New Products

-

Welch Vacuum - Gardner Denver Welch BTpro40

Welch BTpro40 (CSA) Certified ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Welch’s BTpro vacuum pump series has a flow and vacuum level to provide fast performance for your size of rotary evaporator, glass reactor, purge oven, or winterization filtration apparatus. These chemical duty PTFE diaphragm pumps are oil-free. The pumping action and deep vacuum comes from the movement of PTFE diaphragms within PTFE heads. All wetted services in the flow path are made of fluoroplastic making the BTpro pump highly chemically resistant. As a result, the BTpro vacuum pump series is near-zero maintenance. A cold trap placed in-line with BTpro pump is needed if terpenes are part of the flow path. The BTpro40 and BTpro70 models employ patented valve and diaphragm technology that generates a deep 15 Torr vacuum pressure with each PTFE head. In addition, both pump models have built-in tuneable vacuum to control evaporation rate. The tunable vacuum adjustment can also be used to stop accidental bumping/foaming. Model BTpro40 Free Air Displacement@60Hz,lpm(CFM) 40(1.4) Ultimate Vacuum Pressure, Torr 15 Maximum Vacuum, in. Hg 29.3 Horsepower, HP (watts) 1/5(150) Built-in adjustable vacuum Yes Gas Ballast - Head Material PTFE Diaphragm PTFE Inlet/outlet Connection 3/8” barb Agency (National Recognized Lab) CSA Weight, lbs (kg) 15.0(6.8) Overall DimensionsLxWxH in.(cm) 12x7x8.3(31x18x22) Shipping Weight, lbs(kg) 19(8.6) Shipping Carton DimensionsLxWxH in.(cm) 21x14x15(52x35x37)

$2,360.26

-

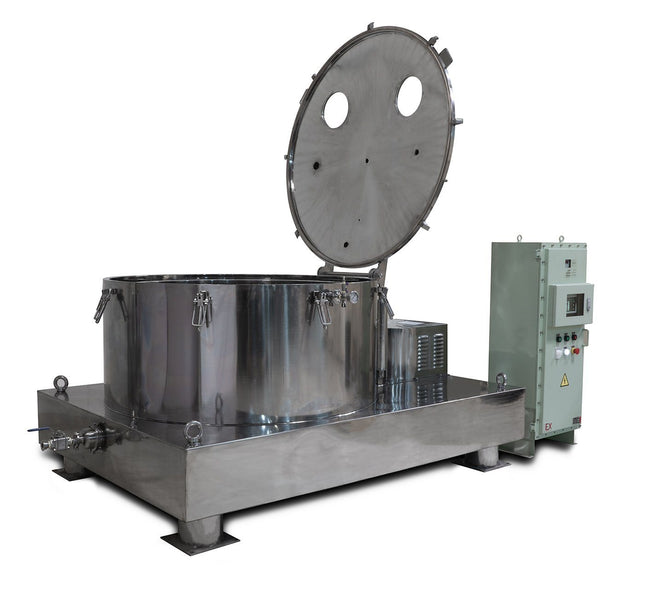

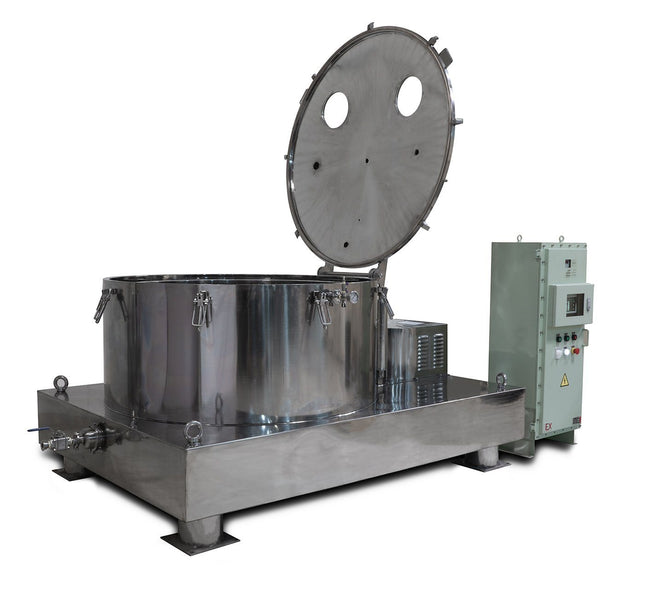

Certified 475L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller - 150Lbs Max Capacity

Certified 475L Ethanol Wash/Dry Centrifuge with Explosion Proof Motor and Controller Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift with a 6000lb+ rating to lift it. Due to the size and weight of this item a custom freight quote will be required. If purchased, BVV will contact the customer to provide shipping options and their price. Confirming logistics will require a 2-3 week lead time. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 800 RPM with Gradual Speed Stepping 430 Separation Factor Multiple Connection Ports/Sizes. High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1.5" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation *BVV Centrifuges are now available certified by PRV Engineers. Field visits/verification letters are an additional $4,000 + travel expenses.* Specifications Capacity 475L Drum Dimensions 47.24" (1200mm) Diameter x 16-3/4" (425mm) Deep Max Capacity 440lbs (200Kg) Speed 800 rpm Separation Factor 430 Electrical 240V 3Ø Weight 5600lbs (2540Kg) Exterior Dimensions 85" x 65" x 49" (2150mm x 1650mm x 1250mm) Viewport Diameter Dual 9" Viewing Ports Connection Size(s): 4" Tri-Clamp Drain Port 1.5" Tri-clamp Jacket Port x 2 1.5" / 2.5" Tri-Clamp Top Ports 1/4" FNPT Top Port KF25 Top Port

$54,841.33 - $60,394.88

-

Certified 45L Jacketed Stainless Steel Centrifuge with Explosion Proof Motor and Siemens Controller

Certified 45L Ethanol Wash/Dry Centrifuge with Explosion Proof Motor and Controller Notice to Customer: This unit has 4 lift points (one in each corner) and requires a forklift to lift it. It will also ship via freight only. Industrial Centrifuges are used to separating liquids from solids and this style of centrifuge excels at alcohol extraction by forcefully separating the alcohol from the biomass. Key Features: Siemens Touch Screen Controller Explosion Proof Controller Housing and Motor Agitation and Spin Dry Modes Max 1500 RPM with Gradual Speed Stepping 566 Separation Factor Multiple Connection Ports/Sizes High Polish Stainless Steel Components Shock absorbing legs Vacuum Jacket with Two 1" Tri-Clamp Fittings Pre-wired and Tested for Easy Installation *BVV Centrifuges are now available certified by PRV Engineers. Field visits/verification letters are an additional $4,000 + travel expenses.* Specifications Capacity 45L Drum Dimensions 17.7" (450mm) Diameter x 11-7/8" (300mm) Deep Max Capacity 15lbs (6.8Kg) Speed 1500 rpm Separation Factor 566 Electrical 240V 1Ø (10.58A) Weight 794lbs (360Kg) Exterior Dimensions 50" x 27.6" x 28.7" (1280mm x 700mm x 730mm) Viewport Diameter 5.5" Connection Size(s): 2" Tri-Clamp Drain Port 1" Tri-clamp Side Port X 2 1" Tri-Clamp Top Port 1.5" Tri-Clamp Top Port 1/4" FNPT Top Port KF25 Top Port

$27,073.57 - $32,627.12

-

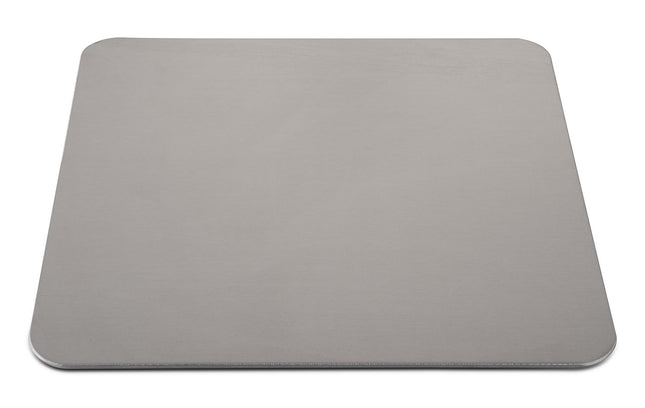

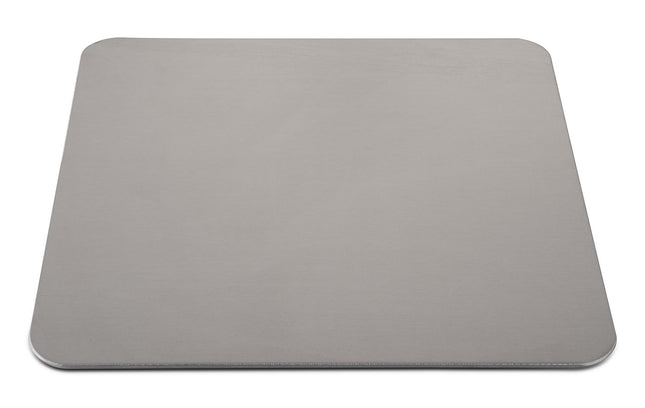

ECO Oven Shelves

ECO Oven Shelves These are stainless steel oven shelves for BVV™ ECO Ovens and fit either a 0.9CF or a 1.9CF ECO Oven. Specifications: 0.9CF - 10.9" (278mm) x 11.2" (285mm) x 1/8" Thickness 1.9CF - 14.1" (359mm) x 15.4" (392mm) x 1/8" Thickness

$44.43 - $58.31

-

35/15 Metal Flask Clamp for 2L and 5L Eco Rotary Evaporators

35/15 Metal Flask Clamp for 2L and 5L Eco Rotary Evaporators This is a replacement clamp for 2L and 5L Eco Rotary Evaporator receiving flask.

$19.44

-

Rubber Fab Rubber Fab PTFE Tri-Clamp Style Gaskets - Type I - Large Sizes

Rubber Fab PTEF Tri-Clamp Style Gaskets - Type I - Large Sizes • 40MOG-C/PTFE (Blue and White are Standard Stock) and is available in the following colors: Red, Green, Yellow, Black, Purple, and Pink - All Colors Available in Pastel Shades • Consult Rubber Fab Sales for Minimums on Non Stock Colored PTFE Gaskets Specifications Brand Rubber Fab UOM EA Product Type Tri-Clamp Gasket - Type I Size Available 5-inch6-inch 8-inch 10-inch 12-inch Material PTFE Color White Min.Temp (°F) -100 Max. Temp (°F) 500 Applications Used widely in the Food, Dairy, Beverage, Biotech, Pharmaceutical, and all other Sanitary Process industries to seal clamp connections in sanitary pipe lines.

$22.21 - $208.26

-

Terpenes Banana Kush

BVV™ Terpenes Banana Kush All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical data sheet. BVV™ Banana Kush Safety Data Sheet BVV™ Banana Kush Technical Data Sheet Banana Kush This sweet, tropical indica-dominant blend gives a soothed, uplifted, creative focus. Banana Kush crosses Skunk Haze and Ghost OG. The fresh banana taste will help increase happiness, better restfulness, creativity, talkativeness, and attention. Fragrance Sweet, fruity, pungent, tropical Effect Soothed, care-free, uplifted, energetic Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$15.27 - $229.08

-

J-KEM Scientific J-KEM Model 150

J-KEM Model 150 An ideal controller for applications that don’t require the precise regulation of J-KEM’s 200-Series controllers. This compact unit packs 1200 watts of power, sufficient for 5 L heating mantles, many ovens, and other devices. Built with J-KEM’s state-of-the-art PID process controller, but does not contain J-KEM’s power control computer. Specifications: 120vac, 10 amps, 1200 wattsWarranty: 2 Years The temperature range desired determines the probe/thermocouple type: J [black] (0 – 800° C) K [yellow] (-50 – 1200° C) T [blue] (-200 – 250° C) Weight: 4 Dimensions: 5.4 x 3.75 x 2.5 in PURCHASE WITH OR WITHOUT SYSTEM ACCESSORIES Complete system includes: one controller, one Teflon thermocouple (12″ long, 1/8″ diameter), one connecting cord, and one 14/20 joint adapter.

$1,046.84 - $1,205.12

-

Beaker & Wrench Beaker & Wrench Turn-key System 6"

Beaker & Wrench Turn-key System Please Note: Lead time 0-4 weeks Get greater consistency, purity, and confidence in every Flower oil distillation when you use our system to monitor and optimize flow rate, temperature, pressure, and wiper speed (RPM) in real time. Fully continuous flow leaves behind less advanced methods with a dependable output of 3-5 liters per hour; maximizing efficiency and minimizing complications. Be assured of the quality of your system. Each system is 6 inch and constructed with fully compliant USA NRTL-certified components, including a display unit and two sensors to track the contents of both streams of fluid as it continuously travels through the glassware. Your system arrives ready to use immediately with all components primed for use. Just roll it off the lift gate and let it get to work. Meet demand and feel confident in the quality of your output with this turn-key system. 6” Stainless Steel Wiped-Film Evaporator Delivers greater consistency, purity, and confidence in every Flower oil distillation. Continuous flow leaves behind less advanced and efficient methods with a dependable input up to 7 liters per hour. Throughput capability Up to 7.0 L/hr Average 3.0-5.0 L/hr True Continuous Feed Peristaltic Inlet pump allows addition of oil while machine is still under vacuum Outlet pumps allow dispensing of products directly into vessel of choice Feed rates adjustable from 10mL to 10L/hr Jacketed body Thermal fluid circulating through jacketed body for consistent temperature Precise temperature control PID temperature controllers on body and all heated lines for creation of precise SOPs Expert On-Site Training and Installation Validation with YOUR oil on the day of install Consultation on how to generate the best SOP for your lab Sample SOP provided for internal use Potency up to 99.8% total Flower content Feed 20L stainless steel feed flask with vacuum inlet line Peristaltic dosing pump for precise, vacuum-held dosing Feed line to evaporator is jacketed and PID controlled Short-Path Evaporator Max evaporator temperature: 200 °C 316 Stainless Steel 316 Stainless Steel Internal condenser (cold finger) 6 rollers Easy to adjust drive system speed Distillate & Residue Discharge Pumps (2 pumps) Gear pump in PID controlled heated design (design temperature 100°C), digitally displayed pump speed. Calibration and secret menu options for optimal SOP development Check valves used as a pressure lock against the atmosphere Vacuum System 21 to 36 CFM Rotary Vane Vacuum pump equipped with vacuum pump oil Diffusion vacuum pump for achieving stable vacuum conditions at low pressures (oil included) Flanged cold trap & collection vessel for cold trap Heating & Cooling by Beaker & Wrench/ Polyscience 1 independent heating unit for the evaporator (oil circulator) 1 independent heating unit (silicone pad) for the residue & distillate line 1 independent heating unit for the feed tank (silicone pad) 1 independent cooling unit for the cold trap (immersion probe) 1 independent chilling unit for the internal condenser (water circulator) Rack/Frame Frame constructed of 80/20 aluminium extrusion and equipped with 4 wheels Power supply & power distribution system 1. Voltage: 120V or 220V Frequency: 60 Hz 3. Number of Phases: 1 (two hot wires) • Power distribution panel Control panel for pumps. Included spare parts. 1 set of rollers 1 set of static gaskets 1 set of shaft sealing for rotary transmission • 1 set of bearings for rotary transmission 1 set of O-rings Documentation Operating instructions Component Certifications See Below Heaters & Chillers CE/ISO9001 Vacuum Pumps Gear Pumps Wiper Drive Power Box Frequency Box Pressure Gauge

$270,735.67

-

Beaker & Wrench Beaker & Wrench Outlet Pump

Beaker & Wrench Outlet Pump Outlet pump comes with: – motor – heater/pump controller – mounting – pump (heated) – If you need custom please purchase custom adapters separately.

$9,996.39

-

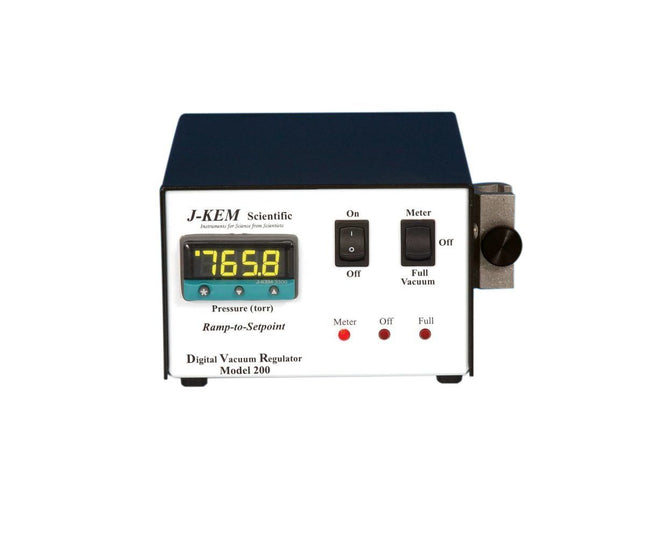

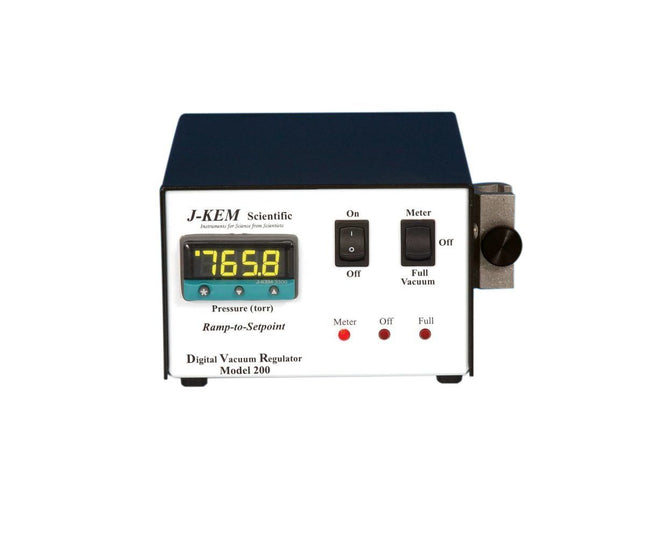

J-KEM Scientific J-KEM DVM-100

J-kem DVM-100 The DVM-100 continuously displays the pressure in a connected piece of equipment on a large digital display. The vapor path of the DVM-100 is 100% stainles steel to provide long life and chemical compatibility. Comes with J-KEM’s KEM-Net software to provide data logging and a real time graphical display of system pressure. The DVM-100 provides vacuum monitoring but not vacuum regulation.

$1,832.67

-

So-Low So-Low Flammable Material Storage Freezer 4.5 Cubic Feet MV23-4UCFMSF

So-Low Flammable Material Storage Freezer 4.5 Cubic Feet MV23-4UCFMSF Please note: This Product may carry up to an 8 week lead time! Description: Flammable Freezers are designed to meet National Fire Protection Agency NFPA and OSHA guidelines for the frozen (-20°C) storage of flammable (volatile) material storage in general laboratory work areas.Upright and undercounter models. Designed exclusively to control flammable material, The So-Low Flammable Material Storage Freezers and Refrigerators are ideal for storage of any flammable material products. There are no electrical components located in the interior of the unit and the compressor's electrical components have been sealed in a vapor-proof enclosure for additional safety. Units are supplied with a power cord to ease installation. Temperature control and temperature recorder options allow for an individualized intensity of temperature control and monitoring. Adjustable legs and shelves add more availability and storage options to fit your laboratories needs. Features: Solid Polyurethane Foam Insulated Doors Epoxy Coated Shelves Adjustable Shelves Adjustable Legs CFC-Free Refrigerant and Insulation Adjustable Thermostat Manual Defrost UL Listed Product Specification Manufacturer So-Low Temperature Range -15°C to -17°C Capacity 4.5 Cubic Fee Exterior w x d x h (inches) 23.625" x 24.25" x 32.187" Door Single Solid, locking Interior Finish Anodized aluminum Casters Four Leveling Legs Insulation Polyurethane foam Refrigerant R134A CFC free Compressor 1/5 hp Condenser Static Defrost Manual Voltage:Domestic 115/60/1 Running Amps/Breaker 2.5/15 Supply Plug 5-15P NEMA UL listed Shipping weight 150 lbs. Warranty -(Domestic) 12 months parts and labor Compressors additional 4 years, no labor. Specification Data Sheet

$3,179.41

-

So-Low So-Low Flammable Material Storage Refrigerators 1°C to 10°C, 14 Cu.Ft, MV4-6UCFMSR

So-Low Flammable Material Storage Refrigerators 1°C to 10°C, 14 Cu.Ft, MV4-6UCFMSR Please note: This Product may carry up to an 11 week lead time! Our Flammable Refrigerators and Freezers are designed to meet National Fire Protection Agency NFPA and OSHA guidelines for the refrigerated storage of flammable (volatile) material storage in general laboratory work areas. Designed exclusively to control flammable material, The So-Low Flammable Material Storage Freezers and Refrigerators are ideal for storage of any flammable material products. There are no electrical components located in the interior of the unit and the compressor's electrical components have been sealed in a vapor-proof enclosure for additional safety. Units are supplied with a power cord to ease installation. Temperature control and temperature recorder options allow for an individualized intensity of temperature control and monitoring. Adjustable legs and shelves add more availability and storage options to fit your laboratories needs. Features Solid Polyurethane Foam Insulated Doors Epoxy Coated Shelves Adjustable Shelves Adjustable Legs CFC-Free Refrigerant and Insulation Adjustable Thermostat Manual Defrost UL Listed Product Specification Manufacturer So-Low Temperature Range 1°C to 7°C Capacity 6.1 Cufic Feet Exterior w x d x h (inches) 23.625" x 24.25" x 32.187" Exterior w x d x h (cm) 68 x 62 x 82 Door Single Solid, locking Interior Finish Anodized aluminum Leg Four Leveling Legs Insulation Polyurethane foam Refrigerant R134A CFC free Compressor 1/5 hp Condenser Static Defrost Manual Voltage:Domestic 115/60/1 Running Amps/Breaker 2.5/15 Supply Plug 5-15P NEMA UL listed Shipping weight 150lbs Warranty -(Domestic) 12 months parts and labor Compressors additional 4 years, no labor. Specification Data Sheet

$3,318.25

-

Replacement Gasket for Dutch Weave Sintered Filter Disks - Buna-N

Replacement Gasket for Dutch Weave Sintered Filter Disks This is a replacement buna-n gasket for dutch weave sintered filter disks.

$11.11 - $30.54

-

Replacement Gasket for Lab Dosing Gun

Replacement Gasket for Lab Dosing Gun 30 Day Limited Warranty This a replacement gasket for the BVV™ Lab Dosing Gun

$16.66

-

Lab Dosing Gun

Lab Dosing Gun 30 Day Limited Warranty This a gun for the BVV™ Semi-Automatic Lab Dosing Gun. It comes bare bones and Includes the following: Lab Dosing Gun Replacement Spring Clip Replacement Gasket 25ml Gun 0.5-2.5ml (0.5ml Increments) 50ml Gun 1-5ml (1ml Increments) Polypropylene Barrel – Chemically Resistant to: Isopropyl Alcohol, Ethanol, Butane, Hexane, Glycerin, Glycols, Terpenes, and most Acids Lure Lock Hub for all types of size attachments Adjustable plunger tension/tightening (*for user preferred plunger action) NOTE: Does not come with Syringe Tips Please Clean Prior to first use gun does not come sterilized.

$118.01

-

Rubber Fab Rubber Fab Tuf-Steel 316L Tri-Clamp Style Gaskets Type I

Rubber Fab Tuf-Steel 316L Tri-Clamp Style Gaskets Type Tuf-Steel is composed of a unique 50/50 blend of nonpigmented PTFE and 316L passivated and atomized stainless Steel° Testing and seven years of documented application usage has demonstrated that Tuf-Steel is the choice for perfect surface performance, outstanding durability and extended service life in both SIP (steam in place) and WFI (water for injection) applications. Tuf-Steel® is ideal for sanitary steam pipe connections in extreme temperatures ranging from -320°F to 550°F. The superior strength of Tuf-Steel® eliminates creep and cold flow providing a leak-free seal and preventing maintenance problems and system downtime. 500 CIP/SIP Cycles guaranteed -325°F to 550°F Superior creep resistance Excellent expansion/contraction stability with minimal thermal expansion Excellent chemical resistance Stops leaks when correctly torqued (50 in./lbs with Torque-Rite® TR-50) No gasket extrusion into the sanitary tube I.D. No obstruction of flow Maintains sealing stability in T processes Non-stick surface Non pigmented Passivated to eliminate rouging Rubber Fab's Type I gaskets are: FDA CFR 177.2600 FDA CFR 177.1550 U.S. Pharmacopeia Class VI Certification ADI Free (Animal Derived Ingredient Free) certified Manufactured according to cGMP Guidelines Sizes Available: 1/2 in. 3/4 in. 1 in. 1 1/2 in. 2 in. 2 1/2 in 3 in. 3 1/2 4 in

$18.05 - $412.35

-

Replacement Luer-Lok Dosing Tips for Lab Dosing Guns - 5 Pack

Replacement Luer-Lok Dosing Tips for Lab Dosing Guns - 5 Pack 5 Pack of replacement 14 gauge stainless steel tips for BVV™ Lab Dosing Guns.

$13.88

-

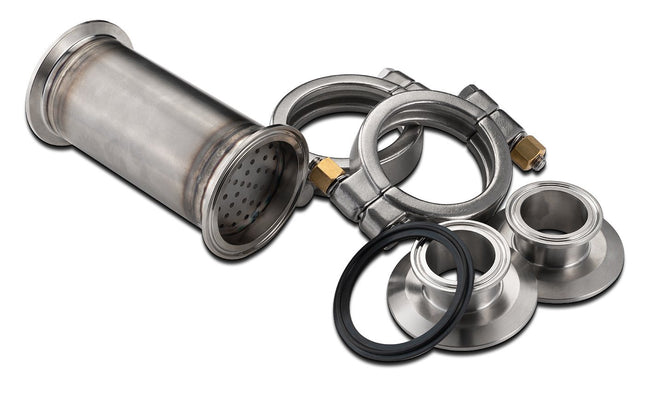

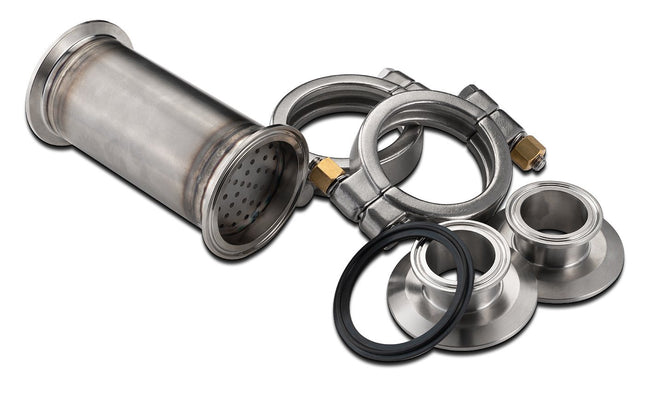

AFS AFS Tri-Clamp Inline Filter Housing for Disposable Color Remediation Cartridges

AFS Tri-Clamp Inline Filter Housing for Disposable Color Remediation Cartridges Note: Disposable cartridges sold separately. (Click Here for Cartridges) This inline housing allows for implementation of the AFS filters into many extraction systems. The AFS filter housing is 2.5" but comes with the adapter flanges for both ends to go inline with a standard 1.5" or 2" tri-clamp system. Kit Includes 2x 2.5" High Pressure Clamps 1x 2.5" Buna-N Gasket 2x Reducers 2.5" to 1.5" or 2" Tri-clamp 1x Cartridge Housing AFS Instruction Manual Download Here AFS SDS Sheet

$277.68 $180.49

-

AFS AFS 2.5" Disposable Color Remediation Cartridge

AFS Disposable Color Remediation Cartridge Note: Stainless Steel filter housing sold separately. (Click Here for Housing) AFS Instruction Manual Download Here AFS Filters are the first and only disposable color remediation filter cartridges for the botanical extraction industry. Our Patent Pending design allows for an easy to use solution implemented into existing extraction systems and is now available as a standard integration from many equipment manufacturers. AFS Filters are a simple solution that allows for the use of prepackaged filters, which are available in different recipes depending on the application. With the integrated 2.5µm paper filter molded and sealed into the cup, there is no media leak through. Pre-packed means there's no need to be an expert in remediation filter media and how to construct filters; as well as eliminates the messy process of building/packing filters yourself. Disposable offers no need for cleaning the filter housings afterward and trying to un-clog stainless filter screens. Less R&D investment, less mess, and less downtime allows for higher throughput and more profit. These come in light, medium, and heavy filtration. Learn more about each: Light Filtration is the trimmed down version of the standard Medium filter. These are best suited for extractions using fresh high-end input materials that only needs a light cleaning. Medium Filtration is our standard go-to filter. This is the most commonly used and sold filter AFS offers.. It's great for general filtration and lightening of extracted products. Heavy Filtration is packed with the highest amount of active extraction media. These filters are best suited for exceptionally dark extractions or for extractions with normal input materials where the desired outcome is closer to clear. Heavy filters offer the highest level of filtration. Technical Specifications: Life Span: 1 Time use, 5-7 lbs. of dry material. Temperature Rating: -40°C-70°C Top Seal: Induction Sealed (No glue is used) Filter: Cellulose Paper Pressure Rating: Recommended 60psi, Paper will hold 80-90 psi Max. Media: Proprietary licensed recipe. Shell Material: Polypropylene Excellent compatibility and Safe for chemicals in our industry (Butane, Propane, Ethanol). Pressure Method: Nitrogen Assist, unless you open blast CRC. Then you can assist with an air compressor. Click here to see SDS Sheet *Please recycle your spent Cartridges.

$58.31 - $733.07

-

Welch Vacuum - Gardner Denver Welch ProBoost Air-Cooled Diffusion Pump

Welch ProBoost Air-Cooled Diffusion Pump Product Details Use Welch ProBoost in conjunction with a backing pump like the CRVpro to get deeper vacuum and higher flow. High Vacuum to 10⁻⁵ torr Use with high vacuum and Schlenk lines Employs air cooled diffusion pump Easy Attachment to backing pump Welch ProBoost is an air cooled gas jet pump (commonly called a diffusion pump). The gas jet is formed by directing boiling silicone vapors through a hollow cone. There are no internal moving parts. The pumping action commences when the vacuum pressure in the still (i.e. wiped film) goes below 0.2 torr (200 millitorr). On an empty, leak free still, ProBoost backed by a rotary vane pump lowers the vacuum pressure to 0.00002 torr (20x lower in pressure than a 2-stage rotary vane vacuum pump can do alone). ProBoost backed by a rotary vane vacuum pump will lower vacuum pressure to below 0.0001 torr in high vacuum and Schlenk lines. This high vacuum is invaluable to improve the results from reactions using air-sensitive compounds such as organometallics, metal amides, and hydrides. ProBoost has a built-in control board for fan and heater. When you turn on ProBoost, the fan and heater both turn on. When you turn off ProBoost, the heater turns off immediately and the fan runs for another 20 minutes to cool the pump. Specifications Maximum Pumping Speed, Air 80 l/sec Ultimate Vacuum Pressure 0.00002 torr Minimum Back Pump FAD at 60 Hz 2.8 CFM Maximum Discharge Pressure 0.2 torr Ambient Environmental Temp 10–30°C Heat-up time 7 minutes Inlet Connection NW50 Discharge Connection NW25 Silicone Oil Capacity Approximately 30 ml Cool Down Time 20 minutes Pump Dimensions, L x W x H 5.5 x 5.4 x 7.5 in Weight 5.6 lbs (2.5 kg) Download Manual

$5,345.29

-

Huber Huber Unistat Tango with Pilot ONE

Huber Unistat Tango with Pilot ONE (Please Note: There is 2-3 weeks Shipping lead time) Unistats are predestined for applications in process and chemical engineering, such as temperature control of reactors, autoclaves, Miniplant/Pilot systems, reactor blocks and calorimeters. Unistat temperature control systems with their unique thermodynamics provide highly accurate and reproducible results, guaranteeing the shortest heating and cooling times and a wide temperature range without fluid change. Environmentally and economically Unistats stand out, offering natural refrigerants and an efficient energy management system for reduced operating costs. . Precise and reproducible temperature control results Fastest heating and cooling rates Wide temperature ranges with no fluid change Pilot ONE controller with 5.7“ touchscreen and comfortable menu navigation Adaptive temperature control, self-optimising Efficient circulation pump 2 x USB (Host and Device), Ethernet and RS232 interfaces Efficient operation saves working time and operating costs Proven functionality for the process industry E-grade "Professional" included Download Data sheet Unistat tango Download Data Sheet Unistat tango w Download Data Sheet Unistat tango wl Operating Manual Click here 3 year Warranty Register General Information & Temperature Controller Unistat Tango Unistat Tango w Unistat Tango wl Temperature range -45...250 °C -45...250 °C -45...250 °C Temperature stability ±0.01 °C ±0.01 ±0.01 °C Temperature control TAC, self-optimizing (True Adaptive Control) TAC, self-optimizing (True Adaptive Control) TAC, self-optimizing (True Adaptive Control) Display resolution 0.01 °C 0.01 °C 0.01 °C Alarm message optical, acoustical optical, acoustical optical, acoustical Controller Pilot ONE (E-grade "Professional") Pilot ONE (E-grade "Professional") Pilot ONE (E-grade "Professional") Safety class III / FL III / FL III / FL Protection class IP20 IP20 IP20 Dimensions (W x D x H) 16.77 x 12.87 x 24.84 inches 16.77 x 12.87 x 24.84 inches 16.77 x 12.87 x 24.84 inches Weight 141.12 pounds 119.07 pounds 132.3 pounds Heating / Cooling Capacity Heating capacity 3 kW 3 kW 3 kW Cooling capacity 250 200 100 0 -20 -40 °C0,7 0,7 0,7 0,7 0,4 0,06 kW 250 200 100 0 -20 -40 °C0,7 0,7 0,7 0,7 0,4 0,06 kW 250 200 100 0 -20 -40 °C0,7 0,7 0,7 0,7 0,4 0,06 kW Cooling machine air-cooled water-cooled air- and water-cooled Refrigerant R1270 (0,15 kg) R1270 (0,09 kg R1270 (0,15 kg) Circulation Pump Pressure pump max. 55 lpm ; 0.9 bar | 14.53 gpm ; 13.05 psi 55 lpm ; 0.9 bar | 14.53 gpm ; 130.5 psi 55 lpm ; 0.9 bar | 14.53 gpm ; 130.5 psi Pump connection M24x1,5 AG male M24x1,5 AG male M24x1,5 AG male Permissible viscosity 50 mm²/s 50 mm²/s Connections Pt100 connection Pt100 Pt100 Pt100 Analogue input via optional Com.G@te via optional Com.G@te via optional Com.G@te Analogue outpu via optional Com.G@te via optional Com.G@te via optional Com.G@te Digital interface RS232, Ethernet, USB Device, USB Host RS232, Ethernet, USB Device, USB Host RS232, Ethernet, USB Device, USB Host Operating Data Permissible ambient temp. 5 to 40 °C 5 to 40 °C 5 to 40 °C Noise level 62 dB(A) - 62 dB(A) Filling volume min. 1.5 Liters | 0.4 gal 1.5 Liters | 0.4 gal 1.5 Liters | 0.4 gal Volume of expansion 2.8 Liters | 0.74 gal 2.8 Liters | 0.74 gal 2.8 Liters | 0.74 gal Cooling water connection - G1/2 AG G1/2 AG Cooling water consumption - 24 l/h 30 l/h Cooling water differential pressure min. - 0,5 bar | 72.5 psi 0,5 bar | 72.5 psi Cooling water pressure max. - 6 bar | 87 psi 6 bar | 87 psi Power supply 208V 2~ 60Hz 208V 2~ 60Hz 208V 2~ 60Hz Current max 18 A 16,5 A 17,5 A Fusing 20 A 2x20 A 2x20 A

$40,124.41 - $43,664.80

-

Huber Huber Unistat 915w with Pilot ONE

Huber Unistat 915w with Pilot ONE (Please Note: There is a 2 - 3 weeks lead time) Unistat Circulators are an ideal solution for fast and precise thermal control of externally connected applications. These systems offer rapid temperature change and a wide temperature range without having to change fluid. The new Pilot ONE controller features a navigation system with easily remembered icons and menus which are sorted by color to make routine work simpler. An amazing software guides you through your set up ensuring all the necessary settings are correct. Precise and reproducible temperature control results Fastest heating and cooling rate Wide temperature ranges with no fluid change Pilot ONE controller with 5.7“ touchscreen and comfortable menu navigation Adaptive temperature control, self-optimising Efficient circulation pump Data communication via LAN, internet, USB, RS232 and RS485 Efficient operation saves working time and operating costs Proven functionality for the process industry E-grade "Professional" included Download Data Sheet Click Here for 3 Year Warranty Online Registration Download Operating Manual General information & Temperature Controller Temperature range -90...250 °C Temperature stability ±0.02 °C ±0.01 °C Temperature control TAC, self-optimizing (True Adaptive Control) Display resolution 0.01 °C Alarm message optical, acoustical Controller Pilot ONE (E-grade "Professional") Safety class III / FL Protection class IP20 Dimensions (W x D x H) 630 x 704 x 1565 mm | 24.8 x 27.72 x 61.61 inches Weight 364 kg | 802.62 pounds Heating / Cooling Capacity Heating capacity 6 kW Cooling capacity 250 200 100 0 -20 -40 -60 -80 -90 °C 6,5 7,5 9 11 11 11 8,2 4,2 1,3 0,6 kW Cooling machine water-cooled Refrigerant 1. stage R507 (A1, H280) (2,9 kg) Refrigerant 2. stage R23 (A1, H280) (1,23 kg) Circulation Pump Pressure pump max. 110 lpm ; 1.5 bar | 29.06 gpm ; 21.75 psi Pump Connection M30x1,5 AG male Permissible viscosity 50 mm²/s Connections Pt100 connection Pt100 Analogue input via optional Com.G@te Analogue output via optional Com.G@te Digital interface RS232, Ethernet, USB Device, USB Host Operating Data Old sku 1055.0011.01 Permissible ambient temp. 5...40 °C Noise level 64 dB(A) Filling volume min. 3.9 Liters | 1.03 gal Volume of expansion 6.5 Liters | 1.72 gal Cooling water connection G3/4 AG Cooling water differential pressure min. 1 bar | 14.5 psi Cooling water pressure max. 6 bar | 87 psi Power supply 460V 3~ 60Hz Current max. 29 A

$190,625.68 - $191,319.87

-

Pure-Flo Perform 5000 Highly Acid Activated Bleaching & Decolorizing Bentonite

Pure-Flo® Perform 5000 Highly Activated Bentonite Clay for Bleaching & Decolorizing Edible Oils pH: 2.7 Pure-Flo® Perform 5000 provides superior bleaching activity for demanding oils. Effective with all types of difficult-to-bleach oil. Pure-Flo® Perform 5000 Technical Data Sheet.pdf Perform 5000 Safety Data Sheet Excellent metals adsorption characteristics (P, Ca, Fe, Mg, Ni, etc.) Excellent Chlorophyll removal Excellent Red and Blue color body removal. Removes soaps and phospholipids Outstanding filtration characteristics, including long filtration cycles and less pressure build up at cycle end. ph:2.7 FDA GRAS (Generally Recognized as Safe) - This product is safe for processing food, as long as its not part of the end product being consumed. NSF- HACCP *Prior to down packing this product was certified Kosher & Hallal. It does not retain its certifications after down packing, Sorry BVV™ doesn't have an on staff Rabbi or Imam on site to re-establish those certifications. Note: Bulk Bags and Bulk sizes are non-stocked items and will be ordered as needed and carry a several weeks lead time and require a forklift or pallet jack

$27.77 - $3,123.87

-

TRS21 2 Piece Piston Tool

BVV-TL1 Included: 2-piece piston tool. This tool is specially used to rebuild BVV-1. It features two posts that lock into the top of the piston and a 5/8” hex head for easy installation. This tool is required to install top piston assembly without damaging the piston. If this tool is not used the customer is responsible for all damage done to piston.

$18.05

-

TRS21 Upgraded Compressor head SS ¼” SAE 45D IN and OUT fittings

BVV-9-1 Included in this kit: TRS21 compressor head SS ¼” SAE 45D IN and OUT fittings, Viton o-rings. Use these fittings to replace the OEM brass fittings on your TRS21. The SS fittings minimize and help eliminate bacterial growth in the recovery process.

$38.87

-

TRS21 / BVV Upgraded Top Piston Assembly

BVV-3 Included in this kit: Top piston assembly with piston seal and piston wear band. This upgrade kit can be used for the following recovery pumps: CPS TRS21 Anti-spark/explosion pump BVV 2 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified BVV 4 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified - Requires 2 kits because this unit has 4 cylinders. BVV CMEP-OL Retro Fit Upgraded Head - Requires 2 kits because this unit has 4 cylinders. BVV 4 Cyl & 2 Cyl Pump Seal Rebuild Instructions If you have upgraded to the 2-piece SS piston design this kit is used to rebuild the piston seal and wear band. Piston tool (SKU: BVV-TL1) and Loctite 242 will be needed to properly install. If tool is not used the customer is responsible for any damage done to piston during assembly.

$152.72

-

TRS21 / BVV Upgraded Stainless Steel 2-Piece Piston and Rod Design for Hydrocarbon Extraction

BVV-1 Included in this kit: Complete connecting rod assemblies with 2-piece SS piston, piston seals, and viton o-rings. This upgrade kit can be used for the following recovery pumps: CPS TRS21 Anti-spark/explosion pump BVV 2 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified BVV 4 Cylinder Butane Recovery Pump ITS/ETL to ANSI/ISA Certified - Requires 2 kits because this unit has 4 cylinders. Looking to rebuild your TRS21 and want to upgrade to a more efficient and longer lasting piston/rod setup? This kit comes with a fully assembled connection rod and 2 piece piston. The piston is made out of SS making it a great choice for any application where bacterial growth must be eliminated. This design focuses on long life piston seal and wear band. This kit utilizes a Viton energized o-ring specifically designed for butane and or propane recovery used in the extraction process. By utilizing this kit the piston seal and wear band can be easily removed without having to disassemble the rod from crank. An inexpensive tool (*NOT INCLUDED* SKU: BVV-TL1) is required to rebuild the seals next time service is needed. The tool uses two posts to lock into the top of the piston and a 5/8” Hex heat to remove the top part of the piston. If you would like to purchase both the piston/rod assembly and tool it’s (SKU:BVV-K1). If the tool is not used the customer is responsible for all damage done to piston. After this has been done the wear ring can slide out and the piston seal can be replaced with a new one, the kit can be purchased for all future piston seal and wear band rebuilds (*NOT INCLUDED* SKU: BVV-3). Loctite 242 (*NOT INCLUDED) will also be required for proper installation. A test was performed between the OEM piston and seal design and the BVV. Results show that the BVV had a much less leak rate than the OEM design. After hours of use the leak rate of the OEM design was unable to recover the complete initial solvent batch. This affects the efficiency of the recovery process.

$256.85

-

TRS21 Complete Connecting Rod Assembly Upgrade Kit

BVV-K1 Included in this kit: Complete connecting rod assemblies with 2-piece SS piston, piston seals, viton o-rings, and 2-piece piston tool. Looking to rebuild your TRS21 and want to upgrade to a more efficient and longer lasting piston/rod setup? This kit comes with a fully assembled connection rod and 2 piece piston. The piston is made out of SS making it a great choice for any application where bacterial growth must be eliminated. This design focuses on long life piston seal and wear band. This kit utilizes a Viton energized o-ring specifically designed for butane and or propane recovery used in the extraction process. By utilizing this kit the piston seal and wear band can be easily removed without having to disassemble the rod from crank. An inexpensive tool (*INCLUDED* SKU: BVV-TL1) is required to rebuild the seals next time service is needed. The tool uses two posts to lock into the top of the piston and a 5/8” Hex heat to remove the top part of the piston. After this has been done the wear ring can slide out and the piston seal can be replaced with a new one, the kit can be purchased for all future piston seal and wear band rebuilds (*NOT INCLUDED* SKU: BVV-3). Loctite 242 (*NOT INCLUDED*) will also be required for proper installation. A test was performed between the OEM piston and seal design and the BVV. Results show that the BVV had a much less leak rate than the OEM design. After hours of use the leak rate of the OEM design was unable to recover the complete initial solvent batch. This affects the efficiency of the recovery process.

$270.74

-

Pure-Flo® B81 Supreme Activated Bleaching & Decolorizing Bentonite for Edible Oils *FDA-GRAS (Compares to T-5™)

Pure-Flo® B81 Supreme Moderately Activated Bentonite Clay for Bleaching & Decolorizing Edible Oils pH:4.4 Pure-Flo® B81 Supreme Offers fats and oils processors surface modified performance at the best value. Excellent for oils with moderate color and chlorophyll levels. Supreme B81 adsorbent has been activated using a proprietary Surface Modification Technology (SMT). Pure-Flo® Supreme B81 Data Sheet.pdf B81 Supreme Safety Data Sheet • Excellent metals adsorption characteristics (P, Ca, Fe, Mg, Ni, etc.)• Removes color bodies from a variety of oils and effectively eliminates chlorophyll from vegetable oils• Removes soaps and phospholipids• Minimizes free fatty acid rise during bleaching• Outstanding filtration characteristics, including long filtration cycles and lesspressure build up at cycle end ph:4.4 FDA GRAS (Generally Recognized as Safe) - This product is safe for processing food, as long as its not part of the end product being consumed. NSF- HACCP *Prior to down packing this product was certified Kosher & Hallal. It does not retain its certifications after down packing, Sorry BVV™ doesn't have an on staff Rabbi or Imam on site to re-establish those certifications. Note: Bulk Bags and Bulk sizes are non-stocked items and will be ordered as needed and carry a several weeks lead time and require a forklift or pallet jack

$27.77 - $3,123.87

-

Cascade Sciences Cascade CVO-2 PRO Vacuum Package

Cascade CVO-2 PRO Vacuum Package The CVO-2 PRO Package is a 2 cubic foot, benchtop vacuum oven with a powerful, 5.4 CFM oil-free scroll pump. It is an ideal benchtop set up for vacuum drying or purging temp sensitive material but at faster rates, with deeper vacuum and optimized vapor flow rates. This complete system will liberate solvents, water or other unwanted compounds in a small batch, laboratory environments. CVO-2 PRO Package Includes: CVO-2 vacuum oven 5 aluminum shelves in 1″, 2″ and 3″ heights for varied configurations Agilent IDP7, 5.4CFM dry scroll pump MAXEVAP vacuum oven to pump connection kit. This special connection kit optimizes flow rates with a large 1″ dia exit path out of oven, large, vacuum rated 1″ diameter lines, a large 1″ diameter vacuum valve and into the 1″ diameter vacuum pump inlet. At no time is the out-gas load restricted or flow reduced. Also includes the KF-25 hardware. The CVO-2 PRO Package allows for easy expansion Easily connect another vacuum oven to the large pumping system to increase capacity and save on future costs. Both oven and pump can run off a single dedicated 120V / 1ph / 20 AMP circuit. Both oven and pump can be built/ configured to run on 220V / 1ph CVO-2 Vacuum Oven NRTL Certified by TUV 5 shelves (11.5″W x 19″D) in a flexible configuration. Stack-able and removable Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reads in inches of mercury Simple, set-point control Smooth, quarter-turn vacuum and vent valves Rear KF-25 port allows for rapid MAXEVAP purging or running feedthroughs inside oven for monitoring 120V (220V available) Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Adjustable leveling feet ensure oven sits solid and level in the workspace CVO-2 Connections 3/8″ Barb for Vacuum Pump 1/4″ Barb for Venting (N2 Connection OK) KF-25 Port for feedthroughs or MAXEVAP Connection Kit Agilent IDP7 Dry Scroll Pump Features Oil-Free. Eliminates contamination risk. Will not smoke out exhaust, no filter required. Quiet (for a vacuum pump) 5.4 CFM pumping speed Ultimate vacuum: 2 x 10-2 Torr 120V or 220V / 1ph power – flexible configuration Adjustable “gas ballast” allows for better solvent tolerance / ingestion Maintenance requires the replacement of a single “tip seal”. Low cost of ownership. Powerful enough to accommodate a second vacuum pump Want Hotter Than 150°C (300°F)? CVO-2-HT (High Temp) has a temperature range Up to 220°C (428°F) The Cascade Difference Vacuum ovens have been around for decades. Basic vacuum ovens are mass-produced and sold by many large scale laboratory equipment distributors. But there are key differences between Cascade and other inexpensive, often imported vacuum ovens: Exceptional Temperature Control & Stability The Cascade CVO-2 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-2 eliminate hot and cold spots, making accurate use of every inch of shelf space. Independent Over-temp Failsafe Protection The Cascade Sciences CVO-2 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 200°C or 392°F. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. NRTL Certification #U8 170464972 077. No Extra cost. The CVO-2 Vacuum Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities.CAN/CSA-C22.2 No. 61010-1:2012+UPD No. 1:2015-07 + UPD No. 2:2016-04CAN/CSA-C22.2 No. 61010-2-010:2015UL 61010-1:2012/R:2016-04UL 61010-2-010:2015EN 61010-1:2010EN 61010-2-010:2014 Rigorous Quality Assurance in an ISO Certified, USA Manufacturing FacilityCascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment:Chambers are vacuum tested after welding for vacuum integrityElectrical & mechanical safety is thoroughly tested in compliance with TUV requirementsFunctional testing verifies user settable items consistent with most lab protocols/usage models Temperature verification includes calibration & temp chamber uniformity following ASTM standards Units are cleaned and packed in ISTA tested, certified packaging materials Digital Vacuum Gauge The digital vacuum gauge installed on the CVO-2 is factory default set to read in inches of mercury (“Hg) with a scale of 0 – 29.9”Hg. Change the unit of vacuum measurement to read in a wide variety of units from mmHg, bar psi, kPa, cm2, mmH20. Zero out the vacuum gauge to calibrate for just above sea level adjustments. Equipped for Inert Gas Backfill. Built-In Safety Relief Introduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the 1/4″ rear vent barb. The maximum backfill pressure is 15psi at the inlet. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection Ports The CVO-2 ovens offer two different vacuum oven connection points. The standard connection is a 3/8″ dia barb located at the rear of the oven. It is connected to the vacuum valve level on the front control panel. For even faster evaporation, purging or drying consider upgrading to the MAXEVAP connection kit. The MAXEVAP connection kit secures to the oven’s rear 1″ dia KF-25 port located on the back center of the chamber. The MAXEVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthroughs, or monitoring sensors inside the vacuum chamber during processing. Stackable Shelf Design For Maximum Temperature Conduction Under vacuum, there is no air inside a vacuum oven. Temperatures are achieved by a process of conduction and radiation to move temperatures into the product inside the oven. Cascade’s stackable shelf design makes the most of this opportunity by making the chamber longer and narrower, rather than square and supplies stackable shelves in multiple height configurations to allow for the fastest, most uniform transfer of heat. Ergonomically Designed, Easy Quarter-Turn Valves For anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vacuum/vent valves. Your wrists will thank you! ANSI Rated Tempered Glass + USA Made Steel Cascade ovens are made in Oregon, USA with high quality materials. Our glass is NGI-USA Tempered and certified to ANSI Z97.1.2007 16CFR / 201 11. Our door handles are rugged brushed steel, not plastic. Our vacuum vessels are constructed with American made steel. We’ve tried lower cost, imported steel, but over time, vacuum chambers made of lesser quality/lower tolerance material cannot withstand the flex and pressure changes of vacuum pumping/venting/purging. This can deteriorate vacuum integrity and the oven will lose its ability to hold vacuum. Door Gasket Options – Ideal For Your Process Cascade’s vacuum ovens come standard with a High Temp Silicone Door Gasket. We also offer a Solvent resistent BUNA gasket as well. Ask us about the variety of door gaskets we can supply based on your application: Silicone, BUNA, Viton, Fluorosilicone. Gaskets will eventually wear out. It’s ideal to keep a few spares on hand. Specifications Capacity Volume 1.67 Cubic Ft. | 47.2 Cubic Liters Interior 12”W x 20”D x 12"H 711mm x 609mm x 609mm Exterior 18.8” W x 24.5” D x 24.5”H 478mm x 622mm x 622mm Temperature Ranges Low-Temp Processing Range 26°F to 250°F (121°C) Temperature Uniformity +/- 1.5°F @ 105°F (40.5°C) Temperature Stability +/- 0.4°F @ 105°F(40.5°C) Heat Up / Stabilization Time to 250°F 120 minutes (to minimize overshoot) High-Temp CVO-10 (SVAC 9.3) Up to 428°F / 220°C Temperature Uniformity +/- 6.5% of setpoint *Note that ambient laboratory conditions can affect temp performance. Vacuum Valve Type Side Mounted Round Vacuum Vacuum Valve ¼ Turn Lever Vent Valve ¼ Turn Lever Lighting Interior LED Strips (Rated to 150C) On low temp CVO-10 only Window Type Glass Tempered NGI-US to ANSI Z97.1.2007 Vacuum Gauge Indication Digital 0 to 29.9″Hg Temperature Controller Screen Type Digital Set Point Accuracy Accurate Within 1°F Failsafe Independent Overtemp Failsafe Ports-Rear Vacuum 3/8″ Barb Vent 1/4″ Barb Auxiliary KF-25 Port Inert Gas Introduction Use 1/4″ Vent Barb 15 psi max inlet pressure Power Options Power 110V – 120V / 1ph / 8A 50/60Hz Cord? Cord Included Outlet Type NEMA 5-15R Power Outlet Shelving Removable? Removable Quantity Included Comes with 5 Each. Fixed. Detail Slide on rails, extend, stay in place. Aluminum Surface Area 11.5″W x 19″D Weight Capacity 50 lbs (22.7kgs) Weight Unit Weight 179 lb (81.2 kg) Shipping Weight 218 lbs (99 Kg) Shipping Details Dimensions 33″L x 33″W x 47″D Class Class 85 Certifications NRTL TUV #U8 170464972 077CAN/CSA-C22.2 No. 61010-1:2012+ UPD No. 1:2015-07 + UPD No. 2:2016-04CAN/CSA-C22.2 No. 61010-2-010:2015UL 61010-1:2012/R:2016-04UL 61010-2-010:2015EN 61010-1:2010EN 61010-2-010:2014 Vacuum Pump Agilent IDP3 Vacuum Pump Oil-Free, Scroll Pump 2.1 CFM 120V | 1ph Ultimate Pressure 29.9 ”Hg | 2.5 x10-1 torr Gasket Options Solvent Resistant BUNA Option Rated to 105°C (221°F) Viton Option Rated to 205°C (401°F) CVO-2-2 (220V) Power Specs 220 – 240V / 1ph / 4A 50/60 Hz (Cord Included) NEMA 6-15R Power Outlet Warranty Length 1 Year Exclusions Gaskets Not Incuded The CVO-2 comes in both low temp and high temp versions. The low temp version has excellent temperature uniformity for temperature sensitive material. The higher temp version, 220°C has a uniformity about 6.5% of setpoint. At time of order we will verify the high / low temp version you require.*Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product. Manual Pump Specs View NRTL Certification Vacuum Pressure Chart Vacuum Gauge Manual Calibration

$14,768.98

-

Cascade Sciences Cascade Mobile Stand, Large, Steel, Blue

Cascade Mobile Stand, Large, Steel, Blue This item carries up to a 2 week lead time. Mobile Cart, LargeLarge mobile cart steel, blue powder coat, fits cold trap, vacuum pump, & assorted temp control units

$1,527.23

-

Cascade Sciences Cascade CVO-5 DOUBLE UP Vacuum Package, 120V

Cascade CVO-5 DOUBLE UP Vacuum Package, MAXTRAP -50C Cold Trap Cascade’s CVO-5 DOUBLE UP Vacuum Package is ideal for large volume production with the flexibility of small batch management. The package offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, slurries, or any temperature sensitive material. Cascade’s MAXTRAP Vacuum Cold Traps extend vacuum pump life by trapping excess moisture and volitales during vacuum drying or purging. Typically ships in 3-5 weeks CVO-5 DOUBLE-UP Package Includes: 2x Cascade Sciences CVO-5 Vacuum Ovens 1x Heavy-Duty Industrial Mobile Cart 10x Adjustable, Removable Shelves 2x Adjustable Side Shelves 2x MAXEVAP Connection Kits 1x Agilent IDP15 Oil-Free Vacuum Pump, 9cfm WITH MAXTRAP50 ( -50°C Cold Trap) 1x MAXTRAP50 -50°C Cold Trap 1x Mobile Trapstand for MAXTRAP50 WITH MAXTRAP105 ( -105°C Cold Trap) 1x MAXTRAP105 -105°C Cold Trap 1x Mobile Trapstand for MAXTRAP105 The 5 cubic foot vacuum ovens are stacked on an industrial grade, mobile rack for mobility and ease of cleaning the laboratory. Casters are lockable. Side mounted pump shelf allows for easy powering ON/OFF of vacuum pump. CVO-5 Vacuum Oven Features NRTL Certified by TUV 5 each adjustable shelves Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Bright LED lights in window for visibility of sensitive material Touchscreen LED Control Panel with adjustable settings Smooth, quarter-turn vacuum and vent valves Energize vacuum pump from control panel Rear KF-25 port allows for rapid MAXEVAP purging or running feedthroughs inside oven for monitoring 120V or 220V power options are available Stainless Steel option available Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Adjustable leveling feet ensure your unit sits solid and level in the workspace Made in USA Agilent IDP15 Oil-Free Scroll Pump Features 9 CFM pumping speed Quiet. Less noisy that diaphragm or oil-rotary vane pumps No Inlet / Exhaust Filters Required Hour Meter For Tracking Service Intervals 1 Year Warranty NRTL Certified /Made in USA Expert Rebuild/Maintenance Available Maintenance is the replacement of a single interior tip seal. Order our IDP15 Tip Seal Replacement Kit or ask us about our maintenance service. Pull Deeper Vacuum / Better Vapor Tolerance With Gas Ballast Positions. The IDP15 has two gas ballast ports that assist the pump in handling condensing gases such as water vapor, or other gaseous products that become liquids or solvents when reaching atmospheric pressure. MAXTRAP -50°C/-105°C Cold Trap Features Cascade’s COLDWELL 304 Stainless Steel Trap 3 Quart Capacity Viton Gasket Labconco -50°C/-105°C Refrigerated Base Green CFC / HFC Free Refrigerants KF-25 Inlet/Outlet, Connection Line & Hardware 3mm Neoprene Insulator Cap Requires 800ml (~ 3.5 cups) of a transfer fluid such as ethanol. Not Included. Quality Made in USA NRTL Certified Model CVO-5 VOLUME:4.5 Cubic Ft. (127 Cubic Liters) SHELVING:Includes 5 removable, adjustable (recommend 8 MAX)Surface Area: 18″W x 24″DWeight Capacity: 50 lbs (22.7Kg)Aluminum OVEN INTERIOR:18”W x 24”D x 18”H457mm x 609mm x 457mm OVEN EXTERIOR:33.3” W x 38.6” D x 31.8”H846mm x 980mm x 808mm WEIGHT:360 lbs / 163.3 Kg TEMPERATURE RANGE:Operating Range: Ambient +14.4°C to 150°C / +26°F to 302°F TEMPERATURE UNIFORMITY:@ 105°F +/- 2.0°F@ 200°F +/- 3.6°F@ 300°F +/- 5.5°F @ 40°C +/- 1.0°C@ 90°C +/- 2.0°C@ 150°C +/- 3.0°C TEMPERATURE STABILITY:@ 105°F +/- 0.2°F@ 200°F +/- 0.4°F@ 300°F +/- 0.2°F @ 40°C +/- 0.1°C@ 90°C +/- 0.2°C@ 150°C +/- 0.1°C HEAT UP FROM AMBIENT TO STABILIZATION TIME:To 105°F (40°C) 60 minutesTo 200°F (90°C) 126 minutesTo 300°F (150°C) 180 minutes (170 minutes for 220V version) COOL DOWN TIME:From 105°F (40°C) 345 minutesFrom 200°F (90°C) 285 minutesTo 300°F (150°C) 335 minutes (460 minutes for 220V version) *Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product, ambient lab conditions. VACUUM VALVE:¼ Turn Lever VENT VALVE:¼ Turn Lever INTERIOR LIGHTING:LED Strips (Rated to 150°C) GLASS WINDOW:Tempered NGI-US to ANSI Z97.1.2007 VACUUM GAUGE:Digital, selectable to read in inches mercury (Hg) or torr, barr CONTROLLER:Touch ScreenAccurate Within 1°FIndependent Overtemp FailsafeEasy updates with USB port PORTS (REAR):Vacuum = 3/8th BarbVent = ¼” BarbAuxiliary KF-25 Port INERT GAS INTRODUCTION:¼” Vent Barb15 psi max inlet pressure POWER:110V – 120V / 1ph / 14A 50/60HzCord IncludedNEMA 5-15 Power Outlet 1105 BTU/hrRating at max power 220V – 240V / 1ph / 7A 50/60Hz AvailableCord IncludedNEMA 6-15R Power Outlet 1228 BTU/hrRating at max power INCLUDED ACCESSORIES:5 Shelves20 Clips4 Leveling FeetPower Cord DOOR GASKET:18” x 18” Cured SiliconeTemp Silicone rated to 446°F(230°C) SHIPPING DIMENSIONS:41”L x 41”W x 45”HClass 85Shipping Weight: 449 lbs / 204 Kg Agilent IDP15 Oil-Free Scroll Pump PUMP TYPE:Oil-Free, Scroll PUMPING SPEED:9 CFM ULTIMATE PRESSURE:10 x 10-3 Torr POWER:120V / 1ph (220V available) INTAKE CONNECTION: KF-25 DIMENSIONS (L X W X H):19.08” x 9.22” x 14.3” WEIGHT: 75 lbs MAXTRAP -50°C/-105°C Cold Trap POWER:115V / 1ph / 3 AMP (60Hz)Cord IncludedCFC / HCFC Free Refrigerants DIMENSIONS:13.5″ W x 23.5″ D x 12.0″ H WEIGHT:COLDWELL Stainless Trap 14 lbsThermo Mechanical Base 60 lbsShipping Weight 95 lbs INCLUDED CONNECTIONS:1 each 4′ KF-25 flanged vacuum rated line1 each KF-25 Centering Ring1 each KF-25 Clamp User Manual CVO-5 DOUBLEUP Package with MAXTRAP Spec Sheet

$58,912.08 - $61,372.31

-

Cascade Sciences Cascade CVO-5 DOUBLE UP Vacuum Package

Cascade CVO-5 DOUBLE UP Vacuum Package Cascade’s CVO-5 DOUBLE UP Vacuum Package is ideal for large volume production with the flexibility of small batch management. The package offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, slurries, or any temperature sensitive material. Typically ships in 3-5 weeks 2x Cascade Sciences CVO-5 Vacuum Ovens 1x Heavy-Duty Industrial Mobile Cart 10x Adjustable, Removable Shelves 2x Adjustable Side Shelves 2x MAXEVAP Connection Kits 1x Agilent IDP15 Oil-Free Vacuum Pump, 9cfm Model CVO-5 VOLUME:4.5 Cubic Ft. (127 Cubic Liters) SHELVING:Includes 5 removable, adjustable (recommend 8 MAX)Surface Area: 18″W x 24″DWeight Capacity: 50 lbs (22.7Kg)Aluminum OVEN INTERIOR:18”W x 24”D x 18”H457mm x 609mm x 457mm OVEN EXTERIOR:33.3” W x 38.6” D x 31.8”H846mm x 980mm x 808mm WEIGHT:360 lbs / 163.3 Kg TEMPERATURE RANGE:Operating Range: Ambient +14.4°C to 150°C / +26°F to 302°F TEMPERATURE UNIFORMITY:@ 105°F +/- 2.0°F@ 200°F +/- 3.6°F@ 300°F +/- 5.5°F @ 40°C +/- 1.0°C@ 90°C +/- 2.0°C@ 150°C +/- 3.0°C TEMPERATURE STABILITY:@ 105°F +/- 0.2°F@ 200°F +/- 0.4°F@ 300°F +/- 0.2°F @ 40°C +/- 0.1°C@ 90°C +/- 0.2°C@ 150°C +/- 0.1°C HEAT UP FROM AMBIENT TO STABILIZATION TIME:To 105°F (40°C) 60 minutesTo 200°F (90°C) 126 minutesTo 300°F (150°C) 180 minutes (170 minutes for 220V version) COOL DOWN TIME:From 105°F (40°C) 345 minutesFrom 200°F (90°C) 285 minutesTo 300°F (150°C) 335 minutes (460 minutes for 220V version) *Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product, ambient lab conditions. VACUUM VALVE:¼ Turn Lever VENT VALVE:¼ Turn Lever INTERIOR LIGHTING:LED Strips (Rated to 150°C) GLASS WINDOW:Tempered NGI-US to ANSI Z97.1.2007 VACUUM GAUGE:Digital, selectable to read in inches mercury (Hg) or torr, barr CONTROLLER:Touch ScreenAccurate Within 1°FIndependent Overtemp FailsafeEasy updates with USB port PORTS (REAR):Vacuum = 3/8th BarbVent = ¼” BarbAuxiliary KF-25 Port INERT GAS INTRODUCTION:¼” Vent Barb15 psi max inlet pressure POWER:110V – 120V / 1ph / 14A 50/60HzCord IncludedNEMA 5-15 Power Outlet 1105 BTU/hrRating at max power 220V – 240V / 1ph / 7A 50/60Hz AvailableCord IncludedNEMA 6-15R Power Outlet 1228 BTU/hrRating at max power INCLUDED ACCESSORIES:5 Shelves20 Clips4 Leveling FeetPower Cord DOOR GASKET:18” x 18” Cured SiliconeTemp Silicone rated to 446°F(230°C) SHIPPING DIMENSIONS:41”L x 41”W x 45”HClass 85Shipping Weight: 449 lbs / 204 Kg User Manual CVO-5 DOUBLEUP Package with MAXTRAP Spec Sheet

$48,558.87

-

Ashless Filter Papers - 350MM - Quantitative

Ashless Filter Papers - 350MM - Quantitative Quantitative and qualitative filter papers provide laboratory grade filtration for extraction systems and are specifically used in combination with a Buchner funnel to remove fats, waxes and any other unwanted contaminants from your solution. These filter papers are used in the pre-processing stage of short path distillation to clean up the material prior to processing. Key Features: ISO 9001 Approved Manufactured from alpha-cellulose and cotton linters High Purity and low background Consistent performance Whatman equivalent quality Pre-Cut for ease of use Specifications: Classification Quantitative Sizes Available: AFP-1 11um - Medium AFP-4 20um - Fast Quantity per Pack 100 Diameter 350mm (13.78")

$131.90

-

316L Stainless Dutch Weave Sintered Filter Disk 1 micron and up - BUNA-N

316L Dutch Weave Sintered Filter Disk **Note: This product comes with Filter Disk and Gasket ONLY. Filter Plate and Spool are NOT included. Recommended Filter plate click here. These 316L stainless steel dutch weave filter disks come with a custom made gasket to allow the user to insert filtration between clamping ends of any Tri-Clamp interface. The interface fits so snug, its inherent design prevents any blow-by. BVV™ 316L Dutch Weave Sintered Filter Disk - Data Sheet Pressure Ratings w/o any backing support; strait pipe connection: 1.5" 200PSI 2" 200PSI 3" 200PSI 4" 200PSI 6" 50PSI 8" 10PSI *Supporting Back Plate Required P# FP800-V3 10" 10PSI *Supporting Back Plate Required P# FP1000-V3 12" 10PSI *Supporting Back Plate Required P# FP1200-V3

$41.65 - $805.27

-

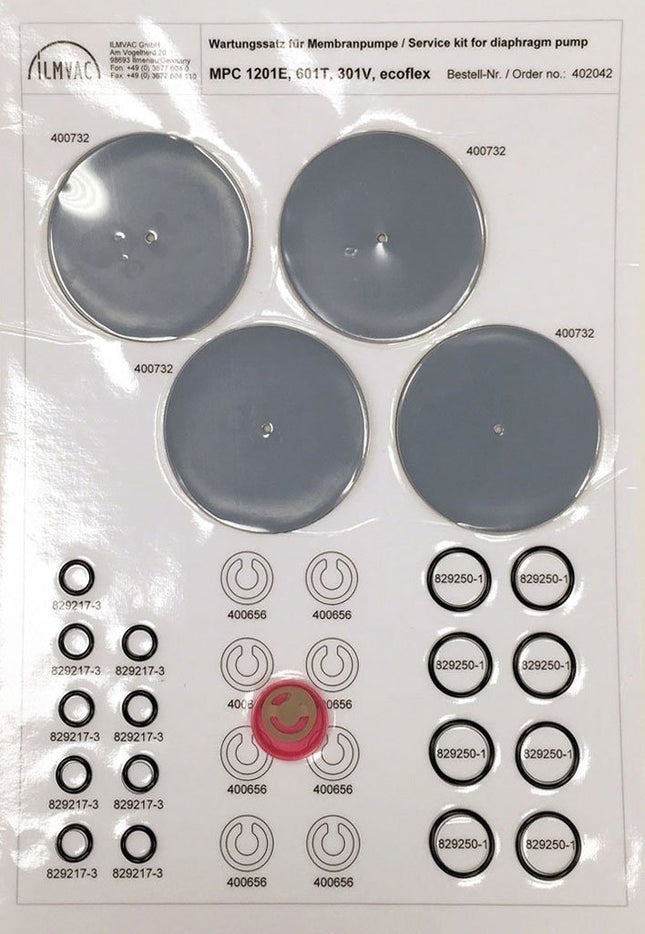

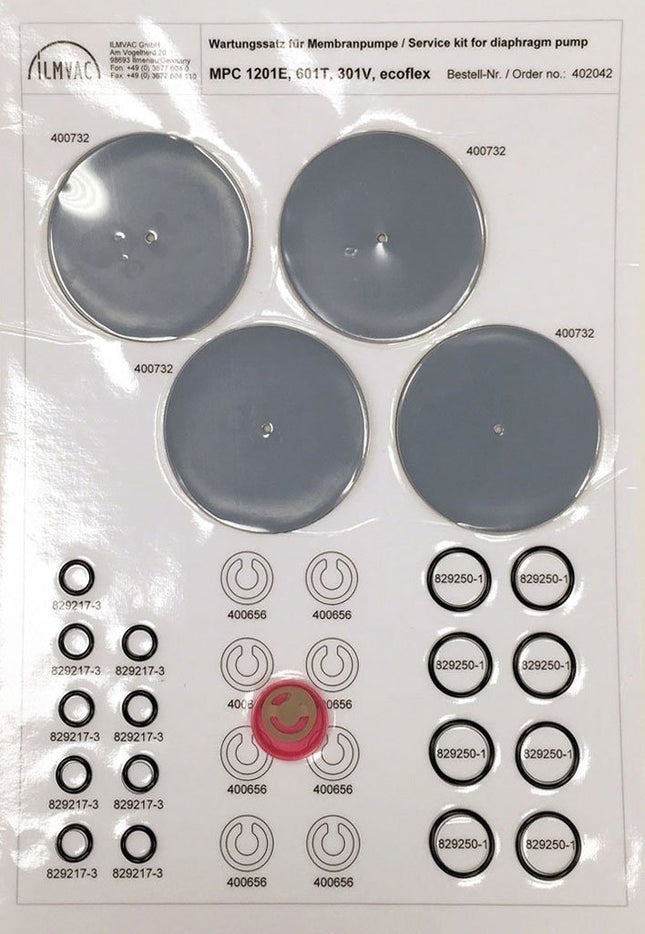

Welch Vacuum - Gardner Denver Welch 2052/2054 4 Head Diaphragm Replacement Kit

Welch 2052/2054 4 Head Diaphragm Replacement Kit ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Diaphragm pumps require rebuild and seal replacements.

$799.71

-

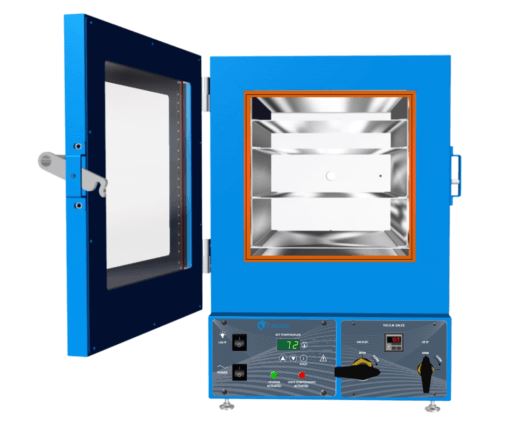

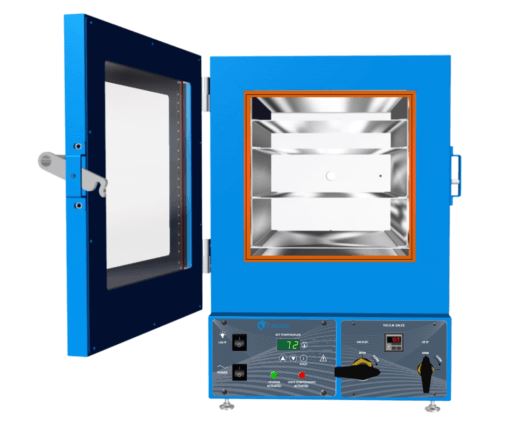

Cascade Sciences Cascade CVO-2 Vacuum Oven

Cascade CVO-2 Vacuum Oven (Oven Only) This item carries up to a 1-2 week lead time. Model CVO-2 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, slurries, or any temperature sensitive material. This vacuum oven liberates solvents, water, and other unwanted compounds in small batch, R&D and lab environments. NRTL Certified. CVO-2 Vacuum Oven Features NRTL Certified by TUV 5 shelves (11.5″W x 19″D) in a flexible configuration. Shelves are stackable and removable Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven Solvent resistant BUNA door gasket Bright LED lights in window for visibility of sensitive material Digital vacuum gauge reads in inches of mercury Simple, set-point control Smooth, quarter-turn vacuum and vent valves Rear KF-25 port allows for rapid MAXEVAP purging or running feedthroughs inside oven for monitoring 120V (220V available) Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA Adjustable leveling feet ensure oven sits solid and level in the workspace CVO-2 Connections 3/8″ Barb for Vacuum Pump 1/4″ Barb for Venting (N2 Connection OK) KF-25 Port for feedthroughs or MAXEVAP Connection Kit Need A Complete CVO-2 Vacuum Package? Cascade has taken the guess work out of pairing the right vacuum oven with the proper pump. We offer two complete CVO-2 vacuum oven packages with everything you need for vacuum drying. Both packages feature clean, quiet, Agilent oil-free scroll pumps. The CVO-2 STANDARD Package is an ideal package for vacuum drying or purging requiring a steady, gentle, non-turbulent purge. The CVO-2 PRO Package is ideal for higher thru-put, faster purge times pulling deeper vacuum. CVO-2 Comes In Low & High Temp Models Low & High Temp Specifications CVO-2 (Low Temp) Temperature Processing Range -3ºC to 121°C (26°F to 250°F) Temperature Uniformity +/- 1ºC at 40.5°C (+/- 1.5°F at 105°F) Temperature Stability +/- 0.5°C at 40.5°C (+/- 0.4 at 105°F) CVO-2-HT (High Temp) Temperature Processing Range Up to 220°C (428°F) Temperature Uniformity +/- 6.5% of setpoint The Cascade Difference Vacuum ovens have been around for decades. Basic vacuum ovens are mass-produced and sold by many large scale laboratory equipment distributors. But there are key differences between Cascade and other inexpensive, often imported vacuum ovens. Exceptional Temperature Control & Stability The Cascade CVO-2 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-2 eliminate hot and cold spots, making accurate use of every inch of shelf space. Independent Over-temp Failsafe Protection The Cascade Sciences CVO-2 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 200°C or 392°F. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs. NRTL Certification #U8 170464972 077. No Extra cost. The CVO-2 Vacuum Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities. CAN/CSA-C22.2 No. 61010-1:2012 +UPD No. 1:2015-07 + UPD No. 2:2016-04 CAN/CSA-C22.2 No. 61010-2-010:2015 UL 61010-1:2012/R:2016-04 UL 61010-2-010:2015 EN 61010-1:2010 EN 61010-2-010:2014 Rigorous Quality Assurance in an ISO Certified, USA Manufacturing Facility Cascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment: Chambers are vacuum tested after welding for vacuum integrity Electrical & mechanical safety is thoroughly tested in compliance with TUV requirements Functional testing verifies user settable items consistent with most lab protocols/usage models Temperature verification includes calibration & temp chamber uniformity following ASTM standards Units are cleaned and packed in ISTA tested, certified packaging materials Digital Vacuum Gauge The digital vacuum gauge installed on the CVO-2 is factory default set to read in inches of mercury (“Hg) with a scale of 0 – 29.9”Hg. Change the unit of vacuum measurement to read in a wide variety of units from mmHg, bar psi, kPa, cm2, mmH20. Zero out the vacuum gauge to calibrate for just above sea level adjustments. Equipped for Inert Gas Backfill. Built-In Safety Relief Introduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the 1/4″ rear vent barb. The maximum backfill pressure is 15PSI. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window. Flexible Pumping / Feedthru Connection Ports The CVO-2 ovens offer two different vacuum oven connection points. The standard connection is a 3/8″ dia barb located at the rear of the oven. It is connected to the vacuum valve level on the front control panel. For even faster evaporation, purging or drying consider upgrading to the MAXEVAP connection kit. The MAXEVAP connection kit secures to the oven’s rear 1″ dia KF-25 port located on the back center of the chamber. The MAXEVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthroughs, or monitoring sensors inside the vacuum chamber during processing. Stackable Shelf Design For Maximum Temperature Conduction Under vacuum, there is no air inside a vacuum oven. Temperatures are achieved by a process of conduction and radiation to move temperatures into the product inside the oven. Cascade’s stackable shelf design makes the most of this opportunity by making the chamber longer and narrower, rather than square and supplies stackable shelves in multiple height configurations to allow for the fastest, most uniform transfer of heat. Ergonomically Designed, Easy Quarter-Turn Valves For anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vacuum/vent valves. Your wrists will thank you! ANSI Rated Tempered Glass + USA Made Steel Cascade ovens are made in Oregon, USA with high quality materials. Our glass is NGI-USA Tempered and certified to ANSI Z97.1.2007 16CFR / 201 11. Our door handles are rugged brushed steel, not plastic. Our vacuum vessels are constructed with American made steel. We’ve tried lower cost, imported steel, but over time, vacuum chambers made of lesser quality/lower tolerance material cannot withstand the flex and pressure changes of vacuum pumping/venting/purging. This can deteriorate vacuum integrity and the oven will lose its ability to hold vacuum. Door Gasket Options – Ideal For Your Process Cascade’s vacuum ovens come standard with a solvent resistant BUNA door gasket. For higher temp applications, we offer a cured Silicone gasket as well. Ask us about the variety of door gaskets we can supply based on your application: Silicone, BUNA, Viton, Fluorosilicone. Gaskets will eventually wear out. It’s ideal to keep a few spares on hand. Model CVO-2 Vacuum Oven Specifications: Capacity Volume 1.67 Cu Ft (47.2 L) Interior 12″W x 20″D x 12″H (305mm x 508mm x 305mm) Exterior 18.8″W x 24.5″D x 24.5″H (478mm x 622mm x 622mm) Product Weight 148 lbs (67.1 kgs) Temperature Temperature Range -3ºC to 121°C (26°F to 250°F) Temperature Uniformity +/- 1ºC at 40.5°C (+/- 1.5°F at 105°F) Temperature Stability +/- 0.5 at 40.5°C (+/- 0.4°F at 105°F) Vacuum Vacuum Valve 1/4 Turn Lever Vent Valve 1/4 Turn Lever Vacuum Gauge Digital. 0 to 29.9″Hg Temperature Controller Digital Set Point Accurate Within .5ºC (1°F) Independent Overtemp Failsafe Ports (Rear) Vacuum 3/8″ Barb Vent 1/4″ Barb Auxiliary KF-25 Port Inert Gas Introduction Use 1/4″ Vent Barb 15 psi max inlet pressure Power Options 110V – 120V / 1ph / 6A 50/60Hz (Cord Included) NEMA 5 – 15 Power Outlet Full Power 2456 BTU/hr *(220V Optional) Shelving Includes 5 shelves in a flexible configurationShelves are stackable and removable1″ High = 1 each2″ High = 2 each3″ high = 2 each Surface Area 11.5″W x 19″D Weight Capacity 50 lbs (22.7 kgs) Door Interior Lighting LED Strips (Rated to 150°C) Glass Window Tempered NGI-US to ANSI Z97.1.2007 Gasket Type 12″ x 12″ Solvent Resistant BUNA Standard Gasket Rated to 105°C (221°F) Gasket Options: High Temp Silicone Option rated to 30°C (446°F)Viton Option rated to 205°C (401°F) Shipping & Weights Unit Weight 179 lb (81.2 kg) Shipping Weight 218 lbs (99 kg) Shipping Dimensions 33″L x 33″W x 47″D (Class 85) Product Certifications: NRTL TUV #U8 170464972 077CAN/CSA-C22.2 No. 61010-1:2012+ UPD No. 1:2015-07 + UPD No. 2:2016-04CAN/CSA-C22.2 No. 61010-2-010:2015UL 61010-1:2012/R:2016-04UL 61010-2-010:2015EN 61010-1:2010EN 61010-2-010:2014 Warranty: 1 Year (Gaskets not included) *Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product. NTRL Certification PDF Manual Vacuum Pressure Chart Vacuum Gauge Manual Calibration

$9,564.61

-

NRE 10L 20L 50L Check Valve Gasket

Check valve to be placed between the condenser and receiving flask on BVV rotary evaporators. The outer diameter of the joint is 60mm.

$83.30

-

Raschig Ring 1LB

Raschig Ring 1LB Raschig rings are pieces of tube used in large numbers as a packed bed within columns for distillation. These glass rings provide a large surface area within the volume of the column for interaction between liquid and gas vapors. Our rings are made from borosilicate glass and are food grade quality. 8mm X 8mm *BVV recommends all users of any and all glassware to operate inside a ventilated fume hood with sufficient blast shields to prevent injury in case of fatigued glass failure. *BVV is not responsible or liable for the result of any failures from use, and/or loss of subsequent hardware contamination/failure with or without the result of material loss or damaged caused to surroundings. By purchasing our premiere lines of laboratory glassware the user is responsible to operate in the recommended environment safely. We recommend all users to operate in a legal and licensed facility where safety is the number 1 goal.

$83.30 - $159.66

-

Hang On Bracket Pipe Hangers

Hang On Bracket Pipe Hangers These Hang On Bracket Pipe Hangers combine both out pipe hangers and hang-on brackets and are Designed to fit on our racks. They range in sizes from 3" - 14" Diameter. Depending on size and availability, these may come with blue or purple rubber lining. ***NOTE: If you are planning to use a pipe hanger on a Dewaxing or Jacketed Column please choose a size that is 2" larger than the tri-clamp size.

$52.76 - $155.50

-

Terpenes Jack Herer

BVV™ Terpenes Jack Herer All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical data sheet. BVV™ Jack Herer Safety Data Sheet BVV™ Jack Herer Technical Data Sheet Jack Herer: Named for a legendary activist, this profile is a legend itself. Heavy fuel aroma spills out with pepper, citrus balancing it out. Fragrance Gas, lemon and clove Effect Uplifting and insightful Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$15.27 - $229.08

-

Terpenes Grape Ape

BVV™ Terpenes Grape Ape All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical data sheet. BVV™ Grape Ape Safety Data Sheet BVV™ Grape Ape Technical Data Sheet Grape Ape: The Grape Ape cultivar that inspired our terpene profile is descended from cultivars as varied as Mendocino Purps, Skunk, and a legendary Afghani landrace. The combination of these parents has created a profile that gives the aroma of grapes, tropical fruit, earth and a pine forest. These varied smells merge into a soothing wave. Linalool and ocimene lend a hand with floral, fruity tones and enhance the chill vibe of myrcene. Fragrance Berry, Lavender, and Piney Effect Eases minor pain, Stress relieving, Soothes anxiety and tension. Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$15.27 - $229.08

-

Terpenes Blueberry Afgoo

BVV™ Terpenes Blueberry Afgoo All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical data sheet. BVV™ Blueberry Afgoo Safety Data Sheet BVV™ Blueberry Afgoo Technical Data Sheet BVV™ Food Grade Certificate Blueberry Afgoo Blueberry Afgoo is an relaxing strain that was created by crossing Blueberry and Afgoo. The Blueberry Afgoo terpene profile has a pleasing palette of pine, skunk, and berry. Fragrance Piney, Skunky, Berry Effect Promotes Relaxation, Improves Sleep, Stress Relief. Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$15.27 - $229.08

-

Terpenes Strawnana

BVV™ Terpenes Strawnana All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical datasheet. BVV™ Strawnana Safety Data Sheet BVV™ Strawnana Technical Data Sheet Strawnana is a sweet berry strain is a hybrid crossing Banana Kush and Bubble Gum’s strawberry phenotype. Indica dominant, Strawnana delivers an uplifting, peaceful euphoria. Fragrance Strawberry, Sweet, Berry Effect Promotes Relaxation, Improves Sleep, Stress Relief, Mood Elevating Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$15.27 - $229.08

-

Terpenes GG4

BVV™ Terpenes GG4 All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical data sheet. BVV™ GG4 Safety Data Sheet BVV™ GG4 Technical Data Sheet GG#4 is an award-winning hybrid strain. It is potent and indica dominant. Pungent, earthy, pine aromas accompany heavy, happy soothing effects. This strain is the offspring of Chem’s Sister, Sour Dubb, and Chocolate Diesel, and it will have you feeling “glued” to the couch. Fragrance Earth, Pine, Fuel Effect Euphoric, Soothing, Heavy and Extreme Couch-lock Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$15.27 - $229.08

-

Terpenes Gelato