BVV Loyalty - BVV

Male Elbow

BVV™ Male Elbow BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are NPT threads (National Pipe Taper) and will compress against other Female/Male NPT threads creating a tighter and tighter connection. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. **NOTE: Pre-Taped option comes from BVV Pre-taped with Yellow UL Listed Gas PTFE Tape on the Male NPT threads ONLY for a +0.50c charge per male npt end. (JIC Threads DO NOT need to be taped.) MNPT Elbows allow the user to sharply turn the flow of the system by 90 degrees allowing for more clearance or better positioning of the fitting or valve on the extraction system. BVV™ Male Elbow - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4"-18 FNPT 3/8"-18 FNPT Sizes Available: 1/4" 3/8"

$8.39

Rubber Cones Set of 9

These rubber cones are used for adapting and creating a seal on buchner funnel systems or applications where varying sizes are needed. Color is white and comes with 9 comes the smallest one being a solid stopper.

$27.96

KF-25 Flange Kit

Complete KF-25 Flange Kit The Complete Kit for KF-25 Vacuum Fittings. Connect your flange to a pipe with this complete kit from BVV™. It includes Clamp, O-ring, and Flange

$48.93

5 Pack of Metal Keck Clips for 24/40 Joints

5 Pack of Metal Keck Clips for 24/40 Joints 5 Pack of Metal Keck Clips for 24/40 joints. Universal clips for ground joints manufactured from high-grade stainless steel. These clips fit snugly and are not overly difficult to slide on and off.

$15.38

37 Degree FJIC Cap

BVV™ - FJIC Cap BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. JIC connections do not require thread sealant because they seal off the flared surface of the fitting JIC Fittings are also not the same size as NPT fittings but do have the same size nomenclature. When connecting JIC fittings to one another it is recommended by Best Value Vacs to use 2 wrenches - 1 to tighten the fitting and 1 to hold back against the force applied to create resistance and ensure a better seal. Female JIC caps are designed for capping off male JIC threaded connections on extraction system BVV™ FJIC Cap - Data Sheet Specifications Material 304 Stainless Steel Sizes Available: 1/4" 3/8" 1/2"

$8.39

10" Tri-Clamp Spools

10" Tri-Clamp/ Tri Clover Spools Sizes Available: 10" x 10" Tri-Clamp/ Tri Clover Spool Specifications: Tri-Clamp Size 10" Material 304 Stainless Steel Standard 3A High Polish Spool OD 10" Spool ID 9.732" Flange OD 10.57" Bead Center 10.12" OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 10" Tri-Clamp Spools - Drawing Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$307.58

Nickel Plated Brass 1/4" NPT Female to 1/4" Barb Fitting

Nickel Plated Brass 1/4" NPT Female to 1/4" Barb Fitting allows the user to adapt a male NPT thread to a 1/4" Hose barb for flexible tubing. Note: This connection requires PTFE tape on the threaded side to create a leak free seal.

$4.89

Replacement Sight Glass Gasket 2 Pack - Buna-N

Replacement Sight Glass Gasket 2 Pack - Buna-N These are replacement BUNA-N gaskets for BVV™ Brand Sight Glasses. Comes with 2 per pack.

$25.17 - $81.09

Best Value Vacs 2 Quart Tall Stainless Steel Vacuum Chamber

2 Quart Vacuum Chamber (Comes with 2 Year Limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 - 2B Stainless Steel Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 6.75” Tall X 4.75” Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$125.83

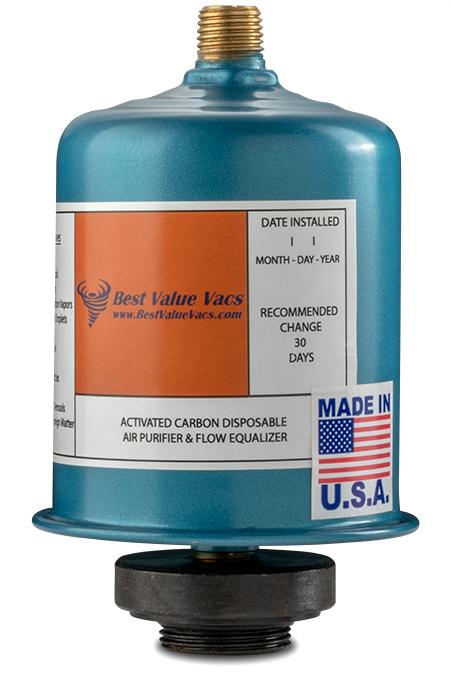

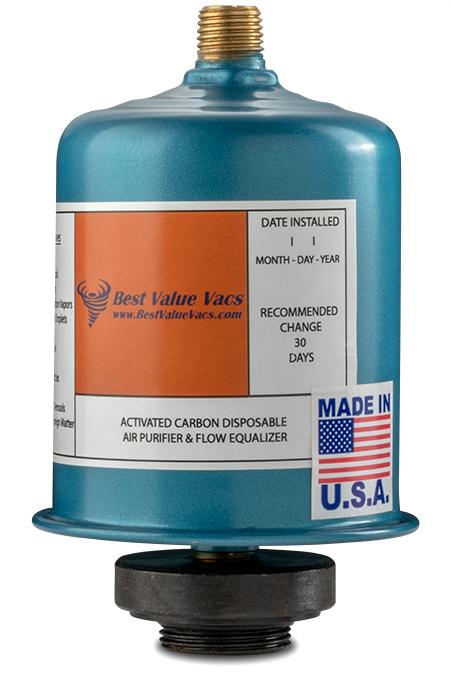

CPS Vacuum Pump Activated Carbon Exhaust Filter

Carbon Exhaust Filter for CPS Vacuum Pumps Replaces Koby Junior (US Patent# 3169112A) CPS Vacuum Pump Activated Carbon Filter for use with CPS brand vacuum pumps. This filter will adsorb contaminants such as oil aerosols, oil vapors, certain other hydrocarbon vapors, and trace moisture. They also trap all foreign solid particles and bacteria down to 0.5 microns in size. Key Features: Purifies Exhaust Gases from Vacuum Pumps Up to 19 CFM 0.5 Micron Filtration levels. Helps Maintain Safe Working Environment Adsorbs Organic Vapors and Small Particles High-Efficiency Filtration Minimal Pressure Drop Maintenance Free - Completely Disposable Pressure Safe to 90 PSI M26 x 1.0 - Carbon Steel Pump Connection Filter connections 1/4" NPT Pipe Fitting Connections Removes the following contaminants: Oil Mist Oil Aerosols Oil Vapors Hydrocarbon Vapors Moisture Droplets Dust Pipe Scale Rust Fine Particles Odors Organic Aerosols Other Foreign Matter Lifespan:720 hrs. of continuous operation. (Then replacement is recommended) **NOTE PUMP NOT INCLUDED

$160.78

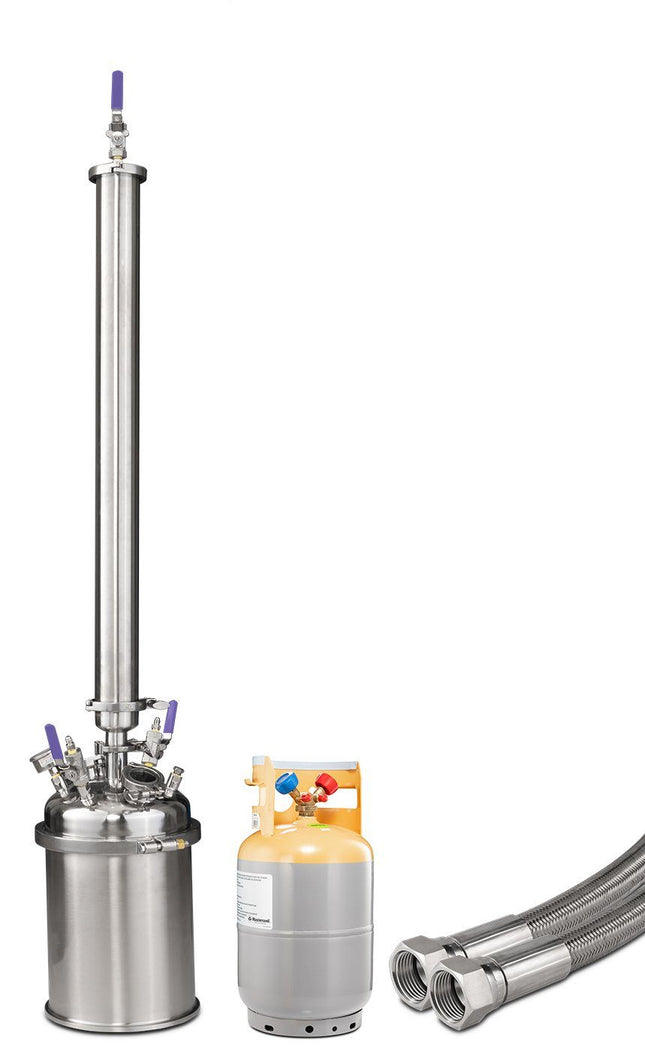

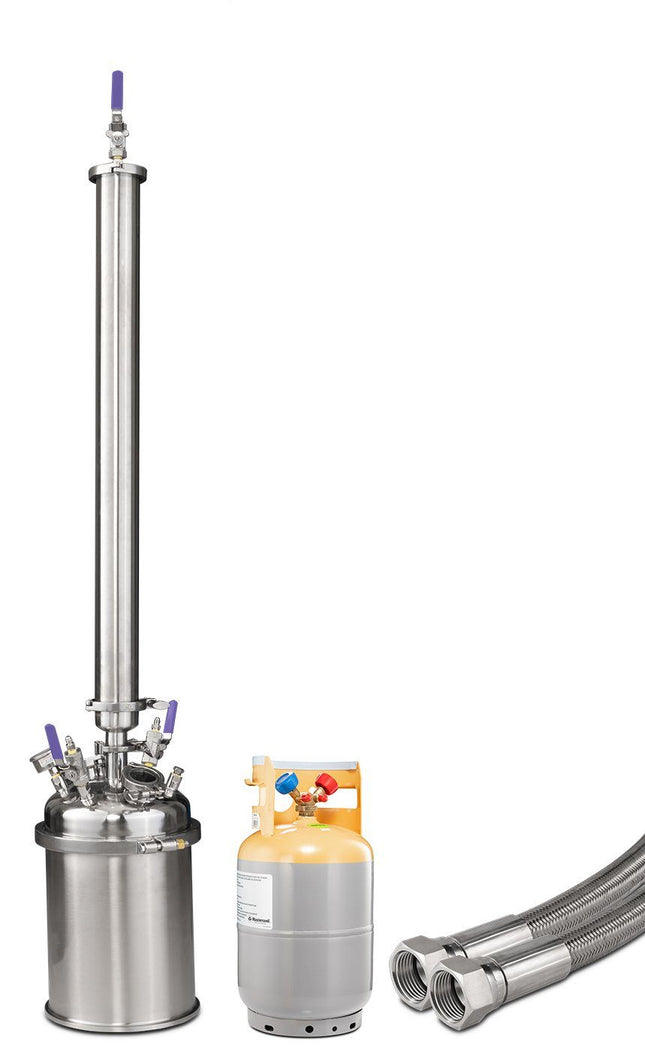

1LB Passive Closed Loop Extraction Kit

Passive Closed Loop Extraction System ***NOTICE TO CUSTOMER: THIS ITEM WILL SHIP BY FREIGHT ONLY*** (System comes with 1 yr. limited warranty) ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors We believe it’s better to buy everything you need in one shot, so we’ve created a package that includes a vacuum chamber, vacuum pumps, and complete extraction system. The best part? Buying this kit will save you money compared to purchasing each component individually Closed Loop Extraction Process The 1lb closed loop hydrocarbon extraction system performs botanical extraction within a sealed, vacuumed system. Utilizing a top-fill input, solvent washes thru the material column, collecting oils as it passes over the material. The oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and standard LP tank. This model has minimal features to keep cost low, while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Solvent is input into the material column with a showerhead endcap, ensuring the full material column is saturated with solvent. The Professional comes with a sleeved spool, allowing users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is the premium version of the Professional. It features all American made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, jacketed collection base, and all high-pressure clamps. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base 0.9CF ECO Oven V7S 7CFM Single Stage Vacuum Pump BVV 316SS Full Bore Valves Showerhead Dewaxer Ball Valve Splatter Platter Base 0.9CF ECO Oven V7S 7CFM Single Stage Vacuum Pump SSP Valves Showerhead Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump Unit Includes: 6"x6" Welded Bottom Base 6"x6" Open Spool Assembled 6" extractor lid 3"x24" Material column with reducer & top cap Mastercool 6LB Solvent Recovery Tank (1) 1/4" 48" FJIC Stainless Steel hose (1) 1/4" 60" FJIC Stainless Steel hose (1) 1/4" FJIC HVAC hose Standard pressure single pin clamp and 1 full gasket set Instruction Manual Specifications: 3"x 24" 304 Stainless Steel Material Column-1lb capacity (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple 37 degree FJIC port connections 304 Stainless Steel Base Container 6" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure/standard pressure, easy clean unit BUNA-N Gaskets are designed for Oil Processing Temp range -40-200F, and have superior solvent resistance Base unit Maximum Capacity: 395 cubic inches, (6.472 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$3,734.33 - $6,169.12

Fully Jacketed Base with 1.5" Tri-Clamp Drain Port

Fully Jacketed Base with 1.5" Tri-Clamp/ Tri-Clover Drain Port This Fully Jacketed Base features a full outer jacket to allow the circulation of heat transfer fluid. The base also has a sanitary Tri-Clamp port welded through the jacket and base for easier drainage of processed material and extract from the stainless steel base. This base is made out of 304 High Polish Stainless steel and has 2 1/2" FNPT Ports on the outer jacket to allow the circulation of fluid to heat or chill the base and also has a 1.5" Tri-Clamp port that allows the drainage of material from inside the base without having to lift it up and tip it over. Specifications Material 304 Stainless Steel Sizes Available: 10" Tri-Clamp X 12" 12" Tri-Clamp x 12" Drain Port Size 1.5" Tri-Clamp Jacket Port Size 1/2" FNPT

$629.15 - $768.96

1/4" Manual Shut-Off Ball Valve

1/4" Female Swivel x 1/4" Male Swivel Valve BVV™ brand Female Brass Swivel valve with a 1/4" Female SAE swivel end with O-ring and 1/4" Male SAE end connect to FJIC or HVAC hoses.

$18.18

4 Way Vacuum Manifold

4 Way Vacuum Manifold The Vacuum Manifold can be used in conjunction with any vacuum application. It allows the user to selectively choose where to apply vacuum pressure. It is available in 1/4" or 3/8" barb connections and is assembled using 304-grade stainless steel parts. Please refer to the following example applications: Rotary evaporator vacuum distribution Multiple vacuum chambers with a single vacuum pump Air inlet to a vacuum system ***Note: Vacuum Manifold is intended for use with vacuum pressure only. It is not rated for positive pressure.***

$209.72

N-Hexane 99.5% Lab Grade

BVV™ Ultra High Purity Lab Grade N-Hexane (Note: Container style and color may vary) BVV™ Ultra High Purity Lab Grade N-Hexane is a perfect solution for cleaning up and clarifying the extracted material and removing the green colored plant material and some waxes out of the product to produce a cleaner end result when distilling extracts. Chemical Formula: C6H14 Molecular Weight: 86.178 g·mol−1 CAS Registry Number: 110-54-3 Appearance Colorless Liquid Odor: Petrolic Density 0.6606 g mL−1 Boiling Point: 68.5 °C / 155.2 °F Solubility in water: 9.5 mg L−1 GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H302, H305, H315, H336, H361fd, H373, H411 GHS Precautionary Statements P201, P202, P210, P233, P235, P240, P241, P242, P243, P260, P264, P271, P273, P280, P281, P301+P330+P331, P302+P352, P303+P361+P353, P304+P340, P308+P313, P310, P312, P314, P332+P313, P363, P370+P378, P391, P403+P233, P405, P501 UN Identification Number: 1208 Proper Shipping Name: Hexanes Transport Hazard Class: 3 Packing Group: II DOT Placard: n-Hexane Safety Data Sheet (SDS)

$40.54 - $1,293.24

3 Piece Heavy Duty 8" Tri-Clamp 304SS

3 Piece Heavy Duty Tri-Clamp/Tri Clover 304SS This 3 Piece Heavy Duty Tri-Clamp is made out of 304 stainless steel and has a 3 segment locking function allowing even pressure around the connection point gasket so it does not bulge out in a certain direction creating a better overall seal on the system. This clamp will fit a standard 8" tri-clamp connection

$111.85$69.91

Best Value Vacs 10 Gallon Aluminum Side Mount Vacuum Chamber

Best Value Vacs 10 Gallon Aluminum Side Mount Vacuum Chamber (Comes with 2 Year Limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 15" Tall x 14" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BVV Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. GlassVac chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$436.21

Hemispherical Endcap with 1.5" Side Port

Hemispherical Endcap with 1.5" Side Port This Hemispherical Endcap has a unique drain port welded on to the side of it to easily clear out any material without having to have multiple extra clamps, gaskets, and bends. This end cap is made out of 304 stainless steel and has a 1.5" Tri-Clamp/ Tri Clover side port with a high polish interior. Specifications Material 304 Stainless Steel Sizes Available 6" 8" 10" 12"

$139.81 - $272.63

BVV™ Refrigerant Recovery Scale -150KG

BVV™ Refrigerant Recovery Scale - 150KG This is the BVV™ Brand 150Kg (330LB) Refrigerant Recovery Scale which provides the user with the information of how much Refrigerant/Solvent is being filled into the tank or how much has been removed from the tank being weighed. What's in the box: Refrigerant Scale x 1 AAA Alkaline Battery x 5 User Manual x 1 Nylon Carrying Case x 1 Specifications Maximum Capacity 150kg (330lb) Resolution 5g(0.2oz) Accuracy +/- 0.05% rdg + 0.1oz(25g) Battery 5 AAA batteries Battery Life 40 hours Operating Temp. 14°F - 104°F Storage Temp. 5°F - 122°F Temperature Fluctuation Range 9°F/h Relative Humidity 50-85% Dimensions 10.7 x 10.7 x 2.9in (271 x 271 x 74mm)

$258.65

Universal Vacuum Chamber Gasket

Universal Vacuum Chamber Gasket Our patented gasket #9475627 This vacuum chamber gasket is made out of durable and heat resistant silicone. It features a large flange on a single side so the user can adapt one of our lids to varyingly sized vessels. Gasket Specifications: 10.75" - Can Fit lids 10.75" in Diameter and up to 3/4" in thickness 12.75" - Can Fit lids 12.75" in Diameter and up to 1" in thickness

$55.92 - $62.91

Neocision Rotary Evaporator Gaskets

Neocision Rotary Evaporator Gaskets Part General Use Main Seal Evaporating Flask to Main body 60/80 Gasket Main Condenser to Auxiliary Condenser (10-50L) 50/70 Gasket Bump Trap to main body (10-50L) 40/60 Gasket Bump Trap to Auxiliary Condenser (10-50L) 30/50 Gasket Collection Flask to Valves (10-50L) 25/49 Gasket Collection Flask to Valves (5L Only)

$27.96 - $174.76

BVV™ Drink Koozie

BVV™ Koozie

$6.99

Refinement Filter with 20L Collection Base

The BVV™ Refinement Filter is a stainless steel filtration system that provides large scale, high flow filtering, with greatly improved functionality compared to a traditional Buchner filter. Utilizing a collection base for vacuum assistance and storage of material, the Refinement Filter allows for benchtop filtration with a longer lifespan and ease of use. Key Features: Stainless steel design for greater thermal conductivity and improved lifespan Easy to clean and disassemble with Tri-Clamp stainless steel parts Small tabletop footprint with wide mouth design Secondary collection vessel for vacuum and storage of material Liquid dip tube for direct injection into rotary evaporator after filling Includes 5' of 3/8" Tygon and 1/4" Gum Rubber Vacuum Tubing Key Specifications: 216 cubic inches of liquid volume (3.5 Liters) 20 Liter Collection Base Dedicated Vacuum Valve Dedicated Dip Tube Valve Drop-In Filter Plate with 100 Mesh Screen Silicone gaskets with high alcohol resistance 1/4" and (2)3/8" Stainless steel barb connections Polycarbonate sights for easy viewing Operation Instructions: Before beginning filtration, place refinement filter in freezer for best thermal conductivity Place Refinement Filter on bench top and secure mesh or filter paper (paper sold separately) with drop in ring. Place collection base on floor and connect preferred tubing from bottom of refinement filter to the middle port on collection base Attach vacuum system to dedicated vacuum valve Begin to pour solution into filter Close dedicated dip tube valve and start vacuum Once solution has been completely filtered, stop vacuum system and disconnect from dedicated vacuum valve Connect dedicated dip tube valve to injection valve on rotovap Begin rotovap procedure Open dedicated dip tube valve and begin injecting filtered solution into rotovap

$1,677.72 - $2,202.01

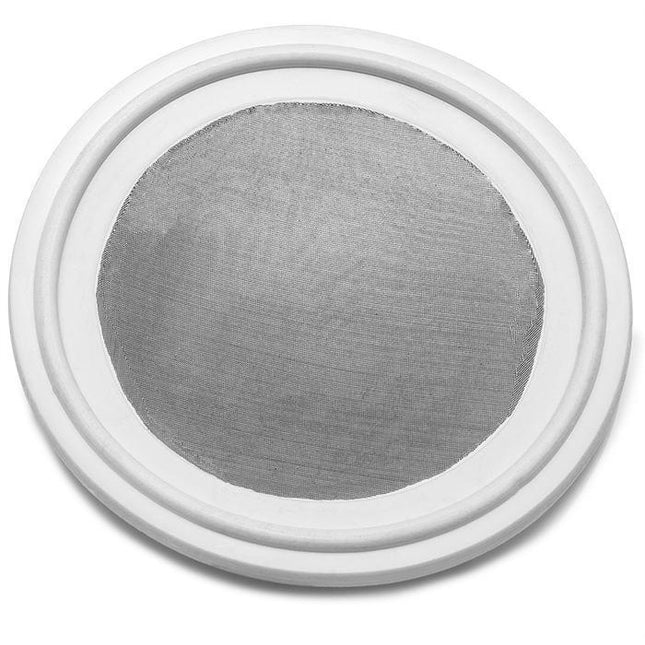

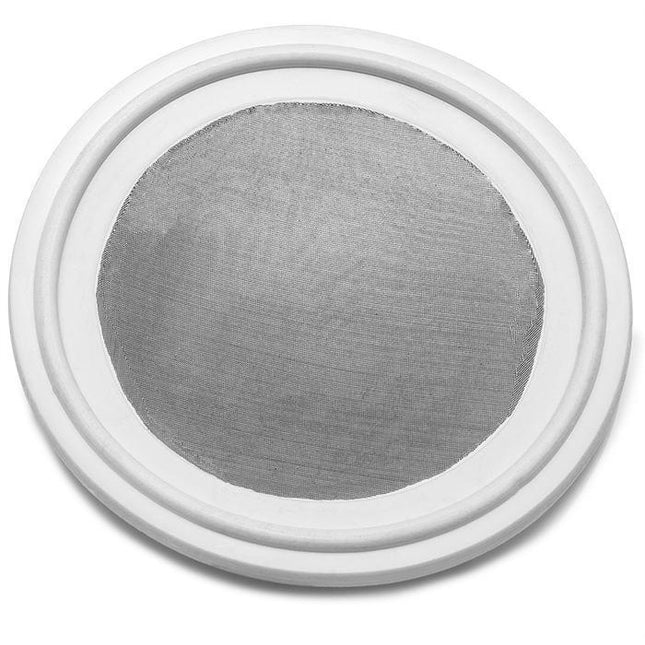

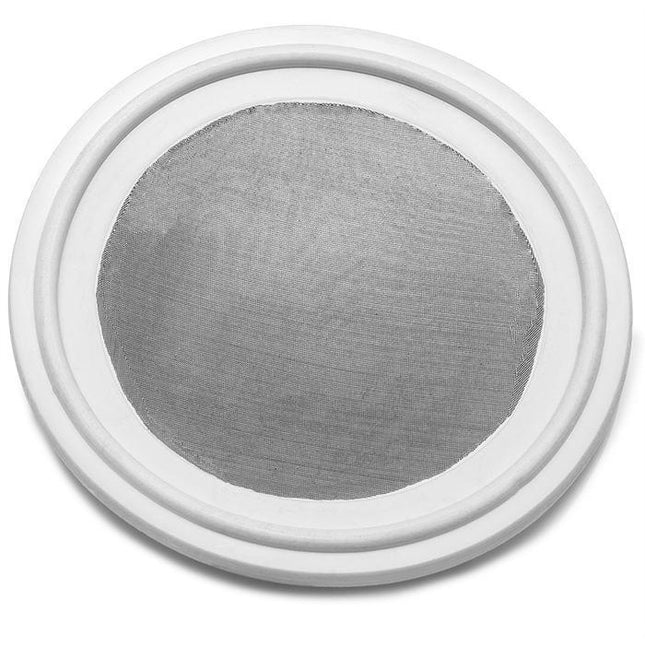

Silicone 100 Mesh (150 Micron)

Silicone 100 Mesh (150 Micron) These white silicone mesh gaskets are meant for filtration with alcohol systems because of their great resistance to many of the common forms of alcohol. They are NOT recommended for use with Butane or Propane. Mesh / Micron Filter Chart For Further Chemical Resistance specifications please refer to this chart: Chemical Compatibility Database Specifications Maximum Pressure Not Rated Temperature Range -40 to 450F Color White - CLEAR Material Silicone Screen Material 316 Stainless Steel Standards Met 3A and FDA Chemical Resistance Alcohols: Amyl D - Poor Benzyl N / A Butyl B - Good Diacetone D- Poor Ethyl B - Good Hexyl B - Good Isobutyl A - Excellent Isopropyl A - Excellent Methyl A - Excellent Octyl B - Good Propyl A - Excellent Butane D - Poor Propane D - Poor

$27.96 - $174.76

2 Pack Magnetic PTFE Stirrer - L Style - 28mm

2 Pack Magnetic PTFE Stir Bar - L Style - 28mm Shop this 2 Pack Magnetic PTFE Stirring Bar to stir liquids in a closed container on BVV™! Used in short-path distillation. Find product details below. Specifications: L Style 28mm Length Material: High-temperature PTFE Quantity: 2

$9.79

Best Value Vacs 2 Gallon Aluminum Side Mount Vacuum Chamber

2 Gallon Side Mount Vacuum Chamber (Comes with 2 Year Limited warranty This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 6.5" Tall x 10" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$153.79

BVV Lab Stand

Metal-Base Lab Stand This lab stand has a metal base that measures 5.5" x 7-3/4" x 7/8" and the rod comes in two heights: 24 and 36 inches. It also has 2 pre-threaded holes that are in the center and near the edge of the base to allow multiple positions when attaching the rod.

$55.92 - $69.91

BVV™ 8" Vacuum Chamber Gasket

BVV™ 8" Vacuum Chamber Gasket Our patented gasket #9475627 This Gasket fits the following Vacuum Chamber Lids: Best Value Vacs 1.75 Quart Pyrex Vacuum and Degassing Chamber Best Value Vacs 2 Quart Flat Stainless Steel Vacuum and Degassing Chamber Best Value Vacs 1 Gallon Tall Stainless Steel Vacuum and Degassing Chamber Best Value Vacs 1.5 Gallon Tall Stainless Steel Vacuum and Degassing Chamber Glass Vac 1 Gallon Tall Stainless Steel Vacuum Chamber Glass Vac 1.5 Gallon Tall Stainless Steel Vacuum Chamber 1 Gallon Resin Trap Vacuum Chamber 1.5 Gallon Resin Trap Vacuum Chamber

$23.77

2LB Apollo Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well ventilated areas. Check with your local fire marshal for guidance when operating indoors 2lb Closed Loop Reclamation Extraction System (System comes with 1 yr. limited warranty) The 2lb closed loop hydrocarbon extraction system performs botanical extraction within a sealed, vacuumed system. Utilizing a top-fill input, solvent washes thru the material column, collecting oils as it passes over the material. Oil bearing solvent is collected in the collection base under the material column. Once collected, solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. This unit can be upgraded into an Active recovery unit by purchasing the upgrade kit. TRS21 Active Closed Loop Recovery Kit Extractor Configurations: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and standard LP tank. This model has minimal features to keep cost low, while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Solvent is input into the material column with a showerhead endcap, ensuring the full material column is saturated with solvent. The Professional comes with a sleeved spool, allowing users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is our fully upgraded Apollo model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. It features a larger bore on valves and hoses, all American made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, sleeved dewaxing column, jacketed collection base, and a stainless steel LP tank. The Elite series boasts increased efficiency on both solvent input and recovery by bumping up all valves and lines to 3/8” JIC. The stainless steel LP tank is able to be opened and cleaned, making solvent contamination a non-issue. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base BVV 316SS Full Bore Valves Showerhead Dewaxer Ball Valve Splatter Platter Base SSP Valves Showerhead Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter SSLP 3/8" Valves & Hoses Unit Includes: Collection Base 10"x10" Welded Bottom Base Assembled 10" extractor lid 3"x36" Material column with reducer & top cap #30 LP tank 60" High Pressure PTFE Braided SS Hose 10" clamp, (2)3" clamps and a 1.5" clamp with gaskets Instruction Manual Specifications: 3"x 36" 304 Stainless Steel Material Tube 2lb (900g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple port connections for _" 316 Stainless JIC 37 Degree 304 Stainless Steel Base Container 10" diameter by 10" tall Tri-Clamps at all interfaces make for a high pressure, easy clean unit. Viton Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 55" x 10" Diameter overall size Weight: 38 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Base unit Maximum Capacity: 785 cubic inches, (12.8704 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$1,230.33 - $4,054.49

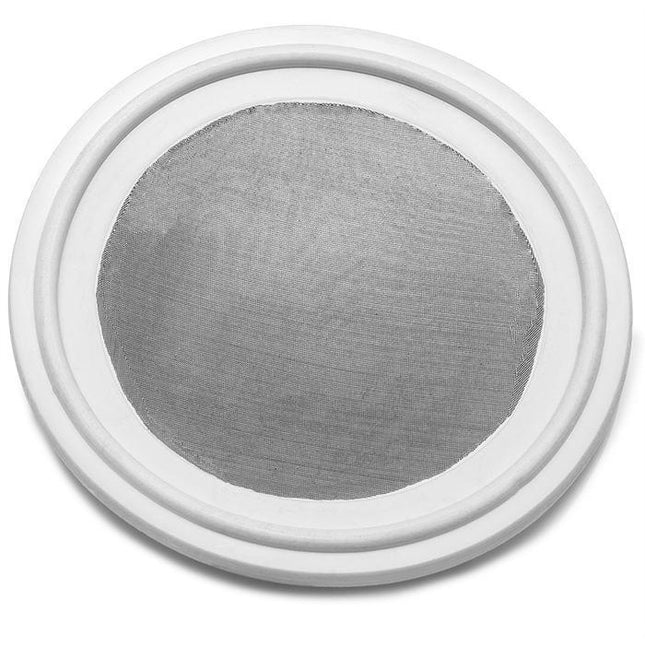

Silicone 550 Mesh (25 Micron)

Silicone 550 Mesh (25 Micron) These white silicone mesh gaskets are meant for filtration with alcohol systems because of their great resistance to many of the common forms of alcohol. They are NOT recommended for use with Butane or Propane. Mesh / Micron Filter Chart For Further Chemical Resistance specifications please refer to this chart: Chemical Compatibility Database Specifications Maximum Pressure Not Rated Temperature Range -40 to 450F Color White Material Silicone Screen Material 316 Stainless Steel Standards Met 3A and FDA Chemical Resistance Alcohols: Amyl D - Poor Benzyl N / A Butyl B - Good Diacetone D- Poor Ethyl B - Good Hexyl B - Good Isobutyl A - Excellent Isopropyl A - Excellent Methyl A - Excellent Octyl B - Good Propyl A - Excellent Butane D - Poor Propane D - Poor

$32.16 - $209.72

Silicone 300 Mesh (50 Micron)

Silicone 300 Mesh (50 Micron) These white silicone mesh gaskets are meant for filtration with alcohol systems because of their great resistance to many of the common forms of alcohol. They are NOT recommended for use with Butane or Propane. Mesh / Micron Filter Chart For Further Chemical Resistance specifications please refer to this chart: Chemical Compatibility Database Specifications Maximum Pressure Not Rated Temperature Range -40 to 450F Color White Material Silicone Screen Material 316 Stainless Steel Standards Met 3A and FDA Chemical Resistance Alcohols: Amyl D - Poor Benzyl N / A Butyl B - Good Diacetone D- Poor Ethyl B - Good Hexyl B - Good Isobutyl A - Excellent Isopropyl A - Excellent Methyl A - Excellent Octyl B - Good Propyl A - Excellent Butane D - Poor Propane D - Poor

$26.56 - $181.75

Vacuum Trap

Vacuum/Cold Trap - 24/40 Male Joint w/ GL-14 8mm hose barb port. Place the vacuum trap in dry ice or another source of extreme cold for use as a cold trap. Trap is openable to remove trapped condensate. For increased efficieny, tandem multiple traps together inline. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$41.94

KF Vacuum Flange Reducer Adapter

This 304 Stainless Steel KF Vacuum Flange Reducer / Adapter is designed to convert K16 to KF25 or KF25 to K40 and vise versa.

$53.13

1/2" x 1/8" Wall - Heavy Duty Silicone Tubing For Flow

Silicone Tubing (**Note: This tubing is only for flow and is NOT vacuum rated) The most outstanding properties of silicone tubing are its flexibility and resistance to temperature extremes. These, plus its good electrical properties and ability to self-extinguish, make silicone tubing an excellent choice for appliances and computers Peroxide-cured silicone contains no sulfur or other acid-producing chemicals, thereby eliminating the possibility of staining, corroding, or deteriorating materials it contacts. It is extremely resistant to ozone and U.V. over long time periods. Care is recommended in the selection of fittings and clamps for silicone as sharply barbed fittings or unlined metal clamps could tear into the tubing wall and possibly cause a failure. silicone may be low-pressure steam sterilized in-line or autoclaved at up to 250°F in a normal autoclaving cycle. However, if exposed to repeated steam sterilization or long-term high temperature or pressure, silicone will eventually relax and become gummy. It should then be replaced. Please call or email BVV to request different sizes and thickness (1/16" to 3/4"ID) - Colors for industrial applications are available through minimum order. Key Features: Made from FDA-sanctioned ingredients Able to resist extreme temperature variation: -100°F to 500°F Translucent natural color for visual contact with the flow resilient, stretchable, and resistance to compression set Odorless, tasteless and inert Good electrical and weatherability properties - resists U.V., ozone, gases, and moisture Certified by the National Sanitation Foundation (NSF-51) for food equipment materials MADE IN THE U.S.A. Specifications/Physical Properties Hardness, Shor A +/-5 50 Tensile Strength, PSI 1100 Elongation at Break % 375 Brittle Temperature °F -100 Max Operating Temperature °F 500 Max Operating Temperature for NSF °F 350 Comp. Set 22 Hrs. at 177°F, % 35 Tear Resistance (PPI minimum) 100 Tubing Specifications Chart ID (IN.) OD (IN.) STANDARD LENGTH WORKING PSI @ 70°F BURST PSI @ 70°F LBS PER 100FT 1/16 1/8 100 10 30 0.50 1/16 3/16 100 20 60 1.34 3/32 5/32 100 10 30 0.66 3/32 7/32 100 15 45 1.58 1/8 3/16 100 10 30 0.88 1/8 1/4 100 20 60 2.00 1/8 5/16 100 25 75 3.32 1/8 3/8 100 28 84 4.92 5/32 9/32 100 20 60 2.14 5/32 11/32 100 20 60 3.64 3/16 1/4 100 5 15 1.22 3/16 5/16 100 20 60 2.64 3/16 3/8 100 20 60 4.12 3/16 7/16 100 15 45 6.14 1/4 5/16 100 10 30 1.50 1/4 3/8 100 5 15 3.34 1/4 7/16 100 20 60 5.12 1/4 1/2 100 15 45 7.50 5/16 7/16 100 10 30 3.66 5/16 1/2 100 10 30 6.30 3/8 1/2 100 10 30 4.32 3/8 9/16 100 10 30 7.15 3/8 5/8 100 10 30 10.16 3/8 3/4 100 15 45 16.72 7/16 5/8 100 10 30 7.70 1/2 5/8 100 5 15 5.84 1/2 11/16 100 5 15 9.50 1/2 3/4 100 10 30 13.12 1/2 7/8 100 10 30 15.00 5/8 3/4 100 5 15 6.86 5/8 13/16 100 5 15 11.34 5/8 7/8 100 5 15 13.38 5/8 1 100 10 30 22.86 3/4 1 50 5 15 17.64 3/4 1-1/8 50 10 30 26.56

$62.91 - $461.37

Male Hollow Stopper

Male Hollow Stopper Male Hollow Stoppers are used for capping off or plugging a female join to prevent contamination or close off a port on a glassware system. These glass stoppers are hollow on the inside and require vacuum grease to create a seal when having 2 ground surfaces touching in a vacuum application. Joint Sizes Available: 14/20 Ground Joint 24/40 Ground Joint *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$11.18 - $15.38

16.75" Diameter LID

BVV™ 16.75" Diameter LID Our patented gasket #9475627 Disclaimer: LID ONLY - does not include hardware unless selected through drop-downs or ordered separately. Hardware - includes Valve Manifold, Gauge, and Gasket. (Does not include 50-micron air filter or vacuum hose. This is a Replacement Lid for the following Vacuum Chambers: Best Value Vacs 7 Gallon Aluminum Vacuum and Degassing Chamber Best Value Vacs 15 Gallon Aluminum Vacuum and Degassing Chamber

$142.61 - $286.61

Postal Scale 110lb Max, Ounces, Grams, Lbs, Kg

The SF-890 is a postal scale that comes with a detached digital display for easy reading of large items. Batteries included 2xAA, as well as a wall plug to power the unit. This scale works best for items over 1lb. Low weight items (ie. 1-10grams is difficult to accurately detect)

$55.92

316L Stainless Dutch Weave Sintered Filter Disk 1 micron and up - Silicone

316L Dutch Weave Sintered Filter Disk **Note: This product comes with Filter Disk and Gasket ONLY. Filter Plate and Spool are NOT included. Recommended Filter plate click here. These 316L stainless steel dutch weave filter disks come with a custom made gasket to allow the user to insert filtration between clamping ends of any Tri-Clamp interface. The interface fits so snug, its inherent design prevents any blow-by. Sintered Filter Disk Technical Data Sheet Pressure Ratings w/o any backing support; strait pipe connection: 1.5" 200PSI 2" 200PSI 3" 200PSI 4" 200PSI 6" 50PSI 8" 10PSI *Supporting Back Plate Required P# FP800-V3 10" 10PSI *Supporting Back Plate Required P# FP1000-V3 12" 10PSI *Supporting Back Plate Required P# FP1200-V3

$41.94 - $810.90

1/4" x 1/8" Wall - Heavy Duty Silicone Tubing For Flow

SILCON® Silicone Tubing (**Note: This tubing is only for flow and is NOT vacuum rated) The most outstanding properties of SILCON tubing are its flexibility and resistance to temperature extremes. These, plus its good electrical properties and ability to self-extinguish, make SILCON tubing an excellent choice for appliances and computers Peroxide-cured SILCON contains no sulfur or other acid-producing chemicals, thereby eliminating the possibility of staining, corroding, or deteriorating materials it contacts. It is extremely resistant to ozone and U.V. over long time periods. Care is recommended in the selection of fittings and clamps for SILCON as sharply barbed fittings or unlined metal clamps could tear into the tubing wall and possibly cause a failure. SILCON may be low-pressure steam sterilized in-line or autoclaved at up to 250°F in a normal autoclaving cycle. However, if exposed to repeated steam sterilization or long-term high temperature or pressure, silicone will eventually relax and become gummy. It should then be replaced. Please call or email Best Value Vacs to request different sizes and thickness (1/16" to 3/4"ID) - Colors for industrial applications are available through minimum order. Key Features: Made from FDA-sanctioned ingredients Able to resist extreme temperature variation: -100°F to 500°F Translucent natural color for visual contact with the flow resilient, stretchable, and resistance to compression set Odorless, tasteless and inert Good electrical and weatherability properties - resists U.V., ozone, gases, and moisture Certified by the National Sanitation Foundation (NSF-51) for food equipment materials MADE IN THE U.S.A. Specifications/Physical Properties Hardness, Shor A +/-5 50 Tensile Strength, PSI 1100 Elongation at Break % 375 Brittle Temperature °F -100 Max Operating Temperature °F 500 Max Operating Temperature for NSF °F 350 Comp. Set 22 Hrs. at 177°F, % 35 Tear Resistance (PPI minimum) 100 Tubing Specifications Chart ID (IN.) OD (IN.) STANDARD LENGTH WORKING PSI @ 70°F BURST PSI @ 70°F LBS PER 100FT 1/16 1/8 100 10 30 0.50 1/16 3/16 100 20 60 1.34 3/32 5/32 100 10 30 0.66 3/32 7/32 100 15 45 1.58 1/8 3/16 100 10 30 0.88 1/8 1/4 100 20 60 2.00 1/8 5/16 100 25 75 3.32 1/8 3/8 100 28 84 4.92 5/32 9/32 100 20 60 2.14 5/32 11/32 100 20 60 3.64 3/16 1/4 100 5 15 1.22 3/16 5/16 100 20 60 2.64 3/16 3/8 100 20 60 4.12 3/16 7/16 100 15 45 6.14 1/4 5/16 100 10 30 1.50 1/4 3/8 100 5 15 3.34 1/4 7/16 100 20 60 5.12 1/4 1/2 100 15 45 7.50 5/16 7/16 100 10 30 3.66 5/16 1/2 100 10 30 6.30 3/8 1/2 100 10 30 4.32 3/8 9/16 100 10 30 7.15 3/8 5/8 100 10 30 10.16 3/8 3/4 100 15 45 16.72 7/16 5/8 100 10 30 7.70 1/2 5/8 100 5 15 5.84 1/2 11/16 100 5 15 9.50 1/2 3/4 100 10 30 13.12 1/2 7/8 100 10 30 15.00 5/8 3/4 100 5 15 6.86 5/8 13/16 100 5 15 11.34 5/8 7/8 100 5 15 13.38 5/8 1 100 10 30 22.86 3/4 1 50 5 15 17.64 3/4 1-1/8 50 10 30 26.56

$53.13 - $160.78

Heating Jacket for Molecular Sieve Filter Drier

Heating Jacket for Best Value Vacs Molecular Sieve Filter Drier This Heating Jacket will fit the Best Value Vacs Molecular Sieve Filter Drier. It has hook and loop velcro to attach around 3" Diameter columns. The width of the heating jacket measures 240mm (9.45") and the length measures 317mm (12.48") Feature: UL Listed Fahrenheit Digital Controller. Min Temp: Ambient + 5 Max Set Temp: 160°F Ultimate Max Temp: 248°F Voltage: 110VAC Only Power Consumption: Digital Control: Increments of 1 Degree. Accuracy: +/- 0.2 Degrees Units: Degrees Fahrenheit Instructions: Fully included Relay Lifespan: Approx. 10 million cycles User can reprogram: Yes

$125.83

MCT Oil Coconut Based USP Food Grade

MCT Oil Coconut Based USP Food Grade 60/40 - 60%C8 / 40%C10 Soy Free, Non-GMO, Gluten Free, Dye Free, Dairy Free/Vegan Medium Chain Triglycerides (MCT’s) are fats that are naturally found in coconut and palm kernel oil. MCT’s are more easily and rapidly digested than other types of fats, as they require lower amounts of enzymes and bile acids for intestinal absorption. MCT’s are metabolized very quickly in the liver and are reported to encourage energy expenditure, and not fat storage. Numerous studies suggest that substituting MCT Oil for other fats in a healthy diet may therefore help to support healthy weight and body composition.* Suggested Usage As a dietary supplement, take 1 tablespoon (15 mL) 1 to 3 times daily. MCT Oil can also be used as a substitute for conventional oils in salad dressings, sauces or cooking as a source of beneficial fatty acids. Not recommended for use in frying due to low boiling point Caution: For adults only. MCT Oil may cause GI upset. To reduce these effects, take with food. Consult physician if pregnant/nursing, taking medication, or have a medical condition. Keep out of reach of children. Storage Guidance: Store in a cool, dry and dark environment in a tightly sealed original container. After opening, product can be refrigerated or stored at cool room temperature. Please note*** These statements have not been evaluated by the Food and Drug Administration. This product is not intended to diagnose, treat, cure or prevent any disease. BVV MCT Oil - COA BVV MCT Oil - SDS

$30.76 - $2,936.01

Best Value Vacs 3 Gallon Wide Stainless Steel Side Mount Vacuum Chamber

Best Value Vacs 3 Gallon Wide Stainless Steel Side Mount Vacuum and Degassing Chamber (Comes with 2 Year Limited Warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User-friendly vacuum connections that fit most vacuums in the industry 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 8" Tall x 10.5" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$208.32

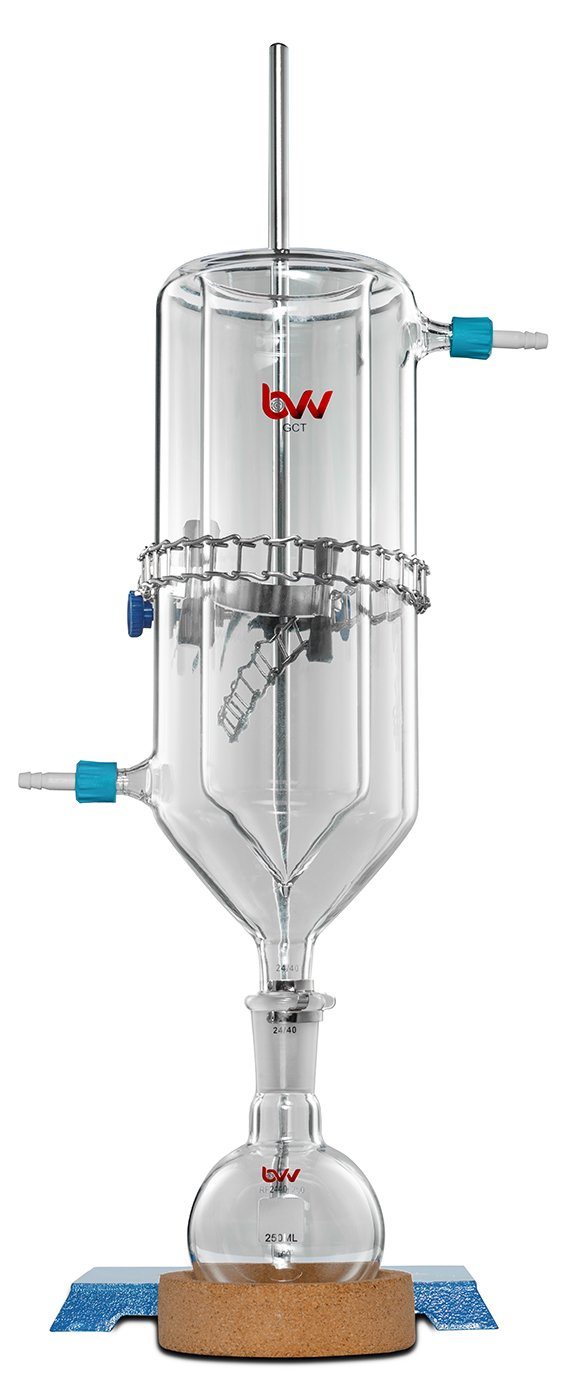

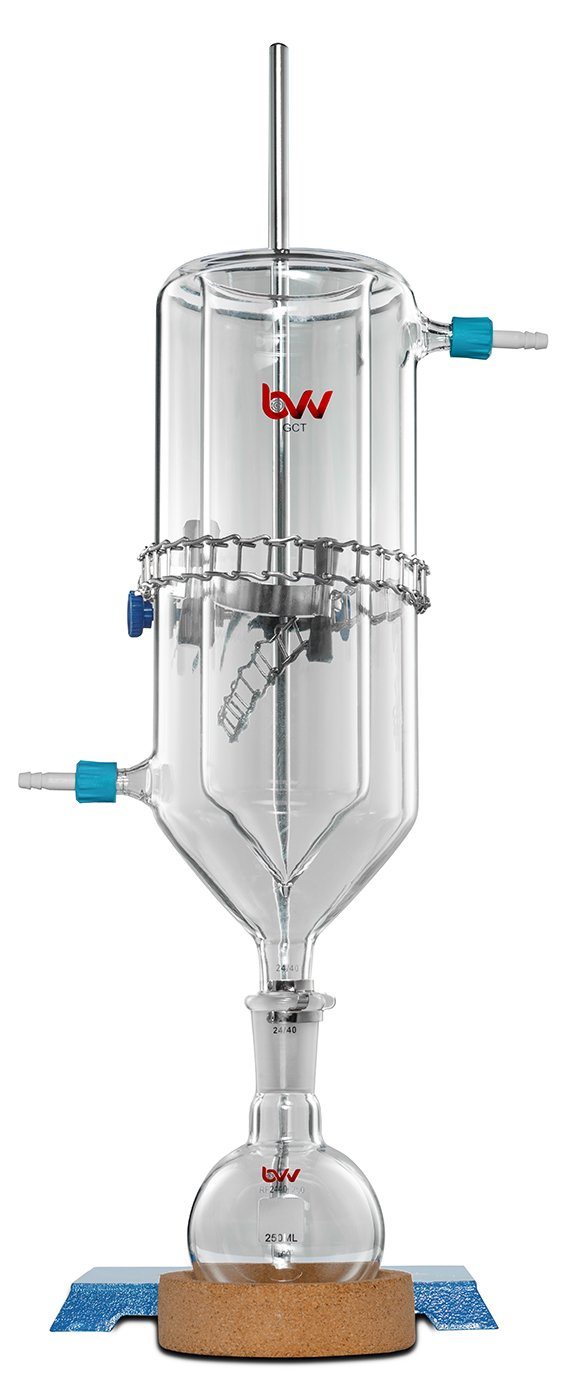

Dewar Style Glass Cold Trap Kit

Dewar Style Glass Cold Trap The Dewar Style Glass Cold Trap with GL-14 Barb Fittings allows the user to load dry ice into the inner portion of the cold trap from the top to allow maximum condensation temperatures. This protects your vacuum pump and captures any vapors that were lost during evaporation or distillation. Made in the USA. Dewar Style Glass Cold Traps includes the following: Metal Keck Clip Boss Head Lab Stand Chain Clamp 250ml Round Bottom Flask 24/40 Joint 250-500ml Cork Stand Specifications: USA Made 24/40 Male Ground Joint GL-14 8mm Barb Connections OD = 3.8" ID = 2.75" Height = 14.75" *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$489.34

2 Pack Magnetic PTFE Stirring Bar - B Style - 40mm

2 Pack Magnetic PTFE Stirring Bar - B Style - 40mm 2 Pack Magnetic PTFE Stirring Bar Specifications: B Style 40mm Length Material: High temperature PTFE Quantity: 2

$11.18

8" x (3) 1.5" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid

8" x (3) 1.5" Tri-Clamp Tri Clover x (4) 1/4" FNPT Hemispherical Lid Our Tri-Clamp Hemisperical Lid delivers superior rating performance and is commonly found in systems operating over 100 PSI. This End Cap comes with Four 1/4"-18 FNPT Threaded connection and Three 1.5" Tri-Clamp ferrule welded to the end cap with a 3" Tube Extension Below the Lid. The tube extension is designed to keep extracts from dripping on the inside of the lid, to minimize cleanup and maximize yield. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid and the 1.5" Tri-Clamp Connection. These 7 connections are welded on a 8" Hemispherical Tri-Clamp End Cap. Specifications: Material: 304 Stainless Steel Connection Types: 1.5" Tri-Clamp - 3" Tube Extension Below Lid on Center Tri-Clamp Port 8" Tri-Clamp 1/4" - 18 FNPT Standard: 3A BVV™ 8" x (3) 1.5" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid - Drawing BVV™ 8" x (3) 1.5" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid - End Cap Chart

$230.69

1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen - GLASS LID

1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen - W/GLASS LID This is a complete Cold Trap and will come assembled for instant use. This Cold Trap is made of 304SS MADE IN USA, utilizing Glass lids for Durability, flexibility and Chemical Resistance to alcohol and solvents. This system is Recommended to protect pump from condensable vapors. This Trap comes with an industrial grade, heat cured silicone gasket designed only for our systems. There is nothing of equal quality in the market. The gasket itself is reversible (doubling the life of our system guaranteed) allowing customers to instantly take it off and flip it over. No adhesives are used! The system will maintain a vacuum seal only under vacuum. The vacuum pump will hold the interior 2 quart container for your Dry Ice Slurry in compression with the larger outer lid. The larger outer Lid will be held in compression with 1.5 gallon outer container. The connections on both sides are 1/4" MJIC flares or 1/4" Barbs that will connect to 1/4" HVAC or FJIC stainless steel hose. The Center Slurry Container has a lid for it, This lid simply helps prevent evaporation of your slurry. Temperature rated for -100-160F This Cold Trap comes assembled and includes: (1) 1.5gl high strength Stainless steel outer container (made of solid 304 stainless made in USA) (1) 2q interior Slurry Container (made of solid 304 stainless made in USA) (2) 1/2" thick clear Glass lids (2) Industrial grade silicone gasket (1) 1/4" HVAC Hose 5' Can withstand max working temps of 392F gasket only 60A durometer density (1) Max vacuum -29.5inHg (+/-.5Hg) (2) 1/4" MJIC or Barb Fittings Outside Container Internal Dimensions: 7.25" Diameter X 8.25" Tall To help remove condensable vapors, or when liquid nitrogen traps are not practical, our Cold Trap is the best option for preventing vapors from getting into your vacuum pump and contaminating it. This 1.5 gallon trap uses Glass lids for durability, flexibility, and chemical resistance. The system doesn’t use adhesives, and comes standard with a reversible gasket for enhanced quality that doubles its life. Made in the USA, the BVV™ Cold Trap comes with all parts pre-assembled, so you can get to work straight out of the box. Inside Container Internal Dimension: 4.75 Diameter by 6.5 Tall

$370.50

KF-25 Stainless Steel Ball Valve (Nitrogen Tested)

KF-25 (NW25) Stainless Steel Ball Valve This ball valve has a KF25 (NW25) High Vacuum Flange to adapt to any other KF25 pump or manifold if needed and is made out of 304 stainless steel with a PTFE seat and seals. BVV™ Tri Clamp Ball Valve - Data Sheet

$153.79

BVV 4 Cylinder Butane Recovery Pump - Meets ANSI 12.12.01

Butane Recovery Pump RECOVER MORE WITH LESS BVV is proud to introduce our new and powerful line-up of Butane & Propane Recovery Pumps. Blending compact design with improved Gen III Pistons from RKMAC, this collection of pumps can help you recover 1lb. Butane / 0:51 Seconds! This pump Assembled in the USA and all the critical parts are domestically made. Finding parts won't be an issue with this pump. The piston seals are rated to 450F and the average operating temperature of the pump is 175F leading to a long service life. Built to meet ANSI/ISA 12.12.01 for Use in Hazardous locations Class I & II, Division 2 and Class III, Divisions 1 & 2 environments. The computer controlled brushless DC motor operates at 3000 RMP nearly twice as fast as any other pump in its class. BVV Butane & Propane Recovery Pump Features: Process up to hundreds of pounds of vapor recovery before rebuild Equipped with oil-less reciprocating compressors for a clean product Designed and Assembled in the U.S.A. with domestic and global parts Affordable and highly cost efficient Available in 2-Cylinder, 4-Cylinder, CMEP Retrofit Comes with a 1-year Manufacturer’s Warranty covering Hemp usage Rated universal voltage 100-240V AC 50/60 Hz 1Ph Built with high efficiency Brushless DC Motor used for variable speed control Equipped with Viton O-Ring Seals for Butane/Propane gas and oil compatibility Piston Seal rebuild kits are USA made and available Part# BVV-3. Certified by ITS/ETL to ANSI/ISA 12.12.01 Noise level: 93.0 dB @ 1m Technical Data Sheet Product Brochure BVV™ 2 & 4 Cylinder Rebuild Instruction Manual Shop all recovery pumps here. *Butane recovery results were achieved on a collection base pressure greater than 30psi and using a recovery cylinder with a pressure <10psi. A dry ice coil was used in between the output port of the pump and the recovery cylinder to condense vapor.

$3,005.92

You have seen 288 out of 712 products