Products

-

The Press Club 1.75" x 4" ROSIN BAGS

ALL ROSIN BAG SIZES & ROSIN PRESSING ACCESSORIES PLATES: 3" x 5", 4" x 7", Press Light, Insulators ROSIN BAGS: 1.25" x 4", 1.5" x 4", 1.75" x 4", 2" x 4", 2.5” x 4.5”, 1.5" x 9", 2” x 9”, 2.5" x 9", 3” x 6”, 3" x 9", 3.5" x 9", 4" x 7", 4" x 12", 5" x 5", 2" Filter Tubes LIMITED EDITION: Round Rosin Bags, Tube Sock Rosin Bags, THCA Mechanical Separate Sheets, Resin Magnets FUNNELS: 1.25" Funnel, 1.5" Funnel, 2" Funnel, 2.5" Funnel (Coming Soon) DRY SIFT SCREENS: 24" x 12" x 1.25" (Individual / Sets Available) WASH WORK BAGS: 6" Cube, 12" Cube BUBBLE WASH BAGS: 5 Gallon Premium, 5 Gallon All-Mesh, 10 Gallon, 20 Gallon, 32 Gallon, 44 Gallon, 65 Gallon WASHING ACCESSORIES: XL Drying Screens, 0.5mm Collection Card, 5 Gallon Neoprene Insulator Wrap PARCHMENT PAPER: 5" x 5", 6" x 12", 8" x 16", 10" x 10", Roll PARCHMENT ALTERNATIVE: 5 x 5 PTFE Sheets, PTFE Roll PRE-PRESS MOLDS: Pollen Press, 2" x 4", 2" x 9", 2.5" x 2.5", 2.5" x 4.5", 2.5" x 9", 3" x 5", 3" x 9", 4" x 4", 4" x 7" COLLECT: Large Rosin Stamp, 6" Cold Plate, Glass Dab Tool Kit STORAGE: 5 x 5 FEP Sheets, Self Vacuum Cure Jars, Hydro Stones ACCESSORIES: Magnets, Trash Bin Organizer, ISO Station, Terp Pearls, Stickers, T-Shirt

$12.95 - $59.95

-

Neocision 1.9CF BVV Neocision ETL Lab Certified Vacuum Oven

1.9CF BVV™ Neocision Certified Lab Vacuum Oven - 5 Wall Heating, LED's, 11 Shelves Standard - 3 Year Warranty Disclaimer This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! Backed by our 3 Year Parts and Labor Warranty. Introduction Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. Performance Capabilities At BVV™, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Range: Room Temp+18°F to 212°F Temperature Uniformity: within 5% of the temperature setpoint. Heat-Up Time: 45 minutes to preheat. Optimal saturation reached in 120 minutes, over 30 minutes faster than competitors. Ultimate Vacuum: <500 µmHg / mTorr / micron Time to Vacuum: 4 minutes to 29"Hg using our VE Series 4cfm Dual Stage Vacuum Pump. Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. Technical Data Electrical Voltage 120V Frequency 60Hz Power 650W Current 10A Plug IEC C13 (unit ships with detachable NEMA 5-15p cable) Internal Chamber Heating Superior 5 Wall Heating (left, right, top, bottom, rear) Chamber Material Stainless Steel Dimensions (LxWxH) 14.5" x 16" x 13.5" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 11 Slide-in Shelves Shelf Dimensions (LxW) 13" x 15" Shelf Capacity 195 in2 Total Shelf Capacity 2145 in2 / 14.9 ft2 Safety Seal Silicone on Tempered Glass Window Dimensions (LxH) 15.25" x 12.75" Lights 4 strips of LEDs provide clear, bright view of the interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 28.5" x 23" x 22" Weight 160 lbs Support Heavy Duty Casters and Adjustable Leveling Feet Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connections Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose and adjusting wrenches. User Manual Included Vacuum Pump Sold Separately. Recommended Pump VE Series 4cfm Dual Stage Vacuum Pump Warranty 3 Years Capacity and Throughput Planning Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122 Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 *Candy Drying with a BVV Vacuum Oven Recipe Guide Note: This item is a freight ship item and will ship Via Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise Ground Freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$1,975.00

-

1.9CF Neocision Lab Certified Vacuum Oven and V4D 4CFM 2 Stage Pump Kit

1.9CF Neocision Lab Certified Vacuum Oven and V4D Series Pump Kit DISCLAIMER This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! INTRODUCTION Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. PERFORMANCE CAPABILITIES At BVV™, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Range: Room Temp+18°F to 212°F Temperature Uniformity: within 5% of the temperature setpoint. Heat-Up Time: 45 minutes to preheat. Optimal saturation reached in 120 minutes, over 30 minutes faster than competitors. Ultimate Vacuum: <500 µmHg / mTorr / micron Time to Vacuum: 4 minutes to 29"Hg. Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. SPECIFICATIONS Electrical Voltage 120V Frequency 60HZ Power 650W Current 10A Plug IEC C13 (unit ships with detachable NEMA 5-15p cable) Internal Chamber Heating Superior 5 Wall Heating (left, right, top, bottom, rear) Temperature Range RT+18°-212°F Chamber Material Stainless Steel Dimensions (LxWxH) 14.5" x 16" x 13.5" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 11 Slide-in Shelves Shelf Dimensions (LxW) 13" x 15" Shelf Capacity 195 in2 Total Shelf Capacity 2145 in2/ 14.9 ft2 Door Seal Silicone on Tempered Glass Window Dimensions (LxH) 15.25" x 12.75" Lights 4 strips of LEDs provide clear, bright view of interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 28.5" x 23" x 22" Weight 160 lbs Support Heavy Duty Casters and Adjustable Leveling Feet Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connection Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose and adjusting wrenches. User Manual Included Warranty 3 year oven warranty Vacuum Pump BVV™ V4D 4CFM Two Stage Vacuum Pump CAPACITY AND THROUGHPUT PLANNING Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise Ground Freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$2,330.00

-

SSP Corporation 1/2 in. Tube Fitting x 1/4-18 MNPT, 316 SS

Body Material 316 SS Connection 1 - Type Tube Fitting Connection 1 - Size 1/2 in Connection 2 - Type Male National Pipe Thread Connection 2 - Size 1/4-18 Brand Series Duolok Shape Elbow End Connections TF x MNPT Production Category 1 End Connection Type Duolok Tube End by Male National Pipe Thread

$25.00 $15.00

-

1/2" 37 Degree JIC Braided Stainless Steel Hose

1/2" 37° JIC Braided Stainless Steel Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have female JIC swivel on each end and they DO NOT require Teflon tape to create a seal and they should always be tightened and untightened using 2 wrenches. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 1/2" 37° Female JIC Swivel (3/4-16) Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65° to 450°F Pressure Rating 1500 PSI Chemical Resistance Excellent Max Bend Radius 5-1/2"

$61.00 - $160.00

-

1/2" Clear Reinfornced PVC Tubing

1/2" Clear Reinforced PVC Tubing Crystal clear Phthalate, BPA Free PVC compound, formulated with ingredients in compliance with applicable ratings: NSF-51 Certified USP Class VI Rated Compound, FDA Ingredients, Self-Extinguishing and Reinforced with braided polyester yarn. Key Features: Constructed with Phthalate Free compounds. NSF-51 certified material. Crystal clear - allows visual confirmation of product flow. Longitudinally reinforced to reduce elongation under pressure. Lightweight. Self-extinguishing. Non-marking. Silicone-free. Non-conductive. One-piece lengths. Resistant to chemicals (see chemical-resistance chart). Compound hardness 80A Phthalate Free! Common Applications: Food & beverage. Agriculture Drain Line Hose/Tubing Bundling Industrial Air and Water Hose Light Vacuum Liquid and Powder Transfer Medical and Pharmaceutical Sight Gauge Water Lines

$14.00 - $58.00

-

1/2" Compression Gauge

Glycerin Filled Gauge with 1/2" Compression Base - (-30)-1000 PSI Glycerin filled compound gauge has a 1/2" Compression stainless steel connection with a readout of (-30)-1000 PSI. Use a compound gauge when measuring a system that is pushing both positive and negative pressure on the gauge.

$35.00

-

1/2" FNPT End Caps

1/2" FNPT End Caps These End Caps come with a 1/2"-14 FNPT Threaded connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/2" port on a Tri-Clamp/ Tri Clover lid. These 1/2" FNPT endcaps also provide the user with a larger diameter for gases or flow of liquid which can greatly increase run times for an extraction system. Specifications Material: 304 Stainless Steel Standard: 3A High Polish Connection Type(s): Tri-Clamp 1/2" - 14 FNPT Sizes Available: 1.5" 2" 3" 4" 6" BVV™ 1/2" FNPT End Caps - Drawing BVV™ 1/2" FNPT End Caps - End Cap Chart

$30.00 - $180.00

-

1/2" Fractional Tube Fitting Hose

1/2" Fractional Tube Fitting Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have a tube stub on each end that fits a standard compression fitting. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 1/2" Tube Stub Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65°F to 450°F (-54°C - 232°C) Pressure Rating 1500 PSI Chemical Resistance Excellent Max Bend Radius 5 1/2"

$75.00 - $130.00

-

1/2" Gum Rubber Tubing for Vacuum

1/2" Gum Rubber Tubing Pure gum rubber tubing is ideal for vacuum applications and will not collapse under a vacuum like other soft/low durometer tubing on the market. Please refer to this chemical compatibility chart: Cole-Parmer Chemical Compatibility - Natural Rubber Key Features: Tear Resistant Retains Memory Safely conducts many acids, chemicals, and gases Resistant to cold and hot temperature variations Very versatile Flexible and soft Developed especially for mechanical vacuum pumps Specifications Hardness Rating Soft Hardness Durometer 45A Material Gum Rubber ID 1/2" OD 1-1/8" Wall Thickness 5/16" Flexibility Very Flexible Temperature Range -70° to 180°F Maximum Vacuum 29 in. of Hg @ 72°F Compatible Tube Fittings Barbed Connections Color Beige

$96.00 - $680.00

-

Insulon 1/2" Insulon Vacuum Jacketed Hose, Low Pressure

1/2" Insulon Vacuum Jacketed Hose, Low Pressure Technical Specifications: Hose Size 1/2” ID DN (ISO 10380) 12 Product Category LP (Low Pressure) Inner Hose ID 0.472” Tube Stub OD 0.500” Tube Stub Thickness 0.035” Outer Hose OD 1.27” Static Bend Radius 3.33” Dynamic Bend Radius 10.24” Lengths 2 – 20’ Operating Temperature -270°C to 900°C (-454°F to 1652°F) Material 316L stainless steel Maximum Allowable Working Pressure (MAWP) by Temperature: Product Category Hose Size Max Temperature (C) Max Temperature (F) MAWP (PSI) Low Pressure (LP) 1/2" ID 21 70 72 Low Pressure (LP) 1/2" ID 66 150 67 Low Pressure (LP) 1/2" ID 93 200 64 Low Pressure (LP) 1/2" ID 121 250 62 Low Pressure (LP) 1/2" ID 149 300 60 Low Pressure (LP) 1/2" ID 166 330 58 Low Pressure (LP) 1/2" ID 204 400 56 Low Pressure (LP) 1/2" ID 232 450 56 Low Pressure (LP) 1/2" ID 260 500 55 Low Pressure (LP) 1/2" ID 316 600 55 Low Pressure (LP) 1/2" ID 371 700 55 Low Pressure (LP) 1/2" ID 427 800 54 Low Pressure (LP) 1/2" ID 482 900 53 Low Pressure (LP) 1/2" ID 538 1000 53 Low Pressure (LP) 1/2" ID 593 1100 48 Low Pressure (LP) 1/2" ID 649 1200 44 Low Pressure (LP) 1/2" ID 704 1300 40 Low Pressure (LP) 1/2" ID 760 1400 35 Low Pressure (LP) 1/2" ID 816 1500 28 Low Pressure (LP) 1/2" ID 899 1650 18

$260.00 - $1,172.00

-

1/2" MNPT x Tri-Clamp End Caps

1/2" MNPT End Caps These End Caps come with a 1/2"-14 MNPT Threaded connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/2" port on a Tri-Clamp/ Tri Clover lid. These 1/2" MNPT endcaps also provide the user with a larger diameter for gases or flow of liquid which can greatly increase run times for an extraction system. Specifications Material: 304 Stainless Steel Standard: 3A High Polish Connection Type(s): Tri-Clamp 1/2" - 14 MNPT Sizes Available: 1.5" 2" 3" 4" 6"

$30.00 - $83.00

-

1/2" x 0.035 wall 316SS Hard Line Tubing 5FT

1/2" 316SS Hard Line Tubing 5FT Stainless Steel 316 Hard line tubing for compression fitting connections and systems. Specifications Length 5' Material 316 Stainless Steel ASTM A-269 Max Allowed Working Pressure (PSIG) 1/2" x .035 2339

$130.00

-

1/2" x 1/8" Wall - Heavy Duty Silicone Tubing For Flow

Silicone Tubing (**Note: This tubing is only for flow and is NOT vacuum rated) The most outstanding properties of silicone tubing are its flexibility and resistance to temperature extremes. These, plus its good electrical properties and ability to self-extinguish, make silicone tubing an excellent choice for appliances and computers Peroxide-cured silicone contains no sulfur or other acid-producing chemicals, thereby eliminating the possibility of staining, corroding, or deteriorating materials it contacts. It is extremely resistant to ozone and U.V. over long time periods. Care is recommended in the selection of fittings and clamps for silicone as sharply barbed fittings or unlined metal clamps could tear into the tubing wall and possibly cause a failure. silicone may be low-pressure steam sterilized in-line or autoclaved at up to 250°F in a normal autoclaving cycle. However, if exposed to repeated steam sterilization or long-term high temperature or pressure, silicone will eventually relax and become gummy. It should then be replaced. Please call or email BVV to request different sizes and thickness (1/16" to 3/4"ID) - Colors for industrial applications are available through minimum order. Key Features: Made from FDA-sanctioned ingredients Able to resist extreme temperature variation: -100°F to 500°F Translucent natural color for visual contact with the flow resilient, stretchable, and resistance to compression set Odorless, tasteless and inert Good electrical and weatherability properties - resists U.V., ozone, gases, and moisture Certified by the National Sanitation Foundation (NSF-51) for food equipment materials MADE IN THE U.S.A. Specifications/Physical Properties Hardness, Shor A +/-5 50 Tensile Strength, PSI 1100 Elongation at Break % 375 Brittle Temperature °F -100 Max Operating Temperature °F 500 Max Operating Temperature for NSF °F 350 Comp. Set 22 Hrs. at 177°F, % 35 Tear Resistance (PPI minimum) 100 Tubing Specifications Chart ID (IN.) OD (IN.) STANDARD LENGTH WORKING PSI @ 70°F BURST PSI @ 70°F LBS PER 100FT 1/16 1/8 100 10 30 0.50 1/16 3/16 100 20 60 1.34 3/32 5/32 100 10 30 0.66 3/32 7/32 100 15 45 1.58 1/8 3/16 100 10 30 0.88 1/8 1/4 100 20 60 2.00 1/8 5/16 100 25 75 3.32 1/8 3/8 100 28 84 4.92 5/32 9/32 100 20 60 2.14 5/32 11/32 100 20 60 3.64 3/16 1/4 100 5 15 1.22 3/16 5/16 100 20 60 2.64 3/16 3/8 100 20 60 4.12 3/16 7/16 100 15 45 6.14 1/4 5/16 100 10 30 1.50 1/4 3/8 100 5 15 3.34 1/4 7/16 100 20 60 5.12 1/4 1/2 100 15 45 7.50 5/16 7/16 100 10 30 3.66 5/16 1/2 100 10 30 6.30 3/8 1/2 100 10 30 4.32 3/8 9/16 100 10 30 7.15 3/8 5/8 100 10 30 10.16 3/8 3/4 100 15 45 16.72 7/16 5/8 100 10 30 7.70 1/2 5/8 100 5 15 5.84 1/2 11/16 100 5 15 9.50 1/2 3/4 100 10 30 13.12 1/2 7/8 100 10 30 15.00 5/8 3/4 100 5 15 6.86 5/8 13/16 100 5 15 11.34 5/8 7/8 100 5 15 13.38 5/8 1 100 10 30 22.86 3/4 1 50 5 15 17.64 3/4 1-1/8 50 10 30 26.56

$45.00 - $360.00

-

1/4" 316SS Hard Line Tubing 5FT

1/4" 316SS Hard Line Tubing 5FT Stainless Steel 316 Hard line tubing for compression fitting connections and systems. Specifications Length 5' Material 316 Stainless Steel ASTM A-269 Max Allowed Working Pressure (PSIG) 1/4" x .035 5100 1/4" x .049 7500 1/4" x .065 10300 3/8" x .035 3300 3/8" x .049 4800 3/8" x .065 6550

$50.00 - $60.00

-

1/4" 37 Degree Female JIC Braided Stainless Steel Hose

1/4" 37° Female JIC Stainless Steel PTFE Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have female JIC swivel on each end and they DO NOT require Teflon tape to create a seal and they should always be tightened and untightened using 2 wrenches. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 1/4" 37° Female JIC Swivel (7/16-20 Thread) Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -94°F to 500°F (-70°C - 260°C) Pressure Rating 2100 PSI Chemical Resistance Excellent Max Bend Radius 3"

$40.00 - $110.00

-

SSP Corporation 1/4" Cap

SSP Instrumentation Duolok® tube fittings are designed, manufactured and quality controlled to be totally “interchangeable” with the Swagelok® brand of tube fittings. Component by component examination plainly shows the two brands as completely “componentintermixable.” The precision manufacturing of both products to stringent tolerances under rigid quality control procedures ensures the safety, performance and reliability of service whenever Duolok® and Swagelok® component parts are mixed and used in accordance with published installation and service recommendations. Specifications Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Duolok Pressure Rating = Tubing Rating SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA! Dimensions A 0.92 in C 0.70 in D 0.60 in G 9/16 in H 1/2 in T 1/4 in B 0.63 in

$5.00 $2.00

-

Parker 1/4" Female NPT Parker Quick Disconnect - BODY

1/4" Female NPT Parker Quick Disconnect - BODY 60 Series Couplers (hydraulic, fluids, gas, steam) up to 5000 psi, connect with ISO 7241 seriesB, 60 Series Nipples. Parker's 60 Series bave double shut-off poppet valves and are interchangeable with other quick disconnects complying with ISO Series B. These general purpose quick couplings are available in a wide range of sizes and materials to be versatile for use with several fluids, including high temperature steam. Parker's 60 Series is multi-purpose for a vareity of applications and pressures up to 5000 PSI. Steam version couplers are brass with double interface O-rings and stainless steel locking balls. Seal material is Ethylene Propylene and 3/8"" size has a grip-ring sleeve for easy operation when wearing gloves Technical Specifications: Maximum Working Pressure (PSI) 5000 Maximum Working Pressure (BAR) 340 Flow Rate (GPM) 3 Flow Rate (LPM) 11 Media Hydraulic Industry Standards ISO 7241-1, Series B Coupling Half Coupler Minimum Working Temperature (F) -40 Minimum Working Temperature (C) -40 Maximum Working Temperature (F) 250 Maximum Working Temperature (C) 121 Valve Style Poppet Sleeve Type Manual Sleeve Locking Mechanism Locking Balls Vacuum Rating (INCH of HG) 27.4 Vacuum Rating (BAR) -0.9 Thread Style Female Technical Characteristics Sizes: 1/8" - 2-1/2" Materials: Steel, Brass, 303 Stainless Steel, 316 Stainless Steel Port Ends: Female NPTF, Female ORB Seal Options: Coupler Options include: Markets Industrial Construction Chemical Processing Commercial Cleaning Agriculture Features/Benefits: Globally interchangeable with other manufacturer's couplings complying to ISO 7241 series B Multi-purpose coupling, widely used in varied applicationsSteel couplers have a hardened sleeve for strength and durability Metal valve stop prevents flow checking to provide steady performance Steam version couplers have Ethylene Propylene seals to withstand high temperatures and the 3/8"" has a grip-ring sleeve for easy operation when wearing gloves. Brass couplers have double O-rings for redundant sealing and stainless steel locking balls for corrosion resistance 316 Stainless Steel couplers have Flourocarbon seals for checmical compatibility Optional coupler sleeve lock helps to prevent accidental disconnection Applications Industrial hydraulic lines Food and chemical processing Water and coolant lines High pressure fluid transfer High temperature fluid transfer Mobile equipment Cleaning equipment Dry cleaning Steam Systems

$115.00

-

Parker 1/4" Female NPT Parker Quick Disconnect - STEM

1/4" Female NPT Parker Quick Disconnect - STEM 60 Series Nipples ( hydraulic, fluids, gas, steam up to 5000 PSI, connect with ISO 7241 series B, 60 Series Couplers. Parker's 60 Series have double shut-off poppet valves and are interchangeable with other quick disonnects and complying with ISO 7241 series B. These general purpose quick couplings are available in a wide range of sizes and materials to be versatile for use with several fluids, influding high temperature steam. Parker's 60 Series is multi-purpose for a variety of applications and pressures up to 5000 PSI. Technical Characteristics: Sizes: 1/8" - 2-1/2" Materials: Steel, Brass, 303 Stainless Steel, 316 Stainless Steel Port Ends: Female NPTF, Female ORB Seal Options: Nitrile, EPR, Flourocarbon, Neoprene Coupler Options include: Sleeve Lock, Valve Actuater, Steam Compatibility Markets: Industrial Construction Chemical Processing Commercial Cleaning Agriculture Features/Benefits: Globally interchangeable with other manufacturer's couplings complying to ISO 7241 series B Multi-purpose coupling, widely used in varied applications Steel nipples have a hardened body for strength and durability Metal valve stop prevents flow checking to provide steady performance Steam version couplers have Ethylene Propylene seals to withstand high temperatures and the 3/8"" has a grip-ring sleeve for easy operation when wearing gloves. Metal valve stop prevents flow checking to provide steady performance Nipple options include high temperature steam compatibility Applications: Industrial hydraulic lines Food and chemical processing Water and coolant lines High pressure fluid transfer High temperature fluid transfer Mobile equipment Cleaning equipment Dry cleaning Steam and some gases Technical Specifications: Maximum Working Pressure (PSI) 5000 Maximum Working Pressure (BAR) 340 Flow Rate (GPM) 3 Flow Rate (LPM) 11 Media Hydraulic Industry Standards ISO 7241-1, Series B Coupling Half Nipple Minimum Working Temperature (F) -40 Minimum Working Temperature (C) -40 Maximum Working Temperature (F) 250 Maximum Working Temperature (C) 121 Valve Style Poppet Sleeve Type Manual Sleeve Locking Mechanism Locking Balls Vacuum Rating (INCH of HG) 27.4 Vacuum Rating (BAR) -0.9 Thread Style Female Plating N/A Valve Material 303 Stainless Ball Material Stainless steel

$58.00

-

1/4" FNPT End Caps

1/4" FNPT End Caps These End Caps come with a 1/4"-18 FNPT Threaded connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp/ Tri Clover lid Specifications Material 304 Stainless Steel Connection Type: Tri-Clamp 1/4" - 18 FNPT Standard: 3A Sizes Available: 1.5" 2" 3" 4" 6" BVV™ Solid 1/4" FNPT End Caps - Drawing BVV™ Solid 1/4" FNPT End Caps - End Cap Chart

$19.00 - $78.00

-

1/4" Fractional Tube Fitting Hose

1/4" Fractional Tube Fitting Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have a tube stub on each end that fits a standard compression fitting. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 1/4" Tube Stub Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65°F to 450°F (-54°C - 232°C) Pressure Rating 2100 PSI Chemical Resistance Excellent Max Bend Radius 3"

$49.00 - $77.00

-

1/4" Gum Rubber Tubing for Vacuum

1/4" Gum Rubber Tubing Pure gum rubber tubing is tear-resistant, ideal for vacuum applications and will not collapse under a vacuum-like other soft/low durometer tubing on the market. Please refer to this chemical compatibility chart: Cole-Parmer Chemical Compatibility - Natural Rubber Key Features: Tear Resistant Retains Memory Safely conducts many acids, chemicals, and gases Resistant to cold and hot temperature variations Very versatile Flexible and soft Developed especially for mechanical vacuum pumps Specifications Hardness Rating Soft Hardness Durometer 45A Material Gum Rubber ID 1/4" OD 3/4" Wall Thickness 1/4" Flexibility Very Flexible Temperature Range -70° to 180°F Maximum Vacuum 29 in. of Hg @ 72°F Compatible Tube Fittings Barbed Connections Color Beige

$45.00 - $420.00

-

1/4" ID 3/8" OD Clear PVC Tubing

1/4" ID 3/8" OD Clear PVC Tubing Features: High gloss crystal clear appearance with glass smooth interior to reduce sediment buildup Blue tint to enhance clarity NSF-51 certified material Self-extinguishing Compound hardness 73 ±3 Shore "A" Phthalate Free! Applications: Tubing for laboratories Water distillation lines Deionized water systems Air conditioning drainage Refrigeration drainage Air lines Bottling plants Beverage dispensing units Ice making machines Printing press equipment High efficiency furnace drainage Transfer of weak chemicals and acids Temperature Range: 25 ºF (-4 ºC) to 150 ºF (65 ºC) Specifications: Nominal ID: 1/4 in6.4 mm Nominal OD: 3/8 in9.5 mm Nominal Wall: 1/16 in1.6 mm Working Pressure @ 70F: 55 psi

$5.50 - $51.00

-

Kuri Tec 1/4" ID Heavy Wall Spiral Wire Reinforced Clear PVC Vacuum Hose

1/4" Reinforced Clear PVC Vacuum Hose Crystal clear Phthalate Free PVC compound, formulated with ingredients in compliance with applicable FDA(03) requirements, meets USDA(18), 3A(01), NSF(13) and RoHS(16) criteria. This hose is reinforced with helically-wound spring steel wire to prevent it from collapsing under a vacuum and prevent kinking or deformation of the tubing. Key Features: Vacuum Rated to 29.9" HG @ 70°F Spiral wire reinforcement prevents kinking or collapsing and prevent expansion under higher pressure applications Crystal clear tubing allows visual confirmation of product flow Glass smooth interior prevents build-up of material inside the tubing Electrogalvanized helical steel wire can be used for static dissipation. (This product is designed to dissipate static electricity when the metal wire is properly connected to ground through the fitting or other means Resistant to wide range of chemicals Self extinguishing Non-marking Silicone Free One-piece lengths Common Applications: Full Vacuum Lines Industrial Vacuum Pumps Food and beverage dispensing Air and water supply lines Pneumatic parts transfer Car wash applications Coolant lines Air breathing lines Deionized water systems Specifications Series K1760 Sized Code 04 Service Temperature Range 25 to 150°F (-4 to 65°C) Nominal ID 1/4" (6.4mm) Nominal OD 0.460" (11.7mm) Max Working Pressure @ 70°F (20°C) 150 Psi Max Working Pressure @ 122°F (50°C) 70 Psi Standard Length Coils 100ft Approx. Wt. per Pkg. 7.0lb Brand Kuri Tec® Packaging Coils Material NSF-51 Applications / Materials Conveyed Air and Water supply lines Air breathing lines Car Wash Applications Coolant Lines Deionized Water Systems Food & Beverage dispensing Full Vacuum Lines Industrial Vacuum Lines Pneumatic Parts Transfer Min. Bend Radius @ 70°F 1" Type Reinforced Water Supply and Food Grade Hose Style Standard Wall PVC Food and Beverage Vacuum/Transfer Hose Inside Tube Material Crystal Clear Phthalate Free PVC Compound Cover Material Crystal Clear Phthalate Free PVC Compound Reinforcement Material Helically-wound spring steel wire Color Crystal Clear Medium Temperature(Min) 25°F (-4°C) Medium Temperature(Max) 150°F (65°C) Weight per Foot 0.07lbs/ft Performance Clear PVC wire reinforced for vacuum; Kink Resistant

$19.00 - $208.00

-

Insulon 1/4" Insulon Vacuum Jacketed Hose, Low Pressure

1/4" Insulon Vacuum Jacketed Hose, Low Pressure Due to vendor policies, any of these Insulon Vacuum Jacketed Hoses are final sale, non-returnable, and non-refundable. Technical Specifications: Hose Size 1/4" ID DN (ISO 10380) 6 Product Category LP (Low Pressure) Inner Hose ID 0.236” Tube Stub OD 0.250” Tube Stub Thickness 0.035” Outer Hose OD 1.05” Static Bend Radius 2.65” Dynamic Bend Radius 8.86” Lengths 2 – 20’ Operating Temperature -270°C to 900°C (-454°F to 1652°F) Material 316L stainless steel Maximum Allowable Working Pressure (MAWP) by Temperature: Product Category Hose Size Max Temperature (C) Max Temperature (F) MAWP (PSI) Low Pressure (LP) 1/4" ID 21 70 72 Low Pressure (LP) 1/4" ID 66 150 67 Low Pressure (LP) 1/4" ID 93 200 64 Low Pressure (LP) 1/4" ID 121 250 62 Low Pressure (LP) 1/4" ID 149 300 60 Low Pressure (LP) 1/4" ID 166 330 58 Low Pressure (LP) 1/4" ID 204 400 56 Low Pressure (LP) 1/4" ID 232 450 56 Low Pressure (LP) 1/4" ID 260 500 55 Low Pressure (LP) 1/4" ID 316 600 55 Low Pressure (LP) 1/4" ID 371 700 55 Low Pressure (LP) 1/4" ID 427 800 54 Low Pressure (LP) 1/4" ID 482 900 53 Low Pressure (LP) 1/4" ID 538 1000 53 Low Pressure (LP) 1/4" ID 593 1100 48 Low Pressure (LP) 1/4" ID 649 1200 44 Low Pressure (LP) 1/4" ID 704 1300 40 Low Pressure (LP) 1/4" ID 760 1400 35 Low Pressure (LP) 1/4" ID 816 1500 28 Low Pressure (LP) 1/4" ID 899 1650 18

$240.00 - $1,008.00

-

1/4" Manual Shut-Off Ball Valve

1/4" Female Swivel x 1/4" Male Swivel Valve BVV™ brand Female Brass Swivel valve with a 1/4" Female SAE swivel end with O-ring and 1/4" Male SAE end connect to FJIC or HVAC hoses.

$13.00

-

1/4" MNPT x 1/4" FNPT Stainless Steel Miniature Butterfly Handle Ball Valve -20 to 230C

1/4" MNPT x 1/4" FNPT Stainless Steel Miniature Butterfly Handle Ball Valve This 316 Stainless Steel Miniature Ball Valve features a stainless steel ball and Modified PTFE (Dyneon™ TFM1600) seats and packing on the inside. It has an overall length of 2-3/4" and has a 1/4 turn butterfly style valve. Technical Data Sheet Pressure Tested in compliance with API 598 Ninth Edition 2009: Sec.5 and Sec.6 Specification Standard: ASTM A351 Stem: 316 Stainless Steel Seat: PTFE Temperature Rating: -20C - 230C Pressure Rating: 1000 PSI (W.O.G. Water, Oil, Gas) Body: Cast 316 / CF8M Stainless Steel Cap: Cast 316 / CF8M Stainless Steel Ball Cast 316 / CF8M Stainless Steel Heat Treatment: Solutiom Annealed 1050-1100C Stem Packing: PTFE Thrust Washer: PTFE

$42.00

-

1/4" x 1/8" Wall - Heavy Duty Silicone Tubing For Flow

SILCON® Silicone Tubing (**Note: This tubing is only for flow and is NOT vacuum rated) The most outstanding properties of SILCON tubing are its flexibility and resistance to temperature extremes. These, plus its good electrical properties and ability to self-extinguish, make SILCON tubing an excellent choice for appliances and computers Peroxide-cured SILCON contains no sulfur or other acid-producing chemicals, thereby eliminating the possibility of staining, corroding, or deteriorating materials it contacts. It is extremely resistant to ozone and U.V. over long time periods. Care is recommended in the selection of fittings and clamps for SILCON as sharply barbed fittings or unlined metal clamps could tear into the tubing wall and possibly cause a failure. SILCON may be low-pressure steam sterilized in-line or autoclaved at up to 250°F in a normal autoclaving cycle. However, if exposed to repeated steam sterilization or long-term high temperature or pressure, silicone will eventually relax and become gummy. It should then be replaced. Please call or email Best Value Vacs to request different sizes and thickness (1/16" to 3/4"ID) - Colors for industrial applications are available through minimum order. Key Features: Made from FDA-sanctioned ingredients Able to resist extreme temperature variation: -100°F to 500°F Translucent natural color for visual contact with the flow resilient, stretchable, and resistance to compression set Odorless, tasteless and inert Good electrical and weatherability properties - resists U.V., ozone, gases, and moisture Certified by the National Sanitation Foundation (NSF-51) for food equipment materials MADE IN THE U.S.A. Specifications/Physical Properties Hardness, Shor A +/-5 50 Tensile Strength, PSI 1100 Elongation at Break % 375 Brittle Temperature °F -100 Max Operating Temperature °F 500 Max Operating Temperature for NSF °F 350 Comp. Set 22 Hrs. at 177°F, % 35 Tear Resistance (PPI minimum) 100 Tubing Specifications Chart ID (IN.) OD (IN.) STANDARD LENGTH WORKING PSI @ 70°F BURST PSI @ 70°F LBS PER 100FT 1/16 1/8 100 10 30 0.50 1/16 3/16 100 20 60 1.34 3/32 5/32 100 10 30 0.66 3/32 7/32 100 15 45 1.58 1/8 3/16 100 10 30 0.88 1/8 1/4 100 20 60 2.00 1/8 5/16 100 25 75 3.32 1/8 3/8 100 28 84 4.92 5/32 9/32 100 20 60 2.14 5/32 11/32 100 20 60 3.64 3/16 1/4 100 5 15 1.22 3/16 5/16 100 20 60 2.64 3/16 3/8 100 20 60 4.12 3/16 7/16 100 15 45 6.14 1/4 5/16 100 10 30 1.50 1/4 3/8 100 5 15 3.34 1/4 7/16 100 20 60 5.12 1/4 1/2 100 15 45 7.50 5/16 7/16 100 10 30 3.66 5/16 1/2 100 10 30 6.30 3/8 1/2 100 10 30 4.32 3/8 9/16 100 10 30 7.15 3/8 5/8 100 10 30 10.16 3/8 3/4 100 15 45 16.72 7/16 5/8 100 10 30 7.70 1/2 5/8 100 5 15 5.84 1/2 11/16 100 5 15 9.50 1/2 3/4 100 10 30 13.12 1/2 7/8 100 10 30 15.00 5/8 3/4 100 5 15 6.86 5/8 13/16 100 5 15 11.34 5/8 7/8 100 5 15 13.38 5/8 1 100 10 30 22.86 3/4 1 50 5 15 17.64 3/4 1-1/8 50 10 30 26.56

$42.00 - $215.00

-

The Press Club 10 GALLON ALL MESH BUBBLE WASH BAGS 1-PACK

THE PRESS CLUB IS THE ONLY WASH BAGS OFFICIALLY ENDORSED & RECOMMENDED BY @BCBUBBLEMAN. READ THE FULL ANNOUNCEMENT HERE. ------------------------------------------------------------------- NEW TO WASHING? Read WHAT IS BUBBLE HASH?, HOW TO WASH BUBBLE HASH and HOW TO PRESS BUBBLE HASH ROSIN STARTER GUIDE The Press Club Wash Bags are the last set of bubble wash bags you'll ever own! Made from premium, food-grade material specifically for washing you can stop second guessing whether you have the right or best bags in the industry. All our bubble wash bags are hand sewn with our proprietary pink stitching, making them 2x stronger than competitors. You can be confident our bags will perform the same no matter if it's your 1st or 1000th wash. We're so confident our bubble wash bags will stand the test of time, every bag comes with a Lifetime Warranty. If you have any manufacturer issues, we'll be more than happy to replace the bag for you! KEY FEATURES Fits All Standard 10 Gallon Buckets Hand Sewn With Our Proprietary Pink Stitch w/ Food-Grade Materials Military-Grade Waterproof & No Flaking Bag Liner Premium Drawstring & Cord Locks To Secure Bags Lifetime Warranty On All Wash Bags Includes Meshed Carrying Case For 2-Way Drying & Storage Made In USA AVAILABLE MICRONS 220 Micron (Work Bag), 190 Micron, 160 Micron, 120 Micron, 90 Micron, 73 Micron, 45 Micron, 25 Micron AVAILABLE PACKS 1-Pack All-Mesh (Pick From All Available Microns) 4-Pack All-Mesh (Pick Any 4) 8-Pack All-Mesh (Includes All Available Microns) DRYING SCREENS SOLD SEPARATELY ALL ROSIN BAG SIZES & ROSIN PRESSING ACCESSORIES PLATES: 3" x 5", 4" x 7", Press Light, Insulators ROSIN BAGS: 1.25" x 4", 1.5" x 4", 1.75" x 4", 2" x 4", 2.5” x 4.5”, 1.5" x 9", 2” x 9”, 2.5" x 9", 3” x 6”, 3" x 9", 3.5" x 9", 4" x 7", 4" x 12", 5" x 5", 2" Filter Tubes LIMITED EDITION: Round Rosin Bags, Tube Sock Rosin Bags, THCA Mechanical Separate Sheets, Resin Magnets FUNNELS: 1.25" Funnel, 1.5" Funnel, 2" Funnel, 2.5" Funnel (Coming Soon) DRY SIFT SCREENS: 24" x 12" x 1.25" (Individual / Sets Available) WASH WORK BAGS: 6" Cube, 12" Cube BUBBLE WASH BAGS: 5 Gallon Premium, 5 Gallon All-Mesh, 10 Gallon, 20 Gallon, 32 Gallon, 44 Gallon, 65 Gallon WASHING ACCESSORIES: XL Drying Screens, 0.5mm Collection Card, 5 Gallon Neoprene Insulator Wrap PARCHMENT PAPER: 5" x 5", 6" x 12", 8" x 16", 10" x 10", Roll PARCHMENT ALTERNATIVE: 5 x 5 PTFE Sheets, PTFE Roll PRE-PRESS MOLDS: Pollen Press, 2" x 4", 2" x 9", 2.5" x 2.5", 2.5" x 4.5", 2.5" x 9", 3" x 5", 3" x 9", 4" x 4", 4" x 7" COLLECT: Large Rosin Stamp, 6" Cold Plate, Glass Dab Tool Kit STORAGE: 5 x 5 FEP Sheets, Self Vacuum Cure Jars, Hydro Stones ACCESSORIES: Magnets, Trash Bin Organizer, ISO Station, Terp Pearls, Stickers, T-Shirt

$44.95

-

The Press Club 10 GALLON ALL MESH BUBBLE WASH BAGS 8-PACK

THE PRESS CLUB IS THE ONLY WASH BAGS OFFICIALLY ENDORSED & RECOMMENDED BY @BCBUBBLEMAN. READ THE FULL ANNOUNCEMENT HERE. ------------------------------------------------------------------- NEW TO WASHING? Read WHAT IS BUBBLE HASH?, HOW TO WASH BUBBLE HASH and HOW TO PRESS BUBBLE HASH ROSIN STARTER GUIDE The Press Club Wash Bags are the last set of bubble wash bags you'll ever own! Made from premium, food-grade material specifically for washing you can stop second guessing whether you have the right or best bags in the industry. All our bubble wash bags are hand sewn with our proprietary pink stitching, making them 2x stronger than competitors. You can be confident our bags will perform the same no matter if it's your 1st or 1000th wash. We're so confident our bubble wash bags will stand the test of time, every bag comes with a Lifetime Warranty. If you have any manufacturer issues, we'll be more than happy to replace the bag for you! KEY FEATURES Fits All Standard 10 Gallon Buckets Hand Sewn With Our Proprietary Pink Stitch w/ Food-Grade Materials Military-Grade Waterproof & No Flaking Bag Liner Premium Drawstring & Cord Locks To Secure Bags Lifetime Warranty On All Wash Bags Includes Meshed Carrying Case For 2-Way Drying & Storage Made In USA AVAILABLE MICRONS 220 Micron (Work Bag), 190 Micron, 160 Micron, 120 Micron, 90 Micron, 73 Micron, 45 Micron, 25 Micron AVAILABLE PACKS 1-Pack All-Mesh (Pick From All Available Microns) 4-Pack All-Mesh (Pick Any 4) 8-Pack All-Mesh (Includes All Available Microns) DRYING SCREENS SOLD SEPARATELY ALL ROSIN BAG SIZES & ROSIN PRESSING ACCESSORIES PLATES: 3" x 5", 4" x 7", Press Light, Insulators ROSIN BAGS: 1.25" x 4", 1.5" x 4", 1.75" x 4", 2" x 4", 2.5” x 4.5”, 1.5" x 9", 2” x 9”, 2.5" x 9", 3” x 6”, 3" x 9", 3.5" x 9", 4" x 7", 4" x 12", 5" x 5", 2" Filter Tubes LIMITED EDITION: Round Rosin Bags, Tube Sock Rosin Bags, THCA Mechanical Separate Sheets, Resin Magnets FUNNELS: 1.25" Funnel, 1.5" Funnel, 2" Funnel, 2.5" Funnel (Coming Soon) DRY SIFT SCREENS: 24" x 12" x 1.25" (Individual / Sets Available) WASH WORK BAGS: 6" Cube, 12" Cube BUBBLE WASH BAGS: 5 Gallon Premium, 5 Gallon All-Mesh, 10 Gallon, 20 Gallon, 32 Gallon, 44 Gallon, 65 Gallon WASHING ACCESSORIES: XL Drying Screens, 0.5mm Collection Card, 5 Gallon Neoprene Insulator Wrap PARCHMENT PAPER: 5" x 5", 6" x 12", 8" x 16", 10" x 10", Roll PARCHMENT ALTERNATIVE: 5 x 5 PTFE Sheets, PTFE Roll PRE-PRESS MOLDS: Pollen Press, 2" x 4", 2" x 9", 2.5" x 2.5", 2.5" x 4.5", 2.5" x 9", 3" x 5", 3" x 9", 4" x 4", 4" x 7" COLLECT: Large Rosin Stamp, 6" Cold Plate, Glass Dab Tool Kit STORAGE: 5 x 5 FEP Sheets, Self Vacuum Cure Jars, Hydro Stones ACCESSORIES: Magnets, Trash Bin Organizer, ISO Station, Terp Pearls, Stickers, T-Shirt

$274.95

-

The Press Club 10 GALLON ALL MESH BUBBLE WASH BAGS PICK ANY 4-PACK

THE PRESS CLUB IS THE ONLY WASH BAGS OFFICIALLY ENDORSED & RECOMMENDED BY @BCBUBBLEMAN. READ THE FULL ANNOUNCEMENT HERE. ------------------------------------------------------------------- NEW TO WASHING? Read WHAT IS BUBBLE HASH?, HOW TO WASH BUBBLE HASH and HOW TO PRESS BUBBLE HASH ROSIN STARTER GUIDE The Press Club Wash Bags are the last set of bubble wash bags you'll ever own! Made from premium, food-grade material specifically for washing you can stop second guessing whether you have the right or best bags in the industry. All our bubble wash bags are hand sewn with our proprietary pink stitching, making them 2x stronger than competitors. You can be confident our bags will perform the same no matter if it's your 1st or 1000th wash. We're so confident our bubble wash bags will stand the test of time, every bag comes with a Lifetime Warranty. If you have any manufacturer issues, we'll be more than happy to replace the bag for you! KEY FEATURES Fits All Standard 10 Gallon Buckets Hand Sewn With Our Proprietary Pink Stitch w/ Food-Grade Materials Military-Grade Waterproof & No Flaking Bag Liner Premium Drawstring & Cord Locks To Secure Bags Lifetime Warranty On All Wash Bags Includes Meshed Carrying Case For 2-Way Drying & Storage Made In USA AVAILABLE MICRONS 220 Micron (Work Bag), 190 Micron, 160 Micron, 120 Micron, 90 Micron, 73 Micron, 45 Micron, 25 Micron AVAILABLE PACKS 1-Pack All Mesh (Pick From All Available Microns) 4-Pack (Pick Any 4) 8-Pack All Mesh (Includes All Available Microns) DRYING SCREENS SOLD SEPARATELY ALL ROSIN BAG SIZES & ROSIN PRESSING ACCESSORIES PLATES: 3" x 5", 4" x 7", Press Light, Insulators ROSIN BAGS: 1.25" x 4", 1.5" x 4", 1.75" x 4", 2" x 4", 2.5” x 4.5”, 1.5" x 9", 2” x 9”, 2.5" x 9", 3” x 6”, 3" x 9", 3.5" x 9", 4" x 7", 4" x 12", 5" x 5", 2" Filter Tubes LIMITED EDITION: Round Rosin Bags, Tube Sock Rosin Bags, THCA Mechanical Separate Sheets, Resin Magnets FUNNELS: 1.25" Funnel, 1.5" Funnel, 2" Funnel, 2.5" Funnel (Coming Soon) DRY SIFT SCREENS: 24" x 12" x 1.25" (Individual / Sets Available) WASH WORK BAGS: 6" Cube, 12" Cube BUBBLE WASH BAGS: 5 Gallon Premium, 5 Gallon All-Mesh, 10 Gallon, 20 Gallon, 32 Gallon, 44 Gallon, 65 Gallon WASHING ACCESSORIES: XL Drying Screens, 0.5mm Collection Card, 5 Gallon Neoprene Insulator Wrap PARCHMENT PAPER: 5" x 5", 6" x 12", 8" x 16", 10" x 10", Roll PARCHMENT ALTERNATIVE: 5 x 5 PTFE Sheets, PTFE Roll PRE-PRESS MOLDS: Pollen Press, 2" x 4", 2" x 9", 2.5" x 2.5", 2.5" x 4.5", 2.5" x 9", 3" x 5", 3" x 9", 4" x 4", 4" x 7" COLLECT: Large Rosin Stamp, 6" Cold Plate, Glass Dab Tool Kit STORAGE: 5 x 5 FEP Sheets, Self Vacuum Cure Jars, Hydro Stones ACCESSORIES: Magnets, Trash Bin Organizer, ISO Station, Terp Pearls, Stickers, T-Shirt

$159.95

-

10 Gallon Aluminum - POT ONLY

10 Gallon Aluminum - POT ONLY This is a replacement part for the following Vacuum Chambers: Best Value Vacs 10 Gallon Aluminum Vacuum and Degassing Chamber Dimensions: 15" Tall x 14" Diameter Material: 3004 Aluminum

$130.00

-

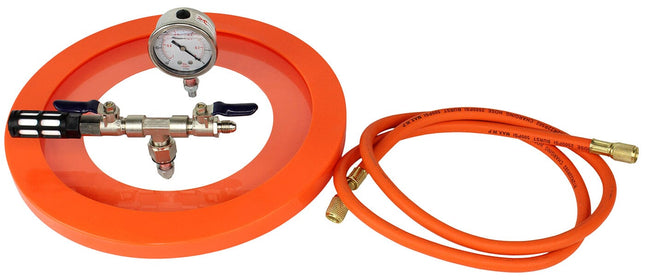

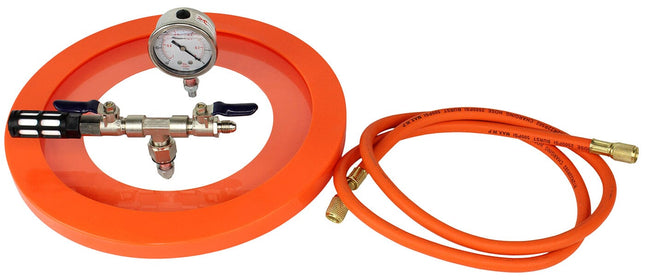

10 Gallon Aluminum Side Mount Vacuum Chamber

10 Gallon Aluminum Side Mount Vacuum Chamber (Comes with 2 Year Limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 15" Tall x 14" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BVV Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. GlassVac chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$312.00

-

10 Gallon Resin Trap Vacuum Chamber

10 Gallon Resin Trap Vacuum Chamber (Comes with 2 Year Limited warranty) Designed, built, and 100% tested in Chicago, Illinois, the Resin Trap Vacuum Chamber is the perfect application for a successful, high-quality end product. With its unique, patent pending gasket design (Utility Patent #14/533,548), this shatter chamber can easily withstand 10,000 uses with proper care and maintenance. The gasket itself is reversible, doubling the system's life by allowing customers to instantly take it off and flip it over. No adhesives necessary. The maximum allowed temperature of this chamber is 160f. The individual components of this chamber are rated at higher temperatures, however, as a vacuum vessel, we limit maximum operational temperature to 160f. Every chamber is tested prior to shipping to lose no more than 2.5inHg/24hrs. Specifications Key Features: Comes with 2 year limited warranty Resin traps come complete with glycerin-filled vacuum gauge, fittings for use with 1/4" vacuum tubing, nickel plated brass ball valve and instruction manual. Capture excess resin and protect your pump! Unique Catch Port Design: An additional hose can be installed at the port inside the tank to facilitate accurate collection of resin. 5 Feet Reinforced Vacuum Hosing to Connect Directly to the Vacuum Pump 1/4" SAE port. Measuring range of vacuum gauge:0-29.25inHg Silicone gasket to be used over 10,000 times without deterioration. This Kit Includes: (1) 10 Gallon Aluminum Chamber (1) Industrial grade silicone gasket Gasket can withstand 390°F max temp. 60A durometer density (1) Glycerin filled vacuum gauge (must be regulated upon arrival) Max vacuum -29Hg (+/-.5Hg) at sea level (1) Leak free nickel plated 1/4" Hvac Flare Valve (1) ¼” Barbed Connection (1) 5' Purple BVV™ Hvac Hose (1) 5' Clear Vacuum Tubing Internal Dimensions: 15" Tall x 14" Diameter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents.• GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent Pump Facts: We recommend the oil is changed every 50-75 of operating hours. CFM is a measure of cubic feet per minute. Single stage pumps reach a max vacuum of 50-75 microns (0=complete vacuum). Dual/Two stage pumps reach a max vacuum of 10-15 microns (0=complete vacuum). See FAQ at the top for product safety warnings. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$312.00

-

10 Ton Low Temp Glycol Chiller

Discover the Cold Shot Chillers® advantage. Crafted for reliability and user-friendly operation, These portable air-cooled chillers are proudly manufactured in the USA, utilizing proven components and backed by round-the-clock support from a network of technicians in the US. Engineered for a lifetime of service, these chillers ensure precise temperature control. Robust compressors paired with a generous reservoir deliver impressive cooling capacities, keeping your operations smooth even during the hottest months. Choose Cold Shot Chillers® for a reliable, long-lasting cooling solution. Key Features: Integrated Controls: PLC controlled with self-diagnostics. WIFI/LAN/LTE connectivity for predictive maintenance through Guardian™ app. Email/text notifications for predictive maintenance milestones, technical alarms, fault codes, and alerts. Quality Construction: Copeland Scroll technology for efficiency. Stainless Steel/Copper Braze Plate for durability. External Brass Service Valves for easy maintenance. Large Copper Condensing Coil with Aluminum Fins or Micro Channel for effective cooling. Powder-Coated, Heavy-Gauge Steel Cabinet for rugged protection. Additional Specifications: Rugged Stainless Steel Centrifugal Pumps for high flow and dependability. Oversized Magnetic Contactors for longevity. Lifetime Warranty for peace of mind. Benefits: Long Life – Dependable – Economical to Operate. Compact Efficiency for space-saving installations. Easy Maintenance and Repair for user-friendly operation. Rugged Protection while allowing for easy maintenance and wash down. High Flow – Long Life – Dependable performance. Rugged Dependability with a Lifetime Warranty. Specifications: 10 tons (120,000 BTU/35.16KW) 41 Gallon Stainless Steel Reservoir Tank with Lid This Low Temp Model has a leaving fluid temperature range of 20F-70F/-6C-21C. 1.25” MNPT Inlet and Outlet Stainless Steel 1.5 HP Centrifugal Pump outputs 40 GPM at 30 PSI Single Phase (230V/1P/60HZ/81.5A) and Three Phase (230V/3P/60HZ/63.9A) power available Casters Included (two swivel locking and two fixed) Large Reservoir easily filled from outside, and level indicated with sight gauge 1-Year Parts Warranty 5-Year Warranty on Compressor Welded steel powder-coated frame and full metal cabinet with copper piping connections Digital Temperature controller with Self-Diagnostic control system Rugged Protection, while still easy to maintain and Wash Down High Flow Pump, Long Life, Dependable units! Stainless Steel Plate Evaporators Vacuum brazed with Copper Dependable Copeland Welded hermetic Scroll Compressors 61.5"x43"x66.6" 1100 lb UL Certified Please Note: This unit REQUIRES a qualified electrician to wire the necessary plug to the cord. *Please Note: This unit is rated for indoor use only. If you require a chiller rated for outdoor use, please contact our customer service department to request a special order. Cold Shot Chillers are available suitable for outdoor use with ambient temperature ratings as low as -20F.

$25,500.00

-

10" Cold Trap with KF25 Ports

10” X 10” KF25 Cold Trap Kit Cold traps are used in vacuum applications where contaminating vapors may be present, and a cold trap is required to assure vapors are condensed before reaching the vacuum pump. They can be used with any pump but are mostly used with rotary vane pumps. Protecting your pump will greatly increase the life of all your seals and internal components it will also assure that a full vacuum is pulled based on the pump’s capabilities. BVV’s 10”X10” KF25 Cold Trap features 2 qty. KF25 ports. The lower port is connected to the system that is under vacuum and the top to the vacuum pump. The KF25 allows for a larger bore and works great for high flow applications. This kit comes with 2 qty. KF25 rings and 2 qty. KF25 clamps ready to be connected in line with your setup. The internal pot is stainless steel and can hold 1.5 gallons which will hold the dry ice slurry or other method of getting cold. A silicone O-ring sits around the 1.5-gallon pot and creates a seal with the top of the 10”X10” base. For more specifications, please view table and diagrams below. Product Information Sheet **This cold trap comes pre-tested to pull down to 30 microns** **This cold trap is rated for applications down to 30 microns. If your application requires a deeper vacuum, please DO NOT USE THIS COLD TRAP** Specifications Model CTRAP10X10-B Material of Base and Internal Pot Stainless Steel Gasket Material Silicone Lid Material Silicone + Glass Vacuum Rating 30 microns Weight 29lbs Overall Height 11.5” Overall Diameter (Including Ports) 14” Cold Trap Surface Area 234.45 sq.in Internal Pot Volume 1.5 gallons Chemical Compatibility with Glass Lid Ethanol Excellent Acetone Good Water Excellent Propylene Glycol Excellent Isopropyl Alcohol Excellent Chemical Compatibility with Silicone O-Ring and Lid Seal Ethanol Good Acetone Good Pentane Good Hexane Good Heptane Good View of 10” x 10” Cold Trap

$1,250.00

-

10" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves

10" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 10" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with (2)1/4" and (1)3/8" 37° JIC Flares, and compound gauge. These lids are made out of 304 stainless steel and have (1) 1.5" and (2) 2" Tri-Clamp ports with the middle 1.5" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2) 1/4" and (1) 3/8" 37° JIC Tri-Clamp Size(s) (1) 1.5" Ports x (2) 2" x 10" Tri-Clamp Nitrogen Tested Yes

$542.00

-

10" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves

10" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 10" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with 1/4" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have (1) 1.5" and (2) 2" Tri-Clamp ports with the middle 1.5" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" 37° JIC Tri-Clamp Size(s) (1) 1.5" Ports x (2) 2" x 10" Tri-Clamp Nitrogen Tested Yes

$466.00

-

10" Tri-Clamp Spools

10" Tri-Clamp/ Tri Clover Spools Sizes Available: 10" x 10" Tri-Clamp/ Tri Clover Spool Specifications: Tri-Clamp Size 10" Material 304 Stainless Steel Standard 3A High Polish Spool OD 10" Spool ID 9.732" Flange OD 10.57" Bead Center 10.12" OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 10" Tri-Clamp Spools - Drawing Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$220.00

-

10" Tri-Clamp x (2) 2" Tri-Clamp x 1.5" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid

10" Tri-Clamp/ Tri Clover x (2) 2" Tri-Clamp x 1.5" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid This End Cap comes with Four 1/4"-18 FNPT Threaded connection and One 1.5" Tri-Clamp ferrule and Two 2" Tri-Clamp ferrules welded to the end cap with a sanitary weld with a 3" Tube Extension Below the Lid. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid and the 1.5" Tri-Clamp Connection. These 7 connections are welded on a 10" Hemispherical Tri-Clamp End Cap. Specifications Material: 304 Stainless Steel Connection Type: 1.5" Tri-Clamp - 3" Tube Extension Below Lid on Center Tri-Clamp Port 2" Tri-Clamp 10" Tri-Clamp 1/4" - 18 FNPT Standard: 3A BVV™ 10" Tri-Clamp x (2) 2" Tri-Clamp x 1.5" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid - Drawing BVV™ 10" Tri-Clamp x (2) 2" Tri-Clamp x 1.5" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid - End Cap Chart

$255.00

-

10" Vacuum Chamber Digital Heat Pad

10" Vacuum Chamber Digital Heat Pad Please Read Before You Buy! Chamber NOT Included, Sold Separately. Heat Pad must fit correct size of the chamber! Fits 2&3 Gallon aluminum pots and 1.6 Flat Chamber This Digital Heat Pad will adhere to the bottom of a chamber vessel with a peel and stick backing. This unit will hold a temperature within a degree to the set temperature (dependent on the environment and air movement). The temperature offset must be found to set the controller accurately. (See ‘Operation’ instructions in the operation manual) Included with this Digital Heat Pad: Instructions on how to operate and set parameters. Simple standoff bumpers (provide thermal separation between the vessel and the work surface) Thermal tape (best method to check and verify temperature) Specs: UL Listed Fahrenheit Digital Controller. Min Temp: Ambient + 5 Max Set Temp: 160°F Ultimate Max Temp: 248°F Voltage: 110VAC Only Power Consumption: 220-watt Digital Control: Increments of 1 Degree. Accuracy: +/- 0.2 Degrees Units: Degrees Fahrenheit Instructions: Fully included Relay Lifespan: Approx. 10 million cycles User can reprogram: Yes

$100.00

-

10" x (3) 1.5" x (2)1/4" FNPT Tri-clamp Endcap

10" x (3) 1.5" x (2)1/4" FNPT Tri-clamp/ Tri Clover Endcap This End Cap come with Two 1/4"-18 FNPT Threaded connection and Three 1.5" Tri-Clamp ferrule welded to the end cap with a sanitary weld with a 0.5" Tube Extension center ferrule Below the Lid. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid and the 1.5" Tri-Clamp Connection. These 5 connections are welded on a 10" Tri-Clamp End Cap. Specifications Material: 304 Stainless Steel Connection Type: 1.5" Tri-Clamp - 0.5" Tube Extension on center ferrule Below Lid 10" Tri-Clamp 1/4" - 18 FNPT Standard: 3A BVV™ 10" x (3) 1.5" x (2)1/4" FNPT Tri-clamp Endcap - Drawing BVV™ 10" x (3) 1.5" x (2)1/4" FNPT Tri-clamp Endcap - End Cap Chart

$230.00

-

10.75 Glass Resin Trap Lid

10.75" Glass Resin Trap Lid Made from tempered soda lime glass and available with an industrial-grade silicone gasket capable of withstanding a 390F max temperature our 10.75" Glass Resin Trap Lid carries excellent temperature and solvent compatibility. All pictured fittings are included. This 10.75" Glass Resin Trap Lid can be purchased as a complete Resin trap kit including our 2 Gallon Aluminum Chamber Pot within our 2 Gallon Resin Trap Vacuum W/ Glass Lid listing.

$115.00 - $125.00

-

10.75 Vacuum Chamber Lid w/ Universal Silicone Gasket

10.75 Vacuum Chamber Lid w/ Universal Silicone Gasket Specifications:• 3/4" Thick Acrylic Lid• 10.75" Diameter• Silicone Shatter Vac Gasket has 2-3/8" Margin, Inside Diameter is 6" - Gasket can withstand 390F Max Temp (Lid Limited to 160F) - 60A durometer density - 2mm Thick• Can Fit a Chamber with a Diameter between 6.5" and 10.5" Includes:• 50 Micron Air Filter• 5' Reinforced Vacuum Hose• 1/4 Female Flare pump Adapter• Glycerin Filled Vacuum Gauge• Tested Valve Manifold

$110.00

-

10.75" / 11.25" Chamber Gasket - Purple

Our patented gasket #9475627 This gasket is made of 100% virgin silicone and fits the following sized vacuum chambers: 2 Gallon Chambers 3 Gallon Chambers 10.75" and 11.25" Sized lids.

$38.00

-

10.75" Diameter GLASS LID

BVV™ 10.75" Diameter Glass LID Our patented gasket #9475627 Disclaimer: LID ONLY - does not include hardware unless selected through drop-downs or ordered separately. Hardware - includes Valve Manifold, Gauge, and Gasket. (Does not include 50-micron air filter or vacuum hose. This is a Replacement Lid for the following Vacuum Chambers: Best Value Vacs 2 Gallon Aluminum Side Mount Vacuum and Degassing Chamber Best Value Vacs 2 Gallon Aluminum Vacuum and Degassing Chamber Best Value Vacs 3 Gallon Aluminum Side Mount Vacuum and Degassing Chamber Best Value Vacs 3 Gallon Aluminum Vacuum and Degassing Chamber Best Value Vacs 3 Quart Pyrex Vacuum and Degassing Chamber

$65.00 - $95.00

-

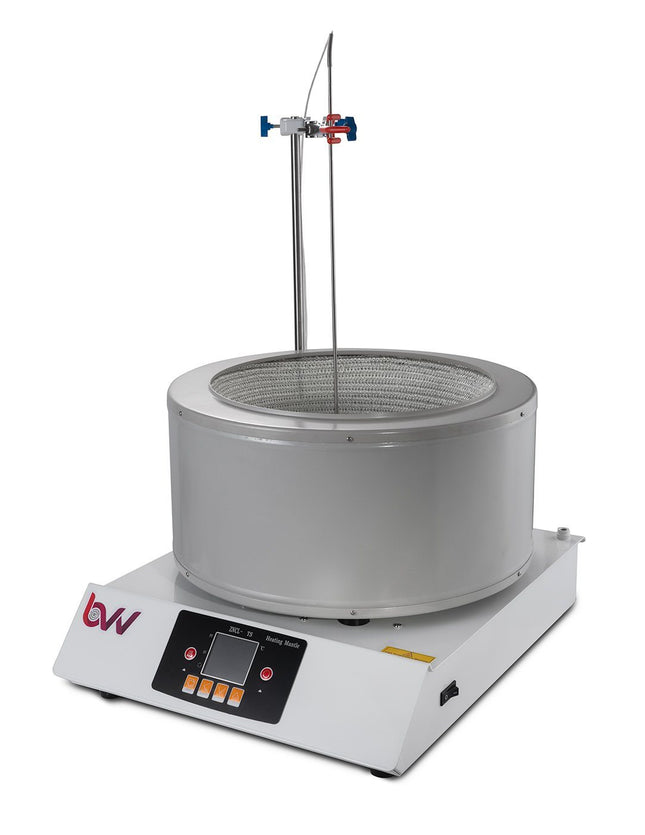

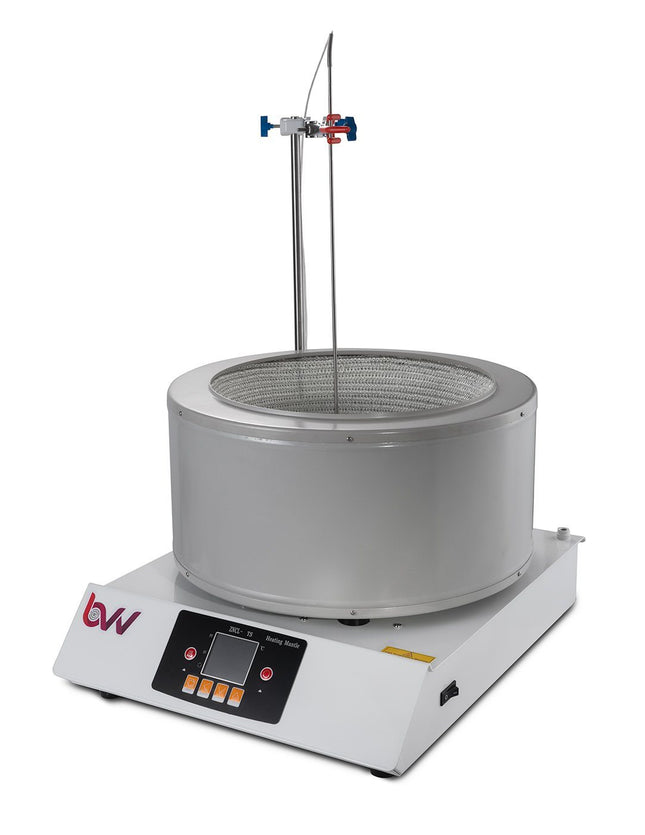

10L Digital Heating and Stirring Mantle

10L Digital Heating and Stirring Mantle Digital Heating and Stirring Mantles give the operator the most precise temperatures and readouts during distillations. These mantles autotune to specific user input to provide consistent results. Each mantle is equipped with large digital display that will give you readouts for both set temperature, actual temperature, and stirring speed. Each mantle also comes with a vertical brace bar and boss head as well as a temperature probe which plugs directly into the mantle. For first time use, the mantle should have an initial burn out done. This will burn off any residual oils used in the production of the insulation rope. The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Specifications Capacity: 10L (10000mL) Power Supply: 220V 60Hz Adjustable Rotation Speed: 50-1800 RPM Motor Power: 40W, DC14-24V Heating Power 180-2200W Temperature Control Accuracy: +/- 1C Intelligent Temperature Control: Yes Temperature Range: RT+10-380C Insulation Material: Alkali-free Glass Fiber, temperature resistant up to 450C Shipping Dimensions: 23 x 23 x 16 in. Weight: 20 lbs

$1,250.00

-

Neocision 10L Neocision Dual Head Short Path Distillation Kit

10L Neocision Dual Head Short Path Distillation Kit This unit carries a 2 day lead time. The 10L Neocision Distillation Turnkey Setup features our Dual 10L P5 Distillation Heads and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market. You will also receive a Dual Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The 10L Neo Kit Includes: 10L Neocision Kit with Dual P5 Distillation Heads KF-25 90 Degree Long Manifold and Metering Valve Dual Dewar Style Glass Cold Trap Bullseye Precision Vacuum Gauge Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$8,500.00

You have seen 96 out of 1693 products