BVV Loyalty - BVV

Lab Dosing Gun Filler 50 Milliliter Pistol Grip (1ml Incremental Shots)

Heated Filling Gun 30 Day Limited Warranty The BVV™ Semi-Automatic Lab Dosing Gun can is easily adjusted to fill in 1ml, 2ml, 3ml, 4ml, and 5ml increments. You can quickly and accurately fill your cartridges. The heated barrel has a digital controller that allows the user to set a temperature from (Room Temperature - 190°F) in increments of 1.0°F. The Filler comes ready to use, first clean the components, plug it in and attach the included 14 Gauge Tip. Specifications: Polypropylene Barrel – Chemically Resistant to: Isopropyl Alcohol, Ethanol, Butane, Hexane, Glycerin, Glycols, Terpenes, and most Acids 14 Gauge lure lock needle included 110V USA Plug Adjusts from 1-5ml Shots (1ml increments) Lure Lock Hub for all types of size attachments Extra Barrel Plunger Gasket included Adjustable plunger tension/tightening (*for user preferred plunger action) Built-in Temperature Cutoff @190F. 5ft Power Cord 3ft Heat Cord to Control Box. Assembled weight 1lb. 8oz. Cleaning: NOTE: Please Clean Prior to first use gun does not come sterilized. Cleaning the barrel and components can be done with De-limonene, other chemicals can be used, however, *The Barrel Gasket is made of Nitrile and can degrade with overexposure to chemicals like Isopropyl Alcohol. To Fill the Syringe:Advance the plunger all the way to the needle tip of the barrel. Place the needle into the Oil and pull the plunger all the way back until it stops. The barrel will be filled. Increasing the Max Temperature: The Max Temperature Setting is 190°F. To increase the temperature beyond that, the user will need to follow the included instruction to unlock and change the max temp. (Absolute Max. is 212°F) Lab Dosing Gun User Manual PDF

$245.00

Short Sight Glass

Short Sight Glass These short sight glasses are a great additions closed-loop extraction system to view the liquefied solvent flowing through your system and see the color before the purging process is completed. The short sight glass also allows the user to add a viewing port to their system without adding a lot of additional height compared to a normal Tri-Clamp sight glass. Unlike many competitors, this sight glass is also nitrogen tested for leaks at 100 PSI before it is sent to the customer to ensure safe operation of their extraction system. ***Note: Does not include clamp or gasket. Sizes Available: 1.5" - 2" - 3" - 4" - 6" - 8" - 10"(with cage) - 12" (with cage) Specifications: Sight Glass Material: 304 Stainless Steel Glass Material: Borosilicate Gasket Material: Buna Connection Type: Tri-Clamp x Tri-Clamp BVV™ SSG - Data Sheet Specifications Diameter (Inches) Height (Inches) Weight (Lbs) 1.5" 3.25 3-3/4 1.81 2" 4 3-3/4 2.7 3" 5 4-3/8 4.13 4" 6-1/2 4-1/2 6.8 6" 8 4-1/8 8.09 8" 10.5 5-5/8 15.12 10" 13 8-1/8 38 12" 15.5 8-1/8 64

$85.00 - $580.00

Female NPT Shower Head End Caps

Female NPT Shower Head End Caps Shower Head End Caps Tri Clamp/ Tri Clover help disperse solvent input into a system which creates better material saturation when flooding a material column. This helps to prevent channeling, ensuring all the material is saturated. Specifications: Material: 304 Stainless Steel Connection Type: Tri-Clamp 1/4" - 18 FNPT 3/8" -18 FNPT 1/2" - 14 FNPT Standard: 3A Sizes Available: 1.5" 2" 3" 4"

$30.00 - $62.00

Polycarbonate Tri-Clamp Sight Glass - Made in USA

Polycarbonate Tri-Clamp/ Tri Clover Sight Glass Polycarbonate Tri-Clamp sight glasses are a great and cost effective way to add viewing ports to your system. These sight glasses are 1 piece CNC machined out of 0.25" thick sheets of polycarbonate and rated up to 250, 225, and 175 PSI for 1.5", 2", and 3" Tri-Clamp sizes. These sight glasses come with a protective film of plastic over the viewing area to protect it from being damaged during shipping and testing the customer will need to remove this upon usage. ***Note: Gasket and Clamp sold separately. Specifications: Material Polycarbonate Window Diameter: 1.5" 1-1/4" 2" 1-3/4" 3" 2-3/4" Maximum PSI @70F: 1.5" 250 2" 225 3" 175

$25.00 - $38.00

20LB High Purity USA 70/30% N-Butane/Propane Blend - 99.5% Guaranteed - Buy 2 Get 1 Free (Add 3 To Cart)

20LB High Purity USA 70/30% N-Butane/Propane Blend - 99.5% Guaranteed - Buy 2 Get 1 Free (Add 3 To Cart) The high-purity 70/30% N-Butane/Propane Blend isn’t just US-sourced. It’s guaranteed to be 99.5% pure. This instrument-grade solvent produces a higher quality extract by reducing mystery oils and other contaminants. Our 70/30% N-Butane/Propane Blend comes in a 20 LB DOT refillable LP tank. Enjoy working with a solvent that’s clean, colorless, and odorless! DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Ground ONLY. Quantities bought in 3 or more will ship via freight unboxed BVV™ always recommends distillation of every solvent before use. Tank contains no diptube. Tank does not include CGA 510 fitting. Must be added through dropdown or bought separately. *Actual liquid weight is 20LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Permitted Sales Include the Following: Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale How To Buy 2 Get 1 Free Simply add 3X of 20LB Tanks to your cart and you will automatically be discounted the third tank. Need one with a CGA fitting two without? Simply add one tank with your desired CGA fitting and add two of the same item selecting "None" for the "CGA fitting" and "Connection Size" options. Want 2 Butane Tanks and 1 Propane Tank? No problem, just add 3 of ANY of our 20LB LPG tanks to your cart and enjoy the third tank free! Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via UPS Ground/Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers. Chemical Formula: C₄H₁₀ + C3H8 Molecular Weight: 58.12 g/mol & 44.10 g/mol CAS Registry Number: 106-97-8 & 74-98-6 Appearance Colorless Odor: Faint Petroleum Density N/A Boiling Point: N/A Solubility in water: Low Solubility GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220, H280 GHS Precautionary Statements P210, P377, P381, P403, P410+P403 UN Identification Number: 1965 Proper Shipping Name: Hydrocarbon Gas Mixture, (Butane/Propane) liquefied, n.o.s. Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Dual Blend Certificate of Analysis (COA) Dual Blend Safety Data Sheet (SDS)

$250.00 - $265.00

Heptane 99% Lab Grade

BVV™ High Purity Lab Grade Heptane (Note: Container style and color may vary) Experience the Exceptional Utility of BVV™ High Purity Lab Grade Heptane in Crystallization and Liquid-Liquid Extraction When it comes to achieving impeccable results in crystallization and liquid-liquid extraction processes, BVV™ High Purity Lab Grade Heptane stands out as the ideal choice. This versatile solvent has been meticulously refined to meet the exacting standards of laboratory and industrial applications, offering unparalleled purity and performance. Why Choose BVV™ High Purity Lab Grade Heptane: Unrivaled Purity: Our heptane boasts an exceptional level of purity, minimizing unwanted impurities and contaminants in your final products. Reliable Performance: Count on BVV™ High Purity Lab Grade Heptane to consistently deliver outstanding results, batch after batch. Versatile Solvent: From crystallization to liquid-liquid extraction, this solvent adapts to various applications, providing flexibility and convenience. Trusted by Professionals: Trusted by laboratories, industries, and professionals worldwide, BVV™ High Purity Lab Grade Heptane is the go-to choice for achieving exceptional purity and clarity in your processes. Elevate your crystallization and liquid-liquid extraction procedures to new heights of precision and quality with BVV™ High Purity Lab Grade Heptane. Discover the difference that purity and performance can make in your applications. Choose BVV™ High Purity Lab Grade Heptane for your next project and unlock the full potential of your crystallization and liquid-liquid extraction processes. Chemical Formula: C7H16 Molecular Weight: 100.205 g·mol−1 CAS Registry Number: 142-82-5 Appearance Colorless Liquid Odor: Petrolic Density 0.6795 g cm−3 Boiling Point: 98.38 °C /209.08 °F Solubility in water: 0.0003% (20 °C GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H304, H315, H336, H410 GHS Precautionary Statements P210, P261, P273, P301+P310, P331 UN Identification Number: 1206 Proper Shipping Name: Heptanes Transport Hazard Class: 3 Packing Group: II DOT Placard: What is Heptane? Heptane is a hydrocarbon compound belonging to the alkane family, which means it consists of hydrogen and carbon atoms arranged in a linear, unbranched chain. Specifically, heptane has seven carbon atoms and sixteen hydrogen atoms, giving it the chemical formula C7H16. It is a colorless, flammable liquid with a gasoline-like odor. Heptane is one of several isomers of the alkane series with seven carbon atoms. It is known for its role as a common solvent in various applications, including laboratory work, chemical processes, and industrial settings. Due to its purity and low reactivity, heptane is often used as a standard reference compound in gas chromatography. Heptane is also used as a fuel component in gasoline, although it is less common than other hydrocarbons like octane. Its properties and applications make it a valuable chemical compound in both the scientific and industrial sectors. What Is Heptane Used For? Heptane has a wide range of applications due to its properties as a hydrocarbon solvent. Some of the common uses of heptane include: Solvent: Heptane is widely used as a solvent in various industries, including chemistry, pharmaceuticals, and manufacturing. It is especially favored for its ability to dissolve a wide range of organic compounds and its low reactivity, which makes it suitable for cleaning, degreasing, and extracting chemicals from natural products. Laboratory and Scientific Research: Heptane is often used in laboratories for tasks such as extracting natural products, preparing chemical samples, and conducting chromatography experiments. Its purity and low reactivity make it a valuable solvent in scientific research. Industrial Cleaning: Heptane is an effective degreaser and cleaner for machinery, equipment, and surfaces in industrial settings. It is commonly used to remove oil, grease, and contaminants from various surfaces. Adhesives and Coatings: Heptane is used in the formulation of adhesives, coatings, and paints. It helps dissolve the components of these products and provides them with the desired consistency. Fuel: While less common than other hydrocarbons like octane, heptane is used as a component in gasoline. It contributes to the overall fuel mixture, affecting properties such as octane rating and combustion characteristics. Extraction: Heptane is employed in the extraction of natural compounds, such as essential oils and flavors, from plant materials. It is particularly useful for extracting nonpolar compounds. Calibration Standard: Heptane is used as a reference compound in gas chromatography and other analytical techniques to calibrate instruments and assess the performance of chromatographic columns. Solvent for Rubber and Plastics: In the rubber and plastics industry, heptane is used as a solvent for processing and manufacturing these materials. Chemical Synthesis: Heptane can be used as a reactant or solvent in chemical synthesis processes to produce various organic compounds. It's important to note that heptane should be handled with care, especially in industrial and laboratory settings, due to its flammability and potential health hazards. Proper safety measures and ventilation are essential when working with this solvent. How Is Heptane Produced? Heptane is primarily produced through the refining of crude oil, a process that separates hydrocarbons of different chain lengths. Here's a simplified overview of the production process: Crude Oil Refining: The production of heptane begins with the refining of crude oil, which contains a mixture of hydrocarbons with varying chain lengths and properties. Fractional Distillation: In the refining process, crude oil is heated and subjected to fractional distillation. This process separates the crude oil into various fractions based on boiling points. Heptane falls within a specific range of boiling points and is separated from other hydrocarbons during this distillation process. Fraction Separation: Once the appropriate fraction is obtained, further separation may be necessary to isolate pure heptane. This can involve additional distillation or purification techniques to remove impurities and other hydrocarbons. Quality Control: The resulting heptane undergoes quality control measures to ensure that it meets the required specifications and purity standards for its intended applications. Quality control may include testing for impurities, moisture content, and other properties. Packaging and Distribution: After quality control, heptane is packaged into containers suitable for its intended use and distribution to various industries and customers. It's worth noting that heptane can also be produced synthetically through chemical processes, such as the hydrogenation of hexene or the cracking of longer hydrocarbon chains. However, the primary source of heptane for industrial and commercial applications is typically derived from crude oil refining due to its cost-effectiveness and abundance. What Are The Hazards Of Heptane? Heptane, a highly flammable hydrocarbon, poses several hazards that individuals and workers should be aware of when handling or working with it. Here are some of the key hazards associated with heptane: Flammability: Heptane is extremely flammable and can ignite easily in the presence of open flames, sparks, or heat sources. It has a wide flammable range and can form explosive mixtures with air. Adequate ventilation and proper storage precautions are essential to prevent fires and explosions. Vapor Inhalation: Inhaling heptane vapors can lead to health risks, including dizziness, headaches, nausea, and respiratory irritation. Prolonged exposure to high concentrations of heptane vapor can result in more severe health effects, such as central nervous system depression and damage to the respiratory system. Skin Contact: Heptane can cause skin irritation and may lead to dermatitis or chemical burns upon prolonged or repeated contact. It can also defat the skin, removing protective oils and potentially resulting in dryness and cracking. Eye Contact: Contact with heptane can cause eye irritation, redness, and discomfort. Proper eye protection, such as safety goggles or a face shield, should be worn when handling heptane to prevent eye exposure. Ingestion: Swallowing heptane can be harmful and should be avoided. Ingestion of heptane may lead to gastrointestinal distress, nausea, vomiting, and abdominal pain. Environmental Impact: Spills or improper disposal of heptane can have negative environmental consequences. Heptane is volatile and can contribute to air pollution. It may also contaminate soil and water if not handled and disposed of properly. Occupational Exposure Limits (OELs): Regulatory authorities, such as OSHA in the United States, have established occupational exposure limits for heptane to protect workers. Adhering to these limits and implementing proper safety measures in the workplace is essential to mitigate exposure risks. It's crucial to handle heptane with caution, follow safety protocols, and use appropriate personal protective equipment (PPE) when working with this solvent. Additionally, safe storage, handling, and disposal practices are essential to minimize the associated hazards and ensure workplace safety. How Can I Safely Use Heptane? Safely using heptane requires following proper procedures and precautions to minimize risks associated with this flammable solvent. Here are some essential guidelines for the safe handling and use of heptane: Personal Protective Equipment (PPE): Wear appropriate PPE, including safety goggles or a face shield, chemical-resistant gloves, lab coats, and closed-toe shoes, to protect your eyes, skin, and clothing from exposure to heptane. Ventilation: Work in a well-ventilated area or use a chemical fume hood to prevent the buildup of heptane vapors. Ensure adequate airflow to disperse fumes. No Open Flames or Sparks: Avoid open flames, sparks, or heat sources in the vicinity of heptane. Heptane is highly flammable and can ignite easily. Electrical Equipment: Use explosion-proof or intrinsically safe electrical equipment and fixtures in areas where heptane is used or stored. Storage: Store heptane in approved safety containers, away from heat sources, direct sunlight, and incompatible materials. Keep containers tightly sealed when not in use. Handling and Transfer: Use spark-resistant tools and equipment when handling heptane. Avoid rough handling or transferring the solvent near open flames or hot surfaces. Spill Response: Have spill response materials, such as absorbent materials and spill kits, readily available to contain and clean up any heptane spills promptly. Labeling: Clearly label heptane containers with appropriate hazard warnings and information to identify the contents. Emergency Equipment: Maintain access to safety equipment, including emergency eyewashes, safety showers, and fire extinguishers, in the workspace. Training: Ensure that personnel handling heptane receive proper training on its hazards, safe handling procedures, and emergency response protocols. Avoiding Skin Contact: Minimize skin contact with heptane. In case of contact, wash the affected area immediately with soap and water. Use barrier creams or protective clothing as an additional precaution. Eye Protection: Wear safety goggles or a face shield to protect your eyes from splashes or accidental exposure. No Smoking or Eating: Prohibit smoking, eating, or drinking in areas where heptane is present, as ingestion or inhalation of heptane can be harmful. Disposal: Follow proper waste disposal procedures for heptane and other hazardous materials. Dispose of waste in accordance with local regulations. Emergency Response: Establish and communicate emergency response procedures for heptane-related incidents, including fire, spills, and exposure incidents. Regular Inspections: Conduct regular inspections of equipment, storage areas, and safety measures to ensure they remain in good condition. It's essential to adhere to safety guidelines, have safety protocols in place, and prioritize the well-being of personnel when working with heptane. Always consult safety data sheets (SDS) and regulatory guidelines specific to heptane in your region for additional safety information and requirements. Is Heptane Miscable With Water? Heptane is not miscible with water. It is considered hydrophobic, which means it does not mix well with water and tends to form separate layers when combined. What Is The Flash Point Of Heptane? The flash point of heptane, specifically n-heptane, is approximately -4 degrees Celsius (24.8 degrees Fahrenheit). This is the temperature at which it can produce enough vapor to ignite briefly if exposed to an open flame or spark. Heptane is considered highly flammable and should be handled with caution in environments where there is a risk of ignition. Heptane Certificate of Analysis (COA) Heptane Safety Data Sheet (SDS)

$18.00 - $610.00

Bolts For High Pressure Clamps

Bolts For High Pressure Clamps When high pressure clamp bolts are used frequently the threads will wear down eventually causing the bolt to fail. User's need to replace their high pressure bolts at the first sign of the threads wearing down or being marred. It is not recommended to tighten these bolts with an impact gun because it may cause the threads to be marred or jump threads causing the bolt to become stuck on the nut. ***Note: Size refers to size of Tri-Clamp not the actual length of the bolt. BVV™ only recommends tightening high pressure clamps with wrenches and making sure the space on each side of the clamp is even. DO NOT tighten with an impact gun. Bolt Available for Clamp Sizes: 1.5" 2" 3" 4" 6"-12" - Fully Threaded Specifications: Material: 18-8 Stainless Steel Threading: 3/8"-16

$2.20 - $4.20

Hose Barb x MNPT

BVV™ Hose Barb x MNPT BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are Hose Barb x NPT threads (National Pipe Taper) and will compress against other Female/Male NPT threads creating a tighter and tighter connection. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. **NOTE: Pre-Taped option comes from BVV Pre-taped with Yellow UL Listed Gas PTFE Tape on the Male NPT threads ONLY for a +0.50c charge per male npt end. (JIC Threads DO NOT need to be taped.) Hose Barb connections will allow the user to connect flexible tubing to the Hose Barb and allow the user a variety of additional options for their extraction system such as circulating fluid through a jacketed base with silicone tubing or pull a vacuum with gum rubber tubing. BVV™ Hose Barb x MNPT- Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4"-18 MNPT 1/2"-14 MNPT 1/4" Hose Barb 3/8" Hose Barb 1/2" Hose Barb Sizes Available: 1/4" Hose Barb x 1/4" MNPT 3/8" Hose Barb x 1/4" MNPT 3/8" Hose Barb x 1/2" MNPT 1/2" Hose Barb x 1/4" MNPT 1/2" Hose Barb x 1/2" MNPT

$5.00 - $16.00

N-Heptane 99.3% Lab Grade

ULTRA High Purity Lab Grade N-Heptane 99.3% Purity (Note: Container style and color may vary) BVV™ ULTRA High Purity Lab Grade N-Heptane is a perfect solution for cleaning up and clarifying the extracted material and removing the green colored plant material and some waxes out of the product to produce a cleaner end result when distilling extracts. Heptane can be used the same as hexane or as a solvent, but has a higher boiling point when needing to remove residuals from extracted material. Chemical Formula: C7H16 Molecular Weight: 100.205 g·mol−1 CAS Registry Number: 142-82-5 Appearance Colorless Liquid Odor: Petrolic Density 0.6795 g cm−3 Boiling Point: 98.38 °C /209.08 °F Solubility in water: 0.0003% (20 °C GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H304, H315, H336, H410 GHS Precautionary Statements P210, P261, P273, P301+P310, P331 UN Identification Number: 1206 Proper Shipping Name: Heptanes Transport Hazard Class: 3 Packing Group: II DOT Placard: N-Heptane Safety Data Sheet (SDS) N-Heptane Certificate of Analysis (COA)

$20.00 - $850.00

Stacking Filter Plate Ring Kit

Stacking Filter Plate Ring KIT This Stacking Filter Plate and Ring Kit allows the user to stack multiple levels of filtration while having the rigidity of a solid filter plate. These components are made out of 304 polished stainless steel and will fit inside of the corresponding Tri-Clamp/ Tri Clover parts. The stainless steel rings are solid and measure 8mm in thickness and the filter plates measure about 3mm in thickness with 6mm holes. This Kit Includes: 1x Filter Plate 2x Drop-in Retaining Rings Sizes Available: 1.5" 2" 3" 4" 6" 8" 10" 12" Specifications Material 304 Stainless Steel Ring Thickness 8mm Plate Thickness 3mm Plate Hole Size 6mm

$30.00 - $145.00

Bottom Weld Tri-Clamp Filter Plate

Bottom Weld Stainless Steel Tri-Clamp / Tri Clover Filter Plate Bottom Weld Stainless steel filter plates offer the user a great solid platform to help with filtration during the extraction process. These filter plates can be used simultaneously with ashless filter papers or any other filtration media like stainless steel ball bearings or steel wool to increase surface and filtration level to remove fats, lipids, waxes and any other unwanted material during the extraction process. **Note: Does not include Clamp, Gasket or Ring Sizes Available: 1.5" 2" 3" 4" 6" 8" 10" 12" Specifications: Material 304 Stainless Steel Standard 3A High Polish Connection Type(s) Tri-Clamp Hole Diameter 5.8mm Height 2" BVV™ Bottom Weld Tri-Clamp Filter Plate - Drawing

$22.00 - $300.00

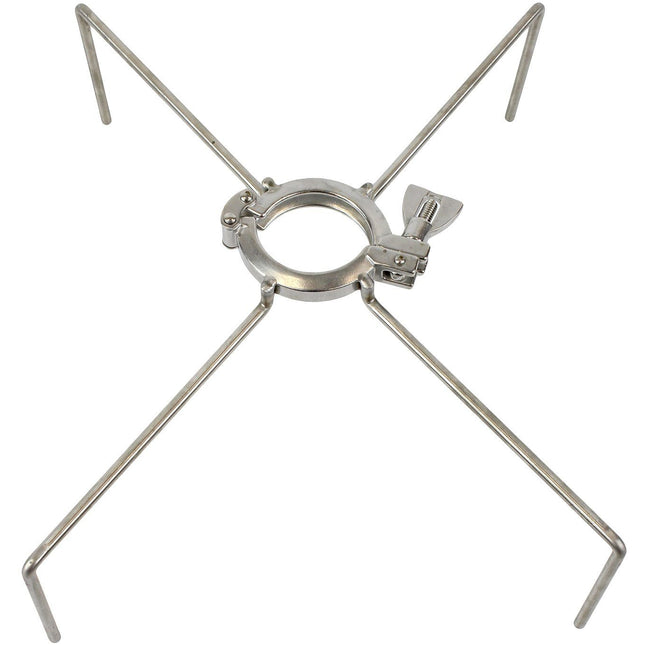

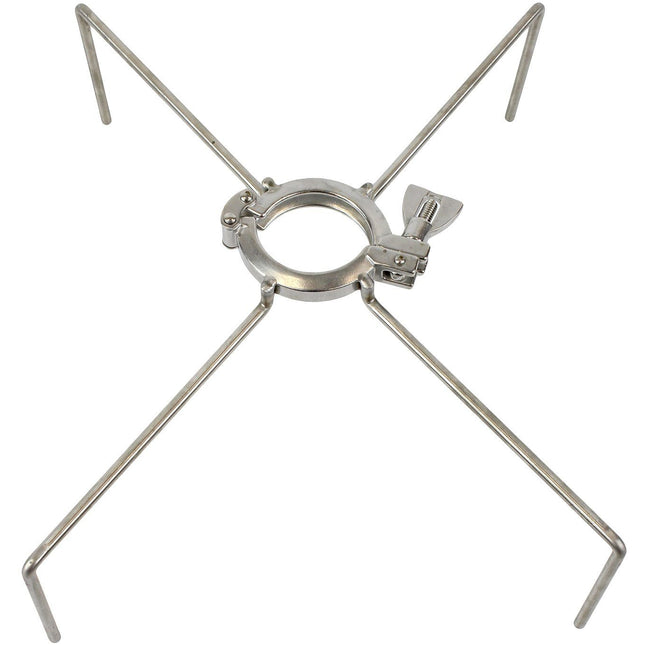

Tri-Clamp Quadpod

Tri-Clamp Quadpod Quadpods provide an excellent solution to holding any Tri-Clamp spool vertically. From closed columns to open blast extraction units, Quadpods are designed to fit over Pyrex dishes without getting in the way. This device has 4 legs, 4.5" in length, and extends 7" outward in each direction. Furthermore, each leg is welded to the clamp to provide a sturdy and durable platform. Sizes Available: 1.5" 2" 3" Specifications: Material 304 Stainless Steel Connection Type(s): Tri-Clamp

$30.00 - $40.00

Filter Plate Kit

Stainless Steel Tri-Clamp / Tri Clover Filter Plate Kit Stainless steel filter plates kits offer the user a great solid platform to help with filtration during the extraction process and they come standard with a 100 mesh (150 Micron) pre-cut stainless steel mesh filter media, solid filter ring, and gasket. These filter plates can be used simultaneously with ashless filter papers or any other filtration media like stainless steel ball bearings or steel wool to increase surface and filtration level to remove fats, lipids, waxes and any other unwanted material during the extraction process. Note: 2" and 8" Sizes come with a Compression ring instead of a solid ring. Sizes Available: 1.5" - Includes Solid Filter Plate Ring 2" - Includes Solid Filter Plate Ring 3" - Includes Solid Filter Plate Ring 4" - Includes Solid Filter Plate Ring 6" - Includes Solid Filter Plate Ring 8" - Includes High Pressure Clamp + Includes Standard COMPRESSION Ring ONLY 10" - Includes High Pressure Clamp + Solid Filter Plate Ring ONLY 12" - Includes High Pressure Clamp + Solid Filter Plate Ring ONLY Specifications: Material 304 Stainless Steel Standard 3A High Polish Connection Type(s) Tri-Clamp Hole Diameter 5.8mm Height 2" Mesh Specs 100 Mesh (150 Micron) - 304 Stainless Steel Gasket Material BUNA-N

$38.00 - $491.00

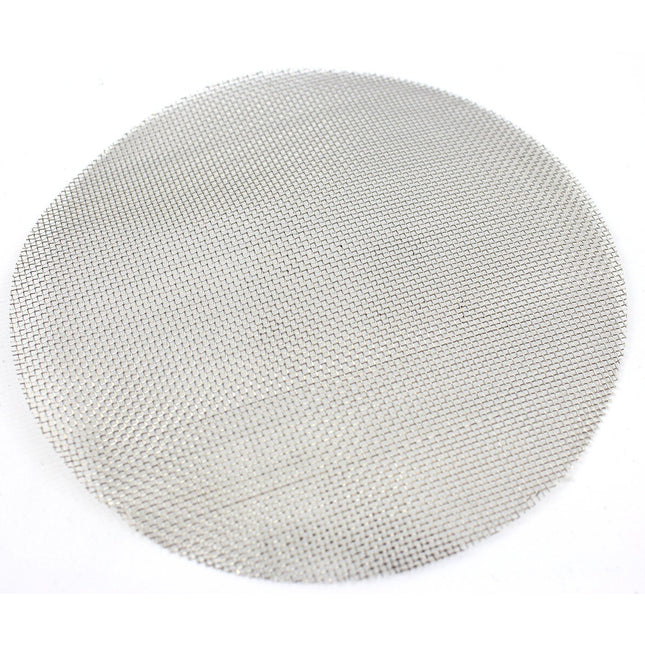

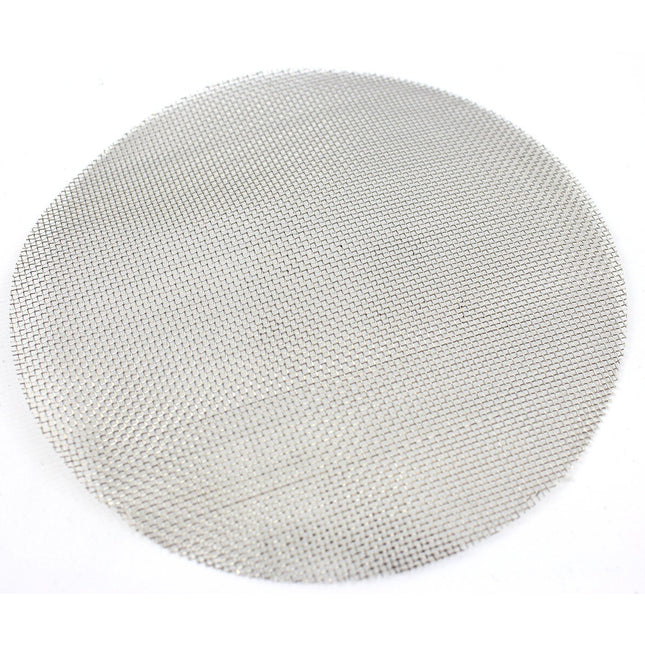

Pre-Cut Stainless Steel Mesh for Tri-Clamp Filter Plates 100 Mesh (150 Micron)

Pre-Cut Stainless Steel Mesh for Tri-Clamp/Tri-Clover Filter Plates 100 Mesh (150 Micron) These Stainless Steel Mesh are pre-cut for convenience to fit inside Tri-Clamp filter plates or spools. They offer great filtration and are very durable and reusable. Additionally, these 150-Micron filter plates will protect and act as a pre-filter for finer mesh screens or filter paper which will prevent the finer micron filter media from becoming clogged. Sizes Available: 1.5" Tri-Clamp 100 Mesh (150 Micron) 2" Tri-Clamp 100 Mesh (150 Micron) 3" Tri-Clamp 100 Mesh (150 Micron) 4" Tri-Clamp 100 Mesh (150 Micron) 6" Tri-Clamp 100 Mesh (150 Micron) 8" Tri-Clamp 100 Mesh (150 Micron) Specifications Material 304 Stainless Steel Mesh Level 100 (150 Micron) *Compression Ring and Filter Plate NOT Included.

$7.00 - $30.00

Fully Jacketed Spools

Fully Jacketed Spools 304 Stainless Steel Fully Jacketed Spools allow the user to circulate water through the base of an extractor or the material column to heat up or chill solvent vapor. Has 1/2" FNPT ports. And attached tri clamp fittings on each end for user convenience. BVV™ Fully Jacketed Spools - Drawings

$110.00 - $680.00

Gas PTFE Tape

Gas PTFE Tape Yellow gas line PTFE Tape is used for hydrocarbon extraction systems and mandatory for any system with solvents. The PTFE tape is a thick threaded sealant that can be used on different plastic and metal pipes. This easy to use tape can be used to help prevent cross threading and form a leak proof seal. Suitable for lines carrying water, oil, gas, and propane. Pressure rating 10,000 PSI.

$5.50 - $7.00

2 Quart Resin Trap / Vacuum and Degassing Chamber

Two-Quart Resin Trap Vacuum + Degassing Chamber (Comes with 2 Year Limited warranty) Designed, built, and 100% tested in Chicago, Illinois, the Resin Trap Vacuum Chamber is the perfect application for a successful, high-quality end product. With its unique, patent pending gasket design (Utility Patent #14/533,548), this shatter chamber can easily withstand 10,000 uses with proper care and maintenance. The gasket itself is reversible, doubling the system's life by allowing customers to instantly take it off and flip it over. No adhesives necessary. The maximum allowed temperature of this chamber is 160f. The individual components of this chamber are rated at higher temperatures, however, as a vacuum vessel, we limit maximum operational temperature to 160f. Every chamber is tested prior to shipping to lose no more than 2.5inHg/24hrs. Specifications Key Features: Comes with 2 year limited warranty Resin traps come complete with glycerin-filled vacuum gauge, fittings for use with 1/4" vacuum tubing, nickel plated brass ball valve and instruction manual. Capture excess resin and protect your pump! Unique Catch Port Design: An additional hose can be installed at the port inside the tank to facilitate accurate collection of resin. 5 Feet Reinforced Vacuum Hosing to Connect Directly to the Vacuum Pump 1/4" SAE port. Measuring range of vacuum gauge:0-29.25inHg Silicone gasket to be used over 10,000 times without deterioration. This Kit Includes: (1) 2 Quart High strength Stainless Steel Chamber (1) Industrial grade silicone gasket Gasket can withstand 390°F max temp. 60A durometer density (1) Glycerin filled vacuum gauge (must be regulated upon arrival) Max vacuum -29Hg (+/-.5Hg) at sea level (1) Leak free nickel plated 1/4" Hvac Flare Valve (1) ¼” Barbed Connection (1) 5' Purple BVV™ Hvac Hose (1) 5' Clear Vacuum Tubing Internal Dimensions: 6.75” Tall X 5.5” Diameter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™, etc.), alcohol, ethanol, acetone and acrylic-based monomers or polymers. The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™, etc.), acetone, acrylic-based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. Pump Facts: We recommend the oil is changed every 50-75 of operating hours. CFM is a measure of cubic feet per minute. Single-stage pumps reach a max vacuum of 50-75 microns (0=complete vacuum). Dual/Two-stage pumps reach a max vacuum of 10-15 microns (0=complete vacuum). See FAQ at the top for product safety warnings. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$105.00 - $110.00

Ashless Filter Papers - 125MM - Quantitative

Ashless Filter Papers - 125MM - Quantitative Ashless quantitative and qualitative filter papers provide laboratory grade filtration for extraction systems and are specifically used in combination with a Buchner funnel to remove fats, waxes and any other unwanted contaminants from your solution. These filter papers are used in the pre-processing stage of short path distillation to clean up the material prior to processing. Key Features: ISO 9001 Approved Manufactured from alpha-cellulose and cotton linters High Purity and low background Consistent performance Low ashless content: <0.007% (Quantitative Filter Paper) Whatman equivalent quality Pre-Cut for ease of use Specifications: Classification Quantitative Sizes Available: BIO-40 8um - Medium BIO-41 20-25um - Fast BIO-42 2.5um - Slow BIO-44 3um - Slow Ash Content <0.007% Quantity per Pack 100 Diameter 125mm (4.92") Technical Data: Grade Particle Retention Appearance Speed Ash Content (%) Basis Weight (g/m2) Wet burst (mm H2O) BIO-1 11um Smooth Medium <0.1 80.0±4.0 >140 BIO-2 8um Smooth Medium <0.1 80.0±4.0 >140 BIO-4 20um Smooth Fast <0.1 80.0±4.0 >120 BIO-5 2.5um Smooth Slow <0.1 80.0±4.0 >180 BIO-6 3um Smooth Slow <0.1 80.0±4.0 >180 BIO-40 8um Smooth Medium <0.007 80.0±4.0 >140 BIO-41 20-25um Smooth Fast <0.007 80.0±4.0 >120 BIO-42 2.5um Smooth Slow <0.007 80.0±4.0 >180 BIO-43 16um Smooth Medium to Fast <0.007 80.0±4.0 >120 BIO-44 3um Smooth Slow <0.007 80.0±4.0 >180

$45.00 - $50.00

Butane/Propane Tank Fitting CGA 510

Custom CGA 510 Butane and Propane Tank Fitting. Removes the need for taping and reduces leak points Specifications: CGA 510 x 1/4" 37° JIC Flared End Material: Brass

$16.00

BVV™ 316SS FNPT Full Bore Ball Valve -40F to 450F

BVV™ 316SS FNPT Full Bore Ball Valve (Compare to Milwaukee 10 Series Ball Valves) This BVV™ 316 stainless steel full bore ball valve is a fire safe ball valve and is 1 piece ball valve construction. It also features a straight body style with Female NPT x Female NPT threaded connections with one side being pinned into place for zero movement during installation. The fire safe ball valve features a maximum pressure rating of 2000 PSI CWP and has a blowout proof stem made of 316SS and the temperature range of this ball valve is -40F° to 450F°. Standard: ASTM A351 Pressure Tested in compliance with API 598 Ninth Edition 2009: Sec.5 and Sec.6 Technical Data Sheet Valve Specifications Sizes Available: 1/4" FNPT 3/8" FNPT 1/2" FNPT Pressure Rating 2000 WOG Temperature Range -40 to 450F° Sizes Available: 1" (Fits 1.5" Tri-Clamp) Torque Specifications Do not Exceed 14.46ft-lbs when tightening.(Note: Overtightening the valve can cause damage to the pin. Doing this will void the valve warranty.) Valve Materials: Body 316SS / CF8M Ball 316 Stainless Steel Stem 316 Stainless Steel Stem Nut 304 Stainless Steel Insert 316 Stainless Steel Seat PTFE / Dyneon TFM1600 Thrust Washer PTFE / Dyneon TFM1600 Stem Packing PTFE / Dyneon TFM1600 Handle 304 Stainless Steel Handle Cov VINYL GRIP Handle Washer (1/2") 304 Stainless Steel Handle Nut 304 Stainless Steel Belleville Washer 304 Stainless Steel PIN 304 Stainless Steel

$60.00

Tri-Clamp Welded Bottom Base

Welded Bottom Tri-Clamp/ Tri Clover Base These stainless steel welded bottom bases are the standard base for our extraction systems and provide the user with a heavy duty and high capacity way to collect and recovery their extracted material and solvent. Many people will have several of these welded bases set aside to quickly swap out their base on their extractor to reduce the time between system runs. Sizes Available: 4" x 4" 6" x 6" 8" x 12" 10" x 10" 12" x 12" Specifications: Material 304 Stainless Steel Standard 3A High Polish Connection Type(s): Tri-Clamp Welded Bottom Thickness 0.25" - 0.50" BVV™ Tri-Clamp Welded Bottom Base - Drawing

$60.00 - $246.00

Closed Column Extractor Starter Kit

Complete Closed Column Extractor Kit BVV has bundled our recommended vacuum chamber, vacuum pump, and column extraction system to offer customers the most cost-effective solution possible. The Closed Column Extractor Kit is designed to pair well with the other products included in the extraction kit. The items in the kit cover every process from start to finish on your essential oil extraction (excluding butane) and is easy for beginner operators to use. The first step of the oil extraction process is to use the closed column extractor to extract the essential oils from the plant material into a pyrex dish. The user then transfers the oil with residual solvent into the two-gallon vacuum chamber; the digital heating pad is attached to the bottom of the chamber after setting the temperature. The V4D 4CFM 2 Stage vacuum pump exerts a high vacuum to purge and degass residual solvent or gases trapped inside the oil. (Note: This process may take up to 5 days.) Once the purging process is complete, the oil extraction can be used immediately or transformed into a variety of applications. Professional Kit Adds the following: Compound Gauge Sight Glass Shower Head Best Value Vacs 2 Gallon Vacuum Chamber 90 Day Registered Warranty Best Value’s unique, patent-pending gasket design (Utility Patent #14/533,548) and formidable chamber are designed to last 10,000 uses with proper care and maintenance. The gasket is made reversible for easy peel-off and peel-on functionality, effectively doubling the life of our system. The chamber is equipped with user-friendly vacuum connections that fit most vacuum pumps on the market. Every chamber is tested before shipping to lose no more than 2.5Hg/24hrs. Product Features: Aluminum Vessel Highly durable and reversible silicone gasket Glycerin-filled vacuum gauge 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum-rated HVAC hose to pull a vacuum. 9" Digital Heat Pad 90 Day Registered Warranty This 9” reprogrammable Digital Heat Pad comes with full, detailed instructions. Product Features UL Listed Fahrenheit Digital Controller Min Temp: Ambient + 5Max Temp: 160F Voltage: 110VAC Only Power Consumption: 218-watt Digital Control: Increments of 1 Degree Accuracy: +/- 0.2 Degrees Relay Lifespan: Approx. 10 million cycles BVV™ V4D 4CFM Two Stage Vacuum Pump This is the BVV™ V4D 4CFM Two Stage Vacuum Pump used in botanical extraction. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Feature Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer oil life Lightweight Rubber Feet for noise dampening Reliable, economical, and efficient Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$695.00 - $955.00

1.5" Standard Closed Column Extractor 45-270g

1.5" Standard Closed Column Extractor DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. DO NOT USE INDOORS *Note: Column capacity may vary depending on the biomass density, moisture content and column packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, heavily dried, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Say goodbye to open blasting. For an optimal and safe extraction process, our Standard Closed Column Extractor allows for maximum solvent pressure, allowing the user to build up solvent pressure to their desire. Simply close the valve, pull a vacuum, and fill the extractor. Parts come neatly packaged and ready to assemble. Key Features and Description: Closed Column Pressure Extractor (Comes with 1 yr. Limited warranty, excludes gaskets and screens) Compound Gauge with (-30)-160 PSI readout. This system allows the user to build up solvent pressure by closing the valve, pulling a vacuum and filling the extractor, Extractor will fill about 85% with solvent before the internal pressure will equal the pressure of the can propellant. The solvent can will fit into either port with a tip adapter supplied with some butane cans, tip adapter required, not included Solvent Soak is expected to be between 30-90 min, but this all depends on material, starting with frozen cans of solvent is recommended This system allows the user to soak the material before opening the bottom valve to release the solvent and oil. Professional Kit Adds the following: Compound Gauge Sight Glass Shower Head Explorer Kit Automatically Includes: 8" x 8" Platinum Cured Silicone Non-Stick Pad 1.5" Tri-Clamp 304 Stainless Steel Material Tube Spool Sizes Specifications: 1.5" x 6" = 30G - 45G 1.5" x 12" = 60G - 90G 1.5" x 18" = 90g - 135G 1.5" x 24" = 120g - 180G 1.5" x 36" = 180G - 270G 304 Stainless Steel Flare End Caps with Heavy Duty Stainless Steel Miniature Ball Valves (1) 1.5" Standard Pressure Tri-Clamp Clamps 1.5" Tri-Clamp Quadpod (1) Buna-N Tri-Clamp Gaskets Buna-N 100 Mesh (150 Micron) Gasket ***Note: Parts and components can be subject to substitutions. Any substituted parts will have the same function and will be of equal or greater value.**** Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$139.00 - $210.00

3CFM Single Stage Vacuum Pump

VE115 Single-Stage 3CFM Vacuum Pump This is the BVV™ Brand VE115 3CFM Single Stage Vacuum Pump. Single-stage vacuums pump exhaust into a chamber in the pump, which separates the oil from the pumped gas. Then, the oil is returned and the gas is exhausted. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer Oil life Lightweight Rubber Feet for noise dampening Reliable, Economical and Efficient Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$138.00

FxFxM Street Tee

BVV™ FxFxM Street Tee BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are NPT threads (National Pipe Taper) and will compress against other Female/Male NPT threads creating a tighter and tighter connection. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. **NOTE: Pre-Taped option comes from BVV Pre-taped with Yellow UL Listed Gas PTFE Tape on the Male NPT threads ONLY for a +0.50c charge per male npt end. (JIC Threads DO NOT need to be taped.) FxFxM Street Tees have 2 Female NPT ports and 1 Male NPT port and depending on the configuration of the application these street tees may offer fewer connection points or better configurability than MxMxF street tees. BVV™ FxFxM Street Tee - Data Sheet

$18.00 - $35.00

Replacement Luer-Lok Dosing Tips for Lab Dosing Guns - 5 Pack

Replacement Luer-Lok Dosing Tips for Lab Dosing Guns - 5 Pack 5 Pack of replacement 14 gauge stainless steel tips for BVV™ Lab Dosing Guns.

$9.00

Best Value Vacs 5 Gallon Aluminum Vacuum Chamber

5 Gallon Vacuum & Degassing Chamber (Comes with 2 yr Limited Warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent-pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specifications Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 10" Tall x 12" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micron Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic-based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic-based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$170.00

BUNA-N 50 Mesh (300 Micron)

BUNA-N 50 Mesh (300 Micron) Tri-Clamp Gasket MADE IN THE U.S.A Mesh / Micron Filter Chart Note: 'Cinnamon' Smelling Gaskets are Chinese made and are not standardized or regulated Disclaimer: BVV™ recommends no more than a -40F operating temperature and is not responsible for the user running their system with incompatible chemicals Why BUNA-N over Viton? Lower Temperature Range Lower Costs Better Compressibility and Springiness Excellent Resistance to Major/Popular Solvents(Butane/Propane) Better Tear Resistance Better Abrasion Resistance Specifications Materials: BUNA-N (Nitrile) 316 Stainless Steel Mesh Overmold Conformance FDA Compliant / Meets 3A Standards Thermal Properties: Low-Temperature Range: -70°F Minimum for Continuous Use(Static): -40°F Brittle Point: -70°F High-Temperature Range: +210°F to +250°F Maximum for Continous Use (Static): +250°F Gas Permeability: Excellent Durometer or Hardness Range: 20-95 Shore A Tensile Strength Range: 200-3,500 PSI Elongation Range(%): 350%-650% Abrasion Resistance: Excellent Resilience / Rebound: Good Chemical Compatibility Butane A - Excellent Propane A - Excellent Alcohols: Amyl B - Good Benzyl D-Severe Effect Butyl C-Fair Diacetone D-Severe Effect Ethyl C-Fair Hexyl A - Excellent Isobutyl B - Good Isopropyl B - Good Methyl A - Excellent Octyl B - Good Propyl A - Excellent

$18.00 - $130.00

9" Vacuum Chamber Digital Heat Pad

9" Vacuum Chamber Digital Heat Pad Please Read Before You Buy! Chamber NOT Included, Sold Separately. Heat Pad must fit correct size of the chamber! Fits our 2, 3 and aluminum pots and 3QT & 1GL Flat Chamber This Digital Heat Pad will adhere to the bottom of a chamber vessel with a peel and stick backing. This unit will hold a temperature within a degree to the set temperature (dependent on the environment and air movement). The temperature offset must be found to set the controller accurately. (See ‘Operation’ instructions in the operation manual) Included with this Digital Heat Pad: Instructions on how to operate and set parameters. Simple standoff bumpers (provide thermal separation between the vessel and the work surface) Thermal tape (best method to check and verify temperature) Specs: UL Listed Fahrenheit Digital Controller. Min Temp: Ambient + 5 Max Set Temp: 160F Ultimate Max Temp: 248F Voltage: 110VAC Only Power Consumption: 220-watt Digital Control: Increments of 1 Degree. Accuracy: +/- 0.2 Degrees Units: Degrees Fahrenheit Instructions: Fully included Relay Lifespan: Approx. 10 million cycles User can reprogram: Yes

$90.00

N-Pentane 99% Lab Grade

BVV™ High Purity Lab Grade N-Pentane 99% (Note: Container style and color may vary) BVV™ High Purity Lab Grade n-Pentane 99% is a hydrocarbon that has properties that are similar to butanes and hexanes. Pentane is a non-polar solvent and refrigerant. Pentane is used for the extraction and eluting of distillates, concentrates, volatiles, and essential oils from plant materials. Pentane can be used with hydrocarbon extraction systems that extract herbal oils, botanical compounds and oils from plants. It is a colorless liquid and has a petroleum-like odor. Chemical Formula: C5H12 Molecular Weight: 72.151 g·mol−1 CAS Registry Number: 109-66-0 Appearance Colorless Liquid Odor: Gasoline-like Density 0.6262 g/mL (20 °C) Boiling Point: 35.9°C /96.5 °F Solubility in water: 40 mg/L (20 °C) GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H304, H336, H411 GHS Precautionary Statements P210, P261, P273, P301+P310, P331 UN Identification Number: 1265 Proper Shipping Name: Pentanes Transport Hazard Class: 3 Packing Group: II DOT Placard: What Is N-Pentane? N-Pentane, also known as normal pentane, is a straight-chain alkane hydrocarbon with the molecular formula C5H12. It is one of the isomers of pentane, a hydrocarbon that consists of five carbon atoms bonded together in a linear, unbranched chain. n-Pentane is called "normal" because its carbon atoms are arranged in a continuous, straight chain, without any branching. What Are The Properties Of N-Pentane? Here are some of the key properties of n-pentane: Physical State: At room temperature and standard atmospheric pressure, n-pentane is a colorless, clear, and highly flammable liquid. Odor: It has a gasoline-like or organic solvent-like odor. Boiling Point: The boiling point of n-pentane is approximately 36.1 degrees Celsius (97 degrees Fahrenheit). This relatively low boiling point makes it useful in various applications. Density: The density of n-pentane at room temperature is about 0.626 grams per milliliter (g/mL). It is less dense than water, which has a density of 1 g/mL. Solubility: n-Pentane is sparingly soluble in water, which means it does not readily mix with water. This is because it is a nonpolar compound, and water is a polar solvent. However, it is highly soluble in nonpolar solvents and organic compounds. Flammability: n-Pentane is highly flammable and poses a fire hazard. It has a low flash point and can easily ignite when exposed to an open flame or heat source. Vapor Pressure: It has a relatively high vapor pressure at room temperature, meaning it readily evaporates into the air. Chemical Structure: As a straight-chain alkane, n-pentane consists of five carbon atoms bonded together in a linear fashion, with 12 hydrogen atoms bonded to these carbons. Molar Mass: The molar mass of n-pentane is approximately 72.15 grams per mole (g/mol). Reactivity: n-Pentane is relatively unreactive under normal conditions and does not readily undergo chemical reactions with common reagents. Uses: It is used as a laboratory solvent, industrial solvent, component in fuel blends, foam blowing agent, and as a chemical reagent in various applications. Safety Precautions: Due to its high flammability, proper safety precautions should be taken when handling n-pentane. It should be stored away from open flames, sparks, and heat sources. Environmental Impact: Like other hydrocarbons, the combustion of n-pentane releases carbon dioxide and other greenhouse gases into the atmosphere, contributing to climate change. n-Pentane is commonly employed in laboratory and industrial settings as a solvent, and its physical and chemical properties make it suitable for various applications. However, its flammability requires careful handling and storage to prevent accidents. What Is The Difference between N-Pentane and ISO-Pentane? n-Pentane and isopentane are two different structural isomers of pentane, each with distinct molecular arrangements. Here are the key differences between n-pentane and isopentane: Structural Arrangement: n-Pentane (Normal Pentane): n-Pentane has a linear, straight-chain structure with five carbon atoms connected in a continuous, unbranched chain. It is sometimes referred to as "normal" pentane due to its unbranched structure. Isopentane (2-Methylbutane): Isopentane has a branched-chain structure with one methyl (CH3) group branching off from the second carbon atom (C2) of the main carbon chain. This branching gives it its common name, "isopentane." Physical Properties: n-Pentane: n-Pentane is a clear, colorless liquid at room temperature and atmospheric pressure. It has a higher boiling point than isopentane and is less volatile. Isopentane: Isopentane is also a clear, colorless liquid at room temperature, but it has a lower boiling point compared to n-pentane. It is more volatile and evaporates more easily. Boiling Points: n-Pentane: The boiling point of n-pentane is approximately 36.1 degrees Celsius (97 degrees Fahrenheit). Isopentane: The boiling point of isopentane is lower, at approximately -11.7 degrees Celsius (11 degrees Fahrenheit). This lower boiling point makes it more suitable for certain applications. Applications: n-Pentane: n-Pentane is used as a laboratory solvent, in the formulation of industrial solvents, and as a component in gasoline and other fuels. Its relatively higher boiling point makes it less volatile and suitable for some applications where slow evaporation is desired. Isopentane: Isopentane is commonly used as a refrigerant and as a component in aerosol propellants, blowing agents for foam production, and as a solvent. Its lower boiling point and greater volatility make it useful in these applications. In summary, n-pentane and isopentane differ in their molecular structures, physical properties, boiling points, and applications. The choice between the two depends on the specific requirements of a given application, with n-pentane being less volatile and isopentane being more volatile. What Is The Structure Of N-Pentane? Pentane is an alkane with the chemical formula C5H12. It is a colorless, flammable liquid that is commonly used as a solvent and a fuel. The structure of pentane is a straight chain of five carbon atoms, with each carbon atom bonded to four hydrogen atoms. The carbon atoms in pentane are arranged in a tetrahedral geometry, with each carbon atom forming four bonds with other atoms. The hydrogen atoms are bonded to the carbon atoms in a single bond. What Is Pentane Used For? Pentane, both in its various isomeric forms (n-pentane and isopentane), has several industrial and commercial applications due to its properties as a hydrocarbon solvent and fuel component. Here are some common uses of pentane: Solvent: Pentane is used as a nonpolar solvent in various laboratory and industrial applications. It is particularly useful for dissolving oils, fats, waxes, and some organic compounds. Its low boiling point and relatively low toxicity make it suitable for these purposes. Foam Blowing Agent: Isopentane (also known as 2-methylbutane) is often used as a blowing agent in the production of polyurethane foams. When mixed with other chemicals, isopentane vaporizes and creates bubbles within the foam, leading to its expansion and formation. Fuel Component: Pentane, primarily in the form of isopentane, is used as a component in gasoline and other fuel blends. It enhances the octane rating of gasoline and helps reduce engine knocking, improving engine performance. Chemical Reagent: Pentane can serve as a chemical reagent in organic synthesis and research. It may be used as a reactant in some chemical reactions or as a medium for certain processes. Extraction: In laboratories, pentane is utilized for liquid-liquid extractions to separate compounds from mixtures based on differences in solubility. It is a common choice for extracting natural products and essential oils. Cleaning Agent: Pentane is employed for cleaning and degreasing purposes in industrial settings. It can effectively remove residues, contaminants, and oils from various surfaces and equipment. Refrigeration: Pentane has been used as a refrigerant in some applications, particularly in the form of isopentane. However, due to environmental concerns and regulations related to ozone depletion, its use as a refrigerant has diminished. Analytical Chemistry: In gas chromatography (GC), pentane is sometimes used as a carrier gas to transport samples through the GC column for analysis. Adhesives and Sealants: Some adhesive and sealant formulations may contain pentane as a solvent or propellant. Aerosol Propellants: Pentane, particularly isopentane, has been used as a propellant in aerosol spray products. Energy Production: In certain regions, pentane may be used as a fuel for heating and electricity generation, although this application is less common. It's important to note that while pentane has various industrial and commercial uses, safety precautions should be taken when handling it due to its flammable nature. Proper storage, ventilation, and safety measures are essential to minimize the risk of accidents. Additionally, environmental regulations and concerns have led to the exploration of alternative substances in some applications where pentane was traditionally used as a refrigerant or propellant. How Is Pentane Produced? Pentane is typically produced from petroleum through refining processes. It is a natural component of crude oil, and the separation and purification of pentane from crude oil involve various refining techniques. Here's an overview of how pentane is produced: Fractional Distillation: Crude oil is first subjected to fractional distillation in an oil refinery. This process separates the crude oil into different fractions based on their boiling points. Pentane, along with other hydrocarbons of similar boiling points, is separated from the crude oil in this initial distillation step. Fraction Separation: The fraction obtained in the distillation containing pentane and similar hydrocarbons is further separated in subsequent distillation columns. These columns are designed to separate hydrocarbons with similar boiling points, and pentane is separated from other hydrocarbons through a series of distillation steps. Purification: After the initial separation, the pentane fraction may still contain impurities and other hydrocarbons. To obtain high-purity pentane, additional purification steps are often employed. One common method is solvent extraction, where selective solvents are used to remove impurities. Adsorption and molecular sieves may also be used for purification. Final Processing: The purified pentane may undergo additional processing steps to meet specific product specifications or requirements. For example, it may be dried to remove any remaining water content. Packaging and Distribution: Once purified and processed, pentane is typically packaged into containers suitable for transportation and distribution. It may be distributed to various industries where it is used for its specific applications. Overall, the production of pentane is part of the larger petroleum refining process, and its availability depends on the composition of the crude oil and the specific refining techniques employed by the refinery. What Are The Hazards Of Pentane? Pentane, like other hydrocarbon compounds, poses certain hazards, especially when handled and used in industrial or laboratory settings. It's essential to be aware of these hazards and take appropriate safety precautions when working with pentane. Here are some of the hazards associated with pentane: Flammable: Pentane is highly flammable and can form explosive mixtures with air when its vapor concentration is within a specific range (approximately 1.5% to 7.8% by volume). This means that even a small spark or open flame can ignite pentane vapors, leading to fires or explosions. Health Hazards: Inhalation of pentane vapor can cause respiratory irritation, dizziness, headache, nausea, and, in severe cases, central nervous system depression. Prolonged exposure to pentane may lead to adverse health effects, including drowsiness, unconsciousness, and even asphyxiation. Irritant: Pentane can be a skin and eye irritant. Contact with the skin may cause irritation, redness, and dermatitis, particularly with prolonged or repeated exposure. Eye contact with pentane can result in irritation, redness, and discomfort. Environmental Impact: Pentane is a volatile organic compound (VOC) that can contribute to air pollution. When released into the atmosphere, it can react with other pollutants and contribute to the formation of ground-level ozone, which is harmful to human health and the environment. Asphyxiation Hazard: Pentane vapors can displace oxygen in poorly ventilated areas, creating an oxygen-deficient atmosphere. This can lead to asphyxiation if pentane is released in a confined space without proper ventilation. To use pentane safely, consider the following precautions: Work in well-ventilated areas or use exhaust systems to prevent the buildup of pentane vapors. Avoid open flames, sparks, and hot surfaces when working with pentane, and ensure that electrical equipment and wiring are explosion-proof in areas where pentane is used. Store pentane in approved containers away from heat, ignition sources, and incompatible materials. Use appropriate personal protective equipment (PPE), including safety goggles, gloves, and lab coats, when handling pentane. Have emergency response measures in place, including fire extinguishers and eyewash stations, when working with pentane. Follow safety data sheet (SDS) guidelines and procedures provided by the manufacturer or supplier of pentane. Educate and train personnel on the safe handling and storage of pentane. It's crucial to have a thorough understanding of the potential hazards associated with pentane and to implement appropriate safety measures to mitigate these risks. Always follow safety guidelines and regulations specific to your workplace or laboratory when working with pentane or any other hazardous chemicals. How Do I Use Pentane Safely? Using pentane safely is essential due to its flammable nature and associated hazards. Whether you're working with pentane in a laboratory, industrial setting, or any other environment, following proper safety procedures is crucial. Here are some steps to use pentane safely: Work in a Well-Ventilated Area: Always work in a properly ventilated area. Ensure that fumes and vapors can be effectively removed to prevent the buildup of pentane in the air. No Open Flames or Sparks: Avoid working near open flames, sparks, or other potential ignition sources. Pentane is highly flammable and can ignite easily. Use Appropriate Containers: Store pentane in approved containers designed for flammable liquids. These containers are typically designed to prevent leaks and resist fire. Keep Away from Heat Sources: Store pentane away from heat sources, including direct sunlight, radiators, and hot surfaces. Static Electricity: Ground yourself and any equipment that could generate static electricity. This helps prevent static sparks that could ignite pentane vapors. Wear Protective Gear: Use appropriate personal protective equipment (PPE), including safety goggles, gloves, and lab coats, to protect your eyes, skin, and clothing from contact with pentane. No Smoking or Eating: Do not smoke or eat while working with pentane. Keep food and beverages away from the work area. Emergency Equipment: Have safety equipment on hand, such as fire extinguishers, eyewash stations, and safety showers, in case of accidents or emergencies. Avoid Confined Spaces: Do not use pentane in confined spaces without proper ventilation. Pentane vapors can displace oxygen, leading to an oxygen-deficient atmosphere. Secure Containers: Ensure that containers are tightly sealed when not in use. Prevent spills and leaks. Safety Data Sheet (SDS): Familiarize yourself with the safety data sheet (SDS) provided by the manufacturer or supplier of pentane. SDS contains important information about the chemical's properties, hazards, and safe handling procedures. Training and Education: Train all personnel working with pentane on its safe handling, storage, and disposal. Ensure that they understand the hazards and know how to respond to emergencies. Labeling and Signage: Clearly label containers of pentane with appropriate warnings and hazard symbols. Use warning signs in areas where pentane is stored or used. Emergency Response: Develop and communicate emergency response plans, including evacuation procedures and fire safety protocols. Conduct regular drills to ensure that personnel are prepared. Proper Disposal: Dispose of pentane and any contaminated materials according to local, state, and federal regulations. Do not pour pentane down drains or dispose of it improperly. Regular Inspections: Periodically inspect equipment, storage areas, and containers for signs of damage or deterioration. Replace damaged equipment or containers promptly. By following these safety guidelines and practices, you can minimize the risks associated with pentane use and create a safer working environment. Always prioritize safety and be prepared to respond to potential emergencies involving pentane or other flammable chemicals. N-Pentane Safety Data Sheet (SDS) N-Pentane Certificate of Analysis (COA)

$37.00 - $1,000.00

1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen

1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen (Comes with 2 Year Limited warranty) This is a complete cold trap and will come assembled for instant use. This cold trap is made of 304SS MADE IN USA, utilizing Polycarbonate lids for durability, flexibility and chemical resistance to Ethanol and Isopropyl (not compatible with Acetone). This system is recommended to protect pump from condensable vapors. This trap comes with an industrial grade, heat cured silicone gasket designed only for our systems. There is nothing of equal quality in the market. The gasket itself is reversible (doubling the life of our system guaranteed) allowing customers to instantly take it off and flip it over. No adhesives are used! The system will maintain a vacuum seal only under vacuum. The vacuum pump will hold the interior 2 quart container for your dry ice slurry in compression with the larger outer lid. The larger outer lid will be held in compression with 1.5 gallon outer container. The connections on both sides are 1/4" MJIC flares or 1/4" Barbs that will connect to 1/4" HVAC or FJIC stainless steel hose. The center slurry container has a lid - this lid simply helps prevent evaporation of your slurry. Temperature rated for -100-160F This cold trap comes assembled and includes: (1) 1.5gl high strength stainless steel outer container (made of solid 304 stainless made in USA) (1) 2q interior slurry container (made of solid 304 stainless made in USA) (2) 1/2" thick clear polycarbonate lids (2) industrial grade silicone gasket (1) 1/4" HVAC hose 5' Can withstand max working temps of 392F gasket only 60A durometer density (1) max vacuum -29.5inHg (+/-.5Hg) (2) 1/4" MJIC or Barb Fittings Outside container internal dimensions: 7.25" diameter X 8.25" tall To help remove condensable vapors, or when liquid nitrogen traps are not practical, our cold trap is the best option for preventing vapors from getting into your vacuum pump and contaminating it. This 1.5 gallon trap uses polycarbonate lids for durability, flexibility, and chemical resistance. The system doesn’t use adhesives, and comes standard with a reversible gasket for enhanced quality that doubles its life. Made in the USA, the BVV™ Cold Trap comes with all parts pre-assembled, so you can get to work straight out of the box. Inside container internal dimension: 4.75" diameter by 6.5" tall

$245.00

20LB High Purity USA ISO-BUTANE R600A - 99.5% Guaranteed - Buy 2 Get 1 Free (Add 3 To Cart)

20LB High Purity USA ISO-BUTANE R600A - 99.5% Guaranteed - Buy 2 Get 1 Free (Add 3 To Cart) DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Ground ONLY. Quantities bought in 3 or more will ship via freight unboxed BVV™ always recommends distillation of every solvent before use. Tank contains no diptube. Tank does not include CGA 510 fitting. Must be added through dropdown or bought separately. *Actual liquid weight is 20LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Permitted Sales Include the Following: Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale At BVV™, quality is everything, and our ISO-Butane is certainly no exception. This ISO-Butane is sourced here in the U.S, so you know it’s going to be of high purity: we guarantee 99.5% purity. With such high quality, you’ll see the results. By cutting down on mystery oils and other contaminants, our instrument-grade solvent will make for a higher quality extract. This solvent is clean, odorless, and colorless, meaning there are zero hydrogen sulfide-based Ethyl Mercaptan odorants. It’ll arrive in a DOT refillable LP tank.. Made to keep you going for a long time, the tank will hold the equivalent of sixty-five 10 oz. butane cans. However, note that the tank doesn’t contain a dip tube. How To Buy 2 Get 1 Free Simply add 3X of 20LB Tanks to your cart and you will automatically be discounted the third tank. Need one with a CGA fitting two without? Simply add one tank with your desired CGA fitting and add two of the same item selecting "None" for the "CGA fitting" and "Connection Size" options. Want 2 Butane Tanks and 1 Propane Tank? No problem, just add 3 of ANY of our 20LB LPG tanks to your cart and enjoy the third tank free! **Notes: Actual ISO-butane liquid weight is 20LB BVV™ always advises distillation of every solvent before using it. DISCLAIMER: Our items are intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. For safe operation, only use the unit in well-ventilated areas. ***Shipping Notes: This item will ONLY ship via UPS Ground, in accordance with FAA regulations. Any orders including solvent will NOT be shipped Expedited. If an order includes solvent as well as additional items, it will all be shipped via UPS Ground/Freight even if you’ve selected Expedited. If you want the non-solvent item to ship Expedited, place 2 separate orders; we won’t split up orders and ship them separately otherwise. We do not ship solvents to Hawaii, Puerto Rico, or any other U.S. Territory outside of the contiguous 48 States. Shipping solvent to Alaska will ONLY be via freight and will be required to travel through Canada. Our shipping policies are in place to ensure safe transport of solvents and prevent any problems with shipping times for Best Value Vacs customers Chemical Formula: C₄H₁₀ Molecular Weight: 58.12 g/mol CAS Registry Number: 75-28-5 Appearance Colorless Odor: Faint Petroleum Density 563 kg/m³ (or 0.563 g/mL) Boiling Point: 10°F (-12°C) Solubility in water: Low Solubility GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220 GHS Precautionary Statements P203, P210, P222, P280, P377, P381, and P403 UN Identification Number: 1969 Proper Shipping Name: Isobutane, liquefied Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Isobutane Certificate of Analysis (COA) Isobutane Safety Data Sheet (SDS)

$250.00 - $265.00

8" x 8" Platinum Cured Silicone Vac Pad

8" x 8" Platinum Cured Silicone Pad

$5.00

Hexane 99% Lab Grade