2LB TFX Closed Loop Extractor

Are you ready to embark on an exciting journey into the world of extraction? Look no further than the TFX, your perfect entry point into the world of closed-loop extraction. The TFX offers exceptional performance right out of the box at an affordable price, making it an excellent choice for both beginners and experienced extractors. But that's not all – the TFX also serves as a versatile foundation for future upgrades and enhancements, allowing you to level up your extraction game over time. Whether you're just starting or aiming to expand your capabilities, the TFX provides a solid base that can be customized to meet your evolving needs. With its adaptable design and compatibility with various upgrades, the TFX empowers you to experiment with new processing techniques and adapt to changing industry demands. Begin your journey with the TFX and open the door to endless possibilities for innovation and growth in the extraction realm.

Introducing the TFX closed-loop extractor, the next step in the evolution of the popular Apollo extractor. The TFX brings a new era of safety, user-friendliness, and performance to the table. Building on the success of its predecessor, the TFX takes operator safety to the next level with enhanced safety mechanisms, including High-pressure Clamps and pressure relief valves as standard features. Extract harvesting is made easier with splatter platter bases, ensuring a cleaner and smoother process. The TFX's optimized design translates to improved ease of use, safety, and performance, resulting in top-quality extracts. The TFX is the cornerstone of many extractors' journeys, offering a reliable, efficient, and future-ready solution to meet your evolving needs.

The TFX closed-loop extractor comes in three model variants, catering to different extraction requirements. The V1 Explorer is the choice for budget-conscious individuals looking to enter the world of extraction affordably. With features like a DOT-Approved carbon steel recovery tank, 1/4" JIC Recovery lines, and polycarbonate sight glasses, it lays the foundation for easy future upgrades.

For those seeking a professional setup from the start, the V2 Professional model is the ideal option. It comes with an upgraded stainless steel recovery tank featuring 1/2" JIC Recovery lines for optimized solvent recovery. Enhanced borosilicate sight glasses provide better visibility during the extraction process.

If you're aiming for the ultimate extraction experience, the V3 Elite model is the answer. This model includes all the upgrades of the professional variant, along with additional features like a solvent dispersal plate for uniform biomass saturation and a jacketed splatter platter for use with a heated circulator, improving solvent recovery efficiency.

The TFX closed-loop extractor lets you choose the perfect model for your budget and needs. Whether you're starting small or aiming for professional-grade capabilities, the TFX series provides the perfect foundation for your extraction journey.

No matter which model you choose – Explorer, Professional, or Elite – the TFX closed-loop extractor offers limitless modification possibilities to enhance your capabilities and stay ahead of industry trends. Optimized for quick wash extraction procedures, the TFX ensures exceptional purity and yield. If you prefer soaking procedures, simply add our 316L SS Tri-Clamp Ball Valve below the material column to adapt the TFX.

For the utmost purity, pair your TFX with an Inline CRC (Color Remediation Column) for the highest quality and purest extracts. Running fresh frozen material? Swap the standard 4"x 24" spool with a Sleeved Spool to preserve your biomass's flavor during extraction. To achieve ultimate clarity, reduce wax content by incorporating an injection coil into your setup.

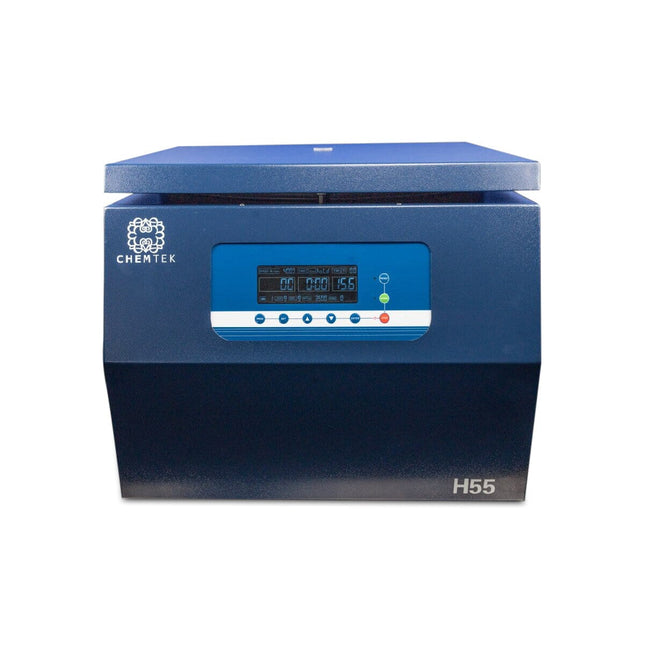

To enhance solvent recovery and reduce loss, consider our BVV 2 Cylinder Active Closed Loop Recovery kit for your TFX closed-loop extractor. This kit boosts solvent recovery efficiency, saving you time and resources.

With the TFX closed-loop extractor and its range of modification options, you have the freedom to customize your extraction setup to match your unique needs. Stay at the forefront of the industry and unlock your extraction process's full potential with the versatile TFX closed-loop extractor.

As a premier extraction equipment manufacturer, we prioritize precision and safety in the extraction process. The TFX is designed with these principles in mind, offering a cutting-edge solution for extraction professionals.

Constructed from high-quality stainless steel, the TFX ensures exceptional durability and resistance to corrosion, providing you with a reliable and long-lasting extraction solution. Its innovative design incorporates advanced safety features, including high-pressure clamps, pressure relief valves, and sight glasses, ensuring operator well-being and operational control.

Its superior design promotes efficient solvent flow and comprehensive material saturation, resulting in high-quality, potent extracts that meet your precise requirements.

When it comes to introductory closed-loop extractors, the TFX sets a new standard with its exceptional performance, safety features, and reliability. With our product, you can streamline extraction operations, boost productivity, and produce premium extracts that surpass industry standards.

At BVV, we take pride in offering top-tier extraction equipment tailored to your unique needs. Our team of experts is dedicated to providing unmatched customer support, assisting your extraction journey and take your business to new heights.

Specifications

4"x24" 1LB Material Column

12"x12" Collection Base Body

12" Collection Base Splatter Platter

100um Nitrile BUNA-N Mesh Gaskets

1.5" Polycarbonate or Borosilicate Sight Glasses

125 PSI ASME Safety Valves

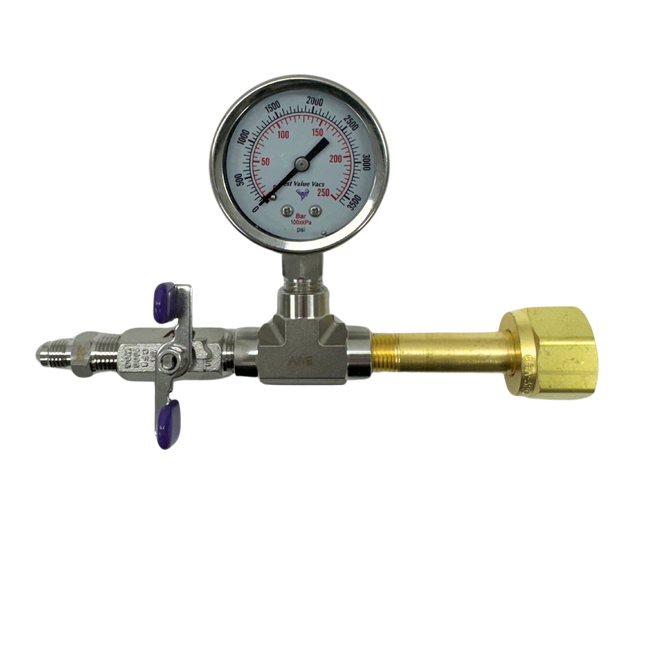

-30hg-250PSI Compound Pressure Gauge

1/4" or 1/2" Full Bore Recovery Lines

1/4" JIC process Flow lines

Explorer

Professional

Elite

DOT Carbon Steel Solvent Tank

Polycarbonate Sight Glasses

1/4" JIC Recovery Lines

Stainless Steel Solvent Tank

Borosilicate Sight Glasses

1/2" JIC Recovery Lines

Stainless Steel Solvent Tank

Borosilicate Sight Glasses

1/2" JIC Recovery Lines

Solvent Dispersal Plate

Jacketed Splatter Platter

***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.***

***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors.

*Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

Read

more

less