EVERY PRODUCT BUT HYDRO FOR WHOLESALE STORE

1/2" Compression End Cap 1.5" Triclamp

1/2" BVV Compression End Caps These End Caps come with a 1/2" Female Compression connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a 1/2" male tube stub connection to the lid. Specifications Material 304 Stainless Steel Connection Type: Tri-Clamp 1/2" Female Compression Connection Standard: 3A

$58.00

Synder NFS Membrane (200-300Da MWCO)

Synder NFS Membrane With a pore size ranging between 0.1-10nm, Synder Filtration's nanofiltration membranes enable the passage of water and certain salts through the membrane while effectively retaining multivalent ions, low molecular weight molecules, sugars, proteins, and various organic compounds. A result of extensive research and development, Synder's NFS, NFX, NFW, and NFG nanofiltration membrane products have demonstrated exceptional resistance to fouling, a high level of selectivity, and the physical durability necessary for diverse industrial separation processes. Specifically, NFS, NFX, and NFW exhibit outstanding rejection of MgSO4 and lactose, while NFG is designed to partially remove monosaccharides from oligosaccharides. These nanofiltration membranes, as a whole, have the capacity to significantly reduce levels of hardness, nitrates, sulfates, tannins, turbidity, color, total dissolved solids (TDS), and moderate levels of salt from feed water streams. The proven performance of Synder's nanofiltration membranes makes them well-suited for a broad spectrum of industrial applications including the desolvation of ethanol from botanical extract solutions. BVV utilizes 4X NFS 2540 Membranes inside our Nanofiltration Skid to recovery ethanol at 30 Gallons per hour. Specifications Polymer: Proprietary PA TFC Approx. Molecular Weight Cutoff: 100-250 DA Typical Operating Flux 30-40 GFD Average Lactose Rejection: 99.5% Average MgSO4 Rejection: 99.5% Average NaCl Rejection: 50% Maximum Operating Pressure <95F/35C: 600PSI/41.4 Bar Maximum Operating Pressure >95F/35C: 435PSI/30 Bar Maximum Pressure Drop per Element: 15PSI/1.0 Bar Maximum Pressure Drop per hosing: 60PSI/4.1 Bar Maximum continuous Operation Temperature: 122F/50C Maximum CIP Temperature: 104F/40C Maximum Temperature Operating pH Range: 3-9.5 Ambient Temperature Operating pH Range: 3-10.5 Maximum Temperature Cleaning pH Range: 2-11 Ambient Temperature Cleaning pH Range: 2-11

$978.00 - $1,245.00

Neocision Vacuum Oven Shelves

Neocision Vacuum Oven Shelves These are stainless steel oven shelves for our Neocision Vacuum Ovens and fit either a 0.9CF or a 1.9CF Neocision Oven. Specifications: 0.9CF - 11" (279mm) x 11.2" (285mm) x 1/8" Thickness 1.9CF - 14" (356mm) x 15.75" (400mm) x 1/8" Thickness

$35.00 - $45.00

BVV Complete Gen III Upgraded Rebuild Kit

BVV Complete Gen III Upgraded Rebuild Kit This upgraded rebuild kit contains everything you need to rebuild your TRS21 recovery pump and give a needed upgrade through improved seals, pistons, and O-rings. This upgrade kit can be used for the following recovery pumps: CPS TRS21 Anti-spark/explosion pump BVV 2 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified BVV 4 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified - Requires 2 kits because this unit has 4 cylinders. This Kit includes the follow items: Upgraded Cylinder Replacement kit with Viton O-rings and Shims Upgraded Gen III 2 pc. SS Connecting Rod Assembly 2 pc 1/4" 45 Degree SAE stainless Steel Fittings

$315.00

Julabo Adapter M16x1 f to NPT 1/2″

Julabo Adapter M16x1 f to NPT 1/2″ 2 Adapters M16x1 f. to NPT 1/2″ m.

$210.00

Neoprene Gasket for Cubes

NEOPRENE GASKET FOR CUBES Replacement Neoprene gasket for acrylic vacuum chambers. The existing gasket will have to be completely removed in order to get the new one to seal. It is recommended to use a cleaning solution such as CitraKlean.

$39.00

Huber DW-Therm HT P20.340.32 Heat transfer fluid 20 to 340 °C

Huber DW-Therm HT 20 to 340 °C Heat transfer fluid Huber heat transfer fluids are recommended for many temperature control applications because they have the best possible thermodynamic and environmental characteristics. Safe reliable operation relies on compliance with safety standards to ensure optimal results. DW-Therm HT is a mixture of partially hydrogenated naphthalenes. It is especially suited for high temperature applications using hydraulically sealed thermostats. Please note: Valid only for Unistats Safety Data sheet Advantage: broad working range from 20 °C up to 340 °C (hydraulically sealed systems) Long lifetime at high temperatures under inert atmosphere: 3 -4 years Good thermal properties for heat transfer High thermo-oxiation stability Properties Working temperature°C 20 to 340 Flash Point °C 190 Flash Point °C approx. 218 Viscosity mm2/s (kinematic at 25 °C) 32 Density g/cm3,(at 20 °C) 1,043 Pour Point °C -30 Ignition temperature °C 385 Colour orange, clear Thermal expansion coefficient 10-5/K not specified Heat conductivity W/(m·K) at 30 °C 0,130 Material incompatibility not specified

$835.00 - $1,440.00

Welch 2019 Diaphragm Pump - vacuum filtration

Welch 2019 Diaphragm Pump - vacuum filtration ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details PTFE Contact Surfaces Light and Portable Economical Model 2019 diaphragm vacuum pump is durable and chemical resistant. Use Model 2019 for vacuum filtration, desiccation, degassing, and other mid-range vacuum applications. Recommended for operations utilizing organic / aqueous solvents and or light acid / base (e.g. acetic acid) solutions. Ideal for single funnel vacuum filtrations, SPE manifolds, or up to 6 holder manifold filtrations. Specifications Free Air Displacement, CFM (l/min) 1.3 (37) Ultimate Vacuum, torr (mbar) 150 (200) Max. Vacuum, in Hg 24 Tubing Needed, I.D. in. (mm) 1/4 (7) Weight, lbs 10.2 Overall Dimensions 8.8 x 5 x 8.8 MODEL 2019B-01 / 2019C‐02

$1,175.00

10L Neocision Dual Head Short Path Distillation Turnkey System

10L Neocision Dual Head Short Path Distillation Turnkey System This unit carries a 2 day lead time. The 10L Neocision Distillation Turnkey Setup features our Dual 10L P5 Distillation Heads and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included is a KF-25 Vacuum Pump giving you extreme power and depth with a long lifespan, the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market, and a BVV 19L Heated Circulator for maximum condensation of vapors. You will also receive a Dual Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The Premium Turnkey Kit Includes: 10L Neocision Kit with Dual P5 Distillation Heads KF-25 2 Meter Bellows Dual Dewar Style Glass Cold Trap Bullseye Precision Vacuum Gauge BVV 19L Heated Circulator Your Choice Of KF-25 Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$13,250.00 - $17,750.00

Vacuubrand MD 4C NT 2.2 CFM Chemistry Diaphragm Pump 110V

Vacuubrand MD 4C NT 2.2 CFM Chemistry Diaphragm Pump 110V MD 4C NT Technical Data Sheet.pdf These three-stage diaphragm pumps are an excellent solution for continuous, oil-free pumping of non-corrosive gases. They reach an excellent ultimate vacuum of 1 mbar. All parts in contact with pumped gases and vapors are made of aluminum, stainless steel and carefully selected plastics suitable for a wide range of applications with non-corrosive gases. The new NT-series provides whisper quiet and ultra-low vibration operation, high leak tightness and improved performance. The highly flexible fabric-reinforced double diaphragm made of FKM is ideal for extended operating life. These three-stage diaphragm pumps are an excellent choice for continuous, contamination-free evacuation and pumping of non-aggressive gases at demanding vacuum conditions. They are especially suitable for applications in physics and analytics. The low ultimate vacuum makes these an attractive alternative to rotary vane pumps in many applications. Typical uses are as backing pump for turbomolecular drag pumps, and for degassing of viscous media. Performance features: Outstanding chemical resistance and superior vapor tolerance Exceptionally high performance even at low vacuum Excellent ultimate vacuum even with gas ballast Whisper quiet and very low vibration Long diaphragm life, maintenance-free drive system Technical Data Max. pumping speed 50 Hz 3.8 m3/h Max. pumping speed 60 Hz 2.5 cfm Ultimate vacuum 1 mbar / 0.75 torr Number of heads 4 Number of stages 3 Lower ambient temperature (operation) 10 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 1.1 bar Anschluss saugseitig small flange KF DN 16 Outlet connection Silencer / G1/4" Rated motor power 0.25 kW Rated motor speed at 50/60 Hz 1500/1800 min-1 Protection class IP 40 Dimension L in mm 328 mm Dimension W in mm 239 mm Dimension H in mm 198 mm Weight 16.4 kg Noise level at 50 Hz, typ. 45 dBA Rated mains voltage range 1 230 V Mains frequency 1 50-60 Hz NRTL certification

$4,990.00

10" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves

10" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 10" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with (2)1/4" and (1)3/8" 37° JIC Flares, and compound gauge. These lids are made out of 304 stainless steel and have (1) 1.5" and (2) 2" Tri-Clamp ports with the middle 1.5" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2) 1/4" and (1) 3/8" 37° JIC Tri-Clamp Size(s) (1) 1.5" Ports x (2) 2" x 10" Tri-Clamp Nitrogen Tested Yes

$370.00

2" Tri-Clamp x 3" x (2) 1/4" MNPT

2" Tri-Clamp Tri Clover x 3" x (2) 1/4" MNPT This specialty spool with a 1/4" MNPT connection can be used for various reasons including a valve manifold to inject solvent into a column from the bottom allowing it to flow upwards spreading the solvent more evenly the top down method.

$25.00

Polyscience 7 Liter Low Profile MX Refrigerated Circulator

Polyscience 7 Liter Low Profile MX Refrigerated Circulator Note: This item may carry up to a 4-6 week lead time. The Polyscience 7 Liter Low Profile MX Refrigerated Circulator is an more ergonomic version of the standard 7L Refrigerated Circulator. It is the ideal low temperature cooler for short path distillation and can also be used to heat jacketed bases and chill jacketed columns for small capacity extraction systems. Specification Description -20, 7 L Low Ref. Circulator Controller Type MX Display 3.75" Touch-Pad LCD Working Temperature Range °C -20° to 135° Temperature Stability °C ±0.07° Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Pump Type Pressure Flammability Class (DIN 12876-1) I (NFL) Working Temperature Range °F -4° to 275° Working Temperature Range °C -20° to 135° Nominal Cooling Capacity @ +20C (W) 200 Reservoir Capacity (gallons) 1.85 Reservoir Capacity (liters) 7 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 6.18 x 5.59 x 5 in Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Temperature Stability °F ±0.13° Temperature Stability °C ±0.07° Display 3.25" LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure Pump Speed One Process Connections 1/2" O.D. Barbed Tubes Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes Reservoir Drain Yes Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 23.2 x 16.2 x 17.3 in Overall Dimensions (L x W x H) (cm) 23.2 x 16.2 x 17.3 in Refrigerant R134a Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 84.0 Shipping Weight (kilograms) 38.1 Catalog Page Number 44-45 60 Hz Only Part Number MX7LR-20-A11B Maximum Pressure (psi) 2.3 Maximum Pressure (bar) 0.16 Maximum Pressure Flow Rate (gpm) 3.60 Maximum Pressure Flow Rate (l/min) 13.5 Cooling Capacity @ -20°C (W) 30 Cooling Capacity @ 0°C (W) 120 Cooling Capacity @ +20°C (W) 200 Cooling Capacity @ +100°C (W) 200 Included Hardware Fitting Kit for External Applications Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/12 Regulatory Approvals ETL Key Features: Large, universal icon and English display On-screen prompts Single-point calibration capability Certifications: Regulatory Approvals: ETL Operator's Manual

$4,200.00

Upgrade Tool for TRS21 Suction Valve

Our specialized tool for use with rebuilding the head on TRS21, makes installation of new Suction Valve O-Rings much easier. Includes (5) Viton O-rings.

$18.00

NEOCISION Cold Trap - ETL Rated - (-80c)

NEOCISION Cold Trap - ETL Rated - (-80c) The BVV™ CT80 Cold Trap is used to condense vapors lost in vacuum applications before they reach the vacuum system. This prolongs the life of the vacuum system, reduces the need to change oil frequently, and efficiently traps vapors otherwise lost to evaporation such as terpenes. The CT80 model reaches a maximum temp of -80°c or -112F under vacuum and contains three traps for maximum efficiency and condensation of vapors. Place in-line between application and your vacuum system. Specifications: Temp Range: -112F to Ambient Internal Dimensions: 180mm Internal Diameter x 210mm Depth (Holds about 1.4 gallons) External Dimensions: 505 x 620 x 750mm Weight: 149lbs Stainless Steel Interior 3x Pyrex Glass Traps 110V Power Please Note: This device is designed for operation on its own independent circuit breaker. For best results, do not use this device on a breaker shared with other equipment. ***Notice to Customers: All units are inspected for broken glass or parts before the unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$5,800.00

24" & 36" Filter Paper (Qualitative, Large Diameter)

Ashless Filter Papers - Qualitative Ashless quantitative and qualitative filter papers provide laboratory grade filtration for extraction systems and are specifically used in combination with a Buchner funnel to remove fats, waxes and any other unwanted contaminants from your solution. These filter papers are used in the pre-processing stage of short path distillation to clean up the material prior to processing. Key Features: ISO 9001 Approved Manufactured from alpha-cellulose and cotton linters High Purity and low background Consistent performance Low ashless content: <0.1% Whatman equivalent quality Pre-Cut for ease of use Specifications: Classification Qualitative Sizes Available: BIO-1 11um - Medium BIO-4 20um - Fast BIO-5 2.5um - Slow BIO-6 3um - Slow Ash Content <0.1% Quantity per Pack 100 Diameter 24 - 36" Technical Data: Grade Particle Retention Appearance Speed Ash Content (%) Basis Weight (g/m2) Wet burst (mm H2O) BIO-1 11um Smooth Medium <0.1 80.0±4.0 >140 BIO-2 8um Smooth Medium <0.1 80.0±4.0 >140 BIO-4 20um Smooth Fast <0.1 80.0±4.0 >120 BIO-5 2.5um Smooth Slow <0.1 80.0±4.0 >180 BIO-6 3um Smooth Slow <0.1 80.0±4.0 >180 BIO-40 8um Smooth Medium <0.007 80.0±4.0 >140 BIO-41 20-25um Smooth Fast <0.007 80.0±4.0 >120 BIO-42 2.5um Smooth Slow <0.007 80.0±4.0 >180 BIO-43 16um Smooth Medium to Fast <0.007 80.0±4.0 >120 BIO-44 3um Smooth Slow <0.007 80.0±4.0 >180

$160.00 - $220.00

CDA 12A w/ Toluene High Purity Extraction Solvent

CDA 12A w/ Toluene HAZMAT ITEMS ARE NON-REFUNDABLE. ALL SALES ARE FINAL (Note: Container style and color may vary) BVV's Ultra High Purity Toluene Denatured Ethanol (CDA 12A) is distinguished by its exceptional purity, Our CDA 12A formulation combines 95% Food Grade/USP/ACS 200 Proof Ethanol, derived from corn, with ~5% high-purity Toluene. Adhering to stringent industry standards, ensuring it meets the precise requirements of our customers, our Ultra High Purity Toluene Denatured Ethanol excels across diverse applications widely adopted as an effective botanical extraction solvent. Being that our Ultra High Purity Denatured Ethanol is made unfit for consumption when denatured with Toluene it is not subject to the Federal Excise Tax on alcohol saving you a huge cost without compromising on it suitability for top-tier extractions. Primarily utilized as pure ethanol in extraction processes, this solvent is favored for its cost-effectiveness and extraction efficiency. Reduce manufacturing costs and increase extraction efficiency with BVV's Ultra High Purity Toluene Denatured Ethanol. Disclaimer: Prices may vary due to market value and for orders of 4 totes or more and a tanker there could be up to a 2 week lead time. Call in for more accurate lead times. Key Features: Significantly Reduced Cost due to the absence of Federal Tax Produces Exceptional Quality Extractions Leaves No Residuals or Tastes Evaporates Completely in a Rotary Evaporator Vapor Pressure: 40.9mmHg at 20°C UN Number 1170 Density: 0.7905g/cm³ Specific Gravity 0.7905 Flash Point: 13.9°C (57°F) Boiling Point: 78.5°C (173°F) Melting Point: -90.0°C (-130°F) Chemical Formula: Ethanol C2H6OToluene C7H8 CAS#(s) Ethanol 64-17-5Toluene 108-88-3 Molecular Weight: 72.1057 Appearance Colorless Liquid Odor: Mint or acetone-like Density 0.7905g/cm³ Boiling Point: 78.5c/173.3F Solubility in water: Miscible GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H319 GHS Precautionary Statements P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P370+P378, P403+P233, P403+P235, P405, P501 UN Identification Number: 1987 Proper Shipping Name: Alcohols Transport Hazard Class: 3 Packing Group: I DOT Placard: What is Denatured Ethanol? Denatured ethanol, also known as denatured alcohol, is ethanol (ethyl alcohol) that has been rendered unfit for human consumption by the addition of denaturants. Denaturants are typically chemicals that make the ethanol taste bad or have toxic effects, and they are added to discourage people from drinking the substance. The denaturation process is done to avoid the high taxes and regulations associated with beverage alcohol, as denatured ethanol is intended for industrial, pharmaceutical, or cosmetic uses rather than for consumption. Common denaturants include toluene, heptane, methanol, isopropyl alcohol, acetone, and other chemicals. Denatured ethanol is widely used in various industries, such as in the production of paints, solvents, cleaning products, and as a fuel for alcohol burners. Why is Ethanol Denatured? Ethanol is denatured, or rendered undrinkable, for several reasons: Tax Purposes: Denaturing ethanol allows for the imposition of lower taxes on industrial or non-beverage alcohol compared to potable alcohol. Governments often place higher excise taxes on alcohol intended for human consumption. Regulatory Compliance: Denaturing ethanol is a regulatory requirement to discourage the illegal diversion of tax-free industrial alcohol for beverage use. The addition of denaturants makes it unpalatable and unsafe for consumption. Public Safety: Making ethanol undrinkable helps prevent accidental or intentional ingestion of industrial alcohol, which can be toxic. Denaturing agents are chosen to deter people from attempting to use denatured alcohol as a substitute for beverage alcohol. Industrial Use: Denatured ethanol is widely used in various industries, including pharmaceuticals, cosmetics, and manufacturing. It serves as a solvent, fuel, or raw material in these applications. Common denaturants include substances like heptane, toluene, methanol, isopropanol, and various chemicals that make the alcohol unsuitable for human consumption while maintaining its usability in industrial processes. The specific denaturing formulations, such as CDA 12-A mentioned earlier, are defined by regulatory agencies to ensure compliance with safety and tax regulations. What is denatured ethanol used for? Denatured ethanol is used for various industrial and commercial purposes where the alcohol is needed for its properties but should not be consumed. Here are some common applications: Industrial Solvent: Denatured ethanol is widely used as a solvent in industries such as pharmaceuticals, cosmetics, and manufacturing. It is effective in dissolving a variety of substances. Cleaning Agent: Due to its solvent properties, denatured ethanol is used as a cleaning agent for surfaces, equipment, and machinery in industrial and commercial settings. Fuel Additive: Denatured ethanol is sometimes used as a fuel additive, especially in the blending of gasoline. It can improve combustion efficiency and reduce emissions. Paint and Coating Industry: It is used as a solvent in the formulation of paints, varnishes, and coatings. Pharmaceuticals: Denatured ethanol is used in the pharmaceutical industry for various purposes, including the extraction of medicinal compounds. Laboratory Use: In laboratories, denatured ethanol is often used for tasks like sterilization and as a solvent for experiments. Inks and Dyes: It is employed in the production of inks and dyes due to its ability to dissolve pigments. Adhesives and Sealants: Denatured ethanol is used in the formulation of adhesives and sealants. Window Cleaning: It is used in commercial window cleaning solutions. Automotive Industry: In the automotive industry, denatured ethanol is used for cleaning and degreasing. What can be used to denature ethanol? Here are examples of common Completely Denatured Alcohol (CDA) formulations used to denature ethanol: CDA 12-A To every 100 gallons of alcohol, add either: Five gallons of n-heptane or 5 gallons of toluene. CDA-19 To every 100 gallons of ethyl alcohol (not less than 160 proof), add: 4.0 gallons of either methyl isobutyl ketone, mixed isomers of nitro propane, or methyln-butyl ketone 1.0 gallon of either kerosene, deodorized kerosene, gasoline, unleaded gasoline, rubber hydrocarbon solvent, or heptane. CDA-20 To every 100 gallons of ethyl alcohol (not less than 195 proof), add a total of: 2.0 gallons of either unleaded gasoline, rubber hydrocarbon solvent, kerosene, or deodorized kerosene, or any combination of these. What does CDA mean? Completely Denatured Alcohol (CDA) is a type of denatured alcohol that has been rendered unfit for human consumption by the addition of denaturing agents. Denatured alcohol is ethanol (ethyl alcohol) that has been intentionally adulterated to make it toxic, foul-tasting, or otherwise undrinkable. This denaturing process is done to exempt the alcohol from excise duty and other taxes, as it's not intended for use in beverages. The denaturing agents used in CDA can vary, but they often include chemicals such as methanol, isopropanol, or other substances that make the alcohol unpalatable and potentially harmful if ingested. The specific formulation of denatured alcohol may be regulated by government authorities to ensure it meets safety standards and legal requirements. CDA is commonly used in industrial applications, as a solvent, fuel, or as a cleaning agent. It's important to note that due to the addition of denaturing agents, CDA should not be used for purposes that involve contact with the human body or ingestion. Safety precautions, including proper ventilation, should be followed when working with denatured alcohol. What is CDA 12A? CDA 12-A is a formulation specified by the Alcohol and Tobacco Tax and Trade Bureau (TTB) for Completely Denatured Alcohol (CDA). The formula is defined under §21.26 as Formula No. 12-A. The composition of CDA 12-A is as follows: For every 100 gallons of alcohol, add either: 5 gallons of n-heptane or 5 gallons of toluene. This denaturing process renders the ethanol unfit for consumption while meeting regulatory requirements for various industrial applications. CDA formulations, including CDA 12-A, are used to denature ethanol for purposes such as industrial solvents, cleaning agents, and manufacturing processes. Can you remove Toluene from CDA 12A? When toluene is added to ethanol it creates an azeotrope between the ethanol and n-heptane. An azeotrope is defined as a mixture of two liquids that have a constant boiling point and composition through distillation. This azeotrope results in the ethanol and n-heptane evaporating at the same temperature, making it extremely difficult to separate the two through distillation. While these azeotropic solvents are still easily recovered from a botanical extract at a relatively low boiling point around 78C/173F using a rotary evaporator or falling film evaporator, it is near impossible to separate the two via distillation. What is an Azeotrope? An azeotrope is a mixture characterized by having identical concentrations in both its vapor and liquid phases. This stands in contrast to ideal solutions, where one component is usually more volatile than the other, allowing for separation through distillation. When an azeotrope forms, the concentrations in both phases remain the same, hindering separation through traditional distillation methods. Azeotropes consist of a blend of at least two different liquids, and this mixture can exhibit either a higher or lower boiling point than either of its individual components. Azeotropes become relevant when certain liquid fractions resist alteration through distillation processes. In typical mixtures, components can be extracted using Fractional Distillation, a process involving repeated distillation stages. The more volatile component vaporizes and is collected separately, while the less volatile component remains in the distillation container, resulting in two distinct, pure solutions.

$10.00 - $200.00

Extend Protection Plan

Extend Protection Plan

$0.09 - $49.99

Superfine Agar Powder for Mushrooms Mycology Petri Dishes

Superfine Agar Powder Bacteriological, Food Grade, USP-NF Our Agar Powder is extracted from Red Seaweed. Our agar is a complex polysaccharide and is a top choice for mycology cultures. This superfine agar dissolves quickly and has a high gel strength making it an excellent choice for a variety of applications an petri dishes. Gel Strength (1.5%) : 1020 gm/cm² Gel Temperature: 38-40°C (100-104°F) CAS# 9002-18-0 Gluten Free Allergen Free Vegan & Vegetarian approved Non-GMO Shelf Life: 2 years pH: 5.5-8.5 Superfine Agar Powder Certificate of Analysis Directions for Use: Mix 10g of superfine agar powder per 500ml of distilled water. Boil and stir until powder is fully dissolved. Sterilize the mixture for 45min @15psi 250°F (121°C) in a pressure cooker or autoclave. Allow mixture to cool to approximately 140°F (60°C) *To avoid excessive condensation. Fill dishes with 15ml of mixture, approximately ~30-35 dishes.

$21.00 - $150.00

ChemTek Medium Fuge Bags - 50 Pack

ChemTek Medium Fuge Bags - 50 Pack Centrifuge bags used for separations Specifications: Size: 50-Pack Dimensions:H: 7” W: 5” Micron Size: 25 Micron Material: Food Grade Nylon

$30.00

1/4" Fractional Tube Fitting Hose

1/4" Fractional Tube Fitting Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have a tube stub on each end that fits a standard compression fitting. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 1/4" Tube Stub Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65°F to 450°F (-54°C - 232°C) Pressure Rating 2100 PSI Chemical Resistance Excellent Max Bend Radius 3"

$39.00 - $60.00

BVV Vacuum Pump Mechanism Rebuild Kits

This rebuild kit is the entire pump mechanism for the BVV vacuum pump. It includes all gaskets and vanes already installed and ready to bolt on the vacuum pump. Select your pump model in the dropdown list.

$35.00 - $64.00

2L Short Path Parts Kit with Dry Ice Cold Trap

2L Short Path Parts Kit with Dry Ice Cold Trap This kit includes all the parts and fixturing to build a distillation setup with a 2L boiling flask. No heating or cooling equipment is included.

$750.00

1/2" Clear Reinfornced PVC Tubing

1/2" Clear Reinforced PVC Tubing Crystal clear Phthalate, BPA Free PVC compound, formulated with ingredients in compliance with applicable ratings: NSF-51 Certified USP Class VI Rated Compound, FDA Ingredients, Self-Extinguishing and Reinforced with braided polyester yarn. Key Features: Constructed with Phthalate Free compounds. NSF-51 certified material. Crystal clear - allows visual confirmation of product flow. Longitudinally reinforced to reduce elongation under pressure. Lightweight. Self-extinguishing. Non-marking. Silicone-free. Non-conductive. One-piece lengths. Resistant to chemicals (see chemical-resistance chart). Compound hardness 80A Phthalate Free! Common Applications: Food & beverage. Agriculture Drain Line Hose/Tubing Bundling Industrial Air and Water Hose Light Vacuum Liquid and Powder Transfer Medical and Pharmaceutical Sight Gauge Water Lines

$14.00 - $58.00

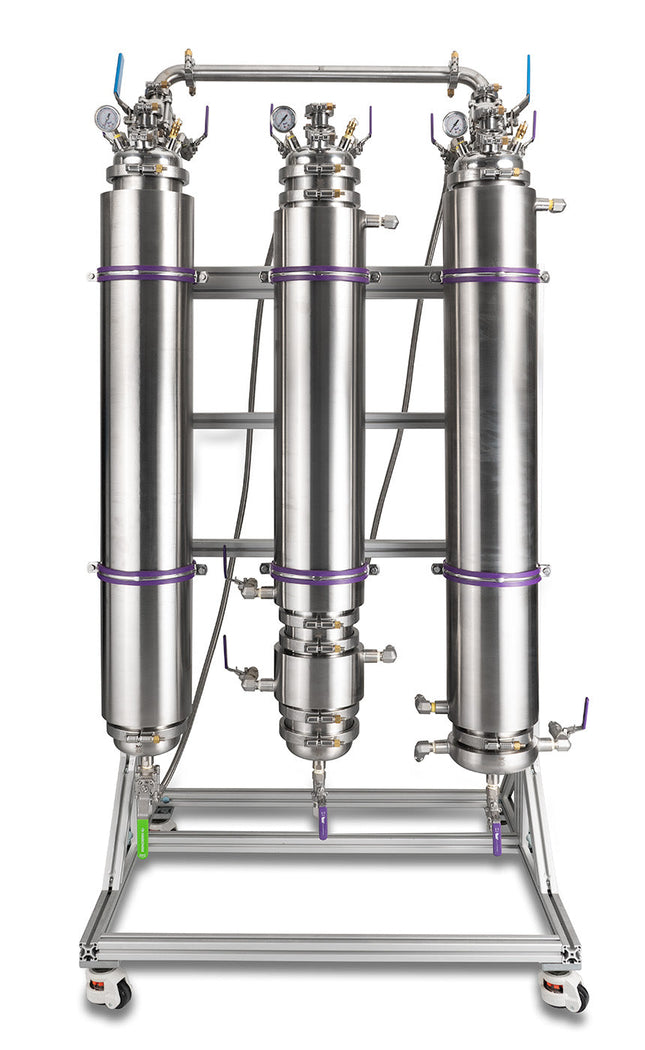

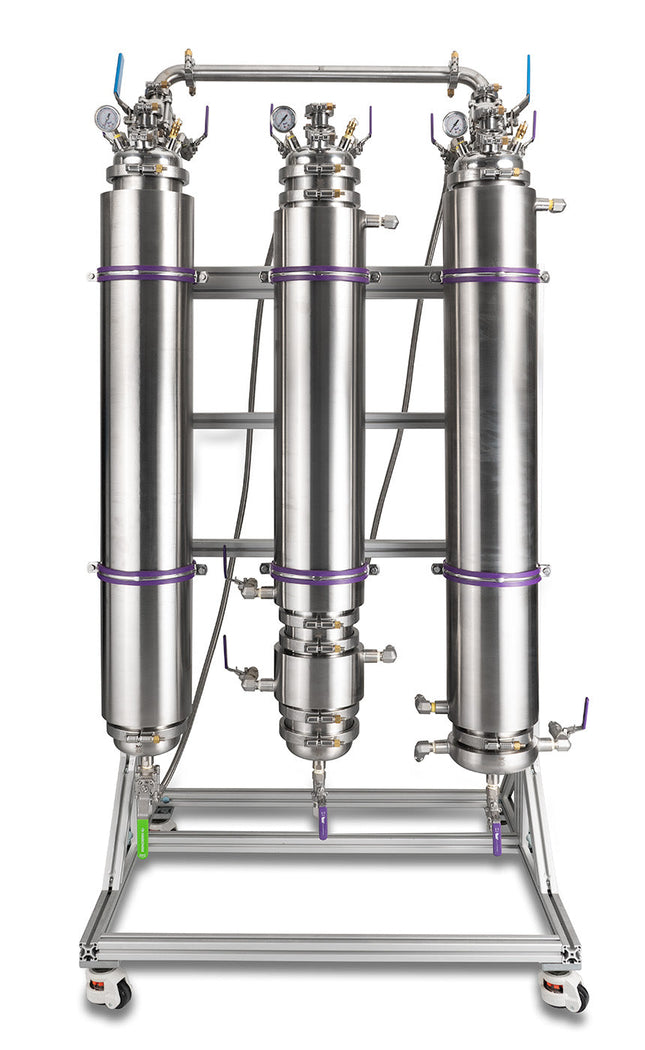

5LB EVO Certified Closed Loop Extractor *49 State Certified

5LB Evo Certified Closed Loop Extractor Equipped with the latest in modern extraction technology the 5lb EVO produces extracts of the highest purity in the shortest time possible through its inline solvent chilling and adsorbent filtration capabilities using its unrestricted passive recovery speeds when paired with our 11KW Express Extraction Heater. Peer reviewed and 3P certified the 5lb EVO meets or exceeds Class 1 Division 1, NFPA 58, and ASME standards. With the ability to process 40+ pounds of biomass material every 8 hours the 5lb Evo provides precision performance without the price. Processing Power Capacity Per Batch: 5LB Cycle Time: 30-45 Minutes Capacity: Up to 40 lb, per 8-hour shift Extracts: isolate/sauce, distillate, vape pens, shatter, and wax/sugar 5LB EVO Certified Closed Loop Technical Data Sheet Specifications 6"x36" 5lb Material Column 6"x6" Adsorbent Filtration Column 1-5um Sintered disk filtration 1.5"x24" Inline molecular sieve column 7X 1.5" Certified Borosilicate Sight Glasses 3X 250 PSI ASME Safety Valves 3X -30hg-250PSI Compound Pressure Gauges 1.5" Full Bore Recovery Lines 1/2" JIC process Flow lines Footprint (DxWxH) 30"x40"x79" Weight: 400 lb Maximum Pressure Rating: 250PSI Compliance Class 1, Division 1 Compliant Designed to ASME standrds NFPA 58 LPG compliant 3P Certifed 49 State compliant: AL, AR, AZ, CA, CO, CT, DE, DC, FL, GA, HI, IA, ID, IL, IN, KS, KY, LA, ME, MD, MA, MI, MN, MS, MO, MT, NE, NV, NH,NM, NY, NC, ND, OH, OK, OR, PA, RI, SC, SD, TN, TX, UT, VA, VT, WA, WV, WY, WI Performance Jacketed or sleeved solvent column for prechilling of solvent & unbridled passive recovery Material Column solvent dispersal plate for complete biomass saturation 1500g Adsorbent filtration column complete with a 1-5um Sintered disk filter stack Independently Jacketed Material column, adsorbent filtration column, & collection column for complete process temperature control 1.5" full bore recovery lines for unrestricted solvent recovery Integrated -1.5"x24" Inline molecular sieve column for preserving solvent's effectiveness Easy to use extract pour spout for streamlined extract harvesting

$10,250.00 - $10,650.00

Table Top Cart Filler XL 6 Liter & Heater Kit

Table Top Cart Filler XL 6 Liter & Heater Kit Fill 6000 1ml Carts per Load This 6 Liter capacity Giant is made to fill. Fully jacketed 304SS with a design that allows the OIL inside to fully drain creating little to no loss. The system is made of all parts that can be sterilized. The body, valves and all connections are 304 Stainless Steel and the hosing is PTFE. The body of the vessel is fully jacked and is recommended to be run with stand alone heater to pre-heat the oil. The hose heated and insulated. The hose temperature is controlled by an analog PID. The hose and PID controller are precision made in the USA. The hose uses Platinum Thermocouples for durability and accuracy, which means you wont run into down time or temperature errors. To use the system you will need Nitrogen to back pressure the oil in the tank. The pressure is regulated by a low pressure regulator. To dispense the end of the hose has a toggle valve that connects to a Lure Lock connection. System Specs. Nitrogen Input MAX Pressure: 150PSI Regulator working pressure: 0.5-30PSI (*recommended pressure 10PSI) Hose Temperature Rating: 50°F - 450°F Controller Temperature Range: 50°F -450° Includes Right Angle Attachment for added user flexibility. Non-Metered Dispensing with toggle valve control. Pressure gauge for pressure monitoring: 0-150PSI BVV™ 5 Liter Heated circulator 275°F Max Temperature *Heater and 10Ft of hose is included in the kit. Ready to Run! BVV 5 Liter Heated Circulator Manual Cleaning: NOTE: Please Clean Prior to first use the system does not come sterilized. A simple IPA wash down will be sufficient. At any point the system can be cleaned using IPA or D-limonene. Note: The heater should be operated with RO water to avoid scale buildup. BVV™'s warranty does not protect heating coils that fail due to scale buildup.

$3,900.00

CHEMTEK W5 Neutral Bleaching Clay

CHEMTEK W5 Neutral Bleaching Clay W5 is a neutral bleaching clay specialized for the removal of heavy metals. While most sorbents will remove heavy metals, the acids involved in the activation process could cause desorption. By neutralizing the clay processors can take advantage of the increased surface area without any risk of desorption. W5 SDS W5 Technical Data Sheet

$40.00 - $1,800.00

8" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves

8" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 8" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with 1/4" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have (3) 1.5" Tri-Clamp ports with the middle 1.5" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" 37° JIC Tri-Clamp Size(s) (3) 1.5" Ports x x 8" Tri-Clamp Nitrogen Tested Yes

$325.00

NRE 5L Evaporating Flask Gasket Set

NRE 5L Evaporating Flask Gasket Set This two part sealing kit will only fit the evaporating flask for the 5L Neocision rotary evaporator.

$145.00

Huber MinOil P20.190.40, Heat transfer fluid 20 to 190 °C

Huber MinOil P20.190.40, Heat transfer fluid 20 to 190 °C P20.190.40 is a high quality mineral oil based heat transfer fluid. It meets the technical safety requirements and tests according to DIN 4754 as well as the recommendations of VDI 3033 (Construction, operation and maintenance of heat transfer systems). Advantages: very good oxidation stability high thermal stability good viscosity-temperature characteristics low tendency to coke extended oil change interval Safety Data Sheet Properties Working temperature °C 20°C…190°C Flash Point °C 190 Fire Point °C not Specified Viscosity mm2/s (kinematic at 25 °C) 40 Density g/cm3 0,86 Pour Point °C > 300 Ignition temperature °C > 300 Color light yellow Thermal expansion coefficient 10-5/K not Specified Heat conductivity W/(m·K) at 25 °C 0,135 Material incompatibility Not Specified

$460.00 - $1,370.00

Vacuubrand MZ 2C NT 1.4 CFM Chemistry Diaphragm Pump 110V

Vacuubrand MZ 2C NT 1.4 CFM Chemistry Diaphragm Pump 110V MZ 2C NT Technical Data Sheet.pdf Chemistry-design diaphragm pumps are an excellent solution for continuous, oil-free pumping of corrosive gases and vapors. The two-stage construction provides the advantageous combination of high pumping speed and low ultimate vacuum. All parts in contact with pumped media are made of chemically resistant fluoroplastics. Well-proven PTFE sandwich diaphragms increase reliability and extend operating life. The pump MZ 2C NT is equipped with a gas ballast valve for continuous condensate purge increasing the pumping capability of condensable vapors. This pump is our most popular chemistry diaphragm pump, and is the heart of a family of VACUUBRAND pumping systems. The NT-series features further improved performance data and superior vapor tolerance. Technical data Unit MZ 2C NT Number of heads / stages 2 / 2 Max. pumping speed at 50/60 Hz m3/h 2.0 / 2.3 Max. pumping speed at 50/60 Hz cfm 1.2 / 1.4 Ultimate vacuum (abs.) mbar/torr 7 / 5 Ultim. vac. (abs.) with gas ballast mbar/torr 12 / 9 Ambient temperature range (operation) °C 10 - 40 Ambient temperature range (storage) °C -10 - 60 Max. back pressure (abs.) bar 1.1 Inlet connection Hose nozzle DN 8-10 mm Outlet connection Hose nozzle DN 8-10 mm Rated motor power kW 0.18 Rated motor speed at 50/60 Hz min-1 1500/1800 Degree of protection IP 40 Dimensions (L x W x H) mm 243 x 243 x 198 Weight kg 11.1 Noise level at 50 Hz, typ. dBA 45 NRTL certification Canada and the USA ATEX conformity (only 230V) II 3/- G IIC T3 X Internal Atm. only Items supplied Pump completely mounted, ready for use, with manual. Accessories Rubber vacuum tubing DN 8 mm (20686001)

$2,930.00

J-KEM Model 250

J-KEM Model 250 The Model 250 has both heating and cooling outlets for maximum versatility. Two heating outlets supply 1800 watts of power for large equipment and heating mantles up to 22L. The third outlet (1800 watts), normally used for cooling, is programmable to supply power below, above, or at the set point. Contains J-KEM’s patented power control computer which provides 0.1° regulation of anything. Specifications: 120vac, 15 amps, 1800 wattsWarranty: 2 Years The temperature range desired determines the probe/thermocouple type: J [black] (0 – 800° C)K [yellow] (-50 – 1200° C)T [blue] (-200 – 250° C)RTD: (-200 – 400° C)

$1,233.00 - $1,427.00

FJIC X 3MM Can Adapter

FJIC X 3MM Can Adapter This adapter allows the user to seamlessly inject canned solvent into a standard 1/4" MJIC connection without releasing solvent to the atmosphere. This FJIC to 3MM adapter conveniently screws onto any 1/4" MJIC connection allowing for the safe injection of canned solvent into a closed loop system.

$35.00 - $37.00

BVV Recovery Pump Top Dead Center Piston Calibration Plate

BVV Butane Recovery Pumps Top Dead Center Calibration Plate & Bolts Use with the Top Dead Center Clearance (TDCC) instructions Use this plate and a depth gauge to measure the Top Dead Center Clearance of the piston/cylinder/head assembly. Shims that come with the piston cylinders are stacked to create an area of displacement between the top of the cylinder and the compressor head. BVV's Recommended depth is 0.012" for the BVV 4 & 2 Cylinder Butane Recovery pumps. This gap is recommended for optimum recovery performance. Top Dead Center Clearance Instructions *Depth Gauge Not included, Any simple depth gauge will work, and you will also need the shims that come in the BVV-6 kit.

$28.00

NEOCISION Cold Trap with Pump - ETL Rated - (-40c)

NEOCISION Cold Trap with Pump - ETL Rated - (-40c) Looking for a cold trap and small application chiller? The BVV™ CT40 features a 2-in-1 use with a cold trap function and built in circulating system for small batch temperature control. Cold Trap Function Use the BVV™ CT40 to condense vapors down to -40°C before they reach your vacuum pump. This prolongs the life of the vacuum system, reduces the need to change oil frequently, and efficiently traps vapors otherwise lost to evaporation such as terpenes. Common applications include short path distillation, rotary evaporation, reactor setups, or any other application where volatile vapors can damage your vacuum pump. Chiller Function Use the BVV™ CT40 for small batch temperature control down to -40°C. Switch out the cold trap configuration with solid lid to turn your cold trap into a chiller. Common applications include condensing coils, small vessel setups, heat exchangers. Operating 2-in-1 Simultaneously Use the BVV™ CT40 as a cold trap and chiller. The unit can be used with the cold trap configuration and circulating function simultaneously. Commonly used as for chilling applications with no additional heat load. BVV™-CTC40-WP Power Requirement AC 110V +/- 10% / 60Hz Relative Humidity < 85% Cooling Capacity 400W Refrigerant R404A Cold Trap Capacity 3 x 300ml Cold Trap Barb Dia. 10mm Reservoir Capacity 6.8L External Dimensions 305 x 485 x 635mm Weight 149 lbs Call in to see how we can pair this unit with your setup Please Note: This device is designed for operation on its own independent circuit breaker. For best results, do not use this device on a breaker shared with other equipment. ***Notice to Customers: All units are inspected for broken glass or parts before the unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$3,100.00

Solvent Pro Series 40/60 Clamp

Solvent Pro Series 40/60 Clamp This is a replacement clamp for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This clamp fits an 40mm(1.57") Inner Diameter and 60mm(2.36") Outer Diameter joint.

$15.00

Triclamp T

Sanitary Tri-Clamp Tee – 304 Stainless Steel (3A Certified) Upgrade your sanitary processing system with BVV’s high-quality Tri-Clamp Tees, precision-engineered from 304 stainless steel for superior corrosion resistance and long-lasting performance. Manufactured in accordance with 3A sanitary standards, these tees are ideal for use in food, beverage, pharmaceutical, and botanical extraction applications. ✅ 3-Way Tee Design for optimal flow distribution✅ High-Polish 304 Stainless Steel – Durable, hygienic, easy to clean✅ Available Sizes: 1.5", 2", and 6" Tri-Clamp connections✅ Compatible with standard Tri-Clamp fittings, gaskets, and clamps✅ Ideal for sanitary process piping, closed-loop extraction, and lab builds BVV’s Tri-Clamp fittings are trusted by industry professionals for their precision, quality, and performance. Whether you’re building out a new system or upgrading your existing setup, our Tri-Clamp Tees deliver reliability where it matters most.

$25.00 - $200.00

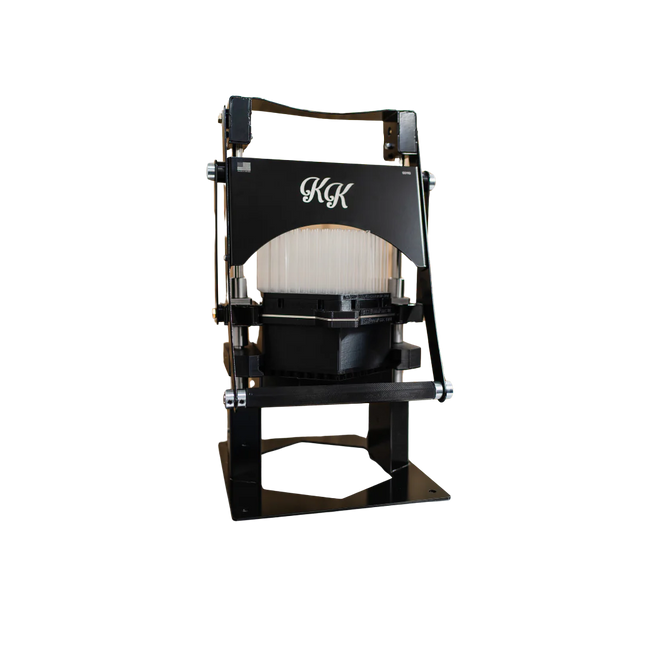

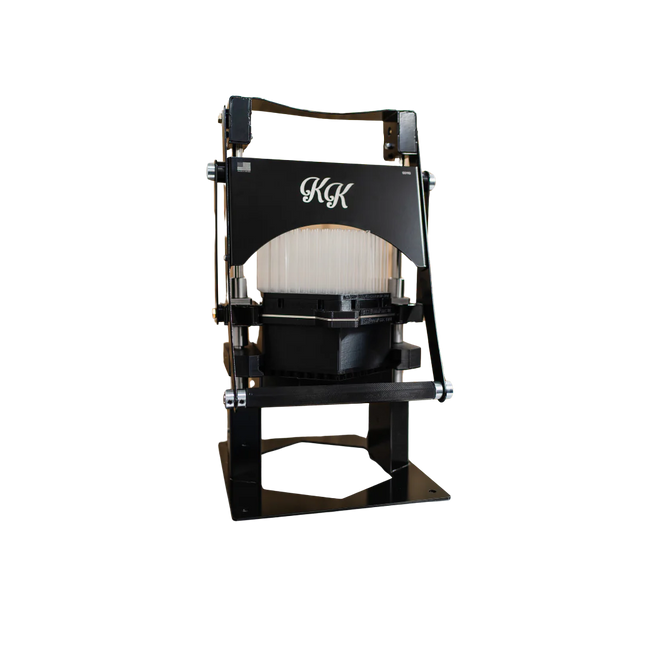

KING KONE CLOSER

KING KONE CLOSER Crown your pre-roll with a Dutch finish in just 4 easy steps. With this closer, you can produce up to 1,000 pre-rolls per hour from start to finish. Out of Stock: Due to high demand and the time required to craft this product, availability may take longer than our other items. At this time, we are not accepting pre-orders. We appreciate your patience as we work to fulfill all orders. Size: 109mm cone/King Size Cone Thank you for your understanding!

$2,000.00

12" Hemispherical Extractor Lid with 6" Triclamp Center

12" Hemispherical Extractor Lid with 6" Triclamp Center This End Cap comes with Four FNPT Threaded connections, two 2" Tri-Clamp ferrules welded to the end cap, and a 6" Tri-Clamp center port. They allow the user to adapt and connect threaded connections to the NPT ports and Tri-Clamp lid connections to the others. These 7 connections are welded on a 12" Hemispherical Tri-Clamp End Cap. Specifications Material: 304 Stainless Steel Connection Types: 2" Tri-Clamp (2x) 6" Center Tri-Clamp Port 12" Tri-Clamp 1/4" - 18 FNPT (x2) 1/2" - 14 FNPT (x2) Standard: 3A

$300.00

Polyethylene Glycol 400 - PEG 400

Polyethylene Glycol 400 Polyethylene glycol 400 has an average molecular weight of 400. It is a clear, viscous liquid at room temperature. APPLICATIONS • Chemical Intermediate• Plasticizer• In cosmetics for preparation of ointments and lotions.• As a mold release agent and lubricant for both natural and synthetic products. Physical Properties Flash point, PMCC, °F 390 Flash point, PMCC, °C 199 Refractive index, 25°C 1.463 Density, g/ml, 20°C (68°F) 1.1254 Weight, lbs/US gal, 20°C (68°F) 9.39 Freezing Range, °F 39-46 Freezing Range, °C 4-8 Viscosity, kinematic cSt at 25°C (77°F) 84 cSt at 98.9°C (210°F) 7.3 Chemical Properties Molecular Weight (range) 380-420 Average number of EO units 8.7 Water Solubility Soluble Potassium acetate, wt% 0.02-0.2 pH, 5% aqueous solution 4.5-7.0 Water, wt% 0.5 max. Color, Pt-Co 50 max. Hydroxyl number, mg KOH/g 267-295 Appearance, 20°C Clear The expiration date is 3 years from the date of manufacture and when the glycol is kept below 100F and out of direct sunlight.

$25.00 - $3,700.00

Inland 70 Ultra Vacuum Pump Oil (Edwards Ultragrade 70)

Inland 70 Ultra Vacuum Pump Oil This is oil is a direct replacement for Edwards Ultragrade 70 oil. Specifications Inland 70 Ultra Vapor Pressure @25°C 1x10^-7 torr Viscosity @ 40°C 72 cSt Pour Point: -10°C Flash Point: 249°C Density: 0.86 g/ml Color: Clear Inland 70 Ultra Safety Data Sheet PDF

$17.00 - $1,856.50

Bullseye Precision Gauge with Agilent 536 KF25, NPT or KF16 Sensor | Vacuum Gauge for Processing

Bullseye Precision Gauge with Agilent 536 KF25, NPT or KF16 Sensor | Vacuum Gauge for Processing A rugged portable vacuum gauge for processing applications that pairs unparalleled vacuum measurement with the Agilent 536 sensor that has an integrated baffle which provides protection and helps reduce risk of sensor failure Numeric & Graphical Displays See vacuum readings in either numbers or easy-to-read graphs Has 12 measurement units for implementation in almost any vacuum application Torr, mbar, bar, kPa, inches of Hg, mm Hg, millitorr, microns, inches of water, PSI, Pa Calibrated & Precise Delivered pre-calibrated with Agilent/ Varian 536 thermocouple sensor under actual vacuum against the NIST standard. Note: NIST certification sent with the gauge is an available option here The 536 all stainless steel sensor with baffle has extended sensor life in the presence of condensable gases and improved performance at higher pressures Vacuum Interface: KF25 or NPT or KF16 Wetted materials: 304L Stainless steel, glass, Type P thermocouple Extended Battery Lifespan Portable | Solid state electronics built into a handheld gauge that operates using AA batteries that lasts up to 70 hours In-lab use | Power gauge using the integrated Micro-USB port for long-term use without the need to change batteries Ideal Vacuum Gauge for Processing Applications Laboratory, freeze drying, low pressure distillations, foreline monitoring, Schlenk lines performance, and transformer dry-out Or any application with higher levels of condensables where sensor failure is more likely Units Torr, mbar, kPa, millitorr, microns, Torr, mbar, bar, kPa, inches of Hg, mm Hg, millitorr, microns, inches of water, PSI, Pa 1E-4 – 1000 Torr Range with Accuracy .001 – 5 Torr Sensor Type Agilent 536-KF25 Dimensions 11 x 10 x 4 in Certifications CE, RoHS

$635.00 - $653.00

Edwards nXDS Series Dry Scroll Pumps Tip Seal Service Kit

Edwards nXDS Series Dry Scroll Pumps Tip Seal Service Kit The nXDS series is the next generation in completely oil free, dry scroll pumps nXDS improves on legacy XDS pumps by offering increased pumping speeds, combined with lower ultimate pressures, lower power consumption and lower noise. Gas ballast allows for pumping of condensable vapours including, water, solvents, dilute acids and bases. nXDS pumps also feature the latest in tip seal technology giving significantly longer life between tip seal changes. Integrated inverter drive with auto sensing voltage input delivers optimized pumping performance globally. nXDS pumps are designed to be completely field serviceable. Features: Lubricant-free within the vacuum envelope and hermetically sealed means totally clean and dry vacuum to prevent cross contamination No atmosphere to vacuum shaft seals means bearings are completely isolated, which prevents process attack and means the bearings run cooler and last longer Simple single sided scroll arrangement combined with an innovative motor and bearing design allows for easy field service with a minimum of special tooling for low cost of ownership and maximum up-time Improved motor and drive efficiencies for reduced power and cost of ownership Advanced interface provides a variety of traditional, analogue and digital control methods enabling remote control/monitoring via USB, RS232 or RS485 One year warranty, as well as technical

$626.00

Pro Series Manifold

Pro Series Manifold with Charging Hose Set R290/R600 This manifold is designed for R290 and R600 Propane and Butane solvents for closed loop extraction systems and for nitrogen assistance to push solvent through the system. When used in an active closed loop recovery and circulation system, the manifold allows the user to control the solvent input via the manifold through the gauges and allows you to monitor the pressure and vacuum of the system while it is running. Specifications: Aluminum Block Body 1/4" SAE Brass Fittings 60mm Gauges Refrigerants: R1270/R290/R600a BAR, PSI, Celsius Temp. Ratings: 100C Pressure Ratings: 800PSI High Side, 500PSI Low Side Includes 3 Multi-Colored Charging Hoses.

$38.00 - $45.00

1LB TFX Closed Loop Extractor

1LB TFX Closed Loop Extractor Are you ready to embark on your extraction journey? Look no further than the TFX, the perfect introductory closed-loop extractor to kickstart your extraction journey. Not only does the TFX deliver exceptional performance at an affordable price right out of the box, but it also serves as an excellent base unit for future upgrades and modifications as level up your extraction game. Whether you're just starting or looking to expand your capabilities, the TFX provides a solid foundation that allows you to tailor your extraction setup to meet your evolving needs. With its versatile design and compatibility with various extractor upgrades, the TFX empowers you to explore new processing techniques and adapt to changing industry demands. Begin your extraction journey with the TFX, and unlock limitless possibilities for innovation and growth in the world of extraction. The TFX closed loop extractor represents the evolution of the highly popular Apollo closed loop extractor, introducing a new era of enhanced safety, ease of use, and performance. Building upon the success of its predecessor, the TFX provides greater safety, ease of use, and performance. Designed with operator safety in mind, the TFX incorporates improved safety mechanisms, including High-pressure Clamps and pressure relief valves standard to ensure maximum safety during the extraction process. Furthermore, the TFX line of closed-loop extractors makes extract harvesting a breeze with splatter platter bases standard. Its optimized design results in superior ease of use, performance, and safety yielding exceptional quality extracts. The TFX closed-loop extractor represents the foundation of most extractors' journey, providing would-be professionals and established professionals alike with a reliable, efficient, and future-proof solution to meet their evolving needs. The TFX line of closed-loop extractors is available in three distinct model variants to suit various extraction needs. The V1 Explorer is the ideal choice for budget-conscious individuals seeking an affordable entry-level option to venture into the world of extraction. This model features a DOT-Approved carbon steel recovery tank, 1/4" JIC Recovery lines, and polycarbonate sight glasses, providing a solid foundation that can be easily upgraded to professional or elite options in the future. For those aiming for a professional setup from the start, the V2 Professional model is the way to go. It includes an upgraded stainless steel recovery tank with 1/2" JIC Recovery lines, ensuring optimized solvent recovery. Additionally, the professional model includes upgraded borosilicate sight glasses, enhancing the visibility of the extraction process. If you're seeking the ultimate extraction experience, the V3 Elite model is your go-to solution. It incorporates all the upgrades of the professional model, including the upgraded stainless steel recovery tank with 1/2" JIC Recovery lines and upgraded borosilicate sight glasses. Moreover, the elite model goes beyond by featuring a solvent dispersal plate for even biomass saturation and a jacketed splatter platter for use with a heated circulator to ditch the hot water bath and further optimize solvent recovery. The TFX closed-loop extractor empowers you to choose the perfect model that suits your budget and requirements, Whether you're starting out or aiming for professional-grade capabilities the TFX Closed Loop Extractor series is the perfect foundation to start your extraction journey. Whether you opt for the Explorer, Professional, or Elite model, the TFX line of closed-loop extractors offers infinite modification possibilities to expand your capabilities and stay ahead of the evolving needs of the industry. While the TFX is specifically optimized for quick wash extraction procedures, ensuring exceptional purity and yield. It can easily be adapted for soaking procedures by adding our 316L SS Tri-Clamp Ball Valve below the material column. For those seeking absolute purity, pairing your TFX with an Inline CRC (Color Remediation Column) allows you to create the highest quality and purest extracts imaginable. If running fresh frozen material is your goal, simply swap out the standard 3"x 24" spool with a Sleeved Spool to chill your material during the extraction process and preserve the flavor of your starting biomass. To achieve absolute clarity in your extracts, reduce wax content by incorporating an injection coil into your setup. If you're looking to reduce solvent loss and improve recovery times, consider adding our BVV 2 Cylinder Active Closed Loop Recovery kit to your TFX closed loop extractor. This kit enhances solvent recovery efficiency, ultimately saving you time and resources. With the TFX closed loop extractor and its extensive range of modification options, you have the freedom to customize your extraction setup to meet your unique requirements. Stay at the forefront of the industry and unlock the full potential of your extraction process with the versatile TFX closed-loop extractor. As a leading manufacturer of extraction equipment, we understand the importance of precision and safety in the extraction process. The TFX is engineered with these principles in mind, offering a cutting-edge solution for extraction professionals. Crafted from high-quality stainless steel, the TFX boasts exceptional durability and corrosion resistance, providing you with a reliable and long-lasting extraction solution. Its innovative design incorporates advanced safety features, including high-pressure clamps, pressure relief valves, and sight glasses, to ensure operator well-being and operational control. Its superior design promotes efficient solvent flow and thorough material saturation, resulting in high-quality, potent extracts that meet your exact specifications. When it comes to introductory closed-loop extractors, the TFX stands out for its exceptional performance, safety, and reliability. With our product, you can streamline your extraction operations, increase productivity, and produce premium extracts that exceed industry standards. At BVV, we take pride in delivering top-notch extraction equipment that caters to your specific needs. Our team of experts is committed to providing unparalleled customer support, assisting you every step of the way, from purchase to setup and beyond. Elevate your butane extraction game with the TFX, the ultimate top-fill closed-loop extractor. Contact us today to start your extraction journey and take your business to new heights. Specifications 3"x24" 1LB Material Column 6"x12" Collection Base Body 6" Collection Base Splatter Platter 100um Nitrile BUNA-N Mesh Gaskets 1.5" Polycarbonate or Borosilicate Sight Glasses 125 PSI ASME Safety Valves -30hg-250PSI Compound Pressure Gauge 1/4" or 1/2" Full Bore Recovery Lines 1/4" JIC process Flow lines Explorer Professional Elite DOT Carbon Steel Solvent Tank Polycarbonate Sight Glasses 1/4" JIC Recovery Lines Stainless Steel Solvent Tank Borosilicate Sight Glasses 1/2" JIC Recovery Lines Stainless Steel Solvent Tank Borosilicate Sight Glasses 1/2" JIC Recovery Lines Solvent Dispersal Plate Jacketed Splatter Platter ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$850.00 - $1,350.00

Huber SilOil M80.100/250.03, Heat transfer fluid -80 to 250°C

Huber SilOil M80.100/250.03, Heat transfer fluid -80 to 250°C SilOil M80.100/250.03 is a low-viscosity silicone fluid which, as a result of its special property profile, is particularly suitable for use as a cold and heat transfer medium in cryostats, thermostats and heat transfer installations. SilOil M80.100/250.03 can be used in the range from -80 °C to 100 °C (for open systems) and to 250 °C with externally sealed systems (Unistats). It should be borne in mind that, at high temperatures, SilOil M80.100/250.03 can be chemically altered by oxidizing media, such as air, or substances with a catalytic effect, such as acids, lyes and various metal compounds. An increase in viscosity, and possibly even gelling of the fluid owing to crosslinking reactions, must be expected in the presence of oxidising agents, while contact with products having a catalytic effect usually induces a process of depolymerization, resulting in a drop in viscosity Safety Data Sheet Advantage: virtually insoluble in water non-corrosive low setting points and vapor pressures high flash points low toxicity odorless no coking tendency under thermal stress high thermal stability resistance to ageing chlorine free Heat transfer fluid M80.100/250.03 Working temperature °C -80 to 100/250 open/closed systems: -80°C - 100°C Unistats (only closed): -80°C - 250°C Material: silicon oil Viscosity at 25°C: 7 mm²/s Color colorless, clear Material incompatibility Silicone rubber

$1,890.00 - $3,610.00

5L Neocision ETL Lab Certified Rotary Evaporator Turnkey System

5L Neocision ETL Lab Certified Rotary Evaporator Turnkey System The 5L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 5L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. 5L NEO Rotary Evaporator Turnkey System setup includes: 5L Neocision ETL Lab Certified Rotary Evaporator Polyscience LS -20C to 40C 1/2HP Chiller w/ Turbine Pump 1/4" Gum Rubber - 100ft 1/4" Silicone Tubing - 25ft Welch BTpro70 Adjustable Stainless Steel Hose Clamps Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware. Specifications: Model 5L Solvent Pro Series Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 110V 50/60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 20-130 RPM Set Temperature RT+5 - 99C Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 5L (5000ml) Receiving Flask Capacity 5L (5000ml) Condenser Style Main + Auxiliary Vertical Double Helix Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 1800w Dimensions 45 x 32 x 15in Weight 155 lbs Vacuum Connection 14mm / .55 in. Barb Condenser Connection 18mm / .70 in. Barb Warranty 1 Year excluding glass parts Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$10,250.00 - $12,250.00

Agilent IDP-15, 9 CFM, Dry Scroll Vacuum Pump

Agilent IDP-15, 9 CFM, Dry Scroll Vacuum Pump Overview The new Agilent IDP-15 dry scroll pump is designed for extremely quiet (<50dBA) and low vibration operation, delivering a peak pumping speed of 9 cfm at 60Hz.With a single-sided scroll design it offers fast, easy yearly maintenance and low cost of ownership. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. Specification Base pressure (50 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Base pressure (60 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Dimensions (WxHxL) 13.1 in x 14.3 in x 19.1 in Exhaust Connection NW16 Height 14.3 in Inlet Connection NW25 Input Voltage 220-230 VAC 100-115 Length 19.1 in Noise Level 50 dB(A) Pumping Speed (50 Hz) 12.8 m3/h 214 L/min 7.5 CFM Pumping Speed (60 Hz) 15.4 m3/h 256 L/min 9.1 CFM Width 13.1 in

$9,503.00 - $10,028.00

You have seen 1056 out of 1674 products