BVV

4" Industrial Plant Material Grinder (Compare to Custom Cones)

BVV 4" Industrial Plant Material Grinder The 4" grinder from BVV will grind your dried plant material into a consistent, manageable size. The grinder is easy to use and can power through over 1.5 lbs per minute or as fast as you can feed it! It can grind dense flower or leafy trim , as long as it is pre dried. This machine will help you keep the trichomes and terpenes in the plant where they should be due to the low operating temperature, in comparison to a common blender or food processor. This Grinder is made of food grade aluminum and stainless steel, and can be broken down for cleaning in a matter of seconds. Very few tools are needed to assemble and operate so you can keep your focus on moving material through this step in your production line. Included with the grinder are two stainless steel screens; 3.8mm small 6mm large Specifications Model Number G400 Voltage 115V / 60Hz Wattage 850w External Dimensions 16" x 9" x 20" Weight 42lbs

$1,999.00

4" Stainless Steel Buchner Funnel

4 Inch Stainless Steel Buchner Funnel 4” Buchner Funnel Kit: This buchner funnel kit adapts to any vessel with a 24/40 joint. The included adapter makes it possible to pull vacuum and use large vessels as a collection. Max internal volume of the buchner funnel is 0.82L, but can be adapted with a larger spool for higher capacity. This kit features: 4” x 4” 304SS spool with a capacity of 0.82L 4” Tri-Clamp Single Hinge Clamp 4”x1.5” 304SS Hemispherical Reducer 1.5” Tri-Clamp Double Hinged Clamp 4” 5 Micron 304SS Sintered Disc Filter 4” 304SS Filter Plate V2 1.5”x24/40 304SS Adapter 24/40 Glass Inlet Straight Adapter with hose connection Recommended items: 110MM sized filter paper, 24/40 jointed glass conical flask. For additional information or questions regarding this kit contact our customer support line.

$370.00

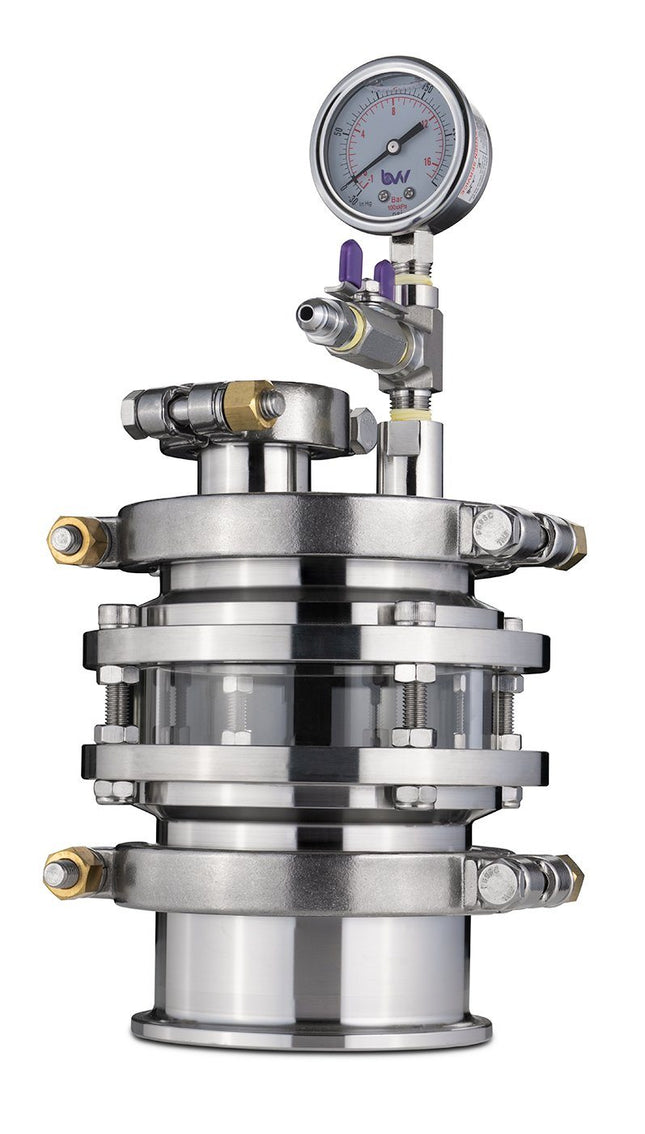

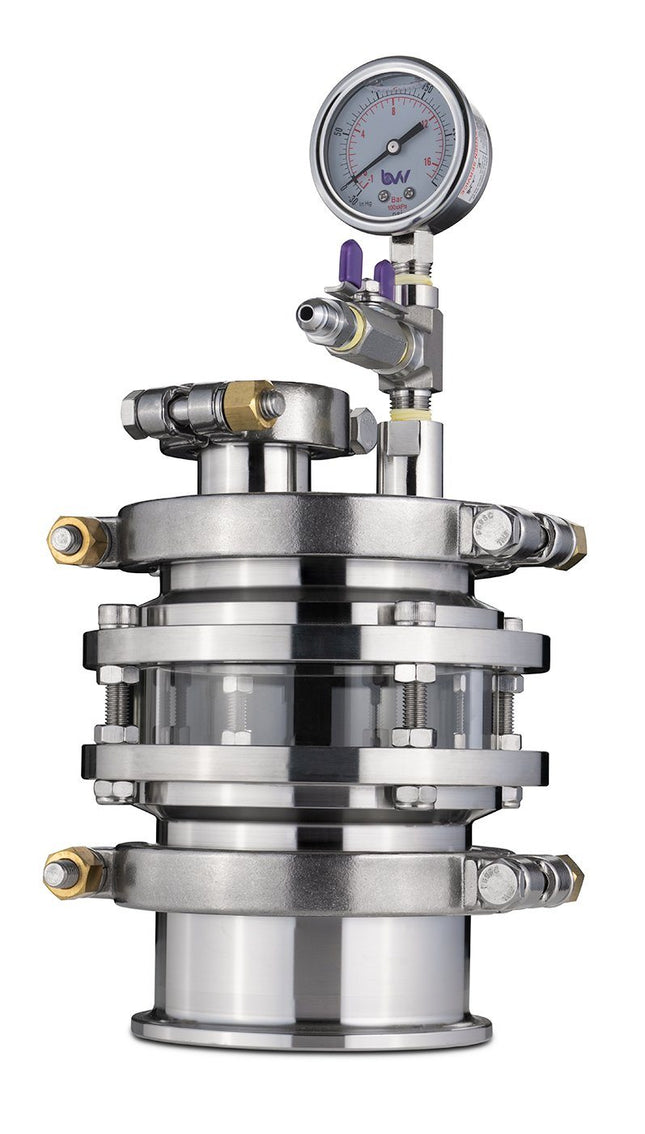

4" Stainless Steel Diamond Miner

4" Stainless Steel Diamond Miner The 4" Diamond miner eliminates the need for glass jars and adds safety to your degassing procedure. It also gives you multiple viewing angles to see your diamond growth. Remove the 4" x 2" splatter platter to easily remove diamonds from your sauce mix. A glycerin filled compound gauge gives you easy readout of pressure inside the vessel. Specifications: 304 grade stainless steel 500ml - 750ml Optimal Capacity 1.5" sight glass 4" sight glass 4" splatter platter High pressure clamps 316 Stainless Steel Valve with 1/4" Flare Connection Temp Range -40 to 230C MAWP: 100 psi

$450.00 - $710.00

4" Tri-Clamp Dewaxer Columns

4" Tri-Clamp/ Tri Clover Dewaxing Columns This is a 4" Tri-Clamp BVV™ Tri-Clamp Dewaxing Spool. It is intended to have dry ice put into the sleeve to chill the material inside the column. **Note: When selecting a Pipe Hanger choose the size that correlates to the Sleeve OD NOT Spool OD Sizes Available: 4" x 8" Tri-clamp Dewaxer Column 4" x 24" Tri-clamp Dewaxer Column 4" x 36" Tri-clamp Dewaxer Column Specifications: Tri-Clamp Size 4" Material 304 Stainless Steel Standard 3A High Polish Sleeve OD 6.000" Spool ID 3.834" Spool OD 4.000" Flange OD 4.682" Bead Center 4.344" Drain Port 1/4"-18 FNPT (Drain Plug Included) OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 4" Tri-Clamp Dewaxer Columns - Drawing

$105.00 - $260.00

4" Tri-Clamp Spools

4" Tri-Clamp/ Tri Clover Spools Sizes Available: 4" x 2" Tri-Clamp Spool 4" x 4" Tri-Clamp Spool 4" x 8" Tri-Clamp Spool 4" x 12" Tri-Clamp Spool 4" x 18" Tri-Clamp Spool 4" x 24" Tri-Clamp Spool 4" x 36" Tri-Clamp Spool 4" x 48" Tri-Clamp Spool Specifications Tri-Clamp Size 4" Material 304 Stainless Steel Standard 3A High Polish Spool OD 4" Spool ID 3.834" Flange OD 4.682" Bead Center 4.344" OD = Outer Dimension ID = Inner DimensionDisclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 4" Tri-Clamp Spools - Drawing Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butae by Size Pounds of Butne mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$25.00 - $135.00

4" Tri-Clamp U-Bend with 2" Side Port

This 4" Tri-Clamp U-Bend is 14" in length from center to center of the 4" ports. There is a 2" port in the middle that is useful to mount sensors, gauges, or sight glasses. The material of this part is 304 Stainless steel.

$275.00

4" Tri-Clamp x (2) 1/4" FNPT

4" Tri-Clamp x (2) 1/4" FNPT These End Caps come with Two 1/4"-18 FNPT Threaded connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid. Specification Material: 304 Stainless Steel Connection Types: Tri-Clamp 1/4" - 18 FNPT Standard: 3A Sizes Available: 4" BVV™ 4" Tri-Clamp x (2) 1/4" FNPT - Drawing BVV™ 4" Tri-Clamp x (2) 1/4" FNPT - End Cap Chart

$42.00

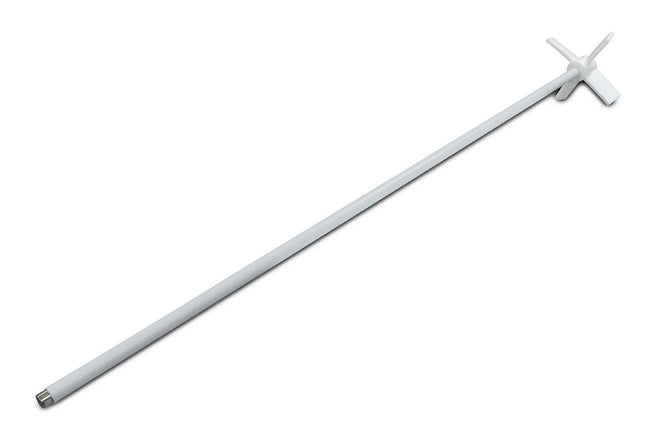

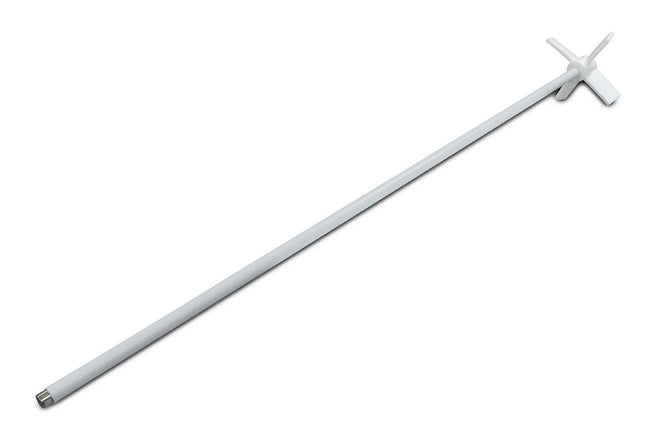

4" Tri-Clamp x (2) 1/4" FNPT w/ Showerhead

4" Tri-Clamp/ Tri Cover x (2) 1/4" FNPT w/ Showerhead These End Caps come with Two 1/4"-18 FNPT Threaded connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid. Shower Head End Caps help disperse solvent input into a system which creates better material saturation when flooding a material column. This helps to prevent channeling, ensuring all the material is saturated. Specifications Material: 304 Stainless Steel Connection Type: Tri-Clamp 1/4" - 18 FNPT Standard: 3A Sizes Available: 4"

$40.00

4" Vacuum Chamber Digital Heat Pad

4" Vacuum Chamber Digital Heat Pad Please Read Before You Buy! Chamber NOT Included, Sold Separately. Heat Pad must fit correct size of the chamber! Fits a 2QT chamber, and a Mini Extractor Base This Digital Heat Pad will adhere to the bottom of a chamber vessel with a peel and stick backing. This unit will hold a temperature within a degree to the set temperature (dependent on the environment and air movement). The temperature offset must be found to set the controller accurately. (See ‘Operation’ instructions in the operation manual) Included with this Digital Heat Pad: Instructions on how to operate and set parameters. Simple standoff bumpers (provide thermal separation between the vessel and the work surface) Thermal tape (best method to check and verify temperature) Specs: UL Listed Fahrenheit Digital Controller. Min Temp: Ambient + 5 Max Set Temp: 160°F Ultimate Max Temp: 248°F Voltage: 110VAC Only Power Consumption: 220-watt Digital Control: Increments of 1 Degree. Accuracy: +/- 0.2 Degrees Units: Degrees Fahrenheit Instructions: Fully included Relay Lifespan: Approx. 10 million cycles User can reprogram: Yes

$75.00

4" x 1.5" x1/4" FNPT Tri-Clamp Endcap

4" x 1.5" x1/4" FNPT Tri-Clamp Tri Clover Endcap This End Caps come with a 1/4"-18 FNPT Threaded connection and 1.5" Tri-Clamp ferrule welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid and the 1.5" Tri-Clamp Connection. These 2 connections are welded on a 4" Tri-Clamp End Cap. Specification Material: 304 Stainless Steel Connection Types: 1.5" Tri-Clamp - 3" Tube Extension Below Lid on Center Tri-Clamp Port 4" Tri-Clamp 1/4" - 18 FNPT Standard: 3A BVV™ 4" x 1.5" x1/4" FNPT Tri-Clamp Endcap - Drawing BVV™ 4" x 1.5" x1/4" FNPT Tri-Clamp Endcap - End Cap Chart

$100.00

4" x 24" Dry Ice Heat Exchanger

This 304 stainless steel heat exchanger is used as a condenser for your extractor setup. It has a sleeve around the heat exchanging tubes and a wide opening at the top to allow users to pour in dry ice to super chill the exchanger. For best results, use dry ice mixed with ethanol to get the most possible contact across the surface area of the tubes. The bottom of the sleeve has a 1/4" NPT drain plug that can be removed to drain ethanol. Connection flanges on top and bottom are 4" Tri-Clamp. We offer a pre built stand alone version that comes with hemispherical caps and JIC connections, but we will be happy to help you configure it any way that you want!

$1,250.00

4.8CF CSA Certified Lab Grade Forced Air Convection Drying Oven – 12 Shelves Standard

4.8CF BVV™ CSA Certified Lab Grade Forced Air Convection Drying Oven – 12 Shelves Standard DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! The 4.8CF CSA Certified Laboratory Grade Drying Oven is our newest addition to the Best Value Vacs line of Laboratory-grade processing equipment. Offering a leading ±1⁰F temperature stability, over 98% heat uniformity, and no overshoot, technicians can now process material with ease and confidence. We regulate heat using a modern, high-precision PID controller with a large, bright display and touchscreen buttons. The interior is a high-polish stainless steel, presenting a clean and easy to maintain surface. Our drying oven comes fully-stocked as a standard- offering ten spacious, wire frame shelves you can easily insert, remove, and clean. With a clear, no-overshoot advantage, there’s simply no better choice for your precision processing needs. Key Oven Features: Long-lifetime convection fan gently circulates air for optimal heat distribution Stainless steel interior for a sanitary, easy-to-clean look 12 spacious, wire racks are easy to insert and remove Level-adjusting caster wheels for mobility and stability Overload circuit breaker for electrical protection Large, tough, stainless steel door handle feels solid and works great Temperature overshoot protection enabled Digital timer allows users precise control of heating cycle Simple and powerful user interface presented in a large, bright, clear display Specifications Electrical 120 VAC / 60Hz / 2050W / USA Plug Internal Chamber Material: Polished Stainless Steel Dimensions (LxWxH): 21.65" x 17.72" x 21.65" Temperature Control LED PID Controller Temperature Range: RT+18F - 572F Temperature Stability: +/- 1F Temp Resolution: +/-0.1F Heat Uniformity: 98% Shelves Up to 12 Removeable Shelves Door Dual Layer Observation Window made from Tempered Glass Replaceable Gasket Material: Silicone Weight & Dimensions Outside Dimensions (LxWxH): 33.07" x 22.83" x 28.74" Weight: 149.91lbs Compliance CSA Certified *ISO 9001:2005 Note: This item is a freight ship item and will ship Via UPS Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise UPS freight Cannot Contact you for a delivery setup window.

$2,550.00

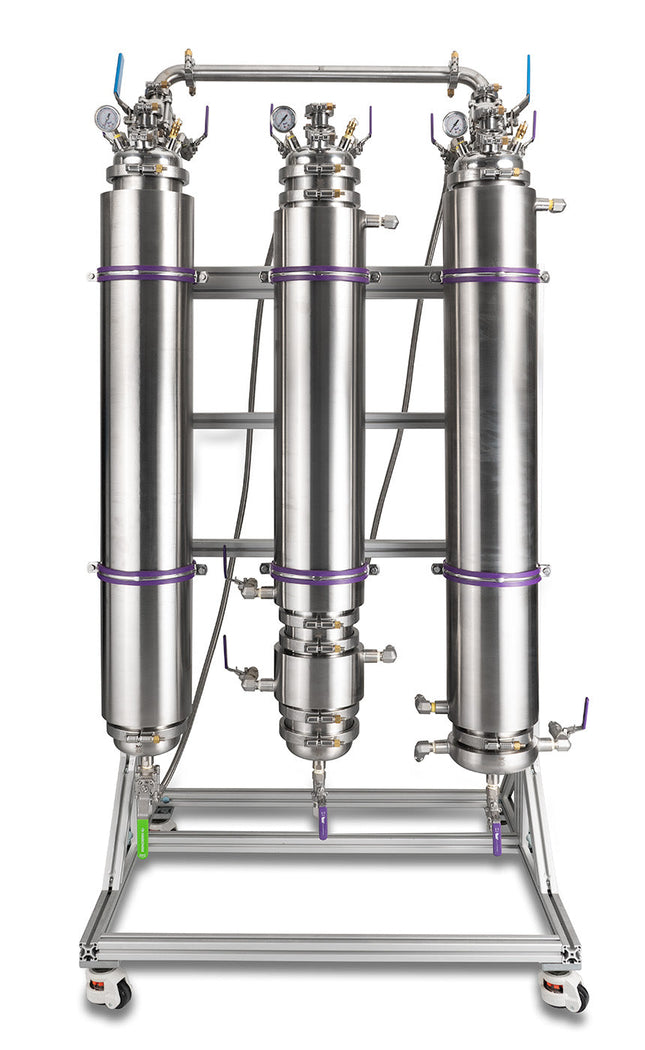

45G Mini Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors Closed Loop Reclamation Extraction System (Comes with 1 yr. Limited warranty) 45G Mini Top Fill Closed Loop Extractor (System comes with 1 yr. limited warranty) What’s a 45G Mini Top Fill Closed Loop Extractor? 45G Mini Top Fill Closed Loop Extractor is an excellent extraction system for small personal test runs. Since it’s a smaller version of our standard top-fill closed loop extractor, it’s great for beginners while still maintaining all the bells and whistles. Our extractor is even the perfect size for a tabletop! How Does the 45G Mini Top Fill Closed Loop Extractor Work? The top-fill closed loop extractor is the safest way to do hydrocarbon extraction. First, solvent washes through the material column and collects oils as it passes over the material. Then, the oil-bearing solvent is collected in the collection base. Once collected, the solvent in this passive unit is distilled and recovered using temperature manipulation. This is what leaves oils behind in the collection base. What’s Included in the 45G Mini Top Fill Closed Loop Extractor? High-Pressure PTFE Braided Stainless Steel Hose Standard Pressure Tri-Clamps Full set of BUNA-N gaskets Includes 100 Mesh (150 Micron) gasket for the material tube Can Tap Tool Instruction Manual 1 Year Limited Warranty and Customer Service 45G Mini Top Fill Closed Loop Extractor System Specifications 1.5"x 6" 304 Stainless Steel Material Tube 304 Stainless Steel Heavy Duty Miniature Ball Valves System Rated to 100PSI Multiple port connections for any 316 Stainless SAE 37 Degree 304 Stainless Steel Base Container 4" diameter by 4" tall Tri-Clamps at all interfaces for high pressure, easy-clean unit High-Quality BUNA-N Gaskets designed for oil processing Operating Temperature Range: -40°F to 160°F Ultimate Vacuum: as low as 10 Microns Designed to run a single can of solvent and reclaim it (420ml) 540 ml max FILL! Construction: All major components made of 304 Stainless Steel Max Vacuum -29.9inHg High Polish Interior Mini CLS / Mini XL Upgrades Explorer Our most standard and economical setup. It’s perfect for entry-level extractors on a budget. It comes with a welded bottom base and stainless reclaim container. This model has minimal features to keep costs low while providing the necessary equipment to get the job done. Includes: Standard Valves Welded Bottom Base Professional This model features upgrades for easier extraction. An inline ball valve allows the solvent to be suspended in the material column and closes the collection base during recovery. The removable bottom to the collection base makes extract removal simple. Includes: Standard Valves Ball Valve Splatter Platter Base Notes and Disclaimer(s): Please note: The solvent Butane isn’t included with any of our systems unless ordered separately or by using the dropdown menu. Orders containing butane won’t ship expedited. Also, column capacity may vary. Capacity is calculated using the industry standard of 4.2g/in3 as the upper limit. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend tightly packing coarse ground material. Shop all Closed-Loop Extractors Disclaimers: This unit is intended for legal purposes only while following local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. Explorer Professional Standard Valves Welded Bottom Base Standard Valves Ball Valve Splatter Platter Base System Specifications: 1.5"x 6" 304 Stainless Steel Material Tube 304 Stainless Steel Heavy Duty Miniature Ball Valves System Rated to 100PSI Multiple port connections for _" 316 Stainless SAE 37 Degree 304 Stainless Steel Base Container 4" diameter by 4" tall Tri-Clamps at all interfaces make for a high pressure, easy-clean unit. High-Quality BUNA-N Gaskets are designed for Oil Processing Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Designed to run a single can of solvent and reclaim it (350ml) Max FILL!! Construction: All major components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior What's Included: High-Pressure PTFE Braided Stainless Steel HoseStandard Pressure Tri-Clamps Full set of BUNA-N gaskets including the 100 Mesh(150 Micron) gasket for the material tube is included Can Tap Tool Instruction Manual 1 Year Limited Warranty and Customer Service *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$325.00 - $420.00

45L Centrifuge Bags

This nylon bag is designed to fit in our BVV brand centrifuges to contain material and be easily swappable after runs to speed up processing times. These bags come with 2 zippers and come in 1, 10, 50, 100, and 200 micron filtration levels. For use with 45L Centrifuges Appx. Size : 17.5" Diameter x 11.75" Height Specifications SKU Appx. Diameter In. Appx. Height in. CFB-45L-XXX 17.5" 11.75" CFB-160L-XXX 32.25" 13" CFB-280L-XXX 39.25" 14" CFB-475L-XXX 47.25" 16.75"

$115.00 - $299.00

475L Centrifuge Bags

This nylon bag is designed to fit in our BVV brand centrifuges to contain material and be easily swappable after runs to speed up processing times. These bags come with 2 zippers and come in 1, 10, 50, 100, and 200 micron filtration levels. For use with 475L Centrifuges Appx. Size : 47.25" Diameter x 16.75" Height Specifications SKU Appx. Diameter In. Appx. Height in. CFB-45L-XXX 17.5" 11.75" CFB-160L-XXX 32.25" 13" CFB-280L-XXX 39.25" 14" CFB-475L-XXX 47.25" 16.75"

$245.00 - $499.00

5 Gallon Aluminum - POT ONLY

5 Gallon Aluminum - POT ONLY This is a replacement part for the following Vacuum Chambers: Best Value Vacs 5 Gallon Aluminum Vacuum and Degassing Chamber SVac 5 Gallon Aluminum Vacuum Chamber Dimensions: 10" Tall x 12" Diameter Material: 3004 Aluminum

$60.00

5 Gallon Aluminum SIDEMOUNT - POT ONLY

5 Gallon Aluminum SIDEMOUNT - POT ONLY ***Note: 'with Hardware' Option only includes the side-mount manifold with gauge pre-installed. (Does Not Include Lid or Gasket) This is a replacement part for the following Vacuum Chambers: Best Value Vacs 5 Gallon Aluminum Side Mount Vacuum and Degassing Chamber Glass Vac 5 Gallon Aluminum Vacuum Chamber Dimensions: 10" Tall x 12" Diameter Hole Size: 21/64 Material: 3004 Aluminum

$64.00 - $84.00

5 Gallon Refinement Filter

The BVV™ 5 Gallon Refinement Filter is a stainless steel filtration system that provides large scale, high flow filtering, with greatly improved functionality compared to a traditional Buchner filter. Utilizing a collection base for vacuum assistance and storage of material, the Refinement Filter allows for benchtop filtration with a longer lifespan and ease of use. Key Features: Stainless steel design for greater thermal conductivity and improved lifespan Easy to clean and disassemble with Tri-Clamp stainless steel parts Small tabletop footprint with wide mouth design Secondary collection vessel for vacuum and storage of material Liquid dip tube for direct injection into rotary evaporator after filling Key Specifications: Large 6" Diameter x 12" Long Dewaxing Column 20 Liter Collection Base 5 micron Sintered Stainless Steel Filter Disc 100 Pack of 6" Ashless Filter Paper (BIO-1-180) Dedicated 3/8" Vacuum Valve Dedicated 3/8" Dip Tube Valve Silicone gaskets with high alcohol resistance 3/8" Stainless steel hose barb connections Polycarbonate sights for easy viewing 2" Tri-Clamp Short Sight Glass for Flow Viewing Operation Instructions: Before beginning filtration, place refinement filter in freezer for best thermal conductivity Secure ashless filter paper with filter plate ring Place collection base on floor and connect tubing from refinement filter to to a vacuum pump Attach vacuum system to the dedicated vacuum valve Begin to pour solution into filter Close dedicated dip tube valve and start vacuum Once solution has been completely filtered, stop vacuum system and disconnect from dedicated vacuum valve Connect dedicated dip tube valve to injection valve on rotovap Begin rotovap procedure Open dedicated dip tube valve and begin injecting filtered solution into rotovap

$1,500.00

5 Gallon Resin Trap Vacuum Chamber

Resin Trap Vacuum Chamber Designed, built, and 100% tested in Chicago, Illinois, the Resin Trap Vacuum Chamber is the perfect application for a successful, high-quality end product. With its unique, patent pending gasket design (Utility Patent #14/533,548), this shatter chamber can easily withstand 10,000 uses with proper care and maintenance. The gasket itself is reversible, doubling the system's life by allowing customers to instantly take it off and flip it over. No adhesives necessary—this is a feature that most other vacuum chambers do not offer. The maximum allowed temperature of this chamber is 160f. The individual components of this chamber are rated at higher temperatures, however, as a vacuum vessel, we limit maximum operational temperature to 160f. Every chamber is tested prior to shipping to lose no more than 2.5 in Hg/24hrs. Key Features: Comes with 2 year limited warranty Resin traps come complete with glycerin-filled vacuum gauge, fittings for use with 1/4" vacuum tubing, nickel plated brass ball valve and instruction manual. Capture excess resin and protect your pump! Unique Catch Port Design: An additional hose can be installed at the port inside the tank to facilitate accurate collection of resin. 5 Feet Reinforced Vacuum Hosing to Connect Directly to the Vacuum Pump 1/4" SAE port. Measuring range of vacuum gauge:0-29.25inHg Silicone gasket to be used over 10,000 times without deterioration. This Kit Includes: (1) 5 Gallon Aluminum Chamber (1) Industrial grade silicone gasket Gasket can withstand 390F max temp. 60A durometer density (1) Glycerin filled vacuum gauge (must be regulated upon arrival) Max vacuum -29Hg (+/-.5Hg) at sea level (1) Leak free nickel plated 1/4" Hvac Flare Valve (1) ¼” Barbed Connection (1) 5' Purple BVV™ Hvac Hose (1) 5' Clear Vacuum Tubing Internal Dimensions: 10" Tall x 12" Diameter Compatibility Explanation BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. Pump Facts: We recommend the oil is changed every 50-75 of operating hours. CFM is a measure of cubic feet per minute. Single stage pumps reach a max vacuum of 50-75 microns (0=complete vacuum). Dual/Two stage pumps reach a max vacuum of 10-15 microns (0=complete vacuum). For shipping info including Import/Export details visit our Shipping page.

$165.00

5 Gallon Vacuum Chamber Digital Heating Jacket

5 Gallon Vacuum Chamber Digital Heating Jacket A vacuum chamber heating jacket provides the user the ability to evenly heat the chamber around the circumference while being very stable and when combined with a heating pad it covers most of the vessel distributing heat on what is being degassed in the vessel. Key Features: Velcro Connections on each end. Digital PID Temperature Controller for accurate and stable control. Made of heat resistant silicone. Specifications: Min Temp: Ambient +5F Max Set Temp: 248F Ultimate Max Temp: 248F Voltage: 110VAC Only Precision: 1 degree F increments. Stability: +/- 0.2 F Dimensions: Approx. 9.8"W x 40"L Instructions Included Relay Lifespan 10million Cycles Reprogrammable: Yes This product comes with the Digital Heating Jacket ONLY, does not include the chamber.

$285.00

5 Pack of Metal Keck Clips for 24/40 Joints

5 Pack of Metal Keck Clips for 24/40 Joints 5 Pack of Metal Keck Clips for 24/40 joints. Universal clips for ground joints manufactured from high-grade stainless steel. These clips fit snugly and are not overly difficult to slide on and off.

$11.00

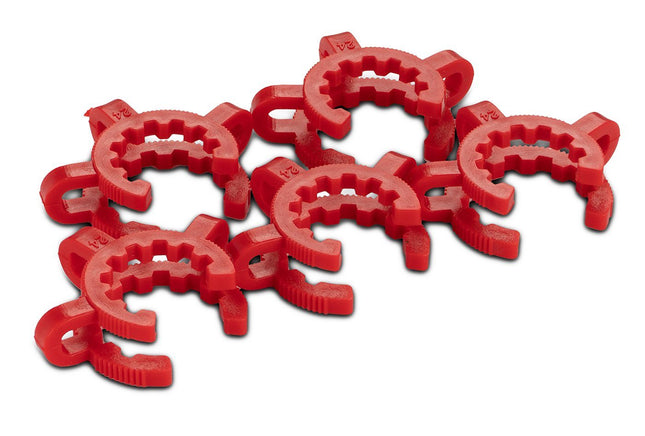

5 Pack of Plastic Keck Clips for 24/40 Joints

5 Pack of Plastic Keck Clips for 24/40 Joints 5 Pack of Plastic Keck Clips for 24/40 joints.

$12.00

5 Ton Low Temp Glycol Chiller

Discover the Cold Shot Chillers® advantage. Crafted for reliability and user-friendly operation, These portable air-cooled chillers are proudly manufactured in the USA, utilizing proven components and backed by round-the-clock support from a network of technicians in the US. Engineered for a lifetime of service, these chillers ensure precise temperature control. Robust compressors paired with a generous reservoir deliver impressive cooling capacities, keeping your operations smooth even during the hottest months. Choose Cold Shot Chillers® for a reliable, long-lasting cooling solution. Key Features: Integrated Controls: PLC controlled with self-diagnostics. WIFI/LAN/LTE connectivity for predictive maintenance through Guardian™ app. Email/text notifications for predictive maintenance milestones, technical alarms, fault codes, and alerts. Quality Construction: Copeland Scroll technology for efficiency. Stainless Steel/Copper Braze Plate for durability. External Brass Service Valves for easy maintenance. Large Copper Condensing Coil with Aluminum Fins or Micro Channel for effective cooling. Powder-Coated, Heavy-Gauge Steel Cabinet for rugged protection. Additional Specifications: Rugged Stainless Steel Centrifugal Pumps for high flow and dependability. Oversized Magnetic Contactors for longevity. Lifetime Warranty for peace of mind. Benefits: Long Life – Dependable – Economical to Operate. Compact Efficiency for space-saving installations. Easy Maintenance and Repair for user-friendly operation. Rugged Protection while allowing for easy maintenance and wash down. High Flow – Long Life – Dependable performance. Rugged Dependability with a Lifetime Warranty. Specifications: 5 tons (60,000 BTU/17.5KW) 25 Gallon Stainless Steel Reservoir Tank with Lid This Low Temp Model has a leaving fluid temperature range of 20F-70F/-6C-21C. Rated to 0°F ambient temperature* 1” MNPT Inlet and Outlet Stainless Steel 1 HP Centrifugal Pump outputs 30 GPM at 30 PSI Single Phase (230V/1P/60HZ/47.2A) and Three Phase (230V/3P/60HZ/35.1A) power available Casters Included (two swivel locking and two fixed) Large Reservoir easily filled from outside, and level indicated with sight gauge 1-Year Parts Warranty 5-Year Warranty on Compressor Welded steel powder-coated frame and full metal cabinet with copper piping connections Digital Temperature controller with Self-Diagnostic control system Rugged Protection, while still easy to maintain and Wash Down High Flow Pump, Long Life, Dependable units! Stainless Steel Plate Evaporators Vacuum brazed with Copper Dependable Copeland Welded hermetic Scroll Compressors 50.5"x38.5"x57" 500 lb UL Certified Please Note: This unit REQUIRES a qualified electrician to wire the necessary plug to the cord. *Please Note: This unit is rated for indoor use only. If you require a chiller rated for outdoor use, please contact our customer service department to request a special order. Cold Shot Chillers are available suitable for outdoor use with ambient temperature ratings as low as -20F.

$15,500.00

5.75" Glass Chamber Lid

BVV 5.75" Glass Chamber Lid This tempered soda lime glass lid is available with or without holes. Both feature 5.75" outer diameter and a thickness off 12mm or .472".

$32.00 - $52.00

5.75" Vacuum Chamber Gasket

5.75" Vacuum Chamber Gasket Our patented gasket #9475627 This Gasket fits the following Vacuum Chamber Lids: 2 Quart Resin Trap / Vacuum and Degassing Chamber Best Value Vacs 2 Quart Stainless Steel Vacuum and Degassing Chamber 1.5 Gallon (2QT Tank) Dry Ice, Liquid Nitrogen Cold Trap (INNER 2QT Containter GASKET)

$19.00

5/16 USS Flat Washer

5/16 USS Flat Washer 5/16 replacement washer for vacuum chamber bulkheads made out of metal.

$0.50

5/16-18 Grade 2 Steel Nylon Locknut - 5 Pack

5/16-18 Grade 2 Steel Nylon Locknut 5/16 - 18 Low Profile Lock Nut. This nut fits on vacuum chamber gauges and manifolds. SOLD AS A 5PACK

$2.00

50L BVV™ Double Jacketed Glass Reactor

The BVV™ Double Jacketed Glass Reactors are ideal for reaction applications involving extreme temperatures. They include an inner jacket for cooling or heating and an outer jacket for vacuum insulation. The outer jacket also alleviates moisture buildup so you can always see exactly what's happening inside the system. Jacketed Reaction vessels are used for synthetic reaction of different types of materials in a controlled temperature and vacuum environment. Reaction Vessels can be used as an all in one tool for extraction, refinement, distillation, and homogenization. Consisting of an inner vessel with either one or two jackets, a reactor uses temperature differentials created by a chiller to change it's internal environment. Reaction vessels also operate under vacuum making them ideal for any atmospheric sensitive applications. They can be made out of glass or stainless steel and range in volume from 1L to 100L+. To run a reaction vessel most efficiently, you will need a chiller capable of bringing the internal temperature of the vessel to an extreme low, a chemical resistant vacuum pump, and a cold trap to catch any vapors that might pass through the condenser during operation. BVV™ Jacketed Reaction vessels are simple, cost-effective, and durable machines that allow you to process material quickly and efficiently. BVV 20L and 50L Glass Reactor Diagram Specifications: Glass Material: GG-17 High Borosilicate Glass Internal Volume: 50L 10.5L Jacket Capacity Shelf Material: Aluminum Alloy Homogenizer Power: 110V/60Hz Homogenizer Speed: 0-400 RPM Digital Homogenizer Control Digital temperature probe readout included Double Jacket 3/4" Jacket Connections 1/4" and 3/8" Vacuum Connections Length: 24 in. Width: 30 in. Height: 90 in. Does not include: Chiller, Vacuum System, Cold Trap Requires Assembly ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS!*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$5,000.00 - $5,400.00

50L Neocision ETL Lab Certified Rotary Evaporator

50L Neocision ETL Lab Certified Rotary Evaporator The 50L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 50L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware/moving parts Specifications: Model 50L NEOCISION Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 220-240V 60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 0-120 RPM Set Temperature 0-99C / 0-210F Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 50L (20000ml) Receiving Flask Capacity 20L (10000ml) Condenser Style Main + Auxiliary Vertical Double Helix Evaporation Capacity Alcohol >/= 12 L/H Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 4.1 kW Dimensions 49 x 24 x 83 in. Weight 155 lbs Vacuum Connection 10mm / 3/8 in. Barb Condenser Connection 10mm / 3/8 in. Barb Warranty 1 Year Excluding: Moving Parts Glassware Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***.

$8,250.00

50L Neocision ETL Lab Certified Rotary Evaporator Turnkey System

50L Neocision ETL Lab Certified Rotary Evaporator Turnkey System 50L NEO Rotary Evaporator Turnkey System setup includes all the necessary components to successfully perform solvent recovery via rotary evaporation. A cold trap should always be used inline between your vacuum system and application to protect the pump from volatile vapors. 10-50L NEO and ECO Rotary Evaporator Diagram 50L NEO Rotary Evaporator Turnkey System setup includes: 50L Neocision ETL Lab Certified Rotary Evaporator Polyscience DuraChill 1.5HP Chiller w/ Turbine Pump 3/8" Gum Rubber - 100ft 3/8" Silicone Tubing - 25ft Welch BTpro100 Diaphragm Pump Adjustable Stainless Steel Hose Clamps This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently.

$21,200.00 - $24,250.00

50L Pre-Built Collection Base

50L Pre-Built Collection Base Designed with hydrocarbon extraction in mind. This pre-build collection base boasts a 50lb butane capacity at an 80% fill making it the perfect fit for extractors looking to process up to 10 lbs of biomass material at a 5:1 Butane to biomass ratio. Complete with 1/2" JIC drain and recovery ports, a 1/4" JIC accessory port, a -30hg -250 PSI compound gauge, and a 125 PSI ASME Pressure relief this collection base is versatile in use and highly compatible with most systems. A main staple in our Research & Development lab and standard with our 10LB ECO Closed Loop Extractor this 50L Pre-built Collection Base is perfect for anyone looking to expand their processing capabilities. For speedy hydrocarbon solvent recovery rates this reactor pairs well with our 11KW Express Extraction Heater for passive recovery rates past 1lb/min. Processing Power Volume: 50 Liters Capacity: 50LB of butane @80% Fill Maximum Pressure Rating: 125PSI Jacket Capacity: 15 liters Specifications 2X Borosilicate Sight glasses 1X 1/2" JIC Drain Port 2X 1/2" JIC Lid Ports 1X 1/4" JIC Lid Port 2X 1/2" Barbed Jacket Connections 1X 125 PSI ASME Safety Valve 1X -30hg-250PSI Compound Pressure Gauges

$2,000.00

50L Solvent Pro Rotary Evaporator Nut and Washer Flask Set

Replacement nut and washer flask set for 50L Solvent Pro Rotary Evaporator

$150.00

50L Stainless Steel Jacketed Reactor

What is a Jacketed Reactor? A reactor is a vessel that contains a chemical reaction, which opens them up for a variety of applications in the chemical processing field. It’s used as a tool for many different processes related to extraction, winterization, distillation, and post-processing. A reactor can come in different sizes, shapes, and forms. It can even come in different materials including stainless steel or glass. In terms of cannabinoid processing, the most common use for a reactor is large-scale winterization. Here, a single or double jacketed reactor is ideal. This is because it allows you to circulate fluid around the exterior or interior jacket, chilling the mixture inside. As the mixture becomes colder, the fats and waxes within it begin to coagulate and fall out of the solution. Reactors can also be used for homogenizing mixtures or as stand-alone extraction vessels. Glass reactors are only able to handle negative pressure which, in turn, limits their usability. Our 50-Liter Stainless Steel Jacketed Reactor is designed for usage with positive pressure. Additionally, the vessel jacket can circulate chilling fluid or act as vacuum insulation. Key Product Features Vessel Capacity: 50 liters (13 gallons) or 10 lbs of botanical material Outer Jacket Capacity: 14.22 L or 3.76 gallons Rated to 100 PSI MAX Product Applications Ethanol Extraction Winterization Filtration Pre-Chilling Solvent Mixing & Homogenization 50LJR Drawing Note: this unit comes with no hardware and is completely bare.

$1,225.00

50L Turnkey Reactor Kit

50L Turnkey Reactor Kit The BVV 50L Double Jacketed Glass Reactor Kit is the ideal solution for small to medium-sized solvent recovery and decarboxylation applications. This kit includes everything to get you up and running including a Single 50L triple-layer Glass Reactor with Condenser, either a BVV 19L Heated circulator capable of heating to 220C or a UL-listed Huber T305 Capable of heating up to 300C, a 1HP Polyscience 6160T for chilling the condenser, a Welch BTpro100 for vacuum, 25ft of 3/8" Gum rubber tubing for vacuum connections, 20ft of reinforced PVC hose for the chiller, 1/2" Stainless Steel JIC Hoses for the heater, 5 Gallons of Therminol Heat transfer fluid and 5 Gallons of Propylene glycol. 50L Double Jacketed Glass Reactor Specifications Glass Material: GG-17 High Borosilicate Glass Internal Volume: 50L 10.5L Jacket Capacity Shelf Material: Aluminum Alloy Homogenizer Power: 110V/60Hz Homogenizer Speed: 0-400 RPM Digital Homogenizer Control Digital temperature probe readout included Double Jacket 3/4" Jacket Connections 1/4" and 3/8" Vacuum Connections Length: 24 in. Width: 30 in. Height: 90 in. Polyscience 6100 1 HP Chiller Specifications 6100 Series 1 HP Chiller with Turbine Pump, 100psi; 13.2l/min Display: LED Working Temperature Range C: -10 to 40 Temperature Stability: +/-0.1 Temperature Calibration Capability: 1-point Pump Type: Turbine Working Temperature Range F: 14 to 104 Working Temperature Range C: -10 to 40 Reservoir Capacity (gallons): 1.11 Reservoir Capacity (liters): 4.2 Reservoir Cover: Screw-on cap Cleanable Air Filter: Yes Cleanable Fluid Filter: Yes Temperature Stability F: +/-0.2 Temperature Stability C: +/-0.1 Display: LED Display Resolution (Read): 0.1 Pump Type: Turbine Process Connections: 1/2" FNPT Over-Temperature Protection / Failsafe Heater Control: Yes Reservoir Liquid Level Indicator: Yes Reservoir Drain: Yes Cool Command Refrigeration Technology: Yes WhisperCool Environmental Control Technology: Yes Maximum Ambient Temperature F: 95 Maximum Ambient Temperature C: 35 Overall Dimensions (LxWxH inches): 27.6 x 14.5 x 22.6 Overall Dimensions (LxWxH cm): 70 x 36.8 x 57.5 Compressor Size (HP): 1 Refrigerant: R134a Shipping Weight (pounds): 199 Shipping Weight (kilograms): 90 Welch BTpro100 Specifications Model BTpro100 Free Air Displacement@60Hz,lpm(CFM) 100(3.5) Ultimate Vacuum Pressure, Torr 6 Maximum Vacuum, in. Hg 29.7 Horsepower, HP (watts) 0.5(390) Built-in adjustable vacuum - Gas Ballast Yes Head Material PTFE Diaphragm PTFE Inlet/outlet Connection NW16 flange1 Agency (National Recognized Lab) cUL Weight, lbs (kg) 40.3(18.3) Overall DimensionsLxWxH in.(cm) 9x15x7(23x38x18) Shipping Weight, lbs(kg) 48.5 (22) Shipping Carton DimensionsLxWxH in.(cm) 18.9x12.6x11.8(48x32x30) HUBER T305 Specifications General Information & Temperature Controller Temperature range 65...300 °C Temperature stability ±0,02 °C Temperature control TAC, self-optimizing (True Adaptive Control) Controller Pilot ONE (E-grade "Basic") Safety class III / FL Protection class IP20 Dimensions (W x D x H) 425 x 250 x 631 mm | 16.73 x 9.84 x 24.84 inches Weight 37 kg | 81.59 pounds Heating / Cooling Capacity Heating capacity 4,8 kW Circulation Pump Pressure pump max. 45 lpm ; 0.9 bar | 11.89 gpm ; 13.05 psi Pump connection M24x1,5 AG male Permissible viscosity 50 mm²/s Connections Pt100 connection Pt100 Analogue input via optional Com.G@te Analogue output via optional Com.G@te Digital interface RS232, Ethernet, USB Device, USB Host Operating Data Old sku 1003.0022.01 Permissible ambient temp. 5 to 40 °C Filling volume min. 1.45 Liters | 0.38 gal Volume of expansion 2.8 Liters | 0.74 gal Power supply 208V 3~ 60Hz Current max. 15 A Fusing 15,5 A

$23,500.00 - $42,000.00

50LTGR-V3 Replacement Parts

50LTGR-V3 Replacement Parts BVV Replacement parts for 20L and 50L glass reactors. They are compatible with SKU: 20LTGR-V3 and SKU: 50LTGR-V3

$40.00 - $710.00

50ml Heated Filling Gun with Stainless Steel Barrel (1ml Incremental Shots)

Heated Filling Gun with Stainless Steel Barrel 30 Day Limited Warranty 2023 Version Upgraded Stainless Barrel! The BVV™ Semi-Automatic Lab Dosing Gun can is easily adjusted to fill in 1ml, 2ml, 3ml, 4ml, and 5ml increments. You can quickly and accurately fill your cartridges. The heated barrel has a digital controller that allows the user to set a temperature from (Room Temperature - 190°F) in increments of 1.0°F. The Filler comes ready to use, first clean the components, plug it in and attach the included 14 Gauge Tip. Specifications: Stainless Steel Barrel – 304 Grade Polished Stainless Steel 14 Gauge lure lock needle included 110V USA Plug Adjusts from 1-5ml Shots (1ml increments) Lure Lock Hub for all types of size attachments Extra Barrel Plunger Gasket included Adjustable plunger tension/tightening (*for user preferred plunger action) Built-in Temperature Cutoff @190F. 5ft Power Cord 3ft Heat Cord to Control Box. Assembled weight 1lb. 8oz. Cleaning: NOTE: Please Clean Prior to first use gun does not come sterilized. Cleaning the barrel and components can be done with De-limonene, other chemicals can be used, however, *The Barrel Gasket is made of Nitrile and can degrade with overexposure to chemicals like Isopropyl Alcohol. To Fill the Syringe:Advance the plunger all the way to the needle tip of the barrel. Place the needle into the Oil and pull the plunger all the way back until it stops. The barrel will be filled. Increasing the Max Temperature: The Max Temperature Setting is 190°F. To increase the temperature beyond that, the user will need to follow the included instruction to unlock and change the max temp. (Absolute Max. is 212°F) Lab Dosing Gun User Manual PDF

$270.00

55 Gallon Hash Ice Water Extraction Washing Vessel

BVV's 55 Gallon Ice Water Extraction Washing Vessel Made in USA Designed with durability and ease of use in mind our Ice Water Extraction Washing Vessels are manufactured from 16 gauge 304 stainless steel crafted with seamless welds for a 100% sanitary construction. Our easy drain barrels come complete with 4X 1.5" Triclamp drains mounted as low as possible for effortless draining of its 55-gallon volume capacity. Perfect for medium to large-scale ice water extraction labs this stand-alone vessel pairs nicely with Boldtbags Large Open Top Wash Bags & Boldt bags 44 gallon Lock-top Full Mesh Stackers. Processing Power Material Capacity Per Batch: 20-30LB Water Capacity: 55 Gallons Cycle Time: 60-90 Minutes Daily Extraction Capacity: Up to 60 lb, per 8-hour shift Specifications 23"x36" 55-gallon Stainless Steel Washing Vessel Seamless 304 Stainless Steel Construction 4X 1.5" Tri-clamp ports for draining, filling, temperature sensing, or sight glasses Performance Low-mounted drain ports for complete draining

$1,500.00

5L BVV™ Rotary Evaporator Glass Axis

Glass axis for 5L BVV Rotary Evaporator *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$60.00

5L ECO V2 Rotary Evaporator Motor

5L ECO V2 Rotary Evaporator Motor This replacement motor fits on 5L rotary evaporators with manual lift baths. The controller connection must have the same 5 pin configuration as the plug shown in the pictures.

$395.00

5L ECO V2 Rotary Evaporator Speed Controller Box

5L ECO V2 Rotary Evaporator Speed Controller Box This is a replacement speed controller for 5L rotary evaporators with a manual lift bath. The cord attaching to your motor must have the same 5 pin orientation shown in the pictures.

$500.00

5L Evaporating Flask

Evaporating flask for 5L Best Value Rotary Evaporator. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$165.00

5L Neocision ETL Lab Certified Rotary Evaporator

5L Neocision ETL Lab Certified Rotary Evaporator The 5L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 5L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware. Specifications: Model 5L Solvent Pro Series Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 110V 50/60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 20-130 RPM Set Temperature RT+5 - 99C Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 5L (5000ml) Receiving Flask Capacity 5L (5000ml) Condenser Style Main + Auxiliary Vertical Double Helix Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 1800w Dimensions 45 x 32 x 15in Weight 155 lbs Vacuum Connection 14mm / .55 in. Barb Condenser Connection 18mm / .70 in. Barb Warranty 1 Year Excluding: Moving Parts Glassware Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$4,000.00

5L Neocision ETL Lab Certified Rotary Evaporator Turnkey System

5L Neocision ETL Lab Certified Rotary Evaporator Turnkey System The 5L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 5L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. 5L NEO Rotary Evaporator Turnkey System setup includes: 5L Neocision ETL Lab Certified Rotary Evaporator Polyscience LS -20C to 40C 1/2HP Chiller w/ Turbine Pump 1/4" Gum Rubber - 100ft 1/4" Silicone Tubing - 25ft Welch BTpro70 Adjustable Stainless Steel Hose Clamps Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware. Specifications: Model 5L Solvent Pro Series Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 110V 50/60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 20-130 RPM Set Temperature RT+5 - 99C Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 5L (5000ml) Receiving Flask Capacity 5L (5000ml) Condenser Style Main + Auxiliary Vertical Double Helix Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 1800w Dimensions 45 x 32 x 15in Weight 155 lbs Vacuum Connection 14mm / .55 in. Barb Condenser Connection 18mm / .70 in. Barb Warranty 1 Year excluding glass parts Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$10,250.00 - $12,250.00

5L Short Path Distillation Kit with P5 Distillation Head

5L Short Path Distillation Kit with P5 Distillation Head This unit carries a 2 day lead time. The 5L Distillation Kit includes everything needed to perform distillation excluding the vacuum pump and chiller. This kit features our USA made P5 Distillation Head, as well as USA, made glass. This Kit is designed for high volume production with the highest quality components for precise, repeatable results time and again. This Kit Does NOT include a vacuum pump or chiller. Please see the below recommendations for both as well as recommended add-ons. Recommended Vacuum Pumps: Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (economy option) Recommended Chillers: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter Refrigerated Circulator (premium option with chilling capability) Recommended Add-Ons: Bullseye Precision Vacuum Gauge (premium vacuum gauge for measuing depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) J-KEM Digital Vapor Temp Monitor (digital vapor temp monitor with data-logging capabilites) Specifications: Boiling Flask Size: 5L Receiving Flask Size: 2x 500mL, 1000mL Batch Capacity approximate: 1000-2500 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Includes: Glass components: 5L Boiling Flask P5V6 Distillation Head Triple Neck Cow 2x 500mL Receiving Flask 1L Receiving Flask 120mm Glass Funnel Dewar cold trap Accessories: PTFE Magnetic Stir Bar Retriever 5 Pack of Metal Keck Clips Dow Corning High Vacuum Silicone Grease Tripod Stand 5L Digital Heating and Stirring Mantle 3-Finger Adjustable Clamp 0-77mm 6" x 6" Scissor Jack 500-1000mL Cork Stand 2x 24/40 ChemglassPTFE Thermometer Inlet Adapter 10ft of Gum Rubber Vacuum Hose 10ft of Silicone Chiller Hose 1/4" Vacuum Manifold Traceable Kangaroo Thermometer - Digital 10 Pack of Adjustable Stainless Steel Tubing Clamps Fiberglass Insulation Rope 10 Feet Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$2,200.00

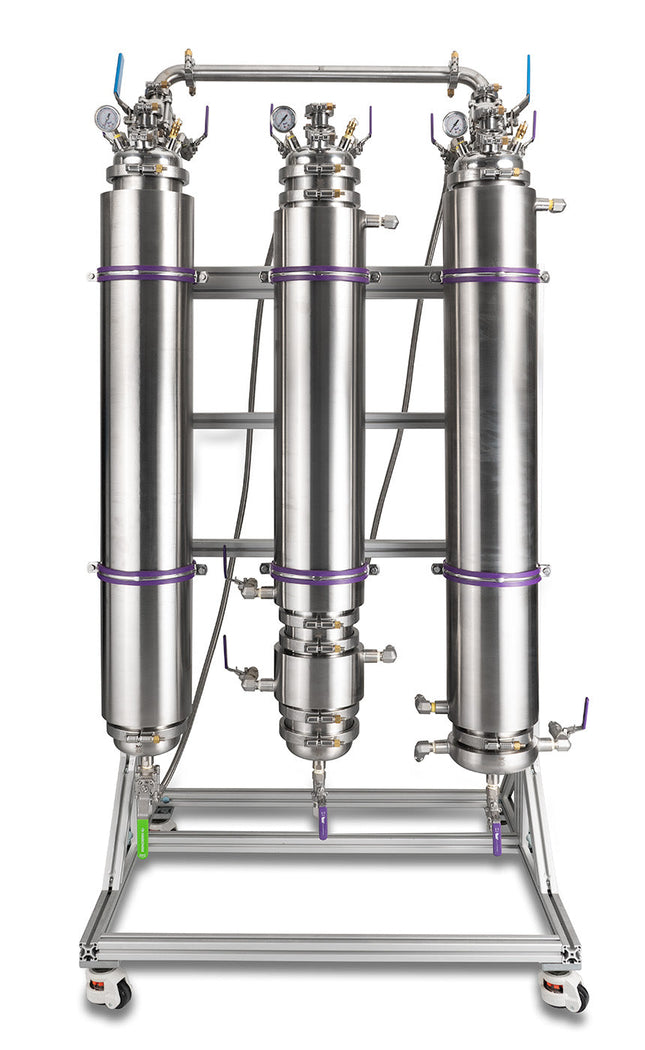

5LB Apollo Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well ventilated areas. Check with your local fire marshal for guidance when operating indoors 5LB Closed Loop Reclamation Extraction System (System comes with 1 yr. limited warranty) Please read Optional Upgrades section for clarification on system upgrades The 5lb closed loop hydrocarbon extraction system performs botanical extraction within a sealed, vacuumed system. Utilizing a top-fill input, solvent washes thru the material column, collecting oils as it passes over the material. Oil bearing solvent is collected in the collection base under the material column. Once collected, solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. This unit can be upgraded into an Active recovery unit by purchasing the upgrade kit. TRS21 Active Closed Loop Recovery Kit Extractor Configurations: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and standard LP tank. This model has minimal features to keep cost low, while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Solvent is input into the material column with a showerhead endcap, ensuring the full material column is saturated with solvent. The Professional comes with a sleeved spool, allowing users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is our fully upgraded Apollo model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. It features a larger bore on valves and hoses, all American made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, sleeved dewaxing column, jacketed collection base, and a stainless steel LP tank. The Elite series boasts increased efficiency on both solvent input and recovery by bumping up all valves and lines to 3/8” JIC. The stainless steel LP tank is able to be opened and cleaned, making solvent contamination a non-issue. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base BVV 316SS Full Bore Valves Showerhead Dewaxer Ball Valve Splatter Platter Base SSP Valves Showerhead Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter SSLP 3/8" Valves & Hoses Unit Includes: Collection Based 12"x12" Welded Bottom Base Assembled 12" extractor lid (2)4"x24" Material column with reducer & top cap #50 LP tank 96" High Pressure PTFE Braided SS Hose 12" clamps, (3)4" clamps and a 2" clamp with gaskets Instruction Manual Specifications: (2) 4"x 24" 304 Stainless Steel Material Tubes 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple port connections for _" 316 Stainless JIC 37 Degree 304 Stainless Steel Base Container 12" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure, easy clean unit. Viton Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches):25" x 7.5' Diameter overall size Weight: 75 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Base unit Maximum Capacity: 1275 cubic inches, (2.553 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$1,075.00 - $3,300.00

5LB EVO Certified Closed Loop Extractor *49 State Certified