EVERY PRODUCT BUT HYDRO FOR WHOLESALE STORE

Hemispherical Reducer with Filter Plate V3

Hemispherical Reducer with Filter Plate V3 This hemispherical reducer has a built-in filter plate that is welded flush with the top of the reducer. This unique design allows the user to save even more space by combining a filter plate and hemispherical reducer. Made out of 304 stainless steel the filter plate is welded into the hemispherical reducer and has Tri-Clamp connections on both ends.

$83.93 - $440.61

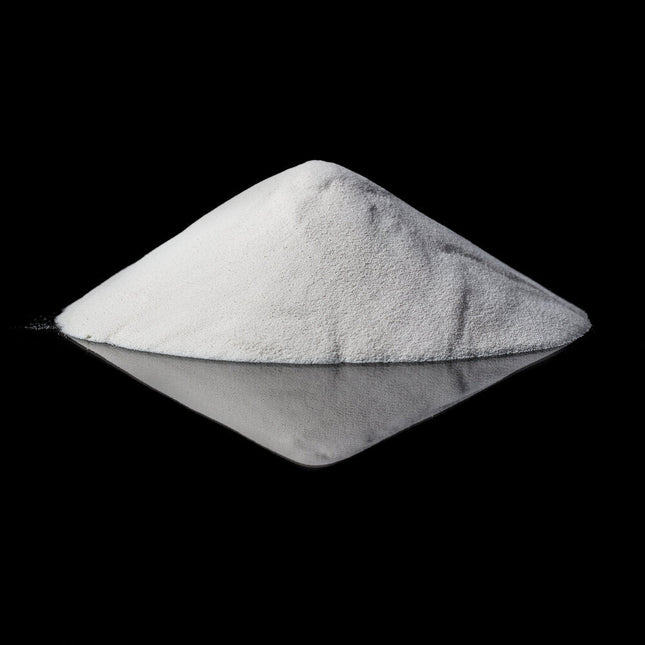

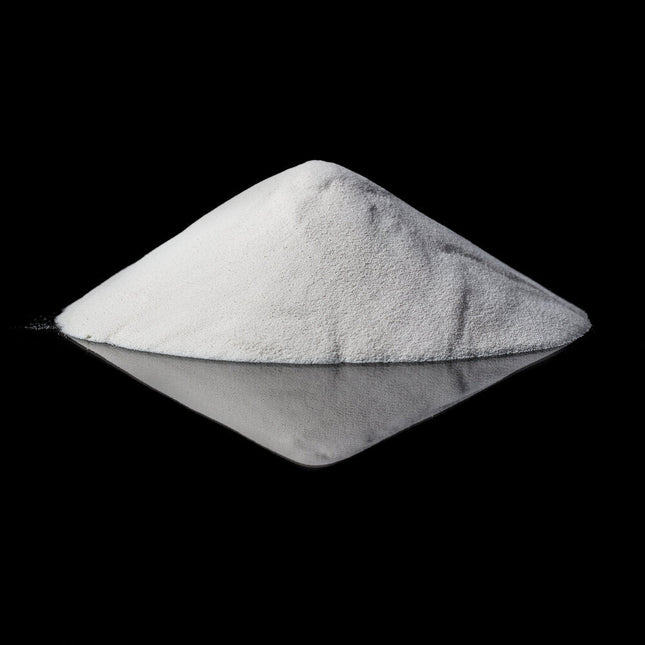

CHEMTEK Granular Activated Alumina

Granular activated alumina is neutral pH adsorbent used to remove moisture, free fatty acids, and phospholipids to speed up crystallization and to improve the end products’ oxidative stability.

$104.91 - $1,119.02

Huber SilOil M80.055.03, Heat transfer fluid -80 to 55 °C

Huber SilOil M80.055.03, Heat transfer fluid -80 to 55 °C *7.5% Huber Tariff Fee Added at Checkout* SilOil M80.055.03 is a low-viscosity silicone fluid which, as a result of its special property profile, is particularly suitable for use as a cold and heat transfer medium in cryostats, thermostats and heat transfer installations. The fluid can be used in the range from -80 °C to 55 °C. It should be borne in mind that, at high temperatures, SilOil M80.055.03 can be chemically altered by oxidising media, such as air, or substances with a catalytic effect, such as acids, lyes and various metal compounds. An increase in viscosity, and possibly even gelling of the fluid owing to crosslinking reactions, must be expected in the presence of oxidising agents, while contact with products having a catalytic effect usually induces a process of depolymerisation, resulting in a drop in viscosity Advantages: virtually insolubile in water non-corrosive low setting points and vapour pressures high flash points low toxicity odourless no coking tendency under thermal stress high thermal stability resistance to ageing chlorine free Safety Data Sheet Heat transfer fluid M80.055.03 Working temperature °C -80 to 55 open/closed systems: -80°C…55°C Material: silicon oil Viscosity at 25°C: 3 mm²/s Colour colourless, clear Material incompatibility Silicone rubber

$1,349.81 - $2,335.95

7.5CF BVV Neocision ETL Lab Certified Vacuum Oven

7.5CF BVV™ Neocision Certified Lab Vacuum Oven, 5 Individually Heated Shelves, LED's - 3 Year Warranty Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! Introduction Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. Performance Capabilities At Best Value Vacs, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Uniformity: within 4% of the temperature setpoint. Heat-Up Time: 20 minutes. Ultimate Vacuum: <500 µmHg / mTorr / micron. Time to Vacuum: 10 minutes to 29"Hg using our VE Series 12cfm Dual Stage Vacuum Pump. Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. Technical Data Electrical Voltage 120V Frequency 60Hz Power 1960W Current 20A Plug IEC C13 (unit ships with detachable NEMA 5-20 cable) Internal Chamber Heating Individual direct-heat shelves Chamber Material Stainless Steel Dimensions (LxWxH) 22" x 23.25" x 25.25" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 5 Heated Shelves Shelf Dimensions (LxW) 21.5" x 21.5" Shelf Capacity 462 in2 Total Shelf Capacity 2311 in2 / 16.1 ft2 Safety Seal Silicone on Tempered Glass Window Dimensions (LxH) 20.25" x 23.75" Lights 4 strips of LEDs provide a clear, bright view of the interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 35" x 33" x 34.5" Weight 430 lbs Support Locking Casters Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connections Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose User Manual Included Vacuum Pump Sold Separately. Warranty 3 Years Capacity and Throughput Planning Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122 Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via UPS Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise UPS freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$11,330.05

P2V4 Neocision Distillation Head - USA Made

P2V4 Neocision Distillation Head P2V4 Short Path Distillation Head includes 4 sets of Vigreux with 24/40 Joints and GL-14 Barb Connections. Key Features: MADE IN THE USA Designed for 1 & 2 Liter Flasks Set of 4 Vigreux to allow for better seperation of fractions without packing material Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$1,049.08$769.32

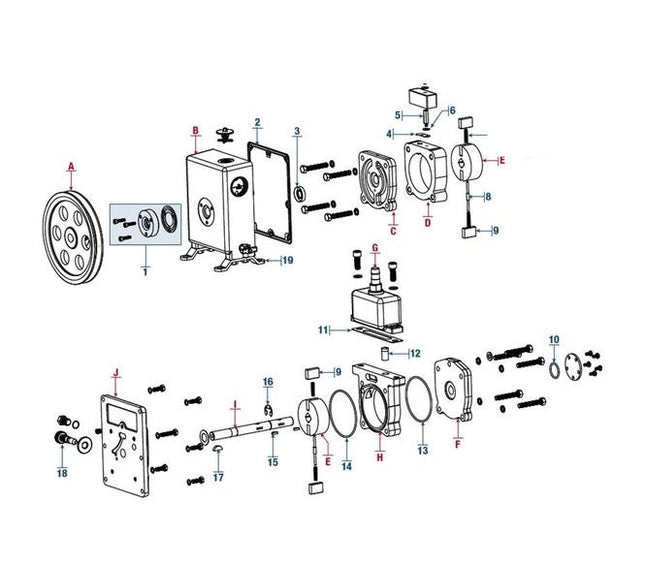

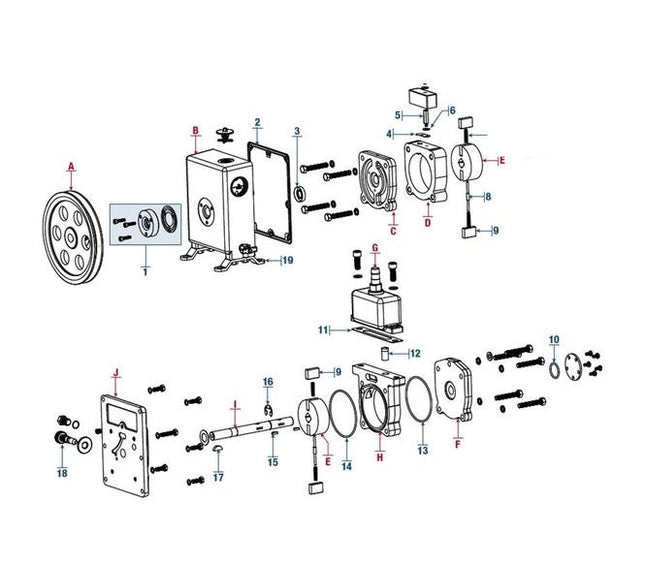

Minor Repair Kit for Welch 1400 DuoSeal

Minor Repair Kit for Welch 1400 DuoSeal This minor repair kit enables refurbishment of DuoSeal pump model 1400. Includes gaskets, seals, valves, o-rings, springs, and mechanical shaft seal. All parts are Welch Original equipment with enhanced chemical resistance. Manufactured to design specifications for top pump durability and performance.

$432.22

5L BVV™ Rotary Evaporator Glass Axis

Glass axis for 5L BVV Rotary Evaporator *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$83.93

Bore Through 1/2" Compression Fitting x 1/2" MJIC

Bore Through 1/2" Compression Fitting x 1/2" MJIC made out of 304 stainless steel.

$16.79

Terpenes Sativa

BVV™ Terpenes Sativa All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical data sheet. BVV Sativa Safety Data Sheet SATIVA: This terpene is robust and has a distinct citrus, menthol flavor with a touch of sour. Sativa tends to be more stimulating and gives you an energy boost. It can uplift mood, and may reduce anxiety. Best for daytime to assist with creativity throughout your day. FRAGRANCE: Spicy and Sweet. EFFECT: Tends to be more stimulating. It can uplift mood, and may reduce anxiety. Best for daytime to assist with creativity throughout your day. Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$15.39 - $230.80

True Terpenes Golden Pineapple

True Terpenes Golden Pineapple Fragrance: Pineapple Effects: Happy Uplifting Golden Pineapple Infused Profile takes the happy and uplifting tropical citrus of Golden Goat and Pineapple Kush and brightens the day with fresh pineapple. Full Flavor. Full Effect. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution. Golden Pineapple-Specific Certificates: Product Specification Certificate of Analysis Safety Data Sheet Food Safety Company-Specific Certificates: ISO 9001:2015 GMP Certification FSSC 22000

$169.95 - $3,147.24

1.5 Gallon Vacuum Chamber Digital Heating Jacket

1.5 Gallon Tall Stainless Steel Vacuum Chamber Digital Heating Jacket Our high-capacity vacuum chamber heating jacket provides the user with the ability to evenly heat the chamber around the circumference while being very stable. When combined with a heating pad, this chamber covers most of the vessels distributing degassed heat in the vessel. This vacuum chamber digital heating jacket allows for accurate and stable control and is reprogrammable. With its unique patented gasket design, this chamber is sure to last 10,000 uses with proper care and maintenance. Key Features: Velcro Connections on each end. Digital PID Temperature Controller for accurate and stable control. Made of heat resistant silicone. Specifications: Min Temp: Ambient +5F Max Set Temp: 160F Ultimate Max Temp: 248F Voltage: 110VAC Only Precision: 1 degree F increments. Stability: +/- 0.2 F Dimensions: Approx. 7.9"W x 24"L Instructions Included Relay Lifespan 10million Cycles Reprogrammable: Yes

$265.77

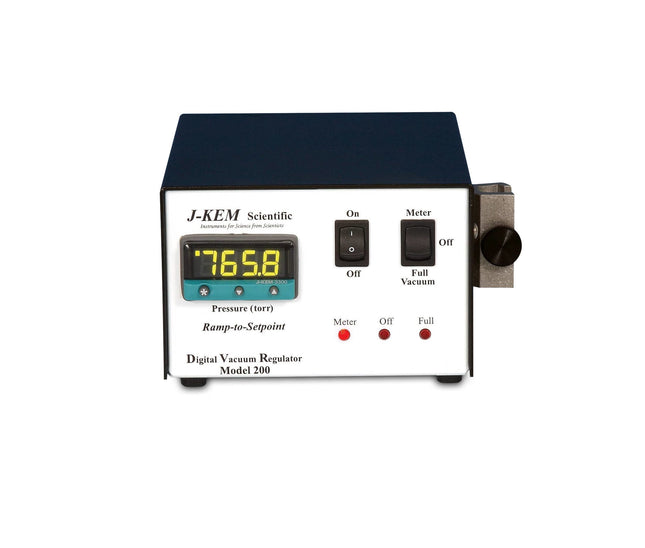

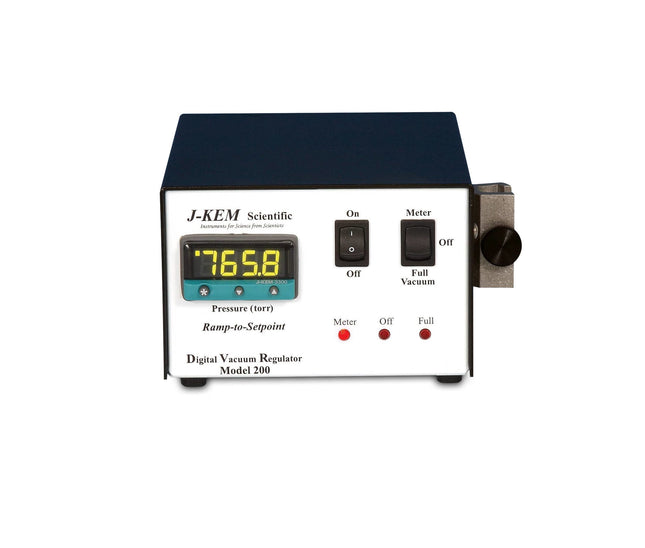

J-KEM DVR-200-EV Digital Vacuum Regulator

J-KEM DVR-200-EV Digital Vacuum Regulator The DVR-200-EV has the same stainless steel pressure transducer inside, but the vacuum valve is outside of the controller. The value of this design is that the vacuum valve can be cleaned or replaced much easier than the valve in the classic DVR-200. Some applications, like distillations or stripping large volumes of solvent, can leave residues inside the valve which causes it to fail. Replacing the vacuum valve is the most frequent repair that J-KEM performs on the DVR-200. Replacing the valve in the classic DVR-200 is difficult and must be returned to J-KEM for repair. With the EV version, the user can disassembled the valve and wash it out, or even replace it in under 5 minutes. For large distillations or botanical applications, J-KEM recommends the DVR-200-EV. No Mercury 100% digital pressure entry and control Wetted parts are 100% stainless steel and Teflon Vacuum ramping feature eliminates bumping Resists: All organic solvents Acids Bases Water Specifications: 100 watts. Vacuum fittings: 1/8″ NPTM. Warranty: Electronics 2 Years, Vacuum Valve 6 months (void if damaged by chemical buildup)

$2,328.95

True Terpenes Thin Mint Cookies Infused

True Terpenes Thin Mint Cookies Infused All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. (Please Note: This product has 1 week lead time) Thin Mint Cookies is yet another Girl Scout Cookies descending profile. FRAGRANCE: The peppery, sweet scent of a bakery forms the base of this profile while notes of lemon and fuel hit the nose first. EFFECT: Thin Mint Cookies is known for a peaceful yet uplifting experience. CERTIFICATES: COA | SDS | FOOD GRADE Storage Requirements Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. DilutionTerpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With CareCan cause skin irritation, do not ingest PRIOR to dilution. TRUE GRADE™ It is our promise to you. Our isolated terpenes are triple-distilled making them the cleanest terpenes in the world. Fresh out of the bottle, undiluted, every single one of our products bests the most rigorous consumer safety standards. GMP | ISO-9001:2015 | FSSC 22000 Blended in cGMP facilities adhering to the requirements for a Quality Management System (QMS) specified by ISO 9001:2015 and FSSC 22000 standards. Analyzed Tested and passed True Grade™ safety specifications for residual solvents, pesticides and heavy metals. Stability Tested Rigorously tested with mid-grade distillate against separation, cloudiness and unacceptable levels of color change. We Qualify True Terpenes implements supply-chain control for all raw materials and is proud to provide True Terpenes’ qualification documents such as certificates, licenses and registrations to be qualified as your supplier. Undiluted We do not add PG, VG, PEG, MCT or Vitamin E Acetate to any of our products. Food Grade Manufactured in cGMP facilities using food grade ingredients. UV Protected This product is packaged in a cobalt blue, UV deterrent and food grade bottle with tamper evident seal. Made in the USA Formulated, blended, manufactured and fulfilled in the United States. Refined Isolates This product contains ultra-pure, molecularly-refined terpene isolates. Only the best.

$169.95 - $3,147.24

Wireless Digital Vacuum Gauge 1~19,000 Microns

VGW-mini Wireless micron vacuum gauge measures vacuum via just one service port and with no loss of refrigerant. Its compact, robust and smart design support HVAC technicians with numerous intelligent features like the graphic display of measurement data in the Elitech Tools App. Its smart Bluetooth integration allows for data to be stored and evaluated reliably and efficiently, thus saving precious time and resources. Product Features High Accuracy The digital vacuum gauge achieves precise deep vacuum measurements down to single digit resolutions and provides notifications when the evacuation target is met. Smart APP Control Control your micron tester remotely and navigate through all measurement data via Smartphone or Tablet. Quickly and conveniently document your job, finalize your report and export - directly from the job site. Intelligent Judgement of H2O Status The vacuum meter automatically judges physical state of H2O by comparing ambient temperature and water saturation temperature corresponding to the vacuum in the system. Large, Easy-to-Read Display Continual digital readout of evacuation process can be viewed easily on the large, full-view LCD screen. Rechargeable Lithium Battery Built-in rechargeable lithium battery can work up to 20 hours per single full charge, saving troubles of frequent battery change. Product Specifications Measuring Range: 0-19000 micron Operating Temperature: -4℉~140℉ (-20°C~60°C) Interface: 1/4 SAE Accuracy: 1~10,000 microns: ±10% of readings ±10 microns10,000~19,000 microns: ±20% of readings Resolution: 0-400 1 Micron400-3000 10 Micron3000-10000 100 Micron10000-19000 250 Micron Vacuum Units microns, mTorr, in/hg, Pa, Torr, KPa, mbar and psia Battery rechargeable lithium battery (1,000mAh) Overload 27.5 bar Certification CE

$244.79

3/8" Clear Reinforced PVC Tubing 20 Foot Roll

3/8" Clear Reinforced PVC Tubing 20 Foot Roll Crystal clear Phthalate, BPA Free PVC compound, formulated with ingredients in compliance with applicable ratings: NSF-51 Certified USP Class VI Rated Compound, FDA Ingredients, Self-Extinguishing and Reinforced with braided polyester yarn. Key Features: Constructed with Phthalate Free compounds. NSF-51 certified material. Crystal clear - allows visual confirmation of product flow. Longitudinally reinforced to reduce elongation under pressure. Lightweight. Self-extinguishing. Non-marking. Silicone-free. Non-conductive. One-piece lengths. Resistant to chemicals (see chemical-resistance chart). Compound hardness 80A Phthalate Free! Common Applications: Food & beverage. Agriculture Drain Line Hose/Tubing Bundling Industrial Air and Water Hose Light Vacuum Liquid and Powder Transfer Medical and Pharmaceutical Sight Gauge Water Lines

$44.76

CHEMTEK Alumina 150

Alumina 150 is a neutral pH adsorbent used to remove moisture, free fatty acids, and phospholipids to speed up crystallization and to improve the end products’ oxidative stability. Alumina 150 SDS

$41.96 - $1,398.77

Upgraded TRS21 Compressor Head

Upgraded TRS21 Compressor Head Complete, Stainless Fittings, Viton Upgrade your TRS21 by purchasing a new Compressor Head with Viton O-rings for butane and propane gas compatibly and stainless steel fittings to meet FDA guidelines on handling of consumable products. This head is assembled here in the USA and is a direct replacement for any TRS21 Compressor Head.

$251.78

Dry Ice Condenser for 2L Electric Lift Rotary Evaporator

Dry Ice Condenser for 2L Best Value Electric Lift Rotary Evaporators. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$489.57

Best Value Vacs 3 Gallon Stainless Steel Vacuum Chamber W/GLASS LID

3 Gallon Stainless Steel Vacuum & Degassing Chamber W/GLASS LID (Comes with 2 Year Limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent-pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User-friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 10-7/8" Tall x 9" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic-based monomers or polymers.The lid may only be cleaned with soapy water. DOES NOT APPLY TO GLASS LID VERSION ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic-based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™, etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$212.61

Extraction RACK # 5

Extraction RACK # 5 (Assembled units come with a 30-day warranty) Note: The unit does not come assembled - select "pre-assembled" from the drop-down menu to have the unit assembled by BVV before shipping Pipe hangers are not included There is no warranty on unassembled units Shipping Notice: If the customer orders the rack as assembled, then the item will only ship via freight and there will be additional shipping charges. Extraction Rack 5 Technical Drawing BVV™ Extraction RACK # 5 is similar to Extraction Rack #3 but with thicker vertical support beams. This rack fits the following BVV™ Extraction Systems: 10LB Mercurius 30LB Closed Loop Extraction System Specifications (Does not include height with casters) Main Base Dimensions 39" X 30" Vertical Dimensions 39" X 48"

$1,363.80 - $1,643.56

Glass Vac 1.5 Gallon TALL Stainless Steel Vacuum Chamber and Vacuum Pump Kit

Glass Vac 1.5 Gallon TALL Stainless Steel Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Glass Vac 1.5 Gallon TALL Stainless Steel Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 - 2B Stainless Steel Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 8-5/8" Tall x 7-1/8" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result from the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$402.85 - $639.24

3/8" Fractional Tube Fitting Hose

3/8" Fractional Tube Fitting Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE by having an inner core of PTFE and protecting that with a braided stainless steel outer sleeve. These hoses have a tube stub on each end that fits a standard compression fitting. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. Stainless Steel Hose Technical Data Sheet Specifications: Connection Type(s): 3/8" Tube Stub Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Swivel Material 304 Stainless Steel Temperature Rating -65°F to 450°F (-54°C - 232°C) Pressure Rating 1500 PSI Chemical Resistance Excellent Max Bend Radius 4"

$71.34 - $174.85

Carbon Chemistry APG Granular (ZeoClear L)

Carbon Chemistry APG Granular (ZeoClear L) An acidic powder media designed for powerful polar adsorption and separation processes. This finely-milled activated alumina provides superior removal of basic compounds and color bodies, making it ideal for precise purification and filtration applications. Its optimized acidic surface chemistry enhances control in separations of basic compounds and targeted impurity removal. Download SDS

$55.95 - $10,071.15

CHEMTEK W4 Pesticide Remediation Bleaching Clay

CHEMTEK W4 Pesticide Remediation Bleaching Clay W4 is an alkaline bleaching clay specialized for the removal of pesticides, chlorophyll, free fatty acids, and oxidized compounds. It removes pesticides through adsorption and hydrolysis. Pesticides undergo alkaline hydrolysis, in which a pH greater than 7 causes chemical degradation of certain pesticides in the presence of ions. W4 SDS W4 Technical Data Sheet

$69.94 - $3,147.24

Dk-Lok V63 Series 1/4" 10-250PSI Adjustable Pressure Relief Valve 316SS

V63 Series 1/4" 10-250PSI Adjustable Pressure Relief Valve 316SS DK-LOK® V63/66 series proportional relief valves provide a wide range of set pressures in order to protect your systems against over pressurization resulting in damage to system components. These proportional relief valves open in direct relation to how quickly the system inlet pressure overcomes the set pressure of the spring. They close in direct relation to how quickly the system inlet pressure drops below the spring set pressure. We offer a variety of connection configurations and seal materials to match your system requirements. DK-LOK V63/66 Series Pressure Relief Valve Data Sheet

$349.69

35/15 Metal Flask Clamp for 2L and 5L Eco Rotary Evaporators

35/15 Metal Flask Clamp for 2L and 5L Eco Rotary Evaporators This is a replacement clamp for 2L and 5L Eco Rotary Evaporator receiving flask.

$19.58

P10V6 Neocision Distillation Head - USA Made

P10V6 Distillation Head P10V6 Distillation Head has 6 sets of vigreux in the distillation column with 45/50 lower joint, 24/40 Thermometer Joint, and a 34/45 side joint and includes GL-14 barb connections. MADE IN THE USA Designed for 10 Liter Flasks Set of 6 vigreux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$839.26

Solvent Pro Series 40/60 Clamp and Gasket Set

Solvent Pro Series 40/60 Clamp and Gasket Set This is a replacement Clamp and Gasket for 5, 10, 30, and 50L Solvent Pro Rotary Evaporators. This Clamp and Gasket fit an 40mm(1.57") Inner Diameter and 60mm(2.36") Outer Diameter joint. The gasket material is made of Silicone surrounded by a PTFE Envelope.

$48.96

Glass Vac 2 Gallon Aluminum Vacuum Chamber and Vacuum Pump Kit

Glass Vac 2 Gallon Aluminum Vacuum Chamber and Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Glass Vac 2 Gallon Aluminum Vacuum Chamber VE115 3CFM Single Stage Vacuum Pump or V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 6.5" Tall x 10" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports VE115 Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Compatibility Explanation: BVV chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. GlassVac chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$416.83 - $633.64

Media Bros CRY™ MEDIUM FLOW

CRY™ MEDIUM FLOW (CRY-M™) FILTER MEDIA FOR BHO EXTRACTION (NON-REACTIVE) This medium flow non-reactive variant of CRY allows operators to increase operating pressures and surface area for a more fine-tuned process. PH 7 DESCRIPTION CRY™ Medium Flow (CRY-M™) is a finer version of CRY™ designed for systems operating at slightly higher PSIs that still need non-reactive high flow outputs and a little extra selectivity. It is not quite powder, but a much finer grain than CRY. The smaller granule size helps prevent channeling that can sometimes occur at higher PSIs. We recommend CRY-M™ for operators who want the same effect as CRY™ but are running at higher pressures or systems with size limitations. For extracts that require additional remediation beyond CRX-M™, CRY-M™ offers a superior polish, effectively addressing color, fats, and lipids. Opt for CRY-M when aiming for effortlessly reproducible results with older biomass. Suggested use: 150–250g per lb. of biomass Packaged in: 1.5 kg pouch, 5 gallon bucket, and 100 kg drum TECHNICAL SPECS Solvent Type Hydrocarbon Color Remediation Level Moderately Heavy/High Pesticide Remediation Level Medium Selectivity/Polarity Level Moderately Selective/Medium Polarity Heavy Metal Remediation Yes Moisture Remediation Level Moderate Fats/Lipids/Waxes Level Medium Crystal Growth Fast Depth Filtration No Flow Rate Moderate Flow pH Level Neutral (pH 7) Best For Slightly Aged Biomass, Medium Quality Suitable for Reruns Yes Distillation Clean-up Moderate Scrub SDS

$41.96 - $2,238.03

Mastercool Blue 60" HVAC Hose

This HVAC hose will fit 1/4" SAE or JIC fittings. One end of the hose has a fitting made to depress a Schrader valve within the male fitting, the other end of the hose is a standard connection.

$20.98

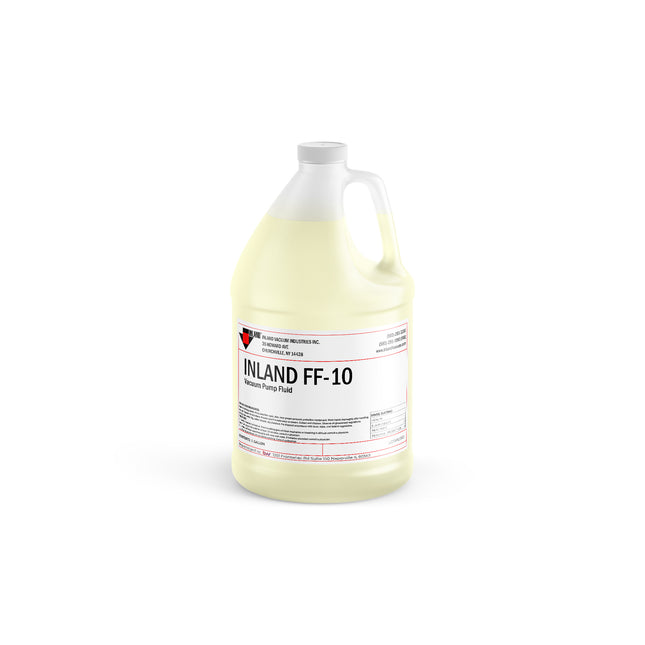

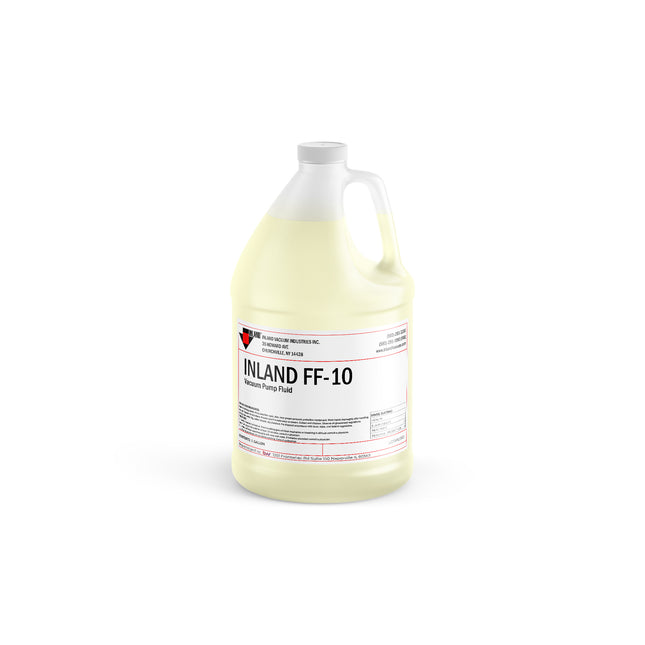

Inland FF-10 Flushing Fluid

Inland FF-10 Flushing Fluid Inland FF-10 is a solvent free hydrocarbon flushing fluid designed to be used as part of a preventive maintenance program. Periodic use of FF-10 will enable the user to remove contaminants and particulates from within all areas of the pump without the worry of contaminating the pump with an expensive solvent Specifications FF-10 Vapor Pressure at 25ºC (torr) 2x10-4 Viscosity at 40ºC (cSt) 28 Viscosity at 100ºC (cSt) 4.5 Flash Point (ºC) 199 Fire Point (ºC) 221 Density at 25ºC (g/ml) 0.85 Inland FF-10 Flushing Fluid Safety Data Sheet SDS

$19.58 - $1,426.75

KF-40 Stainless Steel FNPT End Cap

KF-40 Stainless Steel FNPT End Cap This is a FNPT KF-40 (NW40) Endcap to adapt a KF40 fitting to Female NPT Threads for 1/4", 3/8", and 1/2" NPT.

$47.56 - $54.55

1/2" x 0.035 wall 316SS Hard Line Tubing 5FT

1/2" 316SS Hard Line Tubing 5FT Stainless Steel 316 Hard line tubing for compression fitting connections and systems. Specifications Length 5' Material 316 Stainless Steel ASTM A-269 Max Allowed Working Pressure (PSIG) 1/2" x .035 2339

$153.86

Terpenes WIFI

BVV™ Terpenes WIFI All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical data sheet. BVV WIFI Safety Data Sheet BVV WIFI Technical Data Sheet WIFI: The aroma is earthy, pungent, and sweet. White Fire (Wifi) is great for increasing focus, creativity, happiness, and peacefulness. Euphoric and uplifting blend. FRAGRANCE: Pungent, earthy, sweet, sour EFFECT: Uplifted, focused, energetic, soothing Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$15.39 - $230.80

Terpenes ATF

BVV™ Terpenes ATF All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical data sheet. BVV ATF Safety Data Sheet BVV ATF Technical Data Sheet ATF: ATF is an earthy, sweet, pungent strain. A sativa-dominant strain, ATF is described as, giving a euphoric and soothing high with a strong enhancement of appetite. Its has strong scents of pine, lemon, menthol, and skunk. Its is described as having uplifting and creative effects. FRAGRANCE: Floral, earth, spicy, sweet EFFECT: Uplifting, Creative, Arousing Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$15.39 - $230.80

Jacketed Sucker Pot

Jacketed Sucker Pot This jacketed sucker pot works perfectly as a collection base for extracted oil and easy discharge or as a storage vessel for distillate dispensing. Both of these applications are made easier with the use of a heater running through the jacket. This pot can be mounted to an extraction rack with the use of 8" pipe hangers. Connections: Top: 6" Tri-Clamp Bottom: 1/2" FNPT Jacket: 1/4" FNPT (2x ports)

$419.63

Eco Oven PID Controller with Display Screen

Eco Oven PID Controller with Display Screen Compatible with older Orange/Black Models and newer Purple/White Models. Specifications BVV ECO Temp Range: 0-212°F Temp Accuracy: +/- 1° Built-In Calibration: Yes Temp Display Unit: C or F Timer Range: 0-999 Electrical Requirements: 110v @ 60Hz Compatible Ovens: 09ECO / 19ECO Shipping Dimensions: 5 x 5 x 5 - 1lbs SKU: ECOPID

$307.73

Jacketed Sucker Pot with Ring Stand

Jacketed Sucker Pot with Ring Stand This jacketed sucker pot works perfectly as a collection base for extracted oil and easy discharge or as a storage vessel for distillate dispensing. Both of these applications are made easier with the use of a heater running through the jacket. Connections: -Top: 6" Tri-Clamp -Bottom: 1/4" FNPT -Jacket: 1/4" FNPT (2x ports)

$699.39

Replacement O-ring for Chemglass 1/4" Thermometer Adapters

Black circular replacement op-ring for chemglass 1/4" thermometer adapters.

$1.75

2L Electric Receiving Flask with PTFE Valve

2L Electric Receiving Flask with PTFE Valve This receiving flask fits Best Value Vacs 2L Electric Rotary Evaporators and is made out of GG-17 glass with a PTFE dispensing valve. This Flask has a 35/15 round joint with a 1/2" Hose Barb and Viton gaskets on the Teflon Valve.

$262.97

P5 Distillation Head - USA Made

P5 Distillation Head P5 Packable Distillation Head with 34/45 lower joint and 24/40 upper and side joints. Includes GL-14 Barb Connections. Recommended packing media: Raschig Rings, Porcelain Berl Saddles, Glass Beads, Pro-Pak, or Stainless Steel Wool. Key Features: MADE IN THE USA Designed for 5 Liter Flasks Single set of lowered vigreaux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$769.32$559.51

5 Gallon Aluminum SIDEMOUNT - POT ONLY

5 Gallon Aluminum SIDEMOUNT - POT ONLY ***Note: 'with Hardware' Option only includes the side-mount manifold with gauge pre-installed. (Does Not Include Lid or Gasket) This is a replacement part for the following Vacuum Chambers: Best Value Vacs 5 Gallon Aluminum Side Mount Vacuum and Degassing Chamber Glass Vac 5 Gallon Aluminum Vacuum Chamber Dimensions: 10" Tall x 12" Diameter Hole Size: 21/64 Material: 3004 Aluminum

$89.52 - $117.50

Union Cross

SSP - Union Cross SSP Instrumentation Duolok® tube fittings are designed, manufactured and quality controlled to be totally “interchangeable” with the Swagelok® brand of tube fittings. Component by component examination plainly shows the two brands as completely “componentintermixable.” The precision manufacturing of both products to stringent tolerances under rigid quality control procedures ensures the safety, performance, and reliability of service whenever Duolok® and Swagelok® component parts are mixed and used in accordance with published installation and service recommendations. Specifications Connection Type 1 Duolok Tube Fitting Connection Size 1 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Duolok Pressure Rating = Tubing Rating SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$27.98 - $37.77

ChemTek Small Fuge Bags - 50 Pack

ChemTek Small Fuge Bags - 50 Pack Centrifuge bags used for separations. Specifications: Size: 50-Pack Dimensions: H: 4” W: 2.5” Micron Size: 25 Microns Material: Food Grade Nylon

$39.17

10 Gallon All-Mesh Bubble Wash Bags

10 Gallon All-Mesh Bubble Wash Bags The Press Club Wash Bags are the last set of bubble wash bags you'll ever own! Made from premium, food-grade material specifically for washing you can stop second guessing whether you have the right or best bags in the industry. All Press Club bubble wash bags are hand sewn with our proprietary pink stitching, making them 2x stronger than competitors. You can be confident The Press Club bags will perform the same no matter if it's your 1st or 1000th wash. The Press Club is so confident their bubble wash bags will stand the test of time, every bag comes with a Lifetime Warranty. If you have any manufacturer issues, they will be more than happy to replace the bag for you! KEY FEATURES Fits All Standard 10 Gallon Buckets Hand Sewn With Our Proprietary Pink Stitch w/ Food-Grade Materials Military-Grade Waterproof & No Flaking Bag Liner Premium Drawstring & Cord Locks To Secure Bags Lifetime Warranty On All Wash Bags Includes Meshed Carrying Case For 2-Way Drying & Storage Made In USA AVAILABLE MICRONS 220 Micron (Work Bag), 190 Micron, 160 Micron, 120 Micron, 90 Micron, 73 Micron, 45 Micron, 25 Micron

$62.87

True Terpenes Cherry Pie

True Terpenes Cherry Pie Fragrance: Sweet Dank Earthy Sour Effects: Happy Creative Uplifting A hybrid of Durban Poison and Granddaddy Purple, this earthy berry blend is sweet and sour. Within minutes, it gives feelings of happiness, creativity and is uplifting. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution. Cherry Pie-Specific Certificates: Product Specification Certificate of Analysis Safety Data Sheet Food Safety Company-Specific Certificates: ISO 9001:2015 GMP Certification FSSC 22000

$169.95 - $3,147.24

Solid Cap, PTFE Seal, GL-14 Thread

Cap is made from PBT (thermoplastic polyester) and will withstand temperatures from -45 to 200º C. The seal is PTFE

$11.19

You have seen 1008 out of 1652 products