Top Products

20LB High Purity USA N-Butane R600 - 99.5% Guaranteed - Buy 2 Get 1 Free (Add 3 To Cart)

20LB High Purity USA N-Butane R600 for Extraction - Buy 2 Get 1 Free (Add 3 To Cart) This solvent is instrument-grade and helps produce a higher quality extract through the reduction of mystery oils and contaminants. This N-Butane is colorless, odorless, and clean. Butane is commonly used for butane extractions which occurs in a closed-loop extraction system. Given that butane has a boiling point of 30.2F, it can easily be re-condensed without the use of extreme temperatures. This makes butane the solvent of choice for passive recovery. Butane tends to yield a more stable extract, as polar terpenes are left behind. Another benefit to butane for extraction is that Hydrocarbon extraction is often used in large production. Large amounts of material can be extracted at once, and because these solvents have such low boiling points, they can be distilled from the extract quickly, and without using high temperatures can degrade the product. These solvents are used for full plant extracts, and post-processing can yield various consistencies. This makes butane extraction a preferable method. Shop our entire Solvents and Gas Collection on BVV DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Ground ONLY. Quantities bought in 3 or more will ship via freight unboxed BVV™ always recommends distillation of every solvent before use. Tank contains no dip tube. Tank does not include CGA 510 fitting. Must be added through dropdown or bought separately. *Actual liquid weight is 20LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Permitted Sales Include the Following: Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale Sourced right here in the USA, this high-quality butane is guaranteed to be 99.5% pure. This is a solvent that is instrument-grade and helps produce a higher quality extract through the reduction of mystery oils and contaminants. This butane is clean, colorless, odorless, and free of any hydrogen sulfide-based ethyl mercaptan odorants. Because of this, a finer, higher quality extract is consistently available to our customers. The solvent comes in a DOT transpiration approved tank. Certificate of Analysis (COA) N-Butane Safety Data Sheet *Free of any hydrogen Sulphide based Ethyl Mercaptan Odorants. *This product is clean, colorless, and odorless. *Tank contains no dip tube. How To Buy 2 Get 1 Free Simply add 3X of 20LB Tanks to your cart and you will automatically be discounted the third tank. Need one with a CGA fitting two without? Simply add one tank with your desired CGA fitting and add two of the same item selecting "None" for the "CGA fitting" and "Connection Size" options. Want 2 Butane Tanks and 1 Propane Tank? No problem, just add 3 of ANY of our 20LB LPG tanks to your cart and enjoy the third tank free! *Actual N-butane liquid weight is 20LB Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via Ground/Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers.

$340.79 - $362.09

Closed Column Extractor Starter Kit

Complete Closed Column Extractor Kit BVV has bundled our recommended vacuum chamber, vacuum pump, and column extraction system to offer customers the most cost-effective solution possible. The Closed Column Extractor Kit is designed to pair well with the other products included in the extraction kit. The items in the kit cover every process from start to finish on your essential oil extraction (excluding butane) and is easy for beginner operators to use. The first step of the oil extraction process is to use the closed column extractor to extract the essential oils from the plant material into a pyrex dish. The user then transfers the oil with residual solvent into the two-gallon vacuum chamber; the digital heating pad is attached to the bottom of the chamber after setting the temperature. The V4D 4CFM 2 Stage vacuum pump exerts a high vacuum to purge and degass residual solvent or gases trapped inside the oil. (Note: This process may take up to 5 days.) Once the purging process is complete, the oil extraction can be used immediately or transformed into a variety of applications. Professional Kit Adds the following: Compound Gauge Sight Glass Shower Head Best Value Vacs 2 Gallon Vacuum Chamber 90 Day Registered Warranty Best Value’s unique, patent-pending gasket design (Utility Patent #14/533,548) and formidable chamber are designed to last 10,000 uses with proper care and maintenance. The gasket is made reversible for easy peel-off and peel-on functionality, effectively doubling the life of our system. The chamber is equipped with user-friendly vacuum connections that fit most vacuum pumps on the market. Every chamber is tested before shipping to lose no more than 2.5Hg/24hrs. Product Features: Aluminum Vessel Highly durable and reversible silicone gasket Glycerin-filled vacuum gauge 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum-rated HVAC hose to pull a vacuum. 9" Digital Heat Pad 90 Day Registered Warranty This 9” reprogrammable Digital Heat Pad comes with full, detailed instructions. Product Features UL Listed Fahrenheit Digital Controller Min Temp: Ambient + 5Max Temp: 160F Voltage: 110VAC Only Power Consumption: 218-watt Digital Control: Increments of 1 Degree Accuracy: +/- 0.2 Degrees Relay Lifespan: Approx. 10 million cycles BVV™ V4D 4CFM Two Stage Vacuum Pump This is the BVV™ V4D 4CFM Two Stage Vacuum Pump used in botanical extraction. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Feature Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer oil life Lightweight Rubber Feet for noise dampening Reliable, economical, and efficient Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$986.87 - $1,356.06

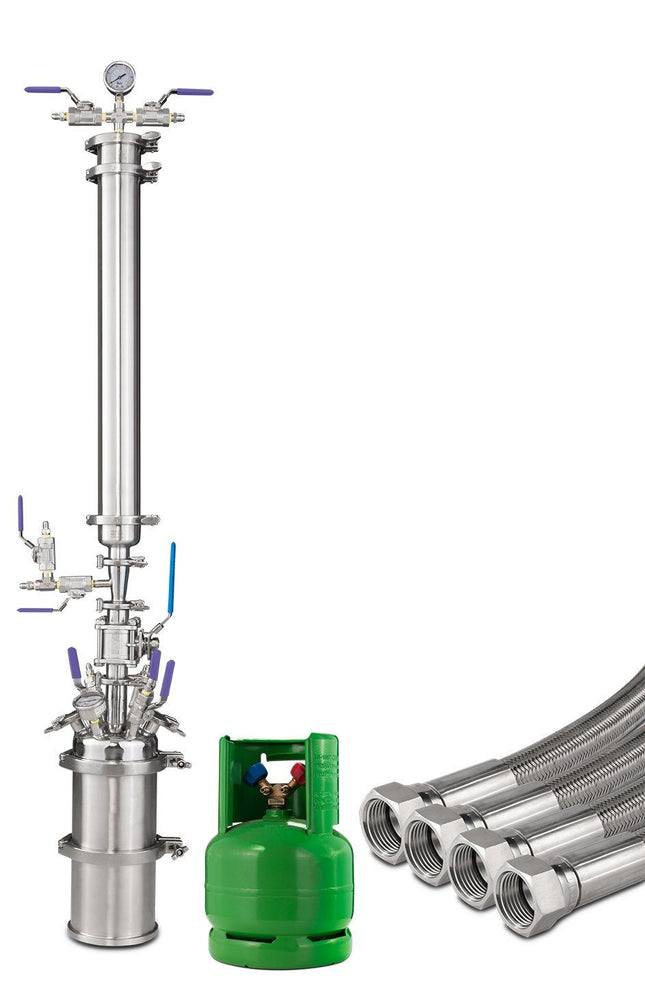

1LB Apollo Top Fill Closed Loop Extractor

1LB Top Fill Closed Loop Extraction System (System comes with 1 yr. limited warranty) The 1lb closed loop hydrocarbon extractor performs incredible botanical extraction within a sealed, vacuumed system. With the help of a top-fill input, solvent washes through the material column, collecting oils as it passes over the material. The oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors. KEY BENEFITS Meets or exceeds all industry listed standards Versatile in running butane, propane, and other blended solvents Perfect for mid to large-scale extraction/production facilities Faster run times and less degradation in the process Extractor Configuration: Explorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Comes with a welded bottom base and standard LP tank. This model has minimal features to keep cost low, while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Solvent is input into the material column with a showerhead endcap, ensuring the full material column is saturated with solvent. The Professional comes with a sleeved spool, allowing users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is the premium version of the Professional. It features all American made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, jacketed collection base, and all high-pressure clamps. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base BVV 316SS Full Bore Valves Showerhead Dewaxer Ball Valve Splatter Platter Base SSP Valves Showerhead Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter Unit Includes: 6"x6" Welded Bottom Base 6"x6" Open Spool Assembled 6" extractor lid 3"x24" Material column with reducer & top cap Mastercool 6LB Solvent Recovery Tank (1) 1/4" 48" FJIC Stainless Steel hose (1) 1/4" 60" FJIC Stainless Steel hose (1) 1/4" FJIC HVAC hose Standard pressure single pin clamp Instruction Manual Specifications: 3"x 24" 304 Stainless Steel Material Column-1lb capacity (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple 37 degree FJIC port connections 304 Stainless Steel Base Container 6" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure/standard pressure, easy clean unit BUNA-N Gaskets are designed for Oil Processing Temp range -40-200F, and have superior solvent resistance Base unit Maximum Capacity: 395 cubic inches, (6.472 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$1,022.37 - $2,804.41

XL Mini Closed Loop Extraction Starter Kit

XL Mini Closed Loop Extraction Starter Kit (System comes with 1 yr. limited warranty) Everything You Need to Get Your Extraction Started Closed-loop extraction is a safe, fast, and efficient solution to removing oils from botanical material. Closed-loop systems allow you to do everything in a closed vessel. BVV™ has bundled our recommended vacuum chamber, vacuum pump, and complete extraction system to offer customers the most cost-effective solution possible. The Mini-XL Closed Loop Extractor Starter Kit is a step up from the closed column extractor starter kit. The Mini-XL Closed Loop Extractor is a tabletop version of a closed-loop extraction system that allows users to run personal or test-sized extractions in a short amount of time. The system also offers users the chance of recovering around 95% of their solvent. Not only does this save a considerable amount of money, but it's also safer for the user performing botanical oil extractions because the entire extraction process is in a closed-loop environment. Mini CLS / Mini XL Upgrades: Explorer: Our standard, most economical setup, perfect for the entry-level extractor on a budget. It comes with a welded bottom base and stainless reclaim container. This model has minimal features to keep costs low while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Coming with a sleeved spool, this model allows users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Explorer Professional Standard Valves Welded Bottom Base Standard Valves Dewaxer Ball Valve Splatter Platter Base Specifications: 1.5"x 12" 304 Stainless Steel Material Tube 90g 304 Stainless Steel Heavy Duty Miniature Ball Valves System Rated to 100PSI Multiple port connections for 1/4" 316 Stainless SAE 37 Degree 304 Stainless Steel Base Container 4" diameter by 8" tall Tri-Clamps at all interfaces make for high pressure, easy-clean unit. Buna-N Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 16" Overall Height x 4" Diameter Weight: 18 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Designed to run two cans of solvent and reclaim it (420ml) 1135ml Max FILL!! Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior Automatically Includes: High-Pressure PTFE Braided Stainless Steel Hose Can Tap Tool 6LB Mastercool Solvent Recovery Tank BVV™ V4D 4CFM Two Stage Vacuum Pump This is the BVV™ V4D 4CFM Two Stage Vacuum Pump used in botanical extraction. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Feature Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer oil life Lightweight Rubber Feet for noise dampening Reliable, economical, and efficient Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend tightly packing coarse ground material. ***Note: Butane (Solvent) is not included with systems unless ordered in the drop-down menu or separately. Any order with butane WILL NOT SHIP EXPEDITED.

$1,407.17 - $1,801.92

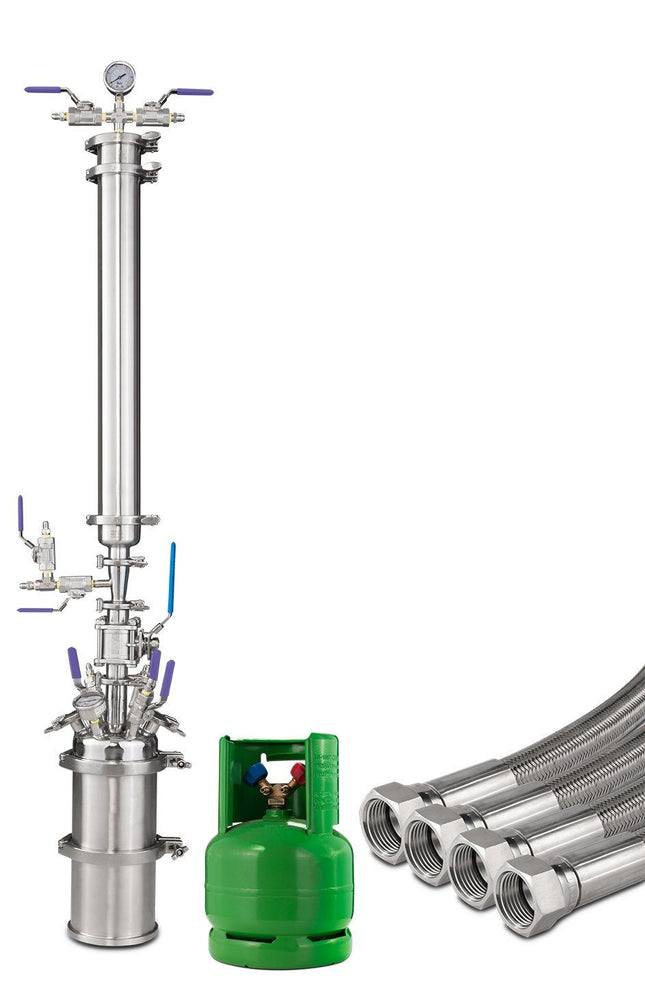

TRS21 Active Closed Loop Recovery Kit

This is an Upgrade Kit which can be added to any one of our passive systems making it into an "Active" Closed Loop System. The Active Recovery Upgrade Kit will increase recovery times by condensing the vapor a lot faster than just a hot/cold differential. This will increase efficiency and productivity, many professionals use this method, as this drives profits. This Kit Includes the Following: TRS21 Refrigerant Recovery Pump Best Value Vacs Large Condensing Coil 1/4" x 24" SS JIC Braided Hose (3) 1/4" x 48" SS JIC Braided Hose 1/4" x 60" SS JIC Braided Hose Molecular Sieve Filter Drier BVV 5' HVAC Hose BVV Vacuum Tee The Upgraded version of the TRS21 comes pre-installed with higher quality internal components that increase recovery speed drastically and also comes with 3/8" JIC and SAE Flares to reduce restrictions in the pump and increase flow/recovery rates. DISCLAIMER: The Upgraded version will still come with standard 1/4" Hoses and Fittings. Upgraded Version Includes: Standard 1/4" Flares Upgraded Inlet/Outlet 3/8" JIC and SAE Flares 2 Piece SS Pistons GEN III Piston Seals Viton O-Rings Stainless Steel Fittings TRS21 Upgrade Kits: TRS21 Upgraded Top Piston Assembly TRS21 Upgraded Stainless Steel 2-Piece Piston and Rod Design for Hydrocarbon Extraction TRS21 Upgraded Compressor head SS ¼” SAE 45D IN and OUT fittings TRS21 Complete Connecting Rod Assembly Upgrade Kit TRS21 2 Piece Piston Tool CPS Rebuild Kits:• TR21X1 Valve Rebuild Kit• TR21X2 Complete Rebuild Kit• TR21X3 Piston Rebuild Kit• TR21X4 Head Rebuild Kit ***Note: Running any solvent that is not authorized by CPS voids all warranty. Running any solvent mixed with any organic plant material will instantly void all warranty. Any Odor coming from the pump or organic plant residuals will also void all warranty.

$2,484.92

1LB MK-V Orthrus Bidirectional Flow Closed Loop Extractor

***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** ***DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors 1LB MK-V Orthrus Bidirectional Flow Closed Loop Extractor (System comes with 1 yr. limited warranty) The 1lb Bi-Directional closed loop increases efficiency by utilizing both a bottom and top solvent input. By using a bottom flood on the first wash, you ensure all material has seen solvent. This method preventing channeling through the material. Finish the run with a top flood input to ensure all residuals have been washed from the material. Oil bearing solvent is collected in the collection base under the material column. Once collected, solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configurations: Explorer: Our standard bi-directional extractor model. Comes with a welded bottom base and standard LP tank. This model provides all the benefits of the Orthrus design without any bells and whistles. The Explorer model is perfect for those looking to get the bi-directional performance but have a budget. Explorer models can be upgraded after purchase. Professional: This model features upgrades to help produce a higher quality extract. Solvent is entered into the system through an injection coil. This coil is chilled with dry ice and alcohol, dropping solvent temperatures to dewax inline. Fats and waxes are not soluble when solvent temperature is subzero, so chilling solvent on input is the simplest way to achieve high clarity extract. The Professional also comes with a removable bottom on the collection base. This makes removal of extract after the run as easy as possible. High pressure clamps give greater solvent compatibility, allowing propane to be used. Elite: The Elite series is our fully upgraded Orthrus model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. The elite series comes with all American instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve and jacketed collection base. Full dewaxing is guaranteed by combining both an injection coil and sleeved column. Both units are packed with dry ice, making both solvent and material sub-zero temperatures. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base Ball Valve BVV 316SS Full Bore Valves Ball Valve HP Clamps Injection Coil w/ Hose Splatter Platter Base SSP Valves Injection Coil Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter Unit Includes: Collection Base 6"x6" Welded Bottom Base 6"x6" Open Spool Assembled 6" bi-flow lid 3"x24" Material column with reducer & top cap 3" filter plate kit 1.5" Solvent input manifold 1.5" Ball Valve Mastercool 6LB Solvent Recovery Tank (2) 1/4" 48" High Pressure PTFE Braided SS Hose 3/8" 48" High Pressure PTFE Braided SS Hose (2)6" clamps, (3)3" clamps and a (3)1.5" clamp with gaskets (2)3" Gaskets w/ filter Instruction Manual Specifications: 3"x 24" 304 Stainless Steel Material Tube 1lb (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple port connections for _" 316 Stainless JIC 37 Degree 304 Stainless Steel Base Container 6" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure, easy clean unit. Viton Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 25" x 7" Diameter overall size Weight: 21 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Base unit Maximum Capacity: 300 cubic inches, (2.553 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$1,703.95 - $6,247.80

1LB MK-V Bi-Directional Closed Loop Extraction Kit

1LB MK-V Bi-Directional Closed Loop Extraction Kit (System comes with 1 yr. limited warranty) We believe it’s better to buy everything you need in one shot, so we’ve created a package that includes a vacuum chamber, vacuum pumps, and complete extraction system. The best part? Buying this kit will save you money compared to purchasing each component individually. ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors The 1lb Bi-Directional closed loop increases efficiency by utilizing both a bottom and top solvent input. By using a bottom flood on the first wash, you ensure all material has seen solvent. This method preventing channeling through the material. Finish the run with a top flood input to ensure all residuals have been washed from the material. Oil bearing solvent is collected in the collection base under the material column. Once collected, solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configurations: Explorer: Our standard bi-directional extractor model. Comes with a welded bottom base and standard LP tank. This model provides all the benefits of the Orthrus design without any bells and whistles. The Explorer model is perfect for those looking to get the bi-directional performance but have a budget. Explorer models can be upgraded after purchase. Professional: This model features upgrades to help produce a higher quality extract. Solvent is entered into the system through an injection coil. This coil is chilled with dry ice and alcohol, dropping solvent temperatures to dewax inline. Fats and waxes are not soluble when solvent temperature is subzero, so chilling solvent on input is the simplest way to achieve high clarity extract. The Professional also comes with a removable bottom on the collection base. This makes removal of extract after the run as easy as possible. High pressure clamps give greater solvent compatibility, allowing propane to be used. Elite: The Elite series is our fully upgraded Orthrus model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. The elite series comes with all American instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve and jacketed collection base. Full dewaxing is guaranteed by combining both an injection coil and sleeved column. Both units are packed with dry ice, making both solvent and material sub-zero temperatures. The material column is fitted with a nitrogen assist port, which helps ensure no solvent gets stuck with the material. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base 0.9CF ECO Oven V7S 7CFM Single Stage Vacuum Pump BVV 316SS Full Bore Valves HP Clamps Injection Coil w/ Hose Splatter Platter Base 0.9CF ECO Oven V7S 7CFM Single Stage Vacuum Pump SSP Valves Injection Coil Dewaxer AVCO Ball Valve HP Clamps Jacketed Base/Platter Nitrogen Assist 0.9CF NEO Oven V7S 7CFM Single Stage Vacuum Pump Unit Includes: Collection Base 6"x6" Welded Bottom Base 6"x6" Open Spool Assembled 6" bi-flow lid 3"x24" Material column with reducer & top cap 3" filter plate kit 1.5" Solvent input manifold 1.5" Ball Valve #30 LP tank (2) 1/4" 48" High Pressure PTFE Braided SS Hose 3/8" 48" High Pressure PTFE Braided SS Hose (2)6" clamps, (3)3" clamps and a (3)1.5" clamp with gaskets Instruction Manual Specifications: 3"x 24" 304 Stainless Steel Material Tube 1lb (450g) 316 Stainless Steel Fully Encapsulated Miniature Ball Valves System Rated to 150PSI Multiple port connections for _" 316 Stainless JIC 37 Degree 304 Stainless Steel Base Container 6" diameter by 12" tall Tri-Clamps at all interfaces make for a high pressure, easy clean unit. Viton Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 25" x 7" Diameter overall size Weight: 21 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Base unit Maximum Capacity: 300 cubic inches, (2.553 Liters) Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$4,778.15 - $9,975.18

2LB MK-V Orthrus Bidirectional Flow Closed Loop Extractor

***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors 2LB MK-V Orthrus Bidirectional Flow Closed Loop Extractor (System comes with 1 yr. limited warranty) The 2lb Bi-Directional closed loop increases efficiency by utilizing both a bottom and top solvent input. By using a bottom flood on the first wash to ensure all material has seen solvent, preventing channeling through the material. Finish the run with a top flood input to ensure all residuals have been washed from the material. Oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configurations: Explorer: Our standard bi-directional extractor model. Comes with a welded bottom base and standard LP tank. This model provides all the benefits of the Orthrus design without any bells and whistles. The Explorer model is perfect for those looking to get the bi-directional performance but have a budget. Explorer models can be upgraded after purchase. Professional: This model features upgrades to help produce a higher quality extract. Solvent is entered into the system through an injection coil. This coil is chilled with dry ice and alcohol, dropping solvent temperatures to dewax inline. Fats and waxes are not soluble when solvent temperature is subzero, so chilling solvent on input is the simplest way to achieve high clarity extract. The Professional also comes with a removable bottom on the collection base. This makes removal of extract after the run as easy as possible. Elite: The Elite series is our fully upgraded Orthrus model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. It features a larger bore on valves and hoses, all American instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, jacketed collection base, and stainless steel LP tank. Full dewaxing is guaranteed by combining both an injection coil and sleeved column. Both units are packed with dry ice, making both solvent and material sub-zero temperatures. The Elite series boasts increased efficiency on both solvent input and recovery by bumping up all valves and lines to 3/8” JIC. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. The stainless steel LP tank is able to be opened and cleaned, making solvent contamination a non-issue.*NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Ball Valve Welded Bottom Base BVV 316SS Full Bore Valves Ball Valve Splatter Platter Base Injection Coil w/ hose SSP Valves Injection Coil Dewaxer AVCO Ball Valve Jacketed Base/Platter 3/8” Valves/Lines SSLP This Unit Includes: Collection Base 10"x10" Welded Bottom Base Assembled 10" Hemispherical bi-flow lid 4"x24" Material column with reducer & top cap 4" filter plate kit 1.5" Solvent input manifold 1.5" Ball Valve #30 LP tank (2) 1/4" 48" High-Pressure PTFE Braided SS Hose 3/8" 48" High-Pressure PTFE Braided SS Hose 10" clamps, (3)4" clamps and a (3)1.5" clamp with gaskets (2)4" Gaskets w/ filter Instruction Manual *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$2,023.44 - $6,531.79

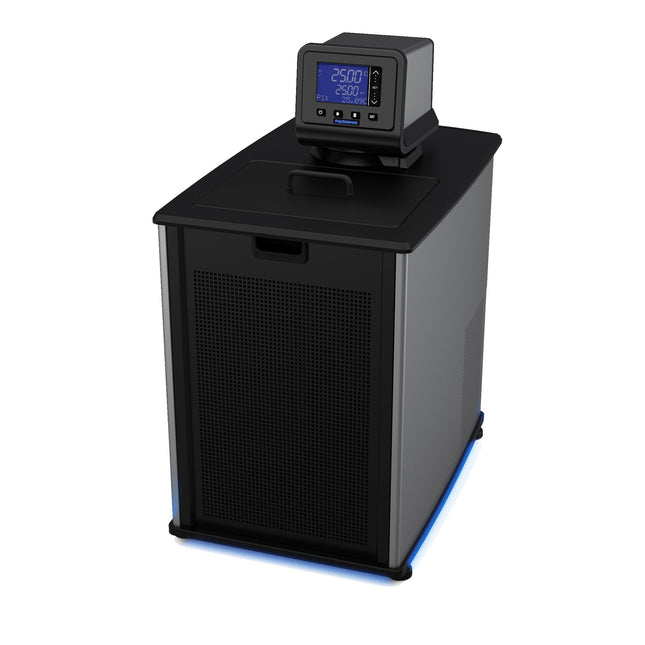

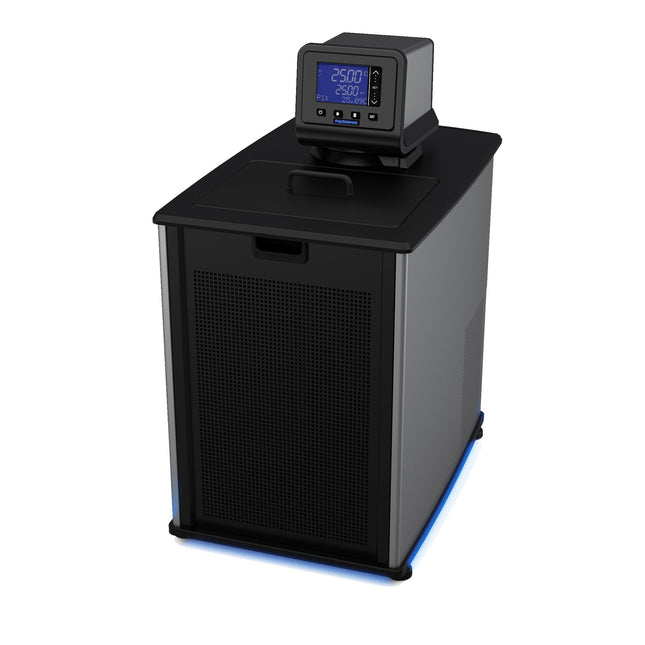

Polyscience 7 Liter MX Refrigerated Circulator (-20°C to 135°C)

Polyscience 7 Liter MX Refrigerated Circulator (-20°C/135°C) Specification Description -20, 7 L Ref. Circulator Controller Type MX Display 3.25" LCD Working Temperature Range °C -20° to 135° Temperature Stability °C ±0.07° Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Pump Type Pressure Flammability Class (DIN 12876-1) I (NFL) Working Temperature Range °F -4° to 275° Working Temperature Range °C -20° to 135° Nominal Cooling Capacity @ +20C (W) 200 Reservoir Capacity (gallons) 1.85 Reservoir Capacity (liters) 7 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 6.18 x 5.59 x 5 in Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Temperature Stability °F ±0.13° Temperature Stability °C ±0.07° Display 3.25" LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure Pump Speed One Process Connections 1/2" O.D. Barbed Tubes Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes Reservoir Drain Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 21.3 x 8.7 x 25.4 in Overall Dimensions (L x W x H) (cm) 54.1 x 22.1 x 64.5 cm Refrigerant R134a Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 84.0 Shipping Weight (kilograms) 38.1 Catalog Page Number 44-45 60 Hz Only Part Number MX07R-20-A11B Maximum Pressure (psi) 2.3 Maximum Pressure (bar) 0.16 Maximum Pressure Flow Rate (gpm) 3.60 Maximum Pressure Flow Rate (l/min) 13.5 Cooling Capacity @ -20°C (W) 30 Cooling Capacity @ 0°C (W) 120 Cooling Capacity @ +20°C (W) 200 Cooling Capacity @ +100°C (W) 200 Included Hardware Fitting Kit for External Applications Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/12 Regulatory Approvals ETL Key Features: Large, Universal icon and English display On-screen prompts Single-point calibration capability Certifications: Regulatory Approvals: ETL Operator's Manual

$5,610.24

2LB MK-V Bi-Directional Closed Loop Extraction Kit

2LB MK-V Bi-Directional Closed Loop Extraction Kit (System comes with 1 yr. limited warranty) We believe it’s better to buy everything you need at one time, so we’ve created a package that includes an orthrus, vacuum pumps, and complete extraction system. The best part? Buying this kit will save you money compared to purchasing each component individually. ***Note: Solvent not included with systems unless ordered separately. Any order with butane WILL NOT SHIP EXPEDITED.*** DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors The 2lb Bi-Directional closed loop increases efficiency by utilizing both a bottom and top solvent input. By using a bottom flood on the first wash to ensure all material has seen solvent, preventing channeling through the material. Finish the run with a top flood input to ensure all residuals have been washed from the material. Oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configurations: Explorer: Our standard bi-directional extractor model. Comes with a welded bottom base and standard LP tank. This model provides all the benefits of the Orthrus design without any bells and whistles. The Explorer model is perfect for those looking to get the bi-directional performance but have a budget. Explorer models can be upgraded after purchase. Professional: This model features upgrades to help produce a higher quality extract. Solvent is entered into the system through an injection coil. This coil is chilled with dry ice and alcohol, dropping solvent temperatures to dewax inline. Fats and waxes are not soluble when solvent temperature is subzero, so chilling solvent on input is the simplest way to achieve high clarity extract. The Professional also comes with a removable bottom on the collection base. This makes removal of extract after the run as easy as possible. Elite: The Elite series is our fully upgraded Orthrus model. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. It features a larger bore on valves and hoses, all American instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, jacketed collection base, and stainless steel LP tank. Full dewaxing is guaranteed by combining both an injection coil and sleeved column. Both units are packed with dry ice, making both solvent and material sub-zero temperatures. The material column is fitted with a nitrogen assist port, which helps ensure no solvent gets stuck with the material. The Elite series boasts increased efficiency on both solvent input and recovery by bumping up all valves and lines to 3/8” JIC. The jacketed collection gives precision during recovery, allowing a heated fluid to be circulated around the base. This method keeps temperature both accurate and consistent. The stainless steel LP tank is able to be opened and cleaned, making solvent contamination a non-issue. *NOTE* This model requires a heater circulator or chiller Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base 1.9 ECO Oven V7S 7CFM Single Stage Vacuum Pump BVV 316SS Full Bore Valves Splatter Platter Base Injection Coil w/ hose 1.9 ECO Oven V7S 7CFM Single Stage Vacuum Pump SSP Valves Injection Coil Dewaxer AVCO Ball Valve Jacketed Base/Platter 3/8” Valves/Lines SSLP Nitrogen Assist 1.9 NEO Oven V7S 7CFM Single Stage Vacuum Pump This Unit Includes: Collection Base 10"x10" Welded Bottom Base Assembled 10" Hemispherical bi-flow lid 4"x24" Material column with reducer & top cap 4" filter plate kit 1.5" Solvent input manifold 1.5" Ball Valve #30 LP tank (2) 1/4" 48" High-Pressure PTFE Braided SS Hose 3/8" 48" High-Pressure PTFE Braided SS Hose 10" clamps, (3)4" clamps and a (3)1.5" clamp with gaskets (2)4" Gaskets w/ filter Instruction Manual *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material.

$6,103.67 - $11,549.20

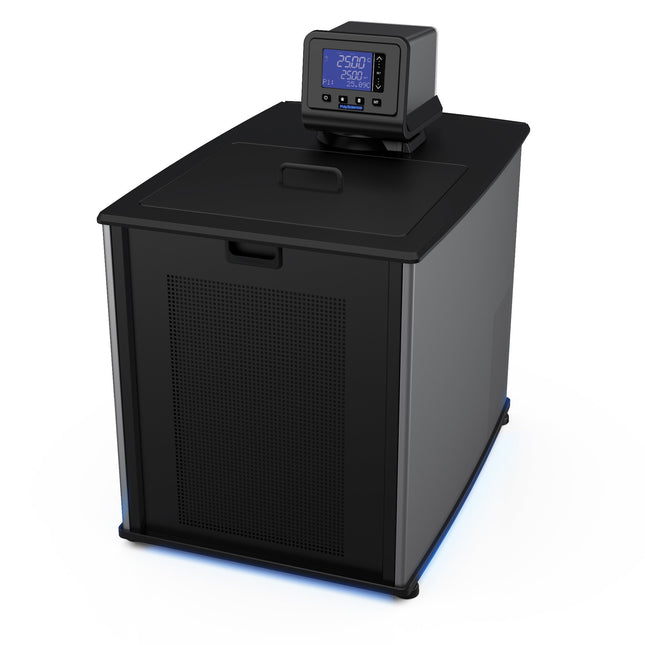

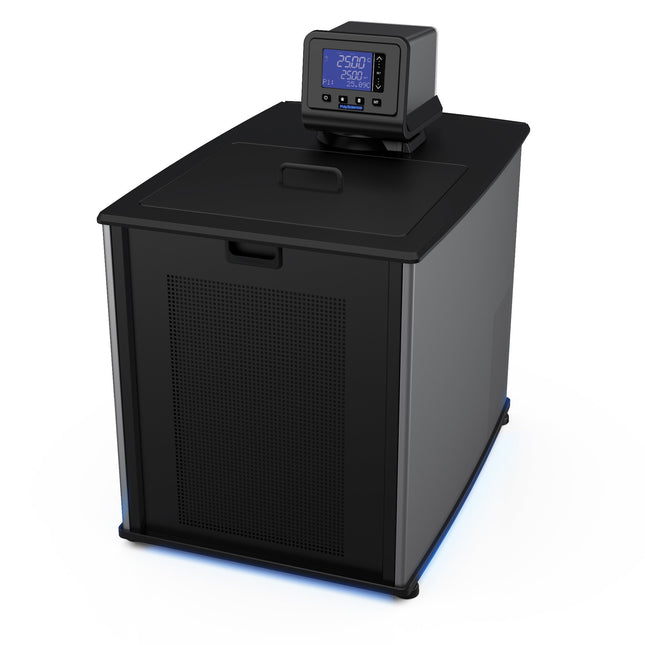

Polyscience 15 Liter Advanced Digital Refrigerated Circulator (-40°C/200°C)

Polyscience 15 Liter Advanced Digital Refrigerated Circulator (-40°C/200°C) Specification Description -40, 15 L Ref. Circulator Controller Type Advanced Digital Display 3.75" Touch-Pad LCD Connectivity Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe Languages Supported 4: French, German, Spanish, English Swivel 180 Rotating Controller Yes Working Temperature Range °C -40° to 200° Temperature Stability °C ±0.01° Fluid Optimization/Specific Heat Tuning Automatic and/or user-adjustable Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 21.2 x 27.6 x 14 cm Pump Type Pressure/Suction External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Working Temperature Range °F -40° to 392° Working Temperature Range °C -40° to 200° Nominal Cooling Capacity @ +20C (W) 1000 Reservoir Capacity (gallons) 3.96 Reservoir Capacity (liters) 15 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 8.35 x 10.88 x 5.5 in Working Access (L x W x D) (cm) 21.2 x 27.6 x 14 cm Temperature Stability °F ±0.02° Temperature Stability °C ±0.01° Display 3.75" Touch-Pad LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure/Suction Pump Speed Variable Process Connections 1/4" (F) NPT Flammability Class (DIN 12876-1) III (FL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes WhisperCool Environmental Control Technology Yes Cool Command Refrigeration Technology Yes Reservoir Drain Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 22.4 x 14.5 x 26.9 in Overall Dimensions (L x W x H) (cm) 56.9 x 36.8 x 68.3 cm Refrigerant R452A Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 118.0 Shipping Weight (kilograms) 53.5 Catalog Page Number 40-41 60 Hz Only Part Number AD15R-40-A11B Maximum Pressure (psi) 4.3 Maximum Pressure (bar) 0.30 Maximum Pressure Flow Rate (gpm) 5.30 Maximum Pressure Flow Rate (l/min) 20.1 Maximum Suction Flow Rate (gpm) 3.9 Maximum Suction Flow Rate (l/min) 14.7 Cooling Capacity @ -20°C (W) 265 Cooling Capacity @ 0°C (W) 650 Cooling Capacity @ +20°C (W) 1000 Cooling Capacity @ +100°C (W) 1000 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/13 Regulatory Approvals ETL Key Features: Intuitive 3.75" (9.5cm) display with touch-pad control 4 Languages: French, German, Spanish, English Swivel 180 Rotating Controller On-board connectivity: Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe On-screen prompts Automatic performance optimization and specific heat tuning Single-point calibration capability Operators Manual

$8,306.73

Polyscience 28 Liter Advanced Digital Refrigerated Circulator (-30°C/200°C)

Polyscience 28 Liter Advanced Digital Refrigerated Circulator (-30°C/200°C) Specification Description -30, 28 L Ref. Circulator Controller Type Advanced Digital Display 3.75" Touch-Pad LCD Connectivity Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe Languages Supported 4: French, German, Spanish, English Swivel 180 Rotating Controller Yes Working Temperature Range °C -30° to 200° Temperature Stability °C ±0.01° Fluid Optimization/Specific Heat Tuning Automatic and/or user-adjustable Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 31.4 x 35.9 x 14 cm Pump Type Pressure/Suction External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Working Temperature Range °F -22° to 392° Working Temperature Range °C -30° to 200° Nominal Cooling Capacity @ +20C (W) 915 Reservoir Capacity (gallons) 7.4 Reservoir Capacity (liters) 28 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 12.35 x 14.13 x 5.5 in Working Access (L x W x D) (cm) 31.4 x 35.9 x 14 cm Temperature Stability °F ±0.02° Temperature Stability °C ±0.01° Display 3.75" Touch-Pad LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure/Suction Pump Speed Variable Process Connections 1/4" (F) NPT External Temperature Control Capability Yes Flammability Class (DIN 12876-1) III (FL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes Reservoir Drain Yes Cooling Coil Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 26.5 x 18 x 26.9 in Overall Dimensions (L x W x H) (cm) 67.2 x 45.7 x 68.3 cm Refrigerant R404A Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 146.0 Shipping Weight (kilograms) 66.1 Catalog Page Number 40-41 60 Hz Only Part Number AD28R-30-A11B Maximum Pressure (psi) 4.3 Maximum Pressure (bar) 0.30 Maximum Pressure Flow Rate (gpm) 5.30 Maximum Pressure Flow Rate (l/min) 20.1 Maximum Suction Flow Rate (gpm) 3.9 Maximum Suction Flow Rate (l/min) 14.7 Cooling Capacity @ -20°C (W) 165 Cooling Capacity @ 0°C (W) 505 Cooling Capacity @ +20°C (W) 915 Cooling Capacity @ +100°C (W) 915 Included Hardware Nylon hose adapters for 3/8", 1/4", and 3/16" Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/10 Regulatory Approvals ETL Key Features: Intuitive 3.75" (9.5cm) display with touch-pad control 4 Languages: French, German, Spanish, English Swivel 180 Rotating Controller On-board connectivity: Ethernet, USB A & B, RS232/addressable RS485, External Temperature Probe On-screen prompts Automatic performance optimization and specific heat tuning Single-point calibration capability Certifications Regulatory Approvals: CE Regulatory Approvals: ETL Operator's Manual

$9,939.68

MVP 6CFM 60 PSI Check Valve Replacement Kit

MVP 6CFM 60 PSI Check Valve Replacement Kit This is a replacement check valve kit for the MVP 6CFM Explosion Proof Recovery Pump. It comes with 4 replacement O-rings, 4 replacement screws and 4 replacement shims. All sales final

$113.60

UL Listed BVV™ Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 5.6CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) Features Our Pro series are our most impressive line of rotary vane pumps available. Known for their high degree of efficiency and deep ultimate vacuum, all Pro models feature a dual-stage, chemical-resistant pump configuration designed to handle abusive, extended vacuum evacuations. Capable enough to comfortably handle laboratory and scientific applications, these pumps are also extremely simple in operation and require minimal maintenance. PTFE chemical resistant pump vanes provide superior corrosion resistance and reliability. Large oil reservoir and adjustable gas ballast standard on every model to increase pump oil lifetime. Internal check-valve included in every unit, prevents accidental pump oil backflow. Exhaust oil filter trap included. DEEP ultimate vacuum and KF25 inlet for optimal pumping speed. Lightweight, with noise-dampening rubber feet. Rugged, reliable, economical, and efficient pump designed for day in, day out use. Air cooled, thermally protected motors enclosed in a durable aluminum housing. Gas ballast valve for deeper vacuum. Steel inlet KF25 flange port with multiple intake size. Plastic handle, skid-resistant rubber base. 1 year limited warranty. Specification Electrical Voltage 120v Frequency 60 Hz Plug NEMA 5-15 US Standard Pump Flowrate 5.6 CFM Configuration 2 Stage Pump Ultimate Vacuum 0.3 Micron Ultimate Vacuum (with ballast) 6 Micron Oil Capacity 1000 ml Recommended Oil Ultragrade 19 Motor Power 1/2 hp Max Speed 1720 RPM Noise Level <56 dB Package Inlet / Exhaust KF25 / NW25 Weight 46 lbs Compliance CE Listed Ships With Exhaust Filter, Pump Oil, User Manual, Power Cable Warranty 1 year Components Pro Series Pump Components(Included exhaust filter not pictured) Performance Comparison Pump speed comparison for our Pro Series pumps. Downloads Maximum Attainable Vacuum at Altitude Reference Chart Vacuum Units Conversion Chart Additional Information How do Rotary Vane pumps work? Rotary vane pumps work by having a rotor with two adjusting vanes continuously rotating and exhausting air or any other molecules in the occupied space. The four stages which a rotary vane pump undergo are shown below Single Stage vs Two Stage Vacuum Pump: BVV™ Pro Series pumps are a dual-stage rotary vane pump style. Dual-stage pumps have two rotors and two sets of vanes that work together to fully pull a medium vacuum (1st stage) and then pull a better vacuum (2nd stage). These pumps will evacuate more quickly and can pull a deeper vacuum when compared to single-stage pumps. What is Gas Ballast and how does it work? During the pumping process the vacuum pump is trying to evacuate gas present in the occupied space, both non-condensable and condensable gases and vapors. Gas ballast helps increase the percentage of non-condensable vapors such that it will allow for the pump to efficiently exhaust all gases and vapors. This in turn will increase the overall efficiency and pumps life. When the pump is being used with non-condensable gases it's safe to keep the gas ballast valve closed. On the other hand, when there is a condensable gas or vapor present, the gas ballast should be opened appropriately. Gas ballast is used at the beginning of the pumping process when condensable gases are known to be present, then it's closed to finish pulling the deepest vacuum. For more info on rotary vane pumps please view our blog post: Rotary Vane Pumps and Gas Ballast Explained. Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$2,484.92

1L Standard Distillation Turnkey Setup

1L Standard Distillation Turnkey Setup The Standard Distillation Turnkey Setup includes all the components necessary to successfully perform distillation at an entry level price point. The Standard Turnkey Setup Includes: 1L Distillation Kit 1/4" Flare x 1/4" Barb Adapter BVV™ 5L Heated Circulator BVV™ V9D 9CFM Two Stage Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$2,981.90 - $3,336.89