BVV

5LB TFX Closed Loop Extractor

5LB TFX Closed Loop Extractor Are you ready to embark on an exciting journey into the world of extraction? Look no further than the TFX – your ultimate entryway into the realm of closed-loop extraction. The TFX not only offers exceptional performance straight out of the box at an affordable price but also serves as a dynamic foundation for future upgrades and enhancements, allowing you to elevate your extraction prowess over time. Whether you're just starting your extraction venture or seeking to amplify your capabilities, the TFX provides a sturdy base that can be tailored to meet your evolving requirements. With its adaptable design and compatibility with various upgrades, the TFX empowers you to experiment with novel processing techniques and adapt to the ever-changing demands of the industry. Initiate your journey with the TFX and unlock boundless possibilities for innovation and expansion in the extraction domain. Introducing the TFX closed-loop extractor – the evolution of the popular Apollo extractor. The TFX heralds a new era of safety, user-friendliness, and performance. Building upon the achievements of its predecessor, the TFX takes operator safety to new heights, featuring enhanced safety mechanisms such as High-pressure Clamps and pressure relief valves as standard features. Harvesting extracts is made effortless with splatter platter bases, ensuring a cleaner and more seamless process. The optimized design of the TFX translates to heightened ease of use, safety, and performance, resulting in top-tier extracts. The TFX stands as the cornerstone of many extractors' journeys, providing a reliable, efficient, and future-proof solution to meet your evolving demands. The TFX closed-loop extractor comes in three model variants, tailored to different extraction needs. The V1 Explorer is the ideal choice for those mindful of their budget, offering an affordable entry point into the extraction world. Equipped with features like a DOT-Approved carbon steel recovery tank, 1/4" JIC Recovery lines, and polycarbonate sight glasses, it establishes the groundwork for seamless future upgrades. For those seeking a professional setup from the outset, the V2 Professional model is the prime selection. It boasts an upgraded stainless steel recovery tank with 1/2" JIC Recovery lines for optimal solvent recovery. Enhanced borosilicate sight glasses provide improved visibility during the extraction process. For the ultimate extraction experience, the V3 Elite model is your answer. It encompasses all the upgrades of the professional variant, along with additional features such as a solvent dispersal plate for uniform biomass saturation and a jacketed splatter platter compatible with a heated circulator, enhancing solvent recovery efficiency. The TFX closed-loop extractor empowers you to choose the model that suits your budget and needs perfectly. Whether you're taking your first steps or aiming for professional-grade capabilities, the TFX series lays the groundwork for your extraction journey. Regardless of your choice – Explorer, Professional, or Elite – the TFX closed-loop extractor offers endless modification possibilities to amplify your capabilities and remain ahead of industry trends. Tailored for quick wash extraction procedures, the TFX guarantees outstanding purity and yield. For those inclined towards soaking procedures, a simple addition of our 316L SS Tri-Clamp Ball Valve beneath the material column transforms the TFX. For utmost purity, pair your TFX with an Inline CRC (Color Remediation Column) to achieve the highest quality and purest extracts. Planning to work with fresh frozen material? Swap out the standard 4"x 24" spools for Sleeved Spools to preserve the biomass's flavor during extraction. To attain unparalleled clarity in your extracts, reduce wax content by integrating an injection coil into your setup. To enhance solvent recovery efficiency and minimize loss, consider adding our BVV 2 Cylinder Active Closed Loop Recovery kit to your TFX closed-loop extractor. This kit optimizes solvent recovery, ultimately saving you valuable time and resources. With the TFX closed-loop extractor and its range of modification options, you have the freedom to tailor your extraction setup to match your distinct requirements. Stay at the forefront of the industry and unlock the full potential of your extraction process with the versatile TFX closed-loop extractor. As a prominent manufacturer of extraction equipment, we prioritize precision and safety in the extraction process. The TFX embodies these principles, offering a state-of-the-art solution for extraction professionals. Engineered from high-quality stainless steel, the TFX guarantees exceptional durability and corrosion resistance, providing you with a dependable and enduring extraction solution. Its innovative design integrates advanced safety features such as high-pressure clamps, pressure relief valves, and sight glasses, ensuring operator well-being and operational control. Its superior design promotes efficient solvent flow and comprehensive material saturation, resulting in high-quality, potent extracts that meet your specific requirements. When it comes to introductory closed-loop extractors, the TFX sets a new benchmark with its exceptional performance, safety features, and reliability. With our product, you can streamline your extraction operations, amplify productivity, and craft premium extracts that surpass industry standards. At BVV, we take pride in offering top-tier extraction equipment tailored to your unique needs. Our team of experts is devoted to providing unparalleled customer support, assisting you every step of the way, from your initial purchase to setup and beyond. Elevate your butane extraction experience with the TFX – the definitive top-fill closed-loop extractor. Reach out to us today to initiate your extraction journey and propel your business to new heights. Specifications 2X 4"x24" 1LB Material Column 12"x12" Collection Base Body 12" Collection Base Splatter Platter 100um Nitrile BUNA-N Mesh Gaskets 1.5" Polycarbonate or Borosilicate Sight Glasses 125 PSI ASME Safety Valves -30hg-250PSI Compound Pressure Gauge 1/4" or 1/2" Full Bore Recovery Lines 1/4" JIC process Flow lines Explorer Professional Elite DOT Carbon Steel Solvent Tank Polycarbonate Sight Glasses 1/4" JIC Recovery Lines Stainless Steel Solvent Tank Borosilicate Sight Glasses 1/2" JIC Recovery Lines Stainless Steel Solvent Tank Borosilicate Sight Glasses 1/2" JIC Recovery Lines Solvent Dispersal Plate Jacketed Splatter Platter ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$1,400.00 - $2,150.00

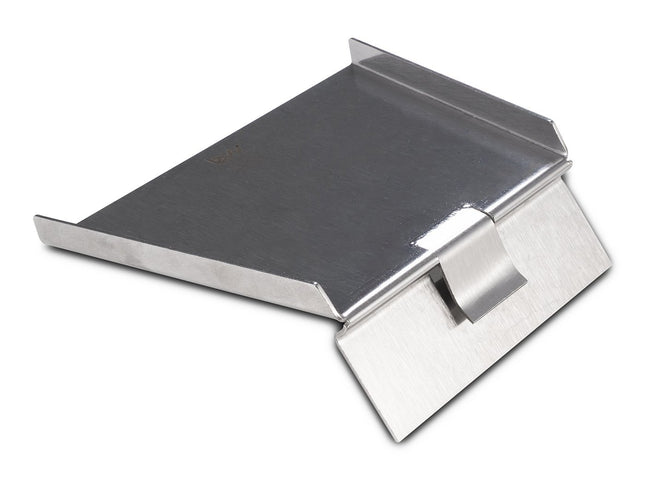

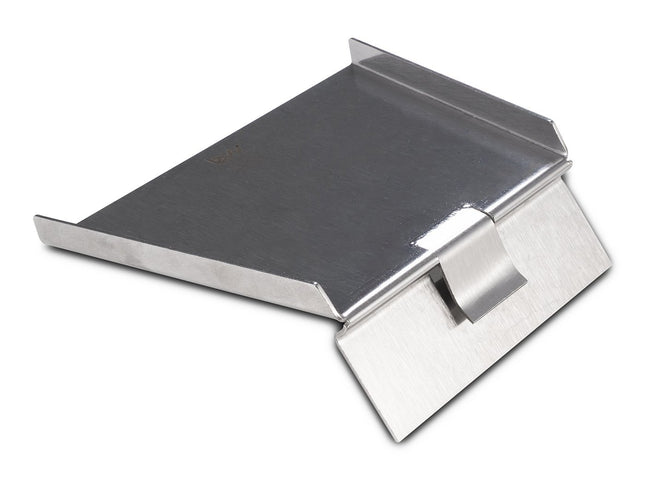

6" - 12" Dewax Dry Ice Funnel

This stainless steel funnel is meant to help get dry ice into 6" - 12" Dewaxing columns. It simply clips on the side of the dewaxer allowing an easier filling of the dry ice into the dewaxing column.

$75.00

6" - 4" Hemi Reducing Elbow

This tri clamp 6” - 4” reducing end cap has a 90 degree bed that works well for the base of heat exchangers and also in falling film evaporators.

$340.00

6" Jacketed Hemispherical Reducer Compression

6" Jacketed Hemispherical Reducer Compression This hemispherical reducer will go from a 6" tri clamp to a 1/2" Compression fitting. The compression fitting is the preferred choice for sanitary connections to eliminate possible contamination from particles getting stuck within threads. The jacket around the outside of the reducer has 2x 1/2" NPT ports to connect to a temperature controlled circulator.

$280.00

6" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves

6" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 6" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 3 BVV 316SS Full Bore Valves with (2)1/4" and (1)3/8" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have 3 1.5" Tri-Clamp ports with the middle port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" and 3/8" 37° JIC Flares -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" and (1) 3/8" 37° JIC Tri-Clamp Size(s) (3) 1.5" Ports x 6" Tri-Clamp Nitrogen Tested Yes

$310.00

6" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves

6" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 6" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with 1/4" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have 3 1.5" Tri-Clamp ports with the middle port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC Flares -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" 37° JIC Tri-Clamp Size(s) (3) 1.5" Ports x 6" Tri-Clamp Nitrogen Tested Yes

$275.00

6" Sauce Separator

6" Sauce Separator Separate diamonds from sauce at scale with our 6" Sauce separator. Simply load your crystallized extract into the top vessel and place it in a heated oven at 120-140F for 4 hours to sweat the sauce from your crystals. Equipped with a 100-micron Buna-N gasket the 6" Sauce Separator allows for easy separation of crystals from the mother liquor. With a max height of 12.5" and a max diameter of 9", the 6" Sauce Separator easily fits within our standard 1.9 CF vacuum ovens. Specifications 6" Splatter Platter for sauce collection 6" 100 Micron BUNA-N Nitrile gasket 6"X6" Body for Extract loading (-30)-250 PSI Compound Gauge 1/4" JIC Butterfly Valve 1.5" Borosilicate Sight Glasses High-Pressure Clamps Dimensions Max Height: 12.5" Max Diameter: 9"

$450.00

6" Spool with 4" Tapered Funnel and KF40 Vac Port

This Tri clamp adapter piece can allow you to hook up a vacuum line to a tri clamp column and shielding the vacuum line from and falling liquids or oils. These are commonly used in falling film recovery applications.

$212.00

6" Stainless Steel Diamond Miner

6" Stainless Steel Diamond Miner This 6" Diamond Miner is used for crystallizing botanical extracts into live resin terpene-rich sauce. This Diamond Miner eliminates the need for glass jars and makes your degassing procedure safer. The premium extractor lid is pre-assembled and nitrogen tested for leaks to ensure the customer receives a leak and worry-free part to use on their extraction system. These valves come with a 1-year manufacturer warranty against defects and are custom-built. Remove the 6" x 2" splatter platter to easily remove diamonds from your sauce mix. Glycerin filled compound gauge gives you an easy readout of pressure inside the vessel. Specifications: 304 Grade Stainless Steel 500-700ml Optimal Capacity (725ml) Max Fill 1.5" sight glass 6" splatter platter High-pressure clamps 316 Stainless Steel Valve with 1/4" Flare Connection Temp Range -40 to 230C Compound Gauge (-30)-(150) MAWP: 100 psi

$350.00 - $650.00

6" Tri-Clamp Dewaxer Columns

6" Tri-Clamp/ Tri Clover Dewaxing Columns This is a 6" Tri-Clamp BVV™ Tri-Clamp Dewaxing Spool. It is intended to have dry ice put into the sleeve to chill the material inside the column. **Note: When selecting a Pipe Hanger choose the size that correlates to the Sleeve OD NOT Spool OD Sizes Available: 6" x 8" Tri-clamp Dewaxer Column 6" x 24" Tri-clamp Dewaxer Column 6" x 36" Tri-clamp Dewaxer Column 6" x 48" Tri-clamp Dewaxer Column Specifications: Tri-Clamp Size 6" Material 304 Stainless Steel Standard 3A High Polish Sleeve OD 8.000" Spool ID 5.782" Spool OD 6.000" Flange OD 6.570" Bead Center 6.176" Drain Port 1/4"-18 FNPT (Drain Plug Included) OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 6" Tri-Clamp Dewaxer Columns - Drawing

$135.00 - $224.00

6" Tri-Clamp Endcap w/ (4) 1/4" FNPT Ports

6" Tri-Clamp Endcap w/ (4) 1/4" FNPT Ports These End Caps come with four 1/4"-18 FNPT Threaded connections welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid. Specification Material: 304 Stainless Steel Connection Type: Tri-Clamp 1/4" - 18 FNPT Standard: 3A Sizes Available: 6" BVV™ 6" Tri-Clamp Endcap w/ (4) 1/4" FNPT Ports - Drawing BVV™ 6" Tri-Clamp Endcap w/ (4) 1/4" FNPT Ports - End Cap Chart

$95.00 - $100.00

6" Tri-Clamp Endcap X (2) 1/4" FNPT Ports

6" Tri-Clamp Tri Clamp Endcap X (2) 1/4" FNPT Ports This 6" Triclamp endcap has 2x 1/4" FNPT ports welded to the top of the endcap allowing for several variations of connections that can customize an extraction system to the user's needs. Specifications: Material - 304 Stainless Steel Connection Type(s) - 6" Tri-clamp and 1/4"-18 FNPT BVV™ 6" Tri-Clamp Endcap X (2) 1/4" FNPT Ports - Drawing BVV™ 6" Tri-Clamp Endcap X (2) 1/4" FNPT Ports - End Cap Chart

$85.00

6" Tri-Clamp Hemispherical Extractor Lid

6" Tri-Clamp Tri Clover x (3) 1.5" TriClamp x (4) FNPT Hemispherical Lid This End Cap comes with Four FNPT Threaded connection and Three 1.5" Tri-Clamp ferrule welded to the end cap with a sanitary weld with a 3" Tube Extension Below the middle port on the lid. These allow the user to adapt and connect a threaded connection to the NPT ports and three 1.5" Tri-Clamp Connections on a 6" Hemispherical Tri-Clamp lid. With this versatile Tri-Clamp Extractor Lid, users can quickly create a leak-proof connection allowing easy assembly or disassembly for routine maintenance and inspection. Specification SKU: 600HEL 600HEL-V2 Material: 304 Stainless Steel 304 Stainless Steel Connection Types: 6" Tri Clamp 3x 1.5" Tri Clamp (Tube Extension Below Center Port) 4x 1/4" FNPT 2x 1/4" FNPT - 2x 1/2" FNPT Standard: 3A BVV™ 6" Tri-Clamp x (3) 1.5" TriClamp x (4) 1/4" FNPT Hemispherical Lid - Drawing BVV™ 6" Tri-Clamp x (3) 1.5" TriClamp x (4) 1/4" FNPT Hemispherical Lid - End Cap Chart

$160.00 - $175.00

6" Tri-Clamp Spools

6" Tri-Clamp / Tri Clover Spools Sizes Available: 6" x 6" Tri-Clamp Spool 6" x 12" Tri-Clamp Spool 6" x 24" Tri-Clamp Spool 6" x 36" Tri-Clamp Spool 6" x 48" Tri-Clamp Spool Specifications: Tri-Clamp Size 6" Material 304 Stainless Steel Standard 3A High Polish Spool OD 6" Spool ID 5.78" Flange OD 6.57" Bead Center 6.156" OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 6" Tri-Clamp Spools - Drawing Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$125.00 - $350.00

6" Tri-Clamp Tall Sight Glass

6" Tri-Clamp/Tri-Clover Tall Sight Glass This massive 6" Tri-Clamp sight glass is one of a kind and a specialty product for Best Value Vacs. It allows customers to attach it to alcohol or steam-based extraction systems or to monitor the flow of large scale sanitary systems. These sight glasses come in either 10, 20, or 30" lengths and the customer has the choice of choosing a Buna-N or Silicone gasket through dropdowns. (Sight Glass Comes Standard with Buna-N.) Specifications Material 304 Stainless Steel / Borosilicate / Nitrile OR Silicone Connection Type 6" Tri-Clamp Length 10" , 20", or 30" Pressure Rating 50 PSI

$440.00 - $710.00

6" Tri-Clamp x (2) 1/4" FNPT ports w/ Shower Head

6" Tri-Clamp Tri Clover x (2) 1/4" FNPT Ports w/ Shower Head These End Caps come with Two 1/4"-18 FNPT Threaded connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid. Shower Head End Caps help disperse solvent input into a system which creates better material saturation when flooding a material column. This helps to prevent channeling, ensuring all the material is saturated. Specifications Material: 304 Stainless Steel Connection Types: Tri-Clamp 1/4" - 18 FNPT Standard: 3A Sizes Available: 6"

$50.00$35.00

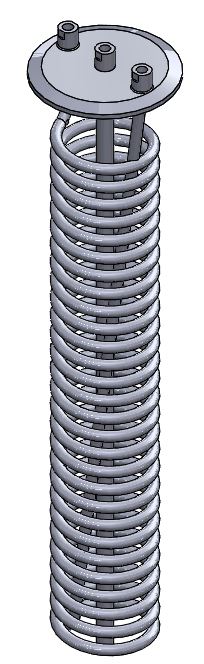

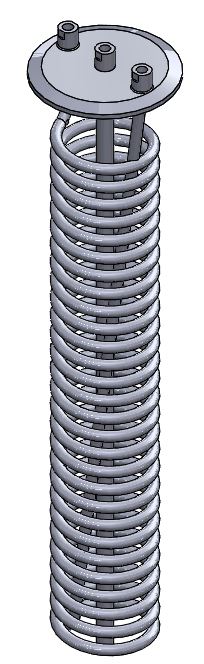

6" Tri-Clamp x 30" Column Cooling Coil with Dip Tube

6" Tri-Clamp x 30" Column Cooling Coil This column cooling coil is designed to fit in 6" Tri-Clamp material columns and allows the user to either chill or heat the column up from the inside which increased the surface area beyond a standard dewaxing jacket and reduces the need for dry ice. This cooling coil is made out of 304 stainless steel and has a 3/8" diameter coil spiraling from (3) 1/4" FNPT ports on the top with 2 of them connecting to the coil and one of the connecting to the dip tube

$300.00

6" Turnkey Falling Film Evaporator

BVV 6" Turnkey Falling Film Evaporator Cutsheet Is your lab floor filled with a fleet of rotary evaporators? Looking to increase solvent recovery throughput? Our new and compact 20GPH Falling Film Evaporator (FFE) has the capability to maximize throughput and replace up to five 50L Rotary Evaporators. The BVV™ 20GPH Falling Film Evaporator is designed to evaporate ethanol that has been diluted in crude oil during a filtration or extraction process. By reducing the vapor pressure inside the system and metering the injection valve, the user can set the heat exchangers to the appropriate temperatures to efficiently evaporate solvent from their crude oil. We paired our FFE with reliable equipment that will keep operations running. End users are required to plumb the process inlet and outlet connections for both heat exchangers. They are supplied with 1.5” sanitary tri-clamp connections. BVV™ can assist with necessary parts needed for a permanent or temporary installation. Temporary installations may be necessary if your lab has limited fume hoods or space which is shared with other processing equipment. Below you will find key features, additional equipment included with the system and the power requirements for each, and real-life efficiencies that were tested. Key Features: · Compact rack design for use in fume hoods (39”x30”x75.5”) · Vernier scale metering valve for controlled injection · Accurate heater and chiller temperature control · Deep vacuum for effective solvent removal · Discharge pumps to eliminate constant reservoir draining and down time · Chemical resistant vacuum pump · Adaptable discharge outlets to customer preference · Insulation to limit thermal loses and reduce condensation (Not Pictured) · Sanitary tri-clamp and compression fittings · Pre-heat injection coil · Injection distribution plate · Tube in shell heat exchanger for efficient evaporation and condensation · Packable vapor path for reduction of contaminants and cleaner separation · Water reservoir for priming the heating system and expansion during operation · The certified model is 22 State certified by PRV Engineers and includes an Infield Verification by PRV Engineers within the purchase price. States include but are not limited to: Alabama, Arizona, Arkansas, California, Colorado, Connecticut, Florida, Illinois, Kansas, Louisiana, Maine, Massachusetts, Missouri, Nevada, North Carolina, Oklahoma, Oregon, Texas, Vermont, Washington, West Virginia, and Wyoming Crude Discharge Pump Easily control discharge speed and collect your extract directly from the 3/8" tube via a collection vessel or swage on a fitting of your preference to pump collected extract to a secondary location. Eliminate constant reservoir draining and operate continuously. Metered Solvent Injection Effectively repeat efficiency and throughput with our vernier scale metering valve. Easy to dial in the desired efficiency and throughput desired by the user. Distribution Plate Directs the injected solvent to be evenly distributed across all tubes in the heat exchanger which maximizes the effective heating surface area. Solvent Discharge and Vacuum Pump The solvent discharge pump eliminates the need for a reservoir and allows you to pump recovered solvent to any desired secondary location. The vacuum pump manifold gives you easy vacuum control during the complete operation. POWER REQUIREMENTS The equipment listed below is included with the system. Check power requirements and amp draw prior to purchasing. Equipment Purpose Power Requirement Amp Draw Notes Hubbell Process Water Heater Heater for Heat Exchanger Column (Evaporation) 240V 3-Phase 87 36kW Heating Capacity Taco ECM High-Efficiency Circulator Water Circulator for Heater 115V 1-Phase 2.5 Max flow rate 52GPM 10 Ton Low Temp Glycol Chiller Chiller for Heat Exchanger Column (Condensation) 230V 3-Phase 64 10 ton Cooling Capacity 2GPM Ethanol Recovery Pump for Vacuum Pump for Ethanol Recovery Discharge 230V 1-Phase 2.4 2GPM Max Flow Rate, Vacuum Check Valve Beaker and Wrench Explosion Proof Oil Pump Pump for Oil Recovery Discharge 230V 1-Phase 1.1 90L/hr. Max Flow Rate, Vacuum Check Valve Welch BTpro100 Diaphragm Pump Vacuum Pump for System 115 1-Phase 3.4 3.5 CFM, 6 Torr Ultimate Vacuum Total Amp Draw 174.4 EFFICIENCY We are proud to present real data with running parameters and efficiencies that reflect the actual operation of our system. Below you will find the tested throughputs and efficiencies that our FFE is capable of handling. Throughput 11 GPH 18 GPH 20 GPH 22 GPH 24 GPH Efficiency 98% 97% 94% 90% 85% ** Efficiency calculated at 10:1 ratio (Ethanol : Crude Oil) with heater temperature of 160°F. Crude is fully dewaxed when going into the falling film evaporator. Solution starts at room temperature. Speeds may differ based on dilution ratio, crude quality, and running parameters. **

$59,000.00 - $62,000.00

6" Vacuum Chamber Digital Heat Pad

6" Vacuum Chamber Digital Heat Pad Please Read Before You Buy! Chamber NOT Included, Sold Separately. Heat Pad must fit correct size of the chamber! Fits a 1 and 1.5 Stainless Steel, 3 Qt Pyrex, and 1.75 Qt Pyrex Chamber This Digital Heat Pad will adhere to the bottom of a chamber vessel with a peel and stick backing. This unit will hold a temperature within a degree to the set temperature (dependent on the environment and air movement). The temperature offset must be found to set the controller accurately. (See ‘Operation’ instructions in the operation manual) Included with this Digital Heat Pad: Instructions on how to operate and set parameters. Simple standoff bumpers (provide thermal separation between the vessel and the work surface) Thermal tape (best method to check and verify temperature) Specs: UL Listed Fahrenheit Digital Controller. Min Temp: Ambient + 5 Max Set Temp: 160°F Ultimate Max Temp: 248°F Voltage: 110VAC Only Power Consumption: 220-watt Digital Control: Increments of 1 Degree. Accuracy: +/- 0.2 Degrees Units: Degrees Fahrenheit Instructions: Fully included Relay Lifespan: Approx. 10 million cycles User can reprogram: Yes

$92.00

6" x 1.5" x (2) 1/4" FNPT Tri-clamp Endcap

6" x 1.5" x (2) 1/4" FNPT Tri-clamp Tri Clover Endcap This End Cap come with Two 1/4"-18 FNPT Threaded connection and 1.5" Tri-Clamp ferrule welded to the end cap with a sanitary weld with a 0.5" Tube Extension Below the Lid. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid and the 1.5" Tri-Clamp Connection. These 3 connections are welded on a 6" Tri-Clamp End Cap. Specification Material: 304 Stainless Steel Connection Types: 1.5" Tri-Clamp - 0.5" Tube Extension Below Lid 6" Tri-Clamp 1/4" - 18 FNPT Standard: 3A BVV™ 6" x 1.5" x (2) 1/4" FNPT Tri-clamp Endcap - Drawing BVV™ 6" x 1.5" x (2) 1/4" FNPT Tri-clamp Endcap - End Cap Chart

$149.00

6" x 4" x 3" x (2) 1/4" FNPT Tri-Clamp Skylight

Specifications: 304 Grade Stainless Steel Reducer 'Skylight' w/ High Polish interior 6" Triclamp x 4" Triclamp x 3" Triclamp (Can be used as viewport to see inside) x (2)1/4" FNPT 7" Tall

$140.00

635G Ms. Cream Food-Grade Nitrous Oxide Tank 99.5% (635g / 321 liters) Made in Italy

Ms. Cream 635g Nitrous Oxide Tank 99.5% Food Grade Made in Italy, Triple Filtered Mr. Cream® is a true culinary gas. Trusted for it high purity and known for not adding any strange or unknown flavors to your cream that other lesser quality import gasses my leave behind. The original brand since the 1930's. At BVV we have tried many and this is the highest purity tank we have carried. This innovative cylinder is the fastest and easiest way to replenish your cream. It is not only a good assistant for making dessert at home but also a new solution for the industrial catering industry! Before using our whipped cream-making equipment you must first read the manufacturer's instructions. This will show you how to safely charge your cream using the cream 635g tank. 635g Charger - 1.14lbs Liquid N2O - 321 Gas Liters of N2O. Cylinder Fitting: M11x1 Thread (compatible with the Best Whip Nitrous Oxide Regulator.) Tank Pressure: 755 PSI Includes 1 nozzle per tank. *At end of use use this nozzle to completely empty the tank for recycling. Do not heat over 120F SUPERIOR GAS QUALITY - Each tank is filled with the purest, and highest quality E942 food grade gas. That is why you will not have a hard time making chocolate or vanilla, mint, or Bailey's flavored cream whipper. Cocktail foams, airy sauce, mousse, and hot or cold foam can be made easily, too. FOOD-GRADE & LONG SHELF LIFE - Ms Cream whipped tanks are made with food-grade compliance and production standards. Each tank has a long shelf life of 5 years so you can use them over a period of time. ANTI-LEAKAGE DESIGN - Ms Cream tanks conform with Manufacturing International Standards such as ISO 9001, and ISO 9002. Any cream dispenser can be used with this cylinder. UNIVERSAL COMPATIBILITY - Compatible with all professional whipped cream makers in the market. From now on, you can easily finish making whipped cream in a few seconds and without leaving odors or contaminants in the dispenser. RECYCLEABLE CONTAINER - Recycle empty tank with other metal recycling. The tank is considered empty if you hear a clicking noise coming form the valve when you shake it. What Is Nitrous Oxide? Nitrous Oxide is a chemical compound with the formula N2O. It is a colorless, non-flammable gas with a slightly sweet odor and taste. Nitrous oxide is often used for various purposes due to its unique properties and effects. What is Nitrous Oxide Used For? Nitrous oxide (N2O) is most commonly used in the culinary world for various purposes, primarily for creating foams, whipped creams, and infusions. Outside the culinary world nitrous oxide is also commonly utilized as a propellant, a cryogenic refrigerant, and as a performance-enhancing additive for internal combustion engines. Here's how nitrous oxide is most commonly used in culinary applications: Whipped Cream: Nitrous oxide is perhaps most well-known in the culinary field for its use in making whipped cream. In this application, heavy cream and sweeteners are combined in a whipped cream dispenser or siphon, and nitrous oxide cartridges are used to pressurize the dispenser. When the cream is released from the dispenser, the sudden release of pressure causes the nitrous oxide to expand and whip the cream into a light and fluffy texture. This method allows for the creation of stable whipped cream that retains its texture for an extended period. Foams: Chefs use nitrous oxide to create foams from various liquids, such as fruit juices, sauces, and purees. To make a foam, the desired liquid is mixed with a gelling agent, strained, and loaded into a whipped cream dispenser along with nitrous oxide. When dispensed, the nitrous oxide aerates the liquid, resulting in a light and airy foam that can be used as a garnish or flavor enhancer. Infusions: Nitrous oxide can be used to infuse liquids with the flavors of herbs, spices, fruits, or other aromatic ingredients. For example, herbs like basil or spices like cinnamon can be placed in a whipped cream dispenser along with a liquid (e.g., oil or alcohol) and nitrous oxide. The pressurized nitrous oxide infuses the liquid with the flavors and aromas of the added ingredients quickly. Cocktails: Some bartenders use nitrous oxide to create foam or froth on cocktails, adding a unique visual and textural element to drinks. This technique is especially popular in molecular mixology. Sauces and Dressings: Nitrous oxide can be used to create light and airy sauces or dressings. By adding nitrous oxide to a mixture of liquids and ingredients, chefs can achieve a desired texture and consistency. Desserts: Nitrous oxide can be used to create innovative desserts, such as foamy fruit purees, mousse-like textures, and light, airy soufflés. It's essential to use food-grade nitrous oxide and follow proper safety precautions when using it in culinary applications. The use of nitrous oxide cartridges and whipped cream dispensers is common in professional kitchens and home cooking to achieve these culinary effects. What Are The Hazards Of Nitrous Oxide? Nitrous oxide (N2O), while commonly used in various applications can pose certain hazards if not used properly. Here are some potential hazards associated with nitrous oxide: Asphyxiation: The most significant hazard of nitrous oxide in culinary use is the risk of asphyxiation. Nitrous oxide can displace oxygen in an enclosed space, leading to oxygen deprivation if inhaled in high concentrations. This can result in dizziness, loss of consciousness, and even death. Frostbite: Nitrous oxide is stored as a compressed liquid and is extremely cold when released. Contact with liquid nitrous oxide can cause frostbite or cold burns to the skin. Care should be taken when handling nitrous oxide cartridges or dispensers. Is Nitrous Oxide Flammable? Nitrous oxide (N2O) is not flammable in the typical sense because it does not support combustion. However, it can contribute to the combustion of other substances. Here's a more detailed explanation: Non-Flammable: Nitrous oxide itself does not burn or catch fire. It is an oxidizer, meaning it can support the combustion of other substances by providing oxygen. When nitrous oxide is used in applications like rocket propulsion or automotive nitrous systems, it does not ignite by itself. Enhancing Combustion: Nitrous oxide is sometimes used in combination with fuel in internal combustion engines to increase power output. In this context, it is often referred to as "nitrous" or "NOS." When nitrous oxide is injected into the engine's intake, it provides additional oxygen, allowing more fuel to burn, resulting in increased engine power. However, it's important to note that this process is controlled and safe when used as intended in automotive applications. Safety Precautions: While nitrous oxide is generally considered safe when used according to manufacturer guidelines, improper handling or misuse can be hazardous. Nitrous oxide should not be exposed to open flames, sparks, or high temperatures, as it can decompose at elevated temperatures and pressure, potentially leading to the release of oxygen and nitrogen gases. In summary, nitrous oxide is not flammable by itself, but it can enhance the combustion of other materials when used in controlled and purposeful applications. When using nitrous oxide, it's essential to follow safety guidelines and avoid exposing it to conditions that could lead to its decomposition or unintended ignition. How Do I Use Nitrous Oxide Safely? Using nitrous oxide (N2O) safely is crucial to prevent accidents and health risks. Here are some general guidelines for using nitrous oxide safely: Follow Manufacturer's Instructions: Always follow the manufacturer's instructions for any equipment or cartridges containing nitrous oxide. Different devices or cartridges may have specific usage guidelines. Ventilation: Ensure that you use nitrous oxide in a well-ventilated area. Adequate ventilation helps disperse any gas leaks and prevents the buildup of nitrous oxide in confined spaces, reducing the risk of asphyxiation. Avoid Direct Inhalation: Never inhale nitrous oxide directly from cartridges, whipped cream dispensers, or any other source. Inhaling nitrous oxide for recreational purposes can be dangerous and is not recommended. Protective Gear: When handling nitrous oxide cartridges or equipment, especially if they contain liquid nitrous oxide, wear appropriate protective gear, such as gloves and safety glasses, to prevent frostbite or cold burns. Store Safely: Store nitrous oxide cartridges and equipment in a cool, dry place away from direct sunlight and heat sources. Keep them out of the reach of children and unauthorized individuals. No Smoking: Avoid smoking or open flames near nitrous oxide, while nitrous oxide is not flammable, it will support combustion to the same extent as oxygen. Training and Education: Ensure that individuals using nitrous oxide equipment are trained in its safe handling and usage. Leak Detection: Regularly check for leaks in nitrous oxide equipment and connections. Use a leak detection solution (soapy water) to identify leaks by observing bubbles at the connections. Proper Disposal: Dispose of used nitrous oxide cartridges and equipment according to local regulations and guidelines. Do not puncture or incinerate cartridges. Emergency Preparedness: Be prepared for emergencies by having safety equipment, such as fire extinguishers and first-aid kits, readily available in areas where nitrous oxide is used or stored. Follow Legal Regulations: Abide by local laws and regulations regarding the sale, purchase, and use of nitrous oxide. In some areas, nitrous oxide may be subject to restrictions due to its potential for misuse. Always exercise caution and prioritize safety when using nitrous oxide, whether it's for culinary, automotive, medical, or other legitimate purposes. If you have specific concerns or questions about the safe use of nitrous oxide in a particular context, consult with experts or regulatory authorities in your area. Chemical Formula: N2O Molecular Weight: 44.013 g/mol CAS Registry Number: 10024-97-2 Appearance Colorless Odor: Characteristic Density 0.115 lb/ft3 Boiling Point: -88.5C (-127.3F) Solubility in water: Completely Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H270, H280, H281, H336 GHS Precautionary Statements P220, P244, P261, P271, P282, P304+P340, P319, P336+P317, P370+P376, P403, P403+P233, P405, P410+P403, P501 UN Identification Number: 1070 Proper Shipping Name: Nitrous Oxide Transport Hazard Class: 2.2, 5.1 Packing Group: None DOT Placard: Nitrous Oxide Safety Data Sheet (SDS)

$21.82 - $130.92

7 Gallon Aluminum - POT ONLY

7 Gallon Aluminum - POT ONLY This is a replacement part for the following Vacuum Chambers: Best Value Vacs 7 Gallon Aluminum Vacuum and Degassing Chamber Dimensions: 8" Tall x 16" Diameter Material: 3004 Aluminum

$108.00

7 Gallon Aluminum Vacuum Chamber Digital Heating Jacket

7 Gallon Aluminum Vacuum Chamber Digital Heating Jacket A vacuum chamber heating jacket provides the user the ability to evenly heat the chamber around the circumference while being very stable and when combined with a heating pad it covers most of the vessel distributing heat on what is being degassed in the vessel. Key Features: Velcro Connections on each end. Digital PID Temperature Controller for accurate and stable control. Made of heat resistant silicone. Specifications: Min Temp: Ambient +5F Max Set Temp: 160F Ultimate Max Temp: 248F Voltage: 110VAC Only Precision: 1 degree F increments. Stability: +/- 0.2 F Dimensions: Approx. 7"W x 53.9"L Instructions Included Relay Lifespan 10million Cycles Reprogrammable: Yes This product comes with the Digital Heating Jacket ONLY, does not include the chamber.

$195.00

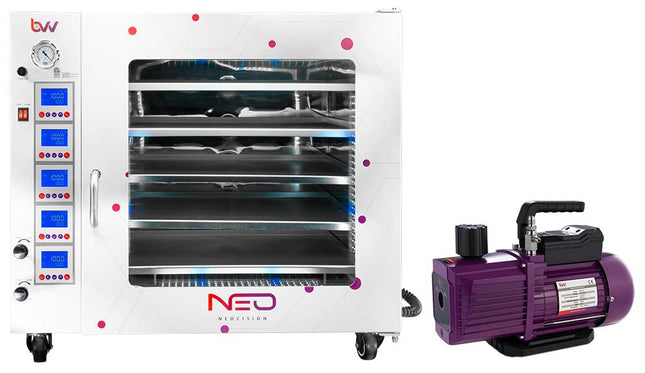

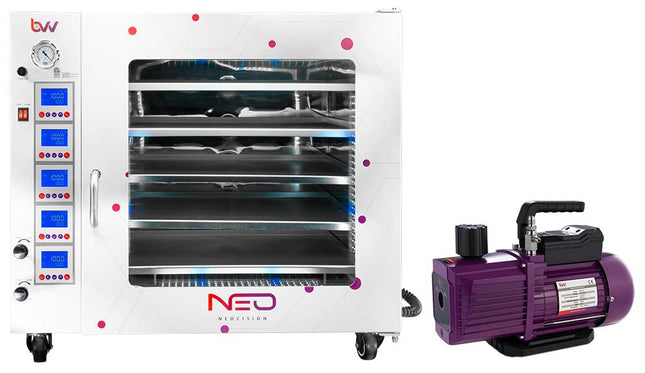

7.5CF BVV™ Neocision Lab Certified Vacuum Oven and and V9D 9CFM Two Stage Vacuum Pump kit

7.5CF BVV™ Neocision Lab Certified Vacuum Oven and V9D 9CFM Two Stage Vacuum Pump Kit Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! INTRODUCTION Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. PERFORMANCE CAPABILITIES At Best Value Vacs, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Uniformity: within 4% of the temperature setpoint. Heat-Up Time: 20 minutes. Ultimate Vacuum: <500 µmHg / mTorr / micron Time to Vacuum: 10 minutes to 29"Hg Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. SPECIFICATIONS Electrical Voltage 120V Frequency 60HZ Power 1960W Current 20A Plug IEC C13 (unit ships with detachable NEMA 5-15p cable) Internal Chamber Heating Individual Direct-Heat shelves Temperature Range RT+18°-212°F Chamber Material Stainless Stee Dimensions (LxWxH) 22" x 23.25" x 25.25" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 5 Heated Shelves Shelf Dimensions (LxW) 21.5" x 21.5" Shelf Capacity 462 in2 Total Shelf Capacity 2311 in2 / 16.1 ft2 Door Seal Silicone on Tempered Glass Window Dimensions (LxH) 20.25" x 23.75" Lights 4 strips of LEDs provide clear, bright view of interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 35" x 33" x 34.5" Weight 430 lbs Support Locking Casters Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connection Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose and adjusting wrenches. User Manual Included Warranty 3 year oven warranty Vacuum Pump Best Value Vacs VE280 9CFM Two Stage Vacuum Pump CAPACITY AND THROUGHPUT PLANNING Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via UPS Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise UPS freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$8,400.00

8 Ton 304SS Puck Press

8 Ton 304SS Puck Press This BVV™ 8 Ton 304SS Puck Press allows users to compress material into an easily manageable puck. Specifications: 304 Stainless Steel Components (Excludes Jack) External Dimensions - 7-1/8" x 7-1/8" x 14" Internal Puck Mold Diameter - 3.75" Mold Height - 3-1/4" Weight - 34LBS

$350.00

8" Hemispherical End Cap with Coil

8" Hemispherical End Cap with Coil This 8" Hemispherical End Cap with Coil comes standard with our 150L Conical Reactor. Complete with 2X 1/2" NPT accessory ports, 2X 1/4" NPT accessory ports, 2X 1/2" NPT ports for the coil, and a single 1.5" tri-clamp top port. This versatile part is perfect for those looking to add extra surface area to their heating or cooling application. From the 8" tri-clamp to the bottom of the coil measures 34".

$450.00$315.00

8" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves

8" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 8" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with 1/4" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have (3) 1.5" Tri-Clamp ports with the middle 1.5" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" 37° JIC Tri-Clamp Size(s) (3) 1.5" Ports x x 8" Tri-Clamp Nitrogen Tested Yes

$325.00

8" Tri-Clamp Dewaxer Column

8" Tri-Clamp/ Tri Clover Dewaxing Columns This is a 8" Tri-Clamp BVV™ Tri-Clamp Dewaxing Spool. It is intended to have dry ice put into the sleeve to chill the material inside the column. **Note: When selecting a Pipe Hanger choose the size that correlates to the Sleeve OD NOT Spool OD Sizes Available: 8" x 36" Tri-clamp Dewaxer Column 8" x 48" Tri-clamp Dewaxer Column Specifications: Tri-Clamp Size 8" Material 304 Stainless Steel Standard 3A High Polish Sleeve OD 10.000" Spool ID 7.782" Spool OD 8.000" Flange OD 8.570" Bead Center 8.150" Drain Port 1/4"-18 FNPT (Drain Plug Included) OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 8" Tri-Clamp Dewaxer Columns - Drawing

$450.00 - $525.00

8" Tri-Clamp Spools

8" Tri-Clamp/ Tri Clover Spools Sizes Available: 8" x 12" Tri-Clamp Spool 8" x 24" Tri-Clamp Spool Tri-Clamp Size 8" Material 304 Stainless Steel Standard 3A High Polish Spool OD 8" Spool ID 7.782" Flange OD 8.57" Bead Center 8.15" OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 8" Tri-Clamp Spools - Drawing Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$129.00 - $318.00

8" x 8" Platinum Cured Silicone Vac Pad

8" x 8" Platinum Cured Silicone Pad

$5.00

8.25" Diameter GLASS LID

BVV™ 8.25" Diameter Glass LID Our patented gasket #9475627 Disclaimer: LID ONLY - does not include hardware unless selected through drop-downs or ordered separately. Hardware - includes Valve Manifold, Gauge, and Gasket. (Does not include 50-micron air filter or vacuum hose.) This is a Replacement Lid for the following Vacuum Chambers: Best Value Vacs 1 Gallon Tall Stainless Steel Vacuum Chamber Best Value Vacs 1.5 Gallon Tall Stainless Steel Vacuum Chamber Best Value Vacs 1.75 Quart Pyrex Vacuum and Degassing Chamber Best Value Vacs 2 Quart Flat Stainless Steel Vacuum and Degassing Chamber

$35.00 - $60.00

8CF CSA Certified Lab Grade Forced Air Convection Drying Oven – 16 Shelves Standard

8CF BVV™ CSA Certified Lab Grade Forced Air Convection Drying Oven – 16 Shelves Standard DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! The 8CF CSA Certified Laboratory Grade Drying Oven is our newest addition to the Best Value Vacs line of Laboratory-grade processing equipment. Offering a leading ±1⁰F temperature stability, over 98% heat uniformity, and no overshoot, technicians can now process material with ease and confidence. We regulate heat using a modern, high-precision PID controller with a large, bright display and touchscreen buttons. The interior is a high-polish stainless steel, presenting a clean and easy to maintain surface. Our drying oven comes fully-stocked as a standard- offering ten spacious, wire frame shelves you can easily insert, remove, and clean. With a clear, no-overshoot advantage, there’s simply no better choice for your precision processing needs. Key Oven Features: Long-lifetime convection fan gently circulates air for optimal heat distribution Stainless steel interior for a sanitary, easy-to-clean look 16 spacious, wire racks are easy to insert and remove Level-adjusting caster wheels for mobility and stability Overload circuit breaker for electrical protection Large, tough, stainless steel door handle feels solid and works great Temperature overshoot protection enabled Digital timer allows users precise control of heating cycle Simple and powerful user interface presented in a large, bright, clear display Specifications Electrical 220 VAC / 60Hz / 2450W / USA Plug Internal Chamber Material: Polished Stainless Steel Dimensions (LxWxH): 23.62" x 19.69" x 29.53" External Dimensions 35" x 25" x 37" Temperature Control LED PID Controller Temperature Range: RT+18F - 572F Temperature Stability: +/- 1F Temp Resolution: +/-0.1F Heat Uniformity: 98% Shelves Up to 16 Removeable Shelves Door Dual Layer Observation Window made from Tempered Glass Replaceable Gasket Material: Silicone Compliance CSA Certified *ISO 9001:2005 Note: This item is a freight ship item and will ship Via Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise freight Cannot Contact you for a delivery setup window.

$3,200.00

9" Vacuum Chamber Digital Heat Pad

9" Vacuum Chamber Digital Heat Pad Please Read Before You Buy! Chamber NOT Included, Sold Separately. Heat Pad must fit correct size of the chamber! Fits our 2, 3 and aluminum pots and 3QT & 1GL Flat Chamber This Digital Heat Pad will adhere to the bottom of a chamber vessel with a peel and stick backing. This unit will hold a temperature within a degree to the set temperature (dependent on the environment and air movement). The temperature offset must be found to set the controller accurately. (See ‘Operation’ instructions in the operation manual) Included with this Digital Heat Pad: Instructions on how to operate and set parameters. Simple standoff bumpers (provide thermal separation between the vessel and the work surface) Thermal tape (best method to check and verify temperature) Specs: UL Listed Fahrenheit Digital Controller. Min Temp: Ambient + 5 Max Set Temp: 160F Ultimate Max Temp: 248F Voltage: 110VAC Only Power Consumption: 220-watt Digital Control: Increments of 1 Degree. Accuracy: +/- 0.2 Degrees Units: Degrees Fahrenheit Instructions: Fully included Relay Lifespan: Approx. 10 million cycles User can reprogram: Yes

$90.00

90-270G Apollo Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors Closed Loop Reclamation Extraction System (System comes with 1 yr. limited warranty) Please Read Optional Upgrades Section for Clarification on System Upgrades The scalable closed loop hydrocarbon extraction system performs botanical extraction within a sealed, vacuumed system. Utilizing a top-fill input, solvent washes through the material column, collecting oils as it passes over the material. The oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configurations: Explorer: Our standard, most economical setup, perfect for the entry-level extractor on a budget. It comes with a welded bottom base and a standard LP tank. This model has minimal features to keep costs low while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Coming with a sleeved spool, this model allows users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow the solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is the premium version of the Professional. It features all American-made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, and all high-pressure clamps. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base BVV 316SS Full Bore Valves Dewaxer Ball Valve Splatter Platter Base SSP Valves Dewaxer AVCO Ball Valve HP Clamps Splatter Platter Base Kit Includes: 6" x 6" Collection Base 1.5" Material Column (12",18",24", or 36") 6lb Recovery Cylinder 1/4" Stainless Steel Braided PTFE hoses Buna-N Gaskets Standard Valves *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$600.00 - $1,630.00

90G XL Mini Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well ventilated areas. Check with your local fire marshal for guidance when operating indoors Closed Loop Reclamation Extraction System (Comes with 1 yr. Limited warranty) 90G XL Mini Top Fill Closed Loop Extractor (System comes with 1 yr. limited warranty) The MiniXL Extractor is an excellent choice for small personal runs or test runs of material and comes in a small tabletop design that is easy to use. Mini CLS / Mini XL Upgrades: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and stainless reclaim container. This model has minimal features to keep cost low while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Coming with a sleeved spool, this model allows users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Explorer Professional Standard Valves Welded Bottom Base Standard Valves Dewaxer Ball Valve Splatter Platter Base Specifications: 1.5"x 12" 304 Stainless Steel Material Tube 90g 304 Stainless Steel Heavy Duty Miniature Ball Valves System Rated to 100PSI Multiple port connections for 1/4" 316 Stainless SAE 37 Degree 304 Stainless Steel Base Container 4" diameter by 8" tall Tri-Clamps at all interfaces make for a high pressure, easy clean unit. Buna-N Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 16" Overall Height x 4" Diameter Weight: 18 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Designed to run two cans of solvent and reclaim them (420ml) 1135ml Max FILL!! Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior Automatically Includes: High-Pressure PTFE Braided Stainless Steel Hose Can Tap Tool 6LB Mastercool Solvent Recovery Tank *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$410.00 - $550.00

90° Degree Elbow Tri-Clamp Bend

90° Degree Elbow Tri-Clamp Bend Specifications: 304 Grade Stainless Steel w/ High Polish interior Fits 1.5", 2",4" or 6" Tri-clamp / Tri Clover Unique 90 Degree Bend Disclaimer:All Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractor DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested.User assumes all responsibility and risks of the system

$25.00 - $205.00

Acetone 99%