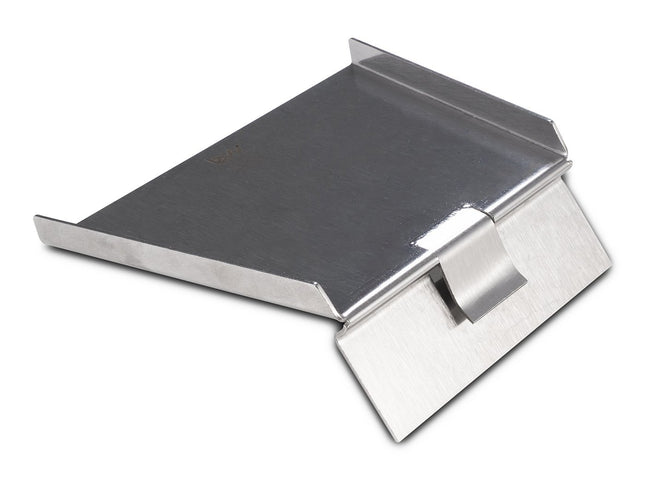

6" - 12" Dewax Dry Ice Funnel

This stainless steel funnel is meant to help get dry ice into 6" - 12" Dewaxing columns. It simply clips on the side of the dewaxer allowing an easier filling of the dry ice into the dewaxing column.

$75.00

8 Ton 304SS Puck Press

8 Ton 304SS Puck Press This BVV™ 8 Ton 304SS Puck Press allows users to compress material into an easily manageable puck. Specifications: 304 Stainless Steel Components (Excludes Jack) External Dimensions - 7-1/8" x 7-1/8" x 14" Internal Puck Mold Diameter - 3.75" Mold Height - 3-1/4" Weight - 34LBS

$350.00

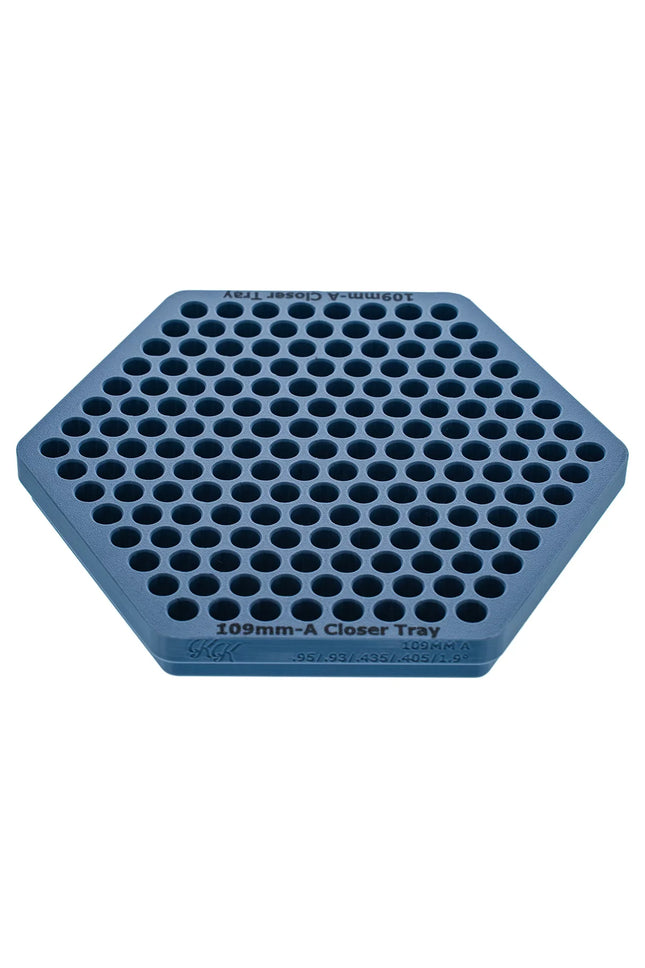

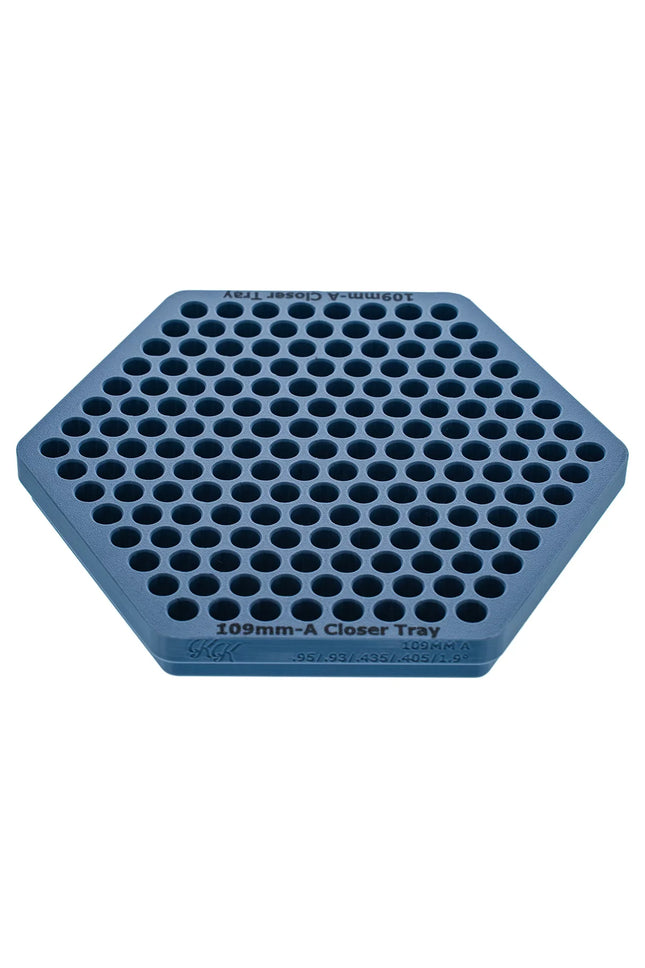

Receiving Tray - 70mm, 84mm, 98mm, 109mm

Receiving Tray - 70mm, 84mm, 98mm, 109mm Dutch Crown Closer Receiving Trays Unlock the full versatility of your Dutch Crown Closer with our range of Receiving Trays, designed to perfectly accommodate additional cone sizes. Whether you’re expanding your cone options or switching sizes for different uses, these trays are essential for precision and ease. Simply match the tray to your desired cone size, and you’re ready to seamlessly close cones with the same perfect finish. Each tray is sold separately, ensuring you have the flexibility to customize your setup as needed. Available Sizes: • 70mm Receiving Tray • 84mm Receiving Tray • 98mm Receiving Tray • 109mm Receiving Tray

$135.00

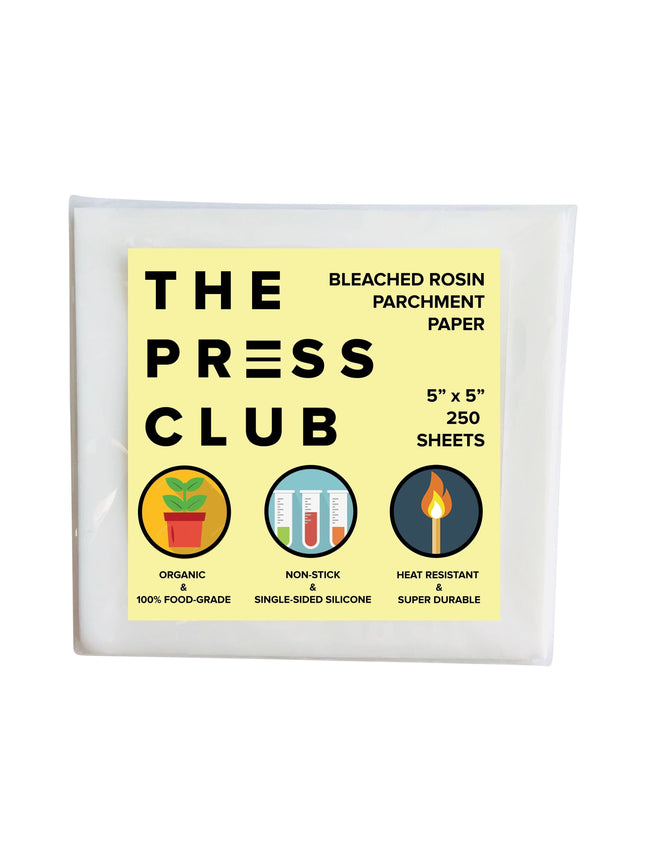

The Press Club Premium Parchment

The Press Club Premium Parchment The Press Club premium parchment is made with a special paper blend specifically formulated for pressing. Press Club parchement paper has been lab-tested and proven to not only improve extraction quality but also increase yields. You cannot find this type of parchment paper anywhere else. 5" x 5"(250 Sheets), 10" x 10"(100 Sheets),6" x 12"(100 Sheets), 8"x 16"(100 Sheets), 23' x 15" Roll 250 Sheets 1-Side Coated Silicone 2x Thicker Than Store Bought Parchment To Prevent Tears 100% Food-Grade & FDA Approved Terpene & Heat Resistant (Up To 475°F) Highest Release Coating For Easy Collecting Satisfaction Guarantee & 365-Day Return Policy Made in USA

$24.95 - $29.95

BVV™ Vacuum Oven Vent Release Stopper

Replacement Cap for eco and neo oven vacuum release knobs. Note the vent release may require the fitting to be greased to hold vacuum.

$8.00

Best Value Vacs 1 Gallon Flat Stainless Steel Vacuum Chamber W/GLASS LID

1 Gallon Shatter Vac Flat Stainless Steel Vacuum Chamber W/ GLASS LID (Comes with 2 Year Limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 3" Tall x 10.25" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. DOES NOT APPLY TO GLASS LID VERSION ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$135.00

12" x (3) 2" x (2) 1/4 FNPT Endcap with Diptube

12" x (3) 2" x (2) 1/4 FNPT Endcap with diptube This End Cap come with a 11-5/16" long diptube, Two 1/4"-18 FNPT Threaded connection and Three 2" Tri-Clamp/ Tri Clover ferrule welded to the end cap with a sanitary weld with a 0.5" Tube Extension on center ferrule Below the Lid. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid and the 2" Tri-Clamp Connection. These 5 connections are welded on a 12" Tri-Clamp End Cap. Specification Material: 304 Stainless Steel Connection Type: 2" Tri-Clamp - 0.5" Tube Extension on center ferrule Below Lid 11-5/16" Diptube 12" Tri-Clamp 1/4" - 18 FNPT Standard: 3A

$260.00

Welch DryFast Collegiate Diaphragm Pump 2014

DryFast Collegiate Diaphragm Pump 2014 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details Chemical Resistant Oil-Free Tuneable Vacuum Welch DryFastTM PTFE Diaphragm Vacuum Pumps enable precise vacuum control for organic evaporations with exclusive Advanced Vapor Management (AVM). Oil-Free, portable, chemical resistant, 1 head diaphragm design simplifies maintenance. Choose from seven dry PTFE vacuum pump models with flows up to 70 L / min and adjustable vacuum down to 2 Torr. Economical DryFastTM vacuum pumps are perfect for tough lab applications. Model Number 2014 Applications Vacuum Filtration, SPE, Rotary Evaporations (volatile solvents <80oC B.P., volume <2 liters), pumping harsh vapors & gases, general laboratory vacuum Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 1.2(35) Free Air Displacement m3/hr (l/min.) @50Hz 1.75(29) Ultimate Pressure 40(53) Maximum Vacuum 28.3 Motor Horsepower (watts) 1/5(150) Adjustable Vac. / Gas Ballast Yes Tubing Needed 1/4(7) Intake Thread NPT M14(1/8) Overall Dimensions LxWxH in. (cm) 12x7.0x8.3 (30.5x 17.8x21.1) Ship Weight 19(8.6) Shipping Carton Dimensions LxWxH in. (cm) 21x14x15 (52x35x37) Adjustable Vacuum Knob

$1,990.00

Straight Inlet Adapter with Hose Barb

Straight Inlet Adapter with Hose Barb This straight inlet adapter allows the user to connect a male and female 24/40 jointed connection and attached a flexible hose for vacuum if needed. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$30.00

Duolok Female Elbow

SSP - Female Elbow SSP Instrumentation TruFit® is manufactured from fully-traceable raw material to close tolerances and superior surface finishes. TruFit® provides optimal performance when installed in accordance with SSP’s recommendations and the design parameters appropriate for each type of connection – tapered thread, straight thread, and weld & braze. TruFit® components are cleaned in accordance with SSP documented work instructions using equipment calibrated to NIST standards with environmentally-safe and stable agents, ultrasonics, and heat/ temperature to remove all residual oil, grease, and loose particles. Stainless steel components are passivated to the requirements of MIL QQ-P-35 and ASTM A 967. ***Note: ALL NPT Threads REQUIRE the user to properly install the fitting by using a thread sealant to prevent leaks. BVV recommends GAS PTFE Tape Specifications Connection Type 1 Female NPT Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Working Pressure (PSIG) 1/4" - 7750 ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA! Dimensions A 1.17 in Bx 0.89 in By 0.89 in C 0.70 in D 0.60 in E 0.19 in G 9/16 in H 11/16 in P 1/4 in T 1/4 in

$8.00 - $25.00

Terpenes Goji

BVV™ Terpenes Goji All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical data sheet. BVV Goji Safety Data Sheet BVV Apple Jack Technical Data Sheet Goji: Goji OG has a unique fruity aroma. It will not only have soothing effects, but will give an uplifted, energetic focus. This sweet, red berry, licorice scented strain is a cross of Snow Lotus and Nepali OG, creating a sativa-dominant hybrid. FRAGRANCE: Spicy, herbal, sweet, licorice EFFECT: Uplifting, happy, hungry, euphoric Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$10.00 - $150.00

Pro Series 14.1CFM Corrosion Resistant Two Stage Vacuum Pump

Brand 14.1CFM Two Stage Pro Series This is the BVV™ Brand 14.1CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 14.1CFM will pull a vacuum down to 0.5 micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Compare to Cacejen or Xeno brand rotary vane vacuum pumps. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 115v 60Hz Pumping Rate: 14.1CFM Ultimate vacuum without gas ballast: 0.5 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2L/2.1 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Weight: 38KG / 84lbs Recommended oil: Ultragrade 19 CE Compliance: Yes Warranty 2 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$1,800.00$1,400.00

Solvent Pro Series 18/35 Gasket

Solvent Pro Series 18/35 Gasket This is a replacement Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This gasket fits an 18mm(0.71") Inner Diameter and 35mm(1.38") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$13.00

Terpenes Orange Cookies

BVV™ Orange Cookies All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical datasheet. Orange Cookies is a sativa dominant hybrid known for it's ability to boost mood while remaining relaxed. FRAGRANCE: Sweet, fruity, and citrusy, with a slight hint of skunk. EFFECT: May help with stress, depression, and anxiety. Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$10.00 - $150.00

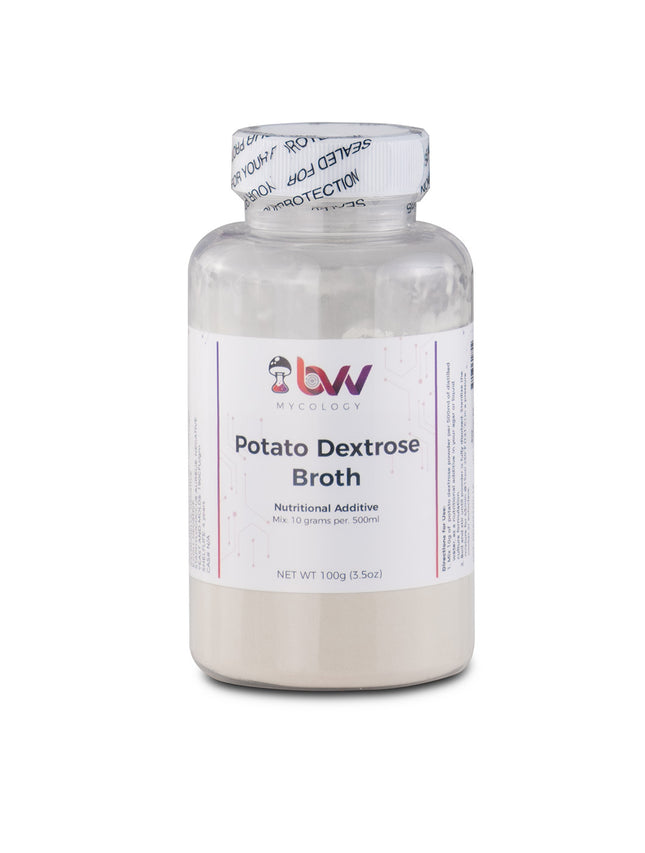

Potato Dextrose Broth for Mushrooms Mycology

Potato Dextrose Broth For Mushroom Mycology Bacteriological GradeBest for Vigorous Mycelia Growth Potato Dextrose Broth (PDB) is a liquid microbiological growth medium made from potato infusion and dextrose, used to cultivate and isolate yeasts and molds from food products and other samples. Its low pH inhibits bacterial growth, while the rich potato and dextrose components provide nutrients for fungal sporulation and pigment production. STORAGE: Cool dry conditions, sealed original package Mix: Mix: 1 gram per. 500ml Directions for Use: 1. Mix 10g of Potato Dextrose Broth per 500ml of liquid culture or agar recipe for vigorous mycelia growth. 2. Boil and stir until powder is fully dissolved. Sterilize the mixture for 45min @15psi 250°F (121°C) in a pressure cooker or autoclave.

$12.00 - $53.00

Duratherm XLT-2 Thermal Fluid

DURATHERM XLT-2 Engineered for long-term operation in heat transfer applications requiring precise temperature control ranging from -84°C (-120°F) up to 177°C (350°F). Ideal for near-cryogenic applications Duratherm XLT-2’s economical cost and wide operating temperature also makes it well-suited for heating and cooling applications found in the food processing, pharmaceutical, chemical and botanical extraction industries. Maximum temperature: 177ºC/350°F Minimum temperature: -84ºC/-120°F Flash point 63ºC/145°F Extreme low-temperature capabilities Stable and non-corrosive Properties remain consistent over temperature range Includes free fluid analysis and tech support Standard Metric TEMPERATURE RATINGS Max Bulk/Use Temp 177°C Max Film Temp. 204°C Pour Point ASTM D97 -90°C SAFETY DATA Flash Point ASTM D92 63°C Fire Point ASTM D92 70°C Autoignition ASTM E-659-78 275°C THERMAL PROPERTIES Thermal Expansion Coefficient Thermal Conductivity W/m·K -40°C 0.119 -18°C 0.116 38°C 0.107 Heat Capacity kJ/kg·K -40°C 1.863 -18°C 1.947 38°C 2.169 PHYSICAL PROPERTIES Viscosity ASTM D445 cSt -40°C 8.68 -18°C 3.78 Density ASTM D1298 kg/l -40°C 0.81 -18°C 0.80 38°C 0.76 Vapor Pressure ASTM D2879 kPa -40°C 0.00 -18°C 0.00 38°C 0.22 Distillation Range ASTM D2887 10% -18°C 90% -18°C Note: The values quoted in the table above are typical of normal production.They do not constitute a specification.

$75.00 - $1,950.00

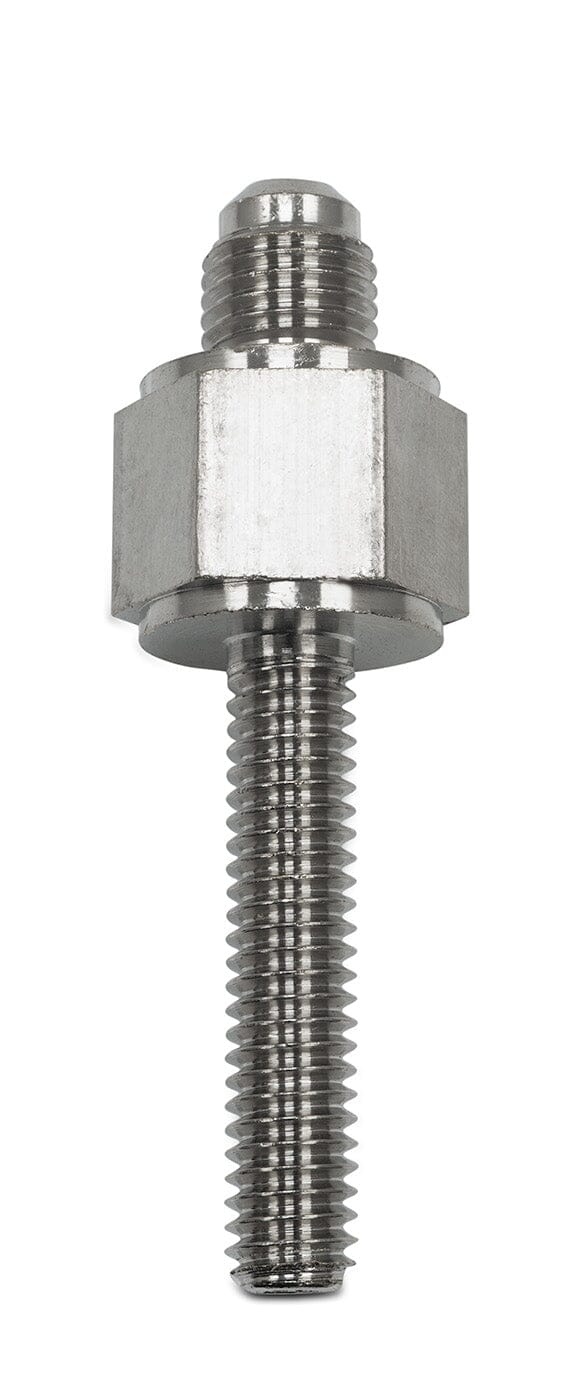

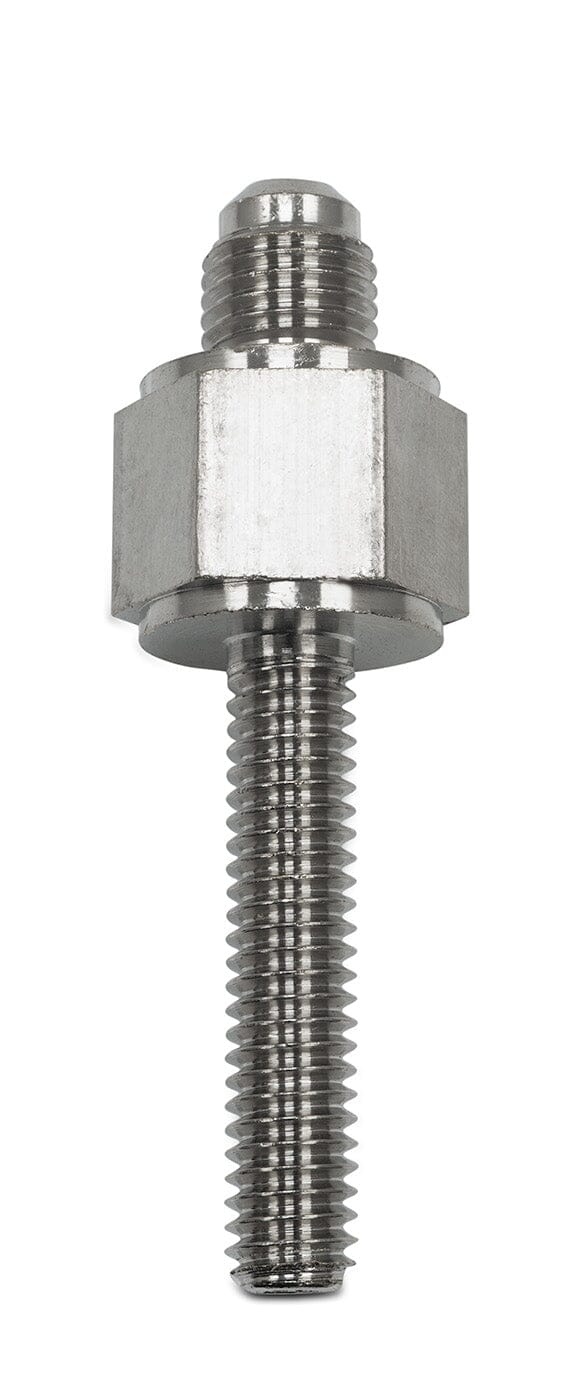

Bulk Head Long with Flare

Long Bulk Head with Flare This Long Bulk Head with Flare comes equipped with an extended 1/5" long thread with 1/4" MJIC flare perfect for applications with larger wall thicknesses. The optimal hole diameter for installing this bulkhead would be 5/16"

$8.00

ChemTek Large Fuge Bags - 50 Pack

ChemTek Large Fuge Bags - 50 Pack Centrifuge bags used for separations. Specifications: Size: 50-Pack Dimensions: H: 7” W: 6.5” Micron Size: 25 Micron Material: Food Grade Nylon

$50.00

Foam Insulation for Hose and Tubing - 6 Feet

Foam Insulation for Hose and Tubing - 6 Feet This foam insulation is good for silicone tubing, stainless steel braided hosing, compression hard line tubing, and more! The inner diameter of the foam can be 3/8", 1/2", or 5/8" and must be selected in the drop down menu. This should correspond with the outer diameter of the hose that you want to insulate. The 3/8" option will slide on your hose or tube while the 1/2" and 5/8" options have a taped seam. All options come in 6' lengths. Sizing Chart: Foam Insulation Size: 3/8" 1/2" 5/8" For Compression Tube Size 3/8" 1/2" - For Stainless Steel Braided Hose Size 3/8" * 1/2" - For Silicone Tube Size 1/4" 3/8" 1/2" Composition Nitrile, PVC Flame/Smoke Rating 25/50 Height 1.375 Insulation Nominal I.D. 3/8" Length 72 R-Value R4.1 Temperature Range -297°F to 220°F (-182.78°C to 104.44°C) Country of Origin USA * The 3/8" foam does not have a seam and cannot be easily slid over stainless steel braided hose with permanent end fixtures.

$34.00 - $35.00

Magnetic PTFE Stirring Bar - L Style - 70mm

Magnetic PTFE Stir Bar - L Style - 70mm Reduce stir bar jumping with the contoured shape of this L Style Magnetic PTFE Stir Bar. Ideal for round-bottom flask stirring applications. This 70mm L Style Magnetic Stir bar is great for round-bottom flasks above 5 liters in capacity. With its PTFE coating this Magnetic Stir Bar carries excellent solvent and temperature compatibility for a variety of applications. Specifications: L Style 70mm Length Material: High-temperature PTFE

$15.00

BVV -80C Chiller - 220v/60hz

BVV -80C Chiller - 220v/60hz This recirculating chiller is great for low temperature applications. With the a powerful pump it is able to circulate fluid while at -80°C. The chiller includes valves for the inlet and outlet port with 3/4" FNPT connections. The chiller also includes two barbs to adapt to 5/8" tubing, along with 2M of insulated silicone tubing. Technical Data 3 Phase Single Phase Reservoir: 10L 10L Flow: 35L/min 35L/min Lift: 12m 12m Refrigerant: R404/R23 R404/R23 Low Temperature: -80℃ -80℃ Cooling capacity: 8048~1260W 7665~1200W @30°C 8048W 7665W @0°C 6021W 5735W @-40°C 4326W 4120W @-80°C 1260W 1200W Max. Input Current: 17 amps 24 amps Power supply: 220V/60Hz/3Φ 220V/60Hz/1Φ Circulator Low-temperature CoolantCirculation Pump Low-temperature CoolantCirculation Pump

$13,000.00 - $15,500.00

Mastercool Nitrogen Pressure Regulator Kit

Mastercool Nitrogen Pressure Regulator Kit Product Description Mastercool’s new nitrogen regulator is specifically designed to meet the specifications of HVAC/R and automotive A/C systems. This single stage nitrogen regulator is used to test systems for leaks when they do not contain refrigerant. 1/4” SAE flare outlet port, with control valve, to keep pressure on the regulator at all times T-Handle for ease of pressure adjustment 63 mm (2 1/2”) gauges with guards High pressure gauge 4400 psig (300 bar) Low pressure gauge 1000 psig (70 bar)

$190.00

20L Neocision Dual Short Path Distillation Turnkey System

20L Neocision Dual Short Path Distillation Turnkey System This unit carries a 2 day lead time. (Note: This kit does NOT include the stainless steel table.) The 20L Neocision Distillation Turnkey Setup features our Dual USA made P10V6 Distillation Heads. Every component in this distillation kit is made for precision, throughput, and repeatable results. You will also receive Dual Dewar Style Ribbed Glass Cold Traps to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The 20L Neo Kit Includes: 20L Neocision Kit with glassware, labware, and Dual P10V6 Distillation Heads. BVV 15 Liter Advanced Digital Heated Circulator Choice of Vacuum Pump KF-25 Bellow Y Manifold Dual Ribbed Dewar Style Glass Cold Trap Non-Mercury Glass Thermometers 20L Digital Heating and Stirring Mantle Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in the boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$13,000.00 - $17,000.00

True Terpenes Forbidden Fruit

True Terpenes Forbidden Fruit Fragrance: Cherry Blossom Grape Fruit Cedar Floral Musky Effects: Relaxing Soothing Uplifting Forbidden Fruit delivers on its name. Created by crossing two flavor forward cultivars Cherry Pie and Tangie, this profile is temptingly good. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution. Forbidden Fruit-Specific Certificates: Product Specification Certificate of Analysis Safety Data Sheet Food Safety Company-Specific Certificates: ISO 9001:2015 GMP Certification FSSC 22000

$121.50 - $2,250.00

Glas-Col Stirmantle

2L Glas-Col Stirmantle Glas-Col offers two types of StirMantles: Electromagnetic (50 to 750 rpm) and Motor Driven (100 to 1850 rpm). The maximum rpms available for each type depends on the viscosity of the solution being heated. Electromagnetic StirMantles are typically used with aqueous solutions like water, while the Motor Driven units use a powerful magnet for higher viscous solution like oils. StirMantles withstands 400°C internal operating temperature. EMS series include the heating mantle, speed control and stir-bar. WARNING: chemical spillage, overheating, overloading, and general misuse will greatly reduce service life! Note: The temperature probe this mantle comes with can only be used with a thermowell. If you are using it with BVV™ glassware you will need to add SKU: TK1/4-12 or TK1/4-18 depending on what mantle size is selected.

$1,050.00$600.00

5L Short Path Distillation Kit with P5 Distillation Head

5L Short Path Distillation Kit with P5 Distillation Head This unit carries a 2 day lead time. The 5L Distillation Kit includes everything needed to perform distillation excluding the vacuum pump and chiller. This kit features our USA made P5 Distillation Head, as well as USA, made glass. This Kit is designed for high volume production with the highest quality components for precise, repeatable results time and again. This Kit Does NOT include a vacuum pump or chiller. Please see the below recommendations for both as well as recommended add-ons. Recommended Vacuum Pumps: Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (economy option) Recommended Chillers: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter Refrigerated Circulator (premium option with chilling capability) Recommended Add-Ons: Bullseye Precision Vacuum Gauge (premium vacuum gauge for measuing depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) J-KEM Digital Vapor Temp Monitor (digital vapor temp monitor with data-logging capabilites) Specifications: Boiling Flask Size: 5L Receiving Flask Size: 2x 500mL, 1000mL Batch Capacity approximate: 1000-2500 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Includes: Glass components: 5L Boiling Flask P5V6 Distillation Head Triple Neck Cow 2x 500mL Receiving Flask 1L Receiving Flask 120mm Glass Funnel Dewar cold trap Accessories: PTFE Magnetic Stir Bar Retriever 5 Pack of Metal Keck Clips Dow Corning High Vacuum Silicone Grease Tripod Stand 5L Digital Heating and Stirring Mantle 3-Finger Adjustable Clamp 0-77mm 6" x 6" Scissor Jack 500-1000mL Cork Stand 2x 24/40 ChemglassPTFE Thermometer Inlet Adapter 10ft of Gum Rubber Vacuum Hose 10ft of Silicone Chiller Hose 1/4" Vacuum Manifold Traceable Kangaroo Thermometer - Digital 10 Pack of Adjustable Stainless Steel Tubing Clamps Fiberglass Insulation Rope 10 Feet Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$2,200.00

Welch 6.1 cfm Full Chemical-Resistant 8-Head Diaphragm Pump

Welch 6.1 cfm Full Chemical-Resistant 8-Head Diaphragm Pump The Welch 6.1CFM Full Chemical-Resistant 8-Head Diaphragm Pump is the ideal choice for 50L Rotary Evaporators and large oven systems. This high capacity, full chemical resistant pump gives users the ability to vac down large capacity spaces quickly, efficiently, and cleanly without worrying about contamination of pump oil. The inner diaphragm is lined with PTFE making it highly chemical resistant and long lasting. It is one of the quietest and cleanest running vacuum pumps on the market. Key Features: Fully Chemical-Resistant Oil-less diaphragm style vacuum pump High capacity vacuum capability Specifications: Electrical Requirements: 110v 60Hz single phase Pumping Rate: 6.1cfm / 174L/min Gasket Material: All-PTFE Ultimate Vacuum level: 6 torr / 8 mbar Maximum Vacuum: 29.9 inHg Inlet / Outlet: KF16 Flange Adjustable vac. / gas ballast: No Unit dimensions (LxWxH in): 21x10x12 in Shipping dimensions (LxWxH in): 28x15x20 in Shipping weight (lbs): 90 Technical Data Free Air Displacement @ 60 Hz, cfm (L/min) 6.1 (173) Ultimate Pressure, torr 6 Motor Power, HP (kW) at 60 Hz Motor Power, HP (kW) at 60 Hz Inlet (Exhaust) Connection Thread NPT NW16 - 1/4" NPT Tubing Needed, I.D. in. (mm) Hose Connector Available Weight, lbs (kg) 72.3 (32.8) Dimensions, LxWxH, in (mm) 21x11x12 (530x280x310) 115V Order Number 2064B-01 ***Note: Purchase of this pump is subject to End User Verification. A certification form must be filled out before completion of purchase.***

$7,300.00

24/29 Valve

24/29 Valve For 10L-50L Best Value Rotary Evaporators. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$35.00

Male Elbow Tube Fitting

SSP - Duolok Male Elbow SSP Instrumentation Duolok® tube fittings are designed, manufactured and quality controlled to be totally “interchangeable” with the Swagelok® brand of tube fittings. Component by component examination plainly shows the two brands as completely “componentintermixable.” The precision manufacturing of both products to stringent tolerances under rigid quality control procedures ensures the safety, performance, and reliability of service whenever Duolok® and Swagelok® component parts are mixed and used in accordance with published installation and service recommendations. Specifications Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Connection Type 2 Male NPT Connection Size 2 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Duolok Pressure Rating = Tubing Rating NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA! Dimensions A 1.06 in Bx 0.77 in By 0.92 in C 0.70 in D 0.60 in E 0.19 in F 0.56 in G 9/16 in H 1/2 in P 1/4 in T 1/4 in

$8.00 - $30.00

1L Standard Distillation Turnkey Setup

1L Standard Distillation Turnkey Setup The Standard Distillation Turnkey Setup includes all the components necessary to successfully perform distillation at an entry level price point. The Standard Turnkey Setup Includes: 1L Distillation Kit 1/4" Flare x 1/4" Barb Adapter BVV™ 5L Heated Circulator BVV™ V9D 9CFM Two Stage Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$2,100.00 - $2,350.00

Edwards E2M28 21 CFM Dual-Stage High Capacity Vacuum Pump

Edwards E2M28 21 CFM Dual-Stage High Capacity Vacuum Pump ***Note: This item Will Ship by Freight only*** The EM range of oil‑sealed rotary pumps – renowned for their high ultimate vacuum, rapid pumping speed, quiet operation and ability to handle vapor – have become the industry standard for laboratory and light industrial applications. The pump is a freestanding unit with the drive provided through a flexible coupling by either a single‑phase or three‑phase (four pole) air cooled motor.Each EM pump is supplied with 2 x 1 liter of Ultragrade 19 oil, O ring and centering ring, two Allen keys and spares seal for oil drain and filter plugs. For PFPE prepared FX pumps Fomblin® to be ordered separately. Technology The motor is totally enclosed and is cooled by the motor-cooling fan which directs air along the motor fins. The motors are fitted with a thermal overload device. When the motor is too hot, the thermal overload device switches off the pump. The thermal overload device has an automatic reset; when the motor cools down, the device resets and the motor will restart.An oil pressure system lubricates the pump shaft bearing surfaces and rotor sealing faces. The pump has an oil distribution valve which prevents discharge of oil to the pump interior after the pump stops. The pumping chambers are air-tight, so this arrangement also prevents suckback unless the gas ballast valve is open.You can inspect the level and condition of oil in the oil box reservoir through the oil sight-glass. An oil filler-plug is fitted to the top of the oil box. The pump has two oil drain-plugs to allow either gravity oil drain or pressure oil drain. Features and Benefits The pump is designed for reliable, long‑term operation. Thermal overload device prevents overheating (single phase only). The drive is provided through a flexible coupling by a single‑phase or three‑phase (four pole) motor. The motors are totally enclosed and are cooled by the motor cooling fan. Full height O ring sealed oil sight glass for easy checking of oil level and condition. Large sight glass and operating oil range. IE3 energy efficient 3 phase motor used with E2M28. Edwards E2M28 21 CFM Dual-Stage High Capacity Vacuum Pump. The EM range of oil-sealed rotary pumps - renowned for its high ultimate vacuum, rapid pumping speed, quiet operation and ability to handle vapour - has become the industry standard laboratory and light industrial applications. The E2M28 pump is a two-stage, direct drive, sliding vane pump. The pump is oil sealed and designed for reliable, long-term operation in both laboratory and industrial environments. The pump is a freestanding unit with the drive provided through a flexible coupling by either a single-phase or three-phase (four-pole) motor. Specifications Displacement 50Hz 32.2 m3h-1 / 19 ft3min-1 60Hz 38.9 m3h-1 / 22.3 ft3min-1 Speed (Pneurop 6602) 50Hz 27.5 m3h-1 / 16.2 ft3min-1 60Hz 33.0 m3h-1 / 19.5 ft3min-1 Ultimate vacuum (total pressure) without gas ballast 1 x 10-3 mbar / 7.5 x 10-4 Torr with gas ballast 1.5 x 10-2 mbar / 1.1 x 10-2 Torr with Fomblin® 1 x 10-2 mbar / 7.5 x 10-3 Torr Inlet connection NW25 flange Outlet connection** Nozzle 15 mm external Ø removable from 3/4 in BSP tapped hole Max allowed pressure at outlet 0.5 bar gauge / 7 psig Max water vapour pumping rate – GB II 220 gh-1 Max inlet pressure for water vapour 30 mbar / 23 Torr Max water vapour pumping rate 0.7 kg h-1 Operating temperature range 13 – 40 °C Nominal rotation speed 1440 / 1720 rpm Motor power 50 Hz 0.75 kW Motor power 60 Hz 0.90 kW Power Connector 1-ph* IEC EN60320 C19 Weight 44 kg / 97 lbs Noise 57 dB(A) @ 50 Hz Oil capacity - max 1.5 litre Oil capacity - min 1.2 litre Recommended oil (supplied) Ultragrade 19 * Pumps listed with IEC connector only ** The FX are supplied with NW25 outlet connection ** POWER CORD NOT INCLUDED. RECOMMEND FOR CUSTOMER TO WIRE PUMP TO OUTLET WITH EXACT LENGTH. DO NOT USE EXTENSIONS** **RECOMMEND FOR CUSTOMER TO HAVE ELECTRICIAN WIRE PUMP TO OUTLET WITH EXACT LENGTH** Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$7,000.00$6,200.00

You have seen 912 out of 1674 products