New Products

-

ChemTek ChemTek Medium Fuge Bags - 50 Pack

ChemTek Medium Fuge Bags - 50 Pack Centrifuge bags used for separations Specifications: Size: 50-Pack Dimensions:H: 7” W: 5” Micron Size: 25 Micron Material: Food Grade Nylon

$41.65

-

ChemTek ChemTek Small Fuge Bags - 50 Pack

ChemTek Small Fuge Bags - 50 Pack Centrifuge bags used for separations. Specifications: Size: 50-Pack Dimensions: H: 4” W: 2.5” Micron Size: 25 Microns Material: Food Grade Nylon

$38.87

-

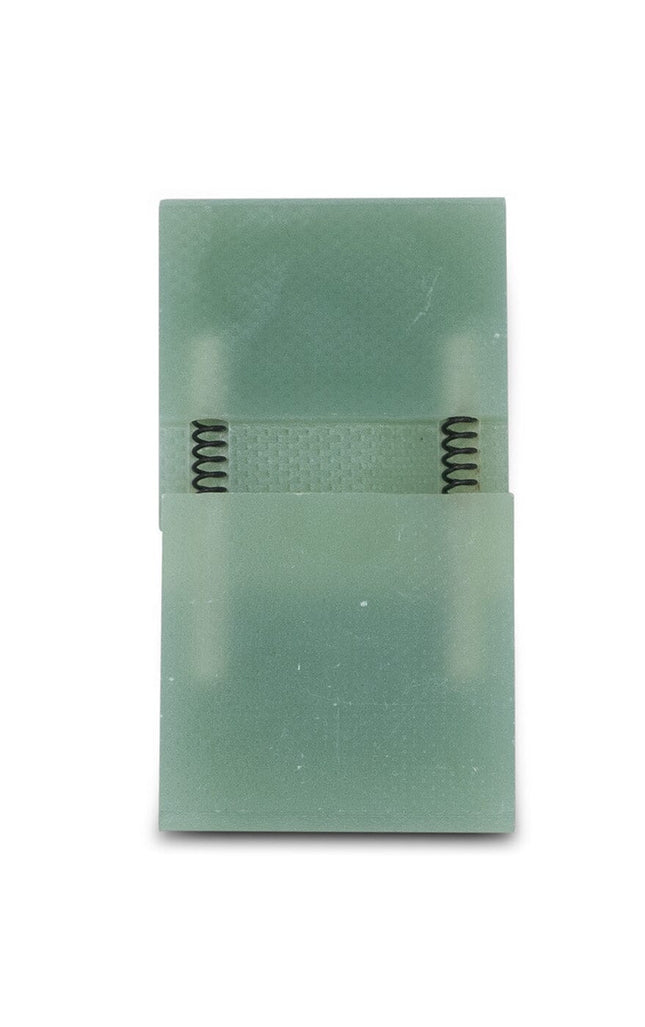

ChemTek ChemTek Wide Mouth Fuge Basket Small - 4 Pack

ChemTek Wide Mouth Fuge Basket - 4 Pack Used for separating oils from solids. Different micron options are available. Specifications: 25 Micron 304 Stainless Steel H: 2.5” W: 3.25”

$69.41

-

ChemTek ChemTek Wide Mouth Basket Support - Large

ChemTek Wide Mouth Basket Support Support for the stainless micron mesh baskets.

$138.82 - $485.87

-

ChemTek ChemTek Wide Mouth Stainless Jar

ChemTek Wide Mouth Stainless Jar Triple-walled vacuum-insulated stainless steel jar for centrifuging. Material: 304 Stainless SteelHeight: 5.3”Width: 2.6” Capacity: 12oz

$37.48

-

ChemTek ChemTek Regular Mouth Fuse Basket - 4 Pack

ChemTek Regular Mouth Fuge Basket - 4 Pack Used for separating oils from solids. Different micron options are available. Specifications: 304 Stainless Steel H: 3.5” W: 2.5”

$69.41

-

ChemTek ChemTek Regular Mouth Basket Support

ChemTek Regular Mouth Basket Support Made for supporting the centrifuge baskets to allow for higher RCF. Specifications: 304 Stainless Steel

$69.41 - $256.82

-

ChemTek ChemTek Regular Mouth Stainless Jar

ChemTek Regular Mouth Stainless Jar Our stainless jar is designed to be used in ChemTek centrifuges to hold the basket and support it during centrifugation. The cup catches all the liquids from the spinning process. It is vacuum insulated and triple-walled for reinforcement. Specifications: Material: 304 Stainless Steel 12oz

$37.48

-

ChemTek ChemTek CHT210R Centrifuge

ChemTek CHT210R Centrifuge CHT210R centrifuges provide excellent performance and easy operation in a compact design that saves valuable time and laboratory space. Each unit comes with 2 rotors for high speed(20x15ml) or large capacity94x750ml) options for refrigerated centrifuging. Specifications: Power Supply: 110V 50/60Hz Max Speed: 21,000 RPM Max RCF: 32, 752 x G Max Capacity:4x750ml Cooling Capacity: -20C to -40C Time Setting Range: 1 - 99min Speed Accuracy: ± 10r/min Noise: ≤65dB Power Consumption: 6Kw Net Weight: 170lbs Comes with: (20) 50ml Tubes (4) Regular Mouth Basket (4) Wide Mouth Baskets (4) Regular Mouth Stainless Jar Lid/Band (4) Wide Mouth Stainless Jar Lid/Band (4) Five 50ml Tube Holder Inserts (4) Regular Mouth Jar Spacer Inserts (4) Wide Mouth Jar Spacer Inserts (1) 50-pack 5”x 7” Double Stitched Fuge Bags (1) 50-pack 6.5”x 7” Double Stitched Fuge Bags (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves (1) Power converter

$18,324.31

-

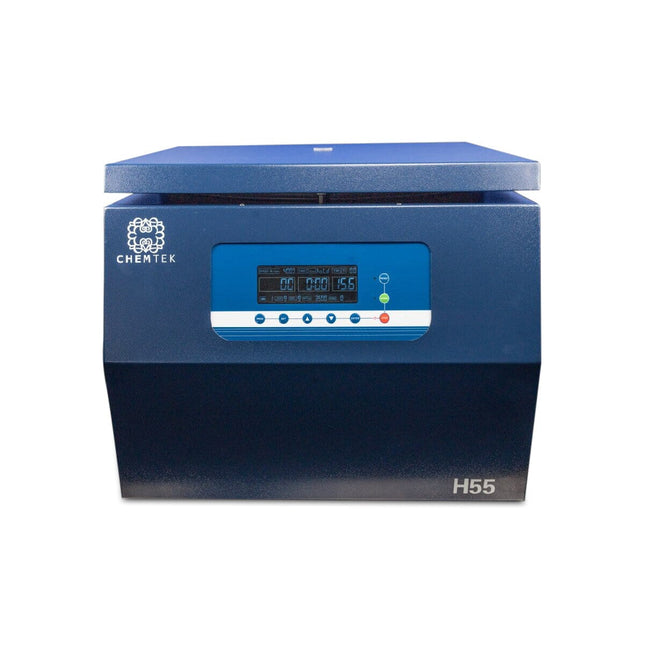

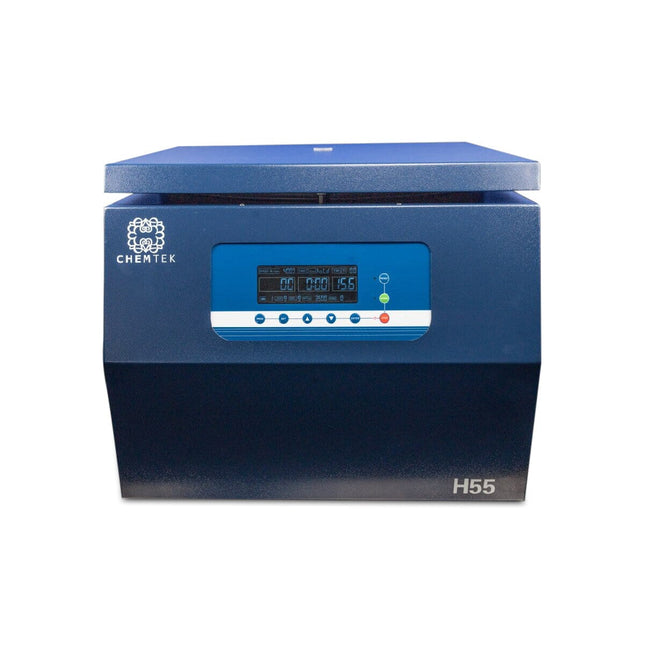

ChemTek ChemTek H55 Centrifuge

ChemTek H55 Centrifuge H55 centrifuges provide excellent performance and easy operation in a compact design that saves valuable time and laboratory space. The H55 is heated to assist with separation. Specifications: Power Supply: 110V 50/60Hz Max Speed: 4000 RPM Max RCF: Max Capacity:4x750ml Heat Capacity: 10C-70C Time Setting Range: 1 - 99min Speed Accuracy: ± 10r/min Noise: ≤65dB Power Consumption: 1500W Dimensions: Net Weight: 170lbs Comes with: (20) 50ml Tubes (4) Regular Mouth Basket (4) Wide Mouth Baskets (4) Regular Mouth Stainless Jar Lid/Band (4) Wide Mouth Stainless Jar Lid/Band (4) Five 50ml Tube Holder Inserts (4) Regular Mouth Jar Spacer Inserts (4) Wide Mouth Jar Spacer Inserts (1) 50-pack 5”x 7” Double Stitched Fuge Bags (1) 50-pack 6.5”x 7” Double Stitched Fuge Bags (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves

$9,856.26

-

ChemTek ChemTek CL5 Centrifuge

ChemTek CL5 Centrifuge CL5 centrifuges provide excellent performance and greater capacity. Each unit comes with 2 rotors for (6)500ml or (4)1000ml bucket options. Specifications: Power Supply: 110V 50/60Hz Max Speed: 5000 RPM Max RCF: 6100xg Max Capacity: 4x1000ml Time Setting Range: Speed Accuracy: ± 10r/min Noise: 65dB Power Consumption: 3 kW Dimensions: Net Weight: 600lbs Comes with: (20) 50ml Tubes (4) Regular Mouth Basket (4) Wide Mouth Baskets (4) Regular Mouth Stainless Jar Lid/Band (4) Wide Mouth Stainless Jar Lid/Band (4) Five 50ml Tube Holder Inserts (4) Regular Mouth Jar Spacer Inserts (4) Wide Mouth Jar Spacer Inserts (1) 50-pack 5”x 7” Double Stitched Fuge Bags (1) 50-pack 6.5”x 7” Double Stitched Fuge Bags (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves

$24,987.70

-

ChemTek ChemTek T55 Centrifuge

ChemTek CLT55 Centrifuge CLT55 centrifuges provide excellent performance and easy operation in a compact design that saves valuable time and laboratory space. Specifications: Power Supply: 110V 50/60Hz Max Speed: 4000 RPM Max Capacity:4x750ml Time Setting Range: Speed Accuracy: ± 10r/min Noise: ≤65dB Power Consumption: 900W Net Weight: 170lbs Comes with: (20) 50ml Tubes (4) Regular Mouth Basket (4) Wide Mouth Baskets (4) Regular Mouth Stainless Jar Lid/Band (4) Wide Mouth Stainless Jar Lid/Band (4) Five 50ml Tube Holder Inserts (4) Regular Mouth Jar Spacer Inserts (4) Wide Mouth Jar Spacer Inserts (1) 50-pack 5”x 7” Double Stitched Fuge Bags (1) 50-pack 6.5”x 7” Double Stitched Fuge Bags (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves (1) Power converter ChemTek CLT55 Centrifuge User Manual

$8,329.23

-

ChemTek ChemTek L550 Centrifuge

ChemTek L550 Centrifuge L550 centrifuges provide excellent performance and easy operation in a compact design that saves valuable time and laboratory space. Specifications: Power Supply:110V 50/60Hz Max Speed:4000 RPM Max RCF:3040xg Max Capacity:4x500ml Time Setting Range:1min - 99min Speed Accuracy:± 10r/min Noise: ≤65dB Power Consumption:750W Net Weight:115lbs Comes with: (16) 50ml Tube (4) Regular Mouth Basket (4) Regular Mouth Stainless Jar Lid/Band (4) Four 50ml Tube Holder Insert (4) Regular Mouth Jar Spacer Insert (1) 50-pack 5”x 7” Double Stitched Fuge Bags (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves ChemTek L550 Centrifuge User Manual ChemTek L550 Centrifuge SDS

$6,524.57

-

ChemTek ChemTek L500 Centrifuge

ChemTek L500 Centrifuge The L500 Benchtop Centrifuge is our introductory model designed to have a very compact footprint to fit on every lab bench. Specifications: Power Supply:110V 50/60Hz Max Speed:4200 RPM Max Capacity:4x50ml Time Setting Range:1min - 99min Speed Accuracy:± 30r/min Noise:≤65dB Power Consumption:250W Net Weight:42lbs Comes with: (16) 50ml Tube (1) 100pack 25 Micron Centrifuge Bags (2.5”x4”) (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves ChemTeck L500 Centrifuge User Manual ChemTeck L500 Centrifuge SDS

$2,498.77

-

ChemTek CHEMTEK ChloroSorb Neutral

CHEMTEK ChloroSorb Neutral ChloroSorb Neutral is an acid-activated bentonite/carbon adsorbent that has been neutralized to a neutral pH of 7. General uses are bleaching, deodorizing, or heavy metal removal. ChloroSorb Neutral SDS

$69.41 - $3,123.46

-

Digital Vacuum Chamber Gauge Upgrade *Wireless

Digital Vacuum Chamber Gauge Upgrade *Wireless After many requests, we have combined our infamous vacuum tight bulkhead with the power of a wireless vacuum gauge that can be a simple upgrade to ANY of our vacuum chamber products or resin traps. For those seeking truly accurate readings at any altitude and wireless monitoring this is the ultimate gauge for any vacuum system!. *To install: All that is required is a 1/2" wrench to remove the original and replace the digital one. The VGW-mini Wireless micron vacuum gauge measures vacuum via just one service port and with no loss of refrigerant. Its compact, robust and smart design support HVAC technicians with numerous intelligent features like the graphic display of measurement data in the Elitech Tools App. Its smart Bluetooth integration allows for data to be stored and evaluated reliably and efficiently, thus saving precious time and resources. Product Features High Accuracy The digital vacuum gauge achieves precise deep vacuum measurements down to single digit resolutions and provides notifications when the evacuation target is met. Smart APP Control Control your micron tester remotely and navigate through all measurement data via Smartphone or Tablet. Quickly and conveniently document your job, finalize your report and export - directly from the job site. Intelligent Judgement of H2O Status The vacuum meter automatically judges physical state of H2O by comparing ambient temperature and water saturation temperature corresponding to the vacuum in the system. Large, Easy-to-Read Display Continual digital readout of evacuation process can be viewed easily on the large, full-view LCD screen. Rechargeable Lithium Battery Built-in rechargeable lithium battery can work up to 20 hours per single full charge, saving troubles of frequent battery change. Product Specifications Measuring Range: 0-19000 micron Operating Temperature: -4℉~140℉ (-20°C~60°C) Interface: 1/4 SAE Accuracy: 1~10,000 microns: ±10% of readings ±10 microns10,000~19,000 microns: ±20% of readings Resolution: 0-400 1 Micron400-3000 10 Micron3000-10000 100 Micron10000-19000 250 Micron Vacuum Units microns, mTorr, in/hg, Pa, Torr, KPa, mbar and psia Battery rechargeable lithium battery (1,000mAh) Overload 27.5 bar Certification CE

$256.82

-

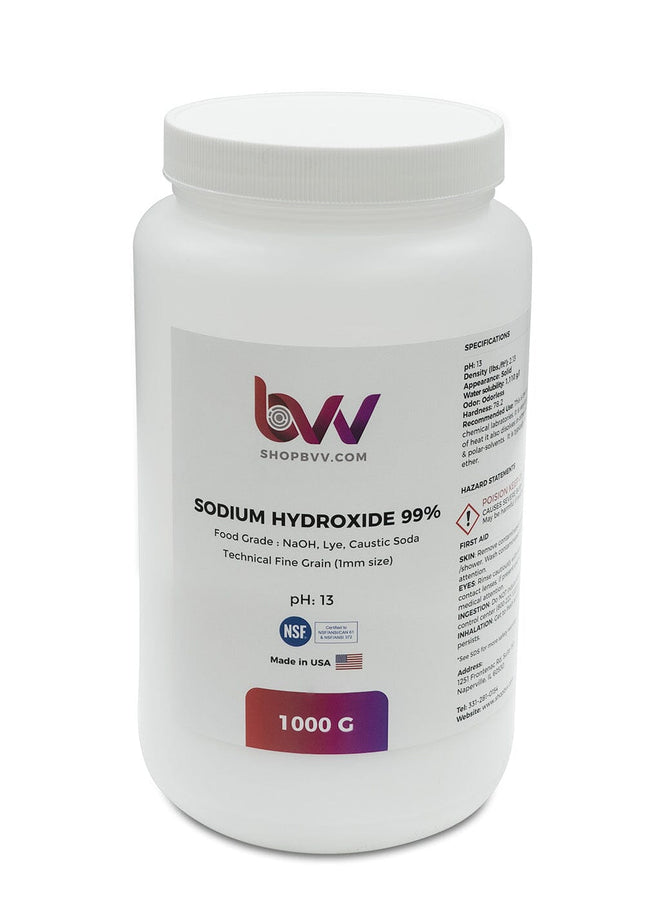

Sodium Hydroxide 99% (Food Safe)

High Purity Sodium Hydroxide 99% NSF Certified (Food Safe Chemical) Sodium Hydroxide is a highly versatile compound that finds extensive use in various applications, including acid-base extractions. As a strong base, Sodium Hydroxide is used to adjust the pH of aqueous solutions, making it an ideal choice for separating acidic and basic compounds during extraction. Also known as caustic soda, Sodium Hydroxide is a highly alkaline compound that is used in a wide range of applications beyond extraction including manufacturing, cleaning, and water treatment. At BVV, we pride ourselves on offering only the highest-quality chemicals and compounds, including Sodium Hydroxide. Our Sodium Hydroxide is a premium-grade product that is manufactured to the highest standards, ensuring exceptional quality and performance for your pH adjustment needs. Our Sodium Hydroxide is NSF certified as a food safe chemical, which means it can be used in a variety of applications including drinking water and is evaluated safe for consumption.Our product is available in a range of sizes and quantities to suit your needs, and our team is always on hand to provide expert advice and support. High Purity Sodium Hydroxide Safety Data Sheet SDS High Purity Sodium Hydroxide Certificate of Analysis COA Chemical Formula: NaOH Molecular Weight: 39.9971 g/mol CAS Registry Number: 1310-73-2 Appearance White, hard (when pure), opaque crystals Odor: Odorless Density 2.13 g/cm3 Boiling Point: 1388°C / 2530°F Solubility in water: 418 g/L (0 °C)1000 g/L (25 °C)3370 g/L (100 °C) GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H290, H302, H314 GHS Precautionary Statements P280, P305+P351+P338, P310 UN Identification Number: 1823 Proper Shipping Name: Sodium Hydroxide, solid Transport Hazard Class: 8 Packing Group: II DOT Placard: What Is Sodium Hydroxide? Sodium hydroxide, commonly known as lye or caustic soda, is a highly versatile and strong alkaline compound. It is represented by the chemical formula NaOH and consists of one sodium (Na+) ion, one hydrogen (H+) ion, and one hydroxide (OH-) ion. Sodium hydroxide is a white, odorless solid at room temperature and is highly soluble in water, producing a highly alkaline solution. It is widely used in various industries and applications, including manufacturing, chemical processes, cleaning agents, soap production, food processing, and more. What Is Sodium Hydroxide Used For? Sodium hydroxide (NaOH), commonly known as caustic soda or lye, has a wide range of industrial, commercial, and household uses due to its strong alkaline properties. Some of the common uses of sodium hydroxide include: Chemical Manufacturing: Sodium hydroxide is a key component in the production of various chemicals, including detergents, soaps, textiles, paper, and synthetic materials. Soap and Detergent Production: It is used in the saponification process to make soap and is also a crucial ingredient in many household and industrial cleaning products. Food Processing: Sodium hydroxide is used to process and refine certain foods, such as in the preparation of olives, cocoa, and chocolate. It is also used for peeling fruits and vegetables. Water Treatment: In water treatment, sodium hydroxide is used to adjust pH levels, remove acidity, and precipitate metals from wastewater. Petroleum Industry: It is used in refining petroleum products, including the removal of impurities from crude oil. Aluminum Production: Sodium hydroxide is employed in the extraction of alumina from bauxite ore and as an electrolyte in the aluminum extraction process. Pulp and Paper Industry: It is used in the pulping and bleaching processes of paper manufacturing. Textile Industry: Sodium hydroxide is utilized to process and dye textiles and fabrics. Pharmaceuticals: It is used in the manufacture of certain drugs and pharmaceutical products. Biodiesel Production: Sodium hydroxide is used as a catalyst in the transesterification process to produce biodiesel from vegetable oils or animal fats. Hydrogen Production: Sodium hydroxide is used to produce hydrogen gas through the electrolysis of water. Cleaning and Degreasing: It is used as a strong cleaning agent for surfaces, equipment, and industrial machinery due to its ability to dissolve oils, fats, and grease. Drain Cleaning: Sodium hydroxide-based drain cleaners are used to unclog and clean drains. pH Adjustment: In laboratories and industrial processes, sodium hydroxide is used to adjust the pH of solutions. It's important to note that sodium hydroxide is a highly caustic and reactive substance, and its use should be handled with care and appropriate safety measures. Is Sodium Hydroxide Lye? Yes, sodium hydroxide is commonly known as lye. Lye is a strong alkaline substance that is often used in various industrial, commercial, and household applications, as mentioned earlier. It is important to handle sodium hydroxide with caution, as it can cause severe burns and irritation if it comes into contact with skin or eyes. Proper safety measures should be taken when working with sodium hydroxide or lye. Are Sodium Hydroxide and Caustic Soda The Same Thing? Yes, sodium hydroxide and caustic soda are the same thing. Caustic soda is a common name for sodium hydroxide, which is a strong alkaline chemical compound. Both terms refer to the same chemical substance with the chemical formula NaOH. It is used in various industrial, commercial, and household applications, including cleaning, manufacturing, and chemical processes. What Is Sodium Hydroxide Structure? Sodium hydroxide (NaOH) has a simple molecular structure consisting of one sodium (Na) atom, one oxygen (O) atom, and one hydrogen (H) atom. The structure of sodium hydroxide can be visualized as follows: In this structure, the sodium atom (Na) is bonded to the oxygen atom (O) through an ionic bond, and the oxygen atom is bonded to the hydrogen atom (H) through a covalent bond. The hydroxide ion (OH-) is formed by the combination of the oxygen and hydrogen atoms, and it is the key component that gives sodium hydroxide its strong alkaline properties. What Is The pH of Sodium Hydroxide? The pH of sodium hydroxide (NaOH) is very high and strongly alkaline. Sodium hydroxide is a strong base and is commonly used to raise the pH of solutions. In its pure form, sodium hydroxide has a pH of approximately 14, which is the highest value on the pH scale. When dissolved in water, it dissociates into hydroxide ions (OH-) and sodium ions (Na+), resulting in a highly alkaline solution with a pH greater than 14. The exact pH of a sodium hydroxide solution will depend on its concentration and the amount dissolved in the solventWhat Are The Hazards of Sodium Hydroxide? Is Sodium Hydroxide A Weak or Strong Base? Sodium hydroxide (NaOH) is considered a strong base. It is highly soluble in water and dissociates completely into sodium ions (Na+) and hydroxide ions (OH-) when dissolved. This complete dissociation results in a high concentration of hydroxide ions in the solution, making sodium hydroxide a strong and effective source of hydroxide ions for chemical reactions. Strong bases like sodium hydroxide have a high tendency to accept protons (H+) from other substances, leading to the characteristic properties of strong bases, such as high alkalinity and the ability to neutralize acids.What Is Sodium Hydroxide? What Are The Hazards of Sodium Hydroxide? Sodium hydroxide (NaOH) is a caustic and highly reactive compound, and its use should be handled with care due to the following hazards: Corrosive to Skin and Tissues: Sodium hydroxide is highly corrosive and can cause severe burns upon contact with the skin, eyes, and mucous membranes. It can damage and destroy living tissue upon contact, leading to chemical burns and tissue damage. Inhalation Hazard: Inhaling sodium hydroxide dust, fumes, or mists can irritate the respiratory tract and cause coughing, shortness of breath, and lung irritation. Prolonged exposure to airborne sodium hydroxide particles can lead to more serious respiratory effects. Eye Irritation: Contact with sodium hydroxide can cause irritation, redness, and damage to the eyes. Severe exposure can lead to permanent eye damage or blindness if not promptly treated. Reactivity: Sodium hydroxide is highly reactive and can react violently with certain substances, especially acids. Mixing sodium hydroxide with acids can result in rapid heat generation, spattering, and potentially explosive reactions. Environmental Impact: Sodium hydroxide is harmful to aquatic life and can lead to water pollution if released into the environment. It is important to properly dispose of sodium hydroxide-containing solutions and prevent their release into water systems. Corrosion of Materials: Sodium hydroxide can corrode metals and other materials, causing structural damage and weakening of containers, pipes, and equipment. Toxicity: Ingesting sodium hydroxide can cause severe internal burns, damage to the digestive system, and even death. Ingestion can lead to life-threatening medical emergencies and requires immediate medical attention. To mitigate these hazards, it is essential to handle sodium hydroxide with proper protective equipment, such as gloves, goggles, and lab coats, in a well-ventilated area. Proper storage, labeling, and disposal procedures should also be followed to prevent accidents and environmental contamination. How Do I Use Sodium Hydroxide Safely? Sodium hydroxide, also known as caustic soda or lye, is a highly caustic and potentially dangerous chemical. It's essential to handle and use it safely to prevent accidents or injuries. Here are guidelines for safely using sodium hydroxide: Protective Equipment: Wear appropriate personal protective equipment (PPE), including chemical-resistant gloves, safety goggles or a full-face shield, a lab coat or chemical-resistant apron, and closed-toe shoes with chemical-resistant soles. Work in a Controlled Environment: Work in a well-ventilated area, such as a fume hood, to minimize exposure to fumes. Adequate ventilation helps disperse any fumes produced during handling. Avoid Skin Contact: In case of skin contact, immediately flush the affected area with plenty of water for at least 15 minutes. Remove contaminated clothing and seek medical attention if irritation or burns occur. Prevent Eye Contact: Wear chemical-resistant safety goggles or a full-face shield to protect your eyes from splashes. If sodium hydroxide comes into contact with your eyes, rinse them immediately with water for at least 15 minutes and seek medical attention. Use Appropriate Containers: Use containers made of materials that are compatible with sodium hydroxide, such as glass or certain types of plastic. Avoid using aluminum or reactive metals. Dilution Procedure: When diluting sodium hydroxide in water, always add the chemical to the water, not the other way around. Stir gently while adding to prevent splashing. Label Containers: Properly label containers holding sodium hydroxide solutions with appropriate hazard warnings and information. Handling Crystals or Pellets: Handle sodium hydroxide crystals or pellets with dry hands or appropriate gloves to avoid skin contact. Always use tools (e.g., scoops or spatulas) to handle solid sodium hydroxide. Do Not Inhale Fumes: Avoid inhaling sodium hydroxide fumes. Work in a well-ventilated area, and if working with large quantities or generating fumes, use a fume hood or wear a chemical-resistant mask with appropriate filters. Emergency Equipment: Have access to emergency equipment, such as eye wash stations and safety showers, in case of accidental exposure. Know the location of fire extinguishers and fire alarm systems. Spill Response: In case of a sodium hydroxide spill, follow your organization's spill response procedures. Typically, this involves containing the spill, neutralizing with an acid if appropriate, and safely cleaning it up. Storage: Store sodium hydroxide in a cool, dry, well-ventilated area, away from incompatible substances (e.g., acids, organic materials). Keep containers tightly closed when not in use. Dispose of Waste Properly: Dispose of sodium hydroxide waste in accordance with local, state, and federal regulations. It is considered hazardous waste and should be handled and disposed of as such. Training and Knowledge: Ensure that personnel working with sodium hydroxide are adequately trained in its safe handling, storage, and disposal. Training should include hazard recognition, first aid procedures, and emergency response protocols. First Aid: Familiarize yourself with the appropriate first aid measures for sodium hydroxide exposure, including how to treat skin contact, eye exposure, and ingestion. Medical Monitoring: If workers are regularly exposed to sodium hydroxide, consider implementing a medical monitoring program to track their health and detect early signs of exposure-related issues. Always follow the safety guidelines and procedures established by your organization or regulatory authorities when working with sodium hydroxide. Remember that sodium hydroxide is a highly caustic substance, and improper handling can result in severe burns or other injuries. Prioritize safety and take appropriate precautions to protect yourself and others from potential hazards associated with sodium hydroxide.

$16.66 - $1,665.85

-

1/4" Fractional Tube Fitting Hose

1/4" Fractional Tube Fitting Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have a tube stub on each end that fits a standard compression fitting. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 1/4" Tube Stub Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65°F to 450°F (-54°C - 232°C) Pressure Rating 2100 PSI Chemical Resistance Excellent Max Bend Radius 3"

$61.08 - $93.01

-

Welded Coil in Coil

Welded Coil in Coil The Jacketed coil is a 40ft length of 1/2" tube that is completely encapsulated by the 3/4" outer jacket. The inner tube has 1/2" compression fittings and the outer tube has 1/2" FNPT connection ports. The built version comes with USA made SSP instrumentation valves with 1/2" JIC connection for the inner tube and either 1/2" MJIC, 1/2" OR 3/4" hose barb connections for the outer tube. The Coil itself is 10" In diameter and can be mounted successfully utilizing one of our 10" Pipe Hangers

$825.98 - $2,071.20

-

120W Motor/gearbox with FWD/REV controller

This controller/ motor can be retrofitted to fit a 20 or 50 liter glass reactor to have additional control to your process.

$1,179.97

-

Extraction RACK #7

Extraction RACK # 7 Rack 7 has 4.5" thick vertical support bars and 3x horizontal bars to complete our strongest standard extraction rack. This rack includes 4x locking caster wheels that can also be adjusted to be level on uneven surfaces. For ease of mounting equipment, we recommend our pipe hangers with hang on brackets Rack Dimensions (L x W x H) 30" x 39" x 60" (Assembled units come with a 30-day warranty) Note: The unit does not come assembled - select "pre-assembled" from the drop-down menu to have the unit assembled by BVV before shipping Pipe hangers are not included There is no warranty on unassembled units Shipping Notice: If the customer orders the rack as assembled, then the item will only ship via freight and there will be additional shipping charges.

$2,290.54 - $2,498.77

-

8" Hemispherical End Cap with Coil

8" Hemispherical End Cap with Coil This 8" Hemispherical End Cap with Coil comes standard with our 150L Conical Reactor. Complete with 2X 1/2" NPT accessory ports, 2X 1/4" NPT accessory ports, 2X 1/2" NPT ports for the coil, and a single 1.5" tri-clamp top port. This versatile part is perfect for those looking to add extra surface area to their heating or cooling application. From the 8" tri-clamp to the bottom of the coil measures 34".

$624.69

-

Dry Ice Maker Machine Food Grade - Ultra Dense Block

Dry Ice Maker Machine Food Grade - Ultra Dense Block This dry ice machine makes ice the way you want it! Using 2 tons of hydraulic force to compress the formed CO2 snow into a solid brick. Other dry ice makers produce a loosely packed brick that sublimates quickly. Our bricks take up to 1.5+ hours to sublimate. All of the parts that touch liquid CO2 or ice are food-grade materials. Must use a CO2 tank with a dip tube!! Otherwise you will not get the liquid CO2 needed to make dry ice. Use Specifications 20lbs of CO2 Retail ($1/lb) (*Bulk rates as low as $0.55/lb) $20 Input of CO2 (LBS) per Use 1.75 Dry Ice Output (LBS) per Use 0.38 Lbs of Dry Ice made from 20 lbs CO2 4.34 Cost per lb of Dry Ice made (approx) $4.61 Brick Formation Time (approx) 25 Seconds Connection for CO2 (includes gasket not shown in photo*) CGA 320 Additionally, this dry ice maker comes with these extra items... 1 white plastic shim 1 Black upper gasket 1-Year BVV Warranty The Upgraded Valve Assembly option will include this manifold. Assembled in the USA by BVV *Extreme cold temperatures will cause red paint to flake off of the jack over time. This is purely cosmetic.

$659.40 - $777.39

-

High Pressure Wood Stabilizing Chamber

High Pressure Wood Stabilizing Chamber A BVV EXCLUSIVE! This is our high pressure wood stabilizing column that can perform rapid wood stabilization @ 1600 PSI (1.5" Diameter Tube) & 450 PSI (3"/ 6" Diameter Tube). This extreme pressure makes the toughest woods easy to impregnate with wood stabilizer in as little as 15min. Then its off to the oven for a quick cure and its finished. The blanks in the photo, all 3 were stabilized and cured in less than 1 hour and 15 min, including cleanup. The system is simple. Load your blanks into the column and fill no more than 75% with resin. (make sure the blanks are submerged) Then close the system and turn on the pump set to desired psi. High Pressure Wood Stabilizing Manual with Assembly The compressor you will need can be ordered from this site (GX Pumps Click This Link). BVV does not yet carry the compressor for this system. But our hose will connect directly to the compressor. If the compressor is out of your reach a high pressure hand pump can be used. (GX Hand Pumps Click This Link) The system comes with an installed safety pressure relief burst disk rated for 1800 PSI. (1.5" Diameter tubes) & 450 PSI. (3"/ 6" Diameter tube) Should you exceed the pressure of the system the disk will rupture releasing pressure. What's Included Wood stabilizing manual *Coming soon for 3"/ 6" Diameter. Braided stainless steel hose 2500 psi rated. Main column, stand and top cap valve manifold assembled. Extra safety burst disk, for 1.5" Diameter Tube. 3"/ 6" Tubes self reset. BVV warranties the main column to be free from any defects for 1 year. All other individual components may hold separate warranty periods. BVV does not warranty any claims where resin has been released/backflowed into the manifold hose or valve. Resin is water washable and should be cleaned after each use, especially if resin has accidentally backflowed into the manifold area.

$433.12 - $1,110.56

-

Neo Diaphragm Replacement Membrane

These replacement diaphragms are used in the BVV V-40 diaphragm vacuum pumps. The V-40 has two diaphragms and will need one two pack to do a rebuild on it.

$111.06 - $222.11

-

NEO 1.4CFM Diaphragm Pump ETL Rated

The BVV V series pumps are Ani-corrosion PTFE diaphragm vacuum pumps. The two head design operates as a two-stage pump to achieve a lower degree of vacuum. They are ideal for pumping corrosive gases and organic solvents. These pumps do not need any pump oil or other lubricants, which means less maintenance and smaller chance for cross contamination. The BVV V-40 is ETL listed to be used in laboratories and comes with a 2 year manufacturer warranty on all non consumable pieces. Model V-40 Power 110V 60Hz, 240 W Ultimate Vacuum 6 torr (8mbar) Maximum Operating Pressure 1 bar Maximum Flow 40 L/min Ambient Temperature 5 - 40°C Pump Head Material PTFE Composite Valve Material FFPM Noise <70db Dimensions 315x165x210mm Weight 10.4 kg For replacement diaphragms, click HERE

$2,325.24

-

2L Standard Short Path Parts Kit

Short Path Distillation Setup Short path distillation is used for compounds that are not stable at high temperatures. It can also be used to purify small amounts of a compound. The 2L Distillation Kit gives users an easy to use system that will get them up and running at an affordable price. It includes all stands, clamps, clips, This Kit Does NOT include a vacuum pump, circulator, or heating source. Please see the below recommendations for both as well as recommended add-ons. Or check out our 2L Standard Distillation Turnkey Setup which includes vacuum pump, circulator, and mantle. Recommended Vacuum Pumps: Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (economy option) Best Value Vacs VE280 9CFM Two Stage Vacuum Pump (economy option) Recommended Circulators: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter MX Refrigerated Circulator (premium option with chilling capability) Recommended Heating Mantle: BVV 2L Heating Mantle Recommended Add-Ons: Glass Dewar Style Cold Trap (recommended cold trap) Bullseye Precison Vacuum Gauge (premium vacuum gauge for measuring depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) Short Path Distillation Kit Specifications: Boiling Flask Size: 2L Recieving Flask Size: 250ml Batch Capacity approximate: 2L = 400-1000 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Comes Standard With The Following: Glass Components: 2L 2-Neck Boiling Flask Short Path Head Triple Neck Cow 3x 250mL Single Neck Receiving Flask 1/8" 14/20 PTFE Thermometer Adapter 1/4" 24/40 PTFE Thermometer Adapter 120mm Glass Funnel Accessories: Magnetic PTFE Stirring Bar Retriever Keck Clips 3 Finger Clamp Adjustable 0-70mm Boss head 6" x 6" Scissor Jack 250-500ml Cork Stand Traceable Kangaroo Thermometer - Digital Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. Learn more about short path distillation components and FAQs with this distillation guide. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$902.33

-

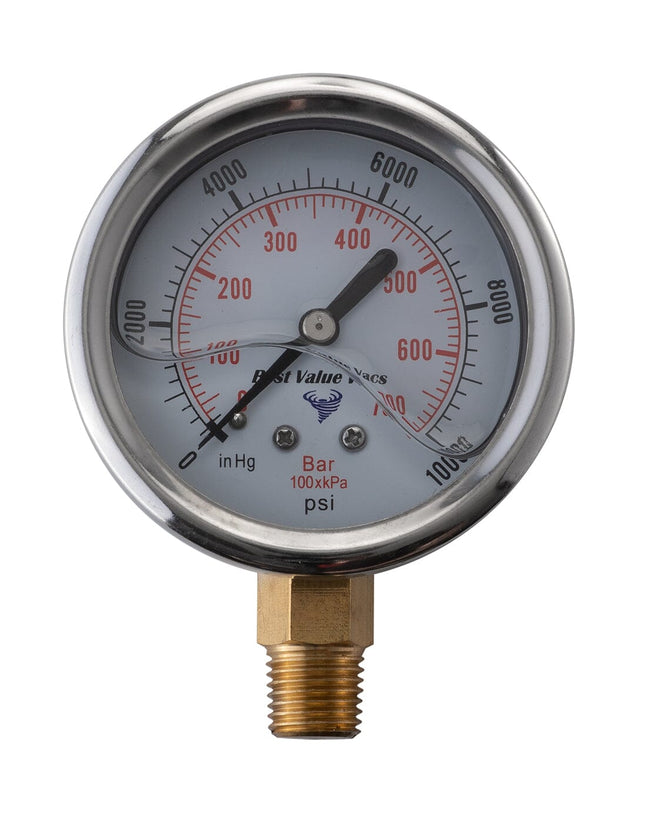

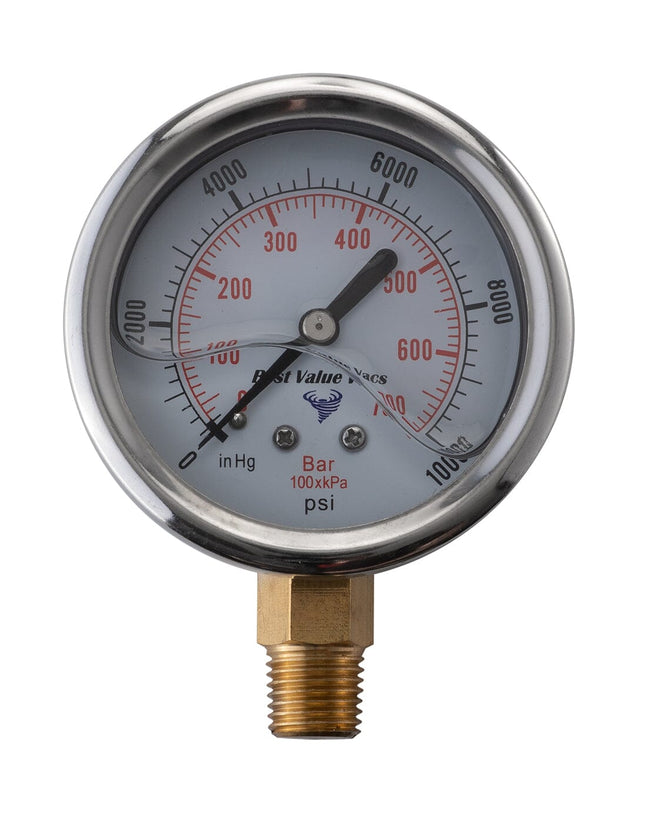

Oil Filled Vacuum/Pressure Gauge - Bottom Mount - 1/4" MNPT

Oil Filled Vacuum/Pressure Gauge The Oil Filled Vacuum/Pressure Gauges have internal parts that are permanently lubricated to assist in smooth movement and fine tuning of the needle. All models are bottom mount with a 1/4" MNPT brass connection. All positive pressure is measured in both PSI and Bar. Negative pressure is measured in inHg and Bar. BVV™ Gauge - TDS

$20.82 $13.88

-

Foam Insulation for Hose and Tubing - 6 Feet

Foam Insulation for Hose and Tubing - 6 Feet This foam insulation is good for silicone tubing, stainless steel braided hosing, compression hard line tubing, and more! The inner diameter of the foam can be 3/8", 1/2", or 5/8" and must be selected in the drop down menu. This should correspond with the outer diameter of the hose that you want to insulate. The 3/8" option will slide on your hose or tube while the 1/2" and 5/8" options have a taped seam. All options come in 6' lengths. Sizing Chart: Foam Insulation Size: 3/8" 1/2" 5/8" For Compression Tube Size 3/8" 1/2" - For Stainless Steel Braided Hose Size 3/8" * 1/2" - For Silicone Tube Size 1/4" 3/8" 1/2" Composition Nitrile, PVC Flame/Smoke Rating 25/50 Height 1.375 Insulation Nominal I.D. 3/8" Length 72 R-Value R4.1 Temperature Range -297°F to 220°F (-182.78°C to 104.44°C) Country of Origin USA * The 3/8" foam does not have a seam and cannot be easily slid over stainless steel braided hose with permanent end fixtures.

$47.20 - $62.47

-

10.75 Glass Resin Trap Lid

10.75" Glass Resin Trap Lid Made from tempered soda lime glass and available with an industrial-grade silicone gasket capable of withstanding a 390F max temperature our 10.75" Glass Resin Trap Lid carries excellent temperature and solvent compatibility. All pictured fittings are included. This 10.75" Glass Resin Trap Lid can be purchased as a complete Resin trap kit including our 2 Gallon Aluminum Chamber Pot within our 2 Gallon Resin Trap Vacuum W/ Glass Lid listing.

$159.64 - $173.53

-

6" Sauce Separator

6" Sauce Separator Separate diamonds from sauce at scale with our 6" Sauce separator. Simply load your crystallized extract into the top vessel and place it in a heated oven at 120-140F for 4 hours to sweat the sauce from your crystals. Equipped with a 100-micron Buna-N gasket the 6" Sauce Separator allows for easy separation of crystals from the mother liquor. With a max height of 12.5" and a max diameter of 9", the 6" Sauce Separator easily fits within our standard 1.9 CF vacuum ovens. Specifications 6" Splatter Platter for sauce collection 6" 100 Micron BUNA-N Nitrile gasket 6"X6" Body for Extract loading (-30)-250 PSI Compound Gauge 1/4" JIC Butterfly Valve 1.5" Borosilicate Sight Glasses High-Pressure Clamps Dimensions Max Height: 12.5" Max Diameter: 9"

$937.04

-

BVV Vacuum Pump Vane Rebuild Kit

These replacement Vane kits are specifically designed for the BVV vacuum pump. Select you model in the dropdown list.

$8.33

-

BVV Vacuum Pump Mechanism Rebuild Kits

This rebuild kit is the entire pump mechanism for the BVV vacuum pump. It includes all gaskets and vanes already installed and ready to bolt on the vacuum pump. Select your pump model in the dropdown list.

$48.59 - $88.85

-

2L Short Path Parts Kit with Dry Ice Cold Trap

2L Short Path Parts Kit with Dry Ice Cold Trap This kit includes all the parts and fixturing to build a distillation setup with a 2L boiling flask. No heating or cooling equipment is included.

$1,318.80

-

12" Collection Base

Pre-Built 12" Collection Base Double your capacity or configure your own custom system with BVV's Pre-Built 12" Collection base. Available in three different variations to suit your application all models of BVV's Pre-Built 12" Collections Base comes standard with high-pressure clamps, borosilicate sight glasses, and full-bore ball valves. Version 1 is the base model equipped with the standard 12" welded base perfect for cost-conscious applications. Version 2 is equipped with a 12"x12" spool & 12" splatter platter to make extract harvesting a breeze, and Version 3 is the top of the line 12" Colleciton base equipped with a 12" jacketed splatter platter for both optimized solvent recovery and ease of harvesting extract. Specifications High Pressure Clamps 2X 2" Borosilicate Sight Glasses 1X 125 PSI ASME Safety Valves 1X -30hg-250PSI Compound Pressure Gauge 1X 1/2" JIC Lid Valve 2X 1/4" JIC Lid Valves Maximum Pressure Rating: 125PSI Variations V1 : 12x12 Base (1200X12B) V2: 12" Splatter Platter base (1200X12S+1200SPL) V3: 12" Jacketed Splatter Platter Base (1200X12S+1200FJS)

$1,631.14 - $2,471.01

-

1.5 Gallon Vacuum Chamber Digital Heating Jacket

1.5 Gallon Tall Stainless Steel Vacuum Chamber Digital Heating Jacket Our high-capacity vacuum chamber heating jacket provides the user with the ability to evenly heat the chamber around the circumference while being very stable. When combined with a heating pad, this chamber covers most of the vessels distributing degassed heat in the vessel. This vacuum chamber digital heating jacket allows for accurate and stable control and is reprogrammable. With its unique patented gasket design, this chamber is sure to last 10,000 uses with proper care and maintenance. Key Features: Velcro Connections on each end. Digital PID Temperature Controller for accurate and stable control. Made of heat resistant silicone. Specifications: Min Temp: Ambient +5F Max Set Temp: 160F Ultimate Max Temp: 248F Voltage: 110VAC Only Precision: 1 degree F increments. Stability: +/- 0.2 F Dimensions: Approx. 7.9"W x 24"L Instructions Included Relay Lifespan 10million Cycles Reprogrammable: Yes

$263.76

-

Master Vapor Pumps Master Vapor MVP-150XL Diaphragm

Master Vapor MVP-150XL Diaphragm Diaphragm replacement kit for use with the MVP-150XL recovery pump. Unit of Measure: EA Height: 2 IN | 5.08 CM Length: 12 IN | 30.48 CM Width: 12 IN | 30.48 CM Volume: .167 FT3 | .005 M3 Chargeable Weight: 2.58 LBS | 1.17 KG

$569.16

-

Large 1-Micron Refinement Filter

Large 1-Micron Refinement Filter Filter large volumes of solutions with ease with our Large 1-micron Refinement filter. complete with our 1-micron Dutch Weave sintered disk these refinement filters provide complete retention of the filter paper making it impossible for suspended particles to bypass the filter paper. Made from the highest quality 304 stainless steel parts this large refinement filter is built to last making it a great alternative to polypropylene filter trolleys. Our Large 1-Micron Refinement filter is available as a complete kit with and without the a Welch BTpro100 Diaphragm Pump. Processing Power Funnel Capacity: 22.24 Liters/5.88 Gallons Collection Capacity: 50 Liters/13.2 Gallons Specifications 12"x12" Funnel Body 12" 1um Dutch Weave Sintered Disk 12" Hemispherical Ring stand 1/2" JIC Drain Valve 50L Stainless Steel Carboy Collection base -30Hg Vacuum Gauge 1/2" JIC Vacuum Port 3/8" JIC Diptube Valve 1/4" JIC Butterfly Accessory Valve 350MM Ashless Filter Paper Silicone Gaskets

$4,025.80 - $9,439.80

-

Benchtop 1 Micron Refinement Filter

Benchtop 1 Micron Refinement Filter Eliminate suspended particles with ease with our 1-micron Refinement filters. Complete with our 1-micron Dutch Weave sintered disk filter plate, these refinement filters provide complete retention of the filter paper,making it impossible for particulate to bypass the paper. Made from the highest-quality 304 stainless steel parts, these benchtop refinement filters are infinitely more robust than your typical porcelain Buchner funnels. They pair nicely with diaphragm vacuum pumps or our spark-free vacuum pumps paired with a cold trap. Processing Power Funnel Capacity: 5.5 Liters/1.45 Gallons Collection Capacity: 11.35 Liters/3 Gallons Specifications 6"x12" Funnel Body 6" 1um Dutch Weave Sintered Disk 6" Hemispherical Ring stand 1/4" Full Bore Ball valve with 1/4" JIC Drain port 3 Gallon Stainless Steel Collection Base with Glass Lid Back Mount Vacuum Gauge 1/4" JIC Butterfly Vacuum Valve 2.5UM 180MM Ashless Filter Paper Nitrile BUNA-N gaskets

$1,565.90

-

XL 1-Micron Refinement Filter

XL 1-Micron Refinement Filter Filter large volumes of solutions with ease with our XL 1-micron Refinement filter. complete with our 1-micron Dutch Weave sintered disk these refinement filters provide complete retentionof the filter paper making it impossible for suspended particles to bypass the filter paper. Made from the highest quality 304 stainless steel parts this XL Refinement Filter is built to last making it a great alternative to polypropylene filter trolleys. Processing Power Funnel Capacity: 44.48 Liters/11.75 Gallons Collection Capacity: 100 Liters/26.41 Gallons Specifications 12"x24" Funnel Body 12" 1um Dutch Weave Sintered Disk 12" Hemispherical Ring stand 1/2" " JIC Drain Valve 100 Liter Stainless Steel Carboy Collection Base -30Hg Vacuum Gauge 1/2" JIC Vacuum Valve 3/8" JIC Diptube Valve 1/4" JIC Butterfly Accessory Valve 350MM Ashless Filter Paper Silicone Gaskets

$4,858.72

-

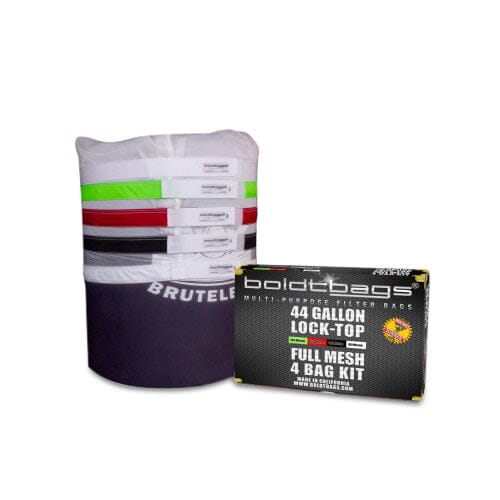

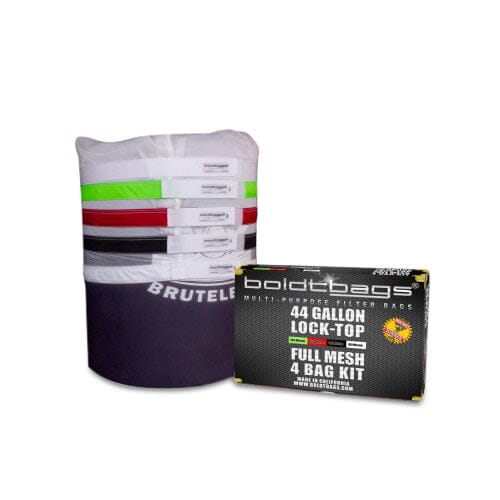

Boldtbags 44 Gallon Boldtbags Full Mesh Stacker Lock-Top w/ Belt Lock

44 Gallon Boldtbags Full Mesh Stacker Lock-Top w/ Belt Lock Lock top bags are the new product made with you in mind. Adjust your bag to the height you need and lock it in for easier product washing and collection. Custom designed with Full Mesh, these bags provide exceptional ice water sieving properties and award winning purity thanks to the large functional surface area and lightweight construction that allows for easy use and award winning results. Ideal purchase for Laboratories. Have a variety of bags to choose from and mix and match for perfect trichlome extraction. Diameter 23.5″ Depth 28.25″ 4 bag kit includes: 190 micron bag (green) 160 micron bag (red) 90 micron bag (black) 45 micron bag (white) Additional belt lock Scraping card 8 bag kit includes: 220 micron bag (blue) 190 micron bag (green) 160 micron bag (red) 120 micron bag (orange) 90 micron bag (black) 73 micron bag (yellow) 45 micron bag (white) 25 micron bag (purple) Additional belt lock Scraping card

$902.33 $347.05

-

Magnetic PTFE Stirring Bar - L Style - 70mm

Magnetic PTFE Stir Bar - L Style - 70mm Reduce stir bar jumping with the contoured shape of this L Style Magnetic PTFE Stir Bar. Ideal for round-bottom flask stirring applications. This 70mm L Style Magnetic Stir bar is great for round-bottom flasks above 5 liters in capacity. With its PTFE coating this Magnetic Stir Bar carries excellent solvent and temperature compatibility for a variety of applications. Specifications: L Style 70mm Length Material: High-temperature PTFE

$24.99

-

Sleeved Recovery Tank

Sleeved Recovery Tank Built for optimized recovery performance and efficient use of dry ice, these sleeved recovery spools are the perfect prechilling and recovery solutions for hydrocarbon extraction. Available in 5LB,10LB, & 22LB butane capacities these sleeved recovery tanks are a great upgrade for any of our 1-5lb extractors. All models of our Sleeved Recovery tank come complete with a 1/2" JIC recovery port, a 1/4" JIC drain port, 2X 1/4" JIC accessories ports, 2X Borosilicate sight glasses, a single -30hg-250PSI Compound Pressure Gauge, and a 125 PSI ASME pressure relief valve to provide maximum compatibility and versatility across processing platforms. Specifications 6"x12", 6"x24", 12"x12" Sleeved spool Hemi ring stand with 1/4" JIC drain valve 2X Borosilicate Sight Glasses 1X 125 PSI ASME pressure relief valve 1X -30hg-250PSI Compound Pressure Gauges 1X 1/2" JIC Recovery Valve 2X 1/4" JIC Accessory Valves 1X JIC Drain Valve Maximum Pressure Rating: 125PSI

$1,624.20 - $2,776.41

-

Beaker and Wrench Explosion Proof Oil Pump

Explosion Proof Oil Pump Optimized for Falling Film Evaporators C1D2 VFD (variable frequency drive, not C1D2 rated) cord is approximately 15′ Motor: 1/4 Horsepower Customizable mounting When ordering: Please indicate in the Note section what machine you will be attaching the Explosion Proof Oil Pump to. We need this information to assure the correct Inlet Adapter is provided and also the dimensions of the mounting configuration you will need. Hazardous Location Clas 1 C,D / 2 E,F,G Nominal Efficiency 85.5% Frame 56CZ Motor Application Hazardous Location Lead Length 6" RPM Range 1101-1200 Standards UL listed (E12044), CSA Certified (LR47504) Frame Material Rolled Steel Duty Continuous HP 1/4 Voltage Compatibility 115/208-230, 120/240 Length Less Shaft 11-7/8" Includes Conduit Box (Unmounted), Leads Through 1" NPT Nipple Motor Shaft Design Keyed Shaft Length 2-1/4" Item Harazardous Location Motor Motor Service Factor: 1.00 1.00 Motor Thermal Protection auto Motor Shaft Rotation CW/CCW Full Load Amps 6.8/3.1-3.4 Overall Length 14-5/16" Voltage 115/208-230 Motor Frame Material Rolled Steel Ins. Class B Motor Mounting Type Face Motor Design Capacitor- Start Shaft Dia 5/8" Hz 60 Motor Bearing Ball Temp. Code T3B Motor Enclosure Design Totally Enclosed Fan-Cooled Nameplate RPM 1140 Max. Ambient Temp 40 Degrees C Phase 1

$10,550.36

-

Nitrogen Pressure Filter

Nitrogen Pressure Filter Is vacuum filtration bottlenecking your processing? Filter faster with BVV's Nitrogen assisted pressure filters. Designed for versatility our prebuilt pressure filters come complete with our 1 micron Dutch Weave Sintered disk for ultra-fine filtration. Process continuous or batch-style solutions in half the time compared to most vacuum filtration applications. Specifications 6"x12" or 12"x12" filtration body 1um Dutch Weave Sintered disc Filter Plate Retention Ring Fast Flow Filter paper Included Solvent dispersal plate 2X Borosilicate Sight Glasses 1X 125 PSI ASME Safety Valves 1X -30hg-250PSI Compound Pressure Gauges 1X 1/2" JIC Lid Valve 2X 1/4" JIC Lid Valves 1X JIC Drain Valve (6NPS: 1/4" 12NPS: 1/2" JIC) Maximum Pressure Rating: 125PSI

$2,221.13 - $4,095.21

-

1/2" x 0.035 wall 316SS Hard Line Tubing 5FT

1/2" 316SS Hard Line Tubing 5FT Stainless Steel 316 Hard line tubing for compression fitting connections and systems. Specifications Length 5' Material 316 Stainless Steel ASTM A-269 Max Allowed Working Pressure (PSIG) 1/2" x .035 2339

$180.47

-

Eccentric Recovery Pump Shaft Adapter

Eccentric Recovery Pump Shaft Adapter Replacement Eccentric adapters for TRS or BVV recovery pumps. Model numbers shown below- BVV-EC-TRS: TRS21 BVV-EC: BVV2CYL BVV4CYL BVVCMEP-RETRO

$69.41 - $104.12

-

Wireless Digital Vacuum Gauge 1~19,000 Microns

VGW-mini Wireless micron vacuum gauge measures vacuum via just one service port and with no loss of refrigerant. Its compact, robust and smart design support HVAC technicians with numerous intelligent features like the graphic display of measurement data in the Elitech Tools App. Its smart Bluetooth integration allows for data to be stored and evaluated reliably and efficiently, thus saving precious time and resources. Product Features High Accuracy The digital vacuum gauge achieves precise deep vacuum measurements down to single digit resolutions and provides notifications when the evacuation target is met. Smart APP Control Control your micron tester remotely and navigate through all measurement data via Smartphone or Tablet. Quickly and conveniently document your job, finalize your report and export - directly from the job site. Intelligent Judgement of H2O Status The vacuum meter automatically judges physical state of H2O by comparing ambient temperature and water saturation temperature corresponding to the vacuum in the system. Large, Easy-to-Read Display Continual digital readout of evacuation process can be viewed easily on the large, full-view LCD screen. Rechargeable Lithium Battery Built-in rechargeable lithium battery can work up to 20 hours per single full charge, saving troubles of frequent battery change. Product Specifications Measuring Range: 0-19000 micron Operating Temperature: -4℉~140℉ (-20°C~60°C) Interface: 1/4 SAE Accuracy: 1~10,000 microns: ±10% of readings ±10 microns10,000~19,000 microns: ±20% of readings Resolution: 0-400 1 Micron400-3000 10 Micron3000-10000 100 Micron10000-19000 250 Micron Vacuum Units microns, mTorr, in/hg, Pa, Torr, KPa, mbar and psia Battery rechargeable lithium battery (1,000mAh) Overload 27.5 bar Certification CE

$242.94

You have seen 384 out of 1656 products