New Products

-

Distillation Head

BVV™ Distillation Head BVV™ Brand Distillation head is made out of 3.3 Boro and comes with (2) 24/40 Ground Male Joints and a 14/20 Female thermometer joint at the top of the head. This head features 2x GL-14 barbs for the condenser and an extended drip tip for the receiving cow. The head measures 8.5" from the bottom 24/40 joint to the top of the head and the condenser is 3.5" long. The head has 2 sets of quad Vigreux and is bent at a 20-degree angle. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$277.51

-

304 Stainless Steel Wool - 2 Pack

304 Stainless Steel Wool This 304 Grade Stainless Steel Wool is a great accessory for any extraction, condensing, or a filtration system. Stainless Steel Wool provides a vastly superior surface area compared to ball bearings and can be packed tighter to increase the surface area. This 304 Stainless Steel Wool comes in a pack of two rolls that roughly measure 15" x 15". BVV™ recommends cleaning this filtration material with high purity alcohol before use to reduce contaminants. Specifications Material 304 Stainless Steel Wire Thickness 0.006" Dimensions 15" x 15"

$27.75

-

8" Tri-Clamp Dewaxer Column

8" Tri-Clamp/ Tri Clover Dewaxing Columns This is a 8" Tri-Clamp BVV™ Tri-Clamp Dewaxing Spool. It is intended to have dry ice put into the sleeve to chill the material inside the column. **Note: When selecting a Pipe Hanger choose the size that correlates to the Sleeve OD NOT Spool OD Sizes Available: 8" x 36" Tri-clamp Dewaxer Column 8" x 48" Tri-clamp Dewaxer Column Specifications: Tri-Clamp Size 8" Material 304 Stainless Steel Standard 3A High Polish Sleeve OD 10.000" Spool ID 7.782" Spool OD 8.000" Flange OD 8.570" Bead Center 8.150" Drain Port 1/4"-18 FNPT (Drain Plug Included) OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 8" Tri-Clamp Dewaxer Columns - Drawing

$485.64 - $797.84

-

20LB High Purity USA 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend - 99.5% Guaranteed - Buy 2 Get 1 Free (Add 3 To Cart)

20LB High Purity USA 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend - 99.5% Guaranteed - Buy 2 Get 1 Free (Add 3 To Cart) HAZMAT ITEMS ARE NON-REFUNDABLE. ALL SALES ARE FINAL. DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Ground ONLY. Quantities bought in 3 or more will ship via freight unboxed BVV™ always recommends distillation of every solvent before use. Tank contains no diptube. Tank does not include CGA 510 fitting. Must be added through dropdown or bought separately. *Actual liquid weight is 20LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Permitted Sales Include the Following: Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale High purity 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend is USA sourced, and guaranteed to be 99.5% pure. This instrument grade solvent helps to produce a higher quality extract by reducing mystery oils and contaminants. Solvent comes in a DOT refillable LP tank. This product is clean, colorless and odorless. How To Buy 2 Get 1 Free Simply add 3X of 20LB Tanks to your cart and you will automatically be discounted the third tank. Need one with a CGA fitting two without? Simply add one tank with your desired CGA fitting and add two of the same item selecting "None" for the "CGA fitting" and "Connection Size" options. Want 2 Butane Tanks and 1 Propane Tank? No problem, just add 3 of ANY of our 20LB LPG tanks to your cart and enjoy the third tank free! Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via UPS Ground/Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers. Chemical Formula: C₄H₁₀ + C3H8 Molecular Weight: 58.12 g/mol & 44.10 g/mol CAS Registry Number: 106-97-8 & 74-98-6 & 75-28-5 Appearance Colorless Odor: Faint Petroleum Density N/A Boiling Point: N/A Solubility in water: Low Solubility GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220, H280 GHS Precautionary Statements P210, P377, P381, P403, P410+P403 UN Identification Number: 1965 Proper Shipping Name: Hydrocarbon Gas Mixture, liquefied, n.o.s. Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Tri-Blend Certificate of Conformance (COC) and Certificates of Analysis (COA's) Tri-Blend Safety Data Sheet (SDS)

$346.89 - $367.70

-

20LB High Purity USA 70/30% N-Butane/Propane Blend - 99.5% Guaranteed - Buy 2 Get 1 Free (Add 3 To Cart)

20LB High Purity USA 70/30% N-Butane/Propane Blend - 99.5% Guaranteed - Buy 2 Get 1 Free (Add 3 To Cart) The high-purity 70/30% N-Butane/Propane Blend isn’t just US-sourced. It’s guaranteed to be 99.5% pure. This instrument-grade solvent produces a higher quality extract by reducing mystery oils and other contaminants. Our 70/30% N-Butane/Propane Blend comes in a 20 LB DOT refillable LP tank. Enjoy working with a solvent that’s clean, colorless, and odorless! DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Ground ONLY. Quantities bought in 3 or more will ship via freight unboxed BVV™ always recommends distillation of every solvent before use. Tank contains no diptube. Tank does not include CGA 510 fitting. Must be added through dropdown or bought separately. *Actual liquid weight is 20LB California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Permitted Sales Include the Following: Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale How To Buy 2 Get 1 Free Simply add 3X of 20LB Tanks to your cart and you will automatically be discounted the third tank. Need one with a CGA fitting two without? Simply add one tank with your desired CGA fitting and add two of the same item selecting "None" for the "CGA fitting" and "Connection Size" options. Want 2 Butane Tanks and 1 Propane Tank? No problem, just add 3 of ANY of our 20LB LPG tanks to your cart and enjoy the third tank free! Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via UPS Ground/Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers. Chemical Formula: C₄H₁₀ + C3H8 Molecular Weight: 58.12 g/mol & 44.10 g/mol CAS Registry Number: 106-97-8 & 74-98-6 Appearance Colorless Odor: Faint Petroleum Density N/A Boiling Point: N/A Solubility in water: Low Solubility GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220, H280 GHS Precautionary Statements P210, P377, P381, P403, P410+P403 UN Identification Number: 1965 Proper Shipping Name: Hydrocarbon Gas Mixture, (Butane/Propane) liquefied, n.o.s. Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Dual Blend Certificate of Analysis (COA) Dual Blend Safety Data Sheet (SDS)

$346.89 - $367.70

-

Fully Jacketed Spools

Fully Jacketed Spools 304 Stainless Steel Fully Jacketed Spools allow the user to circulate water through the base of an extractor or the material column to heat up or chill solvent vapor. Has 1/2" FNPT ports. And attached tri clamp fittings on each end for user convenience. BVV™ Fully Jacketed Spools - Drawings

$152.63 - $943.53

-

Vacuum Filter Trap

Vacuum Filter Trap This Vacuum Filter Trap is designed to remove potential contaminants from the vacuum line to prolong the lifetime of your pump. Packed with oil-free, stainless-steel SS304 wool and made with a glass jar, the filter trap may optionally be used as a low-cost cold trap. Welch Inlet / Exhaust Separator 1423B with stainless steel wool inside for even more filtration. We built out two separate fitting configurations for your convenience: just choose from the drop-down menu above! The trap ships default with two 3/8" Barbed fittings, but you may alternatively select our KF25 x 1/4" JIC fittings to receive your vacuum trap specially designed for use with our ovens! Simply clamp the trap directly onto your oven's KF25 vacuum port, then connect a 1/4" hose to your vacuum pump. Specifications: Inlet/Outlet: 3/8" FNPT (ships with adapters selected above) Jar: 230ml Glass -- Welch Inlet / Exhaust Separator 1423B Steel Wool: Oil-free SS304 Maximum Vacuum: <29"Hg Dimensions: 2.8" dia x 4.3" tall Please note this item does not include any vacuum tubing. To order, we recommend the 3/8" Gum Rubber Vacuum Tubing.

$499.52

-

Whip-it! Whip-it! Premium Butane - Zero Impurities 420ML

Whip-it! Premium Butane - Zero Impurities 420ML DISCLAIMER(S): BOGO is Automatically Included in Pricing BOGO DOES NOT APPLY TO SINGLE CANS Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via Ground/Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! California now prohibits the retail sale of any NON-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Permitted Sales Include the Following: Medical Collectives or Cooperatives operating under CA Health & Safety Code Section 11362.775 Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale Whip-it! butane is the purest butane extracted from the north sea and with over seven decades of gas manufacturing expertise, Whip-It! is proud to offer butane lighter and torch fluid in its finest form, virtually free of contaminants. After extensive research and analysis, our technical team sources the purest natural butane from specific gas fields in the north sea about 200 miles off the Scottish coast. Our premium quality butane will keep your lighters and torches free from clogging and produce the cleanest burn possible. Whip-It! brand Premium North Sea Butane achieved Grade A for the Global Standards of Consumer Products. Whip-it! Premium North Sea Butane has the highest Quality levels backed by worldwide governing bodies of the following Quality Control institutions; BSI ISO9001:2008, British Retail Consortium Certification Body, SGS System Certification, UKAS, ANAB, and IAF. Comes in a 420ML can with ZERO impurities! Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$7.98 - $357.99

-

150L 304SS Jacketed Collection and Storage Vessel with Locking Casters

150L 304SS Jacketed Collection and Storage Vessel with Locking Casters This massive 304 Stainless Steel Jacketed vessel can hold up to 150L of water (~40 gallons) and has a (3) 6" Tri-Clamp/ Tri Clover ports on the top and a 6" Tri-Clamp port on the bottom of the vessel. The outer jacket has 2x 1/2" FNPT ports to allow the circulation of heat transfer fluids and can also be used a vacuum jacket and can hold 21.5L or 5.68 gallons of fluid in the outer jacket. This unit also features 4 stainless steel legs with locking casters to allow the vessel to be moved around easily including 32" and wider doorways. (Note: this unit comes bare and does not include any fittings besides the legs with casters.) BVV™ 150LR - Technical Drawing Specifications Material 304 Stainless Steel Pressure Rating 250 PSI MAX Outer Jacket Rating: 100 PSI Connection Type(s): (3) 6" Tri-Clamp Top Ports 6" Tri-Clamp Bottom Port (2) 1/2" FNPT Ports on the jacket *High Pressure Clamps are required when using pressure greater than 100 PSI ***Note: This item will ship via freight ONLY.

$3,468.86

-

ASME 250 PSI Brass Safety Valve - 1/2" MNPT

ASME 250 PSI Brass Safety Valve - 1/2" MNPT Model “SB” ASME safety valve is a high capacity safety valve. Unique O-ring seal ensures valve is bubble-tight to within 10% of set pressure. Set pressure tolerance is +/-3%. SB50 Outline Drawing SB Flow Charts Specifications Construction: Brass Stainless Steel Springs FKM O-Ring Seal Set Pressure 250 PSI Max Temp. 250ºF

$97.13

-

L.J. Star L.J. Star SSH Series High Pressure Clamps

L.J. Star SSH Series High Pressure Clamps These high pressure clamps are part of a complete line of stainless sanitary clamps made specifically for the pharmaceutical and biotech industries, the Series SSH hygienic clamp incorporates a unique profile and two bolts for greater clamping force. Suitable for high pressure applications. The SSH high-pressure clamp is part of a complete line of hygienic clamps made specifically for the pharmaceutical and biotech industries where joint cleanliness and efficiency are of paramount importance. These stainless steel clamps are made from investment castings to produce a high quality, precision fit assembly. They are designed to provide quick access to the joint for cleaning and inspection without sacrificing safety. Replacement Bolts for L.J. Star SSH Series High Pressure Clamps. These clamps come in five sizes: 1.5, 2, 3, 4, and 6 inches. Nut Sizes for these clamps: 1.5, ,2, 3, & 4 (5/8" Nut) *6" Clamp uses 3/4" Nut. Datasheet - Series SSH (High Pressure) Sanitary Clamp

$76.32 - $222.01

-

L.J. Star 6" ASME VIII Sanitary 316SS Clamp for High Pressure Connections

6" ASME VIII Sanitary 316SS Clamp for High Pressure Connections These heavy duty hygienic ASME VIII clamps are designed for pressure vessels, filter housings and other demanding/pressure intensive applications while operating under sterile conditiions. These clampos meet the requirements of ASME SEction VII Appendinx 24 of the pressure vessel code . All of these sanitary clamps are made from fully traceable 316 stainless steel. The ASME Code Sanitary Clamp is made specifically for the Pharmaceutical and Biotech Industries where joint cleanliness and efficiency are of paramount importance. These stainless steel sanitary fittings and clamps are made from investment castings to produce a high quality, precision fit assembly. The clamps are designed to provide quick access to the joint for cleaning and inspection without sacrificing safety. All sanitary clamps are CE compliant per the Pressure Equipment Directive 97/23/EC and the Machinery Directive 98/37/EC. DATASHEET - ASME Sanitary Clamp Fittings ASME Clamp Instructions

$1,005.97

-

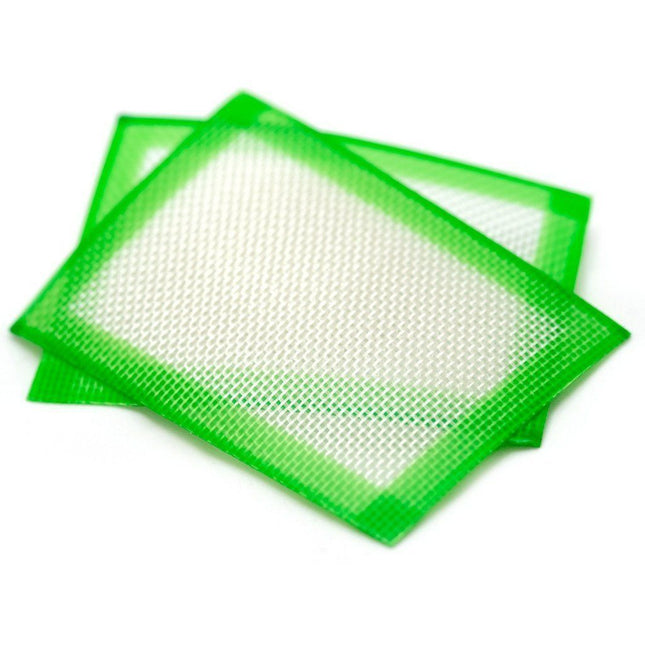

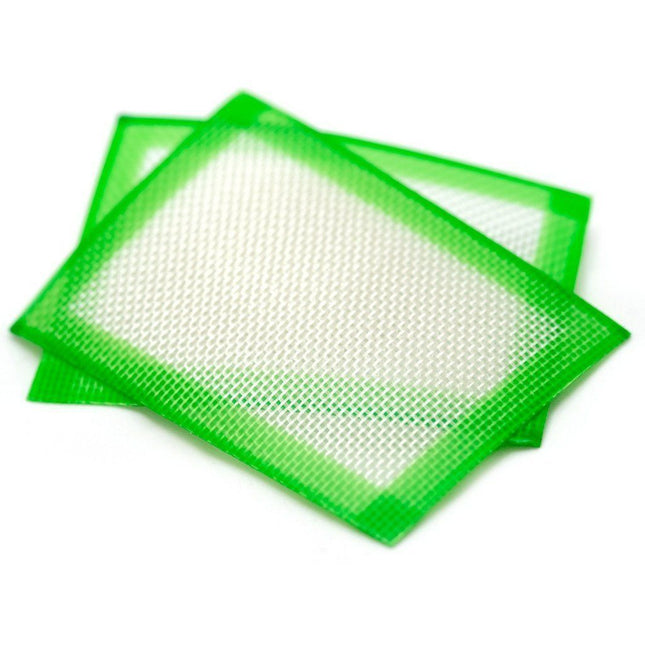

Oil Slick SLICK DUO

SLICK DUO For Dabbers on the go, the Slick® Duo is a pair of Slick® Pads the size of an index card. Completely non-stick, Slick® Duo is the perfect surface for handling your precious extracts.

$11.10 $5.55

-

UL Listed BVV™ Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 21.2CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) This is the BVV™ Brand 21.2CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 21.2CFM will pull a vacuum down to 0.3 microns effortlessly. The pump is designed with corrosion resistance and long-term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 110v 60Hz 1100 Watts Pumping Rate: 21.2CFM Ultimate vacuum without gas ballast: 0.3 micron Ultimate vacuum with gas ballast: 6 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2L/2.1 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Dimensions: 21 x 7.5 x 12 Shipping Dimensions: 29.5 x 9.5 x 16.5 Unit Weight: 95lbs Shipping Weight: 105lbs Recommended oil: Ultragrade 19 Noise level: <58 dB CE Compliance: Yes Warranty: 1 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result in the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$4,856.41

-

UL Listed Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 11.3CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) This is the BVV™ Brand 11.3CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 11.3CFM will pull a vacuum down to 0.3 microns effortlessly. The pump is designed with corrosion resistance and long-term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 110v 60Hz 750 Watts Pumping Rate: 11.3CFM Ultimate vacuum without gas ballast: 0.3 micron Ultimate vacuum with gas ballast: 6 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 1.5L/1.59 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Dimensions: 21 x 7.5 x 12 Shipping Dimensions: 29.5 x 9.5 x 16.5 Unit Weight: 66lbs Shipping Weight: 75lbs Recommended oil: Ultragrade 19 Noise level: <58 dB CE Compliance: Yes Warranty: 1 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result in the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$3,607.62

-

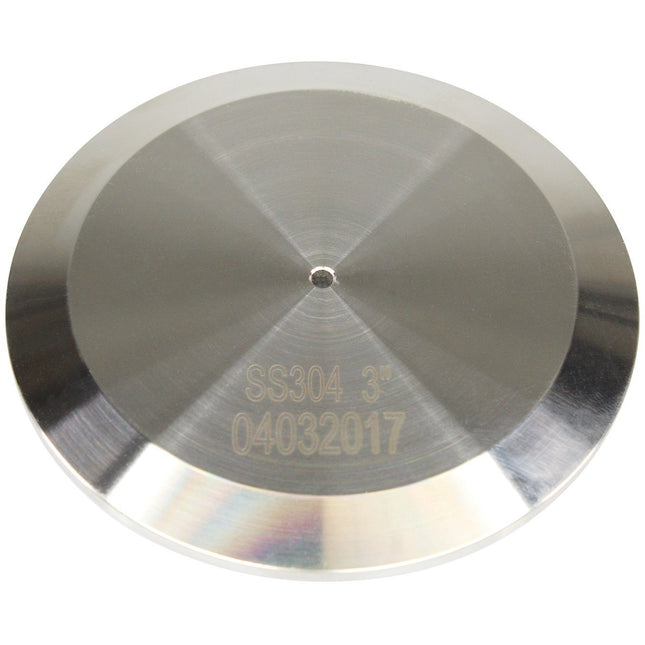

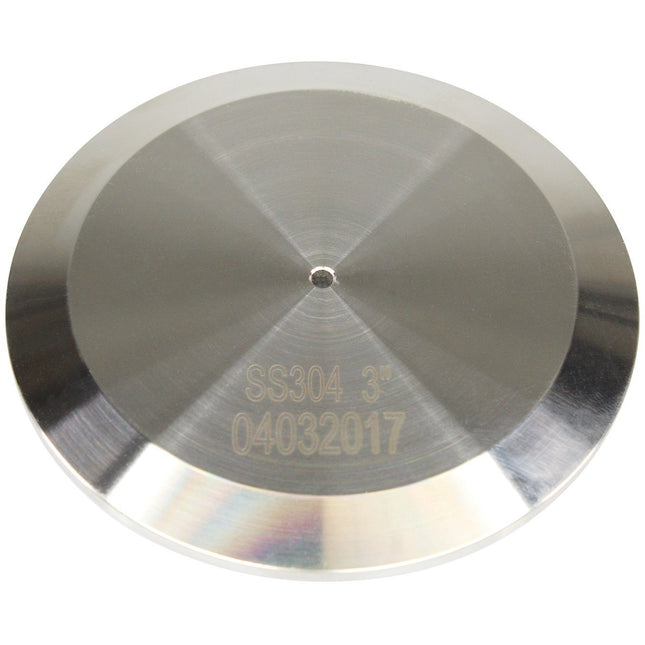

3mm Open Blast End Caps

3mm Open Blast End Caps These Tri-Clamp/ Tri Clover End Caps have a 3mm hole drilled in the center so most butane can tips to easily fit in the hole allowing the user to input solvent into a material column and open blast the material. Specifications: Material: 304 Stainless Steel Connection Type: Tri-Clamp 3mm Hole Standard: 3A Sizes Available: 1.5" 2" 3" 4"

$8.33 - $16.65

-

Female NPT Shower Head End Caps

Female NPT Shower Head End Caps Shower Head End Caps Tri Clamp/ Tri Clover help disperse solvent input into a system which creates better material saturation when flooding a material column. This helps to prevent channeling, ensuring all the material is saturated. Specifications: Material: 304 Stainless Steel Connection Type: Tri-Clamp 1/4" - 18 FNPT 3/8" -18 FNPT 1/2" - 14 FNPT Standard: 3A Sizes Available: 1.5" 2" 3" 4"

$41.63 - $86.03

-

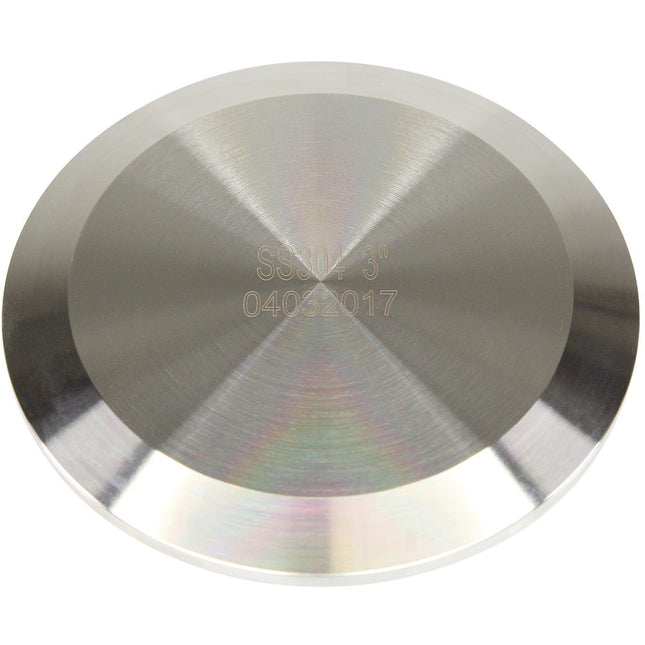

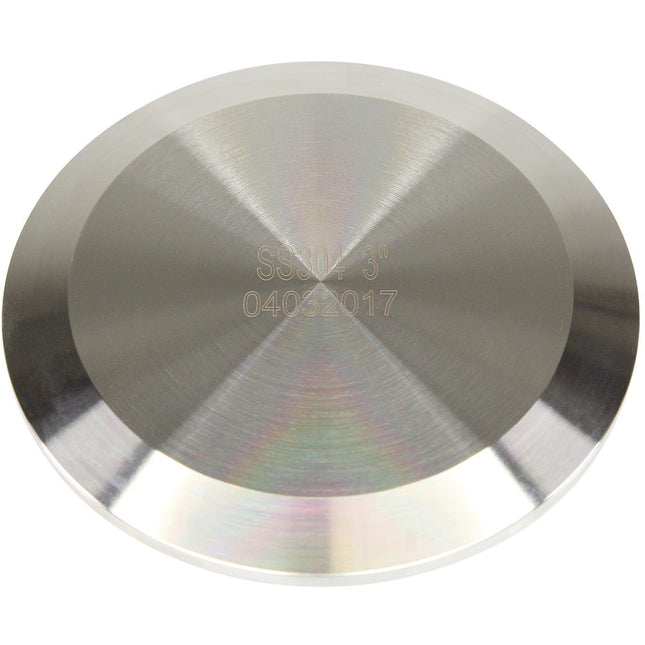

Solid Tri-Clamp End Caps

Solid Tri-Clamp/ Tri Clover End Caps Best Value Vacs Brand Solid Tri-Clamp End Caps provide the user with the option to cap off a spool or lid or for custom fabrication. Specifications: Material: 304 Stainless Steel Connection Type: Tri-Clamp Standard: 3A Sizes Available: 1.5" 2" 3" 4" 6" BVV™ Solid Tri-Clamp End Caps - Drawing BVV™ Solid Tri-Clamp End Caps - End Cap Chart

$16.65 - $81.87

-

Tri-Clamp Ferrule

Tri-Clamp/ Tri Clover Ferrule Tri-clamp ferrules are the bottom of our open blast systems. These ferrules allow the user to use a screened gasket at the end of an open blast spool while providing an open end. Specifications: Material: 304 Stainless Steel Connection Type: Tri-Clamp Standard: 3A Sizes Available: 1.5" 2" 3"

$6.94 - $9.71

-

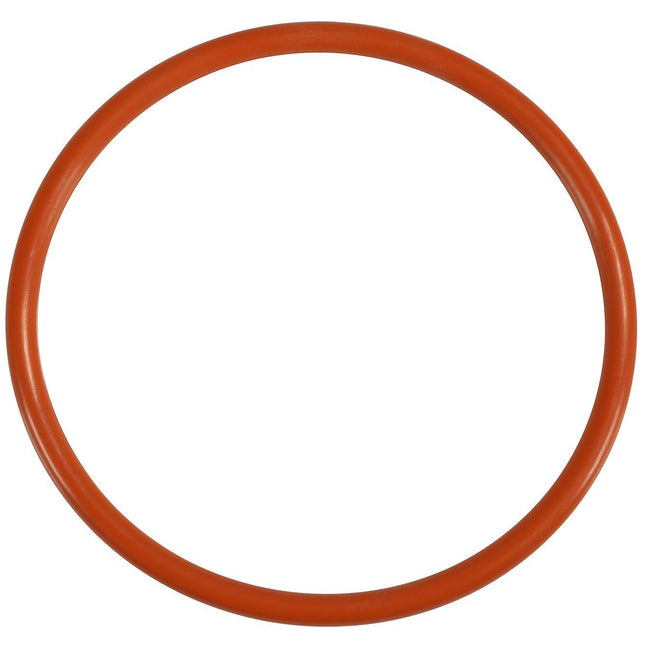

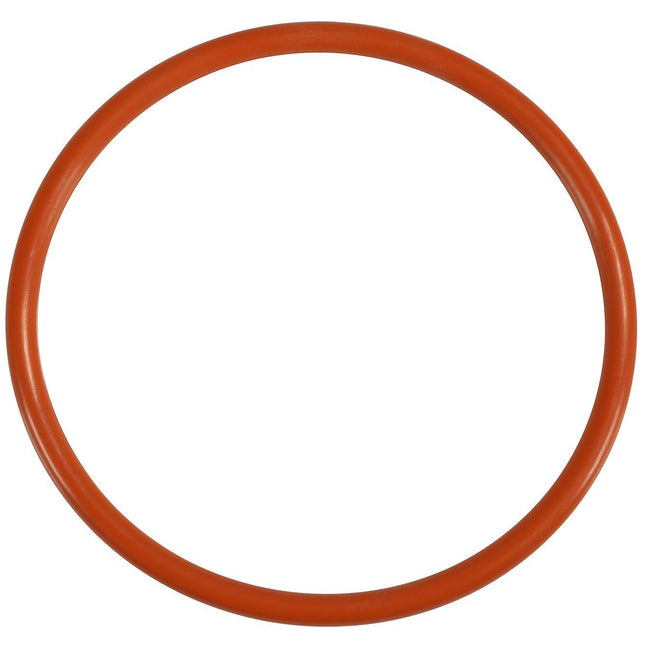

Cold Trap O-ring for Inner Vessel

Cold Trap O-ring for Inner Vessel This is a replacement O-ring gasket for the inner vessel of the cold trap to create a seal between the lid and dry ice container. Material: Silicone

$34.69

-

3CFM Single Stage Vacuum Pump

VE115 Single-Stage 3CFM Vacuum Pump This is the BVV™ Brand VE115 3CFM Single Stage Vacuum Pump. Single-stage vacuums pump exhaust into a chamber in the pump, which separates the oil from the pumped gas. Then, the oil is returned and the gas is exhausted. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer Oil life Lightweight Rubber Feet for noise dampening Reliable, Economical and Efficient Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$208.13

-

37 Degree MJIC x FJIC

BVV™ MJIC x FJIC This unique 304 stainless steel fitting allows the user to adapt a 1/4" 37 Degree MJIC to a 3/8" 37 Degree MJIC or vise versa without having to replace or back out the fitting or taping the fitting. BVV™ MJIC x FJIC - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4" 37° FJIC X 3/8" 37° MJIC 3/8" 37° FJIC X 1/4" 37° MJIC

$8.33 - $9.71

-

Pipe Nipple

BVV™ Pipe Nipple Fully threaded 304 stainless steel pipe nipple allows the user to configure a system while minimizing the length of the system due the extra hex nipple space that a wrench would need. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. **NOTE: Pre-Taped option comes from BVV Pre-taped with Yellow UL Listed Gas PTFE Tape on the Male NPT threads ONLY for a +0.50c charge per male npt end. (JIC Threads DO NOT need to be taped.) BVV™ Pipe Nipple - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4"-18 MNPT 3/8"-18 MNPT 1/2"-14 MNPT 3/4"-14 MNPT 1"-11-1/2 MNPT

$7.63

-

1.5" x 19" x 3/8" FNPT Tri-Clamp Manifold

1.5" x 19" x 3/8" FNPT Tri-Clamp Manifold This Tri-Clamp/ Tri Clover manifold is made out of 304 stainless steel and has 2 1.5" Triclamp connections at each end and (6) 3/8" FNPT threaded ports along the length of the manifold. This allows the customer to adapt this manifold to any extraction system allowing for maximum flow of vapor through the manifold. Specifications Material 304 Stainless Steel Connection Size 1.5" Tri-Clamp 3/8" FNPT Length 19" Standard 3A High Polish

$97.13 $69.38

-

1.5" Fully Jacketed Tri-Clamp x 8" 90 Degree Bend

1.5" Fully Jacketed Tri-Clamp/ Tri Clover x 8" 90 Degree Bend This 1.5" Fully Jacketed Triclamp/ Tri Clover 90 Degree bend is extended out to 8" end to end to add extra length to the fitting. It is made out of 304 Stainless steel with a high polish interior and exterior and has (2) 1/2" FNPT ports on the outer jacket and is made to circulate fluid through the outer jacket to either condense or heat up the internal vapors or liquids. Specifications Material 304 Stainless Steel Connection Size 1.5" Tri-Clamp 1/2" FNPT Length 8" Standard 3A High Polish

$326.07

-

1.5" Tri-Clamp x 8" 90 Degree Bend

1.5" Tri-Clamp/ Tri Clover x 8" 90 Degree Bend This 1.5" Triclamp 90 Degree bend is extended out to 8" end to end to add extra length to the fitting. It is made out of 304 Stainless steel with a high polish interior and exterior. Specifications Material 304 Stainless Steel Connection Size 1.5" Tri-Clamp Length 8" Standard 3A High Polish

$90.19

-

20L Digital Heating Mantle

20L DIGITAL HEATING AND STIRRING MANTLE Digital Heating and Stirring Mantles give the operator the most precise temperatures and readouts during distillations. These mantles autotune to specific user input to provide consistent results. Each mantle is equipped with large digital display that will give you readouts for both set temperature, actual temperature, and stirring speed. Each mantle also comes with a vertical brace bar and boss head as well as a temperature probe which plugs directly into the mantle. For first time use, the mantle should have an initial burn out done. This will burn off any residual oils used in the production of the insulation rope. The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Specifications: Capacity: 20L (20000mL) Power Supply: 220V 60Hz (NEMA 6-20 plug) Adjustable Rotation Speed: 50-1800 RPM Motor Power: 40W, DC14-24V Heating Power 180-2200W Temperature Control Accuracy: +/- 1C Intelligent Temperature Control: Yes Temperature Range: RT+10-380C Insulation Material: Alkali-free Glass Fiber, temperature resistant up to 450C Shipping Dimensions: 25 x 25 x 18 in. Weight: 35 lbs

$1,942.56

-

BVV Lab Stand

Metal-Base Lab Stand This lab stand has a metal base that measures 5.5" x 7-3/4" x 7/8" and the rod comes in two heights: 24 and 36 inches. It also has 2 pre-threaded holes that are in the center and near the edge of the base to allow multiple positions when attaching the rod.

$62.44 - $76.32

-

1/4" FNPT End Caps

1/4" FNPT End Caps These End Caps come with a 1/4"-18 FNPT Threaded connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp/ Tri Clover lid Specifications Material 304 Stainless Steel Connection Type: Tri-Clamp 1/4" - 18 FNPT Standard: 3A Sizes Available: 1.5" 2" 3" 4" 6" BVV™ Solid 1/4" FNPT End Caps - Drawing BVV™ Solid 1/4" FNPT End Caps - End Cap Chart

$26.36 - $108.23

-

Pipe Hangers with Bracket Mount

Pipe Hangers Pipe Hangers Designed to fit on our racks. They range in sizes from 1.5" - 14" Diameter. Disclaimer: 4" and 6" Brackets have a new design incorporating the hang on bracket as one piece. Depending on size and availability, these may come with blue or purple rubber lining. ***NOTE: If you are planning to use a pipe hanger on a Dewaxing or Jacketed Column please choose a size that is 2" larger than the tri-clamp size.

$48.56 - $145.69

-

ASME Certified 50L Jacketed Solvent Tank 304L - Bare

ASME Certified 50L Jacketed Solvent Tank 304L - Bare This is a custom manufactured USA made ASME Certified 50LB Jacketed Collection base with UM Stamp and made out of 304L Stainless Steel. This base is designed to be configured to any application and can even be used as a solvent tank. This tank comes bare with no fittings and will hold around 50LBS of liquid butane and is able to have fluid circulated around the outer jacket to increase recovery speeds in the extraction system. **This Item will ship Via FREIGHT ONLY. Specifications Material 304L Stainless Steel Certification: ABILITY ENGINEERING TECHNOLOGY INC. ASME / UM / NB MAWIWP 350 PSI at 150°F MAWEWP N/A MIN TEMP -20°F at 350PSI Butane Capacity ~50LBS Connection Sizes: 6" Tri-Clamp (2) 1" NPT (2) 1/2" NPT - Outer Jacket Ports (2) 3/8" NPT Weight 146LBS Outer Dimensions: 32-7/8" Tall 14" Diameter Inner Dimensions: 24" Tall 12" Diameter

$2,497.58 $1,387.55

-

Fully Jacketed Base with 1.5" Tri-Clamp Drain Port

Fully Jacketed Base with 1.5" Tri-Clamp/ Tri-Clover Drain Port This Fully Jacketed Base features a full outer jacket to allow the circulation of heat transfer fluid. The base also has a sanitary Tri-Clamp port welded through the jacket and base for easier drainage of processed material and extract from the stainless steel base. This base is made out of 304 High Polish Stainless steel and has 2 1/2" FNPT Ports on the outer jacket to allow the circulation of fluid to heat or chill the base and also has a 1.5" Tri-Clamp port that allows the drainage of material from inside the base without having to lift it up and tip it over. Specifications Material 304 Stainless Steel Sizes Available: 10" Tri-Clamp X 12" 12" Tri-Clamp x 12" Drain Port Size 1.5" Tri-Clamp Jacket Port Size 1/2" FNPT

$624.40 - $763.15

-

Pre-Built 50L Stainless Steel Jacketed Reactor

The 50L Stainless Steel Jacketed Reactor is designed for use with positive pressure. Glass reactors are only able to handle negative pressures which limits their usability. The vessel jacket can be used to circulate chilling fluid or as vacuum insulation. The vessel wild hold 50L (13 gallons) of liquid or 10 lbs of botanical material and the outer jacket capacity is 14.22L or 3.76 gallons of fluid. Reaction Vessel Applications: Ethanol Extraction Winterization Filtration Pre-Chilling Solvent Mixing & Homogenizing Key Features: Vessel Rated to 100 PSI MAX 1/2" MJIC Connection 1/4" MJIC Connection High-Pressure Clamps Minimal footprint 12" Tri-Clamp top ferrule for easy loading and unloading Lockable casters for mobility 6" Tri-Clamp bottom ferrule for easy loading and unloading Modular Tri-Clamp design Polycarbonate sight glasses for easy viewing 1/2" barb connection on the jacket Alcohol resistant silicone gaskets. Low temperature model comes with PTFE gaskets and Borosilicate sight glasses.

$2,879.16

-

J-KEM Scientific J-KEM Model 250

J-KEM Model 250 The Model 250 has both heating and cooling outlets for maximum versatility. Two heating outlets supply 1800 watts of power for large equipment and heating mantles up to 22L. The third outlet (1800 watts), normally used for cooling, is programmable to supply power below, above, or at the set point. Contains J-KEM’s patented power control computer which provides 0.1° regulation of anything. Specifications: 120vac, 15 amps, 1800 wattsWarranty: 2 Years The temperature range desired determines the probe/thermocouple type: J [black] (0 – 800° C)K [yellow] (-50 – 1200° C)T [blue] (-200 – 250° C)RTD: (-200 – 400° C)

$1,710.84 - $1,980.03

-

12" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves

12" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 12" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with (2)1/4" and (1)3/8" 37° JIC Flares, and compound gauge. These lids are made out of 304 stainless steel and have (3) 2" Tri-Clamp ports with the middle 2" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2) 1/4" and (1) 3/8" 37° JIC Tri-Clamp Size(s) (3) 2" Ports x 12" Tri-Clamp Nitrogen Tested Yes

$811.71

-

12" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves

12" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 12" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with 1/4" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have (3) 2" Tri-Clamp ports with the middle 2" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" 37° JIC Tri-Clamp Size(s) (2) 2" Ports x 12" Tri-Clamp Nitrogen Tested Yes

$707.65

-

10" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves

10" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 10" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with (2)1/4" and (1)3/8" 37° JIC Flares, and compound gauge. These lids are made out of 304 stainless steel and have (1) 1.5" and (2) 2" Tri-Clamp ports with the middle 1.5" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2) 1/4" and (1) 3/8" 37° JIC Tri-Clamp Size(s) (1) 1.5" Ports x (2) 2" x 10" Tri-Clamp Nitrogen Tested Yes

$752.05

-

10" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves

10" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 10" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with 1/4" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have (1) 1.5" and (2) 2" Tri-Clamp ports with the middle 1.5" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" 37° JIC Tri-Clamp Size(s) (1) 1.5" Ports x (2) 2" x 10" Tri-Clamp Nitrogen Tested Yes

$646.60

-

6" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves

6" Pre-Built BIFLOW Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 6" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 3 BVV 316SS Full Bore Valves with (2)1/4" and (1)3/8" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have 3 1.5" Tri-Clamp ports with the middle port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" and 3/8" 37° JIC Flares -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" and (1) 3/8" 37° JIC Tri-Clamp Size(s) (3) 1.5" Ports x 6" Tri-Clamp Nitrogen Tested Yes

$613.30

-

6" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves

6" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 6" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with 1/4" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have 3 1.5" Tri-Clamp ports with the middle port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC Flares -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" 37° JIC Tri-Clamp Size(s) (3) 1.5" Ports x 6" Tri-Clamp Nitrogen Tested Yes

$507.84

-

UL Listed BVV™ Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 5.6CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) Features Our Pro series are our most impressive line of rotary vane pumps available. Known for their high degree of efficiency and deep ultimate vacuum, all Pro models feature a dual-stage, chemical-resistant pump configuration designed to handle abusive, extended vacuum evacuations. Capable enough to comfortably handle laboratory and scientific applications, these pumps are also extremely simple in operation and require minimal maintenance. PTFE chemical resistant pump vanes provide superior corrosion resistance and reliability. Large oil reservoir and adjustable gas ballast standard on every model to increase pump oil lifetime. Internal check-valve included in every unit, prevents accidental pump oil backflow. Exhaust oil filter trap included. DEEP ultimate vacuum and KF25 inlet for optimal pumping speed. Lightweight, with noise-dampening rubber feet. Rugged, reliable, economical, and efficient pump designed for day in, day out use. Air cooled, thermally protected motors enclosed in a durable aluminum housing. Gas ballast valve for deeper vacuum. Steel inlet KF25 flange port with multiple intake size. Plastic handle, skid-resistant rubber base. 1 year limited warranty. Specification Electrical Voltage 120v Frequency 60 Hz Plug NEMA 5-15 US Standard Pump Flowrate 5.6 CFM Configuration 2 Stage Pump Ultimate Vacuum 0.3 Micron Ultimate Vacuum (with ballast) 6 Micron Oil Capacity 1000 ml Recommended Oil Ultragrade 19 Motor Power 1/2 hp Max Speed 1720 RPM Noise Level <56 dB Package Inlet / Exhaust KF25 / NW25 Weight 46 lbs Compliance CE Listed Ships With Exhaust Filter, Pump Oil, User Manual, Power Cable Warranty 1 year Components Pro Series Pump Components(Included exhaust filter not pictured) Performance Comparison Pump speed comparison for our Pro Series pumps. Downloads Maximum Attainable Vacuum at Altitude Reference Chart Vacuum Units Conversion Chart Additional Information How do Rotary Vane pumps work? Rotary vane pumps work by having a rotor with two adjusting vanes continuously rotating and exhausting air or any other molecules in the occupied space. The four stages which a rotary vane pump undergo are shown below Single Stage vs Two Stage Vacuum Pump: BVV™ Pro Series pumps are a dual-stage rotary vane pump style. Dual-stage pumps have two rotors and two sets of vanes that work together to fully pull a medium vacuum (1st stage) and then pull a better vacuum (2nd stage). These pumps will evacuate more quickly and can pull a deeper vacuum when compared to single-stage pumps. What is Gas Ballast and how does it work? During the pumping process the vacuum pump is trying to evacuate gas present in the occupied space, both non-condensable and condensable gases and vapors. Gas ballast helps increase the percentage of non-condensable vapors such that it will allow for the pump to efficiently exhaust all gases and vapors. This in turn will increase the overall efficiency and pumps life. When the pump is being used with non-condensable gases it's safe to keep the gas ballast valve closed. On the other hand, when there is a condensable gas or vapor present, the gas ballast should be opened appropriately. Gas ballast is used at the beginning of the pumping process when condensable gases are known to be present, then it's closed to finish pulling the deepest vacuum. For more info on rotary vane pumps please view our blog post: Rotary Vane Pumps and Gas Ballast Explained. Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$2,428.20

-

24" Stainless Steel Packing Rod Extension

24" Stainless Steel Packing Rod Extension This is the Best Value Vacs 24" Extension for the packing rod and can easily be threaded on and off to extend or reduce the size of your packing rod. Specifications: Material: 304 Stainless Steel Length: 24" Thread Size: 1/4"-20

$27.75

-

Stainless Steel Extractor Packing Rod for Material *Fits Tri Clamp spools

Stainless Steel Packing Rod for Material Tubes Stainless Steel Extractor Packing Rods for Material Columns are a great addition to any extraction system because they allow the user to compact the plant material tightly into the column allow for more material per extraction and faster overall processing time. These rods come with a plate that matches the size of the inner diameter of the tri-clamp column utilizing a gasket for a tight fit. The rod is able to be extended with extra 24" sections that can also be purchased separately. Specifications: Plate and Rod Material: 304 Stainless Steel Gasket Flange Material: Viton

$76.32 - $527.27

-

1/2" FNPT End Caps

1/2" FNPT End Caps These End Caps come with a 1/2"-14 FNPT Threaded connection welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/2" port on a Tri-Clamp/ Tri Clover lid. These 1/2" FNPT endcaps also provide the user with a larger diameter for gases or flow of liquid which can greatly increase run times for an extraction system. Specifications Material: 304 Stainless Steel Standard: 3A High Polish Connection Type(s): Tri-Clamp 1/2" - 14 FNPT Sizes Available: 1.5" 2" 3" 4" 6" BVV™ 1/2" FNPT End Caps - Drawing BVV™ 1/2" FNPT End Caps - End Cap Chart

$29.14 - $276.12

-

Glass Vac Glass Vac 1.5 Gallon TALL Stainless Steel Vacuum Chamber and Vacuum Pump Kit

Glass Vac 1.5 Gallon TALL Stainless Steel Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Glass Vac 1.5 Gallon TALL Stainless Steel Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 - 2B Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 8-5/8" Tall x 7-1/8" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result from the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$399.61 - $634.11

-

Glass Vac Glass Vac 5 Gallon Aluminum Vacuum Chamber and V4D 4CFM Two Stage Vacuum Pump Kit

Glass Vac 5 Gallon Aluminum Vacuum Chamber and V4D 4CFM Two Stage Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed and tested in Naperville, Illinois. With our unique patented gasket design, this chamber is sure to withstand 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system), allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Glass Vac 5 Gallon Aluminum Vacuum Chamber V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum Specifications Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 10" Tall x 12" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micron Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result from the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$753.44

-

Glass Vac Glass Vac 3 Gallon WIDE Stainless Steel Vacuum Chamber and Vacuum Pump Kit

Glass Vac 3 Gallon WIDE Stainless Steel Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Glass Vac 3 Gallon WIDE Stainless Steel Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specifications Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 8" Tall x 10.5" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micron Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$394.06 - $664.63

-

Glass Vac Glass Vac 3 Gallon Aluminum Vacuum Chamber and Vacuum Pump Kit

Glass Vac 3 Gallon Aluminum Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Best Value Vacs 2 Gallon Aluminum Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specifications Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 9" Tall x 10" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC HosePlatinum Cured Silicone PadBlack 50 Micron Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$428.75 - $643.82

You have seen 1248 out of 1654 products