New Products

-

5 Gallon Resin Trap Vacuum Chamber

Resin Trap Vacuum Chamber Designed, built, and 100% tested in Chicago, Illinois, the Resin Trap Vacuum Chamber is the perfect application for a successful, high-quality end product. With its unique, patent pending gasket design (Utility Patent #14/533,548), this shatter chamber can easily withstand 10,000 uses with proper care and maintenance. The gasket itself is reversible, doubling the system's life by allowing customers to instantly take it off and flip it over. No adhesives necessary—this is a feature that most other vacuum chambers do not offer. The maximum allowed temperature of this chamber is 160f. The individual components of this chamber are rated at higher temperatures, however, as a vacuum vessel, we limit maximum operational temperature to 160f. Every chamber is tested prior to shipping to lose no more than 2.5 in Hg/24hrs. Key Features: Comes with 2 year limited warranty Resin traps come complete with glycerin-filled vacuum gauge, fittings for use with 1/4" vacuum tubing, nickel plated brass ball valve and instruction manual. Capture excess resin and protect your pump! Unique Catch Port Design: An additional hose can be installed at the port inside the tank to facilitate accurate collection of resin. 5 Feet Reinforced Vacuum Hosing to Connect Directly to the Vacuum Pump 1/4" SAE port. Measuring range of vacuum gauge:0-29.25inHg Silicone gasket to be used over 10,000 times without deterioration. This Kit Includes: (1) 5 Gallon Aluminum Chamber (1) Industrial grade silicone gasket Gasket can withstand 390F max temp. 60A durometer density (1) Glycerin filled vacuum gauge (must be regulated upon arrival) Max vacuum -29Hg (+/-.5Hg) at sea level (1) Leak free nickel plated 1/4" Hvac Flare Valve (1) ¼” Barbed Connection (1) 5' Purple BVV™ Hvac Hose (1) 5' Clear Vacuum Tubing Internal Dimensions: 10" Tall x 12" Diameter Compatibility Explanation BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. Pump Facts: We recommend the oil is changed every 50-75 of operating hours. CFM is a measure of cubic feet per minute. Single stage pumps reach a max vacuum of 50-75 microns (0=complete vacuum). Dual/Two stage pumps reach a max vacuum of 10-15 microns (0=complete vacuum). For shipping info including Import/Export details visit our Shipping page.

$228.91

-

3 Gallon Stainless Steel Resin Trap Vacuum Chamber

3 Gallon Stainless Steel Resin Trap Vacuum Chamber (Comes with 2 Year Limited warranty) Designed, built, and 100% tested in Chicago, Illinois, the Resin Trap Vacuum Chamber is the perfect application for a successful, high-quality end product. With its unique, patent pending gasket design (Utility Patent #14/533,548), this shatter chamber can easily withstand 10,000 uses with proper care and maintenance. The gasket itself is reversible, doubling the system's life by allowing customers to instantly take it off and flip it over. No adhesives necessary. The maximum allowed temperature of this chamber is 160f. The individual components of this chamber are rated at higher temperatures, however, as a vacuum vessel, we limit maximum operational temperature to 160f. Every chamber is tested prior to shipping to lose no more than 2.5inHg/24hrs. Specifications Key Features: Comes with 2 year limited warranty Resin traps come complete with glycerin-filled vacuum gauge, fittings for use with 1/4" vacuum tubing, nickel plated brass ball valve and instruction manual. Capture excess resin and protect your pump! Unique Catch Port Design: An additional hose can be installed at the port inside the tank to facilitate accurate collection of resin. 5 Feet Reinforced Vacuum Hosing to Connect Directly to the Vacuum Pump 1/4" SAE port. Measuring range of vacuum gauge:0-29.25inHg Silicone gasket to be used over 10,000 times without deterioration. This Kit Includes: (1) 3 Gallon Stainless Steel Chamber (1) Industrial grade silicone gasket Gasket can withstand 390°F max temp. 60A durometer density (1) Glycerin filled vacuum gauge (must be regulated upon arrival) Max vacuum -29Hg (+/-.5Hg) at sea level (1) Leak free nickel plated 1/4" Hvac Flare Valve (1) ¼” Barbed Connection (1) 5' Purple BVV™ Hvac Hose (1) 5' Clear Vacuum Tubing Internal Dimensions: 10-7/8" Tall x 9" Diameter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water.• ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents.• GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. Pump Facts: We recommend the oil is changed every 50-75 of operating hours. CFM is a measure of cubic feet per minute. Single stage pumps reach a max vacuum of 50-75 microns (0=complete vacuum). Dual/Two stage pumps reach a max vacuum of 10-15 microns (0=complete vacuum). See FAQ at the top for product safety warnings. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$208.10

-

2 Gallon Resin Trap Vacuum Chamber

2 Gallon Resin Trap Vacuum Chamber (Comes with 2 Year Limited warranty) Designed, built, and 100% tested in Chicago, Illinois, the Resin Trap Vacuum Chamber is the perfect application for a successful, high-quality end product. With its unique, patent pending gasket design (Utility Patent #14/533,548), this shatter chamber can easily withstand 10,000 uses with proper care and maintenance. The gasket itself is reversible, doubling the system's life by allowing customers to instantly take it off and flip it over. No adhesives necessary. The maximum allowed temperature of this chamber is 160f. The individual components of this chamber are rated at higher temperatures, however, as a vacuum vessel, we limit maximum operational temperature to 160f. Every chamber is tested prior to shipping to lose no more than 2.5inHg/24hrs. Specifications Key Features: Comes with 2 year limited warranty Resin traps come complete with glycerin-filled vacuum gauge, fittings for use with 1/4" vacuum tubing, nickel plated brass ball valve and instruction manual. Capture excess resin and protect your pump! Unique Catch Port Design: An additional hose can be installed at the port inside the tank to facilitate accurate collection of resin. 5 Feet Reinforced Vacuum Hosing to Connect Directly to the Vacuum Pump 1/4" SAE port. Measuring range of vacuum gauge:0-29.25inHg Silicone gasket to be used over 10,000 times without deterioration. This Kit Includes: (1) 2 Gallon Aluminum Chamber (1) Industrial grade silicone gasket Gasket can withstand 390°F max temp. 60A durometer density (1) Glycerin filled vacuum gauge (must be regulated upon arrival) Max vacuum -29Hg (+/-.5Hg) at sea level (1) Leak free nickel plated 1/4" Hvac Flare Valve (1) ¼” Barbed Connection (1) 5' Purple BVV™ Hvac Hose (1) 5' Clear Vacuum Tubing Internal Dimensions: 6.5" Tall x 10" Diameter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. Pump Facts: We recommend the oil is changed every 50-75 of operating hours. CFM is a measure of cubic feet per minute. Single stage pumps reach a max vacuum of 50-75 microns (0=complete vacuum). Dual/Two stage pumps reach a max vacuum of 10-15 microns (0=complete vacuum). See FAQ at the top for product safety warnings. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$187.29

-

Cellulose Filter Paper 50 Micron - 5 Pack

Cellulose Filter Paper 50 Micron - 5 Pack This filter paper is 100% synthetic cellulose (polyester plastic) and has no binders or adhesives. This material is very strong and considered un-rippable, but can easily be cut with a pair of scissors and this is the most durable filter paper we sell for larger diameter filtration applications. Polyester is recommended for use with Butane, Ethanol, Alcohol, Hexane, Pentane, and most hydrocarbons. Made in USA Specifications Material 100% Synthetic Cellulose (Polyester Plastic) Temp Range -100F to 300F (-70C to 150C) Thickness: 100 Micron - 0.011" 50 Micron - 0.020" QTY per Pack 5 Sizes Available: 6" 8" 10" 12"

$16.65 - $24.97

-

Cellulose Filter Paper 100 Micron - 5 Pack

Cellulose Filter Paper 100 Micron - 5 Pack This filter paper is 100% synthetic cellulose (polyester plastic) and has no binders or adhesives. This material is very strong and considered un-rippable, but can easily be cut with a pair of scissors and this is the most durable filter paper we sell for larger diameter filtration applications. Polyester is recommended for use with Butane, Ethanol, Alcohol, Hexane, Pentane, and most hydrocarbons. Specifications Material 100% Synthetic Cellulose (Polyester Plastic) Temp Range -100F to 300F (-70C to 150C) Thickness: 100 Micron - 0.011" 50 Micron - 0.020" QTY per Pack 5 Sizes Available: 6" 8" 10" 12"

$19.42 - $29.13

-

6" Tri-Clamp Tall Sight Glass

6" Tri-Clamp/Tri-Clover Tall Sight Glass This massive 6" Tri-Clamp sight glass is one of a kind and a specialty product for Best Value Vacs. It allows customers to attach it to alcohol or steam-based extraction systems or to monitor the flow of large scale sanitary systems. These sight glasses come in either 10, 20, or 30" lengths and the customer has the choice of choosing a Buna-N or Silicone gasket through dropdowns. (Sight Glass Comes Standard with Buna-N.) Specifications Material 304 Stainless Steel / Borosilicate / Nitrile OR Silicone Connection Type 6" Tri-Clamp Length 10" , 20", or 30" Pressure Rating 50 PSI

$610.44 - $985.03

-

Stainless Steel Hang-On Bracket for BVV™ Extraction Racks

Stainless Steel Hang-On Bracket for BVV™ Extraction Racks This heavy duty Stainless steel Hang-On bracket is designed for easy removal of material columns. They are made out of 1/4" thick stainless steel and can fit on either a 1.5" extraction rack bar if needed and include (2) Flathead Hex screws and Nylon lock nuts. (8020 bolts are sold separately.)

$34.68

-

150L 304SS Jacketed Collection and Storage Vessel with 12" Tri-Clamp Port and Locking Casters

150L 304SS Jacketed Collection and Storage Vessel with 12" Tri-Clamp/ Tri Clover Port and Locking Casters This massive 304 Stainless Steel Jacketed vessel can hold up to 150L of water (~40 gallons) and has a 12" Tri-Clamp port on the top and a 6" Tri-Clamp port on the bottom of the vessel. The outer jacket has 2x 1/2" FNPT ports to allow the circulation of heat transfer fluids and can also be used a vacuum jacket and can hold 21.5L or 5.68 gallons of fluid in the outer jacket. This unit also features 4 stainless steel legs with locking casters to allow the vessel to be moved around easily. (Note: this unit comes bare and does not include any fittings besides the legs with casters. Specifications Material 304 Stainless Steel Pressure Rating 150 PSI MAX Connection Type(s): 12" Tri-Clamp Top Port 6" Tri-Clamp Bottom Port (2) 1/2" FNPT Ports on the Jacket ***Note: This item will ship via freight ONLY.

$3,468.41

-

Pro Series Oil Mist Filter Replacement Cartridge

BVV™ Pro Series Oil Mist Filter Replacement Cartridge This is a replacement oil filter cartridge for the BVV™ Pro Series line of vacuum pumps. It is easily swapped out by taking off the oil mist canister from the pump and removing the clamp. The cartridges are sizes for our 5.6CFM, 11.3, and 21.2CFM pro series vacuum pumps. They prevent oil mist vapors from escaping the vacuum pump creating a cleaner air environment during operation.

$166.48 - $221.98

-

Best Value Vacs 10 Gallon Aluminum Side Mount Vacuum Chamber

Best Value Vacs 10 Gallon Aluminum Side Mount Vacuum Chamber (Comes with 2 Year Limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 15" Tall x 14" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BVV Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. GlassVac chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$432.86

-

2L Premium Short Path Distillation Turnkey Setup with P2 Distillation Head

2L Premium Short Path Distillation Turnkey Setup with P2 Distillation Head The 2L Premium Distillation Turnkey Setup features our 2L Distillation Kit with P2 Distillation Head and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included is our Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump giving you extreme power and depth with long lifespan, the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market, and a Polyscience 7L MX Heated Circulator for maximum condensation of vapors. You will also receive a Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The Premium Turnkey Kit Includes: 2L Distillation Kit w/ P2 Distillation Head KF-25 x 1/4" Barb Adapter Dewar Style Glass Cold Trap Bullseye precision Vacuum Gauge Polyscience 7L MX Heated Circulator Pro Series 14.1CFM Corrosion Resistant Two Stage Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once the process is complete, stop heat, stop stir, and stop vacuum. Let the atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$8,324.18 - $10,613.33

-

2L Standard Short Path Distillation Turnkey Setup

2L Standard Short Path Distillation Turnkey Setup The Standard Distillation Turnkey Setup includes all the components necessary to successfully perform distillation at an entry-level price point. Crossbar pictured is not included. We recommend purchasing multiple lab stands to accommodate your specific needs. The Standard Turnkey Setup Includes: 2L Distillation Kit 1/4" Flare x 1/4" Barb Adapter BVV™ 5L Heated Circulator BVV™ V9D 9CFM Two Stage Vacuum Pump High quality and durable Borosilicate 3.3 glass Vacuum-jacketed distillation adapter 3-way cow adapter, accommodating up to 3 pcs of 500mL flasks GCT-01 cold trap guarding from damage of vapors Kangaroo Traceable Digital Thermometer Flexible Gum Rubber Vacuum Tubing and Silicone Tubing for Flow Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. The pump should be run against the dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once the process is complete, stop heat, stop stir, and stop vacuum. Let the atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$3,607.14

-

2L Short Path Distillation Kit with P2 Distillation Head

2L Short Path Distillation Kit with P2 Distillation Head The 2L Distillation Kit w/ P2 Distillation Head includes everything needed to perform distillation excluding the vacuum pump and chiller. This kit features our USA made P2 Distillation Head as well as USA made glass. It is designed with ease of use in mind and includes the highest quality components to ensure results are repeatable time and again. **This Kit Does NOT include a vacuum pump or circulator. Please see the below recommendations for both as well as recommended add-ons. Or check out our 2L Premium Turnkey Setup which includes vacuum pump and circulator.** Crossbar pictured is not included. We recommend purchasing multiple lab stands to accomodate your specific needs. Recommended Vacuum Pumps: Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (USA made economy option) Welch 1400 DuoSeal 0.9 cfm 0.1 Micron Belt Drive Dual-Stage Pump Recommended Circulators: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter MX Refrigerated Circulator (premium option with chilling capability) Recommended Add-Ons: Glass Dewar Style Cold Trap (recommended cold trap) Bullseye Precison Vacuum Gauge (premium vacuum gauge for measuring depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) J-KEM Digital Vapor Temp Monitor (digital vapor temp monitor with data-logging capabilities) Specifications: Boiling Flask Size: 2L Receveiving Flask Size: 250mL Batch Capacity approximate: 2L = 400-1000 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Includes: Glass components: 2L USA Made 2-Neck Boiling Flask P2 USA Made Distillation Head Triple Neck Cow 3x 250mL Receiving Flask 2x 24/40 Chemglass Thermometer Inlet Adapter 120mm Glass Funnel Accessories: Magnetic PTFE Stirring Bar Retriever 5 Pack of Metal Keck Clips Dow Corning High Vacuum Silicone Grease Tripod Stand 2L Digital Heating and Stirring Mantle 3 Finger Clamp Adjustable 0-70mm 6" x 6" Scissor Jack 250-500ml Cork Stand 10ft of Vacuum Hose 10ft of Chiller Hose 1/4" Vacuum Manifold Traceable Kangaroo Thermometer - Digital 10 Pack of Adjustable Stainless Steel Tubing Clamps Fiberglass Insulation Rope 10 Feet 1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen w/ 2x 1/4" Barb Adapters Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$3,052.20

-

1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen

1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen (Comes with 2 Year Limited warranty) This is a complete cold trap and will come assembled for instant use. This cold trap is made of 304SS MADE IN USA, utilizing Polycarbonate lids for durability, flexibility and chemical resistance to Ethanol and Isopropyl (not compatible with Acetone). This system is recommended to protect pump from condensable vapors. This trap comes with an industrial grade, heat cured silicone gasket designed only for our systems. There is nothing of equal quality in the market. The gasket itself is reversible (doubling the life of our system guaranteed) allowing customers to instantly take it off and flip it over. No adhesives are used! The system will maintain a vacuum seal only under vacuum. The vacuum pump will hold the interior 2 quart container for your dry ice slurry in compression with the larger outer lid. The larger outer lid will be held in compression with 1.5 gallon outer container. The connections on both sides are 1/4" MJIC flares or 1/4" Barbs that will connect to 1/4" HVAC or FJIC stainless steel hose. The center slurry container has a lid - this lid simply helps prevent evaporation of your slurry. Temperature rated for -100-160F This cold trap comes assembled and includes: (1) 1.5gl high strength stainless steel outer container (made of solid 304 stainless made in USA) (1) 2q interior slurry container (made of solid 304 stainless made in USA) (2) 1/2" thick clear polycarbonate lids (2) industrial grade silicone gasket (1) 1/4" HVAC hose 5' Can withstand max working temps of 392F gasket only 60A durometer density (1) max vacuum -29.5inHg (+/-.5Hg) (2) 1/4" MJIC or Barb Fittings Outside container internal dimensions: 7.25" diameter X 8.25" tall To help remove condensable vapors, or when liquid nitrogen traps are not practical, our cold trap is the best option for preventing vapors from getting into your vacuum pump and contaminating it. This 1.5 gallon trap uses polycarbonate lids for durability, flexibility, and chemical resistance. The system doesn’t use adhesives, and comes standard with a reversible gasket for enhanced quality that doubles its life. Made in the USA, the BVV™ Cold Trap comes with all parts pre-assembled, so you can get to work straight out of the box. Inside container internal dimension: 4.75" diameter by 6.5" tall

$353.78

-

2L Short Path Distillation Kit

Short Path Distillation Setup Short path distillation is used for compounds that are not stable at high temperatures. It can also be used to purify small amounts of a compound. For those new to this type of distillation, our Short Path Kit includes everything you will need as you get started. All stands, clamps, clips, and tubing are included, which means it’s ready to start working straight out of the box. The cold trap, cow and vacuum grease can all be customized to meet your needs. The 2L Distillation Kit builds upon the same principal as the 1L Distillation Kit, giving users an easy to use system that will get them up and running at an affordable price. It includes all stands, clamps, clips, and tubing needed to begin distilling immediately. This Kit Does NOT include a vacuum pump or circulator. Please see the below recommendations for both as well as recommended add-ons. Or check out our 2L Standard Distillation Turnkey Setup which includes vacuum pump and circulator. Crossbar pictured is not included. We recommend purchasing multiple lab stands to accommodate your specific needs. Recommended Vacuum Pumps: Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (economy option) Best Value Vacs VE280 9CFM Two Stage Vacuum Pump (economy option) Recommended Circulators: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter MX Refrigerated Circulator (premium option with chilling capability) Recommended Add-Ons: Glass Dewar Style Cold Trap (recommended cold trap) Bullseye Precison Vacuum Gauge (premium vacuum gauge for measuring depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) Short Path Distillation Kit Specifications: Boiling Flask Size: 2L Recieving Flask Size: 250ml Batch Capacity approximate: 2L = 400-1000 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Comes Standard With The Following: Glass Components: 2L 2-Neck Boiling Flask Short Path Head Triple Neck Cow 3x 250mL Single Neck Receiving Flask 1/8" 14/20 PTFE Thermometer Adapter 1/4" 24/40 PTFE Thermometer Adapter 120mm Glass Funnel Accessories: Magnetic PTFE Stirring Bar Retriever 5 Pack of Metal Keck Clips Dow Corning High Vacuum Silicone Grease Tripod Stand 2L Digital Heating and Stirring Mantle 3 Finger Clamp Adjustable 0-70mm 6" x 6" Scissor Jack 250-500ml Cork Stand 10ft of Vacuum Hose 10ft of Chiller Hose 1/4" Vacuum Manifold Traceable Kangaroo Thermometer - Digital 10 Pack of Adjustable Stainless Steel Tubing Clamps Fiberglass Insulation Rope 10 Feet 1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen w/ 2x 1/4" Barb Adapters Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. Learn more about short path distillation components and FAQs with this distillation guide. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$1,768.89

-

5L Premium Short Path Distillation Turnkey Setup

5L Premium Distillation Kit This unit carries a 2 day lead time. The 5L Premium Short Path Distillation Turnkey Setup features our 5L Distillation Kit with P5 Distillation Head and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included is our Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump giving you extreme power and depth with a long lifespan, the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market, and a BVV 19L Heated Circulator for maximum condensation of vapors. You will also receive a Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The Premium Short Path Distillation Turnkey Kit Includes: 5L Distillation Kit with P5 Distillation Head KF-25 x 1/4" Barb Adapter Dewar Style Glass Cold Trap Bullseye Precision Vacuum Gauge Polyscience 7L MX Heated Circulator Pro Series 14.1CFM Corrosion Resistant Two Stage Vacuum Pump Short Path Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once the process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$7,630.50

-

5L Short Path Distillation Kit with P5 Distillation Head

5L Short Path Distillation Kit with P5 Distillation Head This unit carries a 2 day lead time. The 5L Distillation Kit includes everything needed to perform distillation excluding the vacuum pump and chiller. This kit features our USA made P5 Distillation Head, as well as USA, made glass. This Kit is designed for high volume production with the highest quality components for precise, repeatable results time and again. This Kit Does NOT include a vacuum pump or chiller. Please see the below recommendations for both as well as recommended add-ons. Recommended Vacuum Pumps: Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (economy option) Recommended Chillers: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter Refrigerated Circulator (premium option with chilling capability) Recommended Add-Ons: Bullseye Precision Vacuum Gauge (premium vacuum gauge for measuing depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) J-KEM Digital Vapor Temp Monitor (digital vapor temp monitor with data-logging capabilites) Specifications: Boiling Flask Size: 5L Receiving Flask Size: 2x 500mL, 1000mL Batch Capacity approximate: 1000-2500 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Includes: Glass components: 5L Boiling Flask P5V6 Distillation Head Triple Neck Cow 2x 500mL Receiving Flask 1L Receiving Flask 120mm Glass Funnel Dewar cold trap Accessories: PTFE Magnetic Stir Bar Retriever 5 Pack of Metal Keck Clips Dow Corning High Vacuum Silicone Grease Tripod Stand 5L Digital Heating and Stirring Mantle 3-Finger Adjustable Clamp 0-77mm 6" x 6" Scissor Jack 500-1000mL Cork Stand 2x 24/40 ChemglassPTFE Thermometer Inlet Adapter 10ft of Gum Rubber Vacuum Hose 10ft of Silicone Chiller Hose 1/4" Vacuum Manifold Traceable Kangaroo Thermometer - Digital 10 Pack of Adjustable Stainless Steel Tubing Clamps Fiberglass Insulation Rope 10 Feet Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$3,052.20

-

Homogenizer Drive Motor

BVV™130 Homogenizer Drive Motor The BVV™130 Homogenizer can quickly emulsify, homogenize, and disperse from 0.1 to 250ml solid media or liquid media depending on the dispersing probe style/head length. During operation, the suspended material is drawn into the core of the homogenizer by a rotor turning at up to 30,000rpm. The media is repeatedly cycled through the narrow slits of the probe where it becomes rapidly torn, separated and emulsified. The BVV™130 produces very little heat during operation and has a 6-speed control dial and is easily held in the hand during operation of the unit. WT130 Homogenizer Drive Motor Key Features: 8,000-30,000 RPM Range 6 Speed easily adjustable control dial One-handed operation Specifications Speed Control / Range 6 Position Dial / 8,000 - 30,000 RPM Power Consumption 130w Voltage 110v @ 60Hz Noise Level 54 dB(A) @ 30,000 RPM BVV™130 Homogenizer Drive Motor 850103019999 compare to SCILOGEX D160 Drive Motor 850103019999

$180.36 $110.99

-

Apiezon Apiezon N Cryogenic Vacuum Grease

Apiezon N Cryogenic Vacuum Grease Apiezon N Grease is silicone-free and widely recognized and recommended as the cryogenic vacuum grease of choice. This cryogenic grease is specially formulated to exhibit craze-free performance characteristics at low temperatures and withstand frequent cycling between cryogenic temperatures as low as -273°C and +30°C. Safety Data Sheet Thermal Conductance Sheet Technical Data Sheet Apiezon N Grease: Cryogenic High Vacuum Grease Properties Apiezon N Grease is a silicone- and halogen-free cryogenic high vacuum grease which: can withstand frequent cycling between cryogenic temperatures as low as -273°C and +30°C is craze-free at cryogenic temperatures has the ability to fill the micropores of adjoining surfaces, so improve thermal contact does not suffer from contamination problems associated with silicone based greases such as 'creep' or 'carry over' exhibits a vapour pressure of 6 x 10-10 Torr at 20°C has powerful 'gettering' action, meaning it absorbs potentially harmful grease and chemical impurities on metal and glass surfaces is easy to clean, use and remove as it is soluble in hydrocarbon solvents Please click the links for typical properties and vapour pressure graphs of Apiezon N Grease. Cryogenic Applications of Apiezon N Grease Cryogenic Vacuum Seal Apiezon N Grease exhibits extremely low vapour pressures at ambient temperatures, 6 x 10-10 torr at 20°C, which are further improved by reductions in temperature to the cryogenic region. Its ability to resist cracking at extremely low temperatures makes it particularly useful as a vacuum seal for cryosystems. Apiezon N Grease can be relied upon to form and maintain a vacuum seal for long periods, even when subjected to frequent thermal cycling, withstanding cycling between temperatures as extreme as -273°C and +30°C. Its unique properties mean N Grease is widely used to create a reliable vacuum and pressure-tight seals in, amongst others: vacuum lines; Schlenk lines; cold traps; liquid helium hoses and electron microscopes. Thermal Coupling Apiezon N Grease has a proven track record in improving thermal contact under cryogenic conditions. This is important for the coupling of cooling systems to superconducting magnets, cryostats, temperature sensors or any system that is required to reach cryogenic temperatures as quickly as possible. Low levels of magnetic susceptibility also make it ideal for superconductor manufacturing applications. Sensor Mounting Apiezon N Grease is ideal for use in cryogenic sensor mounting. It is pliable at room temperature and solidifies at cryogenic temperatures to allow for easy mounting and removal of sensors without causing damage. Sample Mounting Important in low-temperature testing of semiconductor chips, laser diodes and crystals, etc., Apiezon N Grease is used to improve thermal contact between the sample boat and cold finger of a cryotstat. This cryogenic thermal contact grease ensures that samples are at the lowest possible temperatures to improve test sensitivities. Ambient Temperature Applications - Added Cushioning Apiezon N Grease can be used in a variety of applications at ambient temperatures such as when added cushioning is required. N Grease has a special additive which gives it a tenacious, rubbery consistency which absorbs vibrations in equipment, making N Grease invaluable in fragile glass to glass joints, like burette taps, which continually risk fracture.

$367.65

-

Apiezon Apiezon H High Temperature Vacuum Grease

Apiezon H High Temperature Vacuum Grease 25g Apiezon H Grease is a silicone-free high vacuum grease perfectly suited for use at high temperatures in both scientific and industrial applications. H Grease has exceptional 'stiction' and thermal conduction properties and has gained prestigious approvals from a variety of international organizations, including BAE Systems, the European Space Agency and NASA. Safety Data Sheet Technical Data Sheet Apiezon H Grease: High Temperature Vacuum Grease Properties Apiezon H Grease is a silicone-free high temperature vacuum grease which: performs well under a wide range of temperatures, from -10 to +240°C, and retains its optimum consistency at temperatures between +10 and +110°C rather than melting, actually becomes stiffer as temperature increases and therefore is not recommended for highly stressed bearings has excellent heat transfer properties conducts heat away from the site of operation, reducing the danger of overheating and damaging heat-sensitive components exhibits good 'stiction' or sticking power has powerful 'gettering' action, meaning it absorbs potentially harmful grease and chemical impurities on metal and glass surfaces is easy to clean and remove as it is soluble in hydrocarbon solvents exhibits a vapor pressure of 1.7 x 10-9 Torr at 20°C Please click the links for typical properties and vapour pressure graphs of Apiezon H Grease. Applications of Apiezon H Grease As a high temperature, low to medium vacuum grease with excellent 'stiction' power and good thermal conduction properties Apiezon H Grease is used for many diverse applications. In particular H Grease is commonly used in scientific and industrial high temperature sealing applications.Thanks to its 'stiction' power Apiezon H Grease is ideal for use with laboratory glassware; it is also favoured by the electronics and space industries where its high thermal conductivity makes it the perfect vacuum grease in situations where heat sink media requires adhesion.Apiezon H grease has been approved by NASA as a material suitable for lubricating the gold-plated threads of small variable capacitors required to operate under high vacuum from -65°C to +125°C to prevent galling.

$367.65

-

Apiezon Apiezon PFPE 501 High Temperature Vacuum Grease

Apiezon PFPE 501 High Temperature Vacuum Grease 100g We are pleased to announce that there is a new addition to the Apiezon range of high vacuum greases. Delivering the quality and reliability synonymous with the Apiezon brand, PFPE 501 is the perfect addition to our range. PFPE 501 is a chemically inert, high temperature and extreme pressure lubricant. With an upper operating temperature of 250°C and vapor pressure of 1.3 x 10-12 at 25°C, it is robust, versatile and can be used for sealing and lubricating under the most extreme operating conditions. This includes environments where aggressive chemicals and strong oxidizing agents are regularly used. As most Apiezon users are more familiar with hydrocarbon chemistry we’d like to provide some background on what PFPE is, and how its molecular structure can explain its physical properties. This information can be found in What is PFPE? Safety Data Sheet Technical Data Sheet Why Use Apiezon PFPE 501 Grease? PFPE based High temperature lubricant Used in oxygen-rich environments Ultra high vacuum Chemically inert Extreme pressure Wide temperature range Benefits of Apiezon PFPE 501 Grease? Extended equipment life High temperature lubricant Reduced equipment downtime Lower service costs Life-time lubrication 10 year shelf life Guaranteed Apiezon quality Expert technical support

$430.08

-

DigiVac Digivac Vapor Pressure Controller

Digivac Vapor Pressure Controller The DigiVac Vapor Pressure Controller is a high-end lab-grade instrument that will allow you to determine set points and maintain vacuum at that specified level. The Vapor Pressure Controller is extremely useful when trying to maintain pressure at a certain level, for example, when trying to control the vacuum level as botanical oils are processed for use in the medical industry. Key Features: USB Communication Maintain Specific Vacuum Levels 3/8" Barbed Hose Connections Digital Readout Compact Design Lab Stand Bulkhead Specifications Sensor Type Sen-775i-NPT-OEM Accuracy +/- 2 Torr Units Torr, mbar Total Range 1 – 775 Torr The Vapor Pressure Controller is DigiVac’s newest product release. This instrument has the ability to help those working in the botanical market easily process plant material through automated distillations. It both measures and maintains the pressure within rotovaps, or any type of vacuum system, following the profile created on the Vapor Pressure Profile Manager - a free, downloadable software that comes with the purchase of a VPC. The front of the gauge is similar in terms of being straightforward. It has displays of both your current vacuum and chosen setpoint, as well as a numerical up/down control, regulation button, and power switch. Just hook your vacuum pump to one side, the rotovap to the other side and plug it in. If you’d like specific ramp rates and time duration, then install the free software, hook up the USB to connect the unit to the computer hosting the software and you can set up your process profile. The vacuum system is what you are going to regulate, an example being your rotovap, vessel, flask or vacuum oven. Once the unit is set up and regulating, the process can also be observed within the software, thus telling you how your system and pump are performing. Resources: DigiVac VPC Blog DigiVac Vapor Pressure Controller Data Sheet DigiVac Vapor Pressure Controller Quick Start Guide

$3,052.20

-

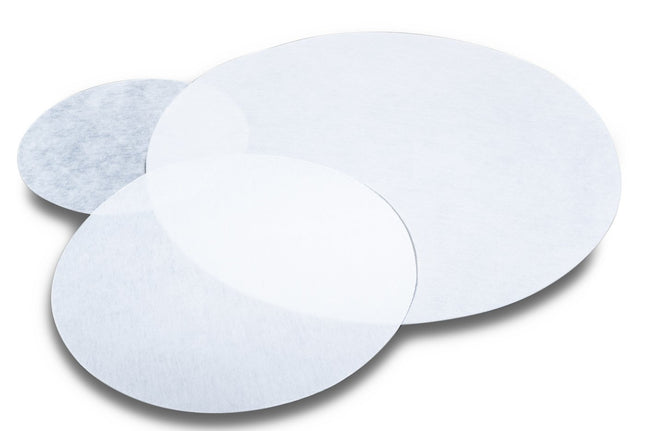

Solvent Pro Injection Valve

Solvent Pro Injection Valve Replacement Injection Valve for Solvent Pro series rotary evaporators with an 18mm ID and 35mm OD flange and a PTFE thread valve with Viton O-ring to provide a leak-proof precision vacuum seal. This valve also has a 3/8" barbed connection with a stem to allow for a PTFE tubing (not included) to inject directly into the rotary flask.

$117.93

-

Solvent Pro 18/35 Collection Flask Valve

Solvent Pro 18/35 Collection Flask Valve This is a replacement collection flask valve for Solvent Pro series rotary evaporators. It features a PTFE threaded valve with Viton O-rings for a precision leak-proof vacuum seal. The flange has an ID of 18mm and an OD of 35mm with a 3/8" hose barb for 3/8" ID hoses.

$83.24

-

Closed Loop Recovery Kit

Closed Loop Recovery Kit This closed loop upgrade kit provides all of the essential ancillary equipment to upgrade an extraction system but does not include an active recovery pump (sold separately). An actively run closed loop extractor will increase productivity by reducing recovery time and overall run time of the system by forcing vapors through a solvent recovery pump. This Kit Includes the Following BVV Large Condensing Coil 1/4" x 24" SS JIC Braided Hose (3) 1/4" x 48" SS JIC Braided Hose 1/4" x 60" SS JIC Braided Hose Molecular Sieve Filter Drier BVV™ 5' HVAC Hose Milwaukee Vacuum Tee Note: This kit DOES NOT include a recovery pump and must be purchased separately.

$825.48 - $1,533.04

-

Glycerin Filled Compound Gauge with 1/4" NPT Back Mount - (-30)-0-250 PSI.

Glycerin Filled Compound Gauge with 1/4" NPT Back Mount BVV™ Glycerin filled compound gauge has a 1/4" MNPT stainless steel connection with a readout of (-30) -250 PSI. BVV™ Compound Gauge - TDS

$41.62

-

Milwaukee Valve Milwaukee Valve 316SS FNPT Ball Valve

Milwaukee Valve 316SS FNPT Ball Valve (10SSOD-02-LL) This top of the line 316 Stainless Steel Milwaukee ball valve is a fire safe ball valve and is 1 piece ball valve construction. It also features a straight body style with Female NPT x Female NPT threaded connections with one side being pinned into place for zero movement during installation. The fire safe ball valve features a maximum pressure rating of 2000 PSI CWP and has a blowout proof stem made of 316SS and the temperature range of this ball valve is -20F° to 450F°. Milwaukee 10 Series Ball Valve Spec Sheet Valve Specifications Sizes Available: 1/4" FNPT 3/8" FNPT 1/2" FNPT Pressure Rating 2000 WOG Temperature Range -20°F to 450°F Valve Materials: Body A351-CF8M Ball Retainer A351-CF8M Ball 316 Stainless Steel Stem 316 Stainless Steel Seat 304 Stainless Steel Thrust Washer 316 Stainless Steel Seat RTFE Thrust Washer RTFE Stem Packing GRAPHOIL Gland 316 Stainless Steel Handle 304 Stainless Steel Handle Nut 304 Stainless Steel Handle Nut 304 Stainless Steel Belleville Washer 304 Stainless Steel PIN 304 Stainless Steel

$62.43 - $69.37

-

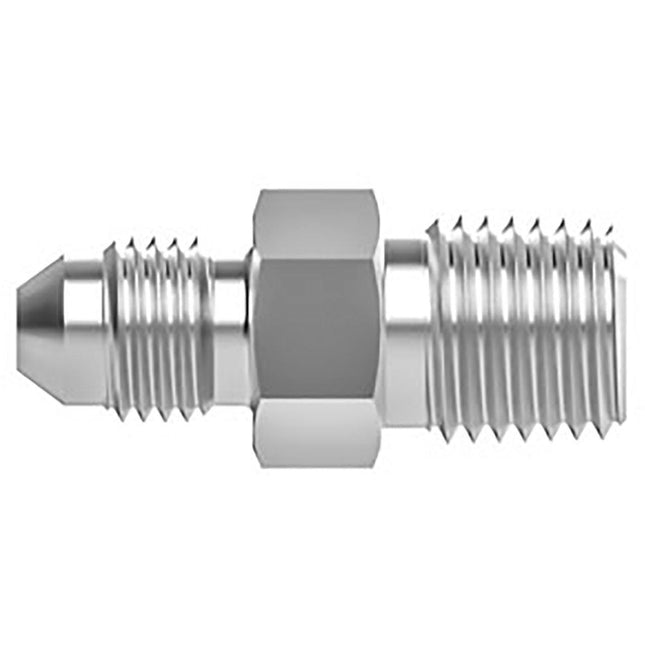

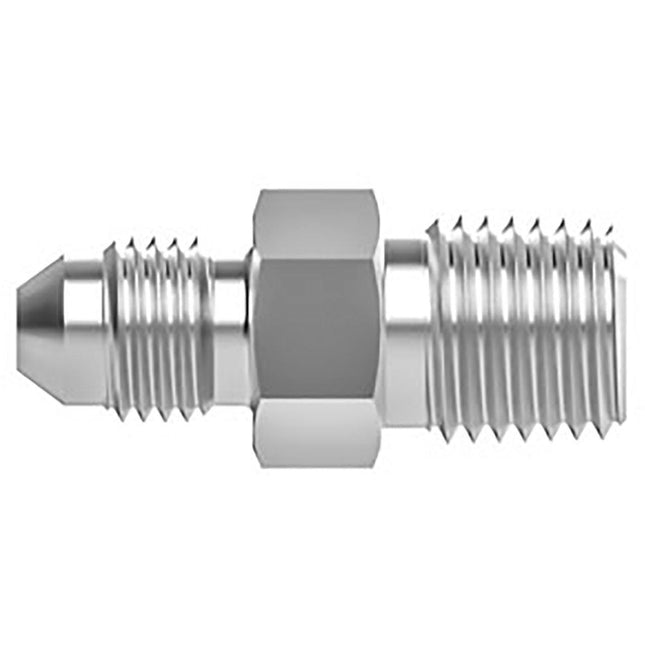

SSP Corporation 37° AN x Male Adapter

SSP - 37° AN x Male Adapter SSP Instrumentation TruFit® is manufactured from fully-traceable raw material to close tolerances and superior surface finishes. TruFit® provides optimal performance when installed in accordance with SSP’s recommendations and the design parameters appropriate for each type of connection – tapered thread, straight thread, and weld & braze. TruFit® components are cleaned in accordance with SSP documented work instructions using equipment calibrated to NIST standards with environmentally-safe and stable agents, ultrasonics, and heat/ temperature to remove all residual oil, grease, and loose particles. Stainless steel components are passivated to the requirements of MIL QQ-P-35 and ASTM A 967. ***Note: ALL NPT Threads REQUIRE the user to properly install the fitting by using a thread sealant to prevent leaks. Best Value Vacs recommends GAS PTFE Tape Specifications Connection Type 1 37° AN Male Connection Size 1 Specified by User Connection Type 2 Male NPT Connection Size 2 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Working Pressure (PSIG) 1/4" - 6000 3/8" - 6000 NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$8.32 - $20.81

-

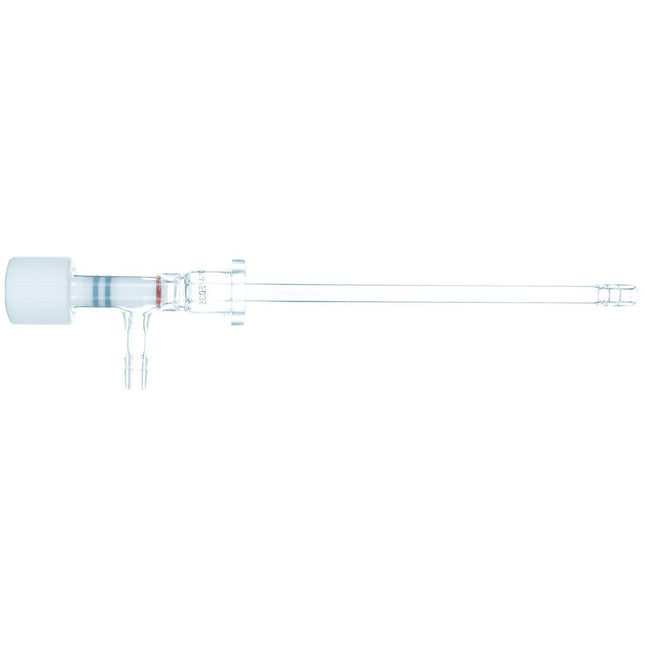

Replacement Trap for CT40 and CT80 Cold Traps

Replacement Trap for CT40 and CT80 Cold Traps This is a replacement glass trap for the SH Scientific CT40 and CT80 model cold traps. The trap fits in the lid of the cold traps and is suspended in the chilling fluid. Specifications: 3/8" Hose Barb Connection 34/45 Joint 2" Diameter x 10" Height Material: Boro 3.3 *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$270.54

-

Scilogex Scilogex DS-160 Homogenizer Probe

Scilogex DS-160 Homogenizer Probe (Probe ONLY - Motor NOT Included) This is the Scilogex DS-160 Homogenizer probe with either a 5mm diameter or 10mm diameter probe and will attach to the D160 drive motor. Each probe is can handle solid/liquid media - please refer to the chart below for additional specifications. Slot Type Specifications: Probe Type Specifications Model # Diameter x Length Media Type Volume DS-160/5 5mm x 50mm immerse length Solid/Liquid 0.1-50ml DS-160/10 10mm x 115mm immerse length Solid/Liquid 1-250ml

$489.74 - $708.94

-

Scilogex Scilogex DS-500 Homogenizer Probe

Scilogex DS-500 Homogenizer Probe (Probe ONLY - Motor NOT Included) This is the Scilogex DS-500 Homogenizer probe with either coarse teeth for solid/liquid media or fine slot teeth for Water in Oil/Oil in Water emulsions both probes are good for volumes from 10-5000ml and will attach to the D500 drive motor. Each probe is 20mm in diameter and has a 215mm immerse length with flat head-open slots. DS-500/5 generator 5mm dia. generator, flat head-open slot, 60mm immerse length for solid/liquid media, volumes 1-50ml Slot Type Specifications: Probe Slot Type Specifications Model # Slot Type Media Type DS-500/1 Flat Head-Open COARSE Solid/Liquid DS-500/2 Flat Head-Open FINE Water in Oil/Oil in Water Emulsions DS-500/5 Flat Head-Open slot Solid/Liquid medium,

$1,115.44 - $1,281.92

-

Solvent Pro Series 40/60 Clamp and Gasket Set

Solvent Pro Series 40/60 Clamp and Gasket Set This is a replacement Clamp and Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This Clamp and Gasket fit an 40mm(1.57") Inner Diameter and 60mm(2.36") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$48.56

-

Solvent Pro Series 60/80 Gasket

Solvent Pro Series 60/80 Gasket This is a replacement Gasket for 10, 30, and 50L Solvent Pro Rotary Evaporators. This gasket fits an 60mm(2.36") Inner Diameter and 80mm(3.15") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$29.13

-

Solvent Pro Series 40/60 Gasket

Solvent Pro Series 40/60 Gasket This is a replacement Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This gasket fits an 40mm(1.57") Inner Diameter and 60mm(2.36") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$27.75

-

Solvent Pro Series 18/35 Gasket

Solvent Pro Series 18/35 Gasket This is a replacement Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This gasket fits an 18mm(0.71") Inner Diameter and 35mm(1.38") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$18.04

-

Solvent Pro Series 40/60 Clamp

Solvent Pro Series 40/60 Clamp This is a replacement clamp for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This clamp fits an 40mm(1.57") Inner Diameter and 60mm(2.36") Outer Diameter joint.

$20.81

-

Solvent Pro Series 18/35 Clamp

Solvent Pro Series 18/35 Clamp This is a replacement clamp for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This clamp fits an 18mm(0.71") Inner Diameter and 35mm(1.38") Outer Diameter joint.

$20.81

-

2L Electric Evaporating Flask Adapter

2L Electric Evaporating Flask Adapter This replacement part is for the 2L Electric Lift Rotary evaporator and connects the evaporating flask to the motor interface. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$131.80

-

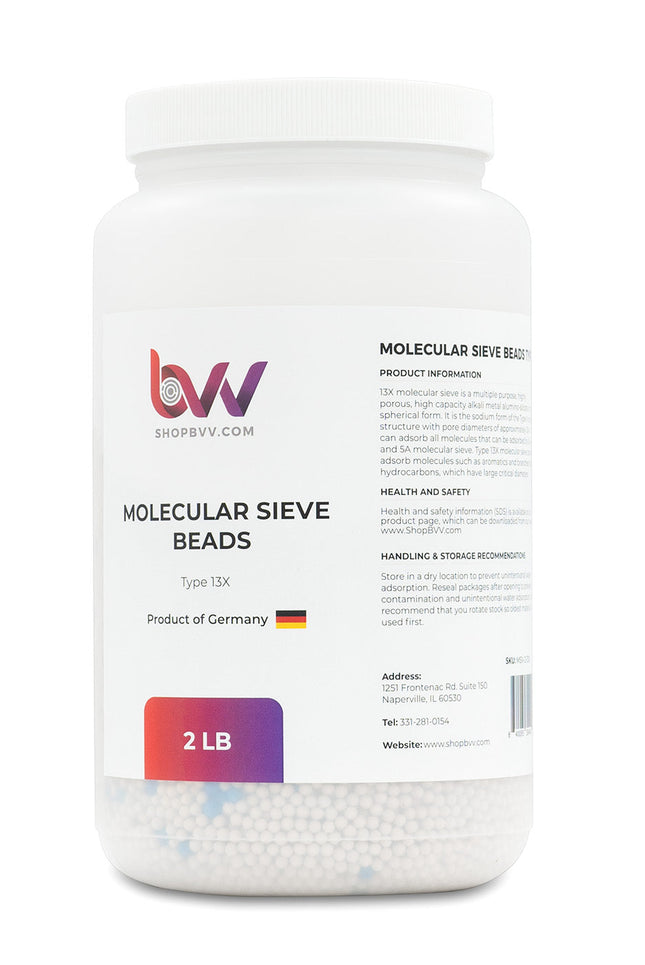

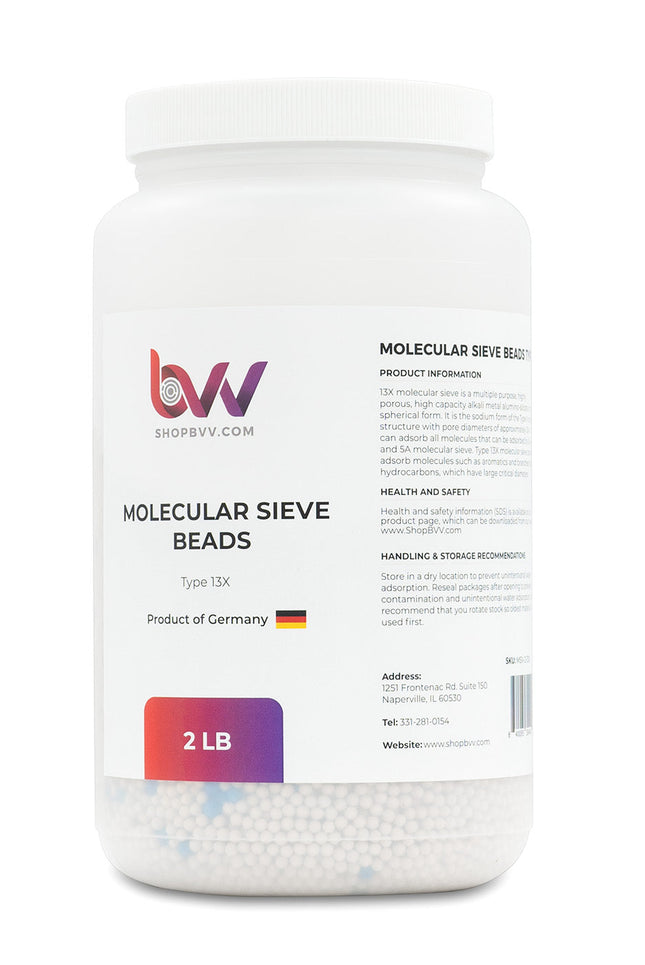

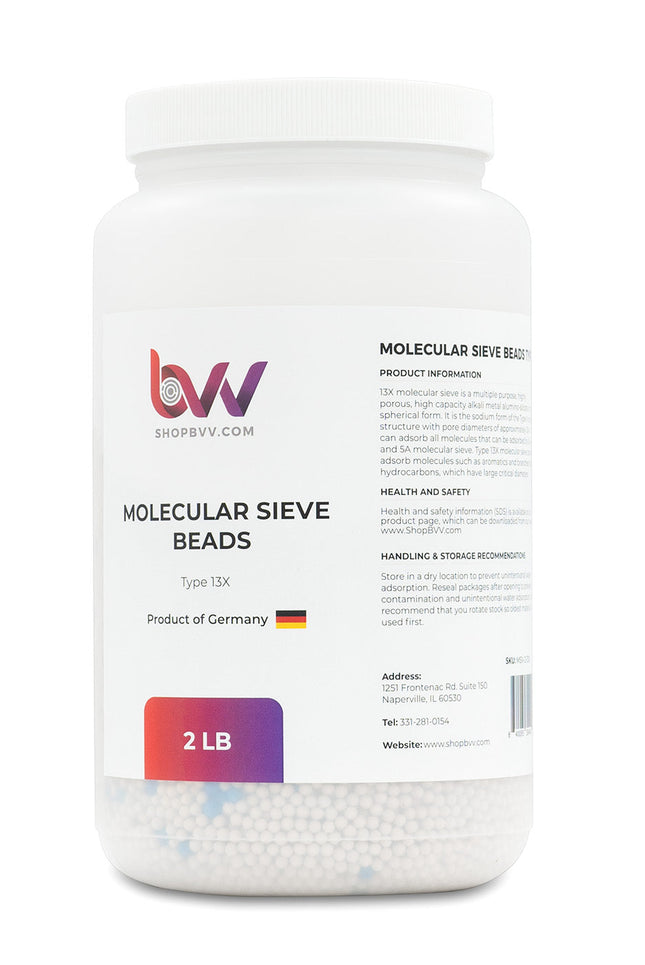

Molecular Sieve Beads Type 13X (10A)

Molecular Sieve Beads Type 13X 13X molecular sieve is a multiple purpose, highly porous, high capacity alkali metal alumino-silicate in the spherical form. It is the sodium form of the Type X crystal structure with pore diameters of approximately 10A. It can adsorb all molecules that can be adsorbed by 3A, 4A, and 5A molecular sieve. Type 13X molecular sieve can also adsorb molecules such as aromatics and branched-chain hydrocarbons, which have large critical diameters. Handling & Storage Recommendations: Store in a dry location to prevent unintentional water adsorption. Reseal packages after opening to prevent contamination and unintentional water adsorption. We recommend that you rotate stock so oldest material is used first. Please read the safety data sheet to ensure proper handling and always wear personal protection equipment when handling molecular sieve. Product Data and Safety Information: Molecular Sieve 13X Technical Data Sheet Molecular Sieve 13X Safety Data Sheet Note: 20lb size comes as set of 2x 10lb containers.

$34.68 - $1,942.31

-

2 Neck Offset Round Heavy Wall Bottom Flask - USA Made