Vacuum Oven Kits

-

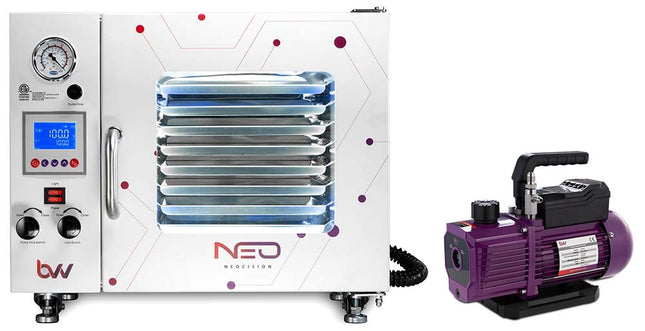

0.9CF BVV™ Neocision Lab Certified Vacuum Oven + V4D 4CFM 2 Stage Pump Kit

0.9CF BVV™ Neocision Lab Certified Vacuum Oven and V4D Series Vacuum Pump Kit DISCLAIMER This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! INTRODUCTION Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. PERFORMANCE CAPABILITIES At Best Value Vacs, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Range: RT+18°-212°F Temperature Uniformity: within 7% of the temperature setpoint. Heat-Up Time: 45 minutes to preheat. Optimal saturation reached in 120 minutes, over 30 minutes faster than competitors. Ultimate Vacuum: <500 µmHg / mTorr / micron Time to Vacuum: 4 minutes to 29"Hg Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. SPECIFICATIONS Electrical Voltage 120V Frequency 60HZ Power 550W Current 10A Plug IEC C13 (unit ships with detachable NEMA 5-15p cable) Internal Chamber Heating Superior 5 Wall Heating (left, right, top, bottom, rear) Temperature Range RT+18°-212°F Chamber Material Stainless Stee Dimensions (LxWxH) 12.75" x 12.625" x 11.625" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 11 Slide-in Shelves Shelf Dimensions (LxW) 11.5" x 11.25" Shelf Capacity 129 in2 Total Shelf Capacity 1035 in2 / 7.2 ft2 Door Seal Silicone on Tempered Glass Window Dimensions (LxH) 11.75" x 11" Lights 4 strips of LEDs provide clear, bright view of interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 24.25" x 19" x 20.75" Weight 160 lbs Support Heavy Duty Casters and Adjustable Leveling Feet Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connection Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose and adjusting wrenches. User Manual Included Warranty 3 year oven warranty Vacuum Pump BVV™ V4D 4CFM Two Stage Vacuum Pump CAPACITY AND THROUGHPUT PLANNING Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise Ground Freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$2,241.67

-

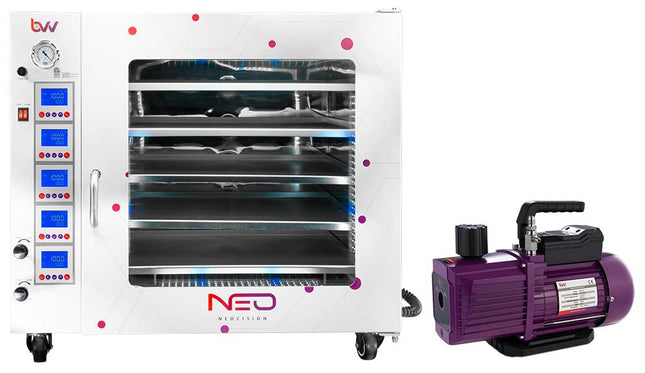

1.9CF BVV Neocision Lab Certified Vacuum Oven and V4D 4CFM 2 Stage Pump Kit

1.9CF BVV™ Neocision Lab Certified Vacuum Oven and V4D Series Pump Kit DISCLAIMER This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! INTRODUCTION Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. PERFORMANCE CAPABILITIES At BVV™, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Range: Room Temp+18°F to 212°F Temperature Uniformity: within 5% of the temperature setpoint. Heat-Up Time: 45 minutes to preheat. Optimal saturation reached in 120 minutes, over 30 minutes faster than competitors. Ultimate Vacuum: <500 µmHg / mTorr / micron Time to Vacuum: 4 minutes to 29"Hg. Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. SPECIFICATIONS Electrical Voltage 120V Frequency 60HZ Power 650W Current 10A Plug IEC C13 (unit ships with detachable NEMA 5-15p cable) Internal Chamber Heating Superior 5 Wall Heating (left, right, top, bottom, rear) Temperature Range RT+18°-212°F Chamber Material Stainless Steel Dimensions (LxWxH) 14.5" x 16" x 13.5" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 11 Slide-in Shelves Shelf Dimensions (LxW) 13" x 15" Shelf Capacity 195 in2 Total Shelf Capacity 2145 in2/ 14.9 ft2 Door Seal Silicone on Tempered Glass Window Dimensions (LxH) 15.25" x 12.75" Lights 4 strips of LEDs provide clear, bright view of interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 28.5" x 23" x 22" Weight 160 lbs Support Heavy Duty Casters and Adjustable Leveling Feet Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connection Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose and adjusting wrenches. User Manual Included Warranty 3 year oven warranty Vacuum Pump BVV™ V4D 4CFM Two Stage Vacuum Pump CAPACITY AND THROUGHPUT PLANNING Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise Ground Freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$3,178.60

-

7.5CF BVV™ Neocision Lab Certified Vacuum Oven and and V9D 9CFM Two Stage Vacuum Pump kit

7.5CF BVV™ Neocision Lab Certified Vacuum Oven and V9D 9CFM Two Stage Vacuum Pump Kit Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! INTRODUCTION Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. PERFORMANCE CAPABILITIES At Best Value Vacs, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Uniformity: within 4% of the temperature setpoint. Heat-Up Time: 20 minutes. Ultimate Vacuum: <500 µmHg / mTorr / micron Time to Vacuum: 10 minutes to 29"Hg Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. SPECIFICATIONS Electrical Voltage 120V Frequency 60HZ Power 1960W Current 20A Plug IEC C13 (unit ships with detachable NEMA 5-15p cable) Internal Chamber Heating Individual Direct-Heat shelves Temperature Range RT+18°-212°F Chamber Material Stainless Stee Dimensions (LxWxH) 22" x 23.25" x 25.25" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 5 Heated Shelves Shelf Dimensions (LxW) 21.5" x 21.5" Shelf Capacity 462 in2 Total Shelf Capacity 2311 in2 / 16.1 ft2 Door Seal Silicone on Tempered Glass Window Dimensions (LxH) 20.25" x 23.75" Lights 4 strips of LEDs provide clear, bright view of interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 35" x 33" x 34.5" Weight 430 lbs Support Locking Casters Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connection Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose and adjusting wrenches. User Manual Included Warranty 3 year oven warranty Vacuum Pump Best Value Vacs VE280 9CFM Two Stage Vacuum Pump CAPACITY AND THROUGHPUT PLANNING Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via UPS Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise UPS freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$11,659.48

-

BVV Space Saver Mobile Oven Cart with Ovens

BVV Space Saver Mobile Oven Cart with Ovens The BVV Space Saver Mobile Oven Cart allows users to greatly increase their output and more efficiently all in one place! There are a total of 4 options in this listing: 1) Three 1.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 2) Two 1.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 3) Three 0.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 4) Two 0.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump If these options don't fit your needs, we also encourage you to expand your options by ordering parts individually or reach out to us (331-281-0154) so we can help create the kit right for you. Included in all the kits is the Heavy Duty Steel Mobile Cart that was designed by us to hold up to three ovens! It also has three height adjustable shelves to suit your needs and can be placed on either side of the bracket. The cart is mobile with its swivel caster wheels and they can can support up to 1,100lbs! The cart can house oven sizes such as the 0.9 and 1.9, Neocision and ECO oven. The oven shelves are made of aluminum and we recommend covering the shelves with silicone pads or a PTFE sheet that can be cut to size. The oven shelves are made of aluminum and we recommend covering the shelves with silicone pads or a PTFE sheet that can be cut to size. It is recommended to change the oil when the color starts to get noticeably darker in the pump. Also included in the kit is our premium Mobil Vacuum Pump Oil. This oil has a longer usable life and does not generate any additional vapor or odor, which will be sure to help your vacuum pump exhaust filter live longer too! Note: The Heavy Duty Steel Mobile Cart shipped does NOT come with the side shelves assembled. Required tool: 5mm ball hex (NOT INCLUDED).

$10,775.30 - $15,629.25

-

Heavy Duty Steel Mobile Cart for Vacuum Ovens

Heavy Duty Steel Mobile Cart for Vacuum Ovens Our heavy-duty cart is designed and built to house a variety of equipment such as vacuum ovens, cold traps, vacuum pumps, etc. The cart can comfortably house up to 3 BVV™ and Across International 0.9 and 1.9 vacuum ovens. The cart offers mobility with their swivel caster wheels and can withstand up to a total of 1,100lbs. Included in the unit are three side shelves in which the height can be adjusted to your needs. The cart was meticulously designed for reliability, customization, and convenience for your process. Features: White powder coated carbon steel. 3-shelf shelving unit 3 laser cut, height adjustable side shelves. 2⅜” diameter hole to help with hose and cable management. 6” front lip for easy oil drainage. Can fit on the left or right side of the bracket Four 3” swivel caster wheels: 2 with brakes and 2 without brakes. Dimensions: 33” (L) x 23” (W) x 61” (H). Additional 13¼” to the length with side shelves added. Made in the USA. Note: The unit shipped does NOT come with the side shelves assembled. Required tool: 5mm ball hex (NOT INCLUDED).

$2,068.17

-

Cascade Sciences Cascade CVO-2 Vacuum Oven

Cascade CVO-2 Vacuum Oven Model CVO-2 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, slurries, or any temperature sensitive material. This vacuum oven liberates solvents, water, and other unwanted compounds in small batch, R&D and lab environments. NRTL Certified. Operating Range: Ambient +10ºC to 150°C (Ambient +18°F to 300°F) Benchtop Size: 1.47 Cubic Ft (47.2L) 12″W x 20″D x 12″H Exceptional Temperature Control & Stability The CVO-2 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-2 eliminate hot and cold spots, making accurate use of every inch of shelf space. Independent Over-temp Failsafe Protection The CVO-2 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 200°C or 392°F. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. Digital Vacuum Gauge The digital vacuum gauge installed on the CVO-2 is factory default set to read in inches of mercury (“Hg) with a scale of 0 – 29.9”Hg. Change the unit of vacuum measurement to read in a wide variety of units from mmHg, bar psi, kPa, cm2, mmH20. Zero out the vacuum gauge to calibrate for just above sea level adjustments. Equipped for Inert Gas Backfill. Built-In Safety Relief Introduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the 1/4″ rear vent barb. The maximum backfill pressure is 15psi at the inlet. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection Ports The CVO-2 ovens offer two different vacuum oven connection points. The standard connection is a 3/8″ dia barb located at the rear of the oven. It is connected to the vacuum valve level on the front control panel. For even faster evaporation, purging or drying consider upgrading to the MAXEVAP connection kit. The MAXEVAP connection kit secures to the oven’s rear 1″ dia KF-25 port located on the back center of the chamber. The MAXEVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthroughs, or monitoring sensors inside the vacuum chamber during processing. Stackable Shelf Design For Maximum Temperature Conduction Under vacuum, there is no air inside a vacuum oven. Temperatures are achieved by a process of conduction and radiation to move temperatures into the product inside the oven. stackable shelf design makes the most of this opportunity by making the chamber longer and narrower, rather than square and supplies stackable shelves in multiple height configurations to allow for the fastest, most uniform transfer of heat. Ergonomically Designed, Easy Quarter-Turn Valves For anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vacuum/vent valves. Your wrists will thank you! Door Gasket Options – Ideal For Your Process Vacuum ovens come standard with a High Temp Silicone Door Gasket. We also offer a Solvent resistant BUNA gasket as well. Ask us about the variety of door gaskets we can supply based on your application: Silicone, BUNA, Viton, Fluorosilicone. Gaskets will eventually wear out. It’s ideal to keep a few spares on hand. Features CVO-2 STANDARD Package Includes: Cascade Sciences CVO-2 (120V) Vacuum Oven Vacuum Oven to Pump Connection Kit Agilent IDP3 Oil-Free Vacuum Pump, 2.1 cfm Features: NRTL Certified by TUV 5 shelves (11.5″W x 19″D) in a flexible configuration. Stack-able and removable Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reports in wide variety of measurement units Simple, set-point control Smooth, quarter-turn vacuum and vent valves Rear KF-25 port allows for rapid MAXEVAP purging or running feedthroughs inside oven for monitoring 120V (220V available) Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Adjustable leveling feet ensure oven sits solid and level in the workspace CVO-2 Connections 3/8″ Barb for Vacuum Pump 1/4″ Barb for Venting (N2 Connection OK) KF-25 Port for feedthroughs or MAXEVAP Connection Kit Specifications Capacity Volume:1.67 Cu Ft (47.2 L) Exterior:20.5″W x 28.8″D x 24.9″H (521mm x 732mm x 633mm) Interior:12.0″W x 20.0″D x 12.0″H (304mm x 508mm x 304mm) Temperature Temperature Range:Ambient +10ºC to 150°C (Ambient +18°F to 300°F) Temperature Uniformity:@ 105°F ±2.5°F@ 200°F ±7.5°F@ 300°F ±16.0°F@ 40°C ±1.4°C@ 90°C ±4.2°C@ 150°C ±8.9°C Temperature Stability:@ 105°F ±0.3°F@ 200°F ±0.3°F@ 300°F ±0.3°F @ 40°C ±0.2°C@ 90°C ±0.2°C@ 150°C ± 0.2°C Heat Up Times:To 105°F 60 minutesTo 200°F 126 minutesTo 300°F 180 minutes To 40°C 60 minutesTo 90°C 126 minutesTo 150°C 180 minutes *Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product and variable ambient conditions. Vacuum Vacuum Valve:1/4 Turn Lever Vent Valve:1/4 Turn Lever Vacuum Gauge:Digital 0 to 29.9″Hg Temperature Controller:Digital Set PointAccurate Within .5ºC (1°F)Independent Overtemp Failsafe Ports (Rear) Vacuum:3/8″ Barb Vent:1/4″ Barb Auxiliary:KF-25 Port Inert Gas Introduction:Use 1/4″ Vent Barb15 psi max inlet pressure Power Options CVO-2 (120V Standard)110V – 120V / 1ph / 8A 50/60Hz (Cord Included)NEMA 5-15R Power OutletFull Power 2456 BTU/hr CVO-2-2 (220V)220 – 240V / 1ph / 4A 50/60 Hz (Cord Included)NEMA 6-15R Power Outlet Shelving Includes 5 aluminum, stackable, removable 1″ High = 1 each2″ High = 2 each3″ high = 2 each Surface Area:11.5″W x 19″D Weight Capacity:50 lbs (22.7 kgs)*Flexible configuration, 4 shelves max Door Interior Lighting:LED Strips (Rated to 150°C) Glass Window:Tempered NGI-US to ANSI Z97.1.2007 Gasket Type:12″ x 12″ High Temp Silicone Standard Gasket Rated to: 230°C (446°F) Gasket Options:Solvent Resistent BUNA Option rated to 105°C (221°F)Viton Option rated to 205°C (401°F) Weight Unit Weight:179 lb (81.2 kg) Shipping Weight:218 lb (99 kg) Shipping Dimensions:33″L x 33″W x 47″D (Class 85) CV0-2 Vacuum Oven Accessories: CVO-2 2″ ShelfCVO-2 3″ ShelfCVO-2 PTFE Sheets

$9,562.16 - $14,572.96

-

Cascade Sciences Cascade CVO-10 Vacuum Oven

Cascade CVO-10 Vacuum Oven High production, large vacuum drying system for vacuum purging production quantities, the Cascade CVO-10 is our largest 10 cubic foot vacuum oven. Model CVO-10 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, and slurries – especially temperature sensitive material. This vacuum oven liberates solvents, water, and other unwanted compounds in large batch production environments. Note that this is a 220V vacuum oven. The Cascade Difference Vacuum ovens have been around for decades. Basic vacuum ovens are mass-produced and sold by many large-scale laboratory equipment distributors. But there are key differences between and other inexpensive, often imported vacuum ovens. Exceptional Temperature Control & StabilityThe CVO-10 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-10 eliminate hot and cold spots, making accurate use of every inch of shelf space. Independent Overtemp Failsafe ProtectionThe CVO-10 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 392°F or 200°C. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. Digital Vacuum GaugeThe digital vacuum gauge installed on the CVO-10 is selectable between inches of mercury (“Hg) or torr, mtorr. Equipped for Inert Gas Backfill. Built-In Safety ReliefIntroduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the ¼” rear vent barb. The maximum backfill pressure is 15PSI. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection PortsFor faster evaporation, purging or drying the CVO-10 includes MAX EVAP connection kit. The MAX EVAP connection kit secures to the oven’s rear 1” dia KF-25 port located on the back center of the chamber. The MAX EVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthrus, or monitoring sensors inside the vacuum chamber during processing. Ergonomically Designed, Easy Quarter-Turn ValvesFor anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vent valve. Your wrists will thank you! Faster Venting With Large ½” Diameter Vent LinesFor large capacity production environments, time is money. The CVO-10 vacuum oven has larger than industry standard vent lines. ½” diameter vent lines means operators spend less time venting the oven. Features CVO-10 PRO Package Includes: Cascade Sciences CVO-10 Vacuum Oven Heavy-Duty Industrial Mobile Cart 9x Total Shelves – 28”W x 24”D MAXEVAP KF-25 Connection for faster purge Agilent IDP15 Oil-Free Vacuum Pump, 9cfm Features: NRTL Certified by TUV 9 sliding, removable shelves that pull out and stay in place for easy load/unload Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Easy mobility as oven sits on heavy duty industrial cart. Pump sits underneath at base of cart Silicone Door Gasket Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reads in inches of mercury or torr Smooth, quarter-turn vent valve Oven to pump connection: Rear KF-25 line, valve 220V / 1ph / 10AMPS plugs into NEMA 16-5R outlet Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Ergonomic. Turn vacuum pump on/off from oven control panel Fast Venting with larger ½” diameter vent line. Allows for nitrogen or other inert gas connection Touch Panel LED control screen with user settable features (torr, mtorr, Hg, Fahrenheit, Celsius) Walls lined with heat conductive copper for improved temp transfer. Known antimicrobial properties can prevent bacteria buildup Specifications VOLUME:9.3 Cubic Ft. (263 Liters) SHELVES:9 total (max), removableFull-extension, stay in placeIntegrated copper strips optimize temp transferSurface area: 28″W x 24″DWeight Capacity Per Shelf: 50 lb / 22.7 kgApprox 930 cubic inches of volume OVEN INTERIOR:28”W x 24”D x 24”H711mm x 609mm x 609mm OVEN EXTERIOR:(not including rack)42” W x 40” D x 67.4”H1067mm x 1021mm x 1712mm WEIGHT:Shipping: 775 lb/ 352 kgNet Weight: 663.0 lb/ 301 kg TEMPERATURE RANGE:Ambient +26° to 302°F / Ambient +14.4°C to 150°C TEMPERATURE UNIFORMITY:@ 105°F +/- 0.2°F – ±2.0°F@ 200°F +/-0.4°F – ±5.5°F@ 300°F +/- 0.2°F – ±8.0°F @40°C +/- 2°C – ±1.0°C@90°C +/- 3°C – ±3.0°C@150°C +/- 4.5°C – ±4.5°C TEMPERATURE STABILITY:@ 105°F +/- 0.2°F – ±0.2°F@ 200°F +/-0.4°F – ±0.4°F@ 302°F +/- 0.2°F – ±0.2°F @40°C +/- 0.1°C – ±0.1°C@93.3°C +/- 0.2°C – ±0.2°C@150°C +/- 0.1°C – ±0.1°C HEAT UP TIME FROM AMBIENT:@ 105°F / 40.5°C – 42 min@ 200°F / 93.3°C – 94 min@ 302°F / 150°C – 175 min COOL DOWN TIMES:@ 105°F / 40.5°C – 330 min@ 200°F / 93.3°C – 94 min@ 302°F / 150°C – 420 min *Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product. VACUUM VALVE:Side Mounted Round VENT VALVE:¼ Turn Lever½” diameter line GLASS WINDOW:Tempered NGI-US to ANSI Z97.1.2007Interior lighting VACUUM GAUGE:Reads in inches mercury or torr(Selectable) CONTROLLER:Touch ScreenAccurate Within 1°FIndependent Overtemp Failsafe PORTS (REAR):Vacuum = KF-25 PortVent = 1/2” Barb INERT GAS INTRODUCTION:Yes. Via 1/2” Vent Barb15 psi max inlet pressure POWER:220V – 240V / 1ph / 10A 50/60HzCord IncludedNEMA 6-15R Power Outlet(System will run on 208V)Oven BTU Rating at 250ºF: 6980 BTUs/hr at full capacity

$34,696.66 - $44,138.06