Meta Purification

-

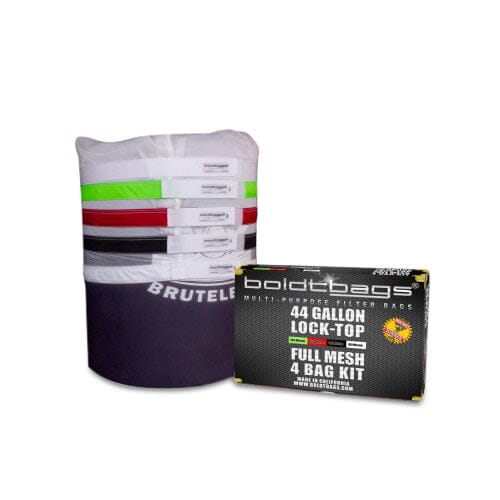

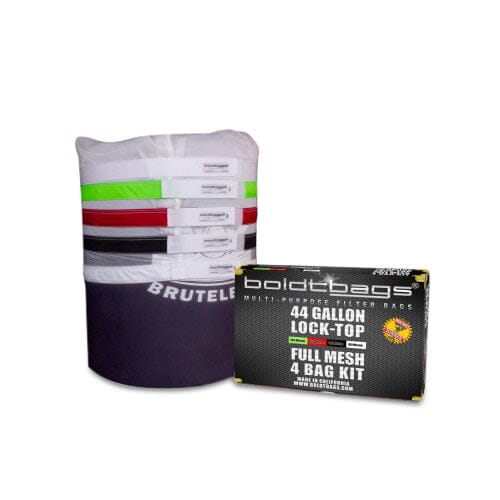

Boldtbags 44 Gallon Boldtbags Full Mesh Stacker Lock-Top w/ Belt Lock

44 Gallon Boldtbags Full Mesh Stacker Lock-Top w/ Belt Lock Lock top bags are the new product made with you in mind. Adjust your bag to the height you need and lock it in for easier product washing and collection. Custom designed with Full Mesh, these bags provide exceptional ice water sieving properties and award winning purity thanks to the large functional surface area and lightweight construction that allows for easy use and award winning results. Ideal purchase for Laboratories. Have a variety of bags to choose from and mix and match for perfect trichlome extraction. Diameter 23.5″ Depth 28.25″ 4 bag kit includes: 190 micron bag (green) 160 micron bag (red) 90 micron bag (black) 45 micron bag (white) Additional belt lock Scraping card 8 bag kit includes: 220 micron bag (blue) 190 micron bag (green) 160 micron bag (red) 120 micron bag (orange) 90 micron bag (black) 73 micron bag (yellow) 45 micron bag (white) 25 micron bag (purple) Additional belt lock Scraping card

$650.00 $250.00

You have seen 97 out of 97 products