Christmas/New Year- 10

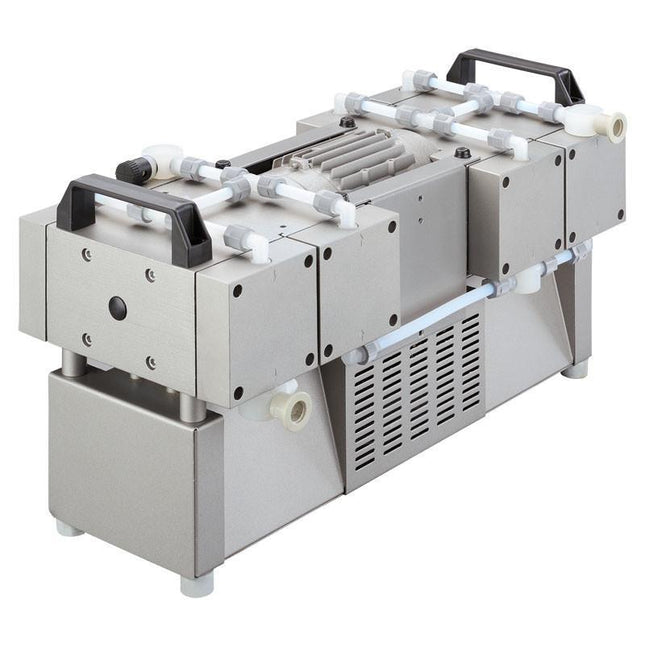

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro8

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro8 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details The new CRVpro family of direct drive vacuum pumps offers increased reliability and longer service interval vs. other direct drive rotary vane vacuum pumps. The CRVpro family consumes up to 36% less oil than comparable pumps. Three features drive these benefits: Runs 10°C cooler than comparable pumps. Slows corrosion. Has a 40% larger oil capacity than comparable pumps. Dilutes aggressive chemicals. Has a chemical resistant coating in the oil case and pump module. Protects non-moving parts. The CRVpro family includes all the features you'd expect in a direct drive rotary vane pump: gas ballast, forced oil lubrication, anti-suckback mechanism and thermal overload protection. Suitable applications include freeze drying, degassing, vacuum ovens and concentrators. 3081-01 is wired for North American 115V, 60Hz operation. Includes North American line cord, vacuum inlet hose barb suitable for gum rubber hose from 5/8" to 3/4" ID, and a charge of oil. 3082-01 is wired for North American 230V, 60Hz operation. Includes 230V North American line cord, UK cord, and skuko cord, and a charge of oil. Direct drive pumps are not recommended for filtration, aspiration, drying electrophoresis gels, or other applications requiring sustained operation above 30 torr Specifications Application CRVpro8 Free Air Displacement @ 60 Hz, cfm (L/min) 5.6 (158) Free Air Displacement @ 50 Hz, m³/hr (L/min) 8 (133) Ultimate Pressure, torr (mbar) 5x10⁻⁴ (4x10⁻⁴) Noise Level, dBA 50 Motor Speed, RPM, @60Hz, @50Hz 1740 (1450) Motor Power, HP (kW) 0.4 (0.5) Oil Capacity, mL 1000 Connection Flanges NW 16 Inlet Hose Connection* 5/8" to 3/4" Weight, lbs (kg) 49.6 (22.5) Dimensions, LxWxH, in (mm) 18.2x6.1x9.1 (463x157x230)

$4,150.00

1.5" Tri-clamp Thermometer

1.5" Tri-clamp Thermometer High-quality adjustable stainless dial 1.5" Tri-clamp thermometer with back mount orientation. This thermometer is perfect for process temperature monitoring in sanitary applications allowing precise monitoring of temperature. The stainless Dial Thermometer face is 3-inch diameter and reads 0 to 220 degrees in Fahrenheit and 0 to 100 degrees in Celsius. This thermometer is 1.5″ Tri-clamp and the probe depth from the tri-clamp is 2″ long.

$50.00

Half Ton - High Purity USA Propane - 99.5% Guaranteed

Half Ton High Purity USA PROPANE - 99.5% Guaranteed DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Freight ONLY. This tank requires a CGA 510 fitting - Sold Separately BVV™ always recommends distillation of every solvent before use. *Actual liquid weight is 420LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Permitted Sales Include the Following: Medical Collectives or Cooperatives operating under CA Health & Safety Code Section 11362.775 Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale High purity Propane is USA sourced, and guaranteed to be 99.5% pure. This instrument grade solvent helps to produce a higher quality extract by reducing mystery oils and contaminants. Solvent comes in a DOT refillable LP tank with liquid withdrawal valve (Diptube). Lot Analysis: Propane: 99.5% + Methane: <1ppm Ethane: 3ppm Isobutane: 2380ppm n-Butane: 251ppm Propylene: <5ppm Isopentane: <1ppm Water: <3ppm Sulfer: <1ppm *Free of any hydrogen Sulphide based Ethyl Mercaptan Odorants. *This product is clean, colorless and odorless. *Actual Propane liquid weight is 420LB Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via UPS Ground/Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers. Chemical Formula: C3H8 Molecular Weight: 44.10 g/mol CAS Registry Number: 74‐98‐6 Appearance Colorless Odor: Gasoline Density 0.116 Boiling Point: ‐40 F Solubility in water: Slightly Soluble GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220 GHS Precautionary Statements P203, P210, P222, P280, P377, P381, and P403 UN Identification Number: 1075 Proper Shipping Name: Petroleum Gases, liquefied Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Propane Certificate of Analysis (COA) Propane Safety Data Sheet (SDS)

$2,400.00

10L Neocision Dual Head Short Path Distillation Kit

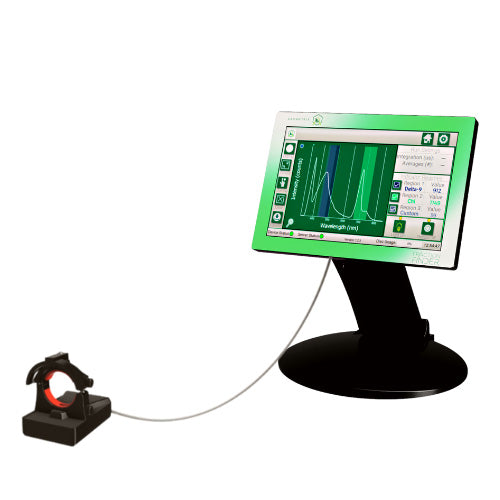

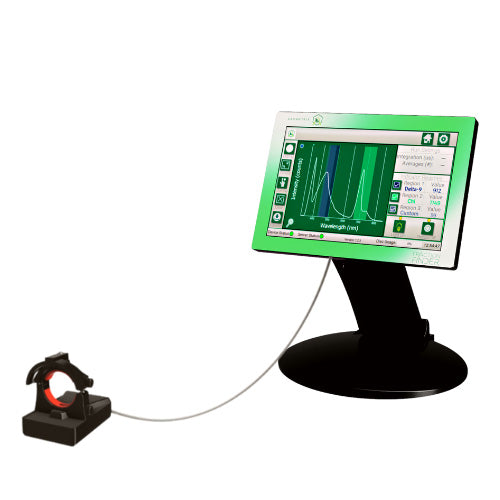

10L Neocision Dual Head Short Path Distillation Kit This unit carries a 2 day lead time. The 10L Neocision Distillation Turnkey Setup features our Dual 10L P5 Distillation Heads and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market. You will also receive a Dual Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The 10L Neo Kit Includes: 10L Neocision Kit with Dual P5 Distillation Heads KF-25 90 Degree Long Manifold and Metering Valve Dual Dewar Style Glass Cold Trap Bullseye Precision Vacuum Gauge Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$9,200.00

Polyscience 10 Liter General Purpose Water Bath

Polyscience 10 Liter General Purpose Water Bath Key Features: Displays actual and set point temperature simultaneously Three push-button pre-sets for frequently used temperatures Integrated timer Hinged gable cover Calibration capability Reservoir sizes from 2 to 28 liters Reservoir made of 304 Stainless Steel Reservoir drain (10 liter and larger baths) Primary and automatic safety thermostats Also compatible with waterless bath beads Specifications Working Temperature Range °F Ambient +10° to 212° Reservoir Capacity (liters) 10 Reservoir/Tank Material Stainless Steel Reservoir Cover Hinged Gable Working Access (L x W x D) (inches) 10.6 x 11.6 x 6 Temperature Stability °F ±0.2° Display 3.25" Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Maximum Ambient Temperature °F 104° Overall Dimensions (L x W x H) (inches) 17 x 15.5 x 15.5 Shipping Weight (pounds) 22.0 60Hz Only Part Number WBE10A11B Included Hardware Sample Tray Heater Wattage 1000 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/8.6 Regulatory Approvals ETL Certifications: Regulatory Approvals: ETL Regulatory Approvals: CE

$974.00

AFS Empty 2.5" CRC Botanical Extraction Filter Cup

2.5" CRC Botanical Extraction Filter Cup

$14.99$11.00

NEO 1.4CFM Diaphragm Pump ETL Rated

The BVV V series pumps are Ani-corrosion PTFE diaphragm vacuum pumps. The two head design operates as a two-stage pump to achieve a lower degree of vacuum. They are ideal for pumping corrosive gases and organic solvents. These pumps do not need any pump oil or other lubricants, which means less maintenance and smaller chance for cross contamination. The BVV V-40 is ETL listed to be used in laboratories and comes with a 2 year manufacturer warranty on all non consumable pieces. Model V-40 Power 110V 60Hz, 240 W Ultimate Vacuum 6 torr (8mbar) Maximum Operating Pressure 1 bar Maximum Flow 40 L/min Ambient Temperature 5 - 40°C Pump Head Material PTFE Composite Valve Material FFPM Noise <70db Dimensions 315x165x210mm Weight 10.4 kg For replacement diaphragms, click HERE

$1,675.00

Certified 280L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller - 85LB Max Capacity

Certified 280L Ethanol Wash/Dry Centrifuge NOTE: This item currently has a 2 week lead time. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift to lift it and will also ship via freight only. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 1000 RPM with Gradual Speed Stepping 559 Separation Factor Multiple Connection Ports/Sizes High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation *BVV Centrifuges are now available certified by PRV Engineers. Field visits/verification letters are an additional $4,000 + travel expenses.* Specifications Capacity 280L Drum Dimensions 39.4" (1000mm) Diameter x 14.17" (360mm) Speed 0-1000r/min Weight 4,188lbs (1900KG) Exterior Dimensions 59.06" x 82.68" x 45.28" (1500x2100x1150mm) Material 304 Stainless Steel Motor Power 11KW Explosions Proof - 220v 60Hz 3 Phase

$36,000.00 - $40,000.00

2" Plastic Drum Faucet

Recommended for dispensing light oils, acids and cleaning solutions. FDA approved high-density polyethylene (HDPE) plastic faucet. The faucet is designed to fit 2" NPT threads and can be used to dispense most non-flammable liquids. Use with plastic and steel drums. Tough polyethylene. FDA compliant. Material: High density polyethylene (HDPE ) is the most commonly used resin. This economical plastic has good impact resistant, is naturally translucent, flexible, and typically used for personal care products, such as shampoo bottles. Adding color will give HDPE an opaque look that will result in an increase in weight and rigidness. We have a variety of these rigid and tough high density polyethylene products in stock, from containers, pails, bottles, caps, tubs, and jugs. HDPE works well in below freezing temperatures. HDPE heat compatibility varies. Generally, it should not be used with products filled at over 145°F.

$25.00$15.00

Welch BTpro70

Welch BTpro70 ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Welch’s BTpro vacuum pump series has a flow and vacuum level to provide fast performance for your size of rotary evaporator, glass reactor, purge oven, or winterization filtration apparatus. These chemical duty PTFE diaphragm pumps are oil-free. The pumping action and deep vacuum comes from the movement of PTFE diaphragms within PTFE heads. All wetted services in the flow path are made of fluoroplastic making the BTpro pump highly chemically resistant. As a result, the BTpro vacuum pump series is near-zero maintenance. A cold trap placed in-line with BTpro pump is needed if terpenes are part of the flow path. The BTpro40 and BTpro70 models employ patented valve and diaphragm technology that generates a deep 15 Torr vacuum pressure with each PTFE head. In addition, both pump models have built-in tuneable vacuum to control evaporation rate. The tunable vacuum adjustment can also be used to stop accidental bumping/foaming. Model BTpro70 Free Air Displacement@60Hz,lpm(CFM) 70(2.5) Ultimate Vacuum Pressure, Torr 15 Maximum Vacuum, in. Hg 29.3 Horsepower, HP (watts) 1/5(150) Built-in adjustable vacuum Yes Gas Ballast - Head Material PTFE Diaphragm PTFE Inlet/outlet Connection 3/8” barb Agency (National Recognized Lab) CSA Weight, lbs (kg) 21.3(9.6) Overall Dimensions LxWxH in.(cm) 13.8x6.8x8.8 35x17x22 Shipping Weight, lbs(kg) 25 (11.3) Shipping Carton Dimensions LxWxH in.(cm) 21x14x15 (52x35x37)

$2,750.00$1,750.00

Welch BTpro40

Welch BTpro40 (CSA) Certified ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Welch’s BTpro vacuum pump series has a flow and vacuum level to provide fast performance for your size of rotary evaporator, glass reactor, purge oven, or winterization filtration apparatus. These chemical duty PTFE diaphragm pumps are oil-free. The pumping action and deep vacuum comes from the movement of PTFE diaphragms within PTFE heads. All wetted services in the flow path are made of fluoroplastic making the BTpro pump highly chemically resistant. As a result, the BTpro vacuum pump series is near-zero maintenance. A cold trap placed in-line with BTpro pump is needed if terpenes are part of the flow path. The BTpro40 and BTpro70 models employ patented valve and diaphragm technology that generates a deep 15 Torr vacuum pressure with each PTFE head. In addition, both pump models have built-in tuneable vacuum to control evaporation rate. The tunable vacuum adjustment can also be used to stop accidental bumping/foaming. Model BTpro40 Free Air Displacement@60Hz,lpm(CFM) 40(1.4) Ultimate Vacuum Pressure, Torr 15 Maximum Vacuum, in. Hg 29.3 Horsepower, HP (watts) 1/5(150) Built-in adjustable vacuum Yes Gas Ballast - Head Material PTFE Diaphragm PTFE Inlet/outlet Connection 3/8” barb Agency (National Recognized Lab) CSA Weight, lbs (kg) 15.0(6.8) Overall DimensionsLxWxH in.(cm) 12x7x8.3(31x18x22) Shipping Weight, lbs(kg) 19(8.6) Shipping Carton DimensionsLxWxH in.(cm) 21x14x15(52x35x37)

$1,860.00$1,700.00

Heavy Duty Steel Mobile Cart for Vacuum Ovens

Heavy Duty Steel Mobile Cart for Vacuum Ovens Our heavy-duty cart is designed and built to house a variety of equipment such as vacuum ovens, cold traps, vacuum pumps, etc. The cart can comfortably house up to 3 BVV™ and Across International 0.9 and 1.9 vacuum ovens. The cart offers mobility with their swivel caster wheels and can withstand up to a total of 1,100lbs. Included in the unit are three side shelves in which the height can be adjusted to your needs. The cart was meticulously designed for reliability, customization, and convenience for your process. Features: White powder coated carbon steel. 3-shelf shelving unit 3 laser cut, height adjustable side shelves. 2⅜” diameter hole to help with hose and cable management. 6” front lip for easy oil drainage. Can fit on the left or right side of the bracket Four 3” swivel caster wheels: 2 with brakes and 2 without brakes. Dimensions: 33” (L) x 23” (W) x 61” (H). Additional 13¼” to the length with side shelves added. Made in the USA. Note: The unit shipped does NOT come with the side shelves assembled. Required tool: 5mm ball hex (NOT INCLUDED).

$1,490.00

Certified 160L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller - 55LB Max Capacity

Certified 160L Ethanol Wash/Dry Centrifuge with Explosion Proof Motor and Controller Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift to lift it. It will also ship via freight only. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 1200 RPM with Gradual Speed Stepping 643 Separation Factor Multiple Connection Ports/Sizes High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation *BVV Centrifuges are now available certified by PRV Engineers. Field visits/verification letters are an additional $4,000 + travel expenses.* Specifications Capacity 160L Drum Dimensions 31.5" (800mm) Diameter x 12.6" (320mm) Depth Speed 0-1200r/min Weight 3307lbs (1500KG) Exterior Dimensions 51.2" x 72.8" x 43.3" (1300 x 1850 x 1100mm) Material 304 Stainless Steel Motor Power 7.5KW Explosion Proof - 220v 60Hz 3 Phase

$33,500.00 - $37,500.00

Neocision Spectra Elite LED Grow Light - DLC Listed

Neocision Spectra Elite LED Grow Light ELITE Neocision Spectra Elite fixtures feature 20.6% blue spectra and 45.1% red spectra witha peak at 660nm for your flowering plants. This unique spectra mix creates stronger plants for nutrient uptake with maximized red for increased photosynthesis. Get increased yields, quality bud formation and high rates of cannabinoid production levels. Neocision Specta Elite Cutsheet DLC Qualified Product List Performance, Specs and Ranking FEATURES: Efficacy up to 2.85 Micromoles / J Industry Leading Horticulture LEDs RJ Port for Plug and Play Control Systems Folding Design for Fast and Easy Installation Leading 660nm LED Count – 150 660nm diodes Per Fixture 7 Year Limited Warranty on Fixture 8 Year Limited Warranty on Driver Looking for bulk purchases? We offer volume discounts and other value-adding services with our partners at RSX Enterprises. Call (331-281-0154) and speak with a rep for more information. SPECTRUM AND EFFICACY PPF Efficacy: 2.85 at 240 VAC Photon Flux (µmol/s) (400-700nm): 1939 Photon Flux Blue (µmol/s) (400-500nm): 400 Photon Flux Green (µmol/s) (500-600nm): 666 Photon Flux Red (µmol/s) (600-700nm): 874 Total Blue/Red - Energy Bands: 1274 % Blue: 20.64% % Green: 34.34% % Red: 45.06% POWER Power Consumption: 680W AC Driver: Sosen Power Factor: >0.95 Surge Protection: 6 KV 208V: 3.44A 240V: 2.98A 277V3: 2.58A DIMENSIONS Fixture Size (driver mounted on the fixture): (L) 43.9” x (W) 43.9” x (H) 4.1” Fixture Size (without driver): (L) 43.9” x (W) 43.9” x (H) 1.6” Power Supply Dimension: (L)23” X (W) 6.5” X (H) 3” Driver Net Weight: 10.1 lb. Fixture Net Weight: 20.4 lb. OTHER Mounting Height >6” above canopy Beam Angle 120 Degree Input Voltage 200 - 277 VAC Manual Dimming Knob Yes Built In Control Ports Yes Power Cord Length (Extensions available) AWG 18, 6 Foot Standard Plug 240 VAC - NEMA 6-15P Substitute Plugs (Upon request at order) 277 VAC, Pigtails Adjustable Height Hanging Kit Included Yes Fixture Warranty 7 Years Limited Driver Warranty 8 Years Limited ETL Safety Certified Conforms to UL 1598:2018 Ed.4Certified to CSA C22.2#250.0:2018 Ed.4*ETL Safety Certified No. 5020070 DLC Listed Yes

$675.00$550.00

Welch BTpro170

Welch BTpro170 ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Welch’s BTpro vacuum pump series has a flow and vacuum level to provide fast performance for your size of rotary evaporator, glass reactor, purge oven, or winterization filtration apparatus. These chemical duty PTFE diaphragm pumps are oil-free. The pumping action and deep vacuum comes from the movement of PTFE diaphragms within PTFE heads. All wetted services in the flow path are made of fluoroplastic making the BTpro pump highly chemically resistant. As a result, the BTpro vacuum pump series is near-zero maintenance. A cold trap placed in-line with BTpro pump is needed if terpenes are part of the flow path. Model BTpro170 2163 Free Air Displacement@60Hz,lpm(CFM) 170 (6.0) 170 (6.0) Ultimate Vacuum Pressure, Torr 6 6 Maximum Vacuum, in. Hg 29.7 29.7 Horsepower, HP (watts) 0.6(440) 0.6(440) Built-in adjustable vacuum - - Gas Ballast Yes Yes Head Material PTFE Coated Al Diaphragm PTFE PTFE Inlet/outlet Connection NW16 flange NW16 flange Agency (National Recognized Lab) cUL cUL Weight, lbs (kg) 72.3 (32.8) 72.3 (32.8) Overall DimensionsLxWxH in.(cm) 21x11x12(53x28x31) 21x11x12(53x28x31) Shipping Weight, lbs(kg) 88.2 (40.1) 88.2 (40.1) Shipping Carton Dimensions LxWxH in.(cm) 23.6x15.8x16.1 60x40x41 23.6x15.8x16.1 60x40x41

$5,400.00$5,000.00

Half Ton - High Purity USA ISO-BUTANE - 99.5% Guaranteed

Half Ton - High Purity USA ISO-BUTANE - 99.5% Guaranteed DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Freight ONLY. This tank requires a CGA 510 fitting - Sold Separately BVV™ always recommends distillation of every solvent before use. *Actual liquid weight is 490LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Permitted Sales Include the Following: Medical Collectives or Cooperatives operating under CA Health & Safety Code Section 11362.775 Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale At BVV™, quality is everything, and our ISO-Butane is certainly no exception. This ISO-Butane is sourced here in the U.S, so you know it’s going to be of high purity: we guarantee 99.5% purity. With such high quality, you’ll see the results. By cutting down on mystery oils and other contaminants, our instrument-grade solvent will make for a higher quality extract. This solvent is clean, odorless, and colorless, meaning there are zero hydrogen sulfide-based Ethyl Mercaptan odorants. It’ll arrive in a DOT refillable LP tank, equipped with liquid withdrawal valve (Diptube). Made to keep you going for a long time. Typical Analysis: ISO-Butane >99.8% Methane <1 ppm Ethane <1ppm N-Butane <2000 ppm Propane <250ppm Isopentane <2 ppm Water <3 ppm Oxygen <5 ppm Nitrogen <10 ppm Sulfur Non-Detected **Notes: Actual ISO-butane liquid weight is 490LB BVV™ always advises distillation of every solvent before using it. DISCLAIMER: Our items are intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. For safe operation, only use the unit in well-ventilated areas. ***Shipping Notes: This item will ONLY ship via UPS Ground, in accordance with FAA regulations. Any orders including solvent will NOT be shipped Expedited. If an order includes solvent as well as additional items, it will all be shipped via UPS Ground/Freight even if you’ve selected Expedited. If you want the non-solvent item to ship Expedited, place 2 separate orders; we won’t split up orders and ship them separately otherwise. We do not ship solvents to Hawaii, Puerto Rico, or any other U.S. Territory outside of the contiguous 48 States. Shipping solvent to Alaska will ONLY be via freight and will be required to travel through Canada. Our shipping policies are in place to ensure safe transport of solvents and prevent any problems with shipping times for Best Value Vacs customers Chemical Formula: C₄H₁₀ Molecular Weight: 58.12 g/mol CAS Registry Number: 75-28-5 Appearance Colorless Odor: Faint Petroleum Density 563 kg/m³ (or 0.563 g/mL) Boiling Point: 10°F (-12°C) Solubility in water: Low Solubility GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220 GHS Precautionary Statements P203, P210, P222, P280, P377, P381, and P403 UN Identification Number: 1969 Proper Shipping Name: Isobutane, liquefied Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Isobutane Certificate of Analysis (COA) Isobutane Safety Data Sheet (SDS)

$2,400.00

20L Neocision Dual Head Short Path Distillation Kit

20L Neocision Dual Head Short Path Distillation Kit This unit carries a 2 day lead time. (Note: This kit does NOT include the stainless steel table.) The 20L Neocision Distillation Kit Setup features our Dual P10V6 Distillation Heads and USA made glass. Every component in this distillation kit is made for precision, throughput, and repeatable results. You will also receive Dual Dewar Style Ribbed Glass Cold Traps to keep all volatiles and solvents out of your vacuum system. This kit gives you the essentials of a short path distillation system and allows you to add a pump and temperature control system of your choosing. The 20L Neo Kit Includes: 20L Neocision Kit with glassware, labware, and Dual P10V6 Distillation Heads. KF-25 Bellow Y Manifold Dual Ribbed Dewar Style Glass Cold Trap Non-Mercury Glass Thermometers 20L Digital Heating and Stirring Mantle Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in the boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$6,800.00 - $7,000.00

36 inch Filtration Funnel V2

Buchner Filtration Kit This filtration kit is operated by using a vacuum pump to pull the solution through the filter paper to remove particulate. The funnel has a 36" perforated plate to support the filter paper.

$7,600.00 - $8,180.00

Side Mount Tri-Clamp Filter Strainer

Side Mount Tri-Clamp Filter Strainer Tri Clamp strainers are used for filtration of solids from fluid process flows. It is recommended that a strainer be placed before a pump when emptying a centrifuge and the like to not allow large solids to enter and damage a pump. This model has 1.5" Tri-Clamp inlet and outlet ports. Side Mount Inline Strainers Tri Clamp inline strainers mount similar to a spool or elbow with both ends clamped into a tri-clamp fitting. The side mount strainer has a unique characteristic, it can be emptied while still attached just by removing the internal basket as long as it is correctly mounted. Liquid should flow in through the side port and out through the bottom port.

$190.00

ASME 150L - 350 MAX working pressure, Pneumatic PSIG 385

ASME 150L - 350 MAX working pressure, Pneumatic PSIG 385 This is a custom manufactured made ASME Certified 150L Jacketed Solvent Tank with ASME Stamp and made out of 304 Stainless Steel. This base is designed to be configured to any application and can even be used as a solvent tank. This tank comes bare with no fittings and will hold 150LBS of liquid butane and is able to have fluid circulated around the outer jacket to increase recovery speeds in the extraction system. This unit also has welded lift points on the top of the tank. Specifications Material 304 Stainless Steel Certification: ASME MAWP @ 100°C / 212°F: Inside 350 PSI / 2.42 MPa Jacket 150 PSI / 1.1 MPa MDMT -40°C / -40°F MIN TEMP -20°F at 350PSI Butane Capacity 150LBS Connection Sizes: (3) 6" Tri-Clamp (2) 1.5" Tri-Clamp (2) 1/2" FNPT Weight 108LBS Outer Dimensions: 44.5" Tall 32.5" W x 32.5" L **This Item will ship Via FREIGHT ONLY.

$8,000.00

Master Vapor MVP Liquid Recovery Pump

Master Vapor MVP Liquid Recovery Pump THE NEW LIQUID Pumps solvent in liquid state Hydrocarbon and ethanol compatible C1D1 and 3rd party Certified Drastically increases evaporation byexpanding surface area andcreating turbulence Electric Driven FDA Food Grade Compliant MADE IN THE USA Engineering Specifications: Maximum pumping outlet pressure - 70 PSI Center Section CO2 charge range 5 to 80 PSI(10-15psi over inlet pressure recommended) CO2 Inlet Size: 1 /4 in. npt(f) Maximum Pump Speed 135 cpm (cycle per minute) Process Inlet and Outlet Size: 1 in. npt Electric Motor: Explosion proof for C101 Hazardous areas Motor Specifications: 2HP, 3,600 rpm, 60Hz Size: 18.3” x 15.4” base x 42.3” tall Weight: 173.2 lb All sales final Technical Data sheet US Metric Maximum Pumping outlet Pressure 70 PSI 0.48 MPa, 4.8 bar Center section CO2 Change range 6 to 80 PSI 0.03-0.55 MPa 0.3-5.5 bar Equipment Withstand Pressure 350 PSI 2.41 MPa, 24.1 bar Maximum CO2 Consumption <0.2 scfh <0.006 cubic meters/hour CO2 inlet size 1/4 in. npt(f) Maximum Pump Speed 135 cpm Process intel and outlet size 1 in. npt Model MVP Liquid, 3 ph, Inverter Rated Power 2 HP 1.5kW Speed 3600 rp, (60 Hz) Gear Ratio 25.85 Voltage 1-phase 208-230/460V Maximum Amperaage Load 5.2 A (230V / 2.6 A (460V) Model MVP Liquid 1PH Power 2 HP 1.5kW Speed 3600 rpm (60 Hz) Gear Ratio 25.85 Maximum Amperaage Load 5.2 A (115V / 10 A (230V) Noise Data Sound Power (measured per ISO-9614-2 88.5 dBa Sound Pressure {Tested 3.28ft (1m) From Equipment} 80.5dBa Materials Process Pressure Section and Reed Valves Stainless Steel Diaphragms Standard: FKM Fluoroelastomer Optional:PTFE Process Vapor Temperature Range FKM: -40 to 275 °F (-40 to 135 C)PTFE: +40 to 220 °F 9+4 to 104 C

$13,700.00 - $14,250.00

20L Neocision ETL Lab Certified Rotary Evaporator Turnkey System

20L Neocision ETL Lab Certified Rotary Evaporator Turnkey System 20L NEO Rotary Evaporator Turnkey System setup includes all the necessary components to successfully perform solvent recovery via rotary evaporation. A cold trap should always be used inline between your vacuum system and application to protect the pump from volatile vapors. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram 20L NEO Rotary Evaporator Turnkey System setup includes: 20L Neocision ETL Lab Certified Rotary Evaporator Polyscience 6160T 1HP Chiller 3/8" Gum Rubber - 25ft 3/8" Tubing - 25ft Welch BTpro100 Diaphragm Pump Adjustable Stainless Steel Hose Clamps Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$19,450.00 - $22,500.00

10L Premium Short Path Distillation Kit with P10 Distillation Head

10L Short Path Distillation Kit with P10 Distillation Head This unit carries a 2 day lead time. (Note: Stainless Steel Table NOT Included.) The 10L Short Path Distillation Kit features our USA made P10 Distillation Head. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Kangaroo digital thermometer which is very rugged and reliable. You will also receive a Ribbed Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Kit gives you the basic necessities of a short path distillation system and allows you to add on a temperature control system and vacuum pump to fit your needs. The 10L Neo Kit Includes: 10L Short Path Distillation Kit including glassware, labware, and P10 Distillation Head. 10L Digital Heating and Stirring Mantle. Valved Vacuum Adapter. Ribbed Dewar Style Glass Cold Trap. Kangaroo Digital Thermometer. Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$4,100.00

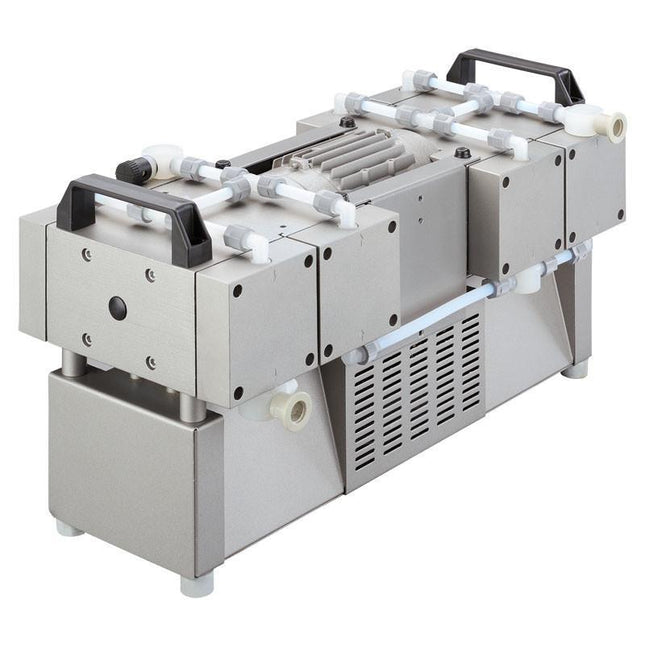

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro4

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro4 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details The new CRVpro family of direct drive vacuum pumps offers increased reliability and longer service interval vs. other direct drive rotary vane vacuum pumps. The CRVpro family consumes up to 36% less oil than comparable pumps. Three features drive these benefits: Runs 10°C cooler than comparable pumps. Slows corrosion. Has a 40% larger oil capacity than comparable pumps. Dilutes aggressive chemicals. Has a chemical resistant coating in the oil case and pump module. Protects non-moving parts. The CRVpro family includes all the features you'd expect in a direct drive rotary vane pump: gas ballast, forced oil lubrication, anti-suckback mechanism and thermal overload protection. Suitable applications include freeze drying, degassing, vacuum ovens and concentrators. 3041-01 is wired for North American 115V, 60Hz operation. Includes North American line cord, vacuum inlet hose barb suitable for gum rubber hose from 5/8" to 3/4" ID, and a charge of oil. 3042-01 is wired for North American 230V, 60Hz operation. Includes 230V North American line cord, UK cord, and skuko cord, and a charge of oil. 3046E-01 comes with an explosion proof motor. Conduit wiring installation required. No cord, plug, or switch provided. Direct drive pumps are not recommended for filtration, aspiration, drying electrophoresis gels, or other applications requiring sustained operation above 30 torr. Specifications Applications CRVpro4 Free Air Displacement @ 60 Hz, cfm (L/min) 2.8 (78) Free Air Displacement @ 50 Hz, m³/hr (L/min) 4 (67) Ultimate Pressure, torr (mbar) 5x10⁻⁴ (4x10⁻⁴) Noise Level, dBA 50 Motor Speed, RPM, @60Hz, @50Hz 1740 (1450) 1750 (1450) Motor Power, HP (kW) 0.4 (0.5) Oil Capacity, mL 1150 Connection Flanges NW 16 Inlet Hose Connection* 5/8" to 3/4" Weight, lbs (kg) 46.3 (21) Dimensions, LxWxH, in (mm) 18.2x6.1x9.1 (463x157x230)

$3,490.00

ASME Certified 50L Jacketed Solvent Tank 304L - Bare

ASME Certified 50L Jacketed Solvent Tank 304L - Bare This is a custom manufactured USA made ASME Certified 50LB Jacketed Collection base with UM Stamp and made out of 304L Stainless Steel. This base is designed to be configured to any application and can even be used as a solvent tank. This tank comes bare with no fittings and will hold around 50LBS of liquid butane and is able to have fluid circulated around the outer jacket to increase recovery speeds in the extraction system. **This Item will ship Via FREIGHT ONLY. Specifications Material 304L Stainless Steel Certification: ABILITY ENGINEERING TECHNOLOGY INC. ASME / UM / NB MAWIWP 350 PSI at 150°F MAWEWP N/A MIN TEMP -20°F at 350PSI Butane Capacity ~50LBS Connection Sizes: 6" Tri-Clamp (2) 1" NPT (2) 1/2" NPT - Outer Jacket Ports (2) 3/8" NPT Weight 146LBS Outer Dimensions: 32-7/8" Tall 14" Diameter Inner Dimensions: 24" Tall 12" Diameter

$1,800.00$1,000.00

2L BVV™ Rotary Evaporator Turnkey Setup

2L BVV™ Rotary Evaporator Turnkey Setup 2L Electric Lift Rotary Evaporator turnkey setup includes all the necessary components to successfully perform solvent recovery via rotary evaporation. A cold trap should always be used inline between your vacuum system and application to protect the pump from volatile vapors. 2L Rotary Evaporator Turnkey Setup includes: 2L Electric Lift Rotary Evaporator 90-day limited warranty (excludes glassware, consumables & moving parts) BVV NEO 1.4 CFM Diaphragm Pump ETL Rated OR. 3.5CFM Dry Floating Scroll Vacuum Pump Polyscience LS -20C to 40C 1/2HP Chiller w/ Turbine Pump OR BVV NEOCISION 20L Chiller (-40C) - ETL Rated 10ft of Vacuum Tubing 20ft of Chiller Tubing 10 Pack of Adjustable stainless steel hose clamps 3/8" Vacuum Manifold Optional add-on : BVV™ CT40 -40°F 300ml x 3 Cold Trap, BVV™ CT80 -112°F 300ml x 3 Cold Trap Optional add-on: J-KEM DVR-200 Digital Vacuum Regulator Optional add-on: Heat Transfer Fluid -- NuTherm PF-50 or Dynalene HC-50 Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to the condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of the condenser, chiller input to bottom of the condenser). Connect vacuum pump to cold trap and connect cold trap to the vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller, and cold trap have reached desired temperatures, turn on the rotovap motor and set the speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once the vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow the solution to enter the evaporating flask. At this point, you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$7,000.00 - $13,500.00

Polyethylene Glycol 400 - PEG 400

Polyethylene Glycol 400 Polyethylene glycol 400 has an average molecular weight of 400. It is a clear, viscous liquid at room temperature. APPLICATIONS • Chemical Intermediate• Plasticizer• In cosmetics for preparation of ointments and lotions.• As a mold release agent and lubricant for both natural and synthetic products. Physical Properties Flash point, PMCC, °F 390 Flash point, PMCC, °C 199 Refractive index, 25°C 1.463 Density, g/ml, 20°C (68°F) 1.1254 Weight, lbs/US gal, 20°C (68°F) 9.39 Freezing Range, °F 39-46 Freezing Range, °C 4-8 Viscosity, kinematic cSt at 25°C (77°F) 84 cSt at 98.9°C (210°F) 7.3 Chemical Properties Molecular Weight (range) 380-420 Average number of EO units 8.7 Water Solubility Soluble Potassium acetate, wt% 0.02-0.2 pH, 5% aqueous solution 4.5-7.0 Water, wt% 0.5 max. Color, Pt-Co 50 max. Hydroxyl number, mg KOH/g 267-295 Appearance, 20°C Clear The expiration date is 3 years from the date of manufacture and when the glycol is kept below 100F and out of direct sunlight.

$25.00 - $3,700.00

PolyScience LS5 Benchtop Chiller with Turbine Pump, 120V, 60Hz

PolyScience LS5 Benchtop Chiller with Turbine Pump, 120V, 60Hz Key Specifications: Description: LS Series 1/2 HP Benchtop Chiller, Turbine Pump; 43.4 psi; 9.8 l/min Display: LED Connectivity: Optional: RS232 Working Temperature Range °C: -20° to 40° Temperature Stability °C: ±0.1° Temperature Calibration Capability: 1-point Pump Type: Turbine Specifications Working Temperature Range °F -4° to 104° Working Temperature Range °C -20° to 40° Reservoir Capacity (gallons) 0.7 Reservoir Capacity (liters) 2.65 Reservoir Cover Screw-on Cap Cleanable Air Filter Yes Temperature Stability °F ±0.2° Temperature Stability °C ±0.1° Display LED Pump Type Turbine Pump Speed Constant, Single Speed Process Connections 1/2" (F) NPT Over-Temperature Protection / Failsafe Heater Control Yes Reservoir Liquid Level Indicator Yes WhisperCool Environmental Control Technology Yes Cool Command Refrigeration Technology Yes Reservoir Drain Yes Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 23.9 x 10 x 19 in Overall Dimensions (L x W x H) (cm) 60.7 x 25.4 x 48.3 cm Compressor Size (HP) 1/2 Refrigerant R452A Shipping Weight (pounds) 102.0 Shipping Weight (kilograms) 46.3 Catalog Page Number 98-99 Part Number LS51TX1A110C Maximum Pressure (psi) 43.4 Maximum Pressure (bar) 3.00 Maximum Pressure Flow Rate (gpm) 2.60 Maximum Pressure Flow Rate (l/min) 9.8 Cooling Capacity @ -20°C (W) 150 Cooling Capacity @ -10°C (W) 345 Cooling Capacity @ -5°C (W) 395 Cooling Capacity @ 0°C (W) 540 Cooling Capacity @ +10°C (W) 790 Cooling Capacity @ +20°C (W) 900 Cooling Capacity @ +30°C (W) 1020 Cooling Capacity @ +40°C (W) 1140 Included Hardware Two sets of Inlet/Outlet Adapters: ½ inch male NPT, 5/8 inch male NPT Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/12 Regulatory Approvals TUV

$5,161.00

Master Vapor MVP-150XL Diaphragm

Master Vapor MVP-150XL Diaphragm Diaphragm replacement kit for use with the MVP-150XL recovery pump. Unit of Measure: EA Height: 2 IN | 5.08 CM Length: 12 IN | 30.48 CM Width: 12 IN | 30.48 CM Volume: .167 FT3 | .005 M3 Chargeable Weight: 2.58 LBS | 1.17 KG

$410.00

Eccentric Recovery Pump Shaft Adapter

Eccentric Recovery Pump Shaft Adapter Replacement Eccentric adapters for TRS or BVV recovery pumps. Model numbers shown below- BVV-EC-TRS: TRS21 BVV-EC: BVV2CYL BVV4CYL BVVCMEP-RETRO

$75.00 - $105.00

Polyscience Durachill Chiller

Polyscience Durachill Chiller; 4.2 L; 208/230 V PolyScience CA10A3T1-41AA1N Offers Features: Large, full-color touchscreen display with intuitive interface and support for five different languages Home screen simultaneously displays set temperature, actual temperature, fluid pressure, fluid level, air filter status and timer Self-changing air filter system eliminates preventative maintenance by automatically changing the filter media at user-definable intervals Continuous fluid level monitoring protects pump and prevents freezing Whispercool® noise reduction system reduces operating noise levels to the almost imperceptible levels while maintaining optimal cooling performance Reduced global warming potential through a highly optimized refrigeration system design that greatly reduces the amount of refrigerant gas needed in the chiller and allows for migration to natural refrigerants that have little or no global warming potential Self-diagnostic system compares the chiller's functionality to its operating state the day it was built to minimize operating downtime and unnecessary service calls Compact, portable design takes up less floor space Cooling at ambient temperatures as high as 30°C Components are recyclable and meet or exceed global environmental standards UV Light Biological Growth Inhibitor System eliminates the need for algaecides User-adjustable temperature, pressure, and flow rate alarms Heat up to 70°C, without additional options Front fill reservoir access Externally accessible adjustable pressure regulator valve Full color touch screen display The color touch screen display gives you all the information you need at a glance. The screen will display continuous status of set temperature, actual temperature, reservoir fill level and output pressure as well as the status of your air filter. System messages are provided in easy to read text instead of confusing error codes. Dynamic self-changing filter Preprogrammed to change its own air filter once a month for a two year period, and the change interval can be adjusted to suit your operating environment. This will dramatically reduce downtime and unnecessary service calls and relieve you of the burden of preventative maintenance on your chiller. UV light biological growth inhibitor The UV Light Biological Growth Inhibitor will continuously control biological growth in the fluid path without the need to add chemical growth inhibitors and preventing algicides from being released into the world's waterways. Front fill reservoir The chiller offers a conveniently located front fill reservoir. You no longer have to go to the back of the chiller top open to fill the reservoir. It has the fill port in the front, making it easy to access, avoiding spills and saving time. Continuous liquid level monitoring Because pump seals will fail in as little as 30 seconds of being run dry, the chiller includes a state-of-the-art capacitance liquid level sensor to protect the pump from premature failure. If the fluid level becomes low, the chiller will give you visual and audible alarms. If the fluid level reaches a point where there's a risk of pulling air into the pump, it will shut the chiller down and present another alarm. Whispercool® noise reduction This high-performance chiller utilizes noise reduction system. The Whispercool® system evaluates the demand for cooling from the application then slows the fan speed to the minimum necessary to achieve control point, making the chiller extremely quiet while maintaining optimal temperature control at the same time. Applications Heat removal Specifications Cooling Capacity At 20°C: 2.9 kWAt 10°C: 1.93 kWAt 0°C: 1 kW Fluid Temperature Range 14 to 158°F (-10 to 70°C) Temperature Stability ±0.1°C Displayable Units Temperature: °C or °FPressure: psi or kPa Pump Inlet and Outlet ½" female NPT Connectivity RS-232, USB Serial Port Emulation, USB TMC, Dry Contact On/Off/Status Selectable Operating Languages English, Spanish, French, German, Mandarin Self-Changing Air Filter Yes UV Biological Growth Inhibitor Yes Ambient Air Temperature Tracking Yes Pump Pressure Range 20 to 90 psi (138 to 689 kPa) Maximum Pump Flow Rate 3.5 gpm (13.2 lpm) Power Requirements 230 V, 60 Hz, 13.5 A Dimensions 33 x 22 x 33" (84 x 56 x 84 cm) Weight 177 lbs (80.3 kg) Data sheet Manual

$8,307.00

Flexible Rubber Foam Pipe Insulation Elbow, 1/2" Thick Wall, 1-3/8" ID

Flexible Rubber Foam Pipe Insulation Elbow Soft and easy to install, this insulation restricts absorption of water, air, and gas. It is often used on cold and hot water lines and refrigeration lines. Seal with contact adhesive (sold separately). To use outdoors, coat in acrylic paint. For Use On Pipe Insulation Type Elbow Elbow Bend 90° Wall Thickness 1/2" ID 1 3/8" OD 2 3/8" For Pipe Size 1 For Copper Tube Size 1 1/4 Temperature Range -295° to 220° F Heat Flow Rate 0.25 Btu @ 75° F Density 4.5 lbs./cu. ft. Material Buna-N/PVC Foam Color Black Flexibility Flexible Cell Type Closed Tube Style Slit Specifications Met ASTM E84 25/50 for Flame and Smoke, ASTM C534 Performance Properties Moisture Resistant R Value 2 Additional Specifications SDS RoHS RoHS 3 (2015/863/EU) Compliant REACH REACH (EC 1907/2006) (01/17/2022, 223 SVHC) Compliant DFARS Specialty Metals COTS-Exempt Country of Origin United States USMCA Qualifying No Schedule B 392690.9988 ECCN EAR99

$11.50

Master Vapor Pumps - MVP Recovery Pump - XL 150 PSI

Master Vapor Pumps - MVP Recovery Pump - XL 150 PSI The Master Vapor Pump Model MVP-150XL is a certified gas recovery pump designed to operate at 150 PSI. It can handle over three times the volume of vapor as our standard MVP-150. This pump is designed specifically for LP-Gas vapor recovery and is ideal for butane or butane / propane mixtures. Please note that this model of the MVP 150 only comes with Three-phase power options available. Engineering Specifications: Recover LP-Gas vapor at OVER 18 CFM (cubic feet per minute) Recover butane at up to 4.5 LB/MIN (pounds per minute) Recover and re-condense butane between 35-50 GPH (gallons per hour) Electric motor: explosion proof for C1D1 hazardous areas; rated Class I Gr C & D, Class II Gr F&G Electric motor: 5 HP, 1800 RPM, 30 HZ Pump speed: 174 CPM (cycles per minute) at 60 HZ Size: 17.0” x 22.8” base x 46.4” tall Weight: 360.5 lb (163 kg) All sales final

$18,480.00

BVV 2540 Nanofiltration Skid

BVV 2540 Nanofiltration Skid Note: This product carries 8 - 12 week lead time Perform organic solvent recovery or botanical extract purification with ease with our 2540 nanofiltration skid. Replace up to 7X 50L Rotary evaporators with a single Skid. BVV's 2540 Nanofiltration Skid is designed to meet Class 1 Division 1 standards. With the ability to recover 30 gallons of ethanol per hour without the application of heat, preserving target compounds and utilizing a fraction of the energy consumption of a traditional falling film qualifying our 2540 Nanofiltration Skid for energy saving rebates. Processing Power Capacity: 15 GPH or 30 GPH of solvent recovery. Solvents: Ethanol, Methanol Specifications 4X 2540 nanofiltration housings Stainless steel 6GPM pump with PTFE seals 7.5HP C1D1 1750 RPM Motor 7.5HP VFD 1/60/230 NEMA 4X enclosure (13A) Insulated 2"x18" Heat Exchanger Polyscience 1.5HP Chiller 230/60/1/23.1 700PSI Pressure Relief Valve C1D1 Flowmeter 2X 0-1000 PSI Pressure Gauges 1.5" Intake & Retentate Lines 1/2" Permeate & Pressure Relief Lines Footprint (DxWxH) 30"x39"x79" Weight: 400 lb Maximum Pressure Rating: 700PSI Performance Variable Frequency Drive-based flow control Complete pressure control with manual pressure controls Retentate cooling with inline Heat exchanger & chiller 700PSI pressure relief valve with diversion line *Components shown are subject to change**This unit is meant for bulk solvent recovery, 90% of the total volume of solvent an additional solvent recovery apparatus is recommended to evaporate to dryness*

$41,000.00 - $45,000.00

Neocision ULTRA-Low Chest Style Freezer with Touch Screen LCD (-86°C) 25 Cubic Feet - ETL Rated

Neocision ULTRA-Low Chest Style Freezer with Touch Screen LCD (-86°C) 25 Cubic Feet - ETL Rated The brand new Neocision ETL Rated 25 cubic foot -86°C Ultra-Low Chest Freezer is a lab grade freezer at an affordable price with great temperature stability. This unit will run productively and adequately while brandishing a sleek design that will fit any lab or office setting. Every unit accompanies various safety and protection features taking into consideration user and item safety. These highlights incorporate high and low-temperature alerts. These units are appropriate for emergency clinics, creature cultivation, pharmaceutical organizations, and research foundations. They are intended to store pharmaceuticals, medication, immunizations, natural materials, testing reagents, research facility materials and can likewise be utilized to pre-chill solvents or winterize material. Key Features: ETL Rated Durable Powder Coated Exterior Touch Screen LCD with Datalogging Capabilities Stainless Steel Interior CFC-Refrigerant Free Power Failure and Over Temp Alarm High and Low Temp Alarms Large Digital Display Heavy Duty Rolling Casters (3) 1" ID Ports for putting lines through the freezer Backup battery Included. Specifications Model Number BVV™-86C25 Voltage 115V / 60Hz / 15A Wattage 1800w Capacity 25cu ft. / 730L Internal Dimensions 34.5" x 51.5" x 23.5" Exterior Dimensions 43" x 76" x 36" Temperature Range -40°C to -86°C Weight 700lbs Rating ETL Rated

$8,000.00$7,000.00

Jacketed Reactor with Motor and Collection Vessel

Jacketed Reactor with Motor and Collection Vessel This jacketed reactor kit includes your choice of a C1D1 motor, standard motor, or non-electric air powered motor (air compressor required). If using an electric motor it will require wiring to the included speed controller. Using the jacketed reactor to heat your solution, use your reactor to mix your solution during the heating process. The condenser and collection vessel allow you to recover residual solvents up to 100L. The collection vessel includes a dip tube to empty the vessel and a 1/4" JIC flare to input pressure into the base to assist in emptying the tank through the dip tube. This system does NOT include a heater or chiller, please inquire with your account representative for recommendations based on your application! Jacket connections are 1/2" hose barbs. Mixer Type Pneumatic Electric C1D1 Electric Horsepower 3/4 HP 3/4 HP 1 HP Power Air Compressor 120V 220V 1ph Reactor Size 150L Collection Size 50L / 100L Jacket Connections 1/2" Hose Barb

$7,022.00 - $13,690.00

50L Turnkey Reactor Kit

50L Turnkey Reactor Kit The BVV 50L Double Jacketed Glass Reactor Kit is the ideal solution for small to medium-sized solvent recovery and decarboxylation applications. This kit includes everything to get you up and running including a Single 50L triple-layer Glass Reactor with Condenser, either a BVV 19L Heated circulator capable of heating to 220C or a UL-listed Huber T305 Capable of heating up to 300C, a 1HP Polyscience 6160T for chilling the condenser, a Welch BTpro100 for vacuum, 25ft of 3/8" Gum rubber tubing for vacuum connections, 20ft of reinforced PVC hose for the chiller, 1/2" Stainless Steel JIC Hoses for the heater, 5 Gallons of Therminol Heat transfer fluid and 5 Gallons of Propylene glycol. 50L Double Jacketed Glass Reactor Specifications Glass Material: GG-17 High Borosilicate Glass Internal Volume: 50L 10.5L Jacket Capacity Shelf Material: Aluminum Alloy Homogenizer Power: 110V/60Hz Homogenizer Speed: 0-400 RPM Digital Homogenizer Control Digital temperature probe readout included Double Jacket 3/4" Jacket Connections 1/4" and 3/8" Vacuum Connections Length: 24 in. Width: 30 in. Height: 90 in. Polyscience 6100 1 HP Chiller Specifications 6100 Series 1 HP Chiller with Turbine Pump, 100psi; 13.2l/min Display: LED Working Temperature Range C: -10 to 40 Temperature Stability: +/-0.1 Temperature Calibration Capability: 1-point Pump Type: Turbine Working Temperature Range F: 14 to 104 Working Temperature Range C: -10 to 40 Reservoir Capacity (gallons): 1.11 Reservoir Capacity (liters): 4.2 Reservoir Cover: Screw-on cap Cleanable Air Filter: Yes Cleanable Fluid Filter: Yes Temperature Stability F: +/-0.2 Temperature Stability C: +/-0.1 Display: LED Display Resolution (Read): 0.1 Pump Type: Turbine Process Connections: 1/2" FNPT Over-Temperature Protection / Failsafe Heater Control: Yes Reservoir Liquid Level Indicator: Yes Reservoir Drain: Yes Cool Command Refrigeration Technology: Yes WhisperCool Environmental Control Technology: Yes Maximum Ambient Temperature F: 95 Maximum Ambient Temperature C: 35 Overall Dimensions (LxWxH inches): 27.6 x 14.5 x 22.6 Overall Dimensions (LxWxH cm): 70 x 36.8 x 57.5 Compressor Size (HP): 1 Refrigerant: R134a Shipping Weight (pounds): 199 Shipping Weight (kilograms): 90 Welch BTpro100 Specifications Model BTpro100 Free Air Displacement@60Hz,lpm(CFM) 100(3.5) Ultimate Vacuum Pressure, Torr 6 Maximum Vacuum, in. Hg 29.7 Horsepower, HP (watts) 0.5(390) Built-in adjustable vacuum - Gas Ballast Yes Head Material PTFE Diaphragm PTFE Inlet/outlet Connection NW16 flange1 Agency (National Recognized Lab) cUL Weight, lbs (kg) 40.3(18.3) Overall DimensionsLxWxH in.(cm) 9x15x7(23x38x18) Shipping Weight, lbs(kg) 48.5 (22) Shipping Carton DimensionsLxWxH in.(cm) 18.9x12.6x11.8(48x32x30) HUBER T305 Specifications General Information & Temperature Controller Temperature range 65...300 °C Temperature stability ±0,02 °C Temperature control TAC, self-optimizing (True Adaptive Control) Controller Pilot ONE (E-grade "Basic") Safety class III / FL Protection class IP20 Dimensions (W x D x H) 425 x 250 x 631 mm | 16.73 x 9.84 x 24.84 inches Weight 37 kg | 81.59 pounds Heating / Cooling Capacity Heating capacity 4,8 kW Circulation Pump Pressure pump max. 45 lpm ; 0.9 bar | 11.89 gpm ; 13.05 psi Pump connection M24x1,5 AG male Permissible viscosity 50 mm²/s Connections Pt100 connection Pt100 Analogue input via optional Com.G@te Analogue output via optional Com.G@te Digital interface RS232, Ethernet, USB Device, USB Host Operating Data Old sku 1003.0022.01 Permissible ambient temp. 5 to 40 °C Filling volume min. 1.45 Liters | 0.38 gal Volume of expansion 2.8 Liters | 0.74 gal Power supply 208V 3~ 60Hz Current max. 15 A Fusing 15,5 A

$23,500.00 - $42,000.00

Siemens Touch Screen Controller with Explosion Proof Housing for Centrifuges

Siemens Touch Screen Controller with Explosion Proof Housing for Centrifuges Disclaimer: When bought separately and NOT with our Centrifuge this item will have no warranty and all sales are final. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Controller: This centrifuge is controlled by a Siemens Smart Line PLC. This PLC is pre-programmed to have both a soaking cycle, shown as AGITATION TIME on the screen, and a spin drying cycle, made of 4 separate specifications. SPIN TIME 1 through 4 allow the user to choose four different speeds and however long they wish to be at each speed. All four parameters labeled as SPIN TIME combine to make one spin cycle when the Spin button is pressed. To change a parameter, simply tap on the number to be changed and type in the desired value when prompted on screen. Any number displayed within a white box can be adjusted. SPEED SET: This number represents the RPM as a percentage of the machine max speed. In this case the max speed is 1500RPM. SET: This column will dictate how long the centrifuge spins for a cycle or at a specified speed within the cycle. For the Agitation Time, the Set value will control the total length of the agitation cycle. The FWD/REV TIME will control how long the basket will spin in one direction before reversing to cause agitation. The “current” value will only count up while at the set speed for the agitation cycle. CURRENT: The “current” column will give a readout of how long the basket has been spinning at the set speed. This value will not increase while the centrifuge is increasing speed between SPIN TIME values. When running the agitation cycle, it will be complete when the count of seconds in the CURRENT reaches the value in the SET column. The centrifuge will stop automatically. For the spin cycle, the centrifuge will go through all 4 set SPIN TIME values, the CURRENT column will only begin to count when the centrifuge is at the set speed. The cycle time will not account for time taken to get up to speed. Temperature: Shows a live readout of the temperature inside the centrifuge.Inlet Valve and Drain Valve: These are two pre-programmed buttons that can be used with electronic valves. This unit does not come standard with these valves, but leaves the option open for them to be added. Electrical Power Size Specification 45L Input: 240V 1ΦOutput: 240V 3Φ 4kW 160L Input: 240V 1ΦOutput: 460V 3Φ 7kW 280L Input: 240V 1ΦOutput: 460V 3Φ 11kW 475L Input: 240V 3ΦOutput: 460V 3Φ 11kW

$7,900.00 - $9,500.00

CHEMTEK ChloroSorb Acidic

ChloroSorb Filtering Media is an acid-activated bentonite/carbon blend for bleaching and deodorization. It is generally used for additional bleaching efficiency in conjunction with other sorbents. Contains 5% carbon. ChloroSorb SDS

$50.00 - $2,000.00

CHEMTEK ChloroSorb Natural

ChloroSorb Natural Filtering Media is a heat-activated bentonite/carbon adsorbent for bleaching and deodorization. Contains 10% carbon. ChloroSorb Natural SDS

$50.00 - $2,000.00

Flexible Rubber Foam Pipe Insulation Tee, 1/2" Thick Wall, 1-3/8" ID

Flexible Rubber Foam Pipe Insulation Tee Soft and easy to install, this insulation restricts absorption of water, air, and gas. It is often used on cold and hot water lines and refrigeration lines. Seal with contact adhesive (sold separately). To use outdoors, coat in acrylic paint. For Use On Pipe Insulation Type Tee Wall Thickness 1/2" ID 1 3/8" OD 2 3/8" For Pipe Size 1 For Copper Tube Size 1 1/4 Temperature Range -295° to 220° F Heat Flow Rate 0.25 Btu @ 75° F Density 4.5 lbs./cu. ft. Material Buna-N/PVC Foam Color Black Flexibility Flexible Cell Type Closed Tube Style Slit Specifications Met ASTM E84 25/50 for Flame and Smoke, ASTM C534 Performance Properties Moisture Resistant R Value 2 Additional Specifications SDS RoHS RoHS 3 (2015/863/EU) Compliant REACH REACH (EC 1907/2006) (01/17/2022, 223 SVHC) Compliant DFARS Specialty Metals COTS-Exempt Country of Origin United States USMCA Qualifying No Schedule B 392690.9988 ECCN EAR99

$15.00

Welch High Capacity Diaphragm Pumps 2062

Welch High Capacity Diaphragm Pumps 2062 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** High Capacity dry diaphragm vacuum pump. PTFE contact surfaces, deep vacuum at with high flow. PTFE Pump, 8 heads. 115V 60HZ 1.5 TORR 119 LPM Specifications Includes 1/4" OD hose barb Common accessory, not included Vacuum Controller Pumping Speed 119 Lit/min. (4.2 CFM) Max. Vacuum 1.5 Torr (2 mbar) 29.9" Hg Tubing Needed 1/4" ID Inlet Connection UNIBARB Exhaust 1/4" OD Dimensions LxWxH inches 21x11x12 Weight 72 LBS Wiring 115V, 60 hz

$6,550.00

CDA 12A w/ Toluene High Purity Extraction Solvent