EVERY PRODUCT BUT HYDRO FOR WHOLESALE STORE

-

Insulon 1/2" Insulon Vacuum Jacketed Hose, Low Pressure

1/2" Insulon Vacuum Jacketed Hose, Low Pressure Technical Specifications: Hose Size 1/2” ID DN (ISO 10380) 12 Product Category LP (Low Pressure) Inner Hose ID 0.472” Tube Stub OD 0.500” Tube Stub Thickness 0.035” Outer Hose OD 1.27” Static Bend Radius 3.33” Dynamic Bend Radius 10.24” Lengths 2 – 20’ Operating Temperature -270°C to 900°C (-454°F to 1652°F) Material 316L stainless steel Maximum Allowable Working Pressure (MAWP) by Temperature: Product Category Hose Size Max Temperature (C) Max Temperature (F) MAWP (PSI) Low Pressure (LP) 1/2" ID 21 70 72 Low Pressure (LP) 1/2" ID 66 150 67 Low Pressure (LP) 1/2" ID 93 200 64 Low Pressure (LP) 1/2" ID 121 250 62 Low Pressure (LP) 1/2" ID 149 300 60 Low Pressure (LP) 1/2" ID 166 330 58 Low Pressure (LP) 1/2" ID 204 400 56 Low Pressure (LP) 1/2" ID 232 450 56 Low Pressure (LP) 1/2" ID 260 500 55 Low Pressure (LP) 1/2" ID 316 600 55 Low Pressure (LP) 1/2" ID 371 700 55 Low Pressure (LP) 1/2" ID 427 800 54 Low Pressure (LP) 1/2" ID 482 900 53 Low Pressure (LP) 1/2" ID 538 1000 53 Low Pressure (LP) 1/2" ID 593 1100 48 Low Pressure (LP) 1/2" ID 649 1200 44 Low Pressure (LP) 1/2" ID 704 1300 40 Low Pressure (LP) 1/2" ID 760 1400 35 Low Pressure (LP) 1/2" ID 816 1500 28 Low Pressure (LP) 1/2" ID 899 1650 18

$364.13 - $1,641.37

-

Insulon 1/4" Insulon Vacuum Jacketed Hose, Low Pressure

1/4" Insulon Vacuum Jacketed Hose, Low Pressure Due to vendor policies, any of these Insulon Vacuum Jacketed Hoses are final sale, non-returnable, and non-refundable. Technical Specifications: Hose Size 1/4" ID DN (ISO 10380) 6 Product Category LP (Low Pressure) Inner Hose ID 0.236” Tube Stub OD 0.250” Tube Stub Thickness 0.035” Outer Hose OD 1.05” Static Bend Radius 2.65” Dynamic Bend Radius 8.86” Lengths 2 – 20’ Operating Temperature -270°C to 900°C (-454°F to 1652°F) Material 316L stainless steel Maximum Allowable Working Pressure (MAWP) by Temperature: Product Category Hose Size Max Temperature (C) Max Temperature (F) MAWP (PSI) Low Pressure (LP) 1/4" ID 21 70 72 Low Pressure (LP) 1/4" ID 66 150 67 Low Pressure (LP) 1/4" ID 93 200 64 Low Pressure (LP) 1/4" ID 121 250 62 Low Pressure (LP) 1/4" ID 149 300 60 Low Pressure (LP) 1/4" ID 166 330 58 Low Pressure (LP) 1/4" ID 204 400 56 Low Pressure (LP) 1/4" ID 232 450 56 Low Pressure (LP) 1/4" ID 260 500 55 Low Pressure (LP) 1/4" ID 316 600 55 Low Pressure (LP) 1/4" ID 371 700 55 Low Pressure (LP) 1/4" ID 427 800 54 Low Pressure (LP) 1/4" ID 482 900 53 Low Pressure (LP) 1/4" ID 538 1000 53 Low Pressure (LP) 1/4" ID 593 1100 48 Low Pressure (LP) 1/4" ID 649 1200 44 Low Pressure (LP) 1/4" ID 704 1300 40 Low Pressure (LP) 1/4" ID 760 1400 35 Low Pressure (LP) 1/4" ID 816 1500 28 Low Pressure (LP) 1/4" ID 899 1650 18

$336.12 - $1,411.69

-

Centrifuge Belt

Centrifuge Belt Replacement Belt for the 160L & 45L Centrifuge. *Each centrifuge may have multiple belts

$182.06 - $245.09

-

ChemTek ChemTek L500 Centrifuge

ChemTek L500 Centrifuge The L500 Benchtop Centrifuge is our introductory model designed to have a very compact footprint to fit on every lab bench. Specifications: Power Supply:110V 50/60Hz Max Speed:4200 RPM Max Capacity:4x50ml Time Setting Range:1min - 99min Speed Accuracy:± 30r/min Noise:≤65dB Power Consumption:250W Net Weight:42lbs Comes with: (16) 50ml Tube (1) 100pack 25 Micron Centrifuge Bags (2.5”x4”) (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves ChemTeck L500 Centrifuge User Manual ChemTeck L500 Centrifuge SDS

$2,520.88

-

120W Motor/gearbox with FWD/REV controller

This controller/ motor can be retrofitted to fit a 20 or 50 liter glass reactor to have additional control to your process.

$1,190.41

-

2L Standard Short Path Parts Kit

Short Path Distillation Setup Short path distillation is used for compounds that are not stable at high temperatures. It can also be used to purify small amounts of a compound. The 2L Distillation Kit gives users an easy to use system that will get them up and running at an affordable price. It includes all stands, clamps, clips, This Kit Does NOT include a vacuum pump, circulator, or heating source. Please see the below recommendations for both as well as recommended add-ons. Or check out our 2L Standard Distillation Turnkey Setup which includes vacuum pump, circulator, and mantle. Recommended Vacuum Pumps: Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (economy option) Best Value Vacs VE280 9CFM Two Stage Vacuum Pump (economy option) Recommended Circulators: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter MX Refrigerated Circulator (premium option with chilling capability) Recommended Heating Mantle: BVV 2L Heating Mantle Recommended Add-Ons: Glass Dewar Style Cold Trap (recommended cold trap) Bullseye Precison Vacuum Gauge (premium vacuum gauge for measuring depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) Short Path Distillation Kit Specifications: Boiling Flask Size: 2L Recieving Flask Size: 250ml Batch Capacity approximate: 2L = 400-1000 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Comes Standard With The Following: Glass Components: 2L 2-Neck Boiling Flask Short Path Head Triple Neck Cow 3x 250mL Single Neck Receiving Flask 1/8" 14/20 PTFE Thermometer Adapter 1/4" 24/40 PTFE Thermometer Adapter 120mm Glass Funnel Accessories: Magnetic PTFE Stirring Bar Retriever Keck Clips 3 Finger Clamp Adjustable 0-70mm Boss head 6" x 6" Scissor Jack 250-500ml Cork Stand Traceable Kangaroo Thermometer - Digital Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. Learn more about short path distillation components and FAQs with this distillation guide. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$665.23

-

Beaker and Wrench Explosion Proof Oil Pump

Explosion Proof Oil Pump Optimized for Falling Film Evaporators C1D2 VFD (variable frequency drive, not C1D2 rated) cord is approximately 15′ Motor: 1/4 Horsepower Customizable mounting When ordering: Please indicate in the Note section what machine you will be attaching the Explosion Proof Oil Pump to. We need this information to assure the correct Inlet Adapter is provided and also the dimensions of the mounting configuration you will need. Hazardous Location Clas 1 C,D / 2 E,F,G Nominal Efficiency 85.5% Frame 56CZ Motor Application Hazardous Location Lead Length 6" RPM Range 1101-1200 Standards UL listed (E12044), CSA Certified (LR47504) Frame Material Rolled Steel Duty Continuous HP 1/4 Voltage Compatibility 115/208-230, 120/240 Length Less Shaft 11-7/8" Includes Conduit Box (Unmounted), Leads Through 1" NPT Nipple Motor Shaft Design Keyed Shaft Length 2-1/4" Item Harazardous Location Motor Motor Service Factor: 1.00 1.00 Motor Thermal Protection auto Motor Shaft Rotation CW/CCW Full Load Amps 6.8/3.1-3.4 Overall Length 14-5/16" Voltage 115/208-230 Motor Frame Material Rolled Steel Ins. Class B Motor Mounting Type Face Motor Design Capacitor- Start Shaft Dia 5/8" Hz 60 Motor Bearing Ball Temp. Code T3B Motor Enclosure Design Totally Enclosed Fan-Cooled Nameplate RPM 1140 Max. Ambient Temp 40 Degrees C Phase 1

$10,643.70

-

Flexible Rubber Foam Pipe Insulation Tee, 1/2" Thick Wall, 1-3/8" ID

Flexible Rubber Foam Pipe Insulation Tee Soft and easy to install, this insulation restricts absorption of water, air, and gas. It is often used on cold and hot water lines and refrigeration lines. Seal with contact adhesive (sold separately). To use outdoors, coat in acrylic paint. For Use On Pipe Insulation Type Tee Wall Thickness 1/2" ID 1 3/8" OD 2 3/8" For Pipe Size 1 For Copper Tube Size 1 1/4 Temperature Range -295° to 220° F Heat Flow Rate 0.25 Btu @ 75° F Density 4.5 lbs./cu. ft. Material Buna-N/PVC Foam Color Black Flexibility Flexible Cell Type Closed Tube Style Slit Specifications Met ASTM E84 25/50 for Flame and Smoke, ASTM C534 Performance Properties Moisture Resistant R Value 2 Additional Specifications SDS RoHS RoHS 3 (2015/863/EU) Compliant REACH REACH (EC 1907/2006) (01/17/2022, 223 SVHC) Compliant DFARS Specialty Metals COTS-Exempt Country of Origin United States USMCA Qualifying No Schedule B 392690.9988 ECCN EAR99

$21.01

-

Flexible Rubber Foam Pipe Insulation Elbow, 1/2" Thick Wall, 1-3/8" ID

Flexible Rubber Foam Pipe Insulation Elbow Soft and easy to install, this insulation restricts absorption of water, air, and gas. It is often used on cold and hot water lines and refrigeration lines. Seal with contact adhesive (sold separately). To use outdoors, coat in acrylic paint. For Use On Pipe Insulation Type Elbow Elbow Bend 90° Wall Thickness 1/2" ID 1 3/8" OD 2 3/8" For Pipe Size 1 For Copper Tube Size 1 1/4 Temperature Range -295° to 220° F Heat Flow Rate 0.25 Btu @ 75° F Density 4.5 lbs./cu. ft. Material Buna-N/PVC Foam Color Black Flexibility Flexible Cell Type Closed Tube Style Slit Specifications Met ASTM E84 25/50 for Flame and Smoke, ASTM C534 Performance Properties Moisture Resistant R Value 2 Additional Specifications SDS RoHS RoHS 3 (2015/863/EU) Compliant REACH REACH (EC 1907/2006) (01/17/2022, 223 SVHC) Compliant DFARS Specialty Metals COTS-Exempt Country of Origin United States USMCA Qualifying No Schedule B 392690.9988 ECCN EAR99

$16.11

-

Flexible Rubber Foam Pipe Insulation Tube Slit, 1/2" Thick Wall, 1-7/8" ID, 6 Feet Long

Flexible Rubber Foam Pipe Insulation Tube Soft and easy to install, this insulation restricts absorption of water, air, and gas. It is often used on cold and hot water lines and refrigeration lines. Seal with contact adhesive (sold separately). To use outdoors, coat in acrylic paint. Slit tubes have an adhesive strip closure. For Use On Pipe Insulation Type Tube Wall Thickness 1/2" ID 1 7/8" OD 2 7/8" For Pipe Size 1 1/2 Length 6 ft. Temperature Range -295° to 180° F Heat Flow Rate 0.25 Btu @ 75° F Density 4.5 lbs./cu. ft. Material Buna-N/PVC Foam Color Black Closure Type Adhesive Strip Flexibility Flexible Cell Type Closed Tube Style Slit Specifications Met ASTM E84 25/50 for Flame and Smoke, ASTM C534 Performance Properties Moisture Resistant R Value 2 Additional Specifications SDS RoHS RoHS 3 (2015/863/EU) Compliant REACH REACH (EC 1907/2006) (06/10/2022, 224 SVHC) Compliant DFARS Specialty Metals COTS-Exempt Country of Origin United States USMCA Qualifying No Schedule B 400911.0000 ECCN EAR99

$61.62

-

High Pressure Heated Stainless Steel Hose, 4FT JIC Fittings, up to 450°F

This item is sold with or without a PID controller. The hose is heated and insulated. The hose temperature is controlled by an Digital PID. The hose and PID controller are made in the USA, and of the best quality. The hose uses Platinum Thermocouples for durability and accuracy, for many many years of service. Hose Temperature Rating: 50°F - 450°F Controller Temperature Range: 50°F -450°F 120 VAC w/ 6ft cord The overall length of the hose is 4ft The hose is Made in the USA. HOSE ID - 0.187" (1/4"Style) HOSE ID - 0.312" (3/8"Style) HOSE ID - 0.406" (1/2"Style) Each side of the heated hose assembly is a JIC 37° Fitting

$840.29 - $1,967.68

-

Ice Water Extraction Kit

BVV's Ice Water Extraction Kit Designed with our solventless extractors in mind BVV's Ice Water Extraction Kit was engineered for durability and ease of use. Comprised of our sanitary grade seamless 55-gallon 304 stainless steel washing vessels. Our easy drain barrels come complete with 4X 1.5" Triclamp drains mounted as low as possible for effortless draining of its 55-gallon volume capacity. Perfect for medium to large-scale ice water extraction labs this kit comes complete with industry-leading Boldtbags Lock-top Full mesh stacker grading bags and a 20lb capacity Large BoldtBags Open Top Washing Bag for unbridled durability and ease of use. The ice Water Extraction Kit comes with your choice of either a low shear Multi-stage pump ideal for gravity draining or a hash-safe pneumatically driven diaphragm pump. Processing Power Material Capacity Per Batch: 20-30LB Water Capacity: 55 Gallons Cycle Time: 60-90 Minutes Daily Extraction Capacity: Up to 60 lb, per 8-hour shift Specifications 2X 23"x36" 55-gallon Stainless Steel Washing Vessel 4X 1.5" Tri-clamp ports 4X BoldtBags Lock-top Full mesh stacker grading bags (190um(Green),160um(Red),90um(Black),45um(White)) 1X Large Boltd Open Top Wash Bag (20lb Capacity) 1X Food grade PTFE mixing paddle 1X 27 GPM Low shear Multistage pump or 16 GPM hash-safe pneumatically driven diaphragm pump. 1X 25Ft 1" Clear Braided PVC Hose 1X 1.5" Tri-clamp Thermometer (0-220F/0-100C) 4X Polycarbonate Sight glasses 2X 1.5" Tri-Clamp Butterfly valves with 1" barbed fittings Performance Seamless sanitary construction Low-mounted drain ports for complete draining Tri-Clamp Thermometer for water temperature measurement Polycarbonate sight glasses for visual monitoring of the process Open Top Wash Bag for easy loading & unloading Low-shear force Multistage pump for gentle water transfer or a hash safe pneumatically driven diaphragm pump

$8,052.80 - $10,363.60

-

BVV 2540 Nanofiltration Skid

BVV 2540 Nanofiltration Skid Note: This product carries 8 - 12 week lead time Perform organic solvent recovery or botanical extract purification with ease with our 2540 nanofiltration skid. Replace up to 7X 50L Rotary evaporators with a single Skid. BVV's 2540 Nanofiltration Skid is designed to meet Class 1 Division 1 standards. With the ability to recover 30 gallons of ethanol per hour without the application of heat, preserving target compounds and utilizing a fraction of the energy consumption of a traditional falling film qualifying our 2540 Nanofiltration Skid for energy saving rebates. Processing Power Capacity: 15 GPH or 30 GPH of solvent recovery. Solvents: Ethanol, Methanol Specifications 4X 2540 nanofiltration housings Stainless steel 6GPM pump with PTFE seals 7.5HP C1D1 1750 RPM Motor 7.5HP VFD 1/60/230 NEMA 4X enclosure (13A) Insulated 2"x18" Heat Exchanger Polyscience 1.5HP Chiller 230/60/1/23.1 700PSI Pressure Relief Valve C1D1 Flowmeter 2X 0-1000 PSI Pressure Gauges 1.5" Intake & Retentate Lines 1/2" Permeate & Pressure Relief Lines Footprint (DxWxH) 30"x39"x79" Weight: 400 lb Maximum Pressure Rating: 700PSI Performance Variable Frequency Drive-based flow control Complete pressure control with manual pressure controls Retentate cooling with inline Heat exchanger & chiller 700PSI pressure relief valve with diversion line *Components shown are subject to change**This unit is meant for bulk solvent recovery, 90% of the total volume of solvent an additional solvent recovery apparatus is recommended to evaporate to dryness*

$57,419.96 - $63,021.91

-

BVV Space Saver Mobile Oven Cart with Ovens

BVV Space Saver Mobile Oven Cart with Ovens The BVV Space Saver Mobile Oven Cart allows users to greatly increase their output and more efficiently all in one place! There are a total of 4 options in this listing: 1) Three 1.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 2) Two 1.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 3) Three 0.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 4) Two 0.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump If these options don't fit your needs, we also encourage you to expand your options by ordering parts individually or reach out to us (331-281-0154) so we can help create the kit right for you. Included in all the kits is the Heavy Duty Steel Mobile Cart that was designed by us to hold up to three ovens! It also has three height adjustable shelves to suit your needs and can be placed on either side of the bracket. The cart is mobile with its swivel caster wheels and they can can support up to 1,100lbs! The cart can house oven sizes such as the 0.9 and 1.9, Neocision and ECO oven. The oven shelves are made of aluminum and we recommend covering the shelves with silicone pads or a PTFE sheet that can be cut to size. The oven shelves are made of aluminum and we recommend covering the shelves with silicone pads or a PTFE sheet that can be cut to size. It is recommended to change the oil when the color starts to get noticeably darker in the pump. Also included in the kit is our premium Mobil Vacuum Pump Oil. This oil has a longer usable life and does not generate any additional vapor or odor, which will be sure to help your vacuum pump exhaust filter live longer too! Note: The Heavy Duty Steel Mobile Cart shipped does NOT come with the side shelves assembled. Required tool: 5mm ball hex (NOT INCLUDED).

$10,871.98 - $15,769.48

-

Jacketed Reactor with Motor and Collection Vessel

Jacketed Reactor with Motor and Collection Vessel This jacketed reactor kit includes your choice of a C1D1 motor, standard motor, or non-electric air powered motor (air compressor required). If using an electric motor it will require wiring to the included speed controller. Using the jacketed reactor to heat your solution, use your reactor to mix your solution during the heating process. The condenser and collection vessel allow you to recover residual solvents up to 100L. The collection vessel includes a dip tube to empty the vessel and a 1/4" JIC flare to input pressure into the base to assist in emptying the tank through the dip tube. This system does NOT include a heater or chiller, please inquire with your account representative for recommendations based on your application! Jacket connections are 1/2" hose barbs. Mixer Type Pneumatic Electric C1D1 Electric Horsepower 3/4 HP 3/4 HP 1 HP Power Air Compressor 120V 220V 1ph Reactor Size 150L Collection Size 50L / 100L Jacket Connections 1/2" Hose Barb

$9,834.22 - $19,172.66

-

2L Rotary Evaporator Power Cable

Replacement Power cable for BVV 2L Rotary Evaporator.

$21.01

-

BVV 2 & 4 Cylinder Recovery Pump Replacement Fan

BVV 2 & 4 Cylinder Recovery Pump Replacement Fan Replacement fan for BVV2CYL and BVV4CYL Recovery pumps.

$70.02

-

Glas-Col Glas-Col Thermocouple Type "J" Mini Plug

Glas-Col Thermocouple Type "J" Mini Plug D x L : 1/4" x 4" Lead Length: 72"

$98.03 $63.02

-

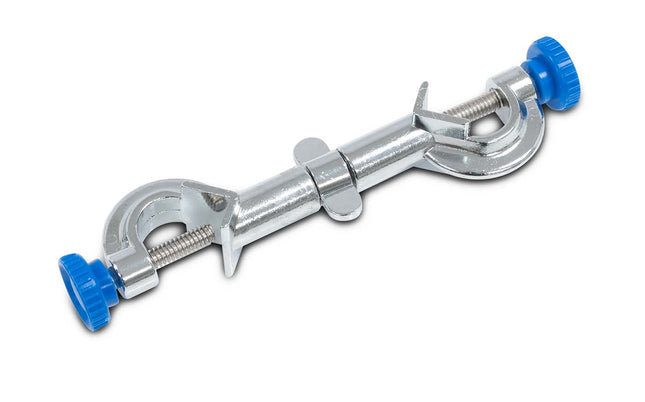

Swivel Bosshead

This swivel boss head is made out of die-cast alloy is nickel plated and will fit rod diameters up to 16mm. The boss head can be adjusted and locked to any angle (360°). It is also designed to carry heavy loads and prevent torque damage. Note:Clamps and rods are NOT included.

$15.41

-

Polyscience Polyscience Durachill Chiller

Polyscience Durachill Chiller; 4.2 L; 208/230 V PolyScience CA10A3T1-41AA1N Offers Features: Large, full-color touchscreen display with intuitive interface and support for five different languages Home screen simultaneously displays set temperature, actual temperature, fluid pressure, fluid level, air filter status and timer Self-changing air filter system eliminates preventative maintenance by automatically changing the filter media at user-definable intervals Continuous fluid level monitoring protects pump and prevents freezing Whispercool® noise reduction system reduces operating noise levels to the almost imperceptible levels while maintaining optimal cooling performance Reduced global warming potential through a highly optimized refrigeration system design that greatly reduces the amount of refrigerant gas needed in the chiller and allows for migration to natural refrigerants that have little or no global warming potential Self-diagnostic system compares the chiller's functionality to its operating state the day it was built to minimize operating downtime and unnecessary service calls Compact, portable design takes up less floor space Cooling at ambient temperatures as high as 30°C Components are recyclable and meet or exceed global environmental standards UV Light Biological Growth Inhibitor System eliminates the need for algaecides User-adjustable temperature, pressure, and flow rate alarms Heat up to 70°C, without additional options Front fill reservoir access Externally accessible adjustable pressure regulator valve Full color touch screen display The color touch screen display gives you all the information you need at a glance. The screen will display continuous status of set temperature, actual temperature, reservoir fill level and output pressure as well as the status of your air filter. System messages are provided in easy to read text instead of confusing error codes. Dynamic self-changing filter Preprogrammed to change its own air filter once a month for a two year period, and the change interval can be adjusted to suit your operating environment. This will dramatically reduce downtime and unnecessary service calls and relieve you of the burden of preventative maintenance on your chiller. UV light biological growth inhibitor The UV Light Biological Growth Inhibitor will continuously control biological growth in the fluid path without the need to add chemical growth inhibitors and preventing algicides from being released into the world's waterways. Front fill reservoir The chiller offers a conveniently located front fill reservoir. You no longer have to go to the back of the chiller top open to fill the reservoir. It has the fill port in the front, making it easy to access, avoiding spills and saving time. Continuous liquid level monitoring Because pump seals will fail in as little as 30 seconds of being run dry, the chiller includes a state-of-the-art capacitance liquid level sensor to protect the pump from premature failure. If the fluid level becomes low, the chiller will give you visual and audible alarms. If the fluid level reaches a point where there's a risk of pulling air into the pump, it will shut the chiller down and present another alarm. Whispercool® noise reduction This high-performance chiller utilizes noise reduction system. The Whispercool® system evaluates the demand for cooling from the application then slows the fan speed to the minimum necessary to achieve control point, making the chiller extremely quiet while maintaining optimal temperature control at the same time. Applications Heat removal Specifications Cooling Capacity At 20°C: 2.9 kWAt 10°C: 1.93 kWAt 0°C: 1 kW Fluid Temperature Range 14 to 158°F (-10 to 70°C) Temperature Stability ±0.1°C Displayable Units Temperature: °C or °FPressure: psi or kPa Pump Inlet and Outlet ½" female NPT Connectivity RS-232, USB Serial Port Emulation, USB TMC, Dry Contact On/Off/Status Selectable Operating Languages English, Spanish, French, German, Mandarin Self-Changing Air Filter Yes UV Biological Growth Inhibitor Yes Ambient Air Temperature Tracking Yes Pump Pressure Range 20 to 90 psi (138 to 689 kPa) Maximum Pump Flow Rate 3.5 gpm (13.2 lpm) Power Requirements 230 V, 60 Hz, 13.5 A Dimensions 33 x 22 x 33" (84 x 56 x 84 cm) Weight 177 lbs (80.3 kg) Data sheet Manual

$11,633.84

-

Siemens Touch Screen Controller with Explosion Proof Housing for Centrifuges

Siemens Touch Screen Controller with Explosion Proof Housing for Centrifuges Disclaimer: When bought separately and NOT with our Centrifuge this item will have no warranty and all sales are final. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Controller: This centrifuge is controlled by a Siemens Smart Line PLC. This PLC is pre-programmed to have both a soaking cycle, shown as AGITATION TIME on the screen, and a spin drying cycle, made of 4 separate specifications. SPIN TIME 1 through 4 allow the user to choose four different speeds and however long they wish to be at each speed. All four parameters labeled as SPIN TIME combine to make one spin cycle when the Spin button is pressed. To change a parameter, simply tap on the number to be changed and type in the desired value when prompted on screen. Any number displayed within a white box can be adjusted. SPEED SET: This number represents the RPM as a percentage of the machine max speed. In this case the max speed is 1500RPM. SET: This column will dictate how long the centrifuge spins for a cycle or at a specified speed within the cycle. For the Agitation Time, the Set value will control the total length of the agitation cycle. The FWD/REV TIME will control how long the basket will spin in one direction before reversing to cause agitation. The “current” value will only count up while at the set speed for the agitation cycle. CURRENT: The “current” column will give a readout of how long the basket has been spinning at the set speed. This value will not increase while the centrifuge is increasing speed between SPIN TIME values. When running the agitation cycle, it will be complete when the count of seconds in the CURRENT reaches the value in the SET column. The centrifuge will stop automatically. For the spin cycle, the centrifuge will go through all 4 set SPIN TIME values, the CURRENT column will only begin to count when the centrifuge is at the set speed. The cycle time will not account for time taken to get up to speed. Temperature: Shows a live readout of the temperature inside the centrifuge.Inlet Valve and Drain Valve: These are two pre-programmed buttons that can be used with electronic valves. This unit does not come standard with these valves, but leaves the option open for them to be added. Electrical Power Size Specification 45L Input: 240V 1ΦOutput: 240V 3Φ 4kW 160L Input: 240V 1ΦOutput: 460V 3Φ 7kW 280L Input: 240V 1ΦOutput: 460V 3Φ 11kW 475L Input: 240V 3ΦOutput: 460V 3Φ 11kW

$11,063.85 - $13,304.63

-

Block Manifold with 8 - 1/2" FNPT ports

Block Manifold with 8 - 1/2" FNPT ports This Manifold has 8x 1/2" FNPT ports that are commonly used for connecting multiple columns or different tanks to one input of vacuum and/or nitrogen. It has six ports on top and one on each end. The manifold has two 5/16 holes that can be used to easily mount on one of our extruded aluminum rack systems.

$420.15 $210.07

-

ChemTek CHEMTEK ChloroSorb Natural

ChloroSorb Natural Filtering Media is a heat-activated bentonite/carbon adsorbent for bleaching and deodorization. Contains 10% carbon. ChloroSorb Natural SDS

$70.02 - $2,800.97

-

Glas-Col Glas-Col Vapor Monitor

Glas-Col Vapor Monitor motor vapor temperature or other processes audible alarm - high, low, t/c break digital display Specifications TC Type "J" MUST BE ORDERED SEPARATELY Range 0 - 999 C Dimensions 4" W x 4" D x 4" H Volts 120 Includes: 6' attached power cord and grid support bracket

$420.15 $210.07

-

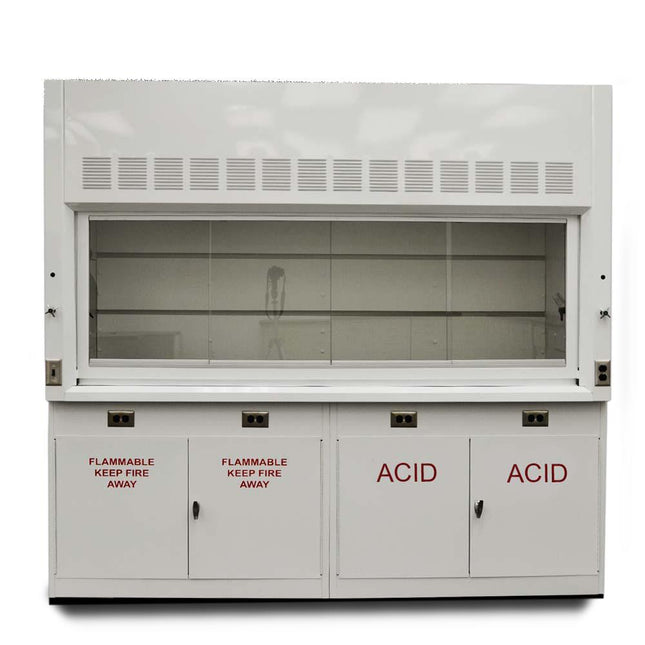

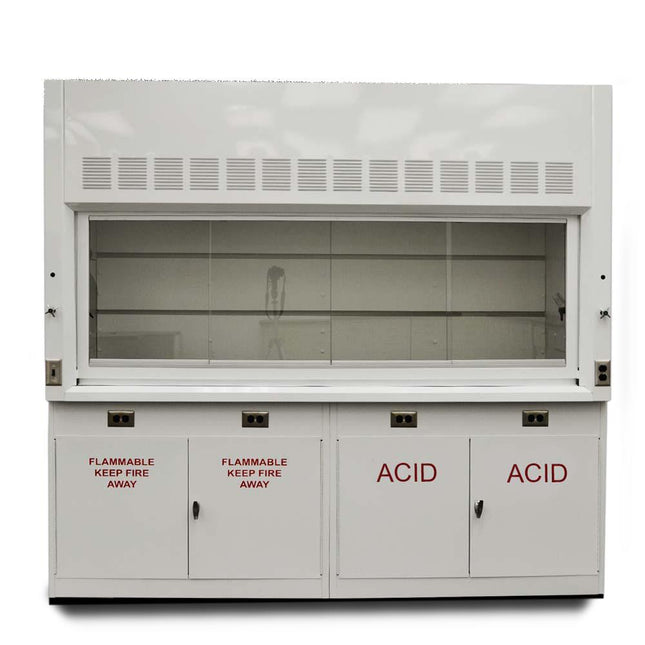

Fisher American Fisher American 8′ Fume Hood w/ Acid Storage Cabinets

Fisher American 8′ Fume Hood w/ Acid Storage Cabinets (Please Note: 2 weeks Lead Time) 8′ Fisher American Scientific Chemical Laboratory Fume Hood with Flammable & Acid cabinets (NLS-804) Unit does Not include blower Add Blower, The blower is ¾ HP Hazardous Location blower C1D1 Call in for Non-Hazardous Blower Pricing Information & Dimensions below: Fume Hood (Exterior) Dimensions: Width: 96″ Depth: 31 1/2″ Height: 54 1/2″ and 89 1/2″ with cabinet Work Area (Interior) Dimensions: Width: 86″ Depth: 23″ Height: 45″ Door opening: 26″ Sash Doors: 4 Fume Hood Accessories: Light on/off Switch 5 AC Power Plug 1 Cold Water Valve 1 Gas Valve 1 Vertical Sliding Sash Door with 4 horizontal sliding glass windows. 1 Flammable Cabinet 1 Acid Cabinet *Polyply Composites U.L. Listed ChemBlok CR-900 laminates are glass reinforced, UV inhibited composites sheet that offer excellent Chemical and flame resistance wherever a cost effective general-purpose corrosion material is required. Typical Properties General Information ASTM Polyply Composites CR-900 U.L Recognition File Number E31703 Meets U.L. Standards 1805 Color (Standards) White Sheet Size 48'' x 96'' length Sheet Thinkness 3/16'' Other Sizes upon Request Specific Gravity 1.8 D-792 Water Absorption (%by weight) 0.093 D-792 Flame Spread 20.2 UL 723/E-84 Smoke Generation, Tunnel Test 166 E-84 Flame Resistance Self Extinguishing Tensile Strength, psi 8,300 D-638 Flexural Strength,psi 20,400 D-790 Compressive Strength 29,200 D-695 IZOD Impact Strength 8.1 D-256 Barcol 50 REAGENT RESISTANCE - PANEL CR900 LOT 07-1087,88 No. Reagent Rating No. Reagent Rating 1 Amyl Acetate 0 26 Iodine, Tincture 2 2 Ethyl Acetate 0 27 Methyl Ethyl Ketone 1 3 Acetic Acid 98% 1 28 Methylene Chloride 2 4 Acetone 1 29 Mono Chlorobenzene 0 5 Acid Dichromate 5% 2 30 Naphthalene 0 6 Butyl Alcohol 0 31 Nitric Acid 20% 0 7 Ethyl Alcohol 0 32 Nitric Acid 30% 0 8 Methyl Alcohol 0 33 Nitric Acid 70% 2 9 Ammonium Hydroxide 28% 0 34 Phenol 90% 0 10 Benzene 1 35 Phosphoric Acid 85% 0 11 Carbon Tetrachloride 1 36 Silver Nitrate Saturated 0 12 Chloroform 1 37 Sodium Hydroxide 10% 0 13 Chromic Acid 60% 2 38 Sodium Hydroxide 30% 0 14 Cresol 1 39 Sodium Hydroxide 40% 0 15 Dichloroacetic Acid 1 40 Sodium Hydroxide, Flake 0 16 Dimethyl Formamide 1 41 Sodium Sulfide, Saturated 0 17 1,4-Dioxane 0 42 Sulfuric Acid 33% 0 18 Ethyl Ether 0 43 Sulfuric Acid 77% 1 19 Formaldehyde 37% 0 44 Sulfuric Acid 96% 3 20 Formic Acid 90% 1 45 Sulfuric Acid 77% + Nitric Acid 70% (50/50) 2 21 Furfural 2 46 Toluene 0 22 Gasoline 0 47 Trichloroethylene 0 23 Hydrochloric Acid 37% 0 48 Xylenes 0 24 Hydrochloric Acid 48% 3 49 Zinc Chloride, Saturated 0 25 Hydrogen Peroxide 3% 0 Unless otherwise indicated, all properties are based on tests performed on standard ASTM Test Samples and according to ASTM test methods Values Shown are for test Samples Made from production materials and are believed to be typical. No warranty is expressed or implied.

$20,762.22 - $27,165.24

-

Master Vapor Pumps Pump Part - MVP - 60 PSI & Liquid - Alignment Housing Kit

Pump Part - MVP - 60 PSI & Liquid - Alignment Housing Kit All sales final

$490.17

-

Master Vapor Pumps Pump Part - MVP - Liquid - Stainless Steel Seat

Pump Part - MVP - Liquid - Stainless Steel Seat All sales final

$336.12

-

Master Vapor Pumps Master Vapor Pumps - MVP Recovery Pump - XL 150 PSI

Master Vapor Pumps - MVP Recovery Pump - XL 150 PSI The Master Vapor Pump Model MVP-150XL is a certified gas recovery pump designed to operate at 150 PSI. It can handle over three times the volume of vapor as our standard MVP-150. This pump is designed specifically for LP-Gas vapor recovery and is ideal for butane or butane / propane mixtures. Please note that this model of the MVP 150 only comes with Three-phase power options available. Engineering Specifications: Recover LP-Gas vapor at OVER 18 CFM (cubic feet per minute) Recover butane at up to 4.5 LB/MIN (pounds per minute) Recover and re-condense butane between 35-50 GPH (gallons per hour) Electric motor: explosion proof for C1D1 hazardous areas; rated Class I Gr C & D, Class II Gr F&G Electric motor: 5 HP, 1800 RPM, 30 HZ Pump speed: 174 CPM (cycles per minute) at 60 HZ Size: 17.0” x 22.8” base x 46.4” tall Weight: 360.5 lb (163 kg) All sales final

$25,881.00

-

Neocision 5L Neocision Short Path Distillation Kit

5L Neocision Short Path Distillation Kit This unit carries a 2 day lead time. The 5L Neocision Short Path Distillation Kit features our 5L Distillation Kit with P5 Distillation Head and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. You will also receive a Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. The Premium Turnkey Kit Includes: 5L Neocision Kit with P5 Distillation Head KF-25 x 1/4" Barb Adapter Dewar Style Glass Cold Trap Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$9,733.38

-

Cascade Sciences Cascade CVO-10 Vacuum Oven

Cascade CVO-10 Vacuum Purge Oven (On Stand) This item carries up to a 1-2 week lead time. Cascade’s Model CVO-10 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, and slurries – especially temperature sensitive material. This vacuum oven liberates solvents, water, and other unwanted compounds. It’s ideal for large batch production environments. Processing Temperature Sensitive Material? The CVO-10 comes in both low temp & high temp versions. Be sure to get the low temp CVO-10 version that has excellent temperature uniformity for products such as pharmaceuticals, slurries or any product that can be damaged or destroyed by temperature fluctuations. CVO-10 Vacuum Oven Features NRTL Certified by TUV 9 sliding, removable shelves that pull out and stay in place for easy load/unload Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Easy mobility as oven sits on heavy duty industrial cart. Pump sits underneath at base of cart. VITON door gasket Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reads in inches of mercury or torr Smooth, quarter-turn vent valve Rear KF-25 port includes MAX EVAP Connection Kit for rapid vacuum drying or running feedthroughs inside oven for monitoring 220V / 1ph / 10AMPS Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Ergonomic. Turn vacuum pump on/off from oven control panel Fast Venting with larger ½” diameter vent line Rear vent barb allows for nitrogen or other inert gas connection Touch Panel LED control screen with user settable features The Cascade Difference Vacuum ovens have been around for decades. Basic vacuum ovens are mass-produced and sold by many large laboratory equipment distributors. But there are key differences between Cascade and other less costly, often imported vacuum ovens. Exceptional Temperature Control & Stability The Cascade CVO-10 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-10 eliminate hot and cold spots, making accurate use of every inch of shelf space. Independent Overtemp Failsafe Protection The Cascade Sciences CVO-10 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 392°F or 200°C. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. NRTL Certification #U8 170464972 077. No Extra cost. The CVO-10 Vacuum Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities. CAN/CSA-C22.2 No. 61010-1:2012 +UPD No. 1:2015-07 + UPD No. 2:2016-04 CAN/CSA-C22.2 No. 61010-2-010:2015 UL 61010-1:2012/R:2016-04 UL 61010-2-010:2015 EN 61010-1:2010 EN 61010-2-010:2014 Rigorous Quality Assurance in an ISO Certified, USA Manufacturing Facility Cascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment. Chambers are vacuum tested after welding for vacuum integrity Electrical & mechanical safety is thoroughly tested in compliance with TUV requirements Functional testing verifies user settable items consistent with most lab protocols/usage models Temperature verification includes calibration & temp chamber uniformity following ASTM standards Units are cleaned and packed in ISTA tested, certified packaging materials Digital Vacuum Gauge The digital vacuum gauge installed on the CVO-10 displays in is factory default set to read in inches of mercury (“Hg) or torr. Log Temperature & Vacuum With Data Port The CVO-10 features a rear mounted data port which outputs a digital log line once per minute. Viewing/logging this data requires terminal emulator software such as the open source (BSD License) emulator Tera Term. Equipped for Inert Gas Backfill. Built-In Safety Relief Introduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the ¼” rear vent barb. The maximum backfill pressure is 15PSI. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection Ports For faster evaporation, purging or drying the CVO-10 includes Cascade’s MAX EVAP connection kit. The MAX EVAP connection kit secures to the oven’s rear 1” dia KF-25 port located on the back center of the chamber. The MAX EVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthrus, or monitoring sensors inside the vacuum chamber during processing. Ergonomically Designed, Easy Quarter-Turn Valves For anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vent valve. Your wrists will thank you! Faster Venting With Large ½” Diameter Vent Lines For large capacity production environments, time is money. The CVO-10 vacuum oven has larger than industry standard vent lines. ½” diameter vent lines means operators spend less time venting the oven. ANSI Rated Tempered Glass + USA Made Steel Cascade ovens are made in Oregon, USA with high quality materials. Our glass is NGI-USA Tempered and certified to ANSI Z97.1.2007 16CFR / 201 11. Our door handles are rugged brushed steel, not plastic. Our vacuum vessels are constructed with American made steel. We’ve tried lower cost, imported steel. But over time, vacuum chambers made of lesser quality/lower tolerance material cannot withstand the flex and pressure changes of vacuum pumping/venting/purging. This can deteriorate vacuum integrity and the oven will lost its ability to hold vacuum. Need A Complete CVO-10 Vacuum Drying or Purge System? Cascade has taken the guesswork out of pairing the right vacuum oven with the proper pump. We offer two complete 10 cubic foot vacuum oven packages that have everything you need to begin vacuum drying on a large scale. The CVO-10 PRO Package pairs the CVO-10 with the clean, quiet, powerful Agilent IDP15 vacuum pump. Purchase the CVO-10 PRO Package and save $1642.86 over retail. The CVO-5 DOUBLE UP Package offers the same 10 cubic foot processing capacity, but in two ovens for smaller, multiple batch management. The TVO-5 DOUBLE UP Package is also self-contained on its own mobile, industrial cart. The TVO-5 DOUBLE UP Package saves $1642.86 over retail. A Vacuum Cold Trap for High Production Environments For high production environments, adding a vacuum cold trap keeps the vacuum pump running optimally, extends time between maintenance and allows reclamation of outgassed materials. Cascade’s MAXTRAP50 is ideally suited for trapping in these high production environments where typical lab grade traps, with small inlets and outlets can slow things down. Specifications Capacity Volume 9.3 Cubic Ft. / 264 Liters Interior 28”W x 24”D x 24”H 711mm x 609mm x 609mm Exterior (Not Including Rack) 44”W x 42”D x 40”H 1118mm x 1067mm x 1016mm 67.6”H with stand Temperature Ranges Low-Temp Processing Range 26°F to 250°F (121°C) Temperature Uniformity +/- 1.5°F @ 105°F (40.5°C) Temperature Stability +/- 0.4°F @ 105°F(40.5°C) Heat Up / Stabilization Time to 250°F 120 minutes (to minimize overshoot) High-Temp CVO-10 (SVAC 9.3) to 428°F / 220°C Available Temperature Uniformity +/- 6.5% of setpoint *Note that ambient laboratory conditions can affect temp performance. Vacuum Valve Type Side Mounted Round Vent Valve Sizes ¼ Turn Lever ½” diameter line Lighting Interior LED Strips (Rated to 150C) On low temp CVO-10 only Window Type Glass Tempered NGI-US to ANSI Z97.1.2007 Vacuum Gauge Indication Reads in inches mercury or torr(Selectable) Temperature Controller Screen Type Touch Screen Accuracy Accurate Within 1°F Failsafe Independent Overtemp Failsafe Ports-Rear Vacuum KF-25 Port Vent 1/2” Barb Data Log temp & vacuum levels Inert Gas Introduction Yes. Via 3/8” Vent Barb 15 psi max inlet pressure Power Options Power 220V – 240V / 1ph / 10A 50/60Hz Cord? Cord Included Outlet Type NEMA 6-15R Power Outlet Shelving Removable? Removable Quantity Included Comes with 9 Each. Fixed. Detail Slide on rails, extend, stay in place. Surface Area 28″W x 24″D Weight Capacity 50 lbs Weight Net Weight 663 lbs / 300.1 Kg Shipping Weight 995 lbs / 351.5 Kg Shipping Details Dimensions 63″L x 60″W x 88″H Class Class 110 Certifications - ISO 9001 - NRTL TUV #U8 170464972 077 - CAN/CSA-C22.2 No. 61010-1:2012 - + UPD No. 1:2015-07 + UPD No. 2:2016-04 - CAN/CSA-C22.2 No. 61010-2-010:2015 - UL 61010-1:2012/R:2016-04 - UL 61010-2-010:2015 - EN 61010-1:2010 - EN 61010-2-010:2014 Warranty Length 1 Year Exclusions Gaskets Not Incuded Dimensional Drawing Download Oven Manual Download DCS Controller Manual View NRTL Certification Contoller Software

$35,007.97

-

J636T Hubbell Process Water Heater 240V 3P with Pump

Hubbell Process Water Heater 240V 3P Process Water Heater 6 Gallon Stainless Steel ASME Vessel 36 kW, 240 volt, 3 phase Complete with electrical operating controls including the following: magnetic contactor, immersion elements, digital temperature controller with safety hi-temperature cut out, low water cut out, and an ASME rated combination temperature and pressure relief valve. Unit is factory assembled, insulated, jacketed, wired, and tested. Unit is ready for electrical and plumbing service connections. This kit includes a stainless steel pump to continuously circulate water through a closed loop system, an expansion chamber may be needed. Professional installation of water lines by a certified plumber is recommended. Water Heater Features Industrial Grade Construction Stainless steel pressure vessel provides maximum service life ASME Section VIII stamped vessel ensures high quality construction Heavy duty construction withstands demanding industrial use Packaged with all electrical operating controls for efficient installation Small reserve capacity lowers peak power demand and reduces operating costs in systems with ON / OFF cyclical demand Hubbell V636T Heater Specs Model J636T Voltage 240V Current Draw (A) 87 Heating Wattage (kW) 36 Storage Capacity (Gal) 6 Inlet / Outlet Connections 3/4" MNPT Circulation Pump Specs Model AHWS-25-60-180 Material Stainless Steel Power 40 W Max Head (Ft.) 18 Max Flow (GPM) 15.8 Max Water Temp (°C) 110 Voltage 220VAC / 1ph Current Draw (A) .2 Max Ambient Temp (°C) 40

$9,243.21

-

KF-40 Tee

This is a KF-40 Flanged Tee for High Vacuum Applications. The Material is 304SS and it has a maximum vacuum rating of 10^-7 torr @ 72F.

$77.03

-

SSP Corporation Female Elbow, 3/8-18 FNPT x 3/8-18 FNPT, 316 SS

Body Material 316 SS Connection 1 - Type Female National Pipe Thread Connection 1 - Size 3/8-18 Connection 2 - Type Female National Pipe Thread Connection 2 - Size 3/8-18 Brand Series TruFit Shape Elbow End Connections FNPT x FNPT Production Category 4 End Connection Type Female National Pipe Thready by Female National Pipe Thread

$28.01 $11.20

-

STIR BARS, MAGNETIC, PTFE, EGG-SHAPED

Egg-shaped magnetic stirring bar provides its own pivot point without separate ring or abrupt change in contour. Designed for use in round bottom vessels, it is shaped to spin freely, unrestricted by the vessel contour. Manufactured with FDA-grade and USP Class VI PTFE. Stir Bar, Magnetic, Egg-shaped, fits 12000mL-22000mL flask, Length x Dia. in inches: 3 x 3/4

$52.24

-

BVV 3-Way Compression Ball Valve

BVV manually operated two-way ball valves provide quick ¼ turn directional flow control of fluids in instrumentation and process systems. This valve body had 3 connections, connection 1 and 3 (pictured left and right) can be switched to be in use with connection 2. If the handle is left in between connections 1 and 3, there will be no flow through the valve. Features: Directional handle indicates flow direction Panel Mountable 90-degree actuation (180 degree to switch outlet ports) Straight through flow path Micro-finished ball provides positive seal Free-floating ball design provides compensation for seat wear for repetitive sealing Blow-out proof ball & stem BVV™ Compression Ball Valve - Data Sheet Specifications Body Material 316L Stainless Steel Pressure Rating @ 100F 1000 PSIG Connection Type 1/3 Double Ferrule Tube Fitting Connection Size 1/3 Specified by User Connection Type 2 Double Ferrule Tube Fitting Connection Size 2 Specified by User Handle Type Nylon-Stainless Steel Insert Handle Color Black Packing Material PTFE

$175.06 - $301.10

-

Angled Compression Ball Valve

BVV manually operated two-way ball valves provide quick ¼ turn directional flow control of fluids in instrumentation and process systems. This Valve body has a 90 degree angle to combine the utility of a ball valve and shape of a compression elbow to eliminate extra parts in the system. Features: Directional handle indicates flow direction Panel Mountable 90-degree actuation Straight through flow path Micro-finished ball provides positive seal Free-floating ball design provides compensation for seat wear for repetitive sealing Blow-out proof ball & stem BVV™ Compression Ball Valve - Data Sheet Specifications Body Material 316L Stainless Steel Pressure Rating @ 100F 1000 PSIG Connection Type 1 Double Ferrule Tube Fitting Connection Size 1 Specified by User Connection Type 2 Double Ferrule Tube Fitting Connection Size 2 Specified by User Handle Type Nylon-Stainless Steel Insert Handle Color Black Packing Material PTFE

$182.06 - $280.10

-

Commercial Vibrating Sifter - 15.50 x 4" (Compare to Custom Cones)

Automatic Vibrating Sifter - Commercial 15.50 x 4" Sifting your plant material is an excellent way to remove stems automatically. This commercial sifting machine was explicitly designed with processors in mind - the stainless steel construction and screens ensure you can easily clean our sifter, and the screen sizes are fine-tuned for the most common sifting needs. The commercial grade sifter offers a larger diameter, coming in at 15.50 inches, compared to the 11.75 inches of the original starter sifter - this means you'll be able to sift more plants in one sitting! Once you've ground your plant material, you only need to pour it into the sifter and switch it on. You can now walk away and wait for your plants to be automatically sifted - no more standing around doing manual sifting. Sifting your biomass will not only ensure no stems make it into your final product but will also ensure nothing else makes it into your product, like large leaves, gravel, or any other foreign matter. Additionally, consistent grinding will make your product burn more evenly and pack more evenly in any cone-filling machine. Plant Material Specific Sifter The commercial sifter was explicitly designed for plant material processors. From its stainless steel construction to multiple screen sizes, our team of Experts is confident this sifter or our other larger sizes will be the perfect addition to your product production process. We offer multiple screen sizes, allowing you to customize the particle size for the plant material in your product. Depending on the strain or weight of the product you are making, you may want to experiment with various screen sizes. Multiple Screen Sizes When it comes to sifting your plant material, you will want to have an ideal particle size for your plant material in mind. If you are still determining what size screen you need, our team of Experts is here to help! Depending on your strain and grinder, your ground biomass will have a different consistency. Additionally, depending on the size of the cone you are using and your desired fill weight, the particle size of your plant material will play a significant role. For example, a smaller particle size will allow you to pack more plant material into a small cone, but a particle size that is too small may lead to a poor, uneven burn. Specifications PURPOSE: Sifting Ground plant materialCONSTRUCTION: Stainless SteelSCREEN DIAMETER: 15.50 inchesMACHINE TYPE: SifterPOWER REQUIREMENT: 120vRATED VOLTAGE: 110VRATED FREQUENCY: 60HzRATED POWER: 50W

$1,400.49

-

BVV 3838 Nanofiltration Skid

BVV 3838 Nanofiltration Skid Note: This product carries 8 - 12 week lead time Perform organic solvent recovery or botanical extract purification with ease with our 3838 nanofiltration skid. Replace up to 22X 50L Rotary evaporators with a single Skid. BVV's 3838 Nanofiltration Skid is designed to meet Class 1 Division 1 standards. With the ability to recover 90 gallons of ethanol per hour without the application of heat, preserving target compounds and utilizing a fraction of the energy consumption of a traditional falling film qualifying our 3838 Nanofiltration Skid for energy saving rebates. Processing Power Capacity: 90 GPH of solvent recovery or purification. Solvents: Ethanol, Methanol Specifications 4X 3838 nanofiltration housings Stainless steel 26GPM pump with PTFE seals 15HP C1D1 1750 RPM Motor 15HP VFD 1/60/230 NEMA 4X enclosure (13A) Insulated 4"x24" Heat Exchanger 5 Ton low-temp glycol Chiller (230V/1P/60HZ/47.2A or 230V/3P/60HZ/35.1A available) 700PSI Pressure Relief Valve C1D1 Flowmeter 0-1000 PSI Pressure Gauges 1.5" Intake & Retentate Lines 1/2" Permeate & Pressure Relief Lines Footprint (DxWxH) 27"x60"x51" Weight: 885 lb Maximum Pressure Rating: 700PSI Performance Variable Frequency Drive-based flow control Complete pressure control with manual pressure controls Retentate cooling with inline Heat exchanger & chiller 700PSI pressure relief valve with diversion line *Components shown are subject to change**This unit is meant for bulk solvent recovery, 90% of the total volume of solvent an additional solvent recovery apparatus is recommended to evaporate to dryness*

$109,237.97

-

5/16-18 Hex Jam Nylon Insert Lock nut Nylock Stainless Steel

5/16-18 Hex Jam Nylon Insert Lock nut Nylock Stainless Steel 5/16 - 18 Low Profile Lock Nut. This nut fits on vacuum chamber gauges and manifolds.

$3.50

-

Glas-Col Glas-Col Thermocouple Type "J"

Glas-Col Thermocouple Type "J" A thermocouple is a sensor that measures temperature. This type of sensor consists of two different types of metals that when welded together create a junction and small voltage which is then read by an indicator or control. Glas-Col offers thermocouples in various types, diameters and probe lengths. Type J: is the most frequently used thermocouple, and it consists of a positive (Iron) and a negative (Constantan) leg. Specifications D x L 1/4" x 18" Lead Length 72"

$399.14 $266.09

-

Glas-Col Glas-Col Digital Temperature Controller Input 2400W, 120V w/Stir Motor Ctrl

Glas-Col Digital Temperature Controller Input 2400W, 120V w/Stir Motor Ctrl Glas-Col invented the Electric Heating Mantle in 1939 and has continued to be the industry leader for Laboratory and Industrial heating ever since. Their products are known for exceptional performance, reliability and durability. Upgrade today to see the Glas-Col difference. Specifications Output PID Range 120 Watts 2400

$1,400.49 $700.24

-

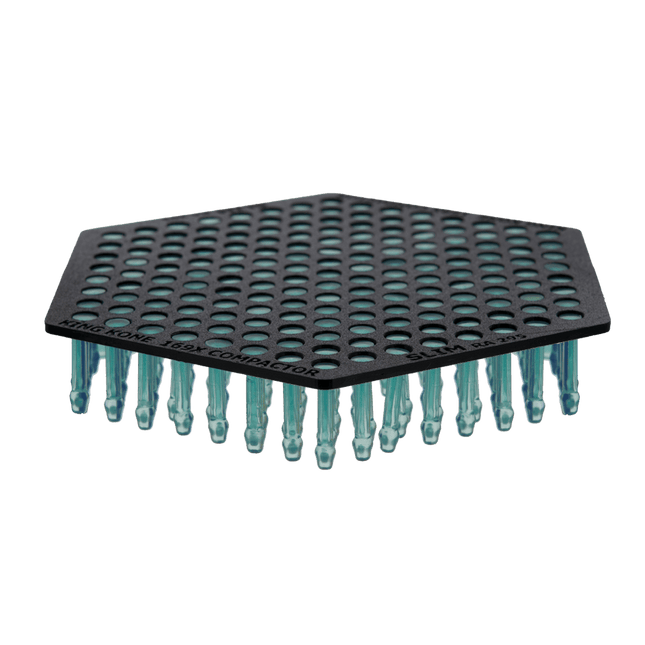

King Kone 115 Extended Tube Packing Fingers - All Tube Sizes

115 Extended Tube Packing Fingers - All Tube Sizes This accessory is an upgraded version of our standard 115 tube packing fingers(typically utilized at the end of the packing process, to pack the end of the product down, in order to close off the tube). The additional advantage of this accessory is the "Height Adjustment Option". It allows for the user to adjust the height of the packing fingers so that it can be used for an additional pack, at any part of the tube packing process. Depending on the product being packed, stickier material may make it more of an obstacle to reach the desired density, especially at the crutch. With these height adjustable packing fingers, an extra pack assisted by the packing fingers, at any length you need, is the easy solution to a perfectly packed pre-rolled tube. Ability to pack: All size straight tubes.

$630.22

-

King Kone 169 Extended Cone Packing Fingers

169 Extended Cone Packing Fingers This accessory is an upgraded version of our standard packing fingers(typically utilized at the end of the packing process, to pack the end of the product down, in order to close off the cone). The additional advantage of this accessory is the "Height Adjustment Option". It allows for the user to adjust the height of the packing fingers so that it can be used for an additional pack, at any part of the cone packing process. Depending on the product being packed, stickier material may make it more of an obstacle to reach the desired density, especially at the crutch. With these height adjustable packing fingers, an extra pack assisted by the packing fingers, at any length you need, is the easy solution to a perfectly packed pre-rolled joint. Ability to pack: 84mm, 98mm, 109mm

$630.22

-

Across International Ai DigiM 10L 300C 1200 RPM Digital Heating & Stirring Mantle

Ai DigiM 10L 300C 1200 RPM Digital Heating & Stirring Mantle Across International heating and stirring mantles come standard with a digital display for the most accurate control. The large display interface makes it easy to quickly and precisely adjust temperature and rotation speeds.The DigiM mantle has two sets of thermocouples for proper temperature and speed detection. The heating jacket is pre-treated before shipment, which ensures that no smoke or odors (caused by heat) are released into your work environment. Model DigiM10 Electrical requirements 110V 60Hz 1-Phase, 2050 watts, 24A or 220V 50/60Hz 1-Phase, 2050 watts, 12A Heating Ambient to 300°C Stirring Min. speed: 110 rpm, max. speed: 1200 rpm Motor power: 40 watts Motor type: brushless DC motor Controller PID control with digital temperature and rotation speed display External thermocouple Type: PT100 Cable length: 43 inches Stainless steel probe length: 15 inches Stainless steel probe diameter: 5 mm Flask holder Maximum flask capacity: 10 liters Top opening diameter: 11.75 inches Depth: 6.5 inches Dimensions (WxDxH) Unit: 18 x 17.5 x 13 inches, shipping: 22 x 21 x 18 inches Weight Unit: 30 lbs, shipping: 40 lbs Safety Thermocouple failure protection Certification ETL tested to UL and CSA standards (optional), CE (standard) Warranty One year Standard package Part description Quantity Part image Ai DigiM 10L digital heating & stirring mantle 1 pc External temperature probeDigiM05, DigiM2, DigiM5: Cable Length: 40”, Probe Length: 9” DigiM10, DigiM20: Cable Length: 43”, Probe Length: 15” 1 pc Internal temperature plug 1 pc Boss head DigiM2, DigiM5:- 1 pc DigiM10 and DigiM20: 2 pcs 1 or 2 pcs Stainless steel support rod DigiM2, DigiM5:- 1 pc DigiM10 and DigiM20: 2 pcs 1 or 2 pcs PTFE-coated stir bar 2 pcs PTFE-coated magnetic stir bar remover 1 pc 4 prong stainless steel clamp opens to 3 1/2" DigiM2, DigiM5:- 1 pc DigiM10 and DigiM20: 2 pcs 1 or 2 pcs User's manual 1 pc

$1,666.58 - $2,786.97

-

Media Bros Media Bros CRAC Filter Media

COLOR REMEDIATION ACTIVATED CARBON (CRAC) FOR ETHANOL EXTRACTION Our powdered version of the G-CRAC, CRAC, is a highly modified bituminous coal carbon with increased surface area. CRAC is unique because it concentrates reactants via adsorption and then promotes their reaction on the pore's surface, which is best suited for heavy environmental clean-up. PH 7 DESCRIPTION Color Remediation Activated Carbon (CRAC) is a top-shelf carbon powder that has revolutionized extraction. Its high-performance selectivity sets it apart from other filter media and is crucial in producing a high-quality extract free of undesirables and impurities. CRAC stands out due to its meticulous preparation process. Its granular consistency makes it easy to handle and is thoroughly sifted, which minimizes the risk of carbon or dust contamination. This commitment to quality creates a safer, cleaner work environment. CRAC is also environmentally friendly; it's non-toxic, biodegradable, and recyclable. This added layer of safety doesn't compromise its effectiveness; instead, it ensures the integrity of the end product and the health of your workforce. CRAC is pH-neutral double activated, which maximizes the carbon's surface potential, allowing for more efficient adsorption and color remediation. By opting for CRAC, you are choosing a product that has been fine-tuned to deliver the best possible extraction results. CRAC stands out not just for what it contains but also for what it doesn't. CRAC delivers all the microporous, mesoporous, and macroporous media you can handle, providing comprehensive remediation of ethanol extract and oil purity you can count on. At Media Bros, we understand the diverse needs of various operations. Hence, CRAC is available in a 1.5 kg pouch, a 4 kg package, a 10 kg bucket, and a 100 kg drum. Regardless of your operation's size, there is a bag of CRAC tailored to your needs. Wine, cheese, peanut butter, jelly, CRAC, and Activated Alumina. The combination of CRAC and Activated Alumina as a filter bed provides a practical and robust solution for ethanol extraction, creating a superior filter blend that enhances the overall remediation process. NSF Certified Use Media Bros Activated Alumina as an alumina media filter bed for best results. TECHNICAL SPECS Solvent Type Hydrocarbon + Ethanol Color Remediation Level Heavy/High Pesticide Remediation Level High Selectivity/Polarity Level Less Selective/Most Polar Heavy Metal Remediation Yes Moisture Remediation Level Low Fats/Lipids/Waxes Level Medium Crystal Growth Fast Depth Filtration No Flow Rate Low Flow pH Level Neutral (pH 7) Best For Older Biomass, Low Quality Suitable for Reruns Yes Distillation Clean-up High Scrub

$105.04 - $5,882.04

-

Media Bros Media Bros -CRY+ FILTER MEDIA

Media Bros -CRY+ FILTER MEDIA CRY+ is our largest granule size. With a mesh size of 16-x30, this media allows operators to run high-flow processes while maintaining a consistent quality output. DESCRIPTION: CRY+™ Filtration Media: High-Flow, High-Efficiency Filtration CRY+™ is our premium filtration media, designed with a larger granule size (16-30 mesh) to deliver unmatched flow rates without compromising the quality of your extraction. Whether you're processing high volumes or working with challenging biomass, CRY+™ ensures consistent, effective results in every run. Engineered for operators who demand speed and precision, CRY+™ is ideal for high-flow processes where residence time and color remediation are key. With a recommended solvent ratio of 6:1 to 10:1 and the ability to operate at room temperature or below -10°C without clogging, CRY+™ offers flexibility and efficiency for modern extraction setups. Key Features: Larger Granule Size (16-30 mesh): Delivers faster flow rates while maintaining purification performance. Needle Valve Recommended: Fine-tune flow rates for optimal color correction, especially when processing dark or oxidized material. Temperature Resilience: Performs optimally at sub-zero temperatures without clogging. Technical Specs: Use a 4-6” diameter CRC column for best results. Recommended operating pressure: 20-45 psi. Media ratio: 200-300g per 1 lb of biomass. Available Exclusively Through Our Dealer NetworkFind a dealer near you to purchase CRY+™: *A needle valve is recommended on the output (bottom) of the filtration column to properly fine-tune your flow rates. If you are processing dark or oxidized material, a tighter flow restriction will increase residence time, allowing for better color correction. TECHNICAL SPECS Solvent Type Hydrocarbon Color Remediation Level Moderately Heavy/High Pesticide Remediation Level Medium Selectivity/Polarity Level Moderately Selective/Medium Polarity Heavy Metal Remediation Yes Moisture Remediation Level Moderate Fats/Lipids/Waxes Level Medium Crystal Growth Fast Depth Filtration No Flow Rate High Flow pH Level Neutral (pH 7) Best For Fresh Frozen, Nugs, High Quality Suitable for Reruns Yes Distillation Clean-up Moderate Scrub SDS

$126.04 - $1,260.44

-

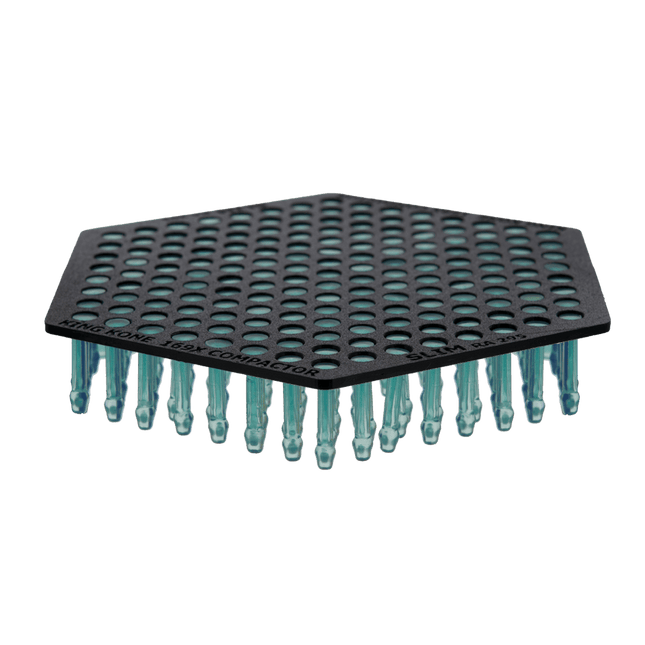

King Kone 169 Standard Cone Packing Fingers - 84mm, 98mm, 109mm

169 Standard Cone Packing Fingers - 84mm, 98mm, 109mm This accessory is utilized at the end of the packing process, to pack the end of the product down, in order to close off the cone. This can help with exposing more paper for the closing process. Ability to pack: 84mm, 98mm, 109mm

$525.18

-

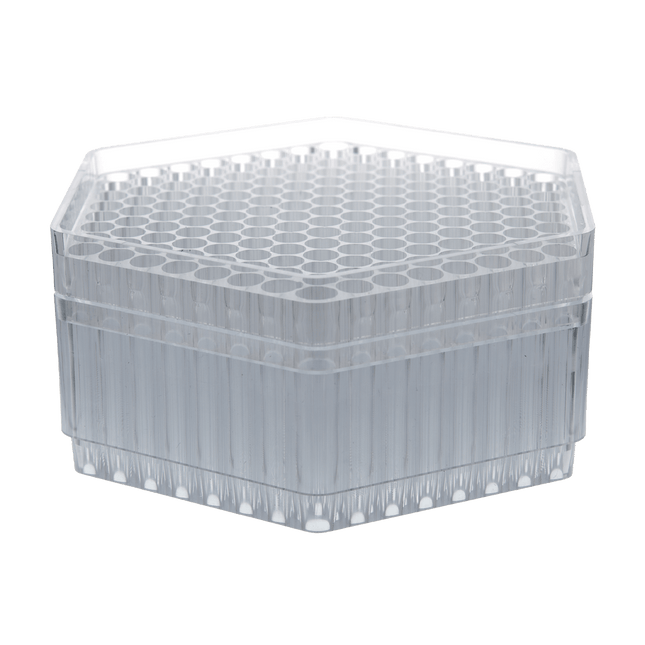

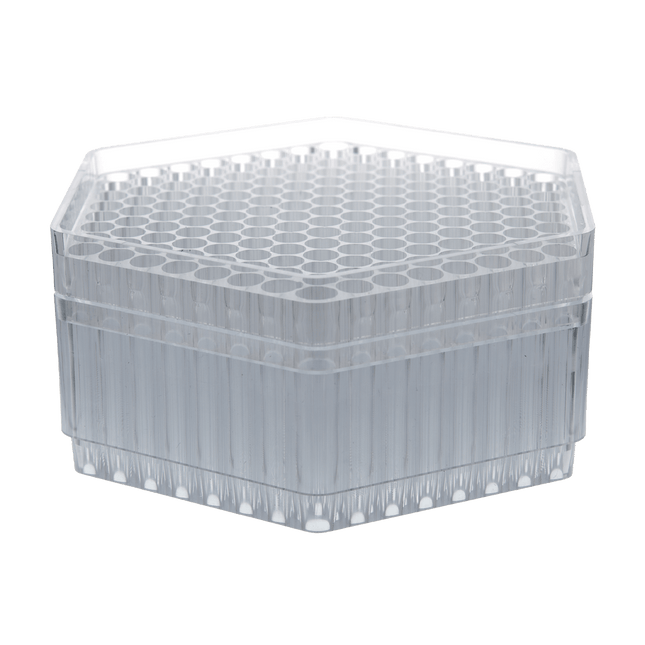

King Kone Clear Standard 2 Tray Set

Clear Standard 2 Tray Set This is the same 2 trays that your King Kone originally comes with, out the box. The bottom tray packs the 84mm cones also known as the 1 ¼ size and the top thinner tray in supplement with the bottom tray can pack the size 98mm and the 109 King sized cones. Some people like to purchase extra sets of these trays so that while one is in use on the machine, the additional tray set could be loaded with cones for the next run. Having an extra set increases production rates and assures that every minute is being used towards increasing results.

$525.18

You have seen 1392 out of 1652 products