Products

-

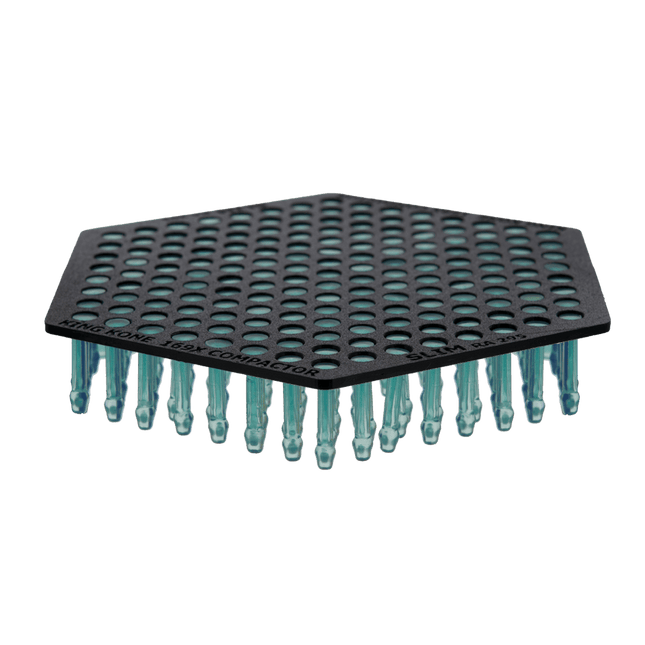

King Kone 169 Extended Cone Packing Fingers

169 Extended Cone Packing Fingers This accessory is an upgraded version of our standard packing fingers(typically utilized at the end of the packing process, to pack the end of the product down, in order to close off the cone). The additional advantage of this accessory is the "Height Adjustment Option". It allows for the user to adjust the height of the packing fingers so that it can be used for an additional pack, at any part of the cone packing process. Depending on the product being packed, stickier material may make it more of an obstacle to reach the desired density, especially at the crutch. With these height adjustable packing fingers, an extra pack assisted by the packing fingers, at any length you need, is the easy solution to a perfectly packed pre-rolled joint. Ability to pack: 84mm, 98mm, 109mm

$450.00

-

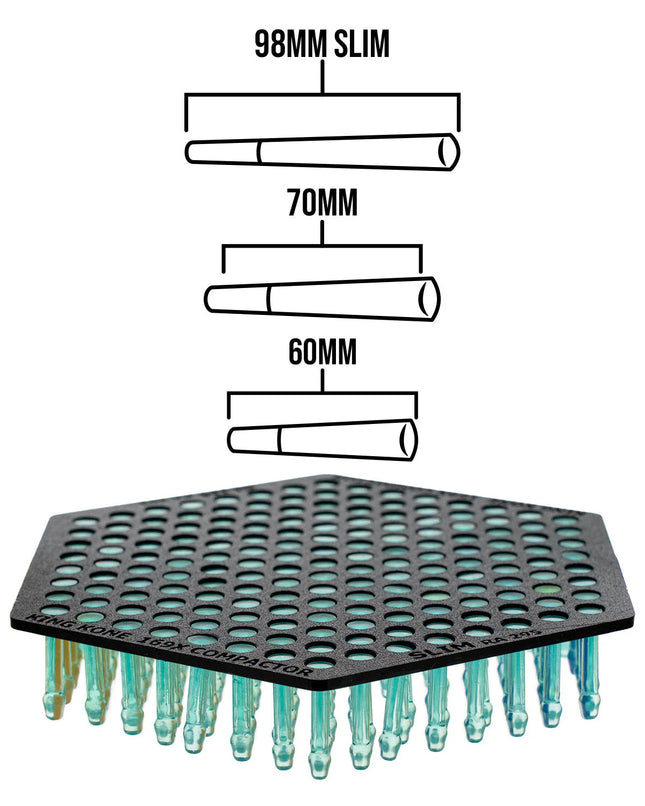

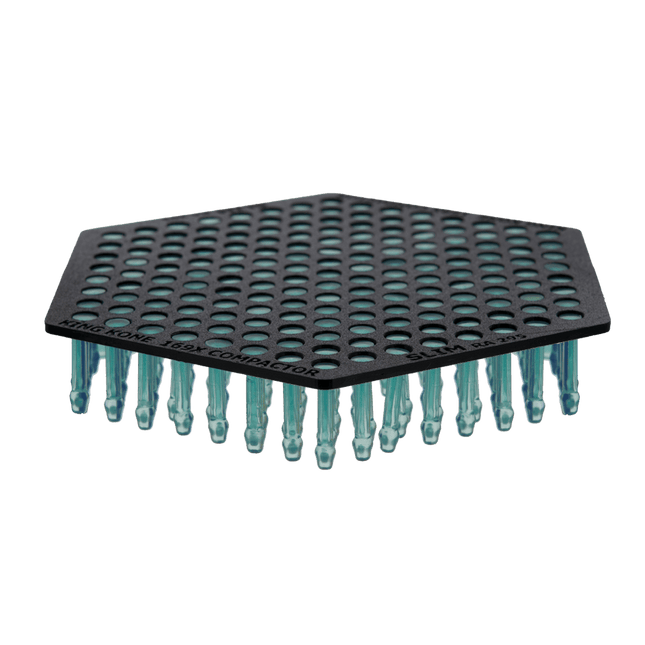

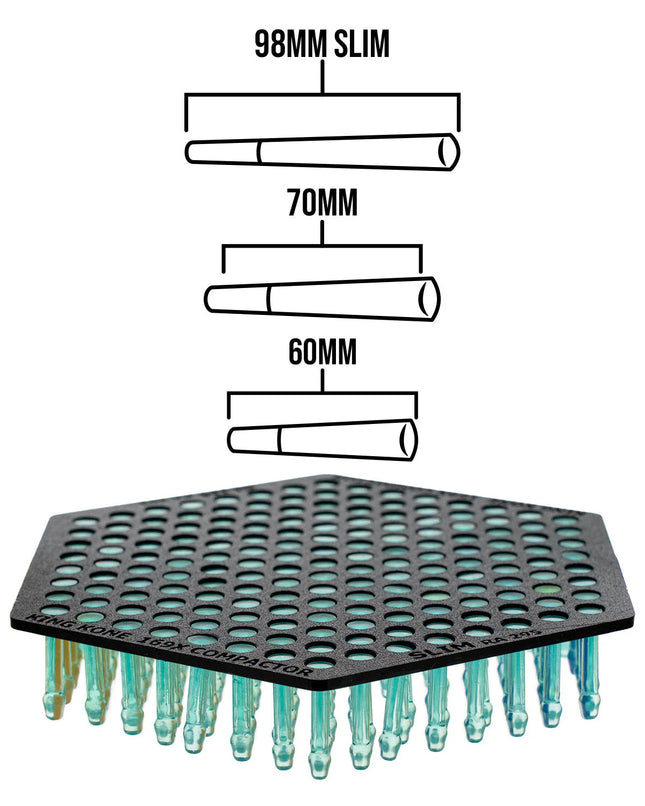

King Kone 169 Slim Cone Packing Fingers - 98mm, 60mm, 70mm

169 Slim Cone Packing Fingers - 98mm, 60mm, 70mm This accessory is utilized at the end of the packing process, to pack the end of the product down, in order to close off the cone. This can help with exposing more paper for the closing process. Ability to pack: 98mm slim, 60mm, 70mm

$375.00

-

King Kone 169 Standard Cone Packing Fingers - 84mm, 98mm, 109mm

169 Standard Cone Packing Fingers - 84mm, 98mm, 109mm This accessory is utilized at the end of the packing process, to pack the end of the product down, in order to close off the cone. This can help with exposing more paper for the closing process. Ability to pack: 84mm, 98mm, 109mm

$375.00

-

16CF Neocision ETL Lab Certified Vacuum Oven

16CF Neocision Certified Lab Vacuum Oven, 8 Individually Heated Shelves, LED's - 3 Year Warranty Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! Introduction Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. Performance Capabilities At Best Value Vacs, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Uniformity: within 4% of the temperature setpoint. Heat-Up Time: 30 minutes. Ultimate Vacuum: <500 µmHg / mTorr / micron. Time to Vacuum: 10 minutes to 29"Hg using our 12CFM Spark Free Vacuum Pump Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. Technical Data Electrical Voltage 120V Frequency 60Hz Power 2000W Current 20A Plug NEMA 5-15 Internal Chamber Heating Individual direct-heat shelves Chamber Material Stainless Steel Dimensions (LxWxH) 25.5" x 32" x 34" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 8 Shelves Shelf Dimensions (LxW) 24.75" x 31.5" Shelf Capacity 780 in^2 Total Shelf Capacity 6240 in^2 Safety Seal Silicone on Tempered Glass Window Dimensions (LxH) 29.25" x 32" Lights 4 strips of LEDs provide a clear, bright view of the interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 37.25" x 45" x 46" Weight 500lbs Support Locking Casters Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connections Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose User Manual Included Vacuum Pump Sold Separately. Warranty 3 Years Capacity and Throughput Planning Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122 Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via UPS Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise UPS freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$15,500.00

-

18% Hydrogen Peroxide Food Grade H2O2

18% Hydrogen Peroxide food grade - You have arrived at professional use and industrial strength. This product is great for heavy duty disinfection, bleaching and environmental sanitation. This strength eliminates viruses, bacteria, mold, attacks and removes odors. Our peroxide is USA made, sourced locally and we replenish the stock frequently to provide the freshest delivered peroxide. Made with high purity deionized water. Dilution: Mix 1 part 18% peroxide with 5 parts distilled or R.O. water to make 3% 1QT Bottle - Makes 1.5 Gallons of 3% Food Grade Peroxide1 Gallon Bottle- Makes 6 Gallons of 3% Food Grade Peroxide5 Gallon Container - Makes 30 Gallons of 3% Food Grade Peroxide

$22.00 - $530.00

-

19 Liter Neocision Heated Circulator - ETL Listed

BVV™ Neocision 19 Liter Heated Circulator - ETL Listed The Neocision 19 Liter Heated Circulator - ETL Listed brings very stable temperature control and lab grade quality at a great price. This refrigerated circulator has a durable powder coated exterior with a stainless steel top, stainless steel interior and a large control head with digital display. This high powered laboratory heater is great for extraction or distillation applications! Key Features: ETL Certified Digital Control Head with Large Display Corrosion Resistant Stainless Steel Top and Interior 220°C Max Temperature Rubber Feet for Vibration Dampening and Noise Reduction 19L Internal Reservoir Capacity Small Table Top Design Side drain valve for water bath 1/2" Male NPT attachments Technical Indicators Index NEO-19H Power Supply Voltage AC220V 60Hz (NEMA L6-30 Plug) Input Power (W) 4100 Temperature Control Range (C°) RT+20 ~ 220 C° Temperature Fluctuation (C°) ±0.1 Pump Flow (Lmin) 10(water ) Filling Volume (L) 22.5 Bath Opening Size (mm) 200 x 120 Dimensions (W x D x H) (mm) 330 x 300 x150

$3,200.00

-

19/26 Inert Gas Valve for BVV™ ECO Rotary Evaporators

19/26 Inert Gas Valve for BVV™ ECO Rotary Evaporators

$35.00

-

190 Proof Ethanol - USP Kosher - Excise Tax Included

Food Grade Alcohol - 190 Proof 95% AVB | Grain Derived Alcohol EXCISE TAX INCLUDED IN PRICING. HAZMAT ITEMS ARE NON-REFUNDABLE. ALL SALES ARE FINAL BVV™ Food / USP Ethanol 190 Proof, This product is the highest purity possible for extraction grade ethanol on the market, at 95% pure. Provides unmatched purity while performing extractions for crude oil or even cleaning equipment. 190 Proof Ethanol is a great choice when processing oil for short path distillation processes because it can be immediately winterized, filtered, and then rotary evaporated to recover the ethanol for later usage. A copy of your unexpired DRIVERS LICENSE, STATE ID CARD, or US PASSPORT and your completed and signed END-USER STATEMENT must be received before we ship out your order. End Users Agreement Chemical Formula: C2H6O Molecular Weight: 46.069 CAS Registry Number: 64-17-5 Appearance Colorless Liquid Odor: wine-like, pungent Density 0.78945 g/cm3 @ 20 °C Boiling Point: 78.23C/172.81F Solubility in water: Miscible GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H319, H360D GHS Precautionary Statements P210, P233, P240, P241, P242, P305+P351+P338 UN Identification Number: 1170 Proper Shipping Name: Ethanol Solution Transport Hazard Class: 3 Packing Group: II DOT Placard: Federal & State Law Requirements You must be the age of 21 or over to purchase this ethanol product. All Alcohol and Tobacco Tax Trade Bureau (TTB), federal, state and local laws must be complied with, and you may be required to provide BVV™ with your state or federal license even when purchasing products that require a federal excise tax payment. (Note: Container style and color may vary) Ethanol 190 Proof USP/Food Grade Certificate of Analysis (COA) Ethanol 190 Proof USP/Food Grade Safety Data Sheet (SDS)

$29.00 - $5,500.00

-

1CFM PTFE Diaphragm Vacuum Pump

1CFM PTFE Diaphragm Vacuum Pump BVV™ 1CFM PTFE Diaphragm Vacuum Pump is a great alternative to a rotary vane vacuum pump because it does not require oil and can run for hours on end without having to be serviced or worry about the pump overheating. This diaphragm pump has a unique design with a built on carrying handle and rubber suction cup feet to reduce noise output and vibration. This pump includes a vacuum gauge (installation required), silencer/air filter, silicone vacuum tubing, power cord and instruction manual. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Oil-Free Operation Easy to Carry Handle Rubberized Suction Cup feet for reduced noise level and vibration Lightweight Screw on Silencer Built-in Vacuum Gauge Corrosion Resistant PTFE Diaphragms Specifications Free Air Displacement 1CFM / 30L/Min Voltage 120v / 60Hz Ultimate Vacuum -28InHg / >= 0.095Mpa Noise Level <60 DB Motor Power 160w Number of Heads 2 Diaphragm Material PTFE Weight 22LB Intake Connection 8mm Barb Fitting Warranty 2 Years Limited

$650.00

-

1L Distillation Kit

1L Distillation Kit The 1L Distillation Kit is a simple, easy to use system designed for small personal use. It includes all stands, clamps, clips, and tubing needed to begin distilling immediately. This Kit Does NOT include a vacuum pump or circulator. Please see the below recommendations for both as well as recommended add-ons. Or check out our 1L Standard Distillation Turnkey Setup which includes vacuum pump and circulator. Recommended Vacuum Pumps: Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump (premium option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (USA made economy option) Best Value Vacs VE280 9CFM Two Stage Vacuum Pump (economy option) Recommended Circulator: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter MX Refrigerated Circulator (premium option with chilling capability) Recommended Add-Ons: Glass Dewar Style Cold Trap (recommended cold trap) Bullseye Precison Vacuum Gauge (premium vacuum gauge for measuring depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) Specifications: Boiling Flask Size: 1L Receveiving Flask Size: 250ml Batch Capacity approximate: 200-400 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Includes: Glass Components: 1L 2-Neck Boiling Flask Short Path Head Triple Neck Cow Receiving Flask 3x 250ml Single Neck Round Bottom Flask 14/20 Thermometer Adapter 24/40 Thermometer Adapter 120mm Glass Funnel 14/20 Stopper 24/40 Stopper Accessories: Magnetic PTFE Stirring Bar Retriever 5 Pack of Metal Keck Clips Dow Corning High Vacuum Silicone Grease Tripod Stand 1L Analog Heating and Stirring Mantle 3 Finger Clamp Adjustable 0-70mm Boss Head -13mm 6" x 6" Scissor Jack 250-500ml Cork Stand 10ft of Vacuum Hose 10ft of Chiller Hose 1/4" Vacuum Manifold Traceable Kangaroo Thermometer - Digital 10 Pack of Adjustable Stainless Steel Tubing Clamps Fiberglass Insulation Rope 10 Feet 1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen w/ 2x 1/4" Barb Adapters Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$1,220.00

-

1L Standard Distillation Turnkey Setup

1L Standard Distillation Turnkey Setup The Standard Distillation Turnkey Setup includes all the components necessary to successfully perform distillation at an entry level price point. The Standard Turnkey Setup Includes: 1L Distillation Kit 1/4" Flare x 1/4" Barb Adapter BVV™ 5L Heated Circulator BVV™ V9D 9CFM Two Stage Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$2,700.00 - $3,050.00

-

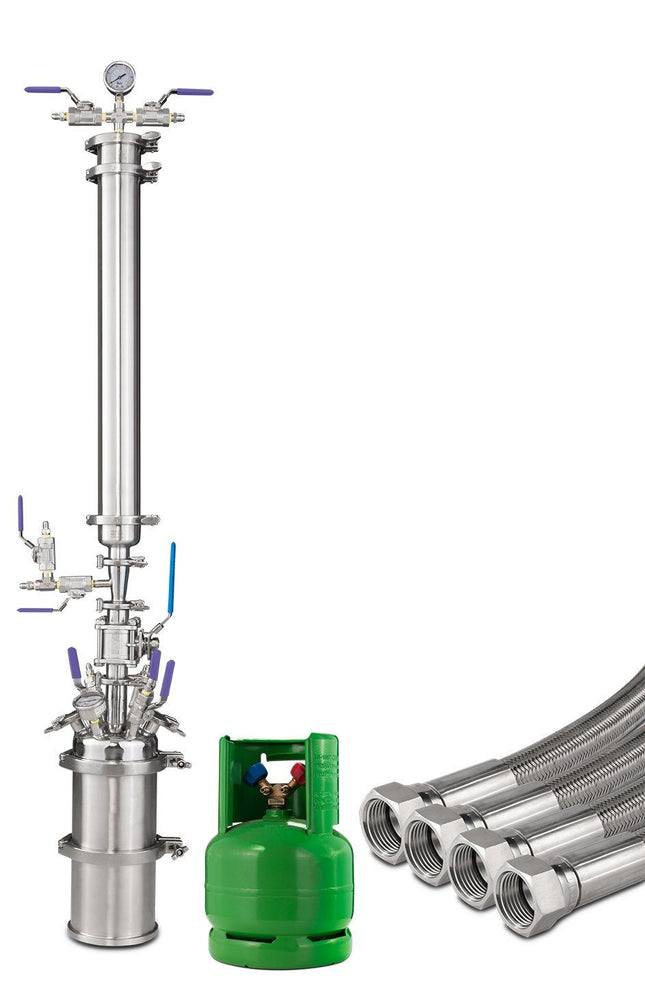

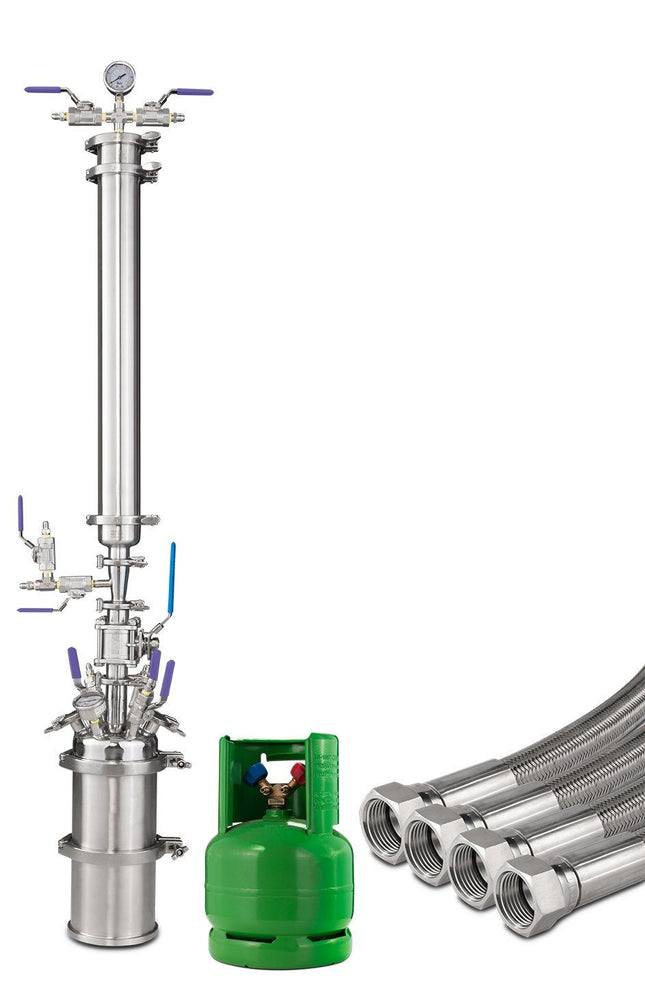

1LB Apollo Top Fill Closed Loop Extractor

1LB Top Fill Closed Loop Extraction System (System comes with 1 yr. limited warranty) The 1lb closed loop hydrocarbon extractor performs incredible botanical extraction within a sealed, vacuumed system. With the help of a top-fill input, solvent washes through the material column, collecting oils as it passes over the material. The oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. KEY BENEFITS Meets or exceeds all industry listed standards Versatile in running butane, propane, and other blended solvents Perfect for mid to large-scale extraction/production facilities Faster run times and less degradation in the process Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and standard LP tank. This model has minimal features to keep cost low, while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Solvent is input into the material column with a showerhead endcap, ensuring the full material column is saturated with solvent. The Professional comes with a sleeved spool, allowing users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is the premium version of the Professional. It features all American made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, jacketed collection base, and all high-pressure clamps. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base BVV 316SS Full Bore Valves Showerhead Dewaxer Ball Valve Splatter Platter Base SSP Valves Showerhead Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter Unit Includes: 6"x6" Welded Bottom Base 6"x6" Open Spool Assembled 6" extractor lid 3"x24" Material column with reducer & top cap Mastercool 6LB Solvent Recovery Tank (1) 1/4" 48" FJIC Stainless Steel hose (1) 1/4" 60" FJIC Stainless Steel hose (1) 1/4" FJIC HVAC hose Standard pressure single pin clamp Instruction Manual Specifications: 3"x 24" 304 Stainless Steel Material Column-1lb capacity (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple 37 degree FJIC port connections 304 Stainless Steel Base Container 6" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure/standard pressure, easy clean unit BUNA-N Gaskets are designed for Oil Processing Temp range -40-200F, and have superior solvent resistance Base unit Maximum Capacity: 395 cubic inches, (6.472 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$978.00 - $2,100.00

-

1LB EVO Closed Loop Extraction Kit

1LB Evo Closed Loop Extraction Kit (System comes with 1 yr. limited warranty) The EVO series of 1LB closed-loop extractors was designed with the evolution of stand-up extractors in mind. The aim of the EVO series of extractors is to provide unparalleled utility and ease of use within a traditional stand-up design. The EVO series was designed to tackle the two most common plights with stand-up extractors, difficulty in extract harvesting, and integration of adsorbent filtration. The Evo series accomplishes both through the use of its elevated extract pour spout and its optional inline color remediation column. Beyond the elevated pour spout and optional inline color remediation column. The EVO series aims to provide unbridled safety and solvent recovery speed through the integration of ASME pressure relief valves on both the material column and collection base standard and full bore 1/2" recovery lines found on the professional, elite, and active explorer models. The 1lb EVO Closed Loop Extraction kit comes complete with a top fill injection manifold including a compound gauge, a 125 psi ASME pressure relief valve, and two full bore ball valves complete with 2x 1/4" Male JIC connections on the explorer and both 1/4" & 1/2" Male JIC connections on the professional and elite models. Just below the injection manifold, all 1lb EVO models have a solvent dispersion plate that evenly disperses solvent into the 3"x 24" 1lb material column which is enclosed by 2x 100 micron Buna-N mesh gaskets. Both the Professional and Elite models come complete with an inline 3" x 6" color remediation column just below the material column with a 300-gram media capacity and a filter stack utilizing both a 5 micron & 1 micron sintered disk. Professional and Elite models also include 25-micron filter paper and a 500-gram sample of Pure-Flo B80 Below the 1lb material column and optional inline color remediation column the 1lb Evo includes the jacketed and elevated pour spout collection base that allows for easy extract harvesting and speedy solvent recovery. The elevated base can accommodate up to a 5:1 solvent to biomass ratio and accept a standard round pyrex dish or a small parchment paper boat below the pour spout. Upon completion of the run, extract removal is made easy by simply draining the extract from the elevated extract pour spout. Both the professional, elite, and active explorer models have increased solvent recovery capability from the jacketed collection base through full bore 1/2" recovery MJIC connections and stainless steel recover hoses. Beyond the larger recovery lines and inline color remediation column the 1lb EVO Elite options come paired with our ETL listed 5 liters Neocision heated circulator and the sleeved EVO recovery tank that allows for the pre-chilling of solvent and speedy solvent recovery, reaching sub 20 minute recovery times on high heat. All varients of the EVO Extraction Kits come equipped with a 1.9CFT vacuum oven, a 7CFM single-stage vacuum pump, a 5' HVAC hose, and an 8"x8" silicone pad. The Explorer & Professional models come with the ECO model vacuum ovens and the Elite versions equipped with the ETL list Neocision 1.9CFT vacuum oven. All EVO closed-loop extraction kits come available with an active recovery option including: BVV 2 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified BVV Large Condensing Coil 1/2" x 24" SS JIC Braided Hose (2) 1/2" x 48" SS JIC Braided Hose (2) 1/2" x 60" SS JIC Braided Hose Molecular Sieve Filter Drier BVV 5' HVAC Hose BVV Vacuum Tee ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. KEY BENEFITS Meets or exceeds all industry listed standards Versatile in running butane, propane, and other blended solvents Perfect for mid to large-scale extraction/production facilities Faster run times and less degradation in the process Easy extract harvesting using the elevated pour spout Inline color remediation Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry-level extractor on a budget. Comes with the jacketed and elevated collection base and 1/4" Male JIC connections on the injection manifold and collection base. The explorer options include a 1.9CFT ECO Vacuum Oven, a 5' HVAC hose, and a 7CFM single-stage vacuum pump. This model does not include the inline color remediation column or 1/2" Male JIC recovery/ injection connections. The Explorer model is forward compatible and can be easily upgraded to include 1/2" lines and the inline color remediation column. *This model does not come with a heated circulator* Professional: This model includes all the features of the explore model with the increased functionality of an inline color remediation column Just under the material column that comes with 25micron filter paper and a 500-gram sample of b80, an upgraded stainless steel recovery tank, and a full bore 1/2" Male JIC connection included on the injection manifold and collection base. The Professional extraction kit options include a 1.9CFT ECO Vacuum Oven, a 5' HVAC hose, and a 7CFM single-stage vacuum pump.*This model does not come with a heated circulator* Elite: The Elite series is the premium version of the Professional. It features the same 1/2" Male JIC, and inline color remediation column upgrades. But also includes the EVO recovery tank and 5 liter ETL listed Neocision heated circulator that allows for pre-chilling and speedy recovery of solvent. The Elite options include a 1.9CFT ETL Listed Neocision Vacuum Oven, a 5' HVAC hose, and a 7CFM single-stage vacuum pump. Passive: Passive recovery is the standard option on the extraction kit with the explorer model coming with 1/4" recovery lines and the professional and elite models coming equipped with 1/2" recovery lines. Active: The Active Recovery Upgrade Kit will increase recovery times by condensing the vapor a lot faster than just a hot/cold differential. All active models come equipped with 1/2" recovery lines and the inclusion of our BVV 2 Cylinder Butane recovery pump, BVV Large Condensing Coil, Molecular Sieve Filter Drier, and all the associated hosing to perform active recovery. Explorer Professional Elite Jacketed & Elevated pour spout collection base Jacketed & Elevated pour spout collection base Inline Color remediation column 25-micron filter paper 500 gram B80 sample 1/2" recovery lines 30# Stainless steel Recovery Tank Jacketed & Elevated pour spout collection base Inline Color remediation column 25-micron filter paper 500 gram B80 sample 1/2" recovery & Injection lines EVO Recovery Tank 5 liter ETL listed Neocision heated circulator with insulated hoses Unit Includes: Full bore injection Manifold complete with a compound gauge,125 PSI ASME pressure relief valve, and 2x 1/4" MJIC connections (1x1/2" MJIC connection on professional & elite models) 3"x24" 1lb Material column with solvent dispersal plate. 3"x6" Color remediation column 300g gram media capacity complete with a filter stack including 5 micron and 1 micron sintered disks (Professional & Elite model) 25-micron ashless filter paper (Professional & Elite) Jacketed & elevated collection base with extract pour spout 6" hemispherical collection base lid complete with borosilicate sight glasses, a compound gauge, 125 PSI ASME pressure relief valve, and full bore ball valves with MJIC Connections. 30# LP storage and recovery tank (Explorer) 30# stainless steel LP tank (Professional) & EVO Recovery tank (Elite) (1) 1/4" 72" FJIC Stainless Steel Injection hose (Explorer & Professional) 1/2" 96" FJIC Stainless Steel Injection Hose (Elite) (1) 1/4" 60" FJIC Stainless Steel Recovery Hose (Explorer) 1/2" 60" FJIC Stainless Steel Recovery Hose (Professional & Elite) High-pressure clamps Specifications: 3"x 24" 304 Stainless Steel Material Column-1lb capacity (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple 37 degree FJIC port connections 304 Stainless jacketed & elevated collection base Tri-Clamps at all interfaces make for a high pressure/standard pressure, easy-clean unit BUNA-N Gaskets are designed for Oil Processing Temp range -40-200F, and have superior solvent resistance Construction: All components are made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$3,809.00 - $8,739.00

-

1LB EVO Closed Loop Extractor

1LB EVO Closed Loop Extraction System (System comes with 1 yr. limited warranty) The EVO series of 1LB closed-loop extractors was designed with the evolution of stand-up extractors in mind. The aim of the EVO series of extractors is to provide unparalleled utility and ease of use within a traditional stand-up design. The EVO series was designed to tackle the two most common plights with stand-up extractors, difficulty in extract harvesting, and integration of adsorbent filtration. The Evo series accomplishes both through the use of its elevated extract pour spout and its optional inline color remediation column. Beyond the elevated pour spout and optional inline color remediation column. The EVO series aims to provide unbridled safety and solvent recovery speed through the integration of ASME pressure relief valves on both the material column and collection base standard and full bore 1/2" recovery lines found on the professional and elite models. The 1lb EVO comes complete with a top fill injection manifold including a compound gauge, a 125 psi ASME pressure relief valve, and two full bore ball valves complete with 2x 1/4" Male JIC connections on the explorer and both 1/4" & 1/2" Male JIC connections on the professional and elite models. Just below the injection manifold, all 1lb EVO models have a solvent dispersion plate that evenly disperses solvent into the 3"x 24" 1lb material column which is enclosed by 2x 100 micron Buna-N mesh gaskets. Both the Professional and Elite models come complete with an inline 3" x 6" color remediation column just below the material column with a 300-gram media capacity and a filter stack utilizing both a 5 micron & 1 micron sintered disk. Professional and Elite models also include 25-micron filter paper and a 500-gram sample of Pure-Flo B80 Below the 1lb material column, and optional inline color remediation column the 1lb Evo includes the jacketed and elevated pour spout collection base that allows for easy extract harvesting and speedy solvent recovery. The elevated base can accommodate up to a 5:1 solvent-to-biomass ratio and accept a standard round pyrex dish or a small parchment paper boat below the pour spout. Upon completion of the run, extract removal is made easy by simply draining the extract from the elevated extract pour spout. Both the professional and elite models have increased solvent recovery capability from the jacketed collection base through full-bore 1/2" recovery MJIC connections and stainless steel recovery hoses. ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. KEY BENEFITS Meets or exceeds all industry-listed standards Versatile in running butane, propane, and other blended solvents Perfect for mid to large-scale extraction/production facilities Faster run times and less degradation in the process Easy extract harvesting using the elevated pour spout Inline color remediation Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry-level extractor on a budget. Comes with the jacketed and elevated collection base and 1/4" Male JIC connections on the injection manifold and collection base. This model does not include the inline color remediation column or 1/2" Male JIC recovery/ injection connections. The Explorer model is forward compatible and can be easily upgrad*This model does not come with a heated circulator*ed to include 1/2" lines and the inline color remediation column. Professional: This model includes all the features of the explore model with the increased functionality of an inline color remediation column Just under the material column that comes with 25micron filter paper and a 500-gram sample of b80, an upgraded stainless steel recovery tank, and a full bore 1/2" Male JIC connection included on the injection manifold and collection base. *This model does not come with a heated circulator* Elite: The Elite series is the premium version of the Professional. It features the same 1/2" Male JIC, and inline color remediation column upgrades. But also includes the EVO recovery tank that allows for pre-chilling and speedy recovery of solvent. *This model does not come with a heated circulator* Certified: The Certified series is the certified version of the elite. It features the same 1/2" Male JIC, and inline color remediation column upgrades. But also includes the EVO recovery tank that allows for pre-chilling and speedy recovery of solvent. This Model is 22 State certified and includes an Infield Verification by PRV Engineers within the purchase price. States include but are not limited to: Alabama, Arizona, Arkansas, California, Colorado, Connecticut, Florida, Illinois, Kansas, Louisiana, Maine, Massachusetts, Missouri, Nevada, North Carolina, Oklahoma, Oregon, Texas, Vermont, Washington, West Virginia, and Wyoming *This model does not come with a heated circulator* Explorer Professional Elite Jacketed & Elevated pour spout collection base Jacketed & Elevated pour spout collection base Inline Color remediation column 25-micron filter paper 500 gram B80 sample 1/2" recovery lines 30# Stainless steel Recovery Tank Jacketed & Elevated pour spout collection base Inline Color remediation column 25-micron filter paper 500 gram B80 sample 1/2" recovery & Injection lines EVO Recovery Tank Unit Includes: Full bore injection Manifold complete with a compound gauge,125 PSI ASME pressure relief valve, and 2x 1/4" MJIC connections (1x1/2" MJIC connection on professional & elite models) 3"x24" 1lb Material column with solvent dispersal plate. 3"x6" Color remediation column 300g gram media capacity complete with a filter stack including 5 micron and 1 micron sintered disks (Professional & Elite model) 25-micron ashless filter paper (Professional & Elite) Jacketed & elevated collection base with extract pour spout 6" hemispherical collection base lid complete with borosilicate sight glasses, a compound gauge, 125 PSI ASME pressure relief valve, and full bore ball valves with MJIC Connections. 30# LP storage and recovery tank (Explorer) 30# stainless steel LP tank (Professional) & EVO Recovery tank (Elite) (1) 1/4" 72" FJIC Stainless Steel Injection hose (Explorer & Professional) 1/2" 96" FJIC Stainless Steel Injection Hose (Elite) (1) 1/4" 60" FJIC Stainless Steel Recovery Hose (Explorer) 1/2" 60" FJIC Stainless Steel Recovery Hose (Professional & Elite) High-pressure clamps Specifications: 3"x 24" 304 Stainless Steel Material Column-1lb capacity (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple 37 degree FJIC port connections 304 Stainless jacketed & elevated collection base Tri-Clamps at all interfaces make for a high pressure/standard pressure, easy-clean unit BUNA-N Gaskets are designed for Oil Processing Temp range -40-200F, and have superior solvent resistance Construction: All components are made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$2,050.00 - $6,850.00

-

1LB Inline CRC Kit

1LB Inline CRC Kit BVV's 1lb Inline CRC Kit can be utilized to adapt any of our 3" diameter 1lb material columns for inline adsorbent filtration. This kit includes a 3"x6" media column with a 300-gram media capacity and a filter stack including a 5 micron & 1 micron Dutch Weave Sintered Filter Discs. This 3" color remediation column is meant to be plumbed between the 3" 1lb material column and the existing hemispherical reducer of any of our 1lb closed loop hydrocarbon extractors.Assembly starts with placing the 1 micron sintered disk and gasket between the extracts hemispherical reducer and the included filter plate securing both with one of the included high-pressure clamps. Next, take the 5-micron sintered disk and the included ashless filter paper and rip around the circumference of the sintered disk, placing both atop the filter plate placing the sintered disc gasket and 3"x6" spool over top before securing both with the remaining high-pressure clamp. Since the spool secures the filter paper in place a filter plate ring is not required. This Kit includes: 3"x6" Tri-clamp Spool (300 gram capacity) 3" V3 Filter Plate 3" 5 Micron Sintered Disk 3" 1 Micron Sintered Disk 2x 3" Buna-N Sintered Disc Gaskets 2x 3" High-pressure Clamp 110MM 25 Micron Ashless Filter Paper (100qty) Your choice of 1000g of UltraClear, B80, Perform 5000 or 500g of Chemtek W1,W2, or W3. Sample Choices: Ultraclear: High-performance granular attapulgite B80: Naturally active attapulgite clay powder Perform 5000: Highly activated attapulgite clay for hard to bleach oils W1: Top-tier Acid activated bentonite clay perfect for preserving terpenes. W2: Natural bleaching clay that prevents terpene isomerization W3: Highly active adsorptive clay designed for difficult to bleach oils

$357.00 - $392.00

-

1LB MK-V Bi-Directional Closed Loop Extraction Kit

1LB MK-V Bi-Directional Closed Loop Extraction Kit (System comes with 1 yr. limited warranty) We believe it’s better to buy everything you need in one shot, so we’ve created a package that includes a vacuum chamber, vacuum pumps, and complete extraction system. The best part? Buying this kit will save you money compared to purchasing each component individually. ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors The 1lb Bi-Directional closed loop increases efficiency by utilizing both a bottom and top solvent input. By using a bottom flood on the first wash, you ensure all material has seen solvent. This method preventing channeling through the material. Finish the run with a top flood input to ensure all residuals have been washed from the material. Oil bearing solvent is collected in the collection base under the material column. Once collected, solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configurations: Explorer: Our standard bi-directional extractor model. Comes with a welded bottom base and standard LP tank. This model provides all the benefits of the Orthrus design without any bells and whistles. The Explorer model is perfect for those looking to get the bi-directional performance but have a budget. Explorer models can be upgraded after purchase. Professional: This model features upgrades to help produce a higher quality extract. Solvent is entered into the system through an injection coil. This coil is chilled with dry ice and alcohol, dropping solvent temperatures to dewax inline. Fats and waxes are not soluble when solvent temperature is subzero, so chilling solvent on input is the simplest way to achieve high clarity extract. The Professional also comes with a removable bottom on the collection base. This makes removal of extract after the run as easy as possible. High pressure clamps give greater solvent compatibility, allowing propane to be used. Elite: The Elite series is our fully upgraded Orthrus model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. The elite series comes with all American instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve and jacketed collection base. Full dewaxing is guaranteed by combining both an injection coil and sleeved column. Both units are packed with dry ice, making both solvent and material sub-zero temperatures. The material column is fitted with a nitrogen assist port, which helps ensure no solvent gets stuck with the material. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump BVV 316SS Full Bore Valves HP Clamps Injection Coil w/ Hose Splatter Platter Base 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump SSP Valves Injection Coil Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter Nitrogen Assist 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump Unit Includes: Collection Base 6"x6" Welded Bottom Base 6"x6" Open Spool Assembled 6" bi-flow lid 3"x24" Material column with reducer & top cap 3" filter plate kit 1.5" Solvent input manifold 1.5" Ball Valve #30 LP tank (2) 1/4" 48" High Pressure PTFE Braided SS Hose 3/8" 48" High Pressure PTFE Braided SS Hose (2)6" clamps, (3)3" clamps and a (3)1.5" clamp with gaskets Instruction Manual Specifications: 3"x 24" 304 Stainless Steel Material Tube 1lb (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple port connections for _" 316 Stainless JIC 37 Degree 304 Stainless Steel Base Container 6" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure, easy clean unit. Viton Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 25" x 7" Diameter overall size Weight: 21 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Base unit Maximum Capacity: 300 cubic inches, (2.553 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$3,016.00 - $5,373.00

-

1LB MK-V Orthrus Bidirectional Flow Closed Loop Extractor

***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors 1LB MK-V Orthrus Bidirectional Flow Closed Loop Extractor (System comes with 1 yr. limited warranty) The 1lb Bi-Directional closed loop increases efficiency by utilizing both a bottom and top solvent input. By using a bottom flood on the first wash, you ensure all material has seen solvent. This method preventing channeling through the material. Finish the run with a top flood input to ensure all residuals have been washed from the material. Oil bearing solvent is collected in the collection base under the material column. Once collected, solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configurations: Explorer: Our standard bi-directional extractor model. Comes with a welded bottom base and standard LP tank. This model provides all the benefits of the Orthrus design without any bells and whistles. The Explorer model is perfect for those looking to get the bi-directional performance but have a budget. Explorer models can be upgraded after purchase. Professional: This model features upgrades to help produce a higher quality extract. Solvent is entered into the system through an injection coil. This coil is chilled with dry ice and alcohol, dropping solvent temperatures to dewax inline. Fats and waxes are not soluble when solvent temperature is subzero, so chilling solvent on input is the simplest way to achieve high clarity extract. The Professional also comes with a removable bottom on the collection base. This makes removal of extract after the run as easy as possible. High pressure clamps give greater solvent compatibility, allowing propane to be used. Elite: The Elite series is our fully upgraded Orthrus model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. The elite series comes with all American instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve and jacketed collection base. Full dewaxing is guaranteed by combining both an injection coil and sleeved column. Both units are packed with dry ice, making both solvent and material sub-zero temperatures. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base Ball Valve BVV 316SS Full Bore Valves Ball Valve HP Clamps Injection Coil w/ Hose Splatter Platter Base SSP Valves Injection Coil Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter Unit Includes: Collection Base 6"x6" Welded Bottom Base 6"x6" Open Spool Assembled 6" bi-flow lid 3"x24" Material column with reducer & top cap 3" filter plate kit 1.5" Solvent input manifold 1.5" Ball Valve Mastercool 6LB Solvent Recovery Tank (2) 1/4" 48" High Pressure PTFE Braided SS Hose 3/8" 48" High Pressure PTFE Braided SS Hose (2)6" clamps, (3)3" clamps and a (3)1.5" clamp with gaskets (2)3" Gaskets w/ filter Instruction Manual Specifications: 3"x 24" 304 Stainless Steel Material Tube 1lb (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple port connections for _" 316 Stainless JIC 37 Degree 304 Stainless Steel Base Container 6" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure, easy clean unit. Viton Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 25" x 7" Diameter overall size Weight: 21 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Base unit Maximum Capacity: 300 cubic inches, (2.553 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$1,720.00 - $4,070.00

-

1LB Passive Closed Loop Extraction Kit

Passive Closed Loop Extraction System ***NOTICE TO CUSTOMER: THIS ITEM WILL SHIP BY FREIGHT ONLY*** (System comes with 1 yr. limited warranty) ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors We believe it’s better to buy everything you need in one shot, so we’ve created a package that includes a vacuum chamber, vacuum pumps, and complete extraction system. The best part? Buying this kit will save you money compared to purchasing each component individually Closed Loop Extraction Process The 1lb closed loop hydrocarbon extraction system performs botanical extraction within a sealed, vacuumed system. Utilizing a top-fill input, solvent washes thru the material column, collecting oils as it passes over the material. The oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and standard LP tank. This model has minimal features to keep cost low, while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Solvent is input into the material column with a showerhead endcap, ensuring the full material column is saturated with solvent. The Professional comes with a sleeved spool, allowing users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is the premium version of the Professional. It features all American made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, jacketed collection base, and all high-pressure clamps. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump BVV 316SS Full Bore Valves Showerhead Dewaxer Ball Valve Splatter Platter Base 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump SSP Valves Showerhead Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump Unit Includes: 6"x6" Welded Bottom Base 6"x6" Open Spool Assembled 6" extractor lid 3"x24" Material column with reducer & top cap Mastercool 6LB Solvent Recovery Tank (1) 1/4" 48" FJIC Stainless Steel hose (1) 1/4" 60" FJIC Stainless Steel hose (1) 1/4" FJIC HVAC hose Standard pressure single pin clamp and 1 full gasket set Instruction Manual Specifications: 3"x 24" 304 Stainless Steel Material Column-1lb capacity (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple 37 degree FJIC port connections 304 Stainless Steel Base Container 6" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure/standard pressure, easy clean unit BUNA-N Gaskets are designed for Oil Processing Temp range -40-200F, and have superior solvent resistance Base unit Maximum Capacity: 395 cubic inches, (6.472 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$2,935.00 - $3,730.00

-

1LB Skylight Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well ventilated areas. Check with your local fire marshal for guidance when operating indoors Closed Loop Reclamation Extraction System (System comes with 1 yr. limited warranty) The 1lb Skylight closed loop hydrocarbon extraction system performs botanical extraction within a sealed, vacuumed system. What sets the skylight apart from the standard 1lb is the kettle top featuring a 3" sight glass to view inside the collection vessel. This is great for beginners on a larger scale, the viewport helps you easily see your oil fall and gives you a great view of your recovery process. Utilizing a top-fill input, solvent washes thru the material column, collecting oils as it passes over the material. The top-fill closed loop extractor is the safest way to do hydrocarbon extraction. Solvent washes through the material column and collects oils as it passes over the material, and the oil-bearing solvent is collected in the collection base. Once collected, the solvent in this passive unit is distilled and recovered using temperature manipulation, leaving oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and standard LP tank. This model has minimal features to keep cost low, while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Solvent is input into the material column with a showerhead endcap, ensuring the full material column is saturated with solvent. The Professional comes with a sleeved spool, allowing users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is the premium version of the Professional. It features all American made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, jacketed collection base, and all high-pressure clamps. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base BVV 316SS Full Bore Valves Showerhead Dewaxer Ball Valve Splatter Platter Base SSP Valves Showerhead Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter Unit Includes: Collection Base 6"x6" Welded Bottom Base 6"x4" Kettle top with 3" Sight Glass Assembled 4" extractor lid 3"x24" Material column with reducer & top cap 6LB Mastercool Solvent Recovery Tank 60" High Pressure PTFE Braided SS Hose (2) 6" clamps, (2) 3" clamps and a 1.5" clamp with gaskets Instruction Manual Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$1,065.00 - $2,250.00

-

1LB TFX Closed Loop Extractor

1LB TFX Closed Loop Extractor Are you ready to embark on your extraction journey? Look no further than the TFX, the perfect introductory closed-loop extractor to kickstart your extraction journey. Not only does the TFX deliver exceptional performance at an affordable price right out of the box, but it also serves as an excellent base unit for future upgrades and modifications as level up your extraction game. Whether you're just starting or looking to expand your capabilities, the TFX provides a solid foundation that allows you to tailor your extraction setup to meet your evolving needs. With its versatile design and compatibility with various extractor upgrades, the TFX empowers you to explore new processing techniques and adapt to changing industry demands. Begin your extraction journey with the TFX, and unlock limitless possibilities for innovation and growth in the world of extraction. The TFX closed loop extractor represents the evolution of the highly popular Apollo closed loop extractor, introducing a new era of enhanced safety, ease of use, and performance. Building upon the success of its predecessor, the TFX provides greater safety, ease of use, and performance. Designed with operator safety in mind, the TFX incorporates improved safety mechanisms, including High-pressure Clamps and pressure relief valves standard to ensure maximum safety during the extraction process. Furthermore, the TFX line of closed-loop extractors makes extract harvesting a breeze with splatter platter bases standard. Its optimized design results in superior ease of use, performance, and safety yielding exceptional quality extracts. The TFX closed-loop extractor represents the foundation of most extractors' journey, providing would-be professionals and established professionals alike with a reliable, efficient, and future-proof solution to meet their evolving needs. The TFX line of closed-loop extractors is available in three distinct model variants to suit various extraction needs. The V1 Explorer is the ideal choice for budget-conscious individuals seeking an affordable entry-level option to venture into the world of extraction. This model features a DOT-Approved carbon steel recovery tank, 1/4" JIC Recovery lines, and polycarbonate sight glasses, providing a solid foundation that can be easily upgraded to professional or elite options in the future. For those aiming for a professional setup from the start, the V2 Professional model is the way to go. It includes an upgraded stainless steel recovery tank with 1/2" JIC Recovery lines, ensuring optimized solvent recovery. Additionally, the professional model includes upgraded borosilicate sight glasses, enhancing the visibility of the extraction process. If you're seeking the ultimate extraction experience, the V3 Elite model is your go-to solution. It incorporates all the upgrades of the professional model, including the upgraded stainless steel recovery tank with 1/2" JIC Recovery lines and upgraded borosilicate sight glasses. Moreover, the elite model goes beyond by featuring a solvent dispersal plate for even biomass saturation and a jacketed splatter platter for use with a heated circulator to ditch the hot water bath and further optimize solvent recovery. The TFX closed-loop extractor empowers you to choose the perfect model that suits your budget and requirements, Whether you're starting out or aiming for professional-grade capabilities the TFX Closed Loop Extractor series is the perfect foundation to start your extraction journey. Whether you opt for the Explorer, Professional, or Elite model, the TFX line of closed-loop extractors offers infinite modification possibilities to expand your capabilities and stay ahead of the evolving needs of the industry. While the TFX is specifically optimized for quick wash extraction procedures, ensuring exceptional purity and yield. It can easily be adapted for soaking procedures by adding our 316L SS Tri-Clamp Ball Valve below the material column. For those seeking absolute purity, pairing your TFX with an Inline CRC (Color Remediation Column) allows you to create the highest quality and purest extracts imaginable. If running fresh frozen material is your goal, simply swap out the standard 3"x 24" spool with a Sleeved Spool to chill your material during the extraction process and preserve the flavor of your starting biomass. To achieve absolute clarity in your extracts, reduce wax content by incorporating an injection coil into your setup. If you're looking to reduce solvent loss and improve recovery times, consider adding our BVV 2 Cylinder Active Closed Loop Recovery kit to your TFX closed loop extractor. This kit enhances solvent recovery efficiency, ultimately saving you time and resources. With the TFX closed loop extractor and its extensive range of modification options, you have the freedom to customize your extraction setup to meet your unique requirements. Stay at the forefront of the industry and unlock the full potential of your extraction process with the versatile TFX closed-loop extractor. As a leading manufacturer of extraction equipment, we understand the importance of precision and safety in the extraction process. The TFX is engineered with these principles in mind, offering a cutting-edge solution for extraction professionals. Crafted from high-quality stainless steel, the TFX boasts exceptional durability and corrosion resistance, providing you with a reliable and long-lasting extraction solution. Its innovative design incorporates advanced safety features, including high-pressure clamps, pressure relief valves, and sight glasses, to ensure operator well-being and operational control. Its superior design promotes efficient solvent flow and thorough material saturation, resulting in high-quality, potent extracts that meet your exact specifications. When it comes to introductory closed-loop extractors, the TFX stands out for its exceptional performance, safety, and reliability. With our product, you can streamline your extraction operations, increase productivity, and produce premium extracts that exceed industry standards. At BVV, we take pride in delivering top-notch extraction equipment that caters to your specific needs. Our team of experts is committed to providing unparalleled customer support, assisting you every step of the way, from purchase to setup and beyond. Elevate your butane extraction game with the TFX, the ultimate top-fill closed-loop extractor. Contact us today to start your extraction journey and take your business to new heights. Specifications 3"x24" 1LB Material Column 6"x12" Collection Base Body 6" Collection Base Splatter Platter 100um Nitrile BUNA-N Mesh Gaskets 1.5" Polycarbonate or Borosilicate Sight Glasses 125 PSI ASME Safety Valves -30hg-250PSI Compound Pressure Gauge 1/4" or 1/2" Full Bore Recovery Lines 1/4" JIC process Flow lines Explorer Professional Elite DOT Carbon Steel Solvent Tank Polycarbonate Sight Glasses 1/4" JIC Recovery Lines Stainless Steel Solvent Tank Borosilicate Sight Glasses 1/2" JIC Recovery Lines Stainless Steel Solvent Tank Borosilicate Sight Glasses 1/2" JIC Recovery Lines Solvent Dispersal Plate Jacketed Splatter Platter ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$1,220.00 - $2,000.00

-

2 Gallon Aluminum - POT ONLY

2 Gallon Aluminum - POT ONLY This is a replacement part for the following Vacuum Chambers: SVac 2 Gallon Aluminum Vacuum Chamber Best Value Vacs 2 Gallon Aluminum Vacuum and Degassing Chamber Dimensions: 6.5" Tall x 10" Diameter Material: 3004 Aluminum

$44.00

-

2 Gallon Aluminum SIDEMOUNT - POT ONLY

2 Gallon Aluminum - POT ONLY ***Note: 'with Hardware' Option only includes the side-mount manifold with gauge pre-installed. (Does Not Include Lid or Gasket) This is a replacement part for the following Vacuum Chambers: SVac 2 Gallon Aluminum Vacuum Chamber Best Value Vacs 2 Gallon Aluminum Side Mount Vacuum and Degassing Chamber Dimensions: 6.5" Tall x 10" Diameter Hole Size: 21/64 Material: 3004 Aluminum

$48.00 - $68.00

-

2 Gallon Resin Trap Vacuum Chamber

2 Gallon Resin Trap Vacuum Chamber (Comes with 2 Year Limited warranty) Designed, built, and 100% tested in Chicago, Illinois, the Resin Trap Vacuum Chamber is the perfect application for a successful, high-quality end product. With its unique, patent pending gasket design (Utility Patent #14/533,548), this shatter chamber can easily withstand 10,000 uses with proper care and maintenance. The gasket itself is reversible, doubling the system's life by allowing customers to instantly take it off and flip it over. No adhesives necessary. The maximum allowed temperature of this chamber is 160f. The individual components of this chamber are rated at higher temperatures, however, as a vacuum vessel, we limit maximum operational temperature to 160f. Every chamber is tested prior to shipping to lose no more than 2.5inHg/24hrs. Specifications Key Features: Comes with 2 year limited warranty Resin traps come complete with glycerin-filled vacuum gauge, fittings for use with 1/4" vacuum tubing, nickel plated brass ball valve and instruction manual. Capture excess resin and protect your pump! Unique Catch Port Design: An additional hose can be installed at the port inside the tank to facilitate accurate collection of resin. 5 Feet Reinforced Vacuum Hosing to Connect Directly to the Vacuum Pump 1/4" SAE port. Measuring range of vacuum gauge:0-29.25inHg Silicone gasket to be used over 10,000 times without deterioration. This Kit Includes: (1) 2 Gallon Aluminum Chamber (1) Industrial grade silicone gasket Gasket can withstand 390°F max temp. 60A durometer density (1) Glycerin filled vacuum gauge (must be regulated upon arrival) Max vacuum -29Hg (+/-.5Hg) at sea level (1) Leak free nickel plated 1/4" Hvac Flare Valve (1) ¼” Barbed Connection (1) 5' Purple BVV™ Hvac Hose (1) 5' Clear Vacuum Tubing Internal Dimensions: 6.5" Tall x 10" Diameter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. Pump Facts: We recommend the oil is changed every 50-75 of operating hours. CFM is a measure of cubic feet per minute. Single stage pumps reach a max vacuum of 50-75 microns (0=complete vacuum). Dual/Two stage pumps reach a max vacuum of 10-15 microns (0=complete vacuum). See FAQ at the top for product safety warnings. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$135.00

-

2 Gallon Resin Trap Vacuum Chamber With Glass Lid