Products

-

Neocision 10L Neocision Dual Head Short Path Distillation Turnkey System

10L Neocision Dual Head Short Path Distillation Turnkey System This unit carries a 2 day lead time. The 10L Neocision Distillation Turnkey Setup features our Dual 10L P5 Distillation Heads and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included is a KF-25 Vacuum Pump giving you extreme power and depth with a long lifespan, the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market, and a BVV 19L Heated Circulator for maximum condensation of vapors. You will also receive a Dual Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The Premium Turnkey Kit Includes: 10L Neocision Kit with Dual P5 Distillation Heads KF-25 2 Meter Bellows Dual Dewar Style Glass Cold Trap Bullseye Precision Vacuum Gauge BVV 19L Heated Circulator Your Choice Of KF-25 Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$13,250.00 - $17,750.00

-

10L Neocision ETL Lab Certified Rotary Evaporator

10L Neocision ETL Lab Certified Rotary Evaporator The 10L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 10L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware. Specifications: Model 10L Solvent Pro Series Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 220-240V 60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 20-130 RPM Set Temperature RT+5-99C Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 10L (10000ml) Receiving Flask Capacity 10L (10000ml) Condenser Style Main + Auxiliary Vertical Double Helix Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 3300w Dimensions 81 x 44 x 20 in. Weight 155 lbs Vacuum Connection 14mm / .55 in. Barb Condenser Connection 18mm / .70 in. Barb Warranty 90 days excluding glass parts Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$4,500.00 $2,000.00

-

10L Neocision ETL Lab Certified Rotary Evaporator Turnkey System

10L NEO Rotary Evaporator Turnkey System 10L NEO Rotary Evaporator Turnkey System setup includes all the necessary components to successfully perform solvent recovery via rotary evaporation. A cold trap should always be used inline between your vacuum system and application to protect the pump from volatile vapors. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram 10L NEO Rotary Evaporator Turnkey System setup includes: 10L Neocision ETL Lab Certified Rotary Evaporator Polyscience 6160T 1HP Chiller 3/8" Gum Rubber - 100ft 3/8" Silicone Tubing - 25ft Welch BTpro100 Diaphragm Pump Adjustable Stainless Steel Hose Clamps This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. **Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$11,200.00 - $14,090.00

-

10L Premium Short Path Distillation Kit with P10 Distillation Head

10L Short Path Distillation Kit with P10 Distillation Head This unit carries a 2 day lead time. (Note: Stainless Steel Table NOT Included.) The 10L Short Path Distillation Kit features our USA made P10 Distillation Head. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Kangaroo digital thermometer which is very rugged and reliable. You will also receive a Ribbed Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Kit gives you the basic necessities of a short path distillation system and allows you to add on a temperature control system and vacuum pump to fit your needs. The 10L Neo Kit Includes: 10L Short Path Distillation Kit including glassware, labware, and P10 Distillation Head. 10L Digital Heating and Stirring Mantle. Valved Vacuum Adapter. Ribbed Dewar Style Glass Cold Trap. Kangaroo Digital Thermometer. Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$4,100.00

-

10L Premium Short Path Distillation Turnkey System

10L Premium Short Path Distillation Turnkey System This unit carries a 2 day lead time. (Note: Stainless Steel Table NOT Included.) The 10L Premium Short Path Distillation Turnkey System features our USA made P10 Distillation Head. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Kangaroo digital thermometer which is very rugged and reliable. You will also receive a Ribbed Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The 10L Neo Kit Includes: 10L Short Path Distillation Kit including glassware, labware, and P10 Distillation Head. 10L Digital Heating and Stirring Mantle. Polyscience 15 Liter Advanced Digital Heated Circulator BVV™ 21.2CFM Pro Series Corrosion Resistant Vacuum Pump Valved Vacuum Adapter. Ribbed Dewar Style Glass Cold Trap. Kangaroo Digital Thermometer. Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$12,100.00

-

10LB+ EVO Certified Closed Loop Extractor

10LB+ EVO Certified Closed Loop Extractor The 10LB+ EVO Certified Closed Loop Extractor builds upon the proven success of the 5LB EVO, pushing the boundaries of performance, capacity, and innovation. Tailored for extractors scaling up their operations, this system retains the advanced features of its predecessor while offering increased throughput and operational efficiency to meet the demands of larger-scale production. With a rugged design suited for both cured and fresh frozen materials, the 10LB+ EVO supports low-temperature extractions and rapid solvent recovery, leveraging 1.5" full-bore recovery lines to reduce cycle times without compromising on extract quality, safety, or ease of operation. Optimized for a 10-pound extraction process at a 5:1 butane-to-biomass ratio, the system includes dual 55LB jacketed and baffled solvent collection/recovery tanks and an additional jacketed material column for pre-packing. This feature enhances efficiency and ensures seamless processing. With 3X 6"x36" jacketed material columns, each equipped with individual inline CRCs (Color Remediation Columns), the 10LB+ EVO guarantees maximum extraction efficiency, exceptional extract purity, terpene preservation, and unmatched filtration flow rates. Engineered for compliance and reliability, the 10LB+ EVO is peer-reviewed and 3P-certified to meet or exceed Class 1 Division 1, NFPA 58, and ASME standards, incorporating 3A sanitary compression and Tri-Clamp fittings for durability and precision. Capable of processing 80+ pounds of biomass per 8-hour shift, this system delivers the scalability, precision, and affordability extractors need to elevate their production capabilities. Key Features 1.5" Full-Bore Recovery LineAccelerate recovery with oversized 1.5” lines, minimizing cycle times and boosting throughput. Inline and Independent Adsorbent Filtration ColumnsEnsure pristine extract clarity and unadulterated terpene profiles with individual inline CRCs for each material column. Optimized for maximum flow rates and minimal retention time to preserve flavor. Independent Solvent InjectionReduce downtime and streamline operations with independant solvent injection for smooth transitions and increased efficiency. Additional Standby Material ColumnIncrease throughput with an extra pre-packed material column, ready to swap in for non-stop processing. Sanitary Compression and Tri-Clamp FittingsBuilt for reliability, the system’s sanitary compression and Tri-Clamp fittings ensure leak-proof assembly and simplified maintenance. Processing Power Capacity Per Batch: 10LB Cycle Time: 30-45 Minutes* Capacity: 80+lb, per 8-hour shift* Extracts: isolate/sauce, distillate, vape pens, shatter, and wax/sugar *Cycle Time & Capacity vary based on heater and chiller pairing* Specifications 3X 6"x36" 5LB Material Column 3X 6"x6" Adsorbent Filtration Column 3X 1-5um Dutch Weave Sintered disk filter stacks 1.5"X 48" Braided Inline molecular sieve recovery line 10X 1.5" Certified Borosilicate Sight Glasses 5X 250 PSI ASME Safety Valves 5X -30hg-250PSI Compound Pressure Gauges 1.5" Full Bore Recovery Lines 1/2" Compression process Flow lines Footprint (DxWxH) 30"x68"x79" Weight: 650 lb Maximum Pressure Rating: 250PSI Compliance Class 1, Division 1 compliant Designed to ASME standards NFPA 58 LPG compliant 3P Certified

$23,000.00

-

Fisher American 10′ Fisher American Fume Hood

10′ Fisher American Fume Hood sku Fume Hood Exterior Dimensions: Work Area (Interior) Dimensions: Fume Hood Accessories: Width: Depth: Height: Width: Depth: Height: NLS-1013 120″ 31 1/2″ 54 1/2″ and 89 1/2″ with cabinet 110″ 23″ 45″ Door opening: 26″ Sash Doors: 4 Light on/off Switch 1 AC Power Plug 1 Cold Water Valve 1 Gas Valve 1 Vertical Sliding Sash Door with 4 horizontal sliding glass windows. 2 ACID Cabinets 1 General Storage NLS-1014 120″ 31 1/2″ 54 1/2″ and 89 1/2″ with cabinet 110″ 23″ 45″ Door opening: 26″ Sash Doors: 4 Light on/off Switch 1 AC Power Plug 1 Cold Water Valve 1 Gas Valve 1 Vertical Sliding Sash Door with 4 horizontal sliding glass windows. 1 x 48″ Flammable Storage 1 x 48″Acid Storage 1 x 24″ 1 Door 1 Drawer Cabinet NLS-1016 120″ 31 1/2″ 54 1/2″ and 89 1/2″ with cabinet 110″ 23″ 45″ Door opening: 26″ Sash Doors: 4 Light on/off Switch 1 AC Power Plug 1 Cold Water Valve 1 Gas Valve 1 Vertical Sliding Sash Door with 4 horizontal sliding glass windows. 1 x 48″ Flammable Storage 1 x 48″ General Storage 1 x 24″ 1 Door 1 Drawer Cabinet NLS-1017 120″ 31 1/2″ 54 1/2″ and 89 1/2″ with cabinet 110″ 23″ 45″ Door opening: 26″ Sash Doors: 4 Light on/off Switch 1 AC Power Plug 1 Cold Water Valve 1 Gas Valve 1 Vertical Sliding Sash Door with 4 horizontal sliding glass windows. 2 x 48″ Flammable Cabinets 1 x 24″ ACID Storage Cabinets

$19,925.00 - $29,350.00

-

11.25" Diameter GLASS LID

BVV™ 11.25" Diameter Glass LID Our patented gasket #9475627 Disclaimer: LID ONLY - does not include hardware unless selected through drop-downs or ordered separately. Hardware - includes Valve Manifold, Gauge, and Gasket. (Does not include 50-micron air filter or vacuum hose. This is a Replacement Lid for the following Vacuum Chambers: Best Value Vacs 3 Gallon Wide Stainless Steel Side Mount Vacuum and Degassing Chamber Best Value Vacs 3 Gallon Wide Stainless Steel Vacuum and Degassing Chamber Best Value Vacs 1 Gallon Flat Stainless Steel Vacuum and Degassing Chamber

$90.00 - $110.00

-

11.25" Diameter LID

11.25" Diameter LID Our patented gasket #9475627 Disclaimer: LID ONLY - does not include hardware unless selected through drop-downs or ordered separately. Hardware - includes Valve Manifold, Gauge, and Gasket. (Does not include 50-micron air filter or vacuum hose. This is a Replacement Lid for the following Vacuum Chambers: Best Value Vacs 3 Gallon Wide Stainless Steel Side Mount Vacuum and Degassing Chamber Best Value Vacs 3 Gallon Wide Stainless Steel Vacuum and Degassing Chamber Best Value Vacs 1 Gallon Flat Stainless Steel Vacuum and Degassing Chamber

$43.00 - $119.00

-

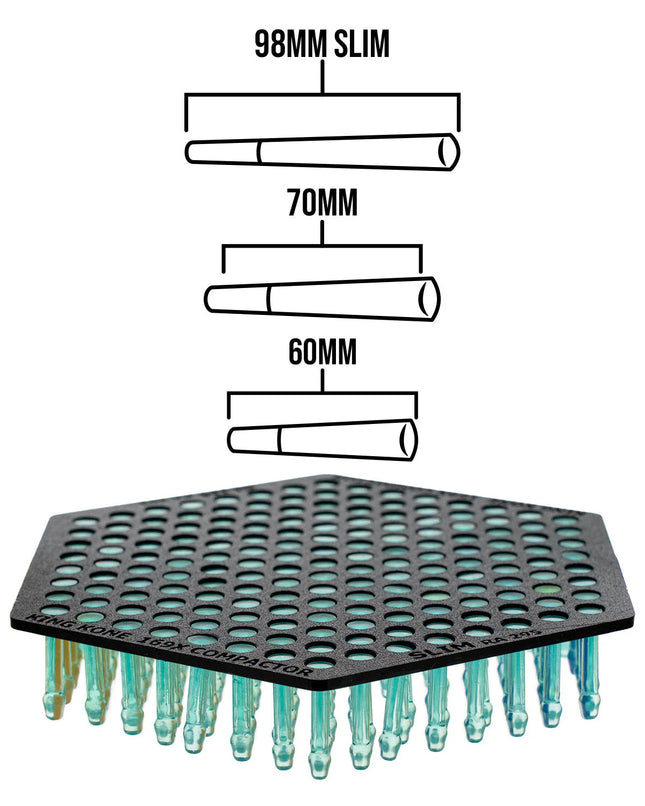

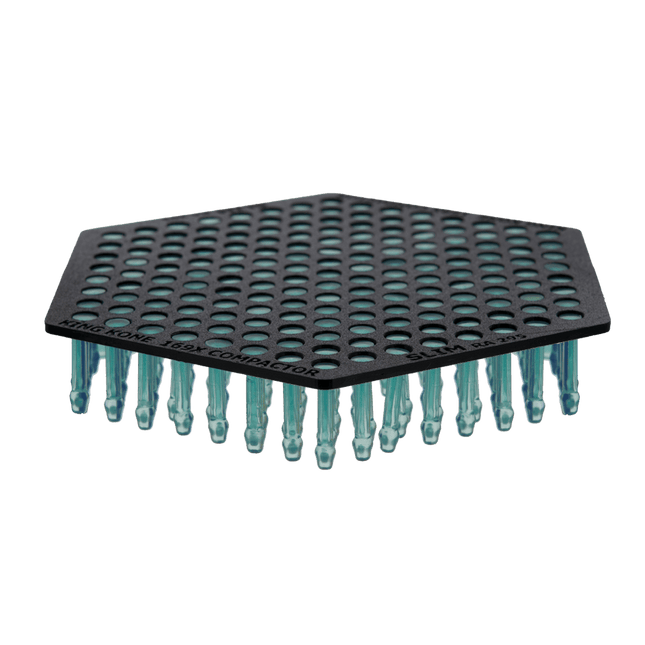

King Kone 115 Extended Tube Packing Fingers - All Tube Sizes

115 Extended Tube Packing Fingers - All Tube Sizes This accessory is an upgraded version of our standard 115 tube packing fingers(typically utilized at the end of the packing process, to pack the end of the product down, in order to close off the tube). The additional advantage of this accessory is the "Height Adjustment Option". It allows for the user to adjust the height of the packing fingers so that it can be used for an additional pack, at any part of the tube packing process. Depending on the product being packed, stickier material may make it more of an obstacle to reach the desired density, especially at the crutch. With these height adjustable packing fingers, an extra pack assisted by the packing fingers, at any length you need, is the easy solution to a perfectly packed pre-rolled tube. Ability to pack: All size straight tubes.

$450.00

-

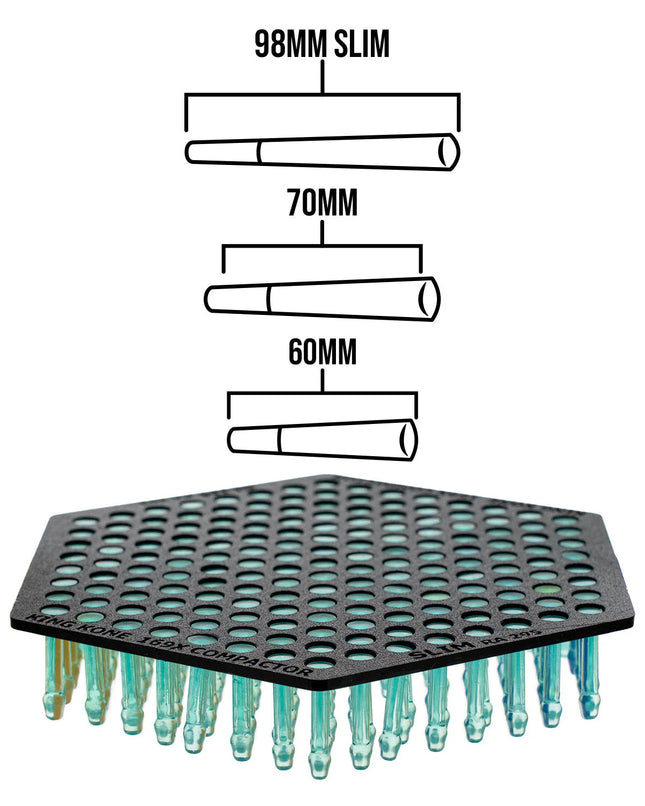

King Kone 115 Tube Packing Fingers - all sizes

115 Tube Packing Fingers - all sizes This accessory is utilized at the end of the packing process, to pack the end of the product down, in order to close off the cone. This can help with exposing more paper for the closing process. Ability to pack all sizes.

$375.00

-

12" Collection Base

Pre-Built 12" Collection Base Double your capacity or configure your own custom system with BVV's Pre-Built 12" Collection base. Available in three different variations to suit your application all models of BVV's Pre-Built 12" Collections Base comes standard with high-pressure clamps, borosilicate sight glasses, and full-bore ball valves. Version 1 is the base model equipped with the standard 12" welded base perfect for cost-conscious applications. Version 2 is equipped with a 12"x12" spool & 12" splatter platter to make extract harvesting a breeze, and Version 3 is the top of the line 12" Colleciton base equipped with a 12" jacketed splatter platter for both optimized solvent recovery and ease of harvesting extract. Specifications High Pressure Clamps 2X 2" Borosilicate Sight Glasses 1X 125 PSI ASME Safety Valves 1X -30hg-250PSI Compound Pressure Gauge 1X 1/2" JIC Lid Valve 2X 1/4" JIC Lid Valves Maximum Pressure Rating: 125PSI Variations V1 : 12x12 Base (1200X12B) V2: 12" Splatter Platter base (1200X12S+1200SPL) V3: 12" Jacketed Splatter Platter Base (1200X12S+1200FJS)

$1,175.00 - $1,780.00

-

12" Hemispherical Extractor Lid with 6" Triclamp Center

12" Hemispherical Extractor Lid with 6" Triclamp Center This End Cap comes with Four FNPT Threaded connections, two 2" Tri-Clamp ferrules welded to the end cap, and a 6" Tri-Clamp center port. They allow the user to adapt and connect threaded connections to the NPT ports and Tri-Clamp lid connections to the others. These 7 connections are welded on a 12" Hemispherical Tri-Clamp End Cap. Specifications Material: 304 Stainless Steel Connection Types: 2" Tri-Clamp (2x) 6" Center Tri-Clamp Port 12" Tri-Clamp 1/4" - 18 FNPT (x2) 1/2" - 14 FNPT (x2) Standard: 3A

$350.00

-

12" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves

12" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 12" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with (2)1/4" and (1)3/8" 37° JIC Flares, and compound gauge. These lids are made out of 304 stainless steel and have (3) 2" Tri-Clamp ports with the middle 2" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2) 1/4" and (1) 3/8" 37° JIC Tri-Clamp Size(s) (3) 2" Ports x 12" Tri-Clamp Nitrogen Tested Yes

$585.00

-

12" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves

12" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 12" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with 1/4" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have (3) 2" Tri-Clamp ports with the middle 2" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" 37° JIC Tri-Clamp Size(s) (2) 2" Ports x 12" Tri-Clamp Nitrogen Tested Yes

$510.00

-

12" Tri-Clamp Dewaxer Columns

12" Tri-Clamp/ Tri Clover Dewaxing Columns This is a 12" Tri-Clamp BVV™ Tri-Clamp Dewaxing Spool. It is intended to have dry ice put into the sleeve to chill the material inside the column. **Note: When selecting a Pipe Hanger choose the size that correlates to the Sleeve OD NOT Spool OD Sizes Available: 12" x 12" Tri-Clamp Dewaxer Column Specifications: Tri-Clamp Size 3" Material 304 Stainless Steel Standard 3A High Polish Sleeve OD 14.000" Spool ID 11.732" Spool OD 12" Flange OD 12.57" Bead Center 12.17" Drain Port 1/4"-18 FNPT (Drain Plug Included) OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested.

$420.00

-

12" Tri-Clamp Spools

12" Tri-Clamp/ Tri Clamp Spools Sizes Available: 12" x 12" Tri-Clamp Spool Specifications: Tri-Clamp Size 12" Material 304 Stainless Steel Standard 3A High Polish Spool OD 12" Spool ID 11.732" Flange OD 12.57" Bead Center 12.17" OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 12" Tri-Clamp Spools - Drawing Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$285.00

-

12" Tri-Clamp x (3) 2" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid

12" Tri-Clamp/ Tri Clover x (3) 2" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid This End Cap comes with Four 1/4"-18 FNPT Threaded connection and Three 2" Tri-Clamp ferrules welded to the end cap with a sanitary weld with a 3" Tube Extension Below the Lid. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid and the 2" Tri-Clamp Connection. These 7 connections are welded on a 12" Hemispherical Tri-Clamp End Cap. Specifications Material: 304 Stainless Steel Connection Types: 2" Tri-Clamp - 3" Tube Extension Below Lid on Center Tri-Clamp Port 12" Tri-Clamp 1/4" - 18 FNPT Standard: 3A BVV™ 12" Tri-Clamp x (3) 2" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid - Drawing BVV™ 12" Tri-Clamp x (3) 2" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid - End Cap Chart

$295.00

-

12" Vacuum Chamber Digital Heat Pad

Chamber NOT Included, Sold Separately. Heat Pad must fit correct size of the chamber! Fits a 5 Gallon Chamber This Digital Heat Pad will adhere to the bottom of a chamber vessel with a peel and stick backing. This unit will hold a temperature within a degree to the set temperature (dependent on the environment and air movement). The temperature offset must be found to set the controller accurately. (See ‘Operation’ instructions in the operation manual) Included with this Digital Heat Pad: Instructions on how to operate and set parameters. Simple standoff bumpers (provide thermal separation between the vessel and the work surface) Thermal tape (best method to check and verify temperature) Specs: UL Listed Fahrenheit Digital Controller. Min Temp: Ambient + 5 Max Set Temp: 160°F Ultimate Max Temp: 248°F Voltage: 110VAC Only Power Consumption: 234-watt Digital Control: Increments of 1 Degree. Accuracy: +/- 0.2 Degrees Units: Degrees Fahrenheit Instructions: Fully included Relay Lifespan: Approx. 10 million cycles User can reprogram: Yes

$110.00

-

Beaker & Wrench 12" Wiped-Film

Beaker & Wrench 12" Wiped-Film Beaker & Wrench continues to be an industry leader, bringing together scientific expertise and real-world industry experience. Take the guess-work out of large scale distillation with their Wiped-Film Evaporation Turn-Key System. It arrives fully functional, meaning you can take advantage of the latest technology immediately and without additional installation or training costs. Other control processes can be subjective and vulnerable to user error, but their automated Wiped-Film Evaporation Turn-Key System will help maximize your product outcomes with greater productivity and maximum purity. 12” Wiped Film Measurements:76”[1.9m] x 30”[0.762m] x 85”[2.16m] Integrated 23″ Touch-Screen Control 200LFeed Tank ACS 100 60 CFMDry Screw Vacuum Pump Dual Stage Cold Trap-50/-100C Inlet and Outlet Gear Pumps(continuous flow) Single-Plug 240V Three-Phase to power the entire machine Six Zone Evaporator Body(1.1m² evaporative area) Consistency is Key Get greater consistency, purity, and confidence in every cannabis oil distillation when you use our system to monitor and optimize flow rate, temperature, pressure, and wiper speed (RPM) in real time. Then… NRTL Certified Each system is 6“ or 12” and constructed with fully compliant USA NRTL-certified components, including a display unit and two sensors to track the contents of both streams of fluid as it continuously travels through the glassware. Get started rapidly with… Set it and Forget it Fully continuous flow leaves behind less advanced methods with a dependable output of 15-30 liters per hour; maximizing efficiency and minimizing complications. Be assured of the quality of your system because we’re… Easy Installation Your system arrives ready to use immediately with all components primed for use. Just roll it off the lift gate and let it get to work. Meet demand and feel confident in the quality of your output with this turn-key system. Don’t make it complicated. Get it right. Lead time: 8-12 weeks from date of payment of 50% deposit, 50% due prior to shipping Specifications Skid Frame: + Dimensions (LxWxH): 76”[1.9m] x 30”[0.762m] x 85”[2.16m] + Weight:1,000 lbs [450Kg] + Material: Extruded Aluminum + 6” castors w/ brakes Shipping Information: + Dimensions (LxWxH): 82.5”[2.01m] x 36.5”[0.93m] x 87.5”[2.22m] + Total Weight: 1200 lbs [545Kg] Electrical Power Distribution Box: + Plug: SCAME SCM563P6W + Input Voltage: 240VAC 3 Phase with Neutral 60 Hz + External Circuit breaker: 60 amp + Nominal current: 24 amps Control Interface + Custom 27” high definition touch screen interface + automated controls + recipe folder +automated sensors and safeties +Error reporting +Software controlled Emergency shutdown Feed Tank: + Volume: 200 Liter + Material: 316 Stainless Steel + double jacketed + Max Temp: [95°C] + Heater: water jacket with 2500kW heater Feed Hose: + Length: 7’-0” [2.13m] + Voltage: 120VAC + Amps: 4.5 Amps + Max Temp: 450°F[220°C] + K-type sensor Rotor: + Wipers: PTFE (Polytetrafluoroethylene) + Mesh Baffles: 316 Stainless Steel + Motor Voltage: 240VAC + Motor Amps: 4(Max) + Motor Watts: 1kw (Continuous) + Speed: 0-400RPM + Dust and Splash Resistant Still Body / Wiped Film Evaporator: + Evaporation Surface Area: 1.1m² + Materials: 316 Stainless Steel + Heat Source: multi-zone Heat Band with independent thermocouples and control + Maximum Power: 12kWatts + Feed Inlet: KF25 + Top and Bottom Connections: 12” sanitary flange + Insulation jacket included Internal condenser: + multi-finger hairpin condenser + Materials: 316 Stainless Steel + Vacuum port: NW80 + Distillate port: KF25 + Residue port: 1.50” Tri-clamp + 2,500w heater + Cooling capacity 8,000w @80c Residue heater: 120VAC, 0.78 amp, 150°C Max Temp, K-type sensor 90W, UR Recognized Heat Pad Residue Outlet Conical shaped Mesh cleanable filter Dual heat pads Clog SensorLiquid level sensor Led lights Condenser Circulator: + Model: BWC-A120 + Bath Volume: ~12L + Bath Fluid: Beaker Kool + multi-fan & Radiator cooling system + Temperature range: 25 to 90°C + Temperature stability: ±1 °C + Heating capacity: 2.5 kW +Cooling capacity: 8kw @80c Gear Pumps: + Voltage: 48VDC + Amperage: 5A + Max Rate: 50.0 L/Hr + Heater: 120v, 0.5amp, 120°C Max Temp, K-type sensor + 45w, UL Recognized Heat Pad + Check Valve Included Dual Stage Cold Trap: + 2 stage cold trap optimized for maximum vacuum protection + Model: Huber TC100 & -100C + CC 508 -50C (1.5kw cooling @ 0c) + Temperature Range: -100 to 100°C Vacuum Gauge: + Model: KJ Lesker

$475,000.00

-

12" x (3) 2" x (2) 1/4 FNPT Endcap

12" x (3) 2" x (2) 1/4 FNPT Endcap This End Cap come with Two 1/4"-18 FNPT Threaded connection and Three 2" Tri-Clamp/ Tri Clover ferrule welded to the end cap with a sanitary weld with a 0.5" Tube Extension on center ferrule Below the Lid. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid and the 2" Tri-Clamp Connection. These 5 connections are welded on a 12" Tri-Clamp End Cap. Specifications Material: 304 Stainless Steel Connection Types: 2" Tri-Clamp - 0.5" Tube Extension on center ferrule Below Lid 12" Tri-Clamp 1/4" - 18 FNPT Standard: 3A BVV™ 12" x (3) 2" x (2) 1/4 FNPT Endcap - Drawing BVV™ 12" x (3) 2" x (2) 1/4 FNPT Endcap - End Cap Chart

$285.00

-

12" x (3) 2" x (2) 1/4 FNPT Endcap with Diptube

12" x (3) 2" x (2) 1/4 FNPT Endcap with diptube This End Cap come with a 11-5/16" long diptube, Two 1/4"-18 FNPT Threaded connection and Three 2" Tri-Clamp/ Tri Clover ferrule welded to the end cap with a sanitary weld with a 0.5" Tube Extension on center ferrule Below the Lid. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid and the 2" Tri-Clamp Connection. These 5 connections are welded on a 12" Tri-Clamp End Cap. Specification Material: 304 Stainless Steel Connection Type: 2" Tri-Clamp - 0.5" Tube Extension on center ferrule Below Lid 11-5/16" Diptube 12" Tri-Clamp 1/4" - 18 FNPT Standard: 3A

$305.00

-

12" x 12" Hemi Lid with Coil V2

12" x 12" Hemi Lid with Coil V2 This 12" Hemi Lid has a built in coil that can be used with a heated circulator to assist with internal temperature control during the recovery process. This hemi lid must be used with our 1200X12S and 1200FJS for proper fitment. PDF DRAWING

$475.00

-

12% Hydrogen Peroxide Food Grade H2O2

12% Food Grade Hydrogen Peroxide This is the highest concentration of hydrogen peroxide we offer. Our food-grade peroxide is clear, colorless, and free of any stabilizers or additives. Peroxide is one of the most effective oxidizers and may be applied to food directly to food products. Our peroxide is certified FCC (Food Chemical Codex). It has been tested and verified for its quality and purity. Our 12% food-grade hydrogen peroxide is 4x strength, when diluted you can make a remarkably large volume of 3% hydrogen peroxide that can be used for a wide variety of applications. Dilution: 1 part 12% H2O2 to 3 part distilled or R.O. water to make 3% Some applications include... Elevating Plant Growth: Diluted hydrogen peroxide supports healthy roots and elevated oxygen availability in the soil. Excellent Cleaner for Food Prep Environments: Hydrogen peroxide is a disinfectant, that kills viruses and various forms of bacteria. Bleaching: Diluted hydrogen peroxide is a mild bleaching agent that can be used to clean stains. Cleansing Fresh Produce: Diluted hydrogen peroxide can be used to clean fruits and vegetables. Mold and Mildew Removal: Hydrogen peroxides strong oxidative qualities breakdown mold and mildew with ease. How to Dilute 12% Hydrogen Peroxide to 3% Hydrogen Peroxide: 12% food-grade hydrogen peroxide Deionized distilled water A clean, empty Gallon bottle for the final 3% hydrogen peroxide solution Measuring cup Funnel Safety goggles Rubber gloves Apron or old clothes Steps to perform dilution: Wear safety goggles, rubber gloves, an apron or old clothing to protect yourself from spills and splashes. Choose a well-ventilated space. Mix 1 part 12% hydrogen peroxide with 3 parts distilled water. Example: Mix 1 cup hydrogen peroxide, with 3 cups of distilled water. This will make an exact 3% solution of hydrogen peroxide. What Is Hydrogen Peroxide? Hydrogen peroxide (H2O2) is a chemical compound composed of two hydrogen atoms and two oxygen atoms. It is a clear, colorless liquid with a slightly more viscous consistency than water. Hydrogen peroxide is commonly used for its powerful oxidizing properties and has a wide range of applications in various industries and household settings. What Are The Properties Of Hydrogen Peroxide? Hydrogen peroxide (H2O2) is a clear, colorless liquid with several notable properties: Chemical Formula: H2O2 - It consists of two hydrogen atoms (H) and two oxygen atoms (O) linked by a single covalent bond, as well as a second oxygen atom connected to one of the hydrogen atoms by a single covalent bond. Molecular Weight: Approximately 34.01 grams per mole. Physical State: Hydrogen peroxide is a liquid at room temperature and pressure (25°C or 77°F). Odor: It has a slightly sharp and distinctive odor. Solubility: Hydrogen peroxide is miscible (mixes completely) with water in all proportions. Density: The density of hydrogen peroxide varies with concentration. A common concentration of 3% hydrogen peroxide has a density of approximately 1.01 grams per milliliter (g/mL). Boiling Point: The boiling point of hydrogen peroxide is approximately 150.2°C (302.4°F). Melting Point: Pure hydrogen peroxide does not have a distinct melting point because it decomposes before reaching a stable liquid state at atmospheric pressure. Reactivity: Hydrogen peroxide is a powerful oxidizing agent and is highly reactive with various substances, including organic compounds and some metals. It readily decomposes into water and oxygen when exposed to heat, light, or certain catalysts. Concentration: Hydrogen peroxide is available in various concentrations, with common household solutions typically being around 3%. Higher concentrations, such as 30% or 35%, are used in industrial and laboratory applications. pH: The pH of hydrogen peroxide solutions varies with concentration but is typically slightly acidic. Stability: Hydrogen peroxide solutions are not indefinitely stable and can decompose over time, especially when exposed to light, heat, or contaminants. Storing hydrogen peroxide in a cool, dark place in a well-sealed container helps preserve its stability. Safety: Concentrated hydrogen peroxide solutions can be hazardous and should be handled with care. Contact with skin or eyes should be avoided, and protective equipment may be required when working with high-concentration solutions. These properties make hydrogen peroxide a versatile chemical with various applications in industries ranging from healthcare and cosmetics to water treatment and rocket propulsion. The concentration and handling precautions should be considered based on the specific use and requirements of the application. What Is Hydrogen Peroxide Used For? Hydrogen peroxide (H2O2) is used for a wide range of purposes in various industries and household settings due to its versatile properties. Some common uses of hydrogen peroxide include: Disinfectant and Antiseptic: Hydrogen peroxide is a common disinfectant and antiseptic agent. It is used to clean wounds, cuts, and minor injuries to prevent infection. In lower concentrations (typically 3%), it can be safely applied to the skin. Hair Bleaching and Dyeing: Many hair bleaching and hair dyeing products contain hydrogen peroxide as it can help break down the natural pigments in hair, lightening its color. Teeth Whitening: Hydrogen peroxide is used in some teeth whitening products and dental treatments to remove stains and discoloration from teeth. Cleaning Agent: It is used as a cleaning agent for surfaces, fabrics, and contact lenses due to its ability to break down and remove organic stains and deposits. Water Treatment: In water treatment processes, hydrogen peroxide can be used to remove contaminants, oxidize organic matter, and disinfect water supplies. Rocket Propellant: In the aerospace industry, highly concentrated hydrogen peroxide (usually around 90% purity) is used as a rocket propellant. Chemical Synthesis: Hydrogen peroxide is used in the synthesis of various chemicals and pharmaceuticals. Environmental Applications: It can be employed for soil and groundwater remediation, helping to break down pollutants and contaminants. Food Industry: In the food industry, hydrogen peroxide can be used for cleaning and disinfection of equipment and packaging materials. Cosmetics: It is used in some cosmetic and personal care products, such as hair dyes, hair bleaches, and skin creams. Textiles: Hydrogen peroxide is used in the textile industry to bleach fabrics and remove stains. Paper and Pulp Industry: It is used for bleaching paper pulp and improving the quality of paper products. Agriculture: In agriculture, hydrogen peroxide can be used as an oxygen source in soil, promoting plant growth. Medical and Laboratory Use: It is utilized for cleaning and sterilizing medical equipment and laboratory instruments. First Aid: Hydrogen peroxide is a household item for treating minor cuts and scrapes. The specific application and concentration of hydrogen peroxide used can vary depending on the intended purpose. Higher concentrations are typically used in industrial and chemical applications, while lower concentrations are common in household and personal care products. It's important to handle hydrogen peroxide with care, follow safety guidelines, and use the appropriate concentration for a given task. How Is Hydrogen Peroxide Produced? Hydrogen peroxide (H2O2) is typically produced through one of two main methods: the anthraquinone process and the direct synthesis process. Both processes involve the reaction of hydrogen and oxygen in the presence of a catalyst to form hydrogen peroxide. Here's an overview of these two methods: Anthraquinone Process: This is the most common method for commercial hydrogen peroxide production. It involves a series of chemical reactions that use anthraquinone derivatives as catalysts. The process typically consists of the following steps: Hydrogenation: Anthraquinone derivatives are hydrogenated with hydrogen gas (H2) to form hydroquinone derivatives. Autoxidation: The hydroquinone derivatives react with oxygen (O2) to form anthraquinone derivatives again, while producing hydrogen peroxide in the process. Extraction: The hydrogen peroxide is then extracted from the reaction mixture. Oxidation of Anthraquinone: The anthraquinone derivatives are oxidized back to their original form for reuse in the process. Direct Synthesis Process: In this method, hydrogen and oxygen are directly combined to produce hydrogen peroxide using a catalyst. The reaction typically occurs in a gas-phase reactor, and the process is often referred to as the "direct synthesis" or "hydrogenation-oxygenation" process. Common catalysts used in this process include palladium or platinum on a support material. While these are the main methods for hydrogen peroxide production, there are other less common methods as well. The choice of production method depends on factors such as the desired concentration of hydrogen peroxide, production scale, and cost considerations. It's worth noting that hydrogen peroxide is a sensitive compound and can decompose over time, especially when exposed to heat, light, or contaminants. Therefore, it requires careful handling and storage to maintain its stability and effectiveness. Does Hydrogen Peroxide Expire? Hydrogen peroxide can degrade over time and may lose its effectiveness, so it can be said to have a shelf life rather than a strict expiration date. The shelf life of hydrogen peroxide depends on several factors, including its concentration, exposure to light, temperature, and how well it's stored. Here are some general guidelines: Concentration: Higher concentrations of hydrogen peroxide (e.g., 30% or 35%) tend to be more stable and have a longer shelf life compared to lower concentrations (e.g., 3% or 6%). Exposure to Light: Hydrogen peroxide is light-sensitive, and exposure to ultraviolet (UV) light can accelerate its decomposition. It is typically sold in brown or opaque containers to protect it from light. Temperature: Storage at higher temperatures can also speed up the decomposition of hydrogen peroxide. It should be stored at a cool, dry place away from heat sources. Contaminants: Contaminants or impurities can catalyze the decomposition of hydrogen peroxide. It's essential to keep the container tightly sealed and free from any potential contaminants. Age: Hydrogen peroxide degrades slowly over time, even when stored correctly. The rate of degradation is higher for lower concentrations. To maximize the shelf life and potency of hydrogen peroxide, follow these recommendations: Store it in its original, tightly sealed container. Keep it in a cool, dark place away from direct sunlight and heat sources. Check the expiration date on the container, if available. If you're unsure about the potency of an old bottle of hydrogen peroxide, consider testing it on a small, non-critical area before using it for medical or cleaning purposes. It's important to note that even if hydrogen peroxide has degraded, it may still be useful for some applications, such as cleaning and disinfecting surfaces. However, for medical or first-aid use, it's best to use hydrogen peroxide that is within its recommended shelf life to ensure its effectiveness. Is Hydrogen Peroxide Safe As Mouthwash? Hydrogen peroxide can be used as a mouthwash, but it should be used with caution and in a diluted form. Here are some important considerations: Dilution: Never use undiluted hydrogen peroxide as a mouthwash. It's too concentrated at its full strength and can cause irritation, burning, and tissue damage. Instead, dilute it with water. A common recommendation is to use a 3% hydrogen peroxide solution, which is typically sold in drugstores. Frequency: Do not use hydrogen peroxide as a mouthwash too frequently. Using it daily or excessively can lead to oral issues, including irritation and disruption of the natural balance of oral bacteria. Duration: When using hydrogen peroxide as a mouthwash, swish it around your mouth for a brief period, typically about 30 seconds, and then spit it out. Do not swallow it. Rinse Thoroughly: After using hydrogen peroxide as a mouthwash, rinse your mouth thoroughly with water to remove any residual hydrogen peroxide. Avoid Ingestion: Do not swallow hydrogen peroxide, even when diluted. Swallowing hydrogen peroxide can lead to stomach upset and other health issues. Consultation: Before using hydrogen peroxide as a mouthwash, it's a good idea to consult with your dentist or oral healthcare provider. They can provide guidance on its safe and appropriate use based on your specific oral health needs. Hydrogen peroxide can help kill harmful bacteria in the mouth and may be used as a short-term remedy for issues like canker sores or minor gum irritations. However, it is not a substitute for regular oral hygiene practices such as brushing, flossing, and using a fluoride-based mouthwash. If you experience any adverse reactions, such as severe irritation, burning, or pain, discontinue use immediately and consult a healthcare professional. It's important to use hydrogen peroxide as a mouthwash cautiously and in accordance with recommended guidelines to avoid potential side effects or harm to oral tissues. What Are The Hazards Of Hydrogen Peroxide? Hydrogen peroxide, while commonly used for various purposes, can pose certain hazards if mishandled or used improperly. Here are some of the potential hazards associated with hydrogen peroxide: Irritation and Burns: Hydrogen peroxide is a strong oxidizing agent and can cause skin and eye irritation upon contact. In higher concentrations or with prolonged exposure, it can lead to chemical burns. Ingestion: Ingesting concentrated hydrogen peroxide can be harmful and even life-threatening. It can cause gastrointestinal irritation, stomach pain, vomiting, and, in severe cases, internal burns or damage. Inhalation: Inhalation of hydrogen peroxide vapors can irritate the respiratory tract, leading to coughing, shortness of breath, and throat irritation. Explosive Hazards: Concentrated hydrogen peroxide solutions can be sensitive to shock, heat, or contamination with organic materials. This can lead to the potential for explosions or fires if mishandled. Skin Sensitization: Prolonged or repeated contact with hydrogen peroxide can lead to skin sensitization, where the skin becomes more sensitive or allergic to the chemical. Environmental Impact: Hydrogen peroxide can be harmful to aquatic life and the environment if not properly disposed of. It should not be released into natural waterways. hydrogen peroxide, consider the following precautions: Dilution: When using hydrogen peroxide, dilute it to the appropriate concentration for the intended purpose. Most household hydrogen peroxide solutions are 3%, while higher concentrations are used for industrial or medical applications. Protective Equipment: When handling concentrated hydrogen peroxide, wear appropriate personal protective equipment, including gloves and safety goggles. Ventilation: Use hydrogen peroxide in well-ventilated areas to minimize inhalation risks. First Aid: In case of skin or eye contact, rinse immediately with plenty of water. If ingested, seek medical attention. Storage: Store hydrogen peroxide in a cool, dark place away from flammable materials and heat sources. Dispose Properly: Dispose of hydrogen peroxide in accordance with local regulations. Do not pour it down drains or release it into the environment. Always follow the safety guidelines and instructions provided on the product label or by the manufacturer. If you have specific concerns or questions about handling hydrogen peroxide for a particular application, it's advisable to consult with a safety professional or chemical expert for guidance. How Can I Use Hydrogen Peroxide Safely? Using hydrogen peroxide safely involves taking appropriate precautions to minimize the risk of accidents or harm. Here are some guidelines for safe handling and use of hydrogen peroxide: Read the Label: Always read and follow the instructions and safety precautions provided on the hydrogen peroxide product label. Different concentrations may have different recommended uses and safety guidelines. Personal Protective Equipment (PPE): Wear appropriate personal protective equipment, including safety goggles or a face shield to protect your eyes. Use gloves made of materials that are compatible with hydrogen peroxide, such as nitrile or latex gloves. Ventilation: Use hydrogen peroxide in a well-ventilated area to minimize exposure to vapors. If you're using it in a confined space, consider using a fume hood or working near an open window or door. Concentration: Ensure that you are using the correct concentration of hydrogen peroxide for your specific application. Most household hydrogen peroxide solutions are typically 3%, but higher concentrations are available for industrial or medical use. Dilution: When diluting concentrated hydrogen peroxide, always add the hydrogen peroxide to water, not the other way around. This helps prevent splattering and potential reactions. Avoid Contaminants: Keep hydrogen peroxide away from organic materials (e.g., paper, cloth) and flammable substances, as it can react with them and potentially cause fires or explosions. Avoid Mixing: Do not mix hydrogen peroxide with other chemicals unless you are following a specific recipe or procedure that requires it. Mixing hydrogen peroxide with certain substances can be dangerous. First Aid: In case of skin contact, immediately rinse the affected area with plenty of water. If hydrogen peroxide comes into contact with your eyes, flush them with water for at least 15 minutes and seek medical attention if irritation persists. If ingested, do not induce vomiting. Seek medical attention immediately. Storage: Store hydrogen peroxide in a cool, dark place, away from direct sunlight and heat sources. Keep the container tightly closed when not in use. Disposal: Dispose of hydrogen peroxide in accordance with local regulations. Do not pour it down drains or release it into the environment. Emergency Response: Have access to an emergency eyewash station and safety shower if you are working with concentrated hydrogen peroxide. Keep a spill kit and appropriate cleanup materials on hand in case of accidents. Training: Ensure that individuals handling hydrogen peroxide are trained in its safe use and understand the potential hazards. If you are unsure about how to use hydrogen peroxide safely for a specific application, consider seeking guidance from a safety professional or chemical expert. Always exercise caution and pr

$19.00 - $500.00

-

12.75" Vacuum Chamber Gasket

BVV™ 12.75" Vacuum Chamber Gasket This Gasket fits the following Vacuum Chamber Lids: Best Value Vacs 5 Gallon Aluminum Side Mount Vacuum and Degassing Chamber Best Value Vacs 5 Gallon Aluminum Vacuum and Degassing Chamber Glass Vac 5 Gallon Aluminum Vacuum Chamber

$38.00

-

120LB DIPTUBE Tank High Purity USA 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend - 99.5% Guaranteed

120LB High Purity USA 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend DIPTUBE - 99.5% Guaranteed Ultra-high purity 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend is USA-sourced and guaranteed to be 99.5% pure. This instrument grade solvent helps to produce a higher quality extract by reducing mystery oils and contaminants. The solvent comes in a DOT refillable LP tank. KEY BENEFITS: Free of any hydrogen Sulphide based Ethyl Mercaptan Odorants. This product is clean, colorless, and odorless. Tank has a diptube liquid withdraw. Sourced and Refined in USA. Actual Isobutane liquid weight is 114LB DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Ground Freight ONLY. BVV™ always recommends distillation of every solvent before use. Tank does not include CGA 555 fitting. Must be added through dropdown or bought separately. Actual liquid weight is 114LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser, you can call in to place an order. Permitted Sales Include the Following: Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for resale. ***Shipping Notes: Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground freight. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via UPS Ground Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers. Chemical Formula: C₄H₁₀ + C3H8 Molecular Weight: 58.12 g/mol & 44.10 g/mol CAS Registry Number: 106-97-8 & 74-98-6 & 75-28-5 Appearance Colorless Odor: Faint Petroleum Density N/A Boiling Point: N/A Solubility in water: Low Solubility GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220, H280 GHS Precautionary Statements P210, P377, P381, P403, P410+P403 UN Identification Number: 1965 Proper Shipping Name: Hydrocarbon Gas Mixture, liquefied, n.o.s. Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Tri-Blend Certificate of Conformance (COC) and Certificates of Analysis (COA's) Tri-Blend Safety Data Sheet (SDS)

$710.00 - $720.00

-

120LB DIPTUBE Tank High Purity USA 70/30% N-Butane/Propane Blend - 99.5% Guaranteed

120LB High Purity USA 70/30% N-Butane/Propane Blend DIPTUBE- 99.5% Guaranteed Ultra high purity 70/30% N-Butane/Propane is USA sourced, and guaranteed to be 99.5% pure. This instrument grade solvent helps to produce a higher quality extract by reducing mystery oils and contaminants. Solvent comes in a DOT refillable LP tank. KEY BENEFITS: Free of any hydrogen Sulphide based Ethyl Mercaptan Odorants. This product is clean, colorless, and odorless. Tank has a diptube liquid withdraw. Sourced and Refined in USA. Actual Isobutane liquid weight is 115LB DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Ground Freight ONLY. BVV™ always recommends distillation of every solvent before use. Tank does not include CGA 555 fitting. Must be added through dropdown or bought separately. Actual liquid weight is 115LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser, you can call in to place an order. Permitted Sales Include the Following: Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for resale. ***Shipping Notes: Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground freight. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via UPS Ground Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers. Chemical Formula: C₄H₁₀ + C3H8 Molecular Weight: 58.12 g/mol & 44.10 g/mol CAS Registry Number: 106-97-8 & 74-98-6 Appearance Colorless Odor: Faint Petroleum Density N/A Boiling Point: N/A Solubility in water: Low Solubility GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220, H280 GHS Precautionary Statements P210, P377, P381, P403, P410+P403 UN Identification Number: 1965 Proper Shipping Name: Hydrocarbon Gas Mixture, (Butane/Propane) liquefied, n.o.s. Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Dual Blend Certificate of Analysis (COA) Dual Blend Safety Data Sheet (SDS)

$710.00 - $720.00

-

120LB DIPTUBE Tank High Purity USA ISO-BUTANE R600A - 99.5% Guaranteed

120LB DIPTUBE Tank High Purity USA ISO-BUTANE R600A DIPTUBE- 99.5% Guaranteed This solvent is instrument-grade and helps produce a higher quality extract through the reduction of mystery oils and contaminants. This solvent is clean, odorless, and colorless, meaning there are zero hydrogen sulfide-based Ethyl Mercaptan odorants. It’ll arrive in a DOT refillable LP tank. KEY BENEFITS: Free of any hydrogen Sulphide based Ethyl Mercaptan Odorants. This product is clean, colorless, and odorless. Tank has a diptube liquid withdraw Sourced and Refined in USA. Actual Isobutane liquid weight is 116LB DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Ground Freight ONLY. BVV™ always recommends distillation of every solvent before use. Tank does not include CGA 555 fitting. Must be added through dropdown or bought separately. Actual liquid weight is 116LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser, you can call in to place an order. Permitted Sales Include the Following: Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for resale Typical Analysis: ISO-Butane >99.8% Methane <1 ppm Ethane <1ppm N-Butane <2000 ppm Propane <250ppm Isopentane <2 ppm Water <3 ppm CO+CO2 <5ppm Oxygen <5 ppm Nitrogen <10 ppm Sulfur Non-Detected ***Shipping Notes: Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground freight. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via UPS Ground Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers. Chemical Formula: C₄H₁₀ Molecular Weight: 58.12 g/mol CAS Registry Number: 75-28-5 Appearance Colorless Odor: Faint Petroleum Density 563 kg/m³ (or 0.563 g/mL) Boiling Point: 10°F (-12°C) Solubility in water: Low Solubility GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220 GHS Precautionary Statements P203, P210, P222, P280, P377, P381, and P403 UN Identification Number: 1969 Proper Shipping Name: Isobutane, liquefied Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Isobutane Certificate of Analysis (COA) Isobutane Safety Data Sheet (SDS)

$710.00 - $720.00

-

120LB DIPTUBE Tank High Purity USA N-BUTANE R600 - 99.5% Guaranteed