Hydrocarbon Extraction

Hydrocarbon extraction is a widely used botanical extraction method that utilizes light hydrocarbon solvents like butane and propane to extract botanical compounds. Hydrocarbon extraction is preferred by many botanical extractors due to its high yields and low solvent recovery temperatures. These highly versatile extraction solvents lend themselves to producing a high purity botanical concentrate with little to no post-processing. Hydrocarbons are a classification of organic compounds made from carbon and hydrogen. Hydrocarbons are formed due to the compression of animal and plant remains over long periods and are pulled from porous rocks where they pool and concentrate. These alkane molecules have an even distribution of electrons, making them nonpolar and well suited for extracting nonpolar botanical compounds.

The most commonly used hydrocarbons for botanical extraction include butane and propane. These hydrocarbons can be utilized on their own to perform botanical extraction, or they can be combined into a blend of hydrocarbon solvents and utilized to extract a fuller spectrum of botanical compounds from biomass material. Typically a blend of n-butane, Isobutane, and propane is utilized to create an extraction solvent with greater affinity to extract a wider variety of compounds found within botanical biomass resulting in a more full-spectrum extract.Both butane and propane are class 1 group D flammable liquified gases that the Food and Drug Administration (FDA) have generally recognized as safe (GRAS). These light hydrocarbons are gaseous at room temperature and ambient pressure where they are denser than air and tend to pool near the floor. When pressurized or placed under reduced temperature they become liquified and can saturate biomass material and extract nonpolar botanical compounds.

Butane and Propane are the preferred extraction solvent of many extractors looking to preserve highly volatile aromatic compounds due to their low boiling point -1C/30.2F for butane and -42C/-43.6F for propane. Since these solvents boil off at a lower temperature than most aromatic compounds, they can be recovered with minimal heat preserving more aromatic compounds in comparison to other high boiling point extraction solvents like ethanol. While butane and propane's low boiling points lend themselves to aromatic compound preservation, it also makes hydrocarbons highly volatile and more hazardous to work with.

Although butane is generally recognized as safe by the FDA and can be consumed by humans in trace amounts, utilizing these highly volatile and flammable hydrocarbons as organic solvents under extreme temperatures and pressures can be dangerous. While it is highly unlikely that hydrocarbon extraction will result in an explosion when performed properly, when utilizing these highly flammable gases, there is always an inherent potential ignition. For this reason, any and all potential sources of heat or flame should be kept far away from areas in which hydrocarbon gases are present. To further mitigate the potential for ignition, hydrocarbon extraction should be performed inside of aC1D1 extraction booth with all the proper safety and protective equipment.

Among the most important pieces of safety equipment for butane and propane extraction is a C1D1 extraction booth which greatly reduces the potential hazard when working with hydrocarbon solvents. A C1D1 hazardous location is where ignitable vapor concentrations exist under normal operating conditions and where a hazard is caused by frequent maintenance, repair work, or equipment failure. Both butane and propane extraction typically fall under a Class 1 Division 1 environment because ignitable concentrations of flammable gasses exist under normal operating conditions. Depending on a specific municipality, the fire inspector may also require said extraction booth to have a fireproof burn rating which is commonly required when dealing with larger volumes of solvent within the enclosed area.

C1D1 Hazardous locations require all electrical/electronics equipment to be designed, tested, and labeled acceptable for use in C1D1 areas. Beyond utilizing appropriately rated electrical/electronic components, most extraction areas will come equipped with an explosion-proof exhaust fan providing a high air exchange rate, along with a lower explosive limit gas detector to alert high levels of gas and trigger an increased rate of exhaust ventilation.

While the use of appropriately rated electrical components within the extraction area drastically lowers the potential of a flammable substance being ignited, one of the more important functions of a C1D1 extraction area is to reduce the risk of an explosion by regulating the airflow of the enclosed space to keep the levels of gases below the lower explosive limit of the used gas.

A C1D1 extraction booth helps mitigate the risk of an explosion through the use of an explosion-proof exhaust fan, providing a high rate of air exchange. It comes with a lower explosive limit gas detector used to alert the user of high levels of gas and trigger an increased rate of exhaust ventilation. When extracting with butane or propane, it's best to keep the percentage of solvent vapors within the enclosure well below 25% of their lower explosive limit which is 1.86% for butane and 2.1% propane.

When performing a butane extraction inside a C1D1 rated Explosion-proof enclosure, only appropriately rated explosion-proof electronics should be utilized, and great care should be taken to limit exposure to open flame or static electricity by bonding metal containers during flammable solvent transfer and grounding equipment. A C1D1 Environment is a must-have to safely and compliantly perform butane extraction and should be worked into the budget of every new butane extraction lab build. While an explosion-proof environment significantly reduces risk during hydrocarbon extraction, to ensure personal safety while performing hydrocarbon extraction, personal protective equipment in the form of safety goggles, nitrile gloves, and antistatic clothing should be worn at all times.

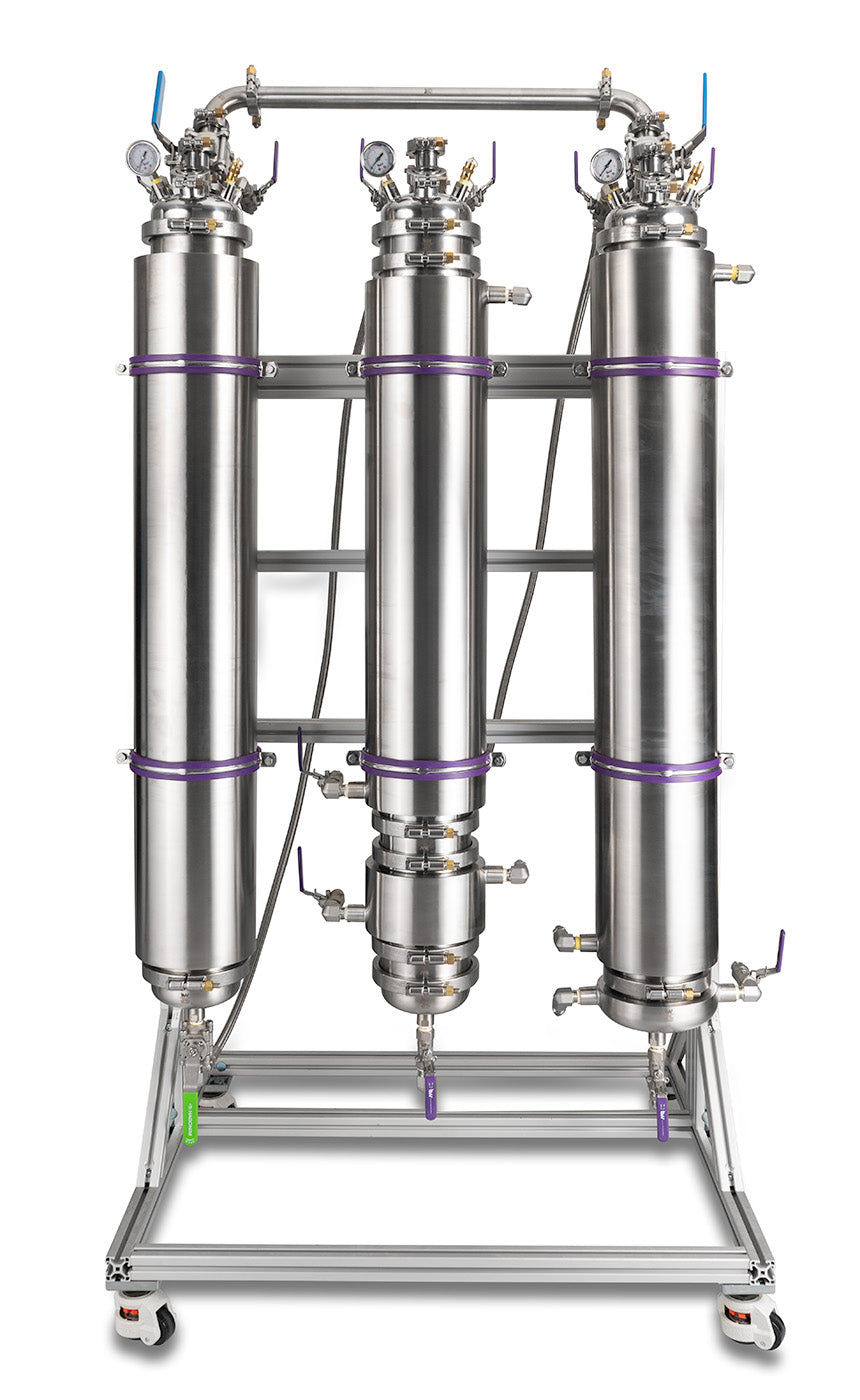

When operating within a C1D1 environment butane extraction is typically performed utilizing a closed-loop butane extractor. A closed-loop system allows for optimal safety as it contains all flammable solvents from the extraction process within a closed system and allows for the recapturing and reuse of solvent.

A typical closed-loop system can be broken down into three basic elements; The solvent tank/ recovery tank where the hydrocarbon blend is stored and recondensed, the material column where the plant matter is loaded and saturated, and the collection vessel where the botanical extract solution is collected and the solvent evaporation process is performed. While these three components are essential to the operation of a closed-loop system, several additional components can be utilized to improve the efficiency of a closed-loop system.

Common optional additions to a closed-loop system include a dewax column used to precipitate and filter plant waxes from the solution, a color remediation column used to filter undesirable color pigments from the extract, and a molecular sieve column used to absorb any water from the solvent during the solvent recovery process. While the function of a dewaxing column can be substituted by chilling the extraction solvent prior to extraction and limiting its retention time, a molecular sieve and color remediation column are highly recommended to improve the overall efficiency of the extraction process. A color remediation column specifically is capable of drastically increasing the purity of the botanical extract and will be covered in great detail in the next chapter.

Hydrocarbon extraction is performed simply by saturating the biomass material with a liquid butane or propane solvent. As the liquid solvent saturates the biomass, it dissolves compounds from the plant material. While this process is rather straightforward, several variables to the initial saturation can be optimized to increase the overall yield and purity of the resulting extract. During the initial saturation, the most effective variables to optimize the efficiency of a butane extraction are solvent temperature, solvent to biomass ratio, and retention time.

Solvent temperature is commonly altered either to increase the purity or overall yield of the butane extraction. The extractor may choose to either chill the solvent to limit the pickup of impurities or extract using a room temperature or "warm" solvent to increase the overall yield of the extract. During extraction, the temperature of a solvent plays a big role in the solubility and saturation capacity of a solvent. Saturation capacity and solubility generally increase or decrease along with the temperature of the solvent.

When a solvent is chilled prior to extraction, its overall solubility is reduced, which helps limit the pickup of undesirable impurities like plant waxes and chlorophyll. While this altered selectivity does come at a price of reduced efficiency in extracting the target compounds, this can be combated by utilizing a higher solvent to biomass ratio.

Butane solvent is typically chilled within a -20C to -80C (-4F to -112F) range, increasing the selectivity of the extraction and limiting the co-extraction of impurities. Common methods of chilling butane solvent include an injection coil submerged in dry ice that the hydrocarbon solvent runs through prior to injection of the material column or a jacked solvent tank connected to a refrigerated circulator to chill the butane solvent prior to the initial saturation.

Conversely, a room temperature or "warm" butane solvent can be utilized to perform the initial saturation. When utilizing a room temperature or "warm" butane extraction, the solvent has greater solubility and saturation capacity allowing the solvent to more effectively dissolve target compounds from the plant matter. While this strategy allows for the target compounds to be more effectively dissolved from the plant matter, it also allows undesirable botanical compounds like color pigments and plant waxes to be more easily dissolved, resulting in a greater number of total impurities. Commonly, a warm extraction is paired with inline adsorbent filtration utilizing a color remediation column allowing for efficient extraction of the target compounds during the initial saturation and removing undesired impurities through filtering resulting in high yield and purity.

Regardless of the extraction temperature strategy, once the solvent has reached the desired extraction temperature, the solvent is then injected into the material column saturating the biomass material. There are two methodologies for saturating the biomass material. Closing the outlet to the material column allows the material column to fill with solvent and fully saturate the plant matter increasing retention time before draining the solvent into the collection vessel. Another way is to leave the outlet of the material column open, allowing the solvent to quickly pass through the material column into the collection vessel, limiting solvent retention time for what is referred to as a quick wash. Retention time is an important factor in allowing the solvent to dissolve the target compounds. Too little retention time can result in reduced yield of target compounds, while too long retention time can allow more undesirable compounds like chlorophyll and plant waxes to be dissolved.

Extended retention times are great for extracting everything from the plant matter. When this strategy is paired with inline adsorbent filtration, it can result in both high yield and purity. Conversely, a short retention time allows for greater purity by minimizing the time the solvent has to co-extract undesirables. When a quick wash/short retention time strategy is utilized in conjunction with chilled solvent, it can result in a concentrate with very low levels of impurities. Utilizing a short retention time and chilled solvent typically results in lower extract yield. This can be combated by utilizing a higher solvent to biomass ratio to ensure the majority of the target compounds are extracted while limiting the pickup of undesirable color pigments and plant waxes. Typically, a solvent to biomass ratio of 3-5:1 is commonly utilized to perform a butane extraction. Up to a 10:1 ratio can be utilized when extracting with cold solvent to ensure the majority of the desired compounds are extracted.

The solvent to biomass ratio is the final factor in the initial saturation that can be optimized. Most commonly, a ratio between 3-5 pounds of butane solvent will be utilized for every 1 lb of biomass loaded into the material column. The greater the total volume of solvent utilized during the initial saturation, the greater the extraction efficiency. More solvent used for the initial saturation typically allows for more of the target compounds to be dissolved from the plant matter. An increased solvent to biomass ratio is especially useful when utilizing a quick wash, short retention time saturation strategy. While this ratio can be further increased to ensure the target compounds are extracted from the plant matter it results in a greater total volume of solvent used, increasing production costs, extending the solvent recovery process, and increasing overall runtime.

After the initial saturation is complete and the entirety of the botanical extract-rich butane solution has been drained into the collection vessel, the bulk of the solvent recovery process is performed by heating the solution to evaporate the butane solvent from the botanical extract solution. The solvent recovery process is a distillation process initiated by applying heat to the extract solution to evaporate the extraction solvent from the botanical extract and the condensation of the ensuing solvent vapors inside a chilled recovery tank. Typically the solution is heated by either submerging the collection vessel in a hot water bath or recirculating hot water through the jacket of the collection base.

The solvent recovery process can be performed utilizing two separate methodologies: active solvent recovery or passive solvent recovery. Both passive and active solvent recovery utilize heat applied to the collection to evaporate the solvent from the extract and cool the recovery tank to condense the butane vapors inside a vessel separate from the extract. Active recovery assists the solvent recovery process by including a recovery pump that aids in the transfer and compression of the gaseous solvent, speeding up the solvent recovery process. While both methodologies have their benefits and drawbacks, both can be utilized to recover butane solvents effectively.

Regardless of the solvent recovery methodology, the collection vessel containing the extract solution is heated to initiate the solvent recovery process. The recovery tank is chilled and commonly pulled under vacuum only if the solvent tank is empty to create pressure and temperature differential between the heated collection base and the chilled recovery tank. This pressure and temperature differential between the two vessels results in the solvent vapors being attracted to the lower pressure and temperature recovery tank once the process connections between the two are opened.

Note that if the recovery tank contains solvent, do not attempt to pull the recovery tank under vacuum as solvent vapors can be pulled out of the vessel into the vacuum pump, potentially causing ignition of the solvent vapor. While reduced pressure within the recovery tank assists in the travel of vapor from the collection vessel to the recovery tank, if the recovery tank still has solvent within it, the solvent recovery process can still be performed relying solely on the temperature differential between the two vessels. However, the pressure from the collection vessel must be greater than the pressure within the recovery tank, which can be ensured by keeping the recovery tank as cold as possible during the recovery procedure.

During the solvent recovery process, the movement of the solvent vapor within the system operates under the principle that gas always seeks the lowest pressure region of a system. The pressure of a hydrocarbon gas directly correlates to its temperature by heating the hydrocarbon solvent within the collection tank, thus increasing its pressure. Moreover, by cooling the solvent recovery tank the ensuing vapors naturally are pulled towards the lower pressure chilled recovery tank where they are condensed and their pressure is reduced.

The efficiency of the solvent recovery process is a function of the thermal energy applied to the collection vessel and the amount of cooling applied to the solvent tank. Since butane and propane have relatively low boiling points, light heat is sufficient to perform the evaporative process. While increased heat will speed up the solvent recovery process, it is a double-edged sword as it may degrade or evaporate the more volatile compounds typically found in the botanical extract like terpenes. During this process, it is important to keep in mind the lowest boiling point of the compounds to be preserved, and stay under that temperature when determining the heat level to apply to the solvent recovery process.

The other side of this solvent distillation process is the condensation of solvent vapors inside the recovery tank. Condensation happens when vapor is cooled or condensed past its condensation point and is initiated by the molecular clustering of vapor within a gaseous volume or at the contact of vapor with a cool enough liquid or surface. This process can be assisted through the use of a condensing coil submerged in dry ice, which provides a high surface area low-temperature zone where vapors can be condensed before entering the recovery tank. Typically the colder the recovery tank or condensing coil, the more efficiently the solvent will be recovered and collected.

While it is typical for the bulk of the butane or propane to be recovered during this time, depending on the specific type of extract to be produced, more or less hydrocarbon solvent may be left to be recovered by the vacuum oven or used to perform evaporative crystallization.

After the desired amount of the hydrocarbon solvent has been recovered, The recovery tank and collection vessels are isolated, and the collection vessel is depressurized after the desired amount of the hydrocarbon solvent has been recovered. The extract is then harvested from the closed-loop system. The residual amount of butane or propane remaining within the extract is purged utilizing a vacuum oven. Once the extract has been purged of all residual solvent, it can be used as is or further refined through distillation or isolation.

After the closed-loop solvent recovery process has been performed and the extract has been harvested from the closed-loop system the butane extraction procedure is complete and the resulting extract can be purged of residual solvent and further refined. Now that we have covered the proper butane extraction safety protocols and extraction methodologies let's dive deeper into the extraction preparation and actual operation of a closed-loop system.

Butane extraction starts with packing the material column with biomass material and proper assembly of the extractor. During the packing of the material column, botanical biomass is loaded into the material column and packed as evenly as possible to reduce channeling of the solution and tight enough to fit the desired amount of material within the column while still being able to agitate the material by hand. Once the material is loaded into the material column, it is important to remove any debris from the tri-clamp ferrules to ensure a tight seal between the tri-clamp gasket and the endcaps continuing the assembly of the material column.

Once the material column has been packed and assembled, continue to assemble the remainder of the system. While assembling the extractor, ensure that all high-pressure clamps are tightened with a torque wrench to manufacturer specification (typically 110 inches per sqft). After assembly, prior to initiating a butane extraction, a pre-assembly inspection and testing of the extractor should always be done to ensure safety during extraction. During the inspection, confirm that all gaskets are free of visible wear and ensure all lines and fittings are intact and appropriately tightened before pressure testing the system.

After assembly and preinspection of the closed-loop extractor, it is important to pressure test the system to ensure no leaks. A leak within the system can result in butane escaping from the system and being released into the atmosphere. To ensure safety during extraction, it is always recommended to pressure test the system after the reassembly of a closed-loop extraction system. To initiate a pressure test, start by ensuring the outlet to the source solvent tank is closed and then open all process flow valves from the closed source solvent tank to the collection tank and pressurize the system with nitrogen to 100 PSI. Once the system has reached 100 PSI, close the nitrogen input valve and allow the system to be held under pressure for at least 30 minutes prior to extraction to ensure pressure can be held.

If pressure is not held during this time, identify where pressure leaks are coming from by spraying all process connections with soapy water. If the process connection is leaking, it will be observed to create additional bubbles. Once a pressure leak has been identified, depressurize the system and disassemble and reassemble the system as necessary, making sure to replace any parts no longer holding a seal. Once reassembled, proceed to pressure test the system again, and disassemble and reassemble as needed until pressure can be maintained. At BVV, we pressure test every vessel at 100 PSI for 24 hours prior to shipment upon disassembly and reassembly of the unit. The same is always recommended, but a shorter pressure test can be utilized at the discretion of the extractor.

Once the system has passed the pressure test, prepare the hydrocarbon solvent for extraction by bringing it to the desired extraction temperature. If utilizing fresh solvent, it is always recommended to distill the solvent to eliminate the risk of contamination from the storage solvent tank before bringing it to the desired extraction temperature. At BVV we have exceptional gas quality that results in a clean distillation, but predistillation is always recommended

To distill fresh solvent, start by first bonding the source solvent tank to the grounded extractor and pulling the entire system under vacuum before injecting butane solvent from the source solvent tank into the collection vessel of the pressure tested closed-loop butane extractor. Once loaded, close the valve to the solvent storage tank and proceed to heat the collection with a hot water bath to 38C/100F. During this time, it is important to also chill down the recovery tank to condense the ensuing vapors. Once the collection vessel and recovery tank have reached their operating temperature, open all process connection valves between the collection vessel and the recovery tank and proceed to evaporate the solvent from the collection vessel, recondensing it back into the recovery tank. Once all the solvent has been evaporated from the collection vessel and condensed into the recovery tank, close the vapor valve on the recovery tank, depressurize the closed-loop system, and disassemble the collection vessel. Clean the inside of the collection tank with ethanol to remove any residue from the freshly distilled solvent.

Now that the solvent has been distilled and the collection vessel has been cleaned of any residue, proceed to reassemble the system as normal. This will ensure that the system is assembled to manufacture specification, all high-pressure clamps are torqued to specification, and all process connections are secure and appropriately tightened. After assembly, proceed to pressure test the system again for a minimum of 30 minutes to ensure proper assembly before preparing for the initial extraction.

Now that the fresh solvent has been distilled, proceed to bring the solvent to the desired extraction temperature while pulling the remainder of the extraction system under vacuum. Pulling the system under vacuum evacuates ambient pressure from the system, creating a low-pressure zone that allows the butane or propane to move through the system more easily and provides a clean atmosphere for the extraction process to be performed. Additionally, pulling an EMPTY recovery tank under vacuum prior to initiating the recovery process creates a low-pressure zone for the solvent vapors to be pushed/pulled towards during recovery.

Before pulling the system under vacuum, start by ensuring the solvent tank is closed off and no residual vapors are within the system. If butane or propane vapors are pulled into a standard vacuum pump, it could cause ignition of the flammable vapors. Once the solvent tank has been confirmed to be closed, open all process connections from the closed source solvent tank to the collection vessel. Connect the vacuum line from the collection vacuum valve to an explosion proof vacuum pump. Ensure all process connections are tightened appropriately and proceed to turn on the vacuum pump and allow the system to be pulled under vacuum to -29.9hg before closing the vacuum valve and turning off the vacuum pump. Once the system has been pulled under vacuum, isolate each component of the extraction system by closing all input and output valves and allowing the hydrocarbon solvent to reach the desired extraction temperature.

Once the extraction solvent reaches the desired temperature, the extraction can be initiated by transferring the solvent from the solvent tank to the material column. If the solvent is warm, the solvent will have its own inherent pressure that can be utilized to inject the solvent into the material column due to the pressure differential being pulled under a vacuum. While this pressure differential is typically sufficient in the transfer from the solvent tank to the material column, if the solvent is chilled enough to reduce the pressure of the hydrocarbon solvent, then nitrogen can be utilized to push the solvent from the recovery tank into the material column of the system. In both cases, nitrogen can push the solvent into the material column by first pressurizing the solvent tank to the desired injection pressure. While higher pressures can be utilized to inject the solvent, 10-25 PSI is typically sufficient in transferring the solvent into the material column.

Once the solvent tank has been pressurized appropriately, place the LP recovery tank on an explosion-proof scale. Tare the scale and open the process connection valves from the source solvent tank to the material column, injecting the desired amount of solvent into the material column, allowing the biomass material to be saturated. If utilizing a quick wash solvent saturation strategy, ensure the process connection valves from the outlet of the material column to the collection vessel are open, allowing the solvent to drain into the collection vessel upon injection. If utilizing a longer saturation, ensure the material column outlet valve is closed, allowing the material to be completely submerged in a solvent for the desired retention time before draining the extraction solution to the collection vessel. Once the entirety of the extraction solution has made its way into the collection vessel, proceed to initiate the solvent recovery process. If nitrogen was utilized to inject solvent into the system ensure it is purged from the collection vessel prior to apply heat by venting the nitrogen from the headspace of the collection vessel through a line into the exhaust of your C1D1 Booth.

To initiate the recovery of solvent within a closed-loop butane extractor, start by closing the inlet valve to the collection vessel and then chill down the solvent tank and heat the collection vessel. If the recovery tank is empty, isolate the recovery tank and pull it under vacuum to create a lower pressure zone for vapors to be pulled towards. Depending on the boiling point of the target compounds to be preserved within the botanical extract, more or less heat may be applied to preserve these compounds. Typically the collection vessel will be heated to a temperature range between 20C/68F and 37C/100F to evaporate the hydrocarbon solvent. The application of heat to the collection vessel can be applied by submerging the collection vessel in a hot water bath or recirculating hot water through the jacket of the collection vessel utilizing a heated circulator.

Commonly the solvent tank will be chilled as cold as possible by either submerging the recovery tank and condensing coil in a dry ice/ethanol slurry or circulating chilled fluid through the jacket of the solvent tank utilizing a refrigerated circulator. Once both the collection vessel and the recovery tank have reached the desired temperature, initiate the solvent recovery process by opening all process connection valves between the collection vessel and the recovery tank. If utilizing an active recovery pump, turn it on at this time. During this time, closely monitor the extract within the collection vessel to gauge the solvent recovery process. The solvent recovery process can be continued until the extract completely solidifies. No more boiling is observed, requiring it to be scraped out of the collection vessel. It can also be stopped once only a small amount of the extraction solvent remains to allow the extract to be poured or drained from the collection vessel and purging the remainder of the solvent utilizing a vacuum oven.

Once the solvent recovery process has been performed to the extractors liking, turn off the recovery pump if utilized, isolate the solvent tank and collection vessel, depressurize the closed-loop extractor, and harvest the extract. Once the extract has been harvested, proceed to your vacuum purging procedure.

HYDROCARBON EXTRACTION STANDARD OPERATING PROCEDURE

-

Purpose

The purpose of this procedure is to provide detailed instructions for closed-loop hydrocarbon extraction.

-

Scope

This procedure applies to all lab technicians tasked with closed-loop hydrocarbon extraction.

-

Definitions/Acronyms

Personal Protection Equipment (PPE) Items worn to protect employees from exposure to hazardous materials and prevention of injury.

Safety Data Sheet (SDS) Provides useful information on chemicals, describing the hazards the chemical presents, and giving information on handling, storage, and emergency measures in case of an accident.

-

Safety

-

SDS Sheets: Butane SDS, Propane SDS, Tri-Blend SDS

-

PPE: The following should be worn by all lab personnel during this refinement procedure:

-

Protective eyewear

-

Lab coat/Anti-static clothing

-

Nitrile Gloves

-

5. Hazard Identification

-

Preparation and Use:

Target compounds will be extracted from biomass material utilizing hydrocarbon solvent.-

Quantity- 3-5lb of hydrocarbon solvent per 1lb of biomass

-

Frequency- An initial volume of solvent is used, no more is added.

-

Location- Hydrocarbon extraction occurs within a C1D1 environment, inside of a closed-loop hydrocarbon extractor (BVV).

-

Potential Hazards and Risks

See hydrocarbon solvent SDS for detailed risks.

6. Preparation

- Load the material column with the desired amount of biomass material packing the material tightly and evenly.

- Clear any excess biomass from the tri-clamp ferrules and fully assemble the remainder of the material column ensuring that all high-pressure clamps are torqued to manufacture specification.

- Proceed to assemble the remainder of the system ensuring all clamps are torqued to manufacturer specifications and all process connection hoses are secured and tightened properly.

- Once the hydrocarbon system assembly is complete proceed to pressure test the system by first ensuring the source solvent tank is closed and all process connections are open from the closed solvent tank to the collection vessel.

- Proceed to inject nitrogen into the injection manifold of the extractor pressurizing the system to 100 PSI before isolating the system.

- Allow the system to remain under pressure for a minimum of 30 minutes to ensure the system is assembled correctly with no leaks.

- If the pressure within the system drops below 100PSI proceed to spray all process connections with soapy water to identify where the leak is coming from. If bubbling is observed at a process connection, a pressure leak has been identified.

- Once the pressure leak has been identified, depressurize the system and disassemble and reassemble as necessary before repressurizing the system again and disassembling and reassembling the system as needed until pressure is maintained.

- Once pressure is held within the system for a minimum of 30 minutes proceed to depressurize the system and proceed to pull the system under vacuum.

- Ground the extractor system ensuring all connections are stable.

- Attach a spark-free vacuum pump to the collection base of the closed-loop system and open all process flow valves from the collection vessel to the closed source solvent tank ensuring the source solvent tank valve is fully closed.

- Turn on the spark-free vacuum pump and allow adequate time for the entire system to be pulled under vacuum. Once the system has reached -29.9mmHg close the vacuum valve, turn off the spark-free pump, and close all processing flow valves on the system isolating each component.

- Proceed to bond the solvent and recovery tanks and transfer 3-5 lbs of distilled hydrocarbon solvent for every 1lb of biomass you plan to extract into the solvent recovery tank of the closed-loop extraction system and proceed to chill the solvent recovery tank to the desired temperature through the use of dry ice or an appropriately sized chiller.

- Once the solvent has reached the desired injection temperature, proceed to start your initial extraction.

7. Procedure

- Pressurize the recovery solvent tank with nitrogen to the desired injection pressure 10-25PSI and open all processing valves from the recovery solvent tank to the material column saturating the material column at a 3-5:1 ratio (solvent: material).

- After the desired saturation of the material column has been achieved, open all processing valves from the material column to the collection vessel allowing the entirety of botanical extract solution to flow into the collection vessel.

- Once the entirety of the solution has been transferred into the collection vessel close the collection vessel inlet valve.

- Proceed to initiate solvent recovery by submerging the collection base in a hot water bath or turning on the heated recirculator setting the temperature to the desired solvent recovery temperature and proceeding to chill the recovery tank to the desired temperature using a dry ice/ethanol slurry or an appropriate refrigerated circulator.

- Once the collection vessel and solvent recovery tank have reached the desired solvent recovery temperatures open the process connections between the collection vessel and the recovery tank to start the solvent recovery process.

- Proceed to recover the hydrocarbon solvent until only extract remains, isolate the recovery tank, depressurize the closed-loop system, and drain or harvest the botanical extract into a clean receptacle.

- Once the botanical extract has been harvested proceed to the vacuum purging procedure.

Disassembly and cleaning

- Depressurize the closed-loop system to ambient pressures by opening the input/output valves on the material column and collection base.

- Once each gauge reads 0PSI proceed to disassemble the system by removing the high-pressure clamps and disposing of the spend biomass material.

- Proceed to clean and sanitize all parts with 200 proof ethanol to remove any particulate, oil, or other contaminants.