New Products

-

Ashless Filter Papers - 125MM - Quantitative

Ashless Filter Papers - 125MM - Quantitative Ashless quantitative and qualitative filter papers provide laboratory grade filtration for extraction systems and are specifically used in combination with a Buchner funnel to remove fats, waxes and any other unwanted contaminants from your solution. These filter papers are used in the pre-processing stage of short path distillation to clean up the material prior to processing. Key Features: ISO 9001 Approved Manufactured from alpha-cellulose and cotton linters High Purity and low background Consistent performance Low ashless content: <0.007% (Quantitative Filter Paper) Whatman equivalent quality Pre-Cut for ease of use Specifications: Classification Quantitative Sizes Available: BIO-40 8um - Medium BIO-41 20-25um - Fast BIO-42 2.5um - Slow BIO-44 3um - Slow Ash Content <0.007% Quantity per Pack 100 Diameter 125mm (4.92") Technical Data: Grade Particle Retention Appearance Speed Ash Content (%) Basis Weight (g/m2) Wet burst (mm H2O) BIO-1 11um Smooth Medium <0.1 80.0±4.0 >140 BIO-2 8um Smooth Medium <0.1 80.0±4.0 >140 BIO-4 20um Smooth Fast <0.1 80.0±4.0 >120 BIO-5 2.5um Smooth Slow <0.1 80.0±4.0 >180 BIO-6 3um Smooth Slow <0.1 80.0±4.0 >180 BIO-40 8um Smooth Medium <0.007 80.0±4.0 >140 BIO-41 20-25um Smooth Fast <0.007 80.0±4.0 >120 BIO-42 2.5um Smooth Slow <0.007 80.0±4.0 >180 BIO-43 16um Smooth Medium to Fast <0.007 80.0±4.0 >120 BIO-44 3um Smooth Slow <0.007 80.0±4.0 >180

$69.40

-

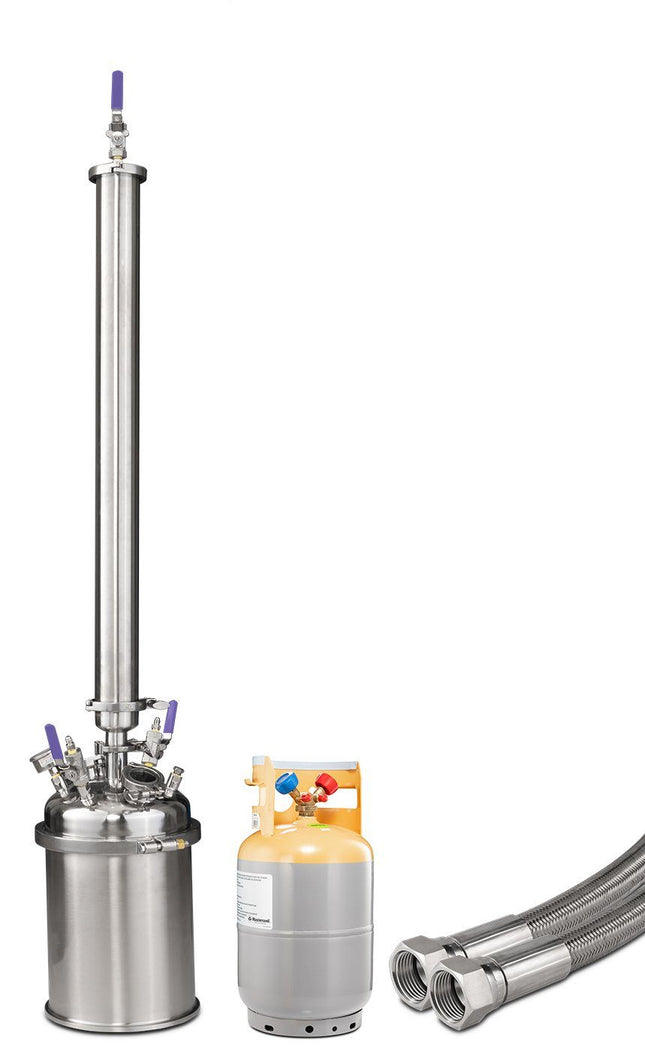

2LB Apollo Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well ventilated areas. Check with your local fire marshal for guidance when operating indoors 2lb Closed Loop Reclamation Extraction System (System comes with 1 yr. limited warranty) The 2lb closed loop hydrocarbon extraction system performs botanical extraction within a sealed, vacuumed system. Utilizing a top-fill input, solvent washes thru the material column, collecting oils as it passes over the material. Oil bearing solvent is collected in the collection base under the material column. Once collected, solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. This unit can be upgraded into an Active recovery unit by purchasing the upgrade kit. TRS21 Active Closed Loop Recovery Kit Extractor Configurations: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and standard LP tank. This model has minimal features to keep cost low, while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Solvent is input into the material column with a showerhead endcap, ensuring the full material column is saturated with solvent. The Professional comes with a sleeved spool, allowing users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is our fully upgraded Apollo model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. It features a larger bore on valves and hoses, all American made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, sleeved dewaxing column, jacketed collection base, and a stainless steel LP tank. The Elite series boasts increased efficiency on both solvent input and recovery by bumping up all valves and lines to 3/8” JIC. The stainless steel LP tank is able to be opened and cleaned, making solvent contamination a non-issue. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base BVV 316SS Full Bore Valves Showerhead Dewaxer Ball Valve Splatter Platter Base SSP Valves Showerhead Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter SSLP 3/8" Valves & Hoses Unit Includes: Collection Base 10"x10" Welded Bottom Base Assembled 10" extractor lid 3"x36" Material column with reducer & top cap #30 LP tank 60" High Pressure PTFE Braided SS Hose 10" clamp, (2)3" clamps and a 1.5" clamp with gaskets Instruction Manual Specifications: 3"x 36" 304 Stainless Steel Material Tube 2lb (900g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple port connections for _" 316 Stainless JIC 37 Degree 304 Stainless Steel Base Container 10" diameter by 10" tall Tri-Clamps at all interfaces make for a high pressure, easy clean unit. Viton Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 55" x 10" Diameter overall size Weight: 38 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Base unit Maximum Capacity: 785 cubic inches, (12.8704 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$1,596.18 - $4,302.74

-

1LB Skylight Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well ventilated areas. Check with your local fire marshal for guidance when operating indoors Closed Loop Reclamation Extraction System (System comes with 1 yr. limited warranty) The 1lb Skylight closed loop hydrocarbon extraction system performs botanical extraction within a sealed, vacuumed system. What sets the skylight apart from the standard 1lb is the kettle top featuring a 3" sight glass to view inside the collection vessel. This is great for beginners on a larger scale, the viewport helps you easily see your oil fall and gives you a great view of your recovery process. Utilizing a top-fill input, solvent washes thru the material column, collecting oils as it passes over the material. The top-fill closed loop extractor is the safest way to do hydrocarbon extraction. Solvent washes through the material column and collects oils as it passes over the material, and the oil-bearing solvent is collected in the collection base. Once collected, the solvent in this passive unit is distilled and recovered using temperature manipulation, leaving oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and standard LP tank. This model has minimal features to keep cost low, while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Solvent is input into the material column with a showerhead endcap, ensuring the full material column is saturated with solvent. The Professional comes with a sleeved spool, allowing users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is the premium version of the Professional. It features all American made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, jacketed collection base, and all high-pressure clamps. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base BVV 316SS Full Bore Valves Showerhead Dewaxer Ball Valve Splatter Platter Base SSP Valves Showerhead Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter Unit Includes: Collection Base 6"x6" Welded Bottom Base 6"x4" Kettle top with 3" Sight Glass Assembled 4" extractor lid 3"x24" Material column with reducer & top cap 6LB Mastercool Solvent Recovery Tank 60" High Pressure PTFE Braided SS Hose (2) 6" clamps, (2) 3" clamps and a 1.5" clamp with gaskets Instruction Manual Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$1,478.20 - $3,122.96

-

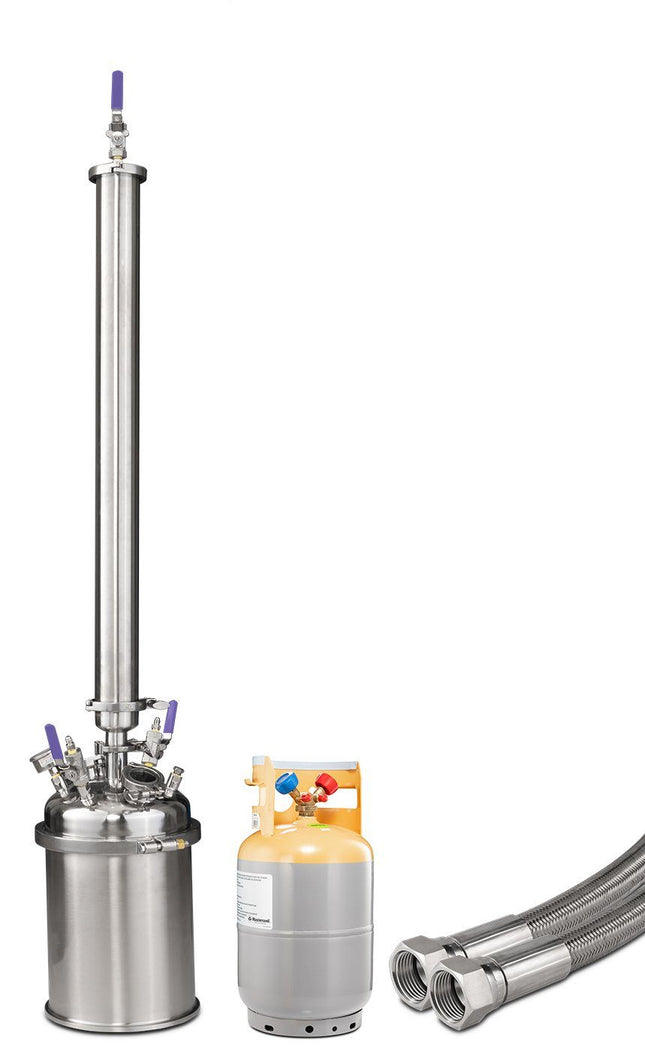

1LB Apollo Top Fill Closed Loop Extractor

1LB Top Fill Closed Loop Extraction System (System comes with 1 yr. limited warranty) The 1lb closed loop hydrocarbon extractor performs incredible botanical extraction within a sealed, vacuumed system. With the help of a top-fill input, solvent washes through the material column, collecting oils as it passes over the material. The oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. KEY BENEFITS Meets or exceeds all industry listed standards Versatile in running butane, propane, and other blended solvents Perfect for mid to large-scale extraction/production facilities Faster run times and less degradation in the process Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and standard LP tank. This model has minimal features to keep cost low, while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Solvent is input into the material column with a showerhead endcap, ensuring the full material column is saturated with solvent. The Professional comes with a sleeved spool, allowing users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is the premium version of the Professional. It features all American made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, jacketed collection base, and all high-pressure clamps. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base BVV 316SS Full Bore Valves Showerhead Dewaxer Ball Valve Splatter Platter Base SSP Valves Showerhead Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter Unit Includes: 6"x6" Welded Bottom Base 6"x6" Open Spool Assembled 6" extractor lid 3"x24" Material column with reducer & top cap Mastercool 6LB Solvent Recovery Tank (1) 1/4" 48" FJIC Stainless Steel hose (1) 1/4" 60" FJIC Stainless Steel hose (1) 1/4" FJIC HVAC hose Standard pressure single pin clamp Instruction Manual Specifications: 3"x 24" 304 Stainless Steel Material Column-1lb capacity (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple 37 degree FJIC port connections 304 Stainless Steel Base Container 6" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure/standard pressure, easy clean unit BUNA-N Gaskets are designed for Oil Processing Temp range -40-200F, and have superior solvent resistance Base unit Maximum Capacity: 395 cubic inches, (6.472 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$1,357.45 - $2,914.76

-

90-270G Apollo Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors Closed Loop Reclamation Extraction System (System comes with 1 yr. limited warranty) Please Read Optional Upgrades Section for Clarification on System Upgrades The scalable closed loop hydrocarbon extraction system performs botanical extraction within a sealed, vacuumed system. Utilizing a top-fill input, solvent washes through the material column, collecting oils as it passes over the material. The oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configurations: Explorer: Our standard, most economical setup, perfect for the entry-level extractor on a budget. It comes with a welded bottom base and a standard LP tank. This model has minimal features to keep costs low while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Coming with a sleeved spool, this model allows users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow the solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is the premium version of the Professional. It features all American-made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, and all high-pressure clamps. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base BVV 316SS Full Bore Valves Dewaxer Ball Valve Splatter Platter Base SSP Valves Dewaxer AVCO Ball Valve HP Clamps Splatter Platter Base Kit Includes: 6" x 6" Collection Base 1.5" Material Column (12",18",24", or 36") 6lb Recovery Cylinder 1/4" Stainless Steel Braided PTFE hoses Buna-N Gaskets Standard Valves *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$1,110.39 - $2,470.61

-

90G XL Mini Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well ventilated areas. Check with your local fire marshal for guidance when operating indoors Closed Loop Reclamation Extraction System (Comes with 1 yr. Limited warranty) 90G XL Mini Top Fill Closed Loop Extractor (System comes with 1 yr. limited warranty) The MiniXL Extractor is an excellent choice for small personal runs or test runs of material and comes in a small tabletop design that is easy to use. Mini CLS / Mini XL Upgrades: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and stainless reclaim container. This model has minimal features to keep cost low while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Coming with a sleeved spool, this model allows users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Explorer Professional Standard Valves Welded Bottom Base Standard Valves Dewaxer Ball Valve Splatter Platter Base Specifications: 1.5"x 12" 304 Stainless Steel Material Tube 90g 304 Stainless Steel Heavy Duty Miniature Ball Valves System Rated to 100PSI Multiple port connections for 1/4" 316 Stainless SAE 37 Degree 304 Stainless Steel Base Container 4" diameter by 8" tall Tri-Clamps at all interfaces make for a high pressure, easy clean unit. Buna-N Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 16" Overall Height x 4" Diameter Weight: 18 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Designed to run two cans of solvent and reclaim them (420ml) 1135ml Max FILL!! Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior Automatically Includes: High-Pressure PTFE Braided Stainless Steel Hose Can Tap Tool 6LB Mastercool Solvent Recovery Tank *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$725.91 - $995.18

-

45G Mini Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors Closed Loop Reclamation Extraction System (Comes with 1 yr. Limited warranty) 45G Mini Top Fill Closed Loop Extractor (System comes with 1 yr. limited warranty) What’s a 45G Mini Top Fill Closed Loop Extractor? 45G Mini Top Fill Closed Loop Extractor is an excellent extraction system for small personal test runs. Since it’s a smaller version of our standard top-fill closed loop extractor, it’s great for beginners while still maintaining all the bells and whistles. Our extractor is even the perfect size for a tabletop! How Does the 45G Mini Top Fill Closed Loop Extractor Work? The top-fill closed loop extractor is the safest way to do hydrocarbon extraction. First, solvent washes through the material column and collects oils as it passes over the material. Then, the oil-bearing solvent is collected in the collection base. Once collected, the solvent in this passive unit is distilled and recovered using temperature manipulation. This is what leaves oils behind in the collection base. What’s Included in the 45G Mini Top Fill Closed Loop Extractor? High-Pressure PTFE Braided Stainless Steel Hose Standard Pressure Tri-Clamps Full set of BUNA-N gaskets Includes 100 Mesh (150 Micron) gasket for the material tube Can Tap Tool Instruction Manual 1 Year Limited Warranty and Customer Service 45G Mini Top Fill Closed Loop Extractor System Specifications 1.5"x 6" 304 Stainless Steel Material Tube 304 Stainless Steel Heavy Duty Miniature Ball Valves System Rated to 100PSI Multiple port connections for any 316 Stainless SAE 37 Degree 304 Stainless Steel Base Container 4" diameter by 4" tall Tri-Clamps at all interfaces for high pressure, easy-clean unit High-Quality BUNA-N Gaskets designed for oil processing Operating Temperature Range: -40°F to 160°F Ultimate Vacuum: as low as 10 Microns Designed to run a single can of solvent and reclaim it (420ml) 540 ml max FILL! Construction: All major components made of 304 Stainless Steel Max Vacuum -29.9inHg High Polish Interior Mini CLS / Mini XL Upgrades Explorer Our most standard and economical setup. It’s perfect for entry-level extractors on a budget. It comes with a welded bottom base and stainless reclaim container. This model has minimal features to keep costs low while providing the necessary equipment to get the job done. Includes: Standard Valves Welded Bottom Base Professional This model features upgrades for easier extraction. An inline ball valve allows the solvent to be suspended in the material column and closes the collection base during recovery. The removable bottom to the collection base makes extract removal simple. Includes: Standard Valves Ball Valve Splatter Platter Base Notes and Disclaimer(s): Please note: The solvent Butane isn’t included with any of our systems unless ordered separately or by using the dropdown menu. Orders containing butane won’t ship expedited. Also, column capacity may vary. Capacity is calculated using the industry standard of 4.2g/in3 as the upper limit. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend tightly packing coarse ground material. Shop all Closed-Loop Extractors Disclaimers: This unit is intended for legal purposes only while following local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. Explorer Professional Standard Valves Welded Bottom Base Standard Valves Ball Valve Splatter Platter Base System Specifications: 1.5"x 6" 304 Stainless Steel Material Tube 304 Stainless Steel Heavy Duty Miniature Ball Valves System Rated to 100PSI Multiple port connections for _" 316 Stainless SAE 37 Degree 304 Stainless Steel Base Container 4" diameter by 4" tall Tri-Clamps at all interfaces make for a high pressure, easy-clean unit. High-Quality BUNA-N Gaskets are designed for Oil Processing Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Designed to run a single can of solvent and reclaim it (350ml) Max FILL!! Construction: All major components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior What's Included: High-Pressure PTFE Braided Stainless Steel HoseStandard Pressure Tri-Clamps Full set of BUNA-N gaskets including the 100 Mesh(150 Micron) gasket for the material tube is included Can Tap Tool Instruction Manual 1 Year Limited Warranty and Customer Service *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$659.29 - $886.92

-

2LB MK-V Bi-Directional Closed Loop Extraction Kit

2LB MK-V Bi-Directional Closed Loop Extraction Kit (System comes with 1 yr. limited warranty) We believe it’s better to buy everything you need at one time, so we’ve created a package that includes an orthrus, vacuum pumps, and complete extraction system. The best part? Buying this kit will save you money compared to purchasing each component individually. ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors The 2lb Bi-Directional closed loop increases efficiency by utilizing both a bottom and top solvent input. By using a bottom flood on the first wash to ensure all material has seen solvent, preventing channeling through the material. Finish the run with a top flood input to ensure all residuals have been washed from the material. Oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configurations: Explorer: Our standard bi-directional extractor model. Comes with a welded bottom base and standard LP tank. This model provides all the benefits of the Orthrus design without any bells and whistles. The Explorer model is perfect for those looking to get the bi-directional performance but have a budget. Explorer models can be upgraded after purchase. Professional: This model features upgrades to help produce a higher quality extract. Solvent is entered into the system through an injection coil. This coil is chilled with dry ice and alcohol, dropping solvent temperatures to dewax inline. Fats and waxes are not soluble when solvent temperature is subzero, so chilling solvent on input is the simplest way to achieve high clarity extract. The Professional also comes with a removable bottom on the collection base. This makes removal of extract after the run as easy as possible. Elite: The Elite series is our fully upgraded Orthrus model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. It features a larger bore on valves and hoses, all American instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, jacketed collection base, and stainless steel LP tank. Full dewaxing is guaranteed by combining both an injection coil and sleeved column. Both units are packed with dry ice, making both solvent and material sub-zero temperatures. The material column is fitted with a nitrogen assist port, which helps ensure no solvent gets stuck with the material. The Elite series boasts increased efficiency on both solvent input and recovery by bumping up all valves and lines to 3/8” JIC. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. The stainless steel LP tank is able to be opened and cleaned, making solvent contamination a non-issue. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base 1.9 NEO Oven V7S 7CFM Single Stage Vacuum Pump BVV 316SS Full Bore Valves Splatter Platter Base Injection Coil w/ hose 1.9 NEO Oven V7S 7CFM Single Stage Vacuum Pump SSP Valves Injection Coil Dewaxer AVCO Ball Valve Jacketed Base/Platter 3/8” Valves/Lines SSLP Nitrogen Assist 1.9 NEO Oven V7S 7CFM Single Stage Vacuum Pump This Unit Includes: Collection Base 10"x10" Welded Bottom Base Assembled 10" Hemispherical bi-flow lid 4"x24" Material column with reducer & top cap 4" filter plate kit 1.5" Solvent input manifold 1.5" Ball Valve #30 LP tank (2) 1/4" 48" High-Pressure PTFE Braided SS Hose 3/8" 48" High-Pressure PTFE Braided SS Hose 10" clamps, (3)4" clamps and a (3)1.5" clamp with gaskets (2)4" Gaskets w/ filter Instruction Manual *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$5,091.12 - $8,813.69

-

1LB MK-V Bi-Directional Closed Loop Extraction Kit

1LB MK-V Bi-Directional Closed Loop Extraction Kit (System comes with 1 yr. limited warranty) We believe it’s better to buy everything you need in one shot, so we’ve created a package that includes a vacuum chamber, vacuum pumps, and complete extraction system. The best part? Buying this kit will save you money compared to purchasing each component individually. ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors The 1lb Bi-Directional closed loop increases efficiency by utilizing both a bottom and top solvent input. By using a bottom flood on the first wash, you ensure all material has seen solvent. This method preventing channeling through the material. Finish the run with a top flood input to ensure all residuals have been washed from the material. Oil bearing solvent is collected in the collection base under the material column. Once collected, solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configurations: Explorer: Our standard bi-directional extractor model. Comes with a welded bottom base and standard LP tank. This model provides all the benefits of the Orthrus design without any bells and whistles. The Explorer model is perfect for those looking to get the bi-directional performance but have a budget. Explorer models can be upgraded after purchase. Professional: This model features upgrades to help produce a higher quality extract. Solvent is entered into the system through an injection coil. This coil is chilled with dry ice and alcohol, dropping solvent temperatures to dewax inline. Fats and waxes are not soluble when solvent temperature is subzero, so chilling solvent on input is the simplest way to achieve high clarity extract. The Professional also comes with a removable bottom on the collection base. This makes removal of extract after the run as easy as possible. High pressure clamps give greater solvent compatibility, allowing propane to be used. Elite: The Elite series is our fully upgraded Orthrus model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. The elite series comes with all American instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve and jacketed collection base. Full dewaxing is guaranteed by combining both an injection coil and sleeved column. Both units are packed with dry ice, making both solvent and material sub-zero temperatures. The material column is fitted with a nitrogen assist port, which helps ensure no solvent gets stuck with the material. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump BVV 316SS Full Bore Valves HP Clamps Injection Coil w/ Hose Splatter Platter Base 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump SSP Valves Injection Coil Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter Nitrogen Assist 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump Unit Includes: Collection Base 6"x6" Welded Bottom Base 6"x6" Open Spool Assembled 6" bi-flow lid 3"x24" Material column with reducer & top cap 3" filter plate kit 1.5" Solvent input manifold 1.5" Ball Valve #30 LP tank (2) 1/4" 48" High Pressure PTFE Braided SS Hose 3/8" 48" High Pressure PTFE Braided SS Hose (2)6" clamps, (3)3" clamps and a (3)1.5" clamp with gaskets Instruction Manual Specifications: 3"x 24" 304 Stainless Steel Material Tube 1lb (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple port connections for _" 316 Stainless JIC 37 Degree 304 Stainless Steel Base Container 6" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure, easy clean unit. Viton Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 25" x 7" Diameter overall size Weight: 21 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Base unit Maximum Capacity: 300 cubic inches, (2.553 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$4,186.15 - $7,457.63

-

1LB Passive Closed Loop Extraction Kit

Passive Closed Loop Extraction System ***NOTICE TO CUSTOMER: THIS ITEM WILL SHIP BY FREIGHT ONLY*** (System comes with 1 yr. limited warranty) ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors We believe it’s better to buy everything you need in one shot, so we’ve created a package that includes a vacuum chamber, vacuum pumps, and complete extraction system. The best part? Buying this kit will save you money compared to purchasing each component individually Closed Loop Extraction Process The 1lb closed loop hydrocarbon extraction system performs botanical extraction within a sealed, vacuumed system. Utilizing a top-fill input, solvent washes thru the material column, collecting oils as it passes over the material. The oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and standard LP tank. This model has minimal features to keep cost low, while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Solvent is input into the material column with a showerhead endcap, ensuring the full material column is saturated with solvent. The Professional comes with a sleeved spool, allowing users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is the premium version of the Professional. It features all American made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, jacketed collection base, and all high-pressure clamps. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump BVV 316SS Full Bore Valves Showerhead Dewaxer Ball Valve Splatter Platter Base 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump SSP Valves Showerhead Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump Unit Includes: 6"x6" Welded Bottom Base 6"x6" Open Spool Assembled 6" extractor lid 3"x24" Material column with reducer & top cap Mastercool 6LB Solvent Recovery Tank (1) 1/4" 48" FJIC Stainless Steel hose (1) 1/4" 60" FJIC Stainless Steel hose (1) 1/4" FJIC HVAC hose Standard pressure single pin clamp and 1 full gasket set Instruction Manual Specifications: 3"x 24" 304 Stainless Steel Material Column-1lb capacity (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple 37 degree FJIC port connections 304 Stainless Steel Base Container 6" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure/standard pressure, easy clean unit BUNA-N Gaskets are designed for Oil Processing Temp range -40-200F, and have superior solvent resistance Base unit Maximum Capacity: 395 cubic inches, (6.472 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$4,073.73 - $5,177.17

-

XL Mini Closed Loop Extraction Starter Kit

XL Mini Closed Loop Extraction Starter Kit (System comes with 1 yr. limited warranty) Everything You Need to Get Your Extraction Started Closed-loop extraction is a safe, fast, and efficient solution to removing oils from botanical material. Closed-loop systems allow you to do everything in a closed vessel. BVV™ has bundled our recommended vacuum chamber, vacuum pump, and complete extraction system to offer customers the most cost-effective solution possible. The Mini-XL Closed Loop Extractor Starter Kit is a step up from the closed column extractor starter kit. The Mini-XL Closed Loop Extractor is a tabletop version of a closed-loop extraction system that allows users to run personal or test-sized extractions in a short amount of time. The system also offers users the chance of recovering around 95% of their solvent. Not only does this save a considerable amount of money, but it's also safer for the user performing botanical oil extractions because the entire extraction process is in a closed-loop environment. Mini CLS / Mini XL Upgrades: Explorer: Our standard, most economical setup, perfect for the entry-level extractor on a budget. It comes with a welded bottom base and stainless reclaim container. This model has minimal features to keep costs low while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Coming with a sleeved spool, this model allows users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Explorer Professional Standard Valves Welded Bottom Base Standard Valves Dewaxer Ball Valve Splatter Platter Base Specifications: 1.5"x 12" 304 Stainless Steel Material Tube 90g 304 Stainless Steel Heavy Duty Miniature Ball Valves System Rated to 100PSI Multiple port connections for 1/4" 316 Stainless SAE 37 Degree 304 Stainless Steel Base Container 4" diameter by 8" tall Tri-Clamps at all interfaces make for high pressure, easy-clean unit. Buna-N Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 16" Overall Height x 4" Diameter Weight: 18 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Designed to run two cans of solvent and reclaim it (420ml) 1135ml Max FILL!! Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior Automatically Includes: High-Pressure PTFE Braided Stainless Steel Hose Can Tap Tool 6LB Mastercool Solvent Recovery Tank BVV™ V4D 4CFM Two Stage Vacuum Pump This is the BVV™ V4D 4CFM Two Stage Vacuum Pump used in botanical extraction. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Feature Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer oil life Lightweight Rubber Feet for noise dampening Reliable, economical, and efficient Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend tightly packing coarse ground material. ***Note: Butane (Solvent) is not included with systems unless ordered in the drop-down menu or separately. Any order with butane WILL NOT SHIP EXPEDITED.

$1,562.87 - $1,884.88

-

Closed Column Extractor Starter Kit

Complete Closed Column Extractor Kit BVV has bundled our recommended vacuum chamber, vacuum pump, and column extraction system to offer customers the most cost-effective solution possible. The Closed Column Extractor Kit is designed to pair well with the other products included in the extraction kit. The items in the kit cover every process from start to finish on your essential oil extraction (excluding butane) and is easy for beginner operators to use. The first step of the oil extraction process is to use the closed column extractor to extract the essential oils from the plant material into a pyrex dish. The user then transfers the oil with residual solvent into the two-gallon vacuum chamber; the digital heating pad is attached to the bottom of the chamber after setting the temperature. The V4D 4CFM 2 Stage vacuum pump exerts a high vacuum to purge and degass residual solvent or gases trapped inside the oil. (Note: This process may take up to 5 days.) Once the purging process is complete, the oil extraction can be used immediately or transformed into a variety of applications. Professional Kit Adds the following: Compound Gauge Sight Glass Shower Head Best Value Vacs 2 Gallon Vacuum Chamber 90 Day Registered Warranty Best Value’s unique, patent-pending gasket design (Utility Patent #14/533,548) and formidable chamber are designed to last 10,000 uses with proper care and maintenance. The gasket is made reversible for easy peel-off and peel-on functionality, effectively doubling the life of our system. The chamber is equipped with user-friendly vacuum connections that fit most vacuum pumps on the market. Every chamber is tested before shipping to lose no more than 2.5Hg/24hrs. Product Features: Aluminum Vessel Highly durable and reversible silicone gasket Glycerin-filled vacuum gauge 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum-rated HVAC hose to pull a vacuum. 9" Digital Heat Pad 90 Day Registered Warranty This 9” reprogrammable Digital Heat Pad comes with full, detailed instructions. Product Features UL Listed Fahrenheit Digital Controller Min Temp: Ambient + 5Max Temp: 160F Voltage: 110VAC Only Power Consumption: 218-watt Digital Control: Increments of 1 Degree Accuracy: +/- 0.2 Degrees Relay Lifespan: Approx. 10 million cycles BVV™ V4D 4CFM Two Stage Vacuum Pump This is the BVV™ V4D 4CFM Two Stage Vacuum Pump used in botanical extraction. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Feature Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer oil life Lightweight Rubber Feet for noise dampening Reliable, economical, and efficient Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$964.65 - $1,325.52

-

Ashless Filter Papers - 110MM - Quantitative

Ashless Filter Papers - 110MM - Quantitative Ashless quantitative and qualitative filter papers provide laboratory grade filtration for extraction systems and are specifically used in combination with a Buchner funnel to remove fats, waxes and any other unwanted contaminants from your solution. These filter papers are used in the pre-processing stage of short path distillation to clean up the material prior to processing. Key Features: ISO 9001 Approved Manufactured from alpha-cellulose and cotton linters High Purity and low background Consistent performance Low ashless content: <0.007% (Quantitative Filter Paper) Whatman equivalent quality Pre-Cut for ease of use Specifications: Classification Quantitative Sizes Available: BIO-40 8um - Medium BIO-41 20-25um - Fast BIO-42 2.5um - Slow BIO-44 3um - Slow Ash Content <0.007% Quantity per Pack 100 Diameter 110mm (4.33") Technical Data: Grade Particle Retention Appearance Speed Ash Content (%) Basis Weight (g/m2) Wet burst (mm H2O) BIO-1 11um Smooth Medium <0.1 80.0±4.0 >140 BIO-2 8um Smooth Medium <0.1 80.0±4.0 >140 BIO-4 20um Smooth Fast <0.1 80.0±4.0 >120 BIO-5 2.5um Smooth Slow <0.1 80.0±4.0 >180 BIO-6 3um Smooth Slow <0.1 80.0±4.0 >180 BIO-40 8um Smooth Medium <0.007 80.0±4.0 >140 BIO-41 20-25um Smooth Fast <0.007 80.0±4.0 >120 BIO-42 2.5um Smooth Slow <0.007 80.0±4.0 >180 BIO-43 16um Smooth Medium to Fast <0.007 80.0±4.0 >120 BIO-44 3um Smooth Slow <0.007 80.0±4.0 >180

$58.30

-

PTFE Envelope Tri-Clamp Gaskets with Viton Filler - USA Made

PTFE Envelope Tri-Clamp/Tri-Clover Gaskets with Viton Filler PTFE Envelope Tri-Clamp Gaskets are the only choice when needing extreme chemical resistance and temperature range. These gaskets are extremely unique in their construction because they have a Viton filler for compressibility surrounded by an 'Envelope' of PTFE which creates a unique combination of chemical resistance while providing an exceptional sealing characteristic. Normal solid PTFE gaskets are very tough to seal on their own and are usually not recommended in vacuum applications due to the gasket being very rigid because PTFE is not very compressible by itself. Tri-Clamp/ Tri-Clover Sanitary Fittings Gaskets create a pressure-tight seam between multiple stationary components, relying on a compression seal to prevent unwanted gas or liquid emissions. ***Note: Best Value Vacs ONLY recommends the use of PTFE Envelope gaskets with High Pressure clamps to ensure a positive seal on the system. Key Features: Excellent resistance to almost all chemicals Excellent Temperature Range Excellent Cleanability due to PTFE (Teflon) Envelope No Chemical Leaching Sizes Available: 1.5" 2" 3" 4" 6" 8" 10" 12" Chemical Compatibility: Material PTFE(Teflon)/Viton Filler(FKM) Color White/Black Connection Type Tri-Clamp Conformance U.S.P. CLASS VI COMPLIANCEPasses USP Class VI Cytotoxicity Testing and is suitable for high purity pharmaceutical grade applications.PTFE is FDA 21, 177,1550 compliant and the FKM(Viton) inner cores are FDA CFR 21, 177.2600 compliant. Thermal Properties: Low Temperature Range -100°F Minimum Continous Use (Static) -65°F Brittle Point -100°F High Temperature Range +400°F Maximum for Continous Use (Static) +400°F Chemical Compatibility: Butane A - Excellent Propane (liquified) A - Excellent Alcohols: Amyl A - Excellent Benzyl A - Excellent Butyl A - Excellent Diacetone A - Excellent Ethyl A - Excellent Hexyl A - Excellent Isobutyl A - Excellent Isopropyl A - Excellent Methyl A - Excellent Octyl A - Excellent Propyl A - Excellent BVV™ PTFE Gasket With Viton Filter - Data Sheet Disclaimer: BVV Recommends no more than a -40F Operating Temperature and is not responsible for the user running their system with incompatible chemicals.

$9.02 - $173.50

-

Silicone Tri-Clamp Gaskets

Silicone Tri-Clamp/ Tri Clover Gaskets Silicone Tri-Clamp Gaskets are intended to be used when using alcohol as an extraction solvent instead of butane or propane. Silicone has an excellent chemical resistance to alcohols and is the preferred gasket material when using Jacketed Reactors or Tri-Clamp Buchner funnels for post-processing winterization because they have very low extractable characteristics. Silicone gaskets also offer a very good temperature range and will retain their original shape even when compressed for a long duration. ***Note: Silicone is not recommended for use with butane or propane solvents. Key Features: Excellent resistance to Alcohols Excellent Temperature Range Excellent Rebound and Memory Very Low extractable characteristics Sizes Available: 1.5" 2" 3" 4" 6" 10" Easy On - Flanged 12" Easy On - Flanged Specifications: Material Silicone Color White Connection Type Tri-Clamp Conformance USP Class VI, FDA and 3A Compliance Thermal Properties: -Low Temperature Range -58°F -Minimum Continous Use (Static) -40°F -Brittle Point -58°F -High Temperature Range +446°F -Maximum for Continous Use (Static) +446°F Durometer or Hardness Range 65 Shore A Abrasion Resistance Excellent Tear Resistance Excellent Compression Resistance Excellent Chemical Compatibility: Butane D - Poor Propane (liquified) D - Poor Alcohols: -Amyl D - Poor -Benzyl N/A -Butyl B - Good -Diacetone D - Poor -Ethyl B - Good -Hexyl B - Good -Isobutyl A - Excellent -Isopropyl A - Excellent -Methyl A - Excellent -Octyl B - Good -Propyl A - Excellent Disclaimer: Best Value Vacs Recommends no more than a -40F Operating Temperature and is not responsible for the user running their system with incompatible chemicals.

$3.96 - $69.40

-

Buna-N Tri-Clamp Gaskets (Made in USA, FDA Compliant / Meets 3A Standards)

BUNA-N Tri-Clamp Gaskets Buna-N Tri-Clamp gaskets are the preferred choice of material when using a closed loop, closed column, or open blast extraction when butane or propane are used as the extraction solvent. Buna-N Gaskets offer a lower temperature rating and have better physical properties than Viton gaskets; the best part is that they cost less than Viton and provide the same chemical resistance to butane and propane. Note: BUNA-N is not recommended for use with certain alcohols Key Features: Lower temperature range Lower costs Better compressibility and springiness Excellent resistance to butane and propane Better tear resistance Better abrasion resistance. FDA CFR 177.2600 – Rubber and Rubber-Like Material for Repeated Use/Contact with Food. FDA CFR 177.1550 – Fluorocarbon Resins for Repeated Use/Contact With Food, Dairy & Pharmaceutical Products. Sizes Available: 1.5" 2" 3" 4" 6" 8" - easy on flanged 10" - easy on flanged 12" - easy on flanged Technical Specifications: Material BUNA-N (Nitrile) Color Black Connection Type Tri-Clamp Conformance FDA Compliant / Meets 3A Standards Thermal Properties: -Low Temperature Range -70°F -Minimum for Continuous Use (Static) -40°F -Brittle Point -70°F -High Temperature Range +210°F to +250°F -Maximum for Continuous Use (Static) +250°F Gas Permeability Excellent Durometer or Hardness Range 65 Shore A Tensile Strength Range 200-3500PSI Elongation Range (%) 350-650% Abrasion Resistance Excellent Tear Resistance Excellent Resilience / Rebound Good Thread Style Female Chemical Compatibility: Butane A - Excellent Propane (liquified) A - Excellent Alcohols: -Amyl B - Good -Benzyl D - Severe Effect -Butyl C - Fair -Diacetone D - Severe Effect -Ethyl C - Fair -Hexyl A - Excellent -Isobutyl B - Good -Isopropyl B - Good -Isopropyl B - Good -Methyl A - Excellent -Octyl B - Good -Propyl A - Excellent No more than a -40 F operating temperature should be used with BUNA-N. BVV is not responsible if incompatible chemicals, solvents, or operating temperatures are used in the user's system.

$1.73 - $55.52

-

Large Rosin Filter Bags - 10 Pack

Large Rosin Filter Bags - 10 Pack DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances Rosin filter bags are instrumental in the rosin extraction process and will yield and help remove unwanted contaminants from your end product. By using filter bags they allow you to pack material in tighter together which allows more pressure to be created on a smaller point. Filtration levels of the bags vary from our lowest 25-micron level to our largest 220-micron level and this allows the user to have a wider selection for their application. These mesh bags are also intended to be tossed out after use because the filtration media will be clogged after usage. Key Features: Increased Yield Higher Possible Pressure Stitched seam to prevent blowouts Wide Range of Micron Levels Sizes Available (Micron): 25μm 45μm 73μm 90μm 120μm 160μm 190μm 220μm Specifications: Bag Dimensions: 5" x 7.5" Material: Nylon Seam Type: Stitched Quantity Per Pack: 10

$13.88 - $19.43

-

Small Rosin Filter Bags - 10 Pack

Small Rosin Filter Bags - 10 Pack DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances Rosin filter bags are instrumental in the rosin extraction process and will yield and help remove unwanted contaminants from your end product. By using filter bags they allow you to pack material in tighter together which allows more pressure to be created on a smaller point. Filtration levels of the bags vary from our lowest 25-micron level to our largest 220-micron level and this allows the user to have a wider selection for their application. These mesh bags are also intended to be tossed out after use because the filtration media will be clogged after usage. Key Features: Increased Yield Higher Possible Pressure Stitched seam to prevent blowouts Wide Range of Micron Levels Ultra fine stitched seam to prevent blowouts Exceptionally fine supplementary nylon mesh for mechanical fractioning Wide range of micron levels Medium filtration with increased yield Sizes Available (Micron): 25μm 45μm 73μm 90μm 120μm 160μm 190μm 220μm Specifications: Bag Dimensions: 2.5" x 3.25" Material: Nylon Seam Type: Stitched Quantity Per Pack: 10

$13.88 $6.94

-

Jacketed Stainless Steel LP Tank with Internal Condensing Coil and Dip Tube

Jacketed Stainless Steel LP Tank with Internal Condensing Coil and Dip Tube (This item will ship via Freight ONLY) Jacketed Stainless Steel LP tanks offer a superior way to decrease contamination of solvent and feature a tri-clamp lid with a high-pressure clamp. This allows easy access to the inside of the tank, making clean out simple, unlike a normal carbon steel LP tanks. These tanks feature an exterior jacket to allow the user to circulate fluid around the outside of the tank while having an internal condensing coil on the inside of the tank to help condense hot vapors. Lids come configured with 3 valves, compound gauge and hose barbs for the internal condensing coils to help condense hot solvent vapor when the recovery stage of the extraction process is started. These tanks come with 1/4" FNPT valves and 1/4" 37 Degree JIC Flares with one port being connected to a dip tube. To avoid contamination of your solvent, the Jacketed Stainless Steel LP Tank is a simple and professional option to reduce cleaning time. Our tri-clamp lid with a high-pressure clamp makes it easy to open up the system and fully clean it out in between uses. The exterior jacket circulates fluid around the outside of the tank which the internal condensing coil condenses hot vapors. These tanks come with 1/4" FNPT valves and 1/4" (or 3/8") 37 Degree JIC Flares with one port being connected to a dip tube. If you are not using the jacket to circulate a chilling fluid, the jacket should be evacuated of all air and closed off. This is also known as a vacuum jacket, it will help to keep the fluid inside the tank at the set temperature and not transfer any temperature with the atmosphere around it. *Tank does not come with solvent Butane Capacity Calculation: All solvent tanks sold by Best Value Vacs have their capacity determined by this calculation and are based on industry standard nomenclature of the water weight tank # system because the specific gravity of water is 1.000 and the DOT 80% fill guideline. Example: 100# Tank = ~100lbs of water weight, Halfton Tank = 1000lbs of water weight. Tank # Water Weight in Lbs Specific Gravity of Butane 0.601 80% Fill Guideline 0.800 (Tank #) * (Specific Gravity of Butane) * ( 80% Fill Guideline) Sizes Available: 25# 50# 100# Specifications Tank/Component Material 304 Stainless Steel Gasket Material BUNA-N Standard 3A High Polish Connection Type(s) 1/4" (7/16-20) x 37° JIC Hose Barb Lid Connection Type(s): Tri-Clamp 1/4"-20 FNPT Hose Barb Butane Capacity: 25# 12.424 50# 24.040 100# 48.080 ***Disclaimer: These are not DOT rated tanks and are not recommended for transportation when filled.

$1,179.78 - $1,734.98

-

Mastercool DOT-Approved Recovery Cylinders

LP Carbon Steel Refrigerant Tank Carbon Steel LP Tanks are the best choice when storing solvents for the long term because of their reliability and inherent safety mechanisms. These tanks are the standard in LP storage and transportation because of their conformance to strict DOT guidelines and UL listings. They come pre-charged with nitrogen gas to help create a dry interior to inhibit the formation of rust on the interior of the tank. Note: When storing these tanks empty the user must either backfill them with nitrogen or maintain and full vacuum to prevent moisture from creating rust on the interior. ***Note: Tank comes charged with nitrogen and does not include solvent and the 1/4" flared connections do not require Teflon tape. Key Features: Valve Type: HVAC Y-Valve 1/4" SAE(Valve Rated for 5 Years) Service Pressure: 400 PSI 1/4" and 3/4" NPT Ports for float switch and other add-ons. Reusable and conforms to DOT-4BA400 specifications and ARI guidelines. The tank is Pre-Charged with Nitrogen gas to provide a clean, dry interior. High gloss powder coated finish for durability. Tank Sizes Available: 6L Mastercool 61010-EUGRN - (NOT DOT RATED) 30# 50# 100# 61010-EUGRN: Y-valve for liquid/vapor TPED approved Single valve for vapor TPED approved Raised collar for ease of handling and protection Tanks Conform to PED and ADR regulations CE and TÜV approved Used for storage and transport of refrigerant gases Size (w x h): 185 mm x 338 mm Standard Specification: ADR/RID2009, EN13322-IN D TUV 1 Service Pressure: 32 bar Air Tightness Pressure: 32 bar Bursting Volumetric Expansion Rate: >20% Tare Weight: 5.18 kg Nominal Water Capacity: 6 l Tank Test Pressure: 48 bar Bursting Pressure: >108 bar Body Material: HP295 1/4″ FL-M (7/16-20) connection Color: green Butane Capacity Calculation: All solvent tanks sold by Best Value Vacs have their capacity determined by this calculation and are based on industry standard nomenclature of the water weight tank # system because the specific gravity of water is 1.000 and the DOT 80% fill guideline. Example: 100# Tank = ~100lbs of water weight, Halfton Tank = 1000lbs of water weight. Tank # Water Weight in Lbs Specific Gravity of Butane 0.601 80% Fill Guidline 0.800 (Tank #) * (Specific Gravity of Butane) * ( 80% Fill Guildine) Specifications Tank/Component Material Carbon Steel/Brass Specifications Met D.O.T. 4BA, D.O.T. 4BW Connection Type(s) 1/4" (7/16-20) SAE Flared Butane Capacity: 6L 6lbs 30# 14.424 50# 24.040 100# 48.080

$152.68 - $520.49

-

1/4" 37 Degree Female JIC Braided Stainless Steel Hose

1/4" 37° Female JIC Stainless Steel PTFE Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have female JIC swivel on each end and they DO NOT require Teflon tape to create a seal and they should always be tightened and untightened using 2 wrenches. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 1/4" 37° Female JIC Swivel (7/16-20 Thread) Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -94°F to 500°F (-70°C - 260°C) Pressure Rating 2100 PSI Chemical Resistance Excellent Max Bend Radius 3"

$52.74 - $145.74

-

3/8" 37 Degree Female JIC Braided Stainless Steel Hose

3/8" 37° Female JIC Stainless Steel Braided PTFE Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have female JIC swivel on each end and they DO NOT require Teflon tape to create a seal and they should always be tightened and untightened using 2 wrenches. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 3/8" 37° Female JIC Swivel (9/16-18) Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65° to 450°F Pressure Rating 1500 PSI Chemical Resistance Excellent Max Bend Radius 4"

$69.40 - $184.60

-

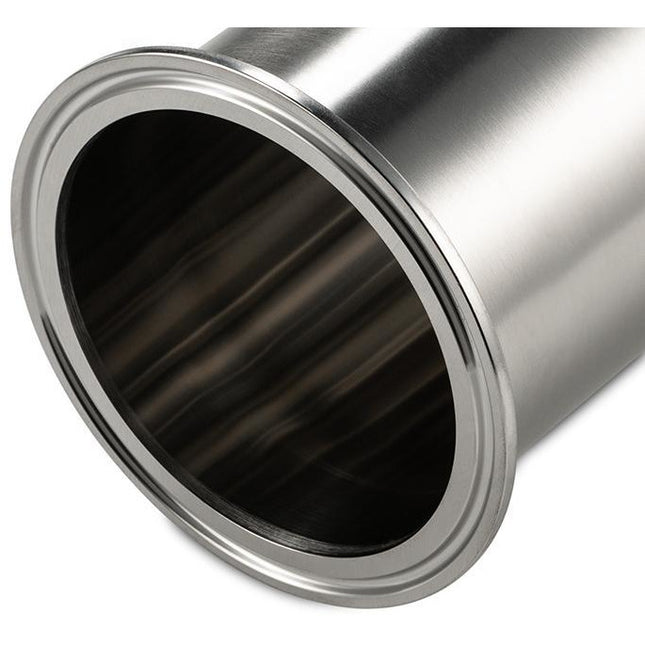

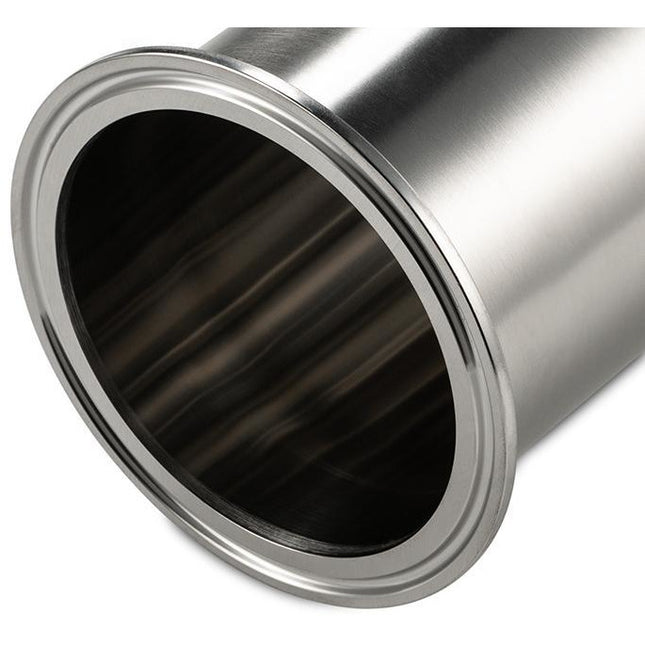

Tri-Clamp Welded Bottom Base

Welded Bottom Tri-Clamp/ Tri Clover Base These stainless steel welded bottom bases are the standard base for our extraction systems and provide the user with a heavy duty and high capacity way to collect and recovery their extracted material and solvent. Many people will have several of these welded bases set aside to quickly swap out their base on their extractor to reduce the time between system runs. Sizes Available: 4" x 4" 6" x 6" 8" x 12" 10" x 10" 12" x 12" Specifications: Material 304 Stainless Steel Standard 3A High Polish Connection Type(s): Tri-Clamp Welded Bottom Thickness 0.25" - 0.50" BVV™ Tri-Clamp Welded Bottom Base - Drawing

$83.28 - $341.44

-

High Pressure Clamps

High Pressure Clamps BVV recommends tightening all High Pressure to their specified Inch-LBS of torque. We do not recommend tightening high-pressure bolts with an impact gun because this may cause threads to jump or be marred which can cause failure of the bolt or seal. For Torque Specification use the link to the data sheet below. Torque Specification Data Sheet Specifications: Mounting Type: Bolted Material: 304 Stainless Steel Bolt Material: 304 Stainless Steel (3/8"-16 Bolt) Nut Material: Brass (5/8 Wrench Size w/ 3/8"-16 Thread Size) Connection Type: Tri-Clamp

$16.66 - $166.56

-

Tri-Clamp Single Hinge Clamp

Tri-clamp/ Tri Clover Single Hinge Clamp BVV™ recommends tightening all Standard Pressure Clamps (Non-High Pressure) to finger tight and then use either a screwdriver or wrench to tighten them approximately 2 full turns to achieve the torque specified on the data sheet. All tightening should be accordance with the data sheet. It is not recommended to overtighten the clamp and bottom it out as this will cause the gasket to be over-compressed and put too much tension on the clamp threads, which could cause it to fail. Overtightening can also cause stretching on the clamp reducing its operational effectiveness. Torque Specification Data Sheet Specifications: Mounting Type: Hinged (The 1.5" Clamp is Double Hinged) Material: 304 Stainless Steel Bolt Material: 304 Stainless Steel (3/8"-16 Bolt) Nut Material: Brass (5/8 Wrench Size w/ 3/8"-16 Thread Size) Connection Type: Tri-Clamp

$12.49 - $115.20

-

Stainless Steel LP Tank - Includes Gas and Liquid Fill/Drain Ports

Stainless Steel LP Tank - Includes Gas and Liquid Fill/Drain Ports Stainless Steel LP tanks offer a superior way to decrease contamination of solvent and feature a tri-clamp lid with a high-pressure clamp. This allows easy access to the inside of the tank, making cleanout simple, unlike a normal carbon steel LP tanks. Tanks feature a safety collar to prevent damage to the valves, as well as a welded ring on the bottom to prevent damage to the tank body and allow better circulation of fluid around the entire tank. Lids come configured with 2 valves and compound gauge and polycarbonate sight glass on the larger #50 and #100 tanks. These tanks come with BVV 1/4" FNPT valves and 1/4" 37 Degree JIC Flares with one port being connected to a dip tube. ***Note: Tank comes empty and does not include solvent. Butane Capacity Calculation: All solvent tanks sold by Best Value Vacs have their capacity determined by this calculation and are based on industry-standard nomenclature of the water weight tank # system because the specific gravity of water is 1.000 and the DOT 80% fill guideline. Example: 100# Tank = ~100lbs of water weight, Halfton Tank = 1000lbs of water weight. Specifications Tank # Water Weight in Lbs Specific Gravity of Butane 0.601 80% Fill Guideline 0.800 (Tank #) * (Specific Gravity of Butane) * ( 80% Fill Guildine) Sizes Available: 30# 50# - 1.5" Tri-Clamp ferrule with sight glass 100# - 1.5" Tri-Clamp ferrule with sight glass Specifications Tank/Component Material 304 Stainless Steel Gasket Material BUNA-N Sight Glass Material (50# and 100# Only) Polycarbonate Standard 3A High Polish Connection Type(s) 1/4" (7/16-20) x 37° JIC Lid Connection Type(s): Tri-Clamp 1/4"-20 FNPT Butane Capacity: 30# 14.424 50# 24.040 100# 48.080 ***Disclaimer: These are not DOT rated tanks and are not recommended for transportation when filled.

$659.29 - $1,152.03

-

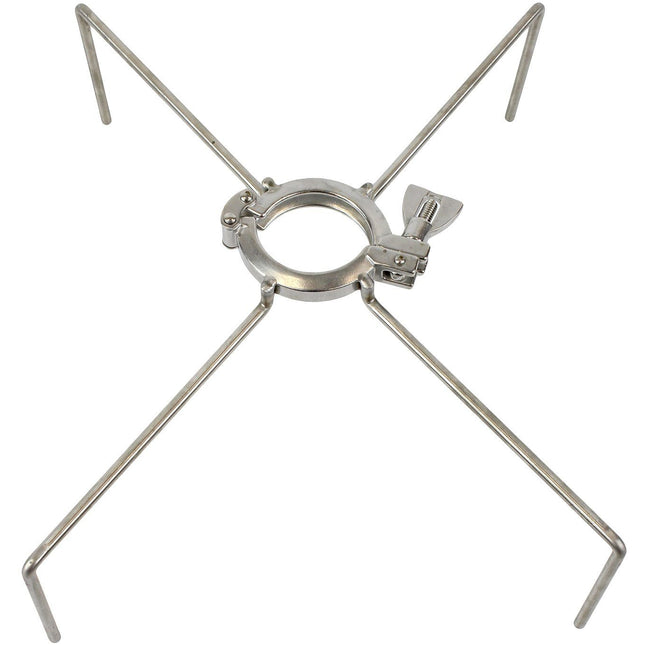

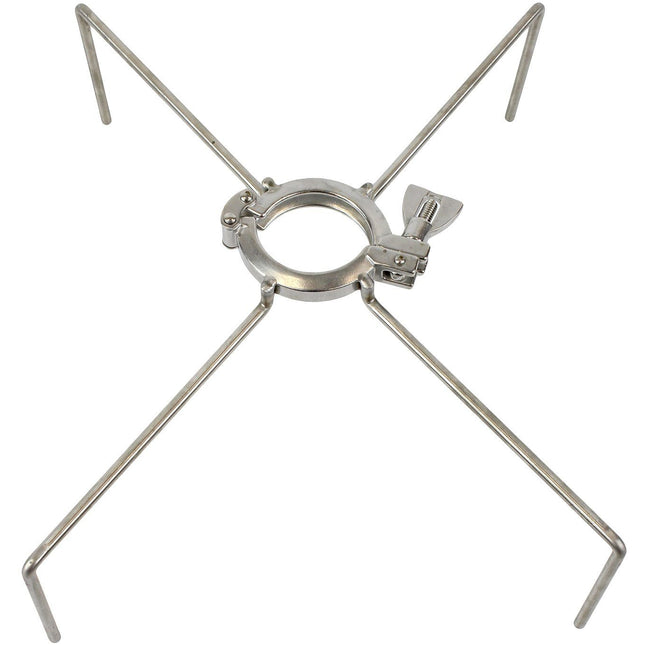

Tri-Clamp Quadpod

Tri-Clamp Quadpod Quadpods provide an excellent solution to holding any Tri-Clamp spool vertically. From closed columns to open blast extraction units, Quadpods are designed to fit over Pyrex dishes without getting in the way. This device has 4 legs, 4.5" in length, and extends 7" outward in each direction. Furthermore, each leg is welded to the clamp to provide a sturdy and durable platform. Sizes Available: 1.5" 2" 3" Specifications: Material 304 Stainless Steel Connection Type(s): Tri-Clamp

$49.97 - $62.46

-

Splatter Platters

Splatter Platters Splatter platters are a huge step up from normal Tri-Clamp/ Tri Clover bases used on extractors because they provide the user a more effective way of pouring and scraping the extracted material out of the base. These splatter platters are much lighter and easier to deal with during the post-extraction process. Sizes Available: 4" 6" 8" 10" 12" Specifications: Material 304 Stainless Steel Standard 3A High Polish Connection Type(s): Tri-Clamp Height 2" BVV™ Splatter Platters - Drawing

$80.50 - $215.14

-

Jacketed Splatter Platters

Jacketed Splatter Platters Fully Jacketed splatter platters are a huge step up from normal splatter platters by providing the user a more efficient recovery of their solvent without having to move or lift the extractor into a hot water bath. These jacketed splatter platters allow the circulation of water through the outer jacket through 2x 1/2" FNPT offset ports on each side of the splatter platter. ***Note: Edges of Jacket may be rounded instead of flat. Sizes Available: 6" 8" 10" 12" Specifications: Material 304 Stainless Steel Standard 3A High Polish Connection Type(s): Tri-Clamp 1/2"-14 FNPT BVV™ Jacketed Splatter Platters - Drawing

$208.20 - $319.24

-

Tri-Clamp Filter Plate

Stainless Steel Tri-Clamp/ Tri Clover Filter Plate Stainless steel filter plates offer the user a great solid platform to help with filtration during the extraction process and they come standard with a 100 mesh (150 Micron) pre-cut stainless steel mesh filter media and a solid filter plate ring (unless otherwise specified). These filter plates can be used simultaneously with ashless filter papers or any other filtration media like stainless steel ball bearings or steel wool to increase surface and filtration level to remove fats, lipids, waxes and any other unwanted material during the extraction process. For 6" sizes and above, a high pressure clamp is recommended for all filtering applications. *Note: Does not include Clamp or Gasket. **Note: 8" Sizes come with a compression ring instead of a solid filter plate ring. Sizes Available: 1.5" - Includes Solid Filter Plate Ring 2" - Includes Solid Filter Plate Ring 3" - Includes Solid Filter Plate Ring 4" - Includes Solid Filter Plate Ring 6" - Includes Solid Filter Plate Ring 8" - Includes Standard COMPRESSION Ring 10" - Includes Solid Filter Plate Ring 12" - Includes Solid Filter Plate Ring Specifications Material 304 Stainless Steel Standard 3A High Polish Connection Type(s) Tri-Clamp Hole Diameter 5.8mm Height 2" Mesh Specs 100 Mesh (150 Micron) - 304 Stainless Steel BVV™ Tri-Clamp Filter Plate - Drawing

$45.80 - $388.63

-

Polycarbonate Tri-Clamp Sight Glass - Made in USA

Polycarbonate Tri-Clamp/ Tri Clover Sight Glass Polycarbonate Tri-Clamp sight glasses are a great and cost effective way to add viewing ports to your system. These sight glasses are 1 piece CNC machined out of 0.25" thick sheets of polycarbonate and rated up to 250, 225, and 175 PSI for 1.5", 2", and 3" Tri-Clamp sizes. These sight glasses come with a protective film of plastic over the viewing area to protect it from being damaged during shipping and testing the customer will need to remove this upon usage. ***Note: Gasket and Clamp sold separately. Specifications: Material Polycarbonate Window Diameter: 1.5" 1-1/4" 2" 1-3/4" 3" 2-3/4" Maximum PSI @70F: 1.5" 250 2" 225 3" 175

$38.86 - $54.13

-

Metaglas METAGLAS® Tri-Clamp Sight Glass

METAGLAS Tri-Clamp/ Tri Clover Sight Glass ***NOTICE TO CUSTOMER: ONLY CONTAINS 1 SIGHT GLASS. Please increase quantity if you want more.*** Data Sheet Metaglas Line Operating and Maintenance Instructions The strongest, most secure sight glass available, Metaglas mechanically prestressed windows, are available in a sanitary clamp design, MetaClamp, for ports and light ports in processing applications or inline visual flow indicators. Application: Sanitary MetaClamps to fit sanitary clamp connections. With simple and fast installation with no risk of breakage, this sleek, compact, one-piece design provides a cleaner look, less bateria traps and unsurpassed safety. The MetaClamp sight glass can be used as a view port mounted on a ferrule, a “cross” for inline visual flow indication or as a light port. Many other connection types are also available, as shown on the reverse side. Materials available include 2205 Duplex Stainless Steel, Hastelloy®, Monel® and Inconel®. Approvals and Technical Data: - USP Class VI (tested to confirm biocompatibility) - BPE Compliant and TÜV Approved - Sight glass fused to metal conforming to DIN7079 - Borosilicate glass to USP Type I and DIN7080 - Standard surface finish of 10 Ra µ-in (0.25µm) - Material to ASTM/ASME, TÜV and DIN/EN standards - Certificate of Conformity to EN 10204-3.1B or 3.1A - Pressure Equipment Directive 97/23/EG How Metaglas® Works: Metaglas provides a level of safety and a useful service life, well beyond that provided by conventional tempered glass or plastic used as sight glass windows. Even in the most extreme temperature (to 572ºF using Hastelloy) or overpressure situations, sudden, total failure essentially never occurs. Patented Metaglas windows are formed by melting borosilicate glass into a precisely formed metal ring. As the glass cools, it solidifies, preventing the metal ring from contracting back to its theoretical size. The result is a uniform, mechanically prestressed fusion of glass and metal that combines excellent optical characteristics with greatly enhanced physical characteristics. Vital in sanitary service, the Metaglas discs have an uninterrupted surface with no crevice to trap bacteria - no epoxies, resins, or glue - a true fusion. The standard surface finish is 10 Ra µ-in (0.25 Ra µm). Electopolishing available upon request.

$659.29 - $693.99

-

Short Sight Glass