EVERY PRODUCT BUT HYDRO FOR WHOLESALE STORE

Master Vapor MVP-150XL Diaphragm

Master Vapor MVP-150XL Diaphragm Diaphragm replacement kit for use with the MVP-150XL recovery pump. Unit of Measure: EA Height: 2 IN | 5.08 CM Length: 12 IN | 30.48 CM Width: 12 IN | 30.48 CM Volume: .167 FT3 | .005 M3 Chargeable Weight: 2.58 LBS | 1.17 KG

$410.00

Sanitary 3-Way Ball Valve 4" Tri-Clamp

Sanitary 3-Way Ball Valve These 3 way ball valves are typically used to drain a system that needs to be routed to multiple different places. The internal ball is an L shape meaning that the middle port should be used as the in and it can be routed to the left or right port. The valve can also be closed off so that the liquid will not move any direction. It can be easily attached to any system using Tri-Clamp flanges. Housing Material: 304 SS Seat Material: PTFE Temperature Range: 0-100°C

$350.00$150.00

50L Turnkey Reactor Kit

50L Turnkey Reactor Kit The BVV 50L Double Jacketed Glass Reactor Kit is the ideal solution for small to medium-sized solvent recovery and decarboxylation applications. This kit includes everything to get you up and running including a Single 50L triple-layer Glass Reactor with Condenser, either a BVV 19L Heated circulator capable of heating to 220C or a UL-listed Huber T305 Capable of heating up to 300C, a 1HP Polyscience 6160T for chilling the condenser, a Welch BTpro100 for vacuum, 25ft of 3/8" Gum rubber tubing for vacuum connections, 20ft of reinforced PVC hose for the chiller, 1/2" Stainless Steel JIC Hoses for the heater, 5 Gallons of Therminol Heat transfer fluid and 5 Gallons of Propylene glycol. 50L Double Jacketed Glass Reactor Specifications Glass Material: GG-17 High Borosilicate Glass Internal Volume: 50L 10.5L Jacket Capacity Shelf Material: Aluminum Alloy Homogenizer Power: 110V/60Hz Homogenizer Speed: 0-400 RPM Digital Homogenizer Control Digital temperature probe readout included Double Jacket 3/4" Jacket Connections 1/4" and 3/8" Vacuum Connections Length: 24 in. Width: 30 in. Height: 90 in. Polyscience 6100 1 HP Chiller Specifications 6100 Series 1 HP Chiller with Turbine Pump, 100psi; 13.2l/min Display: LED Working Temperature Range C: -10 to 40 Temperature Stability: +/-0.1 Temperature Calibration Capability: 1-point Pump Type: Turbine Working Temperature Range F: 14 to 104 Working Temperature Range C: -10 to 40 Reservoir Capacity (gallons): 1.11 Reservoir Capacity (liters): 4.2 Reservoir Cover: Screw-on cap Cleanable Air Filter: Yes Cleanable Fluid Filter: Yes Temperature Stability F: +/-0.2 Temperature Stability C: +/-0.1 Display: LED Display Resolution (Read): 0.1 Pump Type: Turbine Process Connections: 1/2" FNPT Over-Temperature Protection / Failsafe Heater Control: Yes Reservoir Liquid Level Indicator: Yes Reservoir Drain: Yes Cool Command Refrigeration Technology: Yes WhisperCool Environmental Control Technology: Yes Maximum Ambient Temperature F: 95 Maximum Ambient Temperature C: 35 Overall Dimensions (LxWxH inches): 27.6 x 14.5 x 22.6 Overall Dimensions (LxWxH cm): 70 x 36.8 x 57.5 Compressor Size (HP): 1 Refrigerant: R134a Shipping Weight (pounds): 199 Shipping Weight (kilograms): 90 Welch BTpro100 Specifications Model BTpro100 Free Air Displacement@60Hz,lpm(CFM) 100(3.5) Ultimate Vacuum Pressure, Torr 6 Maximum Vacuum, in. Hg 29.7 Horsepower, HP (watts) 0.5(390) Built-in adjustable vacuum - Gas Ballast Yes Head Material PTFE Diaphragm PTFE Inlet/outlet Connection NW16 flange1 Agency (National Recognized Lab) cUL Weight, lbs (kg) 40.3(18.3) Overall DimensionsLxWxH in.(cm) 9x15x7(23x38x18) Shipping Weight, lbs(kg) 48.5 (22) Shipping Carton DimensionsLxWxH in.(cm) 18.9x12.6x11.8(48x32x30) HUBER T305 Specifications General Information & Temperature Controller Temperature range 65...300 °C Temperature stability ±0,02 °C Temperature control TAC, self-optimizing (True Adaptive Control) Controller Pilot ONE (E-grade "Basic") Safety class III / FL Protection class IP20 Dimensions (W x D x H) 425 x 250 x 631 mm | 16.73 x 9.84 x 24.84 inches Weight 37 kg | 81.59 pounds Heating / Cooling Capacity Heating capacity 4,8 kW Circulation Pump Pressure pump max. 45 lpm ; 0.9 bar | 11.89 gpm ; 13.05 psi Pump connection M24x1,5 AG male Permissible viscosity 50 mm²/s Connections Pt100 connection Pt100 Analogue input via optional Com.G@te Analogue output via optional Com.G@te Digital interface RS232, Ethernet, USB Device, USB Host Operating Data Old sku 1003.0022.01 Permissible ambient temp. 5 to 40 °C Filling volume min. 1.45 Liters | 0.38 gal Volume of expansion 2.8 Liters | 0.74 gal Power supply 208V 3~ 60Hz Current max. 15 A Fusing 15,5 A

$23,500.00 - $42,000.00

Replacement PID 3.2TS and 7.5TS

Replacement PID 3.2TS and 7.5TS Specifications SKU FCT30L0-E-F Temperature Range: 32°F - 212°F Dims/weight 4.5 x 4.5 x 4 / 1lb Timer Range 0 -999 Built in Calibration: Yes Temp Display Mode For C Compatible Ovens 32TSO - 32TSB- 75TSO - 75TSB Temperature Accuracy +/- 1°F

$260.00

16CF Neocision ETL Lab Certified Vacuum Oven

16CF Neocision Certified Lab Vacuum Oven, 5 Individually Heated Shelves, LED's - 3 Year Warranty Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! Introduction Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. Performance Capabilities At Best Value Vacs, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Uniformity: within 4% of the temperature setpoint. Heat-Up Time: 30 minutes. Ultimate Vacuum: <500 µmHg / mTorr / micron. Time to Vacuum: 10 minutes to 29"Hg using our 12CFM Spark Free Vacuum Pump Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. Technical Data Electrical Voltage 120V Frequency 60Hz Power 2000W Current 20A Plug NEMA 5-15 Internal Chamber Heating Individual direct-heat shelves Chamber Material Stainless Steel Dimensions (LxWxH) 25.5" x 32" x 34" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 8 Shelves Shelf Dimensions (LxW) 24.75" x 31.5" Shelf Capacity 780 in^2 Total Shelf Capacity 6240 in^2 Safety Seal Silicone on Tempered Glass Window Dimensions (LxH) 29.25" x 32" Lights 4 strips of LEDs provide a clear, bright view of the interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 37.25" x 45" x 46" Weight 500lbs Support Locking Casters Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connections Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose User Manual Included Vacuum Pump Sold Separately. Warranty 3 Years Capacity and Throughput Planning Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122 Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via UPS Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise UPS freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$13,000.00

SSP - Union Elbow - 3/8" Duolok

Stainless Steel SSP -Union Elbow 3/8" Duolok

$42.00

NEO Oven Needle Valve

NEO Oven Needle Valve Replacement Needle valve for vacuum shut off for NEOCISION vacuum ovens

$60.00

Pump Part - MVP - 60 PSI, 150 PSI, Liquid, XL150 - Fill/Vent Fitting Kit

Pump Part - MVP - 60 PSI, 150 PSI, Liquid, XL150 - Fill/Vent Fitting Kit All sales final

$150.00

Fisher American 8′ Wide x 4′ Deep Walk-In Fume Hood

Fisher American 8′ Wide x 4′ Deep Walk-In Fume Hood (Please Note: 2 weeks Lead Time) Description 8′ x 48″ deep ”Walk-In” Fisher American Chemical Laboratory Fume Hood (NLS-H511) Unit does Not include blower Add Blower, The blower is ¾ HP Hazardous Location blower C1D1 Fume Hood Exterior Dimensions: Width: 96″ Depth: 48″ Height: 89″ Work Area (Interior) Dimensions: Width: 86.5″ Depth: 39.5″ Height: 81″ Door Opening: 86.5″ Fume Hood Accessories: 1- Light on/off Switch 1 – LED Light 1 – AC Power Plug 1 – Gas Valve 1 – Cold water valve 4 – Sliding doors *Polyply Composites U.L. Listed ChemBlok CR-900 laminates are glass reinforced, UV inhibited composites sheet that offer excellent Chemical and flame resistance wherever a cost effective general-purpose corrosion material is required. Typical Properties General Information ASTM Polyply Composites CR-900 U.L Recognition File Number E31703 Meets U.L. Standards 1805 Color (Standards) White Sheet Size 48'' x 96'' length Sheet Thinkness 3/16'' Other Sizes upon Request Specific Gravity 1.8 D-792 Water Absorption (%by weight) 0.093 D-792 Flame Spread 20.2 UL 723/E-84 Smoke Generation, Tunnel Test 166 E-84 Flame Resistance Self Extinguishing Tensile Strength, psi 8,300 D-638 Flexural Strength,psi 20,400 D-790 Compressive Strength 29,200 D-695 IZOD Impact Strength 8.1 D-256 Barcol 50 REAGENT RESISTANCE - PANEL CR900 LOT 07-1087,88 No. Reagent Rating No. Reagent Rating 1 Amyl Acetate 0 26 Iodine, Tincture 2 2 Ethyl Acetate 0 27 Methyl Ethyl Ketone 1 3 Acetic Acid 98% 1 28 Methylene Chloride 2 4 Acetone 1 29 Mono Chlorobenzene 0 5 Acid Dichromate 5% 2 30 Naphthalene 0 6 Butyl Alcohol 0 31 Nitric Acid 20% 0 7 Ethyl Alcohol 0 32 Nitric Acid 30% 0 8 Methyl Alcohol 0 33 Nitric Acid 70% 2 9 Ammonium Hydroxide 28% 0 34 Phenol 90% 0 10 Benzene 1 35 Phosphoric Acid 85% 0 11 Carbon Tetrachloride 1 36 Silver Nitrate Saturated 0 12 Chloroform 1 37 Sodium Hydroxide 10% 0 13 Chromic Acid 60% 2 38 Sodium Hydroxide 30% 0 14 Cresol 1 39 Sodium Hydroxide 40% 0 15 Dichloroacetic Acid 1 40 Sodium Hydroxide, Flake 0 16 Dimethyl Formamide 1 41 Sodium Sulfide, Saturated 0 17 1,4-Dioxane 0 42 Sulfuric Acid 33% 0 18 Ethyl Ether 0 43 Sulfuric Acid 77% 1 19 Formaldehyde 37% 0 44 Sulfuric Acid 96% 3 20 Formic Acid 90% 1 45 Sulfuric Acid 77% + Nitric Acid 70% (50/50) 2 21 Furfural 2 46 Toluene 0 22 Gasoline 0 47 Trichloroethylene 0 23 Hydrochloric Acid 37% 0 48 Xylenes 0 24 Hydrochloric Acid 48% 3 49 Zinc Chloride, Saturated 0 25 Hydrogen Peroxide 3% 0 Unless otherwise indicated, all properties are based on tests performed on standard ASTM Test Samples and according to ASTM test methods Values Shown are for test Samples Made from production materials and are believed to be typical. No warranty is expressed or implied.

$20,925.00 - $25,335.00

Welch BTpro170

Welch BTpro170 ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Welch’s BTpro vacuum pump series has a flow and vacuum level to provide fast performance for your size of rotary evaporator, glass reactor, purge oven, or winterization filtration apparatus. These chemical duty PTFE diaphragm pumps are oil-free. The pumping action and deep vacuum comes from the movement of PTFE diaphragms within PTFE heads. All wetted services in the flow path are made of fluoroplastic making the BTpro pump highly chemically resistant. As a result, the BTpro vacuum pump series is near-zero maintenance. A cold trap placed in-line with BTpro pump is needed if terpenes are part of the flow path. Model BTpro170 2163 Free Air Displacement@60Hz,lpm(CFM) 170 (6.0) 170 (6.0) Ultimate Vacuum Pressure, Torr 6 6 Maximum Vacuum, in. Hg 29.7 29.7 Horsepower, HP (watts) 0.6(440) 0.6(440) Built-in adjustable vacuum - - Gas Ballast Yes Yes Head Material PTFE Coated Al Diaphragm PTFE PTFE Inlet/outlet Connection NW16 flange NW16 flange Agency (National Recognized Lab) cUL cUL Weight, lbs (kg) 72.3 (32.8) 72.3 (32.8) Overall DimensionsLxWxH in.(cm) 21x11x12(53x28x31) 21x11x12(53x28x31) Shipping Weight, lbs(kg) 88.2 (40.1) 88.2 (40.1) Shipping Carton Dimensions LxWxH in.(cm) 23.6x15.8x16.1 60x40x41 23.6x15.8x16.1 60x40x41

$5,400.00$5,000.00

So-Low Flammable Material Storage Refrigerators 1°C to 10°C, 14 Cu.Ft, MV4-6UCFMSR

So-Low Flammable Material Storage Refrigerators 1°C to 10°C, 14 Cu.Ft, MV4-6UCFMSR Please note: This Product may carry up to an 11 week lead time! Our Flammable Refrigerators and Freezers are designed to meet National Fire Protection Agency NFPA and OSHA guidelines for the refrigerated storage of flammable (volatile) material storage in general laboratory work areas. Designed exclusively to control flammable material, The So-Low Flammable Material Storage Freezers and Refrigerators are ideal for storage of any flammable material products. There are no electrical components located in the interior of the unit and the compressor's electrical components have been sealed in a vapor-proof enclosure for additional safety. Units are supplied with a power cord to ease installation. Temperature control and temperature recorder options allow for an individualized intensity of temperature control and monitoring. Adjustable legs and shelves add more availability and storage options to fit your laboratories needs. Features Solid Polyurethane Foam Insulated Doors Epoxy Coated Shelves Adjustable Shelves Adjustable Legs CFC-Free Refrigerant and Insulation Adjustable Thermostat Manual Defrost UL Listed Product Specification Manufacturer So-Low Temperature Range 1°C to 7°C Capacity 6.1 Cufic Feet Exterior w x d x h (inches) 23.625" x 24.25" x 32.187" Exterior w x d x h (cm) 68 x 62 x 82 Door Single Solid, locking Interior Finish Anodized aluminum Leg Four Leveling Legs Insulation Polyurethane foam Refrigerant R134A CFC free Compressor 1/5 hp Condenser Static Defrost Manual Voltage:Domestic 115/60/1 Running Amps/Breaker 2.5/15 Supply Plug 5-15P NEMA UL listed Shipping weight 150lbs Warranty -(Domestic) 12 months parts and labor Compressors additional 4 years, no labor. Specification Data Sheet

$2,390.00

10L Neocision ETL Lab Certified Rotary Evaporator

10L Neocision ETL Lab Certified Rotary Evaporator The 10L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 10L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware. Specifications: Model 10L Solvent Pro Series Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 220-240V 60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 20-130 RPM Set Temperature RT+5-99C Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 10L (10000ml) Receiving Flask Capacity 10L (10000ml) Condenser Style Main + Auxiliary Vertical Double Helix Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 3300w Dimensions 81 x 44 x 20 in. Weight 155 lbs Vacuum Connection 14mm / .55 in. Barb Condenser Connection 18mm / .70 in. Barb Warranty 90 days excluding glass parts Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$5,250.00$3,500.00

20L Neocision Dual Head Short Path Distillation Kit

20L Neocision Dual Head Short Path Distillation Kit This unit carries a 2 day lead time. (Note: This kit does NOT include the stainless steel table.) The 20L Neocision Distillation Kit Setup features our Dual P10V6 Distillation Heads and USA made glass. Every component in this distillation kit is made for precision, throughput, and repeatable results. You will also receive Dual Dewar Style Ribbed Glass Cold Traps to keep all volatiles and solvents out of your vacuum system. This kit gives you the essentials of a short path distillation system and allows you to add a pump and temperature control system of your choosing. The 20L Neo Kit Includes: 20L Neocision Kit with glassware, labware, and Dual P10V6 Distillation Heads. KF-25 Bellow Y Manifold Dual Ribbed Dewar Style Glass Cold Trap Non-Mercury Glass Thermometers 20L Digital Heating and Stirring Mantle Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in the boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$6,800.00 - $7,000.00

True Terpenes Pie Hoe - Infused

True Terpenes Pie Hoe All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. (Please Note: This product has 1 week lead time) Pie Hoe Infused Strain Profile takes the sensual and euphoric combination of Grape Pie and Tahoe OG strains and increases the love with silky smooth berry. Full Flavor. Full Effect. FRAGRANCE: Berry EFFECT: Sensual and euphoric CERTIFICATES: COA | SDS | FOOD GRADE Storage Requirements Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. DilutionTerpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With CareCan cause skin irritation, do not ingest PRIOR to dilution. TRUE GRADE™ It is our promise to you. Our isolated terpenes are triple-distilled making them the cleanest terpenes in the world. Fresh out of the bottle, undiluted, every single one of our products bests the most rigorous consumer safety standards. GMP | ISO-9001:2015 | FSSC 22000 Blended in cGMP facilities adhering to the requirements for a Quality Management System (QMS) specified by ISO 9001:2015 and FSSC 22000 standards. Analyzed Tested and passed True Grade™ safety specifications for residual solvents, pesticides and heavy metals. Stability Tested Rigorously tested with mid-grade distillate against separation, cloudiness and unacceptable levels of color change. We Qualify True Terpenes implements supply-chain control for all raw materials and is proud to provide True Terpenes’ qualification documents such as certificates, licenses and registrations to be qualified as your supplier. Undiluted We do not add PG, VG, PEG, MCT or Vitamin E Acetate to any of our products. Food Grade Manufactured in cGMP facilities using food grade ingredients. UV Protected This product is packaged in a cobalt blue, UV deterrent and food grade bottle with tamper evident seal. Made in the USA Formulated, blended, manufactured and fulfilled in the United States. Refined Isolates This product contains ultra-pure, molecularly-refined terpene isolates. Only the best.

$121.50 - $2,250.00

HUBER Unistat T305 with Pilot ONE

HUBER Unistat T305 with Pilot ONE (Please Note: There is a 2 - 3 weeks lead time) The Unistat range inspires with unique thermodynamic properties and a range of functions to meet the highest demands. Unistat technology guarantees precise, reproducible temperature control results, the shortest possible heating and cooling times and large temperature ranges without the need for fluid change. All Unistats are fitted with the innovative Because Unistats are hydraulically sealed, the service life of the temperature control fluid is dramatically increased by preventing oil loss through vapours and oxidation, further saving resources. Unistats are fitted with extensive safety equipment and are therefore suitable for unsupervised continuous operation. Relevant operating conditions are constantly monitored and the system is switched off if necessary or with the process safety feature the emergency cooling circuit is activated. Data sheet 3 Year Warranty Extension General Information & Temperature Controller Temperature range 65...300 °C Temperature stability ±0,02 °C Temperature control TAC, self-optimizing (True Adaptive Control) Controller Pilot ONE (E-grade "Basic") Safety class III / FL Protection class IP20 Dimensions (W x D x H) 425 x 250 x 631 mm | 16.73 x 9.84 x 24.84 inches Weight 37 kg | 81.59 pounds Heating / Cooling Capacity Heating capacity 4,8 kW Circulation Pump Pressure pump max. 45 lpm ; 0.9 bar | 11.89 gpm ; 13.05 psi Pump connection M24x1,5 AG male Permissible viscosity 50 mm²/s Connections Pt100 connection Pt100 Analogue input via optional Com.G@te Analogue output via optional Com.G@te Digital interface RS232, Ethernet, USB Device, USB Host Operating Data Old sku 1003.0022.01 Permissible ambient temp. 5 to 40 °C Filling volume min. 1.45 Liters | 0.38 gal Volume of expansion 2.8 Liters | 0.74 gal Power supply 208V 3~ 60Hz Current max. 15 A Fusing 15,5 A

$23,450.00 - $23,950.00

Polyscience 20 Liter General Purpose Water Bath

Polyscience 20 Liter General Purpose Water Bath Key Features: Displays actual and set point temperature simultaneously Three push-button pre-sets for frequently used temperatures Integrated timer Hinged gable cover Calibration capability Reservoir sizes from 2 to 28 liters Reservoir made of 304 Stainless Steel Reservoir drain (10 liter and larger baths) Primary and automatic safety thermostats Also compatible with waterless bath beads Specifications Working Temperature Range °F Ambient +10° to 212° Reservoir Capacity (liters) 20 Reservoir/Tank Material Stainless Steel Reservoir Cover Hinged Gable Working Access (L x W x D) (inches) 9.5 x 17 x 6 Temperature Stability °F ±0.2° Display 3.25" Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Maximum Ambient Temperature °F 104° Overall Dimensions (L x W x H) (inches) 17.5 x 22.5 x 15.5 Shipping Weight (pounds) 25.0 60Hz Only Part Number WBE20A11B Included Hardware Sample Tray Heater Wattage 1400 Electrical Requirements (VAC/Hz/Ph/A) 240/50/1/6 Regulatory Approvals ETL Certifications: Regulatory Approvals: ETL Approval CE Approval Operator's Manual

$1,174.00

Julabo CORIO CD-BC6 Heating Circulator - New In Stock

Julabo CORIO CD-BC6 Heating Circulator The new generation of laboratory circulators for routine work and standard tasks CORIO™ heating circulators feature professional technology for high standards. These units facilitate internal temperature control in the bath tank or control of externally connected applications. Your advantages Models for internal and external applications Bright, white, easy to read display Very quiet Easy pump change-over between internal and external circulation USB connection High-quality bath tanks made of stainless steel with bath lid and drain tap Integrated cooling coil for counter-cooling Technical Data Order No. 9012506 Model series CORIO Category Heating Circulators Working temperature range (°C) +20 ... +150 Temperature stability (°C) ±0.03 Setting / display resolution 0.01 – 0.1 °C Temperature Display LED Heating capacity (kW) 1 Pump capacity flow rate (l/min) 15 Pump capacity flow pressure (psi) 5.08 Bath opening/bath depth (W x L / D inch) 5.1 x 5.9 / 7.8 Pump connections M16x1 Barbed fittings diameter (inner dia. / mm) 8 / 12 Filling volume (litres) 4.5 ... 6 Ambient temperature 5...40 °C Dimensions W x L x H (inch) 9.5 x 17.4 x 18.5 Weight (LBS) 22.1 Included with each unit 2 each barbed fitting for tubing 8 and 12 mm inner dia.(pump connections M16x1 male) Cooling Coil integrated Bath tank Stainless steel Bath cover integrated

$4,901.00$1,750.00

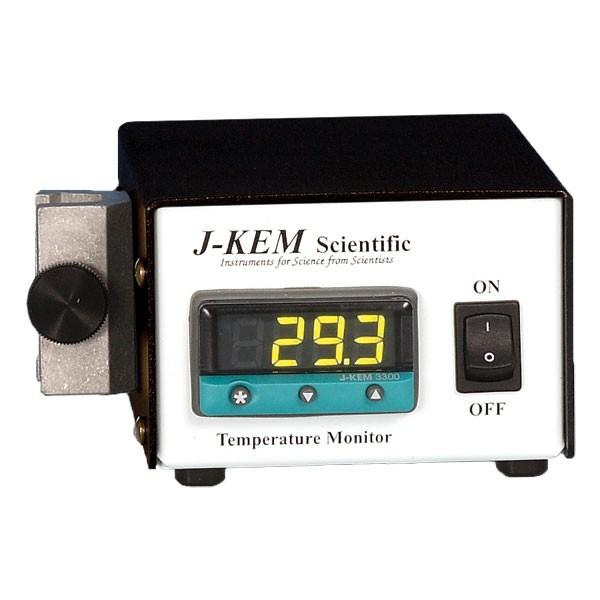

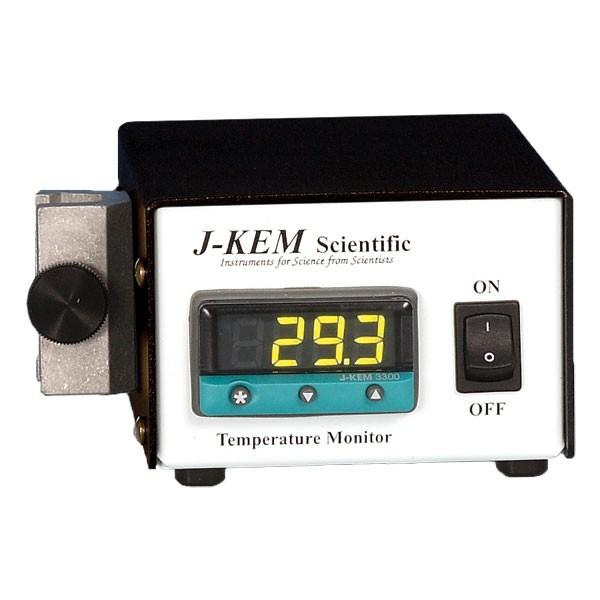

J-KEM Digital Temperature Monitor

J-KEM Digital Temperature Monitor Monitors and displays the temperature of an attached piece of equipment on a bright LED display. Built-in USB and free KEM-Net software provide remote temperature monitoring and data logging to a GLP/GMP compliant file. Audible alarm. Specifications: 120 or 230Vac, 50 watts.Warranty: 2 Years The temperature range desired determines the probe/thermocouple type: J [black] (0 – 800° C) K [yellow] (-50 – 1200° C) T [blue] (-200 – 250° C)

$600.00

2 Gallon Aluminum SIDEMOUNT - POT ONLY

2 Gallon Aluminum - POT ONLY ***Note: 'with Hardware' Option only includes the side-mount manifold with gauge pre-installed. (Does Not Include Lid or Gasket) This is a replacement part for the following Vacuum Chambers: SVac 2 Gallon Aluminum Vacuum Chamber Best Value Vacs 2 Gallon Aluminum Side Mount Vacuum and Degassing Chamber Dimensions: 6.5" Tall x 10" Diameter Hole Size: 21/64 Material: 3004 Aluminum

$48.00 - $68.00

Welch ChemStar 1400N 0.9 cfm 0.1 Micron Belt Drive 2-Stage Pump

Welch ChemStar 1400N 0.9 cfm 0.1 Micron Belt Drive 2-Stage Pump ***Note: This item has a possible 1-2 week lead time depending on stock availability.*** Product Details Low rotation speed for longer service life Vital parts corrosion resistant Large oil reservoir dilutes contaminants ChemStar belt-driven Vacuum Pump is designed to tolerate harsh chemical contamination. Vital pump parts are corrosion resistant. The large oil reservoir with PTFE surfaces dilutes contamination and the low pump rotational speed lessens friction to reduce operating temperature and chemical effects. PTFE surfaces, fluorcarbon gaskets and seals, Nitrogen purge to cool and degas oil. ChemStar system comes with Gold Oil, a synthetic lubricant designed to minimize effects of chemical contaminants. Specifications Model Number 1400N Application Vacuum Manifolds, (Schlenk Lines), High boiling point evaporations (to 195 deg. C), General laboratory. HCl, O3, H2SO4*HBr, HOAC, SOx*Br2, F3CCO2H, H2S*Cl2, CH2O, HNO3*SF6, CF4 Fragments and other gases; Type Belt-Drive Vacuum Pump, chemical resistant Free Air Displacement cfm (l/min.) @60Hz 0.9(25) Ultimate Pressure 1 x10-4(0.00013) Pump RPM 580 Oil Capacity 0.62(0.59) Motor Horsepower (watts) 1/3(250) Adjustable Vac. / Gas Ballast Yes Tubing Needed 7/16(11) ISO Exhaust / Intake Flange NW 16 Overall Dimensions LxWxH in. (cm) 17.8x9x12.6 (45.2x22.9x32) Ship Weight 71(32.3) Shipping Carton Dimensions LxWxH in. (cm) 20.5x13.8x14.5 (52.1x35.1x36.8)

$3,425.00 - $4,350.00

Reducer/Adapter

SSP Reducer/Adapter SSP Instrumentation Duolok® tube fittings are designed, manufactured and quality controlled to be totally “interchangeable” with the Swagelok® brand of tube fittings. Component by component examination plainly shows the two brands as completely “componentintermixable.” The precision manufacturing of both products to stringent tolerances under rigid quality control procedures ensures the safety, performance, and reliability of service whenever Duolok® and Swagelok® component parts are mixed and used in accordance with published installation and service recommendations. Specifications Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Connection Type 2 Tube Stub Connection Size 2 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Duolok Pressure Rating = Tubing Rating SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA! Dimensions A 1.54 in C 0.70 in D 0.60 in E 0.11 in G 9/16 in H 1/2 in T 1/4 in B 1.25 in Tx 1/4 in

$7.50 - $9.00

Female Run Tee

SSP Instrumentation Duolok® tube fittings are designed, manufactured and quality controlled to be totally “interchangeable” with the Swagelok® brand of tube fittings. Component by component examination plainly shows the two brands as completely “componentintermixable.” The precision manufacturing of both products to stringent tolerances under rigid quality control procedures ensures the safety, performance and reliability of service whenever Duolok® and Swagelok® component parts are mixed and used in accordance with published installation and service recommendations. Specifications Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Connection Type 2 Duolok Tube Fitting Connection Size 2 Specified by User Connection Type 3 Female NPT Connection Size 3 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Duolok Pressure Rating = Tubing Rating NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$24.00$15.00

Tool-Less Adapter Assembly

Tool-Less Adapter Assembly This adapter fits on 30mm OD glass flanges. The other side is 1/2" MNPT to connect to various fittings for attaching hoses and like items.

$75.00

BVV Compression 12" Tri-Clamp x (3) 2" Tri-Clamp x (2) 3/8" Compression x 1/4" Compression x 1/2" Compression Hemispherical Lid

BVV Compression 12" Tri-Clamp x (3) 2" Tri-Clamp x (2) 3/8" Compression x 1/4" Compression x 1/2" Compression Hemispherical Lid This End Cap comes with (4) Compression connections and (3) 2" Tri-Clamp ferrules welded to the end cap with a sanitary weld with a 3" Tube Extension Below the Lid. They allow the user to adapt and connect a tube stub connection to the (1) 1/4", (2) 3/8", and (1) 1/2" port on a Tri-Clamp lid and the Tri-Clamp Connections. These 7 connections are welded on a 12" Hemispherical Tri-Clamp End Cap. Specifications Material: 304 Stainless Steel Connection Types: (3) 2" Tri-Clamp with 3" Tube Extension Below Lid on Center Tri-Clamp Port 12" Tri-Clamp (1)1/4", (2) 3/8" and (1)1/2" Female Compression Connections Standard: 3A

$350.00

Best Value Vacs 1.5 Gallon Tall Stainless Steel Vacuum Chamber - W/GLASS LID

Best Value Vacs 1.5 Gallon Tall Stainless Steel Vacuum Chamber - W/GLASS LID This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User-friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 - 2B Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 8-5/8" Tall x 7-1/8" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. DOES NOT APPLY TO GLASS LID VERSION ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$115.00

ULVAC DA-40S 1.6 Cfm Oil-Free Diaphragm Pump - New In Stock

ULVAC DA-40S 1.6 Cfm Oil-Free Diaphragm Pump (Please note: This item has a minimum 6 week Lead Time) This Diaphragm Dry type pump creates vacuum by reciprocate movement of rubber diaphragms. The structure of this pump makes Oil-free environment and maintenance easy. Different pumping speed and two/single stages are optional depending on your required pressure and pumping volume. Applications: Vacuum chucks, wafer and tip handling devices. Vacuum tweezers, medical appliances. Printing equipment. Automatic packing machines. Optical appliances. Specifications Unit 50Hz - 60Hz Actual Pumping Speed L/min 40 - 46 Ultimate pressure Pa 19.9 x 10^3 Motor Single phase, 100V, 60W, 4P, Capacitor run Full load current A 1.6 Weight kg 7.2 Inlet, outlet pipe diameter mm O.D. dia.9 × I.D. dia.5 (Rc 1/4) Ambient temperature °C 7 – 40 Overall dimensions mm 128(W) × 242(L) × 178(H)

$1,100.00$550.00

REFURBISHED BVV4D

Refurbished BVV™ V4D 4CFM Two Stage Vacuum Pump ***NOTE: Refurbished products are 100% re-tested at our warehouse to be fully functional. The customer acknowledges that by buying a refurbished product the item may have imperfections or slight damage to the product such as: Major/Minor Scratches Major/Minor Dents Smells or Odors (Cleaned as much as possible at warehouse) This is the BVV™ V4D 4CFM Two Stage Vacuum Pump used in botanical extraction. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Feature Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer oil life Lightweight Rubber Feet for noise dampening Reliable, economical, and efficient Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports Pump Warranty Information Customers using solvents such as stabilization resin, rotaries (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$340.00$200.00

AVS-16.75X6 Screen (No Housing) (Compare to Custom Cones)

AVS-16.75X6 Screen (No Housing) Description Please note that this screen is for use with Automtic Vibrating Sifter - Industrial 16.25 x 6" Machines ONLY. It is not compatible with the Automatic Vibrating Sifter - Commercial 15.50 x 4". Specifications: COMPATIBLE WITH: Automtic Vibrating Sifter - Industrial 16.25 x 6" (This is not compatible with the Automatic Vibrating Sifter - Commercial 15.50 x 4".) SCREEN DIAMETER: 16.75 Inches SCREEN DEPTH: 6 Inches HOLE SHAPE: Square

$80.00

CNC Packaging C- Solo Cartridge Filling Machine

C- Solo Cartridge Filling Machine C-SOLO KEY FEATURES: Hands Free Foot Pedal Operation Fills up to 2200 units per hour Fills pods, disposables, carts, and luer lock syringes Internally Integrated Heating System Fill Volume from 0.1mL to 1.1mL *available in 3ml upon request* Low Maintenance Design Designed and Manufactured in the USA C-SOLO SPECIFICATIONS: 0.1-1.1mL Filling Volume OR 0.3-3.1mL Filling Volume Filling Accuracy +/- 0.02mL 500mL Capacity 2 zone PID Temperature Control Vessel Temperature from 10° to 75° C Syringe Temperature from 10° to 90° C 0-30psi System Purge Up to 750 psi Injection Pressure REQUIREMENTS: 120vAC 3A Single Phase Filtered, Dry and Oil Free Compressed Air, 80psi 20x20x24” Table Area (LxWxH) Plus Foot pedal Operation Manual

$9,500.00 - $10,500.00

Ai DigiM 5L 300C 1200 RPM PID Controlled Digital Heating Mantle

Ai DigiM 5L 300C 1200 RPM PID Controlled Digital Heating Mantle Across International heating and stirring mantles come standard with a digital display for the most accurate control. The large display interface makes it easy to quickly and precisely adjust temperature and rotation speeds.The DigiM mantle has two sets of thermocouples for proper temperature and speed detection. The heating jacket is pre-treated before shipment, which ensures that no smoke or odors (caused by heat) are released into your work environment. Specifications Model DigiM5 Electrical requirements 110V 60Hz 1-Phase, 1100 watts, 12A or 220V 50/60Hz 1-Phase, 1100 watts, 6A Heating Ambient to 300°C Stirring Min. speed: 110 rpm, max. speed: 1200 rpm Motor power: 40 watts Motor type: brushless DC motor Controller PID control with digital temperature and rotation speed display External thermocouple Type: PT100 Cable length: 43 inches Stainless steel probe length: 15 inches Stainless steel probe diameter: 5 mm Flask holder Maximum flask capacity: 5 liters Top opening diameter: 9 inches Depth: 5.5 inches Dimensions (WxDxH) Unit: 13.5 x 17 x 10 inches, shipping: 20 x 16 x 15 inches Weight Unit: 22 lbs, shipping: 32 lbs Safety Thermocouple failure protection Certification ETL tested to UL and CSA standards (optional), CE (standard) Warranty One year Standard package Part description Quantity Part image Ai DigiM 5L digital heating & stirring mantle 1 set External temperature probeDigiM05, DigiM2, DigiM5: Cable Length: 40”, Probe Length: 9” DigiM10, DigiM20: Cable Length: 43”, Probe Length: 15” 1 pc Internal temperature plug 1 pc Boss head DigiM2, DigiM5:- 1 pc DigiM10 and DigiM20: 2 pcs 1 or 2 pcs Stainless steel support rod DigiM2, DigiM5:- 1 pc DigiM10 and DigiM20: 2 pcs 1 or 2 pcs PTFE coated stir bar 2 pcs PTFE coated magnetic stir bar remover 1 pc 4 prong stainless steel clamp opens to 3 1/2" DigiM2, DigiM5:- 1 pc DigiM10, and DigiM20: 2 pcs 1 or 2 pcs User's manual 1 pc

$990.00 - $1,340.00

Ethylene Glycol 99.9%

Ethylene Glycol 99.9%, also know as the trade name Mono-ethylene Glycol (MEG). Ethylene glycol (EG) is by far the most produced glycol product. This glycol is polyester grade which means its the highest purity 99.9% and is therefore the highest grade available. There are 3 grades available: : fibre, industrial and antifreeze. The markets for EG products are polyester fibres, polyethylene terephthalate (PET) plastics, coolants in automobile antifreeze, and resins. The excellent humectant (hygroscopicity) properties of EG products also make them ideal for use in fibres treatment, paper, adhesives, printing inks, leather and cellophane. Ethylene glycol is also a commonly used with fog generators or artificial smoke production. Ethylene Glycol Certificate of Analysis COA Ethylene Glycol Safety Data Sheet SDS

$18.00 - $2,450.00

Lab Armor BEAD BATH

BEAD BATH Unique DESIGN Lab Armor Bead Baths were specifically designed to work with Lab Armor Beads to optimize their performance. Uniform Temperatures With Bead Bath designed expressly for beads, temperatures are consistent and uniform everywhere in the bath. Thermal uniformity is +/-1.0 at 37ºC. Always On The bath always stays on, so you don’t have to plan around warmup times. You don’t need to worry about refilling or low water burnout because there is no water to evaporate. Lab Armor Bead Baths are up to 50% more energy efficient than a standard lab water bath. Stays Clean Lab Armor reduces the risk of contamination. Contaminated samples and reagents result in distorted data and unpredictable outcomes. Stays Organized Unlike water baths that require racks, floats, and bottleneck weights, Bead Bath naturally holds things in place without accessories. So no more floating accidents.

$1,462.00 - $2,690.00

SCILOGEX SCI550-Pro LCD Digital 7 x 7 Magnetic Hotplate Stirrer, ceramic-glass plate, 110V, 50/60Hz US Plug

SCILOGEX SCI550-Pro 7x7 LCD Digital Hotplate Stirrer 550ºC/1500rpm Max Product Description The SCI550-Pro is one of the most technically advanced hotplate-stirrers in the marketplace. With independent back-lit LCD displays for both heat and stirring functions and PID technology. The SCI550-Pro controls temperature at +/- 1ºC. It also incorporates a DC brushless (spark free) motor for extremely long life and excellent performance. It is widely used in chemical synthesis, physical and chemical analysis, biopharmaceuticals etc. Combining with glass ceramic work plate, brushless DC motor and external temperature sensor, the work plate temperature is optimized up to 550°C. Product Features Easy-to-read independent back-lit LCD displays for heat and stirring. Digital speed controlling, max. speed at 1500rpm Built-in PID controller ensures safe heating of the medium with overheating protection. Heat only, stir only or heat and stir together functions. Max. heating plate temperature 550°C Glass ceramic work plate provides excellent chemical resistant performance and most efficient heat transfer. RS232 for remote control, providing PC control and data transmission. Low temperature stability External temperature control is possible by connecting the temperature sensor (PT1000) with an accuracy at ±0.2°C. Accessory PT-1000 stand available (built in stand mount) Electronic speed control for constant speed even during changes in load Maintenance free DC brushless motor for long life and more stirring power Two rotating knobs enable easy adjustment of speed and temperature. High magnetic adhesion “HOT” warning will flash when the work plate temperature is above 50°C even when the hotplate is turned off. cTUVus approved for UL and CSA 2 YEAR WARRANTY Work plate dimension[W x D] 184x184mm(7 inch) Work plate material Glass ceramic Motor type Brushless DC motor Motor input power 18W Motor output power 10W Power 1050W Heating output 1000W Voltage 110V, 60Hz Stirring positions 1 Max. stirring quantity[H2O] 20L Max. magnetic bar[length] 80mm Speed range 100-1500rpm, resolution ±1rpm Speed display LCD Temperature display LCD Heating temperature range Room Temp.-550°C, increment 1°C Temperature control accuracy ±1°C(<100°C) ±1%(>100°C) Overheating protection 580°C Overheating protection ±0.1°C External temperature sensor PT1000 (accuracy ±0.2) "Hot" warning 50°C Data connector RS232 Protection class IP21 Dimension[WxDxH] 215x360x112mm Weight 5.3kg Permissible ambient temperature and humidity 5-40°C, 80%R Additional Resources and Information Downloadable PDFs SCI550-Pro Manual Hotplates & Stirrers Brochure Hotplates & Stirrers Accessories

$784.00 - $841.00

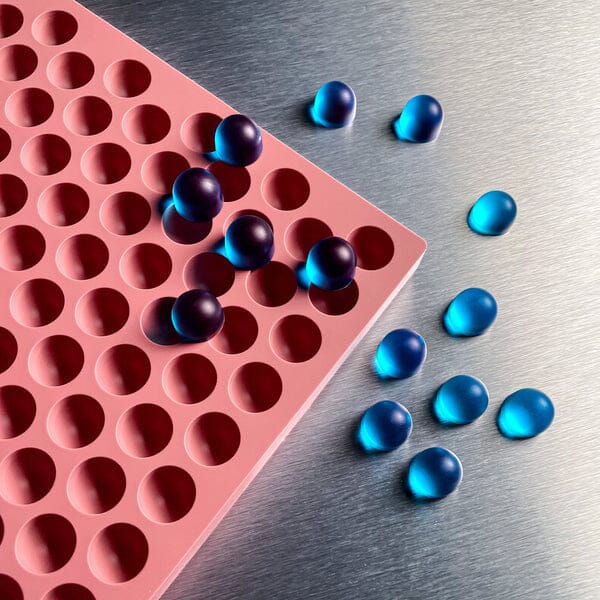

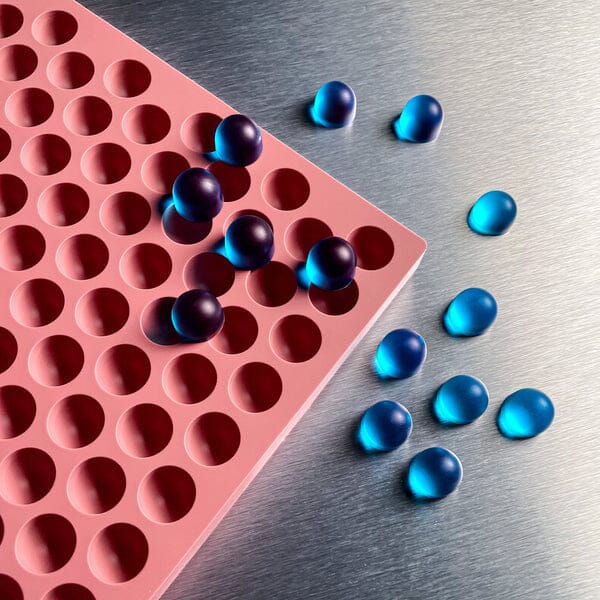

Dark City Molds Gumdrop Gummy Molds

Dark City Molds Gumdrop Gummy Molds Available Sizes: 1.3mL 2.15mL 3.6mL MOLD PROPERTIES 100% FDA Approved Food-Contact Safe Platinum Silicone Temperature Resistant - Freezer, Dishwasher & Oven Safe Half Sheet Molds Are Optimized to Fit 2 Molds Per 18” x 26” Full Size Baking Sheet Strategically Designed Geometry Optimized For Rapid Extraction Proprietary Natural Slip Finish For Oil Free Workflow Precision Diamond Tooled Masters For Superior Detail & Finish Guaranteed Highest Resolution Designs On The Market Rapid Demolding Rates - Extract up to 1000+ Gummies Per Minute Perfect for Gummies, Hard Candies, Caramels, Chews, Chocolates, and More 6-10 Year Expected Lifetime with Proper Care & Use OUR PROMISE Every mold that leaves our facility is covered by DCM’s 18 Month Gold Standard Warranty. If you experience any issues within that period, we'll immediately exchange the mold in question. No hassle. No fuss. Committed to creating the highest quality platinum silicone molds in the world. Whether you’re manufacturing gummies, hard candies, caramels, chews, or other confections, our diamond tooled molds will provide superior finish and detail to ensure maximal aesthetic clarity and operational efficiency for your manufacturing workflow. We’re proud to offer best-in-industry performance with our Rose Pro Series™ silicones as well as the most competitive price points on translucent platinum molds currently available. *Assumes a 1ml : 1.4g recipe ratio. Since weight is a metric of a recipe's specific density, we cannot exactly determine the weight of your specific recipe. Please consult the designated volume (ml) specification above to calculate a more exact weight (g) reading. All Dark City Gold Standard SOPs yield a 1ml : 1.4g ratio. Mold Specifications Sizes Avaliable (Volume) Shape Pieces Per Mold Weight Material Options Mold Dimensions Compatibility Square Molds 2.5mL Square 134 3.5g Rose Pro Series, Translucent 280mm x 392mm Hand Fill, Flood & Scrape, Universal Depositor 2.85mL Square 234 3.5g Rose Pro Series, Translucent 290mm x 390mm Hand Fill, Flood & Scrape, Universal Depositor 3.57mL Square 120 5g Rose Pro Series, Translucent 276mm x 387mm Hand Fill, Flood & Scrape, Universal Depositor 4mL Square 192 5.6g Rose Pro Series, Translucent 290mm x 390mm Hand Fill, Flood & Scrape, Universal Depositor 6mL Square 165 8.4g Rose Pro Series, Translucent 391.6mm x 286.5mm Hand Fill, Flood & Scrape, Universal Depositor Cube Molds 1mL Cube 609 1.5g Rose Pro Series, Translucent 286mm x 398mm Hand Fill, Flood & Scrape, Universal Depositor 1.6mL Cube 275 2.2g Rose Pro Series, Translucent 289mm x 384mm Hand Fill, Flood & Scrape, Universal Depositor 2.2mL Cube 209 3g Rose Pro Series, Translucent 289mm x 365mm Hand Fill, Flood & Scrape, Universal Depositor, Baker Perkins ServoForm Mini 3.4mL Cube 280 4.8g Rose Pro Series, Translucent 275.9mm x 394.7mm Hand Fill, Flood & Scrape, Universal Depositor Triangle Molds 2.66mL Triangle 210 3.7g Rose Pro Series, Translucent 280mm x 379.7mm Hand Fill, Flood & Scrape, Universal Depositor 2.8mL Tetrahedron 95 3.9g Rose Pro Series, Translucent 135mm x 374mm Hand Fill, Flood & Scrape, Universal Depositor 4.1mL Triangle 160 5.7g Rose Pro Series, Translucent 285mm x 384mm Hand Fill, Flood & Scrape, Universal Depositor Mutidose Molds 2.25mL Cube 144 3.2g Rose Pro Series, Translucent 254mm x 355mm Hand Fill, Flood & Scrape, Universal Depositor 3.3mL Rhombus 209 4.6g(each segment: 2.3g*) Rose Pro Series, Translucent 284mm x 375.4mm Hand Fill, Flood & Scrape, Universal Depositor 4mL Square 165 5.5g Rose Pro Series, Translucent 289mm x 380mm Hand Fill, Flood & Scrape, Universal Depositor 12.5mL Rectangle 60 17.5g Rose Pro Series, Translucent 279.3mm x 385.2mm Hand Fill, Flood & Scrape, Universal Depositor 23.5mL Square Rope 20 32g (each segment: 3.2g*) Rose Pro Series, Translucent 258mm x 385mm Hand Fill, Flood & Scrape, Universal Depositor 42.4mL Rectangle 18 59.4g Rose Pro Series, Translucent 240.9mm x 381.3mm Hand Fill, Flood & Scrape, Universal Depositor Cube Molds 1mL Cube 609 15.g Rose Pro Series, Translucent 286mm x 398mm Hand Fill, Flood & Scrape, Universal Depositor 1.6mL Cube 275 2.2g Rose Pro Series, Translucent 289mm x 384mm Hand Fill, Flood & Scrape, Universal Depositor 2.2mL Cube 209 3g Rose Pro Series, Translucent 289mm x 365mm Hand Fill, Flood & Scrape, Universal Depositor 3.4mL Cube 280 4.8g Rose Pro Series, Translucent 275.9mm x 394.7mm Hand Fill, Flood & Scrape, Universal Depositor Coin Mold 2.5mL Coin 120 3.5g Rose Pro Series, Translucent 276mm x 387mm Hand Fill, Flood & Scrape, Universal Depositor 2.17mL Coin 176 3g Rose Pro Series, Translucent 289mm x 374mm Hand Fill, Flood & Scrape, Universal Depositor 2.5mL Coin 120 3.5g Rose Pro Series, Translucent 276mm x 387mm Hand Fill, Flood & Scrape, Universal Depositor 3.26mL Coin 165 4.6g Rose Pro Series, Translucent 289mm x 385mm Hand Fill, Flood & Scrape, Universal Depositor 7.1mL Puck 88 9.9g Rose Pro Series, Translucent 283.2mm x 390.2mm Hand Fill, Flood & Scrape, Universal Depositor 7.1mL (Bit) Coin 88 9.9g Rose Pro Series, Translucent 280.2mm x 386.1mm Hand Fill, Flood & Scrape, Universal Depositor 34.3mL Coin 35 48g Rose Pro Series, Translucent 268.1mm x 371.7mm Hand Fill, Flood & Scrape, Universal Depositor 45.2mL Coin 20 63.3g Rose Pro Series, Translucent 293.0mm x 365.3mm Hand Fill, Flood & Scrape, Universal Depositor Gum Drop 1.3mL Gum Drop 388 1.82g Rose Pro Series, Translucent 286mm x 390mm Hand Fill, Flood & Scrape, Universal Depositor 2.15mL Gum Drop 176 3g Rose Pro Series, Translucent 289mm x 392mm Hand Fill, Flood & Scrape, Universal Depositor 3.6mL Gum Drop 140 5g Rose Pro Series, Translucent 259mm x 363.6mm Hand Fill, Flood & Scrape, Universal Depositor

$195.00 - $250.00

BVV Bead Bath

BVV Bead Bath Introducing the BVV's Bead Bath - A cost-effective Bead Bath for Precise and Contamination-Free Laboratory needs. The Bead Bath is a cost-effective bead bath that allows for precise temperature application to warm your extracts, distillates, and isolates faster than a traditional hot plate eliminating water contamination. Unlike traditional water baths, bead baths replace water with reusable metallic beads, eliminating the risk of experimental contamination and ensuring accurate results. With the Bead Bath, you can say goodbye to high electricity consumption and frequent cleanup. The bead bath's efficient design minimizes power usage, as the beads do not evaporate, and require less maintenance, saving you time and resources. Experience rapid start-up times and uniform heating with the Bead Bath's surround heating feature. This cutting-edge technology guarantees even temperature distribution, preventing hotspots and ensuring consistent and reliable outcomes for your samples. Safety is our top priority, and the Bead Bath is no exception. Equipped with over-temperature protection, this bead bath maintains safe and stable conditions for your valuable samples throughout the entire experiment. Discover the benefits of the BVV Bead bath and revolutionize your laboratory work with contamination-free, precise, and efficient temperature control. Join researchers and professionals worldwide in experiencing the power of the #1 bead bath ranked on Google. Upgrade your experiments with the BVV's Bead Bath. Bath internal dimensions: 2 quart: 6.75” Tall X 4.75” Diameter 1.5 Gallon: 8-5/8" Tall x 7-1/8" Diameter 3 Gallon: 9" Tall x 10" Diameter 7 Gallon: 8" Tall x 16" Diameter Does not include Beads If the option is selected to include aluminum beads, the quantities will be: 2 quart: 2 liters 1.5 Gallon: 4 liters 3 Gallon: 9 liters 7 Gallon: 18 liters

$130.00 - $2,075.00

ChemTek 6" Sweating Baskets

ChemTek 6" Sweating Baskets Sweat the terpene sauce off of your crystalized compounds or dry out sugars. Specifications: 25 Micron 304 Stainless Steel H: 4.5” W: 6”

$25.00 - $80.00

ChemTek Regular Mouth Basket Support

ChemTek Regular Mouth Basket Support Made for supporting the centrifuge baskets to allow for higher RCF. Specifications: 304 Stainless Steel

$50.00 - $185.00

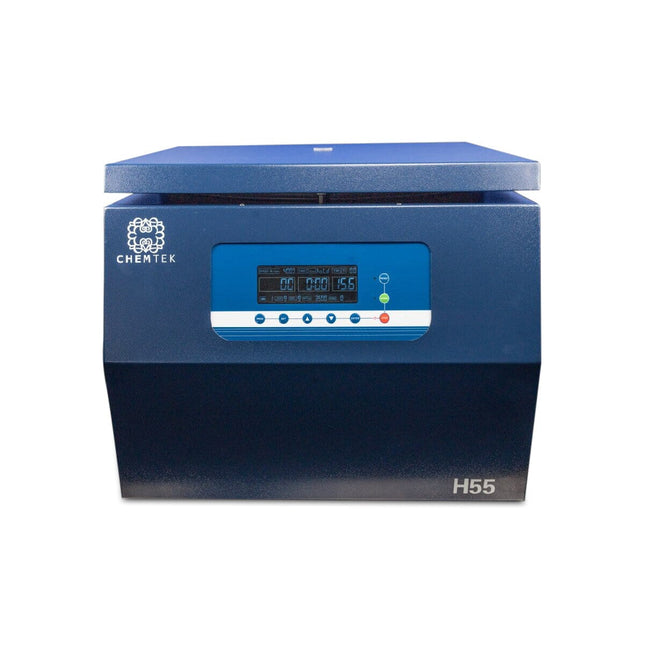

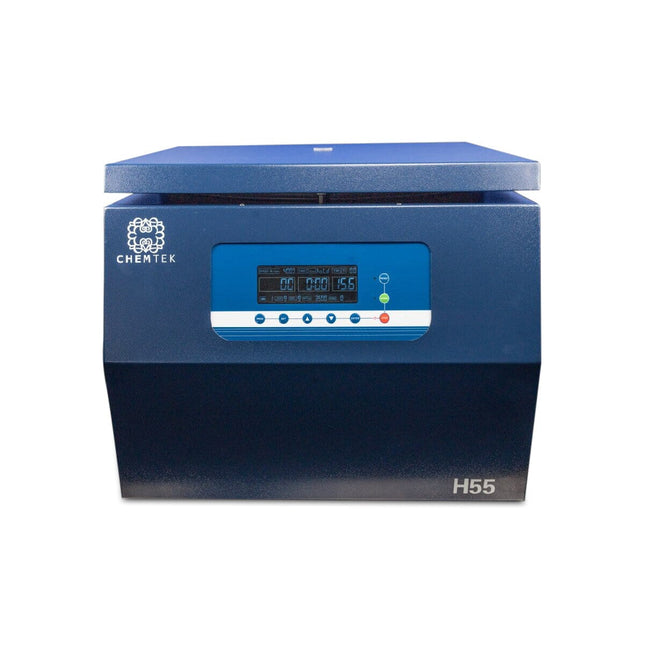

ChemTek H55 Centrifuge

ChemTek H55 Centrifuge H55 centrifuges provide excellent performance and easy operation in a compact design that saves valuable time and laboratory space. The H55 is heated to assist with separation. Specifications: Power Supply: 110V 50/60Hz Max Speed: 4000 RPM Max RCF: Max Capacity:4x750ml Heat Capacity: 10C-70C Time Setting Range: 1 - 99min Speed Accuracy: ± 10r/min Noise: ≤65dB Power Consumption: 1500W Dimensions: Net Weight: 170lbs Comes with: (20) 50ml Tubes (4) Regular Mouth Basket (4) Wide Mouth Baskets (4) Regular Mouth Stainless Jar Lid/Band (4) Wide Mouth Stainless Jar Lid/Band (4) Five 50ml Tube Holder Inserts (4) Regular Mouth Jar Spacer Inserts (4) Wide Mouth Jar Spacer Inserts (1) 50-pack 5”x 7” Double Stitched Fuge Bags (1) 50-pack 6.5”x 7” Double Stitched Fuge Bags (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves

$7,100.00

CHEMTEK ChloroSorb Neutral

CHEMTEK ChloroSorb Neutral ChloroSorb Neutral is an acid-activated bentonite/carbon adsorbent that has been neutralized to a neutral pH of 7. General uses are bleaching, deodorizing, or heavy metal removal. ChloroSorb Neutral SDS

$50.00 - $2,250.00

Extraction RACK #7

Extraction RACK # 7 Rack 7 has 4.5" thick vertical support bars and 3x horizontal bars to complete our strongest standard extraction rack. This rack includes 4x locking caster wheels that can also be adjusted to be level on uneven surfaces. For ease of mounting equipment, we recommend our pipe hangers with hang on brackets Rack Dimensions (L x W x H) 30" x 39" x 60" (Assembled units come with a 30-day warranty) Note: The unit does not come assembled - select "pre-assembled" from the drop-down menu to have the unit assembled by BVV before shipping Pipe hangers are not included There is no warranty on unassembled units Shipping Notice: If the customer orders the rack as assembled, then the item will only ship via freight and there will be additional shipping charges.

$1,415.00

BVV Gift Certificate

Don't know what to get for Christmas? Give a gift certificate

$10.00 - $500.00

Sleeved Recovery Tank

Sleeved Recovery Tank Built for optimized recovery performance and efficient use of dry ice, these sleeved recovery spools are the perfect prechilling and recovery solutions for hydrocarbon extraction. Available in 5LB,10LB, & 22LB butane capacities these sleeved recovery tanks are a great upgrade for any of our 1-5lb extractors. All models of our Sleeved Recovery tank come complete with a 1/2" JIC recovery port, a 1/4" JIC drain port, 2X 1/4" JIC accessories ports, 2X Borosilicate sight glasses, a single -30hg-250PSI Compound Pressure Gauge, and a 125 PSI ASME pressure relief valve to provide maximum compatibility and versatility across processing platforms. Specifications 6"x12", 6"x24", 12"x12" Sleeved spool Hemi ring stand with 1/4" JIC drain valve 2X Borosilicate Sight Glasses 1X 125 PSI ASME pressure relief valve 1X -30hg-250PSI Compound Pressure Gauges 1X 1/2" JIC Recovery Valve 2X 1/4" JIC Accessory Valves 1X JIC Drain Valve Maximum Pressure Rating: 125PSI

$1,000.00 - $1,800.00

55 Gallon Hash Ice Water Extraction Washing Vessel

BVV's 55 Gallon Ice Water Extraction Washing Vessel Made in USA Designed with durability and ease of use in mind our Ice Water Extraction Washing Vessels are manufactured from 16 gauge 304 stainless steel crafted with seamless welds for a 100% sanitary construction. Our easy drain barrels come complete with 4X 1.5" Triclamp drains mounted as low as possible for effortless draining of its 55-gallon volume capacity. Perfect for medium to large-scale ice water extraction labs this stand-alone vessel pairs nicely with Boldtbags Large Open Top Wash Bags & Boldt bags 44 gallon Lock-top Full Mesh Stackers. Processing Power Material Capacity Per Batch: 20-30LB Water Capacity: 55 Gallons Cycle Time: 60-90 Minutes Daily Extraction Capacity: Up to 60 lb, per 8-hour shift Specifications 23"x36" 55-gallon Stainless Steel Washing Vessel Seamless 304 Stainless Steel Construction 4X 1.5" Tri-clamp ports for draining, filling, temperature sensing, or sight glasses Performance Low-mounted drain ports for complete draining

$1,500.00

5/16-18 Grade 2 Steel Nylon Locknut - 5 Pack

5/16-18 Grade 2 Steel Nylon Locknut 5/16 - 18 Low Profile Lock Nut. This nut fits on vacuum chamber gauges and manifolds. SOLD AS A 5PACK

$2.00

Beaker and Wrench KF25 Clamp and Gasket Set

Beaker and Wrench KF25 Clamp and Gasket Set This FK25 Clamp and gasket set is specifically designed to attach a glass KF25 flange to a steel or PTFE flange. The gasket materials are PTFE and Viton.

$115.00

50L Pre-Built Collection Base

50L Pre-Built Collection Base Designed with hydrocarbon extraction in mind. This pre-build collection base boasts a 50lb butane capacity at an 80% fill making it the perfect fit for extractors looking to process up to 10 lbs of biomass material at a 5:1 Butane to biomass ratio. Complete with 1/2" JIC drain and recovery ports, a 1/4" JIC accessory port, a -30hg -250 PSI compound gauge, and a 125 PSI ASME Pressure relief this collection base is versatile in use and highly compatible with most systems. A main staple in our Research & Development lab and standard with our 10LB ECO Closed Loop Extractor this 50L Pre-built Collection Base is perfect for anyone looking to expand their processing capabilities. For speedy hydrocarbon solvent recovery rates this reactor pairs well with our 11KW Express Extraction Heater for passive recovery rates past 1lb/min. Processing Power Volume: 50 Liters Capacity: 50LB of butane @80% Fill Maximum Pressure Rating: 125PSI Jacket Capacity: 15 liters Specifications 2X Borosilicate Sight glasses 1X 1/2" JIC Drain Port 2X 1/2" JIC Lid Ports 1X 1/4" JIC Lid Port 2X 1/2" Barbed Jacket Connections 1X 125 PSI ASME Safety Valve 1X -30hg-250PSI Compound Pressure Gauges

$2,000.00

5/16 USS Flat Washer

5/16 USS Flat Washer 5/16 replacement washer for vacuum chamber bulkheads made out of metal.

$0.50

True Terpenes Hawaiian Haze

True Terpenes Hawaiian Haze Fragrance: Pineapple Coconut Mango Citrus Effects: Soothing Uplifting Hawaiian Haze will have you thinking of your next trip to the islands or that summer you spent by the pool. Hawaiian Haze has a heavy base of coconut and pineapple and layers mango and citrus notes on top. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution. Hawaiian Haze-Specific Certificates: Product Specification Certificate of Analysis Safety Data Sheet Food Safety Company-Specific Certificates: ISO 9001:2015 GMP Certification FSSC 22000

$121.50 - $2,250.00

You have seen 1248 out of 1671 products