BVV (Ok to Discount)

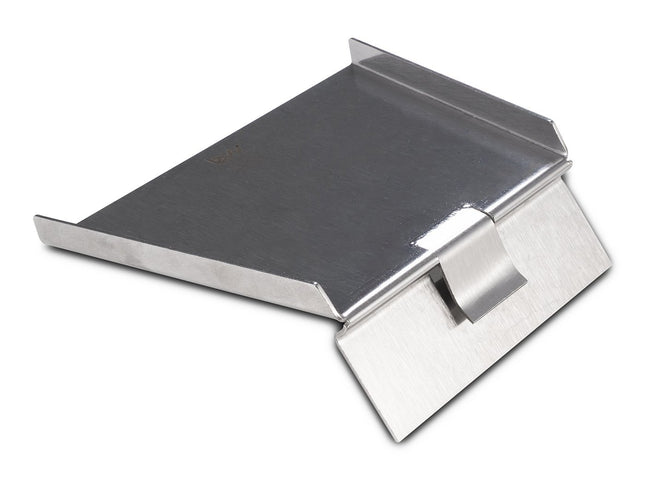

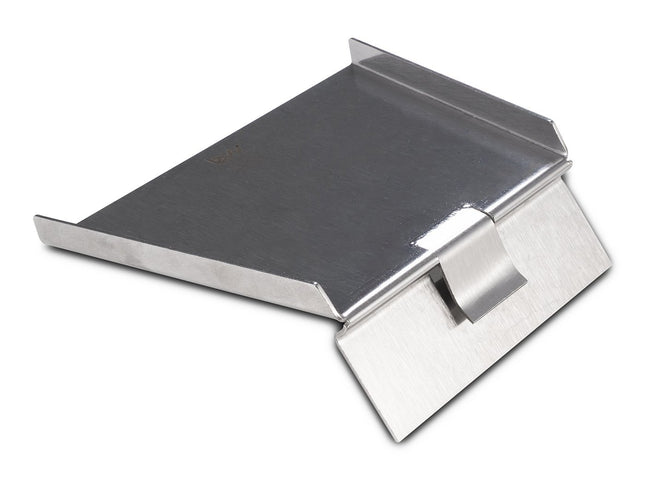

Diamond Sauce Separator for 1.9 ft³ Ovens and Larger

BVV Diamond Sauce Separator The BVV diamond sauce separator is a good compliment to any diamond miner. With this vessel you can easily strain and separate your diamonds from the sauce using the internal basket. You can clean your diamonds like never before with less work. DSS-9 12.25" Exact Height (Fits 1.9 ft³ Vacuum Ovens) 6" Deep Basket (100 micron mesh Dutch Weave) 3"x9" Main Body Spool DSS-12 15.25" Exact Height (Fits larger than 1.9 ft³ Vacuum Ovens) 9" Deep Basket (100 micron mesh Dutch Weave) 3"x12" Main Body Spool Replacement Top Gasket around the basket can be found Here.

$160.00 - $180.00

3.2CF BVV™ Neocision ETL Lab Certified Vacuum Oven

3.2CF BVV™ Neocision Certified Lab Vacuum Oven, 4 Individually Heated Shelves, LED's - 3 Year Warranty Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! Introduction Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. Performance Capabilities At Best Value Vacs, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Uniformity: within 4% of the temperature setpoint. Heat-Up Time: 20 minutes. Ultimate Vacuum: <500 µmHg / mTorr / micron Time to Vacuum: 5 minutes to 29"Hg using our VE Series 12cfm Dual Stage Vacuum Pump. Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours Temperature Range: Room Temp+18°F to 212°F Specifications Electrical Voltage 120V Frequency 60Hz Power 1050W Current 16A Plug IEC C13 (unit ships with detachable NEMA 5-15p cable) Internal Chamber Heating Individual Direct-Heat shelves Chamber Material Stainless Steel Dimensions (LxWxH) 17.7" x 17.7" x 17.7" (450mm x 450mm x 450mm) Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 4 Heated Shelves Shelf Dimensions (LxW) 17" x 17.25" Shelf Capacity 293 in2 Total Shelf Capacity 1173 in2 / 8.2 ft2 Door Seal Silicone on Tempered Glass Window Dimensions (LxH) 15.5" x 16.25" Lights 4 strips of LEDs provide clear, bright view of interior Handle Aluminum Exterior Dimensions (LxWxH) 30" x 27" x 27" Weight 260 lbs Support Locking Casters Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connections Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose User Manual Included Vacuum Pump Sold Separately. Recommended Pump VE Series 9cfm Dual Stage Vacuum Pump Warranty 3 Years Capacity and Throughput Planning Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$4,200.00

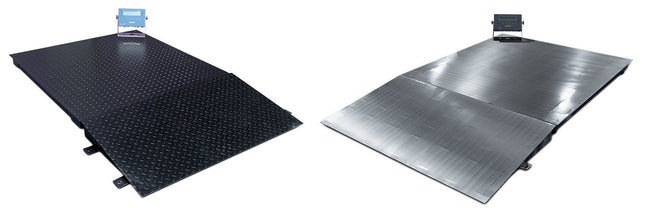

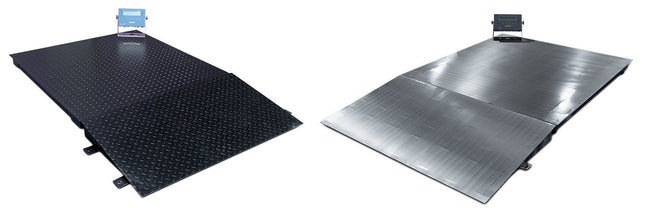

Explosion Proof Platform Scales - 3000KG

These Explosion proof platform scales come with a ramp and can handle a maximum load of 3000KG. Scale measurement: 1200MM X 1200MM (47.24" x 47.24") Scale height: 110mm (4.33") Scale weight: 83KG (182.984LBS) Note: This scale only measures in KG

$1,850.00 - $2,250.00

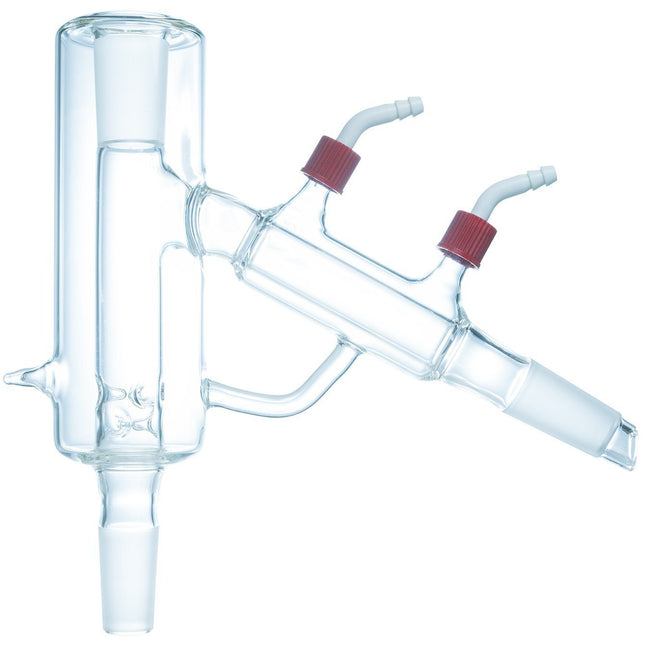

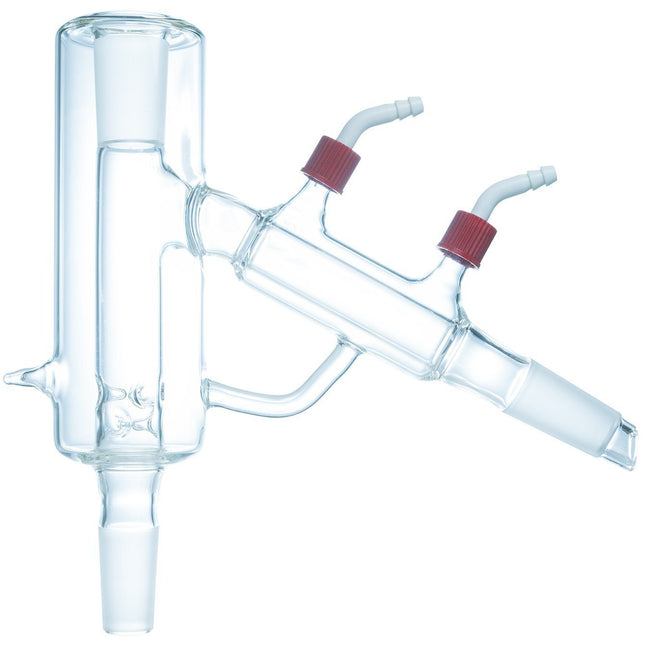

P2 Distillation Head - USA Made

P2 Distillation Head P2 Packable Distillation Head with 24/40 Joints. Includes GL-14 Barb Connections. Recommended packing media: Raschig Rings, Porcelain Berl Saddles, Glass Beads, Pro-Pak, or Stainless Steel Wool. Key Features: MADE IN THE USA Designed for 1 & 2 Liter Flasks Single set of lowered vigreaux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$775.00

1.5 Gallon Tall Stainless Steel - POT ONLY

1.5 Gallon Tall Stainless Steel - POT ONLY This is a replacement part for the following Vacuum Chambers: Best Value Vacs 1.5 Gallon Tall Stainless Steel Vacuum and Degassing Chamber SVac 1.5 Gallon Tall Stainless Steel Vacuum Chamber Dimensions: 8-5/8" Tall x 7-1/8" Diameter Material: 304 - 2B Stainless Steel

$41.00

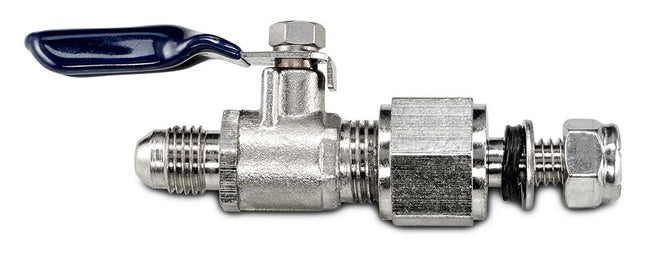

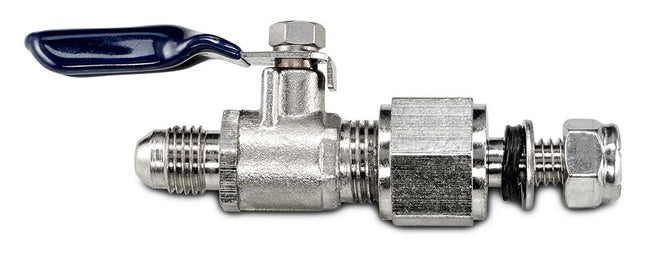

Bulk Head Short with Valve and Flare

Bulk Head Short with Valve and Flare This bulkhead with attached valve is perfect for passing through thin walls in vacuum applications such as vacuum chambers, the maximum recommended wall thickness is 0.25". The gasket design is only meant to hold vacuum, it is not intended to hold pressure. The hole diameter for installing the bulkhead is 5/16". The flare connection is 1/4" JIC.

$14.00

50L Solvent Pro Rotary Evaporator Nut and Washer Flask Set

Replacement nut and washer flask set for 50L Solvent Pro Rotary Evaporator

$120.00

2L Premium Short Path Distillation Turnkey Setup with P2 Distillation Head

2L Premium Short Path Distillation Turnkey Setup with P2 Distillation Head The 2L Premium Distillation Turnkey Setup features our 2L Distillation Kit with P2 Distillation Head and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included is our Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump giving you extreme power and depth with long lifespan, the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market, and a Polyscience 7L MX Heated Circulator for maximum condensation of vapors. You will also receive a Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The Premium Turnkey Kit Includes: 2L Distillation Kit w/ P2 Distillation Head KF-25 x 1/4" Barb Adapter Dewar Style Glass Cold Trap Bullseye precision Vacuum Gauge Polyscience 7L MX Heated Circulator Pro Series 14.1CFM Corrosion Resistant Two Stage Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once the process is complete, stop heat, stop stir, and stop vacuum. Let the atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$6,000.00 - $7,650.00

UL Listed BVV™ Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 11.3CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) This is the BVV™ Brand 11.3CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 11.3CFM will pull a vacuum down to 0.3 microns effortlessly. The pump is designed with corrosion resistance and long-term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 110v 60Hz 750 Watts Pumping Rate: 11.3CFM Ultimate vacuum without gas ballast: 0.3 micron Ultimate vacuum with gas ballast: 6 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 1.5L/1.59 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Dimensions: 21 x 7.5 x 12 Shipping Dimensions: 29.5 x 9.5 x 16.5 Unit Weight: 66lbs Shipping Weight: 75lbs Recommended oil: Ultragrade 19 Noise level: <58 dB CE Compliance: Yes Warranty: 1 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result in the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$2,600.00

3/8" FNPT Stainless Steel Block Manifold

Stainless Steel Block Manifold for Extraction System This solid block 304 stainless steel manifold has (5) 3/8" FNPT ports and (2) 3/8" ID mounting ports to mount to a rack system or any other type of extraction system. Excellent for a variety of pneumatic and hydraulic applications, our manifold is comprised of pre-drilled mounting holes for easy installation. Standard usages include air or fluid connections, part holding, clamping, and under any circumstance connection is needed. Specifications Material 304 Stainless Steel Connection Size 3/8" FNPT Mounting Ports 3/8" ID Length 9" Width 1-1/8" Height 2"

$110.00

20L Digital Heating Mantle

20L DIGITAL HEATING AND STIRRING MANTLE Digital Heating and Stirring Mantles give the operator the most precise temperatures and readouts during distillations. These mantles autotune to specific user input to provide consistent results. Each mantle is equipped with large digital display that will give you readouts for both set temperature, actual temperature, and stirring speed. Each mantle also comes with a vertical brace bar and boss head as well as a temperature probe which plugs directly into the mantle. For first time use, the mantle should have an initial burn out done. This will burn off any residual oils used in the production of the insulation rope. The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Specifications: Capacity: 20L (20000mL) Power Supply: 220V 60Hz Adjustable Rotation Speed: 50-1800 RPM Motor Power: 40W, DC14-24V Heating Power 180-2200W Temperature Control Accuracy: +/- 1C Intelligent Temperature Control: Yes Temperature Range: RT+10-380C Insulation Material: Alkali-free Glass Fiber, temperature resistant up to 450C Shipping Dimensions: 25 x 25 x 18 in. Weight: 35 lbs

$1,400.00

3 Gallon Tall Stainless Steel - POT ONLY

3 Gallon Tall Stainless Steel - POT ONLY This is a replacement part for the following Vacuum Chambers: Best Value Vacs 3 Gallon Stainless Steel Vacuum and Degassing Chamber SVac 3 Gallon Stainless Vacuum Chamber Dimensions: 10-7/8" Tall x 9" Diameter Material: 304 Stainless Steel

$74.00

2L Evaporating Flask

2L evaporating flask for 2L Best Value Electric Lift Rotary Evaporator. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: Best Value Vacs is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$70.00

2 Pack Metal Keck Clips - 45/50

2 Pack Metal Keck Clips - 34/40 Stainless steel clamps to fit 45/50 standard taper joints. Metal clamps are suitable for high temperatures applications

$10.00

BVV™ Inline Strainer 304 Stainless Steel

BVV™ Inline Strainer 304 Stainless Steel BVV™ Inline Tri-Clamp strainers are used when filtering solids from liquids in fluid processing systems. The inside of the strainer is perforated with 2mm holes to collect larger solids when filtering and comes with (1) 3" Single pin clamp and (1) 3" silicone Tri-Clamp gasket. It is recommended that a strainer be placed after a pump, as the suction could damage the strainer core. Specifications Material 304 Stainless Steel Connection Type 1.5" Tri-Clamp Secondary Mesh Perforated Stainless Steel with 2mm Holes

$150.00

Steam Distillation Kit

Steam Distillation Steam distillation is the separation of organic compounds at low temperatures by boiling water. It is widely used for essential oils and terpenes because it does not degrade the organic material as a traditional fractional distillation does. Alternatively, steam distillation can extract a diverse array of immiscible substances. You can use steam distillation for “steam stripping” in petroleum refineries and separate commercially important organic compounds, including fatty acids. Our system is composed of a 6-piece glass distillation set up paired with a separatory funnel. Simply fill the boiling flask with water and the material flask with your organic material, then use the heating mantle to boil the water and pass the steam through the material flask. There is a port above the material flask on the U-Tube to insert a thermometer to more closely monitor the process. The steam passing around the material will lower the boiling point on the surface of the plant material and cause the terpenes to boil off at low temperatures. After moving through the U-Tube the steam and terpenes will condense in the graham condenser and drain into the flask below. After filling the flask, simply swap it and drain the contents into the separatory funnel to remove all water. Steam Distillation is beneficial due to the lower boiling point being able to reduce the decomposition of temperature-sensitive compounds. Here’s a look at the key benefits of steam distillation. Key Benefits of Steam Distillation: Streamlined method produces organic solvent-free products Possesses large capacity for processing at the industrial scale Requires no subsequent separation steps Requires less fuel for the steam boiler for extraction of oils Due to its wide application and inexpensive equipment, steam distillation can be a cost-effective investment Kit Includes: 2L Analog Mantle 2L Boiling Flask 2L Material Flask U-Tube 24/40 Thermometer Adapter 24/40 Male Stopper Graham Condenser 500ml Flask 500ml Separatory Funnel BVV™ Lab Stand Three Finger Clamp Boss Head Please Note: for any replacement parts, please contact us. 2L Dual Neck Flask (SKU: STEAM-01-2000ml) 2L Material Flask (SKU: STEAM-02) U-Tube (SKU: STEAM-03) Graham Condenser (SKU: STEAM-04)

$495.00

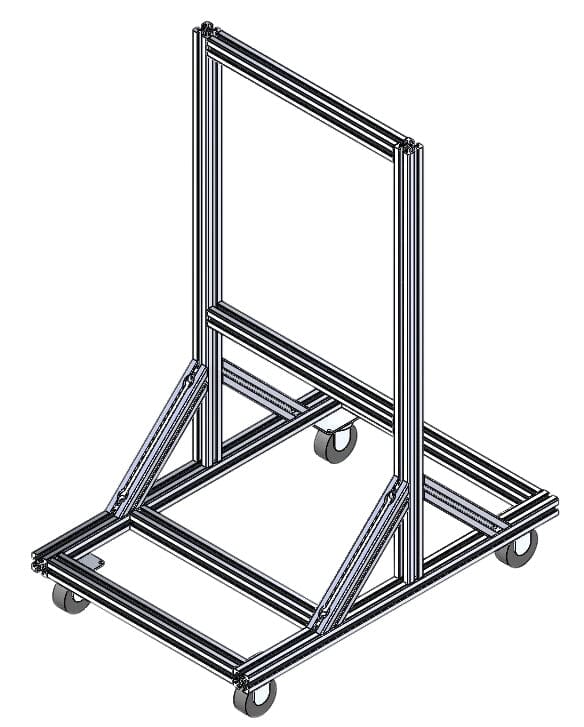

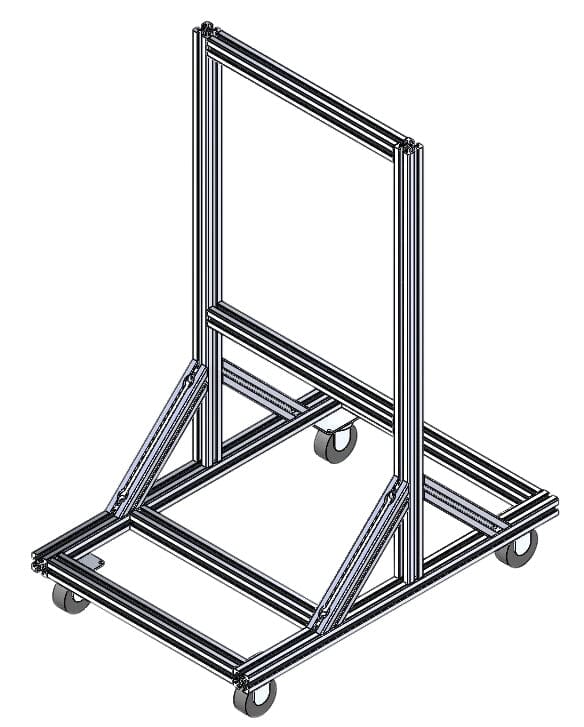

BVV™ Extraction RACK # 6

BVV™ Extraction RACK # 6 (Assembled units come with a 30-day warranty) Note: The unit does not come assembled - select "pre-assembled" from the drop-down menu to have the unit assembled by BVV before shipping Pipe hangers are not included There is no warranty on unassembled units Shipping Notice: If the customer orders the rack as assembled, then the item will only ship via freight and there will be additional shipping charges. Extraction Rack 6 Technical Drawing This rack fits the following BVV™ Extraction Systems: 8.5LB Athena 1LB Icarus 5LB Icarus XL Refinement Filter Stackable Diamond Miner Specifications (Does not include height with casters) Main Base Dimensions 21" X 36" Vertical Dimensions 21" X 30"

$785.00 - $935.00

4.8CF BVV™ CSA Certified Lab Grade Forced Air Convection Drying Oven – 12 Shelves Standard

4.8CF BVV™ CSA Certified Lab Grade Forced Air Convection Drying Oven – 12 Shelves Standard DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! The 4.8CF CSA Certified Laboratory Grade Drying Oven is our newest addition to the Best Value Vacs line of Laboratory-grade processing equipment. Offering a leading ±1⁰F temperature stability, over 98% heat uniformity, and no overshoot, technicians can now process material with ease and confidence. We regulate heat using a modern, high-precision PID controller with a large, bright display and touchscreen buttons. The interior is a high-polish stainless steel, presenting a clean and easy to maintain surface. Our drying oven comes fully-stocked as a standard- offering ten spacious, wire frame shelves you can easily insert, remove, and clean. With a clear, no-overshoot advantage, there’s simply no better choice for your precision processing needs. Key Oven Features: Long-lifetime convection fan gently circulates air for optimal heat distribution Stainless steel interior for a sanitary, easy-to-clean look 12 spacious, wire racks are easy to insert and remove Level-adjusting caster wheels for mobility and stability Overload circuit breaker for electrical protection Large, tough, stainless steel door handle feels solid and works great Temperature overshoot protection enabled Digital timer allows users precise control of heating cycle Simple and powerful user interface presented in a large, bright, clear display Specifications Electrical 120 VAC / 60Hz / 2050W / USA Plug Internal Chamber Material: Polished Stainless Steel Dimensions (LxWxH): 21.65" x 17.72" x 21.65" Temperature Control LED PID Controller Temperature Range: RT+18F - 572F Temperature Stability: +/- 1F Temp Resolution: +/-0.1F Heat Uniformity: 98% Shelves Up to 12 Removeable Shelves Door Dual Layer Observation Window made from Tempered Glass Replaceable Gasket Material: Silicone Weight & Dimensions Outside Dimensions (LxWxH): 33.07" x 22.83" x 28.74" Weight: 149.91lbs Compliance CSA Certified *ISO 9001:2005 Note: This item is a freight ship item and will ship Via UPS Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise UPS freight Cannot Contact you for a delivery setup window.

$2,550.00

Triclamp / Tri Clover Y

Specifications: 304 Grade Stainless Steel w/ High Polish interior Fits 1" or 1.5" Triclamp Unique Y Connection Disclaimer: All Stainless Steel Parts bought seperately to piece together a Closed Loop, Closed Column, or Open Blast Extractor DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested.User assumes all responsibility and risks of the system"

$23.00 - $32.00

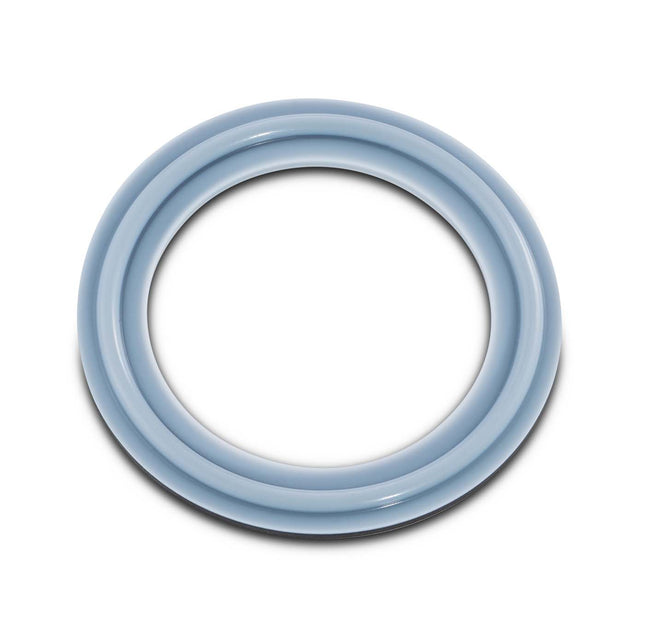

Tef-Flex PTFE / EPDM Unitized Sanitary Tri-Clamp Gasket

Tef-Flex Sanitary Tri-Clamp Gasket Tef-Flex: A Tef-Flex sanitary gasket’s contact surface is a layer of PTFE grafted to an EPDM rubber inner core. This totally bonded construction provides an exceptionally pure and incredibly flexible seal. By grafting the elastomer with a layer of PTFE, Tef-Flex will behave like an elastomer but will prevent product contamination, service interruptions and clean-up costs associated with traditional elastomer seals. The PTFE grafted elastomer in a Tef-Flex sanitary gasket will maintain I.D. without re-torquing or leaking. Key Features: Excellent resistance to almost all chemicals Excellent Temperature Range Excellent Cleanability due to PTFE (Teflon) Excellent Flexibility Sizes Available: 0.5" 0.75" 1" 1.5" 2" 2.5" 3" 4" 6" 8" 10" 12" Chemical Compatibility: Butane A - Excellent Propane (liquified) A - Excellent Alcohols: Amyl A - Excellent Benzyl A - Excellent Butyl A - Excellent Diacetone A - Excellent Ethyl A - Excellent Hexyl A - Excellent Isobutyl A - Excellent Isopropyl A - Excellent Methyl A - Excellent Octyl A - Excellent Propyl A - Excellent Disclaimer: BVV Recommends no more than a -40F Operating Temperature and is not responsible for the user running their system with incompatible chemicals.

$18.00 - $38.00

Rosin Wax Tools with Silicone Cup

This set consists of 5 double-sided food-grade stainless steel rosin collection / wax utensils, one 3ml silicone container (varied color), and a complimentary padded carrying case. Variety of tool tips (probe, scraper, spatula, chisel, spearhead, carver, ballpoint, etc) allows you to work with rosin, wax and other concentrates with ease. Two ballpoint as well as spear-shaped tools are great for breaking out and apart into small pieces as well as rolling up the gooey rosin. Spoon- and paddle-shaped tools can be used to handle sappier concentrates. Knurled handles provide excellent grip, even with wet hands. The tool tips are as follows: Flat paddle with a sharp edge and flat spear on the other end Curved spear-tip and ballpoint Scooped large paddle with round edges and pointy tip Slightly curved paddle and ballpoint Small spoon and pointy tip on the opposite end

$14.00

20L BVV™ Double Jacketed Glass Reactor

The BVV™ Double Jacketed Glass Reactors are ideal for reaction applications involving extreme temperatures. They include an inner jacket for cooling or heating and an outer jacket for vacuum insulation. The outer jacket also alleviates moisture buildup so you can always see exactly what's happening inside the system. Jacketed Reaction vessels are used for synthetic reaction of different types of materials in a controlled temperature and vacuum environment. Reaction Vessels can be used as an all in one tool for extraction, refinement, distillation, and homogenization. Consisting of an inner vessel with either one or two jackets, a reactor uses temperature differentials created by a chiller to change it's internal environment. Reaction vessels also operate under vacuum making them ideal for any atmospheric sensitive applications. They can be made out of glass or stainless steel and range in volume from 1L to 100L+. To run a reaction vessel most efficiently, you will need a chiller capable of bringing the internal temperature of the vessel to an extreme low, a chemical resistant vacuum pump, and a cold trap to catch any vapors that might pass through the condenser during operation. BVV™ Jacketed Reaction vessels are simple, cost-effective, and durable machines that allow you to process material quickly and efficiently. BVV 20L and 50L Glass Reactor Diagram Specifications: Glass Material: GG-17 High Borosilicate Glass Internal Volume: 20L 6.75L Jacket Capacity Shelf Material: Aluminum Alloy Homogenizer Power: 110V/60Hz Homogenizer Speed: 0-400 RPM Digital Homogenizer Control Digital temperature probe readout included Double Jacket 3/4" Jacket Connections 1/4" and 3/8" Vacuum Connections Length: 20 in. Width: 30 in. Height: 76 in. Does not include: Chiller, Vacuum System, Cold Trap Requires Assembly *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. ***Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS!*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$4,500.00 - $4,900.00

45° Tri-Clamp 316 Stainless Steel

45° Tri-Clamp / Tri Clover 316 Stainless Steel Specification Material 316 Stainless Steel Connection Type Tri-Clamp

$7.00 - $10.00

BVV Mineral Oil 7 White "Clear" (USP/NF Food Grade)

BVV Mineral Oil 7 White NF (USP/NF) Food Grade White mineral oil can be used for many applications. Industrial, cosmetics, and food processing. Our Mineral Oil can be used in direct skin and food contact. Our oil is colorless, odorless and tasteless . This mineral oil can act as a non-conductive coolant, thermal fluid, lubricant, release agent, binder, defoamer, protective coating or float, sealing and polishing agent, dust control agent, and more. It has applications in three main areas: The industrial sector Cosmetics Food processing While those three sectors use this element most widely, it has a variety of other applications. White mineral oil is a standard household item, but has also found uses in some niche markets. The substance is versatile and has many properties making it useful in a range of applications. Food Grade Certified to FDA 21 CFR 172.878 BVV Mineral Oil 7 White NF - COA BVV Mineral Oil 7 White NF - Spec Sheet BVV Mineral Oil 7 White NF - SDS What is a food grade mineral oil? To use mineral oil in food preparation, it must be classified as a food-grade mineral oil. This is vital for health and safety as well as legal compliance. The Food and Drug Administration (FDA) has established standards any 'food-grade' substance must meet for both direct additions to foods and uses that may result in incidental contact with food. The requirements for purity, amount used, and processes vary based on how one uses mineral oil. The United States Pharmacopoeia (USP) and the National Formulary (NF) first created guidelines for the use of mineral oil in manufacturing. The FDA requires that food-grade mineral oil meet USP XX test requirements for readily carbonizable substances, which USP released in 1980, and USP XVII test requirements for sulfur compounds. It also needs to meet the specifications in Volume 45 of the Journal of the Association of Official Analytical Chemists. Mineral oil used as a lubricant for food-processing machinery must be registered with NSF International, an independent global food safety organization, as lubricants for incidental food contact to be used in food-processing plants under the jurisdiction of the U.S. Department of Agriculture (USDA). Other organizations oversee mineral oil use in other industries. For example, the Association of American Feed Control Officials (AAFCO) governs its use as a dust control agent for animal feeds. This classification is different, however, from food-grade mineral oil. Mineral oil used in the production of pharmaceuticals must be considered pharmaceutical-grade. The cosmetics and medical industry use highly refined mineral oil to avoid irritating the skin, eyes, and other body parts. Mineral oil chemical formula Mineral oils coming from crude petroleum oils vary in their make-up and contain complex structures. They include mixtures of straight and branched-chain paraffinic, naphthenic, and aromatic hydrocarbons. Alkanes, which are acyclic saturated hydrocarbons, are a significant component. They are made up of hydrogen and carbon atoms in a tree structure where all the carbon-to-carbon bonds are single. Mineral oil typically contains between 15 and 40 hydrocarbons. Mineral oil attributes Understanding the physical and chemical properties of mineral oil will help you to determine how best to use it in your industrial, food-processing, or other processes. These attributes may differ depending on the type of mineral used, how you use it, and whether any other substances get added to the oil. Mineral oil is a clear, colorless, and odorless liquid. This lack of strong physical qualities helps make it valuable in a variety of applications. Manufacturers can add it to products without changing their color, scent, flavor, or other crucial aspects. Mineral oil is also generally regarded as safe for human consumption, but in limited amounts. These features enable its use in the food processing and pharmaceutical sectors. Refined mineral oil does not clog pores, which allows for its use in cosmetics. Mineral oil has a density of 0.85 grams per milliliter (g/ml), and its specific gravity is 0.845 - 0.905. Its kinematic viscosity is greater than or equal to 38.1 millimeters squared per second (mm2/s). It is insoluble in water. The substance has an initial boiling point of 424.4 degrees Fahrenheit (°F) and a boiling range that extends up to 1189.4 °F. Its flash point is 275.00 °F closed cup and 380.00 °F open cup. It has an auto-ignition temperature of 500 °F, and its heat of combustion is 31.5 kilojoules per gram (kJ/g). As mentioned above, mineral oil has an NFPA flammability rating of one, a health rating of zero, and a reactivity rating of zero, meaning it is not a high fire risk. One of the most beneficial attributes of white mineral oil is its lubrication capabilities. This is the primary reason it has so many industrial, mechanical, food-processing, and medical applications. This property plays a crucial role in many manufacturing and food production processes. Its ability to transfer heat and its non-conductivity enable mineral oil's use as a coolant in a various electronic and mechanical equipment, as well as in industrial processes. Its resistance to water and other liquids, as well as insolubility in water, allow mineral oil to function as a sealant and binder in a variety of products. Safety Mineral oil is not regarded as an especially dangerous substance, but like all chemicals, users should handle it with appropriate care and precautions. A Material Safety Data Sheets (MSDS) for mineral oil may include the following information: Eyes: Mineral oil may cause eye irritation if it comes into contact with them. Flush eyes for several minutes and seek medical attention. Skin: It may cause skin irritation if prolonged contact with skin occurs. Remove contaminated clothing and wash affected areas or shower. Get medical attention if irritation persists. Inhalation: Inhaling mineral oil mist may irritate the respiratory tract and lungs. If this occurs, move to fresh air. Get medical attention if irritation persists. Ingestion: Ingestion can cause gastrointestinal irritation and result in nausea, vomiting, and diarrhea. If conscious, rinse mouth and drink water. Do not induce vomiting. If irritation persists, get medical attention. Mineral oil is combustible but has a low flammability rating. Having a National Fire Protection Association (NFPA) rating of one, means mineral oil must be preheated to ignite. Mineral oil has an instability rating of zero, which means it is stable even under fire conditions, and a health rating of zero, meaning it does not create any additional hazards beyond normal combustibility. You can extinguish a mineral oil fire using water fog, foam, dry chemical powder, or carbon dioxide (CO2) but should not use a water jet as this can spread the fire.If you encounter a spill of mineral oil, keep unnecessary personnel away, wear protective equipment, and absorb the spill with an absorbent material before cleaning the affected surface to remove any residue. Applications for mineral oil Mineral oil is inert, which makes it easy to use. Both consumers and businesses in a range of industries use mineral oil for a variety of applications. The three sectors named above primarily use mineral oil, but it appears across a wide range of industries and applications. Here are some of the most common uses in the industrial, personal care, and food production sectors. Use in cosmetics You can find mineral oil in many different cosmetics products including baby lotions, ointment, make-up remover, sunscreens, hair conditioner, and even tissues. Mineral oil is an ideal base material for many of these products because it is inert, colorless, and odorless. Mineral oils may appear in cosmetics as liquid oils or solid waxes. Some kinds of mineral oils are comedogenic, meaning they clog pores. Because of this, the mineral oil used in skincare and cosmetic products is noncomedogenic and does not clog pores. In fact, cosmetics companies often describe mineral oil as having moisturizing, protective, and cleansing properties for the skin. Additionally, these oils are used to give cosmetic products film-forming and water-repellent features as well as increased firmness. Use in food processing The food processing and preparation industries frequently use mineral oil. Sometimes, manufacturers add mineral oil directly to food. At other times, mineral oil assists in the production process but is not added to food directly. As mentioned earlier, all mineral oil that may come into contact with food must achieve classification as food-grade, and it must be used in accordance with all relevant laws and regulations. Food producers use mineral oil as a: Binder, release agent, or lubricant in bakery products, dehydrated foods, egg white solids, and in tablets or capsules for adding nutrients, flavoring, spices, or for use as a dietary supplement Release agent, sealing agent, and polishing agent in confectioners Protective coating on raw fruits and vegetables Defoamer in vinegar and beet sugar production Dough divider Dust control agent for grains. Binder, release agent, and lubricant in the manufacturing of yeast Mineral oil plays a role in some of the non-food products used to prepare, serve, and eat food. In these situations, the oil should also be food-grade. When applied to cookware, bakeware, and cooking utensils, mineral oil prevents food from sticking to them. People rub it onto the surface of wooden cutting boards, bowls, and utensils to prevent them from absorbing water, which can damage them. Mineral oil also prevents wood-based cooking tools from absorbing food liquids and odors, which makes cleaning easier. It acts as a lubricant for food processing equipment as well. Industrial, mechanical, and electrical uses Mineral oil serves to assist with various industrial, mechanical, and electrical purposes. It is an effective lubricant for industrial equipment and often functions as a processing aid. It is an element that helps make up various substances used in industrial processes, such as lubricants, greases, dyes, polymers, and surface treatment products. Mineral oil also acts as a thermal fluid or non-conductive coolant in various electric components. In refrigerators and oil-based electric heaters, mineral oil is used as a cooling liquid. In switchgear, it serves as an insulator and a coolant to diffuse switching arcs. In the production of plastics, mineral oil is used to control the melt flow rate of finished polymer and act as a release agent. Automotive equipment frequently uses mineral oil, primarily as a component in hydraulic liquids in automotive suspension, as well as in lubricants in brake fluids and motor oil.

$15.00 - $750.00

BVV 160L Centrifuge Bags

This nylon bag is designed to fit in our BVV brand centrifuges to contain material and be easily swappable after runs to speed up processing times. These bags come with 2 zippers and come in 1, 10, 50, 100, and 200 micron filtration levels. For use with 160L Centrifuges Appx. Size : 31.25" Diameter x 13" Height Specifications SKU Appx. Diameter In. Appx. Height in. CFB-45L-XXX 17.5" 11.75" CFB-160L-XXX 32.25" 13" CFB-280L-XXX 39.25" 14" CFB-475L-XXX 47.25" 16.75"

$187.00 - $350.00

Neocision 5L - Rotary Evaporator Replacement parts

5L - Rotary Evaporator Replacement parts These replacement parts are specifically for 5L Neocision rotary evaporators. Clamps and gaskets can be found here: Clamps Gaskets

$10.00 - $176.00

45L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller - 15LB Max Capacity

45L Ethanol Wash/Dry Centrifuge with Explosion Proof Motor and Controller Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift to lift it. It will also ship via freight only. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 1500 RPM with Gradual Speed Stepping 566 Separation Factor Multiple Connection Ports/Sizes High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation Specifications Capacity 45L Drum Dimensions 17.7" (450mm) Diameter x 11-7/8" (300mm) Deep Max Capacity 15lbs (6.8Kg) Speed 1500 rpm Separation Factor 566 Electrical 240V 1Ø Weight 794lbs (360Kg) Exterior Dimensions 50" x 27.6" x 28.7" (1280mm x 700mm x 730mm) Viewport Diameter 5.5" Connection Size(s): 2" Tri-Clamp Drain Port 1" Tri-clamp Side Port X 2 1" Tri-Clamp Top Port 1.5" Tri-Clamp Top Port 1/4" FNPT Top Port KF25 Top Port

$19,500.00

50L Neocision ETL Lab Certified Rotary Evaporator

50L Neocision ETL Lab Certified Rotary Evaporator The 50L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 50L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware/moving parts Specifications: Model 50L NEOCISION Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 220-240V 60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 0-120 RPM Set Temperature 0-99C / 0-210F Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 50L (20000ml) Receiving Flask Capacity 20L (10000ml) Condenser Style Main + Auxiliary Vertical Double Helix Evaporation Capacity Alcohol >/= 12 L/H Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 4.1 kW Dimensions 49 x 24 x 83 in. Weight 155 lbs Vacuum Connection 10mm / 3/8 in. Barb Condenser Connection 10mm / 3/8 in. Barb Warranty 1 Year Excluding: Moving Parts Glassware Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***.

$7,250.00

BVV™ Vacuum Oven Vent Release Stopper

Replacement Cap for eco and neo oven vacuum release knobs. Note the vent release may require the fitting to be greased to hold vacuum.

$8.00

XL Refinement Filter

XL Refinement Filter The BVV™ XL Refinement Filter is a stainless steel filtration system that provides industrial scale, high flow filtering, with greatly improved functionality compared to a traditional Buchner filter. Utilizing a collection base for vacuum assistance and storage of material, the XL Refinement Filter allows for industrial filtration with a longer lifespan and ease of use. Key Features: Stainless steel design for greater thermal conductivity and improved lifespan Easy to clean and disassemble with Tri-Clamp stainless steel parts Mobile Rack mounted with wide mouth design **Rack #2 option has extra space to mount additional filters or heat exchangers Secondary collection vessel for vacuum and storage of material Liquid dip tube for direct injection into rotary evaporator after filling Key Specifications: Large 12" Diameter x 24" Long Fully Jacketed Column Massive 20LB (23.5 Gallons / 89 Liters) Fully Jacketed Collection Base 5 micron Sintered Stainless Steel Filter Disc 100 Pack of Qualitative Cellulose Filter Paper Dedicated 3/8" Vacuum Valve Dedicated 3/8" Dip Tube Valve Silicone gaskets with high alcohol resistance 3/8" Stainless steel hose barb connections Polycarbonate sights for easy viewing Jacketed Filter for temperature stability Quick Start Operation Instructions: Before beginning filtration, pre-chill refinement filter for best thermal conductivity Secure ashless filter paper with compression ring connect tubing from refinement filter to a vacuum pump Attach vacuum system to the dedicated vacuum valve Begin to pour solution into filter Close dedicated dip tube valve and start vacuum Once solution has been completely filtered, stop vacuum system and disconnect from dedicated vacuum valve Connect dedicated dip tube valve to injection valve on rotovap Begin rotovap procedure Open dedicated dip tube valve and begin injecting filtered solution into rotovap

$3,050.00 - $4,860.00

6" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves

6" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 6" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 3 BVV 316SS Full Bore Valves with (2)1/4" and (1)3/8" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have 3 1.5" Tri-Clamp ports with the middle port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" and 3/8" 37° JIC Flares -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" and (1) 3/8" 37° JIC Tri-Clamp Size(s) (3) 1.5" Ports x 6" Tri-Clamp Nitrogen Tested Yes

$310.00

5L Main Condenser

Main condenser for 5L Best Value Rotary Evaporator. *Photo does NOT represent the actual part. Photo Coming soon, inquire for photos if you need to order this item please. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$320.00

AFS Ultra Clear Cartridge

BVV™ AFS Disposable Ultra Clear Cartridge Note: Stainless Steel filter housing sold separately. (Click Here for Housing) AFS Instruction Manual Download Here AFS Filters are the first and only disposable color remediation filter cartridges for the botanical extraction industry. The Patent Pending design allows for an easy to use solution implemented into existing extraction systems; and is now available as a standard integration from many equipment manufacturers. AFS Filters are a simple solution that allows for the use of prepackaged filters, which are available in different recipes depending on the application. With the integrated 2.5µm paper filter molded and sealed into the cup there is no media leak through. Pre-packed means there's no need to be an expert in remediation filter media and how to construct filters; as well as eliminates the messy process of building/packing filters yourself. Disposable offers no need for cleaning the filter housings afterwards and trying to un-clog stainless filter screens. Less R&D investment, less mess, and less down time allows for higher throughput and more profit. The media contained in the BVV™ Ultraclear filter cartridge is Ultra-clear is a high-performance granular attapulgite that is effective in removing a wide range of polar impurities including color bodies, surfactants, water, and free fatty acids while maintaining target compounds. As a granular media Ultraclear is easy to use, safe to handle, and does not require baking or wetting before use. Using only made in the USA materials that are FDA-GRAS. Technical Specifications: Life Span: 1 Time use, Good for 5-7 lbs. of dry material. Temperature Rating: -40°C-70°C Top Seal: Induction Sealed (No glue is used) Filter: Cellulose Paper Pressure Rating: Recommended 60psi, Paper will hold 80-90 psi Max. Media: USA Made High-performance granular attapulgite Shell Material: Polypropylene Excellent compatability and Safe for chemicals in our industry (Butane, Propane, Ethanol). Pressure Method: Nitrogen Assist, unless you open blast CRC. Then you can assist with an air compressor. AFS Cup weight: 48g Media Fill Volume: 110-120g Recommend Minimum Biomass: 1lb (lesser biomass will see drastic yield losses) AFS Safety Data Sheets *Please recycle your spent Cartridges. *Yield losses under refinement are to be expected but overall potency will be retained and will proportionally increase.

$55.00

12" x (3) 2" x (2) 1/4 FNPT Endcap with Diptube

12" x (3) 2" x (2) 1/4 FNPT Endcap with diptube This End Cap come with a 11-5/16" long diptube, Two 1/4"-18 FNPT Threaded connection and Three 2" Tri-Clamp/ Tri Clover ferrule welded to the end cap with a sanitary weld with a 0.5" Tube Extension on center ferrule Below the Lid. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid and the 2" Tri-Clamp Connection. These 5 connections are welded on a 12" Tri-Clamp End Cap. Specification Material: 304 Stainless Steel Connection Type: 2" Tri-Clamp - 0.5" Tube Extension on center ferrule Below Lid 11-5/16" Diptube 12" Tri-Clamp 1/4" - 18 FNPT Standard: 3A

$245.00

20L Solvent Pro Rotary Evaporator Nut and Washer Flask Set

Replacement nut and washer flask set for 20L Solvent Pro Rotary Evaporator

$136.00

24/29 Valve

24/29 Valve For 10L-50L Best Value Rotary Evaporators. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$35.00

6" x 4" x 3" x (2) 1/4" FNPT Tri-Clamp Skylight

Specifications: 304 Grade Stainless Steel Reducer 'Skylight' w/ High Polish interior 6" Triclamp x 4" Triclamp x 3" Triclamp (Can be used as viewport to see inside) x (2)1/4" FNPT 7" Tall

$175.00

Baffled Condenser - 6" x 36" with 1.5" Tri-Clamp Side Ports

Baffled Condenser - 6" x 36" with 1.5" Tri-Clamp Side Ports This 304 Stainless Steel Tri-Clamp condenser allows the user to condense hot vapors and solvent while running an extraction system or use it as a heat exchanger if needed. It features internal baffles in the system allowing for better overall heat exchange, 6" Tri-Clamp connections on each end and (2) 1.5" Tri-Clamp ports on the side to allow various connections the user may need. From end to end it is 36" in length. The inside diameter of the tubing measures 7.5mm.

$3,000.00

6" - 12" Dewax Dry Ice Funnel

This stainless steel funnel is meant to help get dry ice into 6" - 12" Dewaxing columns. It simply clips on the side of the dewaxer allowing an easier filling of the dry ice into the dewaxing column.

$65.00

PTFE Valve Core for 5/10/20L for Solvent Pro Rotary Evaporator

PTFE Valve Core for 5/10/20L for Rotary Evaporator This PTFE valve core is a direct replacement for Solvent Pro Series 5L, 10L, and 20L rotary evaporators. They are used on the injection valve, drain valve, and collection flask ancillary valves. The body and seal are made of PTFE making it chemical resistant. **Please confirm you have BVV Solvent Pro Series 5L, 10L, 20L rotary evaporator before purchasing this part. If you need help identifying which model you have, please call in.**

$75.00

5L ECO Nut and Washer Flask Set

Replacement nut and washer flask set for 5L Eco Rotary Evaporator

$45.00

Straight Inlet Adapter with Hose Barb

Straight Inlet Adapter with Hose Barb This straight inlet adapter allows the user to connect a male and female 24/40 jointed connection and attached a flexible hose for vacuum if needed. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$30.00

5L Short Path Distillation Kit with P5 Distillation Head

5L Short Path Distillation Kit with P5 Distillation Head This unit carries a 2 day lead time. The 5L Distillation Kit includes everything needed to perform distillation excluding the vacuum pump and chiller. This kit features our USA made P5 Distillation Head, as well as USA, made glass. This Kit is designed for high volume production with the highest quality components for precise, repeatable results time and again. This Kit Does NOT include a vacuum pump or chiller. Please see the below recommendations for both as well as recommended add-ons. Recommended Vacuum Pumps: Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (economy option) Recommended Chillers: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter Refrigerated Circulator (premium option with chilling capability) Recommended Add-Ons: Glass Dewar Style Cold Trap (recommended cold trap) Bullseye Precision Vacuum Gauge (premium vacuum gauge for measuing depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) J-KEM Digital Vapor Temp Monitor (digital vapor temp monitor with data-logging capabilites) Specifications: Boiling Flask Size: 5L Receiving Flask Size: 2x 500mL, 1000mL Batch Capacity approximate: 1000-2500 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Includes: Glass components: 5L Boiling Flask P5V6 Distillation Head Triple Neck Cow 2x 500mL Receiving Flask 1L Receiving Flask 120mm Glass Funnel Accessories: PTFE Magnetic Stir Bar Retriever 5 Pack of Metal Keck Clips Dow Corning High Vacuum Silicone Grease Tripod Stand 5L Digital Heating and Stirring Mantle 3-Finger Adjustable Clamp 0-77mm 6" x 6" Scissor Jack 500-1000mL Cork Stand 2x 24/40 ChemglassPTFE Thermometer Inlet Adapter 10ft of Gum Rubber Vacuum Hose 10ft of Silicone Chiller Hose 1/4" Vacuum Manifold Traceable Kangaroo Thermometer - Digital 10 Pack of Adjustable Stainless Steel Tubing Clamps Fiberglass Insulation Rope 10 Feet 1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen w/ 2x 1/4" Barb Adapters Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$2,200.00

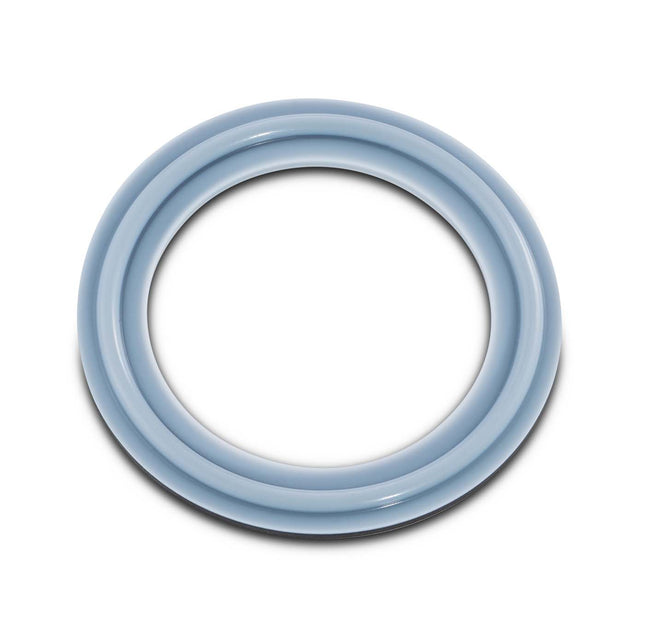

Solvent Pro Series 18/35 Gasket

Solvent Pro Series 18/35 Gasket This is a replacement Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This gasket fits an 18mm(0.71") Inner Diameter and 35mm(1.38") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$13.00

Economy Recirculating Heater Kit

Economy Recirculating Heater Kit The Economy Recirculating Heater Kit is designed to provide efficient heating and circulation at an affordable price. The kit includes a submersible water pump for fluid circulation, an LX or MX immersion heater, and all tubing and hose clamps needed to pair with your system. The tubing is 1/2" ID x 5/8" OD and the pump fitting is 1/2". The pump will circulate up to 594 GPH. Economy Recirculating Heater Kit Includes: Polyscience LX or MX Immersion Circulator EcoPlus Eco 633 Fixed Flow Submersible/Inline Pump 594 GPH 5 Gallon Aluminum Pot 10 Feet of 1/2" Silicone Tubing 10 Pack of Adjustable Stainless Steel Tubing Clamps

$1,700.00

5L BVV™ Rotary Evaporator Glass Axis

Glass axis for 5L BVV™ Rotary Evaporator *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$50.00

Upgraded TRS21 Compressor Head Complete, Stainless Fittings, Viton

Upgraded TRS21 Compressor Head Complete, Stainless Fittings, Viton Upgrade your TRS21 by purchasing a new Compressor Head with Viton O-rings for butane and propane gas compatibly and stainless steel fittings to meet FDA guidelines on handling of consumable products. This head is assembled here in the USA and is a direct replacement for any TRS21 Compressor Head.

$195.00

Glycerin Filled Vacuum Gauge with 1/4" NPT Back Mount -30inHg-0Psi

BVV -30inHg-0Psi BVV™ Glycerin filled vacuum gauge has a 1/4" MNPT brass connection with a readout of (-30) inHg - 0 PSI. The outer diameter of the gauge measures 2.25" We provide adapters to fit your setup in MNPT, FNPT, MJIC, FJIC, and standard compression tubing.

$18.00

You have seen 624 out of 787 products