All products

-

Scilogex SCILOGEX SCI550-H LED Digital 7 x 7 Square Hotplate, ceramic-glass plate, 110V, 50//60Hz, US Plug

SCILOGEX SCI550-H LED Digital 7x7 Hotplate, 550ºC Max Product Description The SCI550-H is one of the most technically advanced hotplates in the marketplace. Simply turn the heat button to set the desired temperature with the LED display and the actual real-time temperature is clearly displayed. Product Features Easy-to-read LED display Ceramic-Glass plate Hot warning above 50°C Accessories available including PT1000 external sensor and reaction blocks cTUVus approved for UL and CSA 2 YEAR WARRANTY Product Specifications Hotplate MODEL SCI550-H Temp range Ambient - 550°C Temp accuracy at plate ±10°C Temp control accuracy with PT- 1000 Sensor ±1°C Temp increments 5°C Heat output 1000W Heating rate (1 liter water) 6K/min Heat display LED Plate size 7 x 7 in. Plate material Ceramic-Glass Dimensions 14"L x 8.5"W x 4.5"H Weight 11lbs Voltage 110Volts 60Hz Additional Resources and Information Downloadable PDFs Scilogex SCI550-H Manual Scilogex Hotplates & Stirrers Brochure Scilogex Hotplate & Stirrers Accessories

$789.63

-

Scilogex SCILOGEX SCI380H-Pro LCD Digital 5.5 x 5.5 in. Hotplate, ceramic plate, 110V, 50/60Hz US Plug

SCILOGEX SCI380H-Pro 5.5 x 5.5 in. LCD Digital Hotplate, 380ºC/1500rpm Max Product Description The new SCI380H-Pro Digital Hotplate is a very economically priced and ideal for accurate heating applications from ambient +5°C to 380°C. Product Features Easy to read backlit LCD display Ceramic plate for chemical resistance and easy clean Electronic speed control for constant speed even during changes in load Brushless DC motor cTUVus approved for UL and CSA 2 Year Warranty Product Specifications Temp range Ambient +5 - 380°C Overheat protection 420°C Temp accuracy at plate ±1(100°C) Temp control accuracy of liquid using PT- 1000 Sensor ±1°C Temp increments 1°C Heat output 500W Power 510W Heating rate (1 liter water) 6K/min Speed display LCD (backlit) Protection class IP21 Plate size 5.5 x 5.5 in. Plate material Ceramic coated aluminum Dimensions 12.5"L x 7"W x 4.2"H Weight 5lbs Voltage 110Volts 60Hz, 510W Additional Resources and Information Downloadable PDFs SCILOGEX SCI380HHotplate Manual SCILOGEX MagneticHotplate-Stirrers Brochure SCILOGEX HotplateStirrers & Accessories

$471.55

-

Scilogex SCILOGEX SCI500HS-Pro LCD Digital 10 x 10 Magnetic Hotplate Stirrer, ceramic-glass plate, 110V, 50/60Hz US Plug

SCILOGEX SCI500HS-Pro LCD Digital 10x10 Magnetic Hotplate Stirrer 500°C/1500rpm Max Product Features Large volume: Up to 30L of liquid on 10-inch hot plate with powerful magnetic stirring Glass ceramic work plate provides excellent chemical resistant performance and efficient heat transfer. LCD display for precise monitoring of speed and temperature. Liquid temperature control is possible by connecting the temperature sensor (PT1000) with an accuracy at ±0.2°C. Digital speed control of 100~1500 rpm Max. heating plate temperature 500°C The "Hot" warning will flash when the work plate temperature is above 50°C even when the hotplate is turned off. Free SD card records the instrument's running data in real time. Timing function: the run time of the instrument can be set. Product Specifications Work plate dimension[W x D] 254x254mm(10inch) Work plate material Glass ceramic Motor type Brushless DC motor Stirring positions 1 Max. Stirring quantity, [H2O] 30L Max. Magnetic bar[length] 80mm Speed range 100-1500rpm resolution±1rpm Speed, Time, Temperature display LCD Timer display 1min-99h59min Heating Temperature range Room Temp. -500°C, increment 1°C Temperature control accuracy ±1°C(100°C) Overheating Protection(°C) 540 Temperature Display Accuracy ±0.1°C External temperature sensor PT1000 (accuracy ±0.2) "Hot" warning (°C) 50 Data Connector SD Card Protection Class IP21 Power 1400W Heating output (W) 1350W Voltage, Frequency 100-120/200-240V 50/60Hz Dimensions [WxDxH] 328x424x138mm Weight (kg) 7.18 Permissible Ambient Temperature and Humidity 5-40° C, 80%RH Additional Resources and Information Downloadable PDFs SCI500HS-Pro Manual Hotplate & Stirrers Accessories

$1,569.50 - $1,674.13

-

Scilogex SCILOGEX SCI-PA LED Digital Circular Magnetic Stirrer, 110-240V, 50/60Hz, US Plug

SCILOGEX SCI-PA Circular-top LED Digital Magnetic Stirrer, 100-1500rpm SCILOGEX SCI-PA LED Digital Magnetic Stirrer, 110V 60Hz Product Features Easy-to-read LED displayDigital speed control within the range of 100-1500rpm Max. stirring quantity of H2O at 3LNylon+GF housing provides a great chemical resistance Electronic speed control for constant speed even during changes in loadNow with a brushless long life DC motorHigh magnetic adhesioncTUVus approved for UL and CSA2 YEAR WARRANTYThe SCI-PA Magnetic Stirrer is an economy LED digital stirrer for basic stirring applications. It is not recommend for any corrosive liquid mixing as the plate is made of ABS plastic.Product Specifications Work plate dimensions (WXD) 135(5 inch)mm Work plate material ABS Motor type DC Motor Motor input power 5W Motor output power 3W Power 15W Voltage 100-120, 60Hz Stirring positions 1 Max. stirring quantity[H2O] 3L Max. magnetic bar[length] 50mm Speed range 100-1500rpm Speed display LED Protection class IP42 Dimension[WxDxH] 150×260×80mm Weight 1.8kg Permissible ambient temperature and humidity 5-40°C, 80%RH Additional Resources and Information Downloadable PDF SCI-PA Manual Hotplate & Stirrers Brochure

$262.28

-

Scilogex SCILOGEX SCI7-S Analog 7?? Square Plate Magnetic Stirrer, ceramic-glass plate 110V/60Hz, US Plug

SCILOGEX SCI7-S 7x7 Analog Magnetic Stirrer, 15-1500rpm SCILOGEX SCI7-S Analog Stirrer, with Ceramic-Glass plate, 110V 60Hz, US plug Product Features Ceramic-glass work plate provides excellent chemical resistance Speed range of 15-1500rpm Max. stirring quantity of H2O - 10L Electronic speed control for constant speed even during changes in load Maintenance free shaded pole motor for long life High magnetic adhesion cTUVus approved for UL and CSA 2 YEAR WARRANTY Product Specifications Work plate dimensions (WXD) 184x184mm(7 inch) Work plate material Glass ceramic Motor type Shaded pole motor Motor input power 15W Motor output power 1.5W Power 30W Voltage 100-120/200-240V,50/60Hz Stirring positions 1 Max. stirring quantity[H2O] 10L Max. magnetic bar[length] 80mm Speed range 100-1500rpm Speed display Scale Protection class IP21 Dimension[WxDxH] 215x360x112mm Weight 3.8kg Permissible ambient temperature and humidity 5-40°C, 80%RH Additional Resources and Information Downloadable PDFs SCI7-S Manual SCILOGEX Hotplates &Stirrers Brochure

$588.74

-

Insulon 3/8" Insulon Vacuum Jacketed Hose, Low Pressure

3/8 Insulon Vaccum Jacketed Hose, Low Pressure Insulon vacuum jacketed hoses for cryogenic and high temperature applications from -270 to 900°C (-454 to 1652°F). High-performance thermal insulation helps fluid transfer systems improve efficiency, safety, and performance. Insulon Hose LP is engineered for low-pressure applications. Insulon Hose LP, 3/8″ ID has a maximum allowable working pressure of 72 psi (4.96 bar) at 23°C. Lengths from 2 to 66 feet.

$347.38 - $1,473.23

-

Scilogex SCILOGEX SCI-PB Analog Circular Stirrer, 110-240V, 50/60Hz, US Plug

SCILOGEX SCI-PB Circular-top Analog Magnetic Stirrer, 15-1500rpm SCILOGEX SCI-PB Analog Circular Stirrer, 110-220V, 50/60Hz, US plug Product Features Electronic speed control for constant speed even during changes in load A wide range of 15-1500rpm Max. stirring quantity of H2O at 3L High magnetic adhesion Now with brushless long life DC motor cTUVus approved for UL and CSA Nylon+GF housing provides a good performance of chemical resistance 2 YEAR WARRANTY The SCI-PB Magnetic Stirrer is an economy stirrer for basic stirring applications. It is not recommended for any corrosive liquid mixing as the plate is made of ABS plastic. Product Specifications Work plate dimension[WXD] Φ135mm(5 inch) Work plate material ABS Motor type DC motor Motor input power 5W Motor output power 3W Power 10W Voltage 100-120V, 60Hz Stirring positions 1 Max. stirring quantity[H2O] 3L Max. magnetic bar[length] 50mm Speed range 0-1500rpm Speed display Scale Protection class IP42 Dimension[WxDxH] 150×260×80mm Weight 1.8kg Permissible ambient temperature and humidity 5-40°C, 80%RH Additional Resources and Information Downloadable PDFs SCI-PB Manual Hotplates & Stirrers Brochure

$212.06

-

Scilogex SCILOGEX SCI-S Circular Analog Magnetic Stirrer, ceramic plate, 110V, 50/60Hz, US Plug

SCILOGEX SCI-S Circular-top Analog Magnetic Stirrer, 15-1500rpm SCILOGEX SCI-S Circular Analog Magnetic Stirrer, ceramic plate, 110V, 50/60Hz, US plug Product Features Electronic speed control for constant speed even during changes in load Speed range of 0-1500 rpm Max. stirring quantity of H2O at 20L Ceramic coated steel plate for anti-corrosion and excellent thermal conductivity Stainless steel work plate cover with ceramic material provides good chemical resistance performance High magnetic adhesion Long life and maintenance free brushless DC motor cTUVus approved for UL and CSA 2 YEAR WARRANTY Product Specifications Work plate dimension[WXD] Φ135mm(5 inch) Work plate material Stainless steel cover with ceramic Motor type Brushless DC motor Motor input power 18W Motor output power 10W Power 30W Voltage 100-120V, 60Hz Stirring positions 1 Max. stirring quantity[H2O] 20L Max. magnetic bar[length] 80mm Speed range 0-1500rpm Speed display Scale Protection class IP42 Dimension[WxDxH] 160×280×85mm Weight 2.8kg Permissible ambient temperature and humidity 5-40°C, 80%RH Additional Resources and Information Downloadable PDFs SCI-S Manual Hotplates & Stirrers Brochure SCILOGEX SCI-S Magnetic Stirrer.mp4 from SCILOGEX on Vimeo.

$495.26

-

Scilogex SCILOGEX SCI40-S Overhead LED Digital Stirrer, with s/steel cross stirrer, 40L Capacity, 100-220V 50/60Hz, US Plug

SCILOGEX SCI40-S (40L) LED Digital Overhead Stirrer 50-2200rpm SCILOGEX SCI40-S Overhead LED Digital Stirrer, 40L Capacity, 100-220V 50/60Hz, US Plug (including steel cross-stirrer Part# 1890007, stand sold separately) Product Features A wide range of speed from 50 to 2200rpm Brushless DC motor for long life and maintenance free Analog speed controls displayed on the LED display for monitoring actual speed High torque for viscous medium stirring Over torque protection automatically stops the motor Safety circuits allow for safe stop function in anti-stall or overload condition A through-shaft design allows for easy adjustment of the impeller position In the event of power loss, the stirrer will resume stirring at the preset speed when the power returns Pass through stirrer rods accepted cTUVus approved for UL and CSA 2 YEAR WARRANTY Product Specifications Maximum stirring capacity 40L Maximum torque 60Ncm Viscosity maximum 50000mPas Speed range 50-2200rpm Speed display accuracy ± 50rpm Speed display resolution ± 10rpm Chuck diameter range 0.5-10mm Dimensions 3.3W x 8.7H x 7.3D in (83W x.220H x 186D mm) Motor rating input 120W Motor rating output 100W Weight 5.5lbs Motor type brushless DC motor Voltage/Power 100-220V, 50/60 Hz/ 130W Speed/Torque display LED Overload protection display LED lights Protection class IP42 Permissible ambient temperature and humidity 5-40°C, 80%RH Additional Resources and Information Downloadable PDFs SCI40-S manual SCILOGEX OverheadStirrers brochure SCILOGEX OverheadStirrers Software SCILOGEX SCI20/40-S LED Digital Overhead Stirrer.mp4 from SCILOGEX on Vimeo.

$1,413.24

-

Scilogex SCILOGEX SCI40-Pro Overhead LCD Digital Stirrer, with stand and s/steel cross srirrer, 40L Capacity, 100-220V 50/60Hz, US Plug

SCILOGEX SCI40-Pro (40L) LCD Digital Overhead Stirrer 50-2200rpm SCILOGEX SCI40-Pro Overhead LCD Digital Stirrer, 40L Capacity, 100-220V 50/60Hz, US Plug (including stand Part# 18900131 and steel cross-stirrer Part# 18900071) Product Features Accurate microprocessor stirring speed control guarantees speed precision RS232 provides PC control and data transmission with free software Provides constant speed even with changes in viscosities of the samples Anti-spill microprocessor control slow start up prevents spillage and splashing Safety circuits allow for safe stop function in anti-stall or overload conditions A through-shaft design allows for easy adjustment of the impeller position Brushless DC motor for long life and maintenance free Torque trend display for real-time information on viscosity changes LCD display for precise monitoring of set and actual speeds, a wide range of speed from 50 to 2200rpm with control accuracy of ±3rpm. Set value and actual value can be displayed for real-time monitoring of torque and speed Pass through stirrer rods accepted PC software control via RS232 interface, for control and documenting all measured values via PC. Download software here cTUVus approved for UL and CSA 2 YEAR WARRANTY Product Specifications Maximum stirring capacity 40L Maximum torque 60Ncm Viscosity maximum 50000mPas Speed range 50-2200rpm Speed display accuracy ± 3rpm Speed display resolution ± 1rpm Chuck diameter range 0.5-10mm Dimensions 3.3W x 8.7H x 7.3Dinches Motor rating input 120W Motor rating output 100W Weight 5.5lbs Motor type brushless DC motor Voltage/Power 100-220V, 50/60 Hz/ 70W Speed/Torque display LCD Overload protection display LED lights Protection class IP21 Data connector RS232 Permissible ambient temperature and humidity 5-40°C, 80%RH Additional Resources and Information Downloadable PDFs SCI40-Pro Manual SCILOGEX OverheadStirrers Brochure SCILOGEX OverheadStirrers Software SCILOGEX SCI20/40-Pro LCD Digital Overhead Stirrer.mp4 from SCILOGEX on Vimeo.

$1,827.59

-

Scilogex Scilogex DS-160 Saw-Tooth Generator Probe for D-160

Scilogex DS-160 Saw-Tooth Generator Probe for D-160 DS-160/T5 Dia 5mm x L 50mm saw-tooth generator probe for D-160, for tissue, volumes 0.1-50ml DS-160/T7 Dia 7mm x L 130mm saw-tooth generator probe for D-160, for tissue, volumes 1-50ml DS-160/T10 Dia 10mm x L 115mm saw tooth generator probe for D-160, for tissue, volumes 1-250ml DS-160/T14 Dia 14mm x L 130mm saw tooth generator probe for D-160, for tissue, volumes 100-1000ml

$485.50 - $1,273.73

-

Scilogex Scilogex Homogenizer Stand

Scilogex Homogenizer Stand(Stand ONLY - Homogenizer NOT Included)This is the Scilogex Homogenizer Stand for the Sciligoex model D160 and D500 homogenizers. This stand is made out of aluminum and features adjustable height knobs and clamp for the homogenizer and the applications needs.

$502.24 - $1,368.60

-

Scilogex Scilogex D160 Homogenizer Package

Scilogex D160 Homogenizer Package 0.1-50ml Homogenizer Package DS-160/5 5mm dia. generator - SCILOGEX D160 Homogenizer Package - Drive Motor, DS-160/5 5mm dia. generator, flat head-open slot, 50mm immerse length, H-370 stand, for solid/liquid media, volumes 0.1-50ml, 110V, 60Hz. 1-250ml Homogenizer Package DS-160/10 10mm dia. generator - SCILOGEX D160 Homogenizer Package -Drive Motor, DS-160/10 10mm dia. generator, flat head-open slot, 115mm immerse length, H-370 stand, for solid/liquid media, volumes 1- 250ml, 110V, 60Hz Motor Only SCILOGEX D160 Homogenizer Drive Motor, 110V/60Hz

$287.39 - $1,351.86

-

Beaker & Wrench 12" Wiped-Film

Beaker & Wrench 12" Wiped-Film Beaker & Wrench continues to be an industry leader, bringing together scientific expertise and real-world industry experience. Take the guess-work out of large scale distillation with their Wiped-Film Evaporation Turn-Key System. It arrives fully functional, meaning you can take advantage of the latest technology immediately and without additional installation or training costs. Other control processes can be subjective and vulnerable to user error, but their automated Wiped-Film Evaporation Turn-Key System will help maximize your product outcomes with greater productivity and maximum purity. 12” Wiped Film Measurements:76”[1.9m] x 30”[0.762m] x 85”[2.16m] Integrated 23″ Touch-Screen Control 200LFeed Tank ACS 100 60 CFMDry Screw Vacuum Pump Dual Stage Cold Trap-50/-100C Inlet and Outlet Gear Pumps(continuous flow) Single-Plug 240V Three-Phase to power the entire machine Six Zone Evaporator Body(1.1m² evaporative area) Consistency is Key Get greater consistency, purity, and confidence in every cannabis oil distillation when you use our system to monitor and optimize flow rate, temperature, pressure, and wiper speed (RPM) in real time. Then… NRTL Certified Each system is 6“ or 12” and constructed with fully compliant USA NRTL-certified components, including a display unit and two sensors to track the contents of both streams of fluid as it continuously travels through the glassware. Get started rapidly with… Set it and Forget it Fully continuous flow leaves behind less advanced methods with a dependable output of 15-30 liters per hour; maximizing efficiency and minimizing complications. Be assured of the quality of your system because we’re… Easy Installation Your system arrives ready to use immediately with all components primed for use. Just roll it off the lift gate and let it get to work. Meet demand and feel confident in the quality of your output with this turn-key system. Don’t make it complicated. Get it right. Lead time: 8-12 weeks from date of payment of 50% deposit, 50% due prior to shipping Specifications Skid Frame: + Dimensions (LxWxH): 76”[1.9m] x 30”[0.762m] x 85”[2.16m] + Weight:1,000 lbs [450Kg] + Material: Extruded Aluminum + 6” castors w/ brakes Shipping Information: + Dimensions (LxWxH): 82.5”[2.01m] x 36.5”[0.93m] x 87.5”[2.22m] + Total Weight: 1200 lbs [545Kg] Electrical Power Distribution Box: + Plug: SCAME SCM563P6W + Input Voltage: 240VAC 3 Phase with Neutral 60 Hz + External Circuit breaker: 60 amp + Nominal current: 24 amps Control Interface + Custom 27” high definition touch screen interface + automated controls + recipe folder +automated sensors and safeties +Error reporting +Software controlled Emergency shutdown Feed Tank: + Volume: 200 Liter + Material: 316 Stainless Steel + double jacketed + Max Temp: [95°C] + Heater: water jacket with 2500kW heater Feed Hose: + Length: 7’-0” [2.13m] + Voltage: 120VAC + Amps: 4.5 Amps + Max Temp: 450°F[220°C] + K-type sensor Rotor: + Wipers: PTFE (Polytetrafluoroethylene) + Mesh Baffles: 316 Stainless Steel + Motor Voltage: 240VAC + Motor Amps: 4(Max) + Motor Watts: 1kw (Continuous) + Speed: 0-400RPM + Dust and Splash Resistant Still Body / Wiped Film Evaporator: + Evaporation Surface Area: 1.1m² + Materials: 316 Stainless Steel + Heat Source: multi-zone Heat Band with independent thermocouples and control + Maximum Power: 12kWatts + Feed Inlet: KF25 + Top and Bottom Connections: 12” sanitary flange + Insulation jacket included Internal condenser: + multi-finger hairpin condenser + Materials: 316 Stainless Steel + Vacuum port: NW80 + Distillate port: KF25 + Residue port: 1.50” Tri-clamp + 2,500w heater + Cooling capacity 8,000w @80c Residue heater: 120VAC, 0.78 amp, 150°C Max Temp, K-type sensor 90W, UR Recognized Heat Pad Residue Outlet Conical shaped Mesh cleanable filter Dual heat pads Clog SensorLiquid level sensor Led lights Condenser Circulator: + Model: BWC-A120 + Bath Volume: ~12L + Bath Fluid: Beaker Kool + multi-fan & Radiator cooling system + Temperature range: 25 to 90°C + Temperature stability: ±1 °C + Heating capacity: 2.5 kW +Cooling capacity: 8kw @80c Gear Pumps: + Voltage: 48VDC + Amperage: 5A + Max Rate: 50.0 L/Hr + Heater: 120v, 0.5amp, 120°C Max Temp, K-type sensor + 45w, UL Recognized Heat Pad + Check Valve Included Dual Stage Cold Trap: + 2 stage cold trap optimized for maximum vacuum protection + Model: Huber TC100 & -100C + CC 508 -50C (1.5kw cooling @ 0c) + Temperature Range: -100 to 100°C Vacuum Gauge: + Model: KJ Lesker

$662,675.99

-

10 Ton Low Temp Glycol Chiller

Discover the Cold Shot Chillers® advantage. Crafted for reliability and user-friendly operation, These portable air-cooled chillers are proudly manufactured in the USA, utilizing proven components and backed by round-the-clock support from a network of technicians in the US. Engineered for a lifetime of service, these chillers ensure precise temperature control. Robust compressors paired with a generous reservoir deliver impressive cooling capacities, keeping your operations smooth even during the hottest months. Choose Cold Shot Chillers® for a reliable, long-lasting cooling solution. Key Features: Integrated Controls: PLC controlled with self-diagnostics. WIFI/LAN/LTE connectivity for predictive maintenance through Guardian™ app. Email/text notifications for predictive maintenance milestones, technical alarms, fault codes, and alerts. Quality Construction: Copeland Scroll technology for efficiency. Stainless Steel/Copper Braze Plate for durability. External Brass Service Valves for easy maintenance. Large Copper Condensing Coil with Aluminum Fins or Micro Channel for effective cooling. Powder-Coated, Heavy-Gauge Steel Cabinet for rugged protection. Additional Specifications: Rugged Stainless Steel Centrifugal Pumps for high flow and dependability. Oversized Magnetic Contactors for longevity. Lifetime Warranty for peace of mind. Benefits: Long Life – Dependable – Economical to Operate. Compact Efficiency for space-saving installations. Easy Maintenance and Repair for user-friendly operation. Rugged Protection while allowing for easy maintenance and wash down. High Flow – Long Life – Dependable performance. Rugged Dependability with a Lifetime Warranty. Specifications: 10 tons (120,000 BTU/35.16KW) 41 Gallon Stainless Steel Reservoir Tank with Lid This Low Temp Model has a leaving fluid temperature range of 20F-70F/-6C-21C. 1.25” MNPT Inlet and Outlet Stainless Steel 1.5 HP Centrifugal Pump outputs 40 GPM at 30 PSI Single Phase (230V/1P/60HZ/81.5A) and Three Phase (230V/3P/60HZ/63.9A) power available Casters Included (two swivel locking and two fixed) Large Reservoir easily filled from outside, and level indicated with sight gauge 1-Year Parts Warranty 5-Year Warranty on Compressor Welded steel powder-coated frame and full metal cabinet with copper piping connections Digital Temperature controller with Self-Diagnostic control system Rugged Protection, while still easy to maintain and Wash Down High Flow Pump, Long Life, Dependable units! Stainless Steel Plate Evaporators Vacuum brazed with Copper Dependable Copeland Welded hermetic Scroll Compressors 61.5"x43"x66.6" 1100 lb UL Certified Please Note: This unit REQUIRES a qualified electrician to wire the necessary plug to the cord. *Please Note: This unit is rated for indoor use only. If you require a chiller rated for outdoor use, please contact our customer service department to request a special order. Cold Shot Chillers are available suitable for outdoor use with ambient temperature ratings as low as -20F.

$32,226.98

-

5 Ton Low Temp Glycol Chiller

Discover the Cold Shot Chillers® advantage. Crafted for reliability and user-friendly operation, These portable air-cooled chillers are proudly manufactured in the USA, utilizing proven components and backed by round-the-clock support from a network of technicians in the US. Engineered for a lifetime of service, these chillers ensure precise temperature control. Robust compressors paired with a generous reservoir deliver impressive cooling capacities, keeping your operations smooth even during the hottest months. Choose Cold Shot Chillers® for a reliable, long-lasting cooling solution. Key Features: Integrated Controls: PLC controlled with self-diagnostics. WIFI/LAN/LTE connectivity for predictive maintenance through Guardian™ app. Email/text notifications for predictive maintenance milestones, technical alarms, fault codes, and alerts. Quality Construction: Copeland Scroll technology for efficiency. Stainless Steel/Copper Braze Plate for durability. External Brass Service Valves for easy maintenance. Large Copper Condensing Coil with Aluminum Fins or Micro Channel for effective cooling. Powder-Coated, Heavy-Gauge Steel Cabinet for rugged protection. Additional Specifications: Rugged Stainless Steel Centrifugal Pumps for high flow and dependability. Oversized Magnetic Contactors for longevity. Lifetime Warranty for peace of mind. Benefits: Long Life – Dependable – Economical to Operate. Compact Efficiency for space-saving installations. Easy Maintenance and Repair for user-friendly operation. Rugged Protection while allowing for easy maintenance and wash down. High Flow – Long Life – Dependable performance. Rugged Dependability with a Lifetime Warranty. Specifications: 5 tons (60,000 BTU/17.5KW) 25 Gallon Stainless Steel Reservoir Tank with Lid This Low Temp Model has a leaving fluid temperature range of 20F-70F/-6C-21C. Rated to 0°F ambient temperature* 1” MNPT Inlet and Outlet Stainless Steel 1 HP Centrifugal Pump outputs 30 GPM at 30 PSI Single Phase (230V/1P/60HZ/47.2A) and Three Phase (230V/3P/60HZ/35.1A) power available Casters Included (two swivel locking and two fixed) Large Reservoir easily filled from outside, and level indicated with sight gauge 1-Year Parts Warranty 5-Year Warranty on Compressor Welded steel powder-coated frame and full metal cabinet with copper piping connections Digital Temperature controller with Self-Diagnostic control system Rugged Protection, while still easy to maintain and Wash Down High Flow Pump, Long Life, Dependable units! Stainless Steel Plate Evaporators Vacuum brazed with Copper Dependable Copeland Welded hermetic Scroll Compressors 50.5"x38.5"x57" 500 lb UL Certified Please Note: This unit REQUIRES a qualified electrician to wire the necessary plug to the cord. *Please Note: This unit is rated for indoor use only. If you require a chiller rated for outdoor use, please contact our customer service department to request a special order. Cold Shot Chillers are available suitable for outdoor use with ambient temperature ratings as low as -20F.

$21,624.16

-

True Terpenes True Terpenes Apple Fritter

True Terpenes Apple Fritter A deep-fried bread base with dried apple, cinnamon, nutmeg, and spice folded in, drizzled with a heavy cream and sugar glaze. Recommended Use and Restrictions on Use This product is concentrated and should not be used undiluted. Based on your use of this product, determine appropriate warnings and directions for your products and applications; also determine safety standards and conduct testing. Avoid contact between this undiluted product and skin, eyes, wood surfaces, and fabrics. Keep this undiluted product away from children and pets. Discontinue use if any adverse reaction occurs. This product has not been evaluated for safe use in e-cigarettes, or in any nicotine-containing or smoking-cessation product. Not for use with tobacco or nicotine. This product is not intended for use by those who are pregnant, nursing, or by those with serious health conditions including but not limited to high blood pressure and diabetes. This product is not intended to diagnose, treat, cure or prevent any disease. Store in original container, sealed tightly, in a cool, dry place away from sunlight or heat sources. This product should not be used beyond its stated expiry date. Products made with this item should be tested to determine suitable shelf life. WARNING True Terpenes cannot anticipate all conditions under which this information and this product, or the products of other manufacturers in combination with this product, may be used. It is the user’s responsibility to stay current with respect to applicable laws and regulatory investigations and findings, and to ensure safe conditions for use, handling, storage and disposal of the product. The user assumes all liability for loss, injury, damage or expense due to unauthorized or improper use, and True Terpenes disclaims all such liability. The information in this sheet was written based on knowledge and experience currently available. To date, True Terpenes has not received any evidence confirming that this product has caused any adverse health consequences. The above information relates only to this product and not to its use in combination with any other material or any particular process, and is designed only as guidance for the handling, use, processing, storage, transportation, and disposal. It should not be considered as a guarantee or quality specification. True Terpenes has performed no testing on this product in e-cig/vaping applications. Applying heat to a compound or mixture of compounds may promote new product formation by thermal degradation. New products could include harmful or potentially harmful compounds. It is the sole responsibility of the individual(s) purchasing this product to assess its safety in the final application. The above information is based on data provided by and collected from recognized sources such as distributors, manufacturers, and technical groups and is considered to be accurate to the best of True Terpenes’ knowledge, based upon current information as of the publish date of this document. It is the responsibility of the user to review all safety information about this product and determine its safety and suitability in their own uses, processes, and operations. Appropriate warnings and safe handling procedures should be provided to all handlers and users of this product, taking into account the intended use and the specific conditions and factors relating to such use in accordance with all applicable laws and regulations. COA & Ingredient Disclaimer This Certificate of Analysis contains specifications and results provided by contract laboratories external to True Terpenes. This document does not relieve the purchaser from conducting their own tests in order to verify the suitability of this product for its application and to comply with all relevant legal requirements for any goods into which this product is incorporated. Botanically derived and/or synthetic compounds found in this product may contain trace compounds which can potentially result in a slight variance between lots. The limits in this Certificate of Analysis may not be inclusive of all compound regulations in your region. Shelf Life Disclaimer Unless otherwise stated on the label, COA, or SDS, the intended use for this product is one year from the date of purchase or listed manufacturing date. It is crucial to observe product label directions and store terpenes properly to maintain product integrity. Terpenes are volatile organic compounds (VOCs) and may degrade over time. Customers may contact our quality department at info@trueterpenes.com to obtain further information regarding a specific production lot. Nutritional Statement True Terpenes certifies that, to the best of our knowledge, the product listed above does not contribute to the nutritional value of flavors due to their extremely low usage levels and therefore falls under the nutritional labeling exemption defined in Section 101.9(a) and (j) of Title 21 of the Code of Federal Regulations. Testimonial Disclaimer In accordance with the FTC guidelines concerning the use of endorsements and testimonials in advertising, please be aware of the following: Testimonials appearing on this website are received in various forms via a variety of submission methods. To the best of True Terpenes’ knowledge, the testimonials reflect the real-life experiences of individuals who used our products and/or services. However, individual results may vary. We do not claim, nor should the reader assume, that any individual experience recounted is typical or representative of what any other consumer might experience. Testimonials are not necessarily representative of what anyone else using our products and/or services may experience. The testimonials displayed are given verbatim except for grammatical or typing error corrections. Some testimonials may have been edited for clarity, or shortened in cases where the original testimonial included extraneous information of no relevance to the general public. True Terpenes is not responsible for the opinions or comments posted on this website, and does not necessarily share the opinions, views, or commentary of postings on this website. All opinions expressed are strictly the views of the poster or reviewer. Testimonials on this website are not intended, nor should they be construed, as claims that the products or services mentioned can be used to diagnose, treat, cure, mitigate or prevent any disease. To the contrary, our products are not intended to diagnose, treat, cure, or prevent any disease. No testimonial has been clinically proven or evaluated, and no health, functional or structural claims whatsoever were made and no statements on this website have been evaluated by the FDA or any other regulatory agencies. Intended Purchasers; Dilution Before Use The products offered on this website are intended for purchase by lawfully operating businesses. These products are not intended for purchase by consumers. Each of these products should be carefully diluted prior to use. COA Apple Fritter COA Lot# 22120103 Apple Fritter COA Lot# 22120201 Apple Fritter COA Lot# 22120203 Apple Fritter COA Lot# 22120510 Apple Fritter COA Lot# 22120811 SDS Apple Fritter SDS PDS Apple Fritter PDS Company Certificates ISO 9001:2015 GMP Certification FSSC 22000 Food Safety True Grade Quality TRUE GRADE™ It is our promise to you. Our isolated terpenes are triple-distilled making them the cleanest terpenes in the world. Fresh out of the bottle, undiluted, every single one of our products bests the most rigorous consumer safety standards. GMP | ISO-9001:2015 | FSSC 22000 Blended in cGMP facilities adhering to the requirements for a Quality Management System (QMS) specified by ISO 9001:2015 and FSSC 22000 standards. Analyzed Tested and passed True Grade™ safety specifications for residual solvents, pesticides and heavy metals. Stability Tested Rigorously tested with mid-grade distillate against separation, cloudiness and unacceptable levels of color change. We Qualify True Terpenes implements supply-chain control for all raw materials and is proud to provide True Terpenes’ qualification documents such as certificates, licenses and registrations to be qualified as your supplier. Undiluted We do not add PG, VG, PEG, MCT or Vitamin E Acetate to any of our products. Food Grade Manufactured in cGMP facilities using food grade ingredients. UV Protected This product is packaged in a cobalt blue, UV deterrent and food grade bottle with tamper evident seal. Made in the USA Formulated, blended, manufactured and fulfilled in the United States. Ships Worldwide True Terpenes ships its botanical aromatic blends worldwide. Refined Isolates This product contains ultra-pure, molecularly-refined terpene isolates. Only the best. Storage RequirementsKeep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. DilutionTerpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier:The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With CareCan cause skin irritation, do not use PRIOR to dilution.

$169.51 - $3,138.99

-

True Terpenes True Terpenes Live Alchemy - Death Star

True Terpenes Live Alchemy - Death Star Death Star is a gas-forward profile that brings in aromas of garlic, diesel, and earthy funk. The fragrance ends with a mildly sweet note of oranges, and overall, the scent is light and airy. Recommended Use and Restrictions on Use This product is concentrated and should not be used undiluted. Based on your use of this product, determine appropriate warnings and directions for your products and applications; also determine safety standards and conduct testing. Avoid contact between this undiluted product and skin, eyes, wood surfaces, and fabrics. Keep this undiluted product away from children and pets. Discontinue use if any adverse reaction occurs. This product has not been evaluated for safe use in e-cigarettes, or in any nicotine-containing or smoking-cessation product. Not for use with tobacco or nicotine. This product is not intended for use by those who are pregnant, nursing, or by those with serious health conditions including but not limited to high blood pressure and diabetes. This product is not intended to diagnose, treat, cure or prevent any disease. Store in the original container, sealed tightly, in a cool, dry place away from sunlight or heat sources. This product should not be used beyond its stated expiry date. Products made with this item should be tested to determine suitable shelf life. WARNING True Terpenes cannot anticipate all conditions under which this information and this product, or the products of other manufacturers in combination with this product, may be used. It is the user’s responsibility to stay current with respect to applicable laws and regulatory investigations and findings and to ensure safe conditions for use, handling, storage, and disposal of the product. The user assumes all liability for loss, injury, damage, or expense due to unauthorized or improper use, and True Terpenes disclaims all such liability. The information in this sheet was written based on knowledge and experience currently available. To date, True Terpenes has not received any evidence confirming that this product has caused any adverse health consequences. The above information relates only to this product and not to its use in combination with any other material or any particular process and is designed only as guidance for the handling, use, processing, storage, transportation, and disposal. It should not be considered as a guarantee or quality specification. True Terpenes has performed no testing on this product in e-cig/vaping applications. Applying heat to a compound or mixture of compounds may promote new product formation by thermal degradation. New products could include harmful or potentially harmful compounds. It is the sole responsibility of the individual(s) purchasing this product to assess its safety in the final application. The above information is based on data provided by and collected from recognized sources such as distributors, manufacturers, and technical groups and is considered to be accurate to the best of True Terpenes’ knowledge, based upon current information as of the publish date of this document. It is the responsibility of the user to review all safety information about this product and determine its safety and suitability in their own uses, processes, and operations. Appropriate warnings and safe handling procedures should be provided to all handlers and users of this product, taking into account the intended use and the specific conditions and factors relating to such use in accordance with all applicable laws and regulations. COA & Ingredient Disclaimer This Certificate of Analysis contains specifications and results provided by contract laboratories external to True Terpenes. This document does not relieve the purchaser from conducting their own tests in order to verify the suitability of this product for its application and to comply with all relevant legal requirements for any goods into which this product is incorporated. Botanically derived and/or synthetic compounds found in this product may contain trace compounds which can potentially result in a slight variance between lots. True Terpenes certifies that this product is not derived from cannabis nor does it contain any cannabinoids or other cannabis-derived extracts. The limits in this Certificate of Analysis may not be inclusive of all compound regulations in your region. Shelf Life Disclaimer Unless otherwise stated on the label, COA, or SDS, the intended use for this product is one year from the date of purchase or listed manufacturing date. It is crucial to observe product label directions and store terpenes properly to maintain product integrity. Terpenes are volatile organic compounds (VOCs) and may degrade over time. Customers may contact our quality department at info@trueterpenes.com to obtain further information regarding a specific production lot. Nutritional Statement True Terpenes certifies that, to the best of our knowledge, the product listed above does not contribute to the nutritional value of flavors due to their extremely low usage levels and therefore falls under the nutritional labeling exemption defined in Section 101.9(a) and (j) of Title 21 of the Code of Federal Regulations. Testimonial Disclaimer In accordance with the FTC guidelines concerning the use of endorsements and testimonials in advertising, please be aware of the following: Testimonials appearing on this website are received in various forms via a variety of submission methods. To the best of True Terpenes’ knowledge, the testimonials reflect the real-life experiences of individuals who used our products and/or services. However, individual results may vary. We do not claim, nor should the reader assume, that any individual experience recounted is typical or representative of what any other consumer might experience. Testimonials are not necessarily representative of what anyone else using our products and/or services may experience. The testimonials displayed are given verbatim except for grammatical or typing error corrections. Some testimonials may have been edited for clarity, or shortened in cases where the original testimonial included extraneous information of no relevance to the general public. True Terpenes is not responsible for the opinions or comments posted on this website, and does not necessarily share the opinions, views, or commentary of postings on this website. All opinions expressed are strictly the views of the poster or reviewer. Testimonials on this website are not intended, nor should they be construed, as claims that the products or services mentioned can be used to diagnose, treat, cure, mitigate or prevent any disease. To the contrary, our products are not intended to diagnose, treat, cure, or prevent any disease. No testimonial has been clinically proven or evaluated, and no health, functional or structural claims whatsoever were made and no statements on this website have been evaluated by the FDA or any other regulatory agencies. Intended Purchasers; Dilution Before Use The products offered on this website are intended for purchase by lawfully operating businesses. These products are not intended for purchase by consumers. Each of these products should be carefully diluted prior to use. Storage RequirementsKeep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. DilutionTerpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier:The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With CareCan cause skin irritation, do not use PRIOR to dilution. COA: Live Alchemy - Death Star COA Lot# 22122807 Live Alchemy - Death Star COA Lot# 23010514 Live Alchemy - Death Star COA Lot# 23010602 Live Alchemy - Death Star COA Lot# 23011605 Live Alchemy - Death Star COA Lot# 23012303 Live Alchemy - Death Star COA Lot# 23012702 Live Alchemy - Death Star COA Lot# 23030202 SDS: Live Alchemy - Death Star SDS PDS: Live Alchemy - Death Star PDS Company Certificates: SO 9001:2015 GMP Certification FSSC 22000 Food Safety

$182.06 - $3,300.13

-

Extend Extend Protection Plan

Extend Protection Plan

$7,671.70

-

Neocision ULTRA-Low Upright Style Freezer with Touch Screen LCD (-86°C) 17.3 Cubic Feet - ETL Rated

Neocision ULTRA-Low Upright Style Freezer with Touch Screen LCD (-86°C) 17.3 Cubic Feet - ETL Rated The BVV™ Neocision Freezers offer optimal temperature control conditions to use in laboratories and medical facilities. The freezers have a quiet operating noise of less than 53 decibels. This freezer has a user friendly touch screen that can be used to monitor many different aspects of the internal systems. The screen will display any errors such as temperature faults or power faults. There is a backup battery that will keep the screen operational though a facility power outage, and it will display the internal temperatures. This information can help the user input dry ice or liquid nitrogen to assist in cooling sensitive materials through a prolonged power outage. The internal chamber has 4 sections that can be used individually or the shelves can be removed or adjusted to fit larger items. Features: Backup Battery Data Logging Gasket Heating Locking Handle Vent Port Interior Chamber Probe High Condenser Temperature Alarm Power Failure Alarm Temperature Sensor Failure Alarm Low Battery Alarm High/Low Temperature Alarm Door Alarm Specifications: Model NEO-86L490 Temperature Range (°C) -50 ~ -86 Temperature Uniformity (°C) ≤6 Cooldown time (hours) ≤6 Capacity (ft^3) 17.3 Exterior Dimensions (LxWxH) (in) 35.8 x 36.5 x 78.3 Interior Dimensions (LxWxH) (in) 23.1 x 25 x 51.5 Door Opening (LxH) (in) 23.1 x 51.5 Insulation thickness (in) 5 Interior Material Stainless Steel Door Sections 4 Shelves 3 Levels 4 Refrigerant Type Non HCFC Voltage 110V AC Power 1500 W Weight (lbs) 732

$9,765.75 $6,277.98

-

The Press Club The Press Club 3" x 5" Easy Drip Rosin Press

3" x 5" Easy Drip Rosin Press Available in two sizes (3” x 5” and 4” x 7”), each press is thoughtfully designed and handcrafted by top solventless experts in the industry. We even developed our own in-house hydraulic ram and pump. WHAT’S INCLUDED WITH EACH KIT - 3" x 5" Rosin Press Kit - 10 Ton Hydraulic Ram / Pump (Hard Case Included), Dual PID Controller, Integrated Easy Drip Tech Tilting Base, Stickers and more 4" x 7" Rosin Press Kit - 20 Ton Hydraulic Ram / Pump (Hard Case Included), Dual PID Controller, Integrated Easy Drip Tech Tilting Base, Stickers and more KEY FEATURES MADE FROM HIGH-QUALITY, INDUSTRIAL-GRADE MATERIALS (Certified American 6061 Aluminum & 304 Stainless Steel) UNDER 45LBS / PORTABLE / TOP HANDLE FOR EASY TRAVELING ULTRA COMPACT & STURDY (measures less than 12” in L x W x H) PATENTED EASY DRIP TECHNOLOGY (go from horizontal to tilted press in less than 3-secs) TOP OF THE LINE INSULATION TO PREVENT HEAT DISSIPATION FROM TOP / BOTTOM PLATES DUAL HEAT CONTROLLER W/ AUTOMATIC SAFETY SWITCH (easily control each top and bottom plate with our easy 2 button set and forget it operation) THE PRESS CLUB BRAND HYDRAULIC RAM / PUMP (HARD CASE INCLUDED) LIFETIME WARRANTY / 2-YEAR WARRANTY ON ELECTRICAL COMPONENTS HANDMADE IN NORTH AMERICA 1018 Cold Rolled Steel w/ Black Zinc Nickel Plating 6061 Aluminum Plates Press Plates

$4,882.88 - $6,277.98

-

The Press Club The Press Club 1.75" x 4" ROSIN BAGS

1.75" x 4" Rosin Bags The Press Club brings science to the art of rosin pressing. The Press Club prides themselves in making the toughest and strongest rosin bags on the market. After years of research and lab testing, all our rosin bags are now made with our proprietary pink stitch and come with a ZERO BLOWOUT GUARANTEE™. If you ever get one, they will replace the bag. It's that simple. Available in 25, 37, 50, 75, 90, 120, 160 and 220 micron. 1.75” x 4” Inch 10-Pack Pre-Flipped Inside-Out 100% Food-Grade Nylon Solvent & Boil Resistant High Pressure Resistance (Over 20 Tons) High Heat Resistance (Up To 375° F) Reusable Over 5x (Simply Wash With Alcohol) Covered By The Press Club’s Zero Blowout Guarantee Satisfaction Guarantee & 365-Day Return Policy Made In USA General Micron Guideline: Dry Sift & Bubble (5, 10, 15, 25, 37, 50) | Flower (75, 90, 120, 160, 220)

$18.07

-

Shaking Incubator

Shaking Incubator Shaker incubator combines incubator and shaker functions together, it provides accurate temp. control, realizes shake incubating and meet bacterium, microbe suspension incubate requirements. It is ideal instruments for Cell culture, fermentation, biochemistry, water quality analysis, plant cultivation and breeding. Technical breakthroughs Unique air flow technology Adopts continuous flow fan technology, air stability, no turbulence, temperature is uniform; Cycle fan speed can be automatically controlled, it can avoid the samples volatile too fast due to cycle fan is too fast. Patented single-axis drive technology Patented single-axis drive and balancing technology, running stable ,low noise and low consumption Pneumatic support technology Adopts pneumatic support, transparent cover height can be adjustable to any position, convenient the operation Large screen LCD display Colorful touch screen can continuously, accurately and real-time display temp., rotation speed and work time. The menu operation interface is easy to understand. Technical features Humanization design Combine incubator, shaker functions together with small space Patented overall design, transparent big view windows, dynamic master the culture effect. With reserve test hole, outer sensors can access to test the inner cabinet temperature(Option) Shaking platform and chamber are made of stainless steel, anti-corrosion and easy to clean Standard configuration is universal clamp, it can used for different vessel with different volume Uninterrupted performance guaranty Brushless DC motor, large start torque, wide speed adjustment, free maintenance. Safety Protection on instruments: Comply international standard secondary temp. limiter alarm system, alert the operator with sound and light alarms, ensure operator is safe without any accident. Protection on key components: Key components have over current, over temp., over load etc safety protection, it can prevent instruments accidents without precautions. Protection on samples: Working chamber temperature higher or lower the set temp., alarm starter cut down the heater, alert the operator with sound and light alarms. Protection on operator: Cabinet and door is special designed for insulation, low heat of cabinet body, ensure operator use instrument without burnt. Breakdown message provided: When the instrument breakdown, the breakdown messages show on the screen to help operator easily check. Convenient data process Equip with USB as options, record temp. parameter changes(Option) Equip with RS232 data interface, through software to remote control machine performance (option) Above two options can be selected only one Technical parameters Model BSI-1 Temp. range RT+5~65℃ Temp. control accuracy 0.1℃ Speed range 40~250rpm Frequency accuracy ±1rpm Platform size(mm) 250×250 Inside height (mm) 195 Overall size W×D×H(mm) 390×590×370 N.W 32 Kg Amplitude 20mm Running time 1-99h59min Powder requirement AC220V/50Hz Rated power 450W Standard configuration 250ml×8pcs

$488.29 $348.78

-

2" Footmaster Leveling Caster Ivory - 550lb cap

2" Footmaster Leveling Caster Ivory This ingenious product combines the mobility of a caster, the height adjustability of a level mount, and the stability of a foot pad. The GD Series leveling caster profile is integral to its function. A thick aluminum frame is used to achieve the combination of being both strong and compact. The swivel section contains 2 sets of ball bearings for easy maneuverability. Bearing raceway sleeves made from hardened steel prevent scouring to the aluminum frame, leading to high performance and dependable reliability. Moving is easy thanks to a 50 mm diameter wheel mated with an axle shaft made of cold forged steel. And once positioned, the caster provides side access to an ABS thermoplastic thumbwheel used to lower the foot pad. As the wheel is lifted off the ground, the foot pad takes over to make the application completely stationary. Making the fine adjustments to achieve the perfect level set, even under heavy loads, is light work for this world renowned leveling caster. When it is time to move again, simply raise the foot pad to restore the freedom of mobility.

$174.39

-

Insulon 3/4" Insulon Vacuum Jacketed Hose, Low Pressure

3/4" Insulon Vacuum Jacketed Hose, Low Pressure Technical Specifications: Hose Size 3/4” ID DN (ISO 10380) 20 Product Category LP (Low Pressure) Inner Hose ID 0.787” Tube Stub OD 0.750” Tube Stub Thickness 0.049” Outer Hose OD 1.62” Static Bend Radius 4.1” Dynamic Bend Radius 11.81” Lengths 2 – 20’ Operating Temperature -270°C to 900°C (-454°F to 1652°F) Material 316L stainless steel Maximum Allowable Working Pressure (MAWP) by Temperature: Product Category Hose Size Max Temperature (C) Max Temperature (F) MAWP (PSI) Low Pressure (LP) 3/4" ID 21 70 43 Low Pressure (LP) 3/4" ID 66 150 40 Low Pressure (LP) 3/4" ID 93 200 38 Low Pressure (LP) 3/4" ID 121 250 37 Low Pressure (LP) 3/4" ID 149 300 36 Low Pressure (LP) 3/4" ID 166 330 35 Low Pressure (LP) 3/4" ID 204 400 34 Low Pressure (LP) 3/4" ID 232 450 34 Low Pressure (LP) 3/4" ID 260 500 33 Low Pressure (LP) 3/4" ID 316 600 33 Low Pressure (LP) 3/4" ID 371 700 33 Low Pressure (LP) 3/4" ID 427 800 32 Low Pressure (LP) 3/4" ID 482 900 32 Low Pressure (LP) 3/4" ID 538 1000 31 Low Pressure (LP) 3/4" ID 593 1100 29 Low Pressure (LP) 3/4" ID 649 1200 26 Low Pressure (LP) 3/4" ID 704 1300 24 Low Pressure (LP) 3/4" ID 760 1400 21 Low Pressure (LP) 3/4" ID 816 1500 17 Low Pressure (LP) 3/4" ID 899 1650 11

$403.19 - $1,918.27

-

WFE Rack 8

Extruded Aluminum Framing Rack This rack is constructed of 1.5" extruded aluminum framing. This framing has slots that can be used for a wide variety of mounting hardware. This large rack is a good size to contain a wiped film or similar distillation equipment, along with three laboratory heaters/chillers stacked on the right side. The rack has six swivel casters for smooth transport with locking wheels in the corners. NOTE: This rack ships unassembled. Allow 6 hours for assembly

$5,440.92

-

ChemTek ChemTek 3" Sweating Baskets

ChemTek 3" Sweating Baskets Sweat the terpene sauce off of your crystalized compounds or dry out sugars. Specifications: 25 Micron 304 Stainless Steel H: 6” W: 3 1/4”

$20.93 - $69.76

-

ChemTek ChemTek Regular Mouth Fuse Basket - 4 Pack

ChemTek Regular Mouth Fuge Basket - 4 Pack Used for separating oils from solids. Different micron options are available. Specifications: 304 Stainless Steel H: 3.5” W: 2.5”

$69.76

-

ChemTek ChemTek CHT210R Centrifuge

ChemTek CHT210R Centrifuge CHT210R centrifuges provide excellent performance and easy operation in a compact design that saves valuable time and laboratory space. Each unit comes with 2 rotors for high speed(20x15ml) or large capacity94x750ml) options for refrigerated centrifuging. Specifications: Power Supply: 110V 50/60Hz Max Speed: 21,000 RPM Max RCF: 32, 752 x G Max Capacity:4x750ml Cooling Capacity: -20C to -40C Time Setting Range: 1 - 99min Speed Accuracy: ± 10r/min Noise: ≤65dB Power Consumption: 6Kw Net Weight: 170lbs Comes with: (20) 50ml Tubes (4) Regular Mouth Basket (4) Wide Mouth Baskets (4) Regular Mouth Stainless Jar Lid/Band (4) Wide Mouth Stainless Jar Lid/Band (4) Five 50ml Tube Holder Inserts (4) Regular Mouth Jar Spacer Inserts (4) Wide Mouth Jar Spacer Inserts (1) 50-pack 5”x 7” Double Stitched Fuge Bags (1) 50-pack 6.5”x 7” Double Stitched Fuge Bags (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves (1) Power converter

$18,415.42

-

ChemTek ChemTek CL5 Centrifuge

ChemTek CL5 Centrifuge CL5 centrifuges provide excellent performance and greater capacity. Each unit comes with 2 rotors for (6)500ml or (4)1000ml bucket options. Specifications: Power Supply: 110V 50/60Hz Max Speed: 5000 RPM Max RCF: 6100xg Max Capacity: 4x1000ml Time Setting Range: Speed Accuracy: ± 10r/min Noise: 65dB Power Consumption: 3 kW Dimensions: Net Weight: 600lbs Comes with: (20) 50ml Tubes (4) Regular Mouth Basket (4) Wide Mouth Baskets (4) Regular Mouth Stainless Jar Lid/Band (4) Wide Mouth Stainless Jar Lid/Band (4) Five 50ml Tube Holder Inserts (4) Regular Mouth Jar Spacer Inserts (4) Wide Mouth Jar Spacer Inserts (1) 50-pack 5”x 7” Double Stitched Fuge Bags (1) 50-pack 6.5”x 7” Double Stitched Fuge Bags (1) Terp SqueeGee (1) 100-Pack of Large Diamond Grip Gloves

$25,111.93

-

8" Hemispherical End Cap with Coil

8" Hemispherical End Cap with Coil This 8" Hemispherical End Cap with Coil comes standard with our 150L Conical Reactor. Complete with 2X 1/2" NPT accessory ports, 2X 1/4" NPT accessory ports, 2X 1/2" NPT ports for the coil, and a single 1.5" tri-clamp top port. This versatile part is perfect for those looking to add extra surface area to their heating or cooling application. From the 8" tri-clamp to the bottom of the coil measures 34".

$627.80

-

Neo Diaphragm Replacement Membrane

These replacement diaphragms are used in the BVV V-40 diaphragm vacuum pumps. The V-40 has two diaphragms and will need one two pack to do a rebuild on it.

$111.61 - $223.22

-

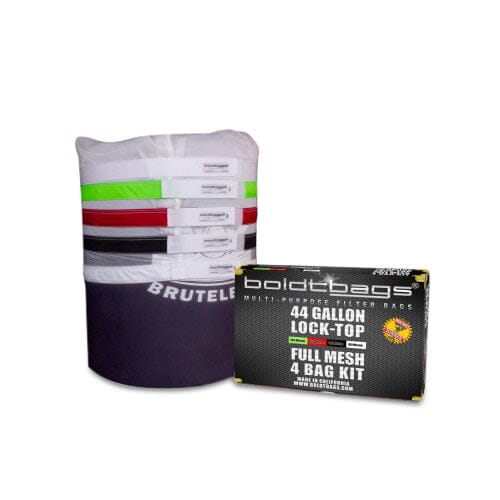

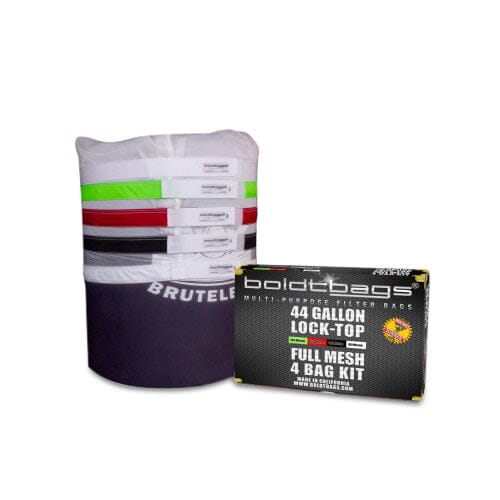

Boldtbags 44 Gallon Boldtbags Full Mesh Stacker Lock-Top w/ Belt Lock

44 Gallon Boldtbags Full Mesh Stacker Lock-Top w/ Belt Lock Lock top bags are the new product made with you in mind. Adjust your bag to the height you need and lock it in for easier product washing and collection. Custom designed with Full Mesh, these bags provide exceptional ice water sieving properties and award winning purity thanks to the large functional surface area and lightweight construction that allows for easy use and award winning results. Ideal purchase for Laboratories. Have a variety of bags to choose from and mix and match for perfect trichlome extraction. Diameter 23.5″ Depth 28.25″ 4 bag kit includes: 190 micron bag (green) 160 micron bag (red) 90 micron bag (black) 45 micron bag (white) Additional belt lock Scraping card 8 bag kit includes: 220 micron bag (blue) 190 micron bag (green) 160 micron bag (red) 120 micron bag (orange) 90 micron bag (black) 73 micron bag (yellow) 45 micron bag (white) 25 micron bag (purple) Additional belt lock Scraping card

$906.82 $348.78

-

MVP-6CFM 1PH Wired - Used

USED-MVP-6CFM 1PH Wired The Master Vapor Pump Model MVP-6CFM is a certified gas recovery pump designed to operate at 60 PSI. This pump is designed specifically for LP-Gas vapor recovery and is ideal for butane or butane / propane mixtures. Disclaimer: This item has been USED for about 400-500 hours of runtime in the BVV R&D lab. It may contain traces of CBD or solvent used in our lab. This specific pump includes a C1D1 receptacle and switch that is already installed. You will need a sealed wire with NEMA 5-20 male plug. For our recommended item click HERE Engineering Specifications: Recover LP-Gas vapor at OVER 6 CFM (cubic feet per minute) Recover butane at up to 1 LB/MIN (pounds per minute) Recover and recondense butane at OVER 12 GPH (gallons per hour) Electric motor: explosion proof for C1D1 hazardous areas; rated Class I Gr C & D, Class II Gr F&G Electric motor: 1 HP, 1800 RPM, 60 HZ Pump speed: 190 CPM (cycles per minute) at 60 HZ Size: 17.0” x 19.9” base x 46” tall Weight: 182.5 lb (82.8 kg) Downloads Product Manual Technical Data Sheet Features and Benefits Sheet

$9,347.22 $5,580.43

-

50L Glass Reactor Shaft Seal Kit 13MM Replacement

50L Glass Reactor Shaft Seal Kit 13MM Replacement This part is made for 50LTGR-V3 reactors. The body is PTFE and has viton shaft seals that are made for mixing shafts with 13mm diameters. It includes a clamp and retaining ring to attach to our glass reactor lids.

$697.55 $558.04

-

Part A 2" Stubby NPT to Cam Lock Adaptor

Part A 2" Stubby NPT to Cam Lock Adaptor This adapter converts 2" (50mm) male NPT pipe threads to a 2" male camlock. The adapter incorporates female NPT threads on one end and male camlock (also known as a quick disconnect or QD) on the other for connecting pipes and valves with different ends. Made of tough polypropylene (PP), this adapter also incorporates an ethylene propylene diene monomer (EPDM) gasket for a leak-tight connection. Shallow profile ensures valve does not protrude past IBC tote cage. Key benefits: Converts 2" male NPT pipe thread to a 2" male camlock 2" long profile does not protrude past IBC cage during transport Made of PP EPDM gasket ensures a secure seal Suitable for use in a wide variety of liquid handling applications Proudly Made in the USA Material: Polypropylene (PP) is a tough plastic that has good chemical resistance. PP is translucent in its natural state but can have a glossy finish when produced with color. Some examples of common products made with PP are dairy and medication containers. Polypropylene is suitable for hot fill applications of up to 165°F and is therefore great for autoclaving. It is not recommended for cold or sub-freezing temperatures. The Cary Company has an assortment of polypropylene plastics available for purchase, such as plastic caps and jars, which have a higher tolerance for chemical products. Disclaimer: This information has been provided as a general guide. It is the customer's responsibility to select the proper container for product and application compatibility. Material PP Dimensions 2.4" Dia. x 1.02" H Weight 0.1 lbs. Case Pack 200 ea. Case Dimensions 15" L x 15" W x 16" H Case Weight 20 lbs. Pallet Pack 6,000 ea. (30 Cases) Pallet Dimensions 40" L x 48" W x 60" H Pallet Weight 600 lbs. Country of Manufacture United States Gasket EPDM Rubber Gasket

$15.35 $9.77

-

Glass Vac 15.25" Diameter LID

Glass Vac 15.25" Diameter LID Disclaimer: This item Includes Lid and Gasket Only This is a Replacement Lid for the following Vacuum Chambers: Glass Vac 10 Gallon Aluminum Vacuum Chamber

$265.07

-

STM Canna STM LaunchPad Weighing Module

STM LaunchPad Weighing Module The First & Only Modular, Commercial Pre-Roll Scale The LaunchPad Weigher is the first and only modular, commercial pre-roll scale which weighs 72-rolls at once and in seconds. The LaunchPad functions as a stand alone machine or better as part of STM Canna’s complete pre-roll workflow system. 72 Rolls Weighed Simultaneously The LaunchPad commercial scale gives your staff the ability to view the weight of each individual pre-roll and identify rejects in an instant with a color-coded display, dramatically increasing production speed and output With this new innovative module, your operation will greatly benefit from reduced labor hours, the ability to maintain precise quality control over the weight of your pre-rolls and maximize profits attributed to under or over filling. Customizable Parameters Target Weight Paper weight % Tolerance View of Min. & Max. Weight by Grams Renowned Service & Support 1-Year Parts & Labor Warranty Dedicated STM Client Services Team Exclusive Client Portal with Library of Training Videos and Information Launchpad User Manual Launchpad Technical Specifications Launchpad Brochure

$59,982.64

-

STM Canna STM Atomic Closer 2.0

STM Atomic Closer The only modular pre-roll closing machine on the market designed to incorporate human touch for true premium quality look and feel. Boasting an ultra compact footprint, this one-of-a-kind system can operate on a tabletop in facilities of all sizes, eliminating the industry's #1 pre-roll bottleneck. Features Compatible with RocketBox and Mini-RocketBox. Tamps & Folds Ends into Beautiful, Consistent Crown. Fastest in the Industry at 72 joints every +/- 40 seconds Daily Capacity of 41,000 +/- Pre-Rolls Easy to Clean and Maintain HMI Touch Screen Control Emergency Stop Switch & Reset Button Adaptable to Future Weighing Machine & Packaging Add-Ons Orders are expected to begin shipping in February 2022. Renowned Training & Support Dedicated STM Client Services Team Exclusive Client Portal with Library of Training Videos and Information STM Atomic Closer Brochure PDF Atomic Closer Technical Specifications PDF Atomic Closer User Manual PDF

$83,699.47

-

STM Canna STM Mini-RocketBox PLUS+

STM Mini-RocketBox PLUS+ The STM Mini-RocketBox PLUS+ pre-roll machine combines power, efficiency, and versatility to maximize your pre-roll production. Capable of producing 143 pre-rolled cones in under a minute, this machine is perfect for startups on a budget. Features 143 Pre-Rolls in 45 Seconds (4x faster than competitors) Compatible with 84 (.5g), 98 (.7g) and 109 (1g) MM Cones Variable Frequencies of Vibrations for Even Filling & Packing Adjustable Top Tray for Adjusting Height of Fill Lift Plate to Ensure Cones Sit Flush with One Another Fully Adjustable Dial for Desired Tightness & Pack Reduces Tedious Manual Labor Durable Stainless Steel for Commercial & Industrial Use Evenly Fills Cones Layer-by-Layer for Optimal Smokability OSHA Compliant What's Included 1 x STM Mini-RocketBox Pre-Roll Machine 1 x Bottom Tray (in size of choice) 1 x Adjustable Top Tray 1 x Loading Box 1 x Finishing Base 1 x 12-Month Parts and Labor Warranty Renowned Training & Support Dedicated STM Client Services Team Exclusive Client Portal with Library of Training Videos and Information Mini-RocketBox PLUS+ User Manual Mini-RocketBox PLUS+ Technical Specifcations Mini-RocketBox PLUS+ Get Started Mini-RocketBox PLUS+ Brochure Mini-RocketBox PLUS+ Comparison Chart

$9,207.71

-

STM Canna STM RocketBox 2.0

STM RocketBox 2.0 The STM Canna Rocketbox 2.0 is the world’s most advanced commercial pre-roll machine, producing over 453 pre-rolled cones in a 60-second cycle. Designed to maximize pre-rolled joint production while significantly decreasing labor costs, the RocketBox 2.0 is the pinnacle of pre-rolled cone machines. Features 453 Pre-Rolled Joints in 60 Seconds Compatible with 84, 98 and 109 MM Cones Proprietary Smart Density Software to Measure & Achieve Weight Accuracy Variable Frequencies of Vibrations for Even Filling & Packing Built-In Training Mode with Tutorials Adjustable Top Tray for Adjusting Height of Fill Lift Plate to Ensure Cones Sit Flush with One Another Precise, Consistent and Repeatable Results Benefits 6x to 7x's Faster, Decreases Labor for All Size Operations Durable for Long-Term Commercial Use Easy On-Boarding and/or Training After Turnover Density Calculator for Scientifically Accurate Weights Up to 25,000 Joints Daily (grow, scale & co-pack) Attachment-Capable (Sifter Launching 2021) Renowned Training & Support Dedicated STM Client Services Team Exclusive Client Portal with Library of Training Videos and Information What's Included 1 x STM RocketBox 2.0 Pre-Roll Machine 1 x Bottom Tray (in size of choice) 1 x Adjustable Top Tray 1 x Loading Box 1 x Finishing Base 1 x Density Testing Beaker 1 x 12-Month Parts and Labor Warranty RocketBox Comparison Chart RocketBox User Manual RocketBox Brochure RocketBox Technical Specifications

$34,807.93

-

STM Canna STM Revolution 2.0

STM Revolution 2.0 Designed specifically for flower, the Revolution 2.0 delivers a homogenous, consistent grind, optimal for evenly packed pre-rolls and high-yield extraction. No plastic whips, meat grinders, blenders or flour mills that heat and pulvarize months of your hard work. Chosen by small craft cultivators and start-ups up to the largest brands and facilities around the world, the STM Revolution 2.0 is an asset that grows with your business, allowing your facility to scale as needed and maintain the highest product integrity (retaining your trichomes & terpenes). Features 15-30 LBS Per Hour of Dry Flower Interchangeable Fine & Coarse Particle Screens for Extraction & Pre-Rolls Minimizes Terpene Loss Self-Regulating, Closed-Loop System to Prevent Clogs Auto-Blade Oscillation Creating Scissor-Like Cuts Auger Timing & Blade Speed Control 7%-10% Optimal Moisture Content Consistent and Repeatable Results What's Included Dual Blade System Fine Partical Screen Coarse Particle Screen Cut-Proof Safety Glovews Renowned Training & Support Dedicated STM Client Services Team Exclusive Client Portal with Library of Training Videos and Information Revolution Get Started Revolution User Manual Revolution Comparison Chart Revolution Brochure Revolution Technical Specifications

$32,017.71

-

STM Canna STM Mini-Revolution

STM Mini-Revolution Designed specifically for flower, the Mini-Revolution delivers a homogenous, consistent grind, optimal for evenly packed pre-rolls and extraction. Features Variable Speed Control (low, medium, and high) Interchangeable Fine & Coarse Blades Cuts Flower Versus Extruding, Smearing, Pressing, or Whipping Less Terpene Loss Than Competitors Homogenous & Consistent Flower Particles Keeps Stems & Seeds Intact For Easy Post-Sifting Designed, Manufactured & Assembled in the USA Durable, Built for Commercial Use Food-Grade Stainless Steel Construction Quiet Operation OSHA Compliant; Equipped with Safety Switch Very Easy to Clean Tabletop Unit, Ergonomic for Small Production Spaces Renowned Training & Support Dedicated STM Client Services Team Exclusive Client Portal with Library of Training Videos and Information Includes Fine Blade Disc Coarse Blase Disc Collection Bin Mini Revolution Brochure Mini Revolution Comparison Chart Mini Revolution Electrical Schematic Mini Revolution Technical Specifications Mini Revolution User Manual

$9,207.71

-

Heavy Duty Steel Mobile Cart Shelves

Heavy Duty Steel Mobile Cart Shelves These are additional shelves that are designed to go with our Heavy Duty Steel Mobile Cart for Vacuum Ovens. These shelves can also fit on either the left or right side of the bracket. What is Included: 1x Shelf 2x Support Brackets (Left and Right Side) 8x M8 Screws + Washers Note: Product does NOT come assembled. Required tool: 5mm ball hex (NOT INCLUDED).

$334.83

-

20L Turnkey Reactor Kit

20L Turnkey Reactor Kit The BVV 20L Double Jacketed Glass Reactor Kit is the ideal solution for small to medium-sized solvent recovery and decarboxylation applications. This kit includes everything to get you up and running including a Single 20L triple-layer Glass Reactor with Condenser, either a BVV 19L Heated circulator capable of heating to 220C or a UL-listed Huber CC-315B capable of heating up to 300C, a 1HP Polyscience 6160T for chilling the condenser, a Welch BTpro100 for vacuum, 25ft of 3/8" Gum rubber tubing for vacuum connections, 20ft of reinforced PVC hose for the chiller, 1/2" Stainless Steel JIC Hoses for the heater, 5 Gallons of Therminol Heat transfer fluid and 5 Gallons of Propylene glycol. 20L Double Jacketed Glass Reactor Specifications Glass Material: GG-17 High Borosilicate Glass Internal Volume: 20L 6.75L Jacket Capacity Shelf Material: Aluminum Alloy Homogenizer Power: 110V/60Hz Homogenizer Speed: 0-400 RPM Digital Homogenizer Control Digital temperature probe readout included Double Jacket 3/4" Jacket Connections 1/4" and 3/8" Vacuum Connections Length: 20 in. Width: 30 in. Height: 76 in. Polyscience 6100 1 HP Chiller Specifications 6100 Series 1 HP Chiller with Turbine Pump, 100psi; 13.2l/min Display: LED Working Temperature Range C: -10 to 40 Temperature Stability: +/-0.1 Temperature Calibration Capability: 1-point Pump Type: Turbine Working Temperature Range F: 14 to 104 Working Temperature Range C: -10 to 40 Reservoir Capacity (gallons): 1.11 Reservoir Capacity (liters): 4.2 Reservoir Cover: Screw-on cap Cleanable Air Filter: Yes Cleanable Fluid Filter: Yes Temperature Stability F: +/-0.2 Temperature Stability C: +/-0.1 Display: LED Display Resolution (Read): 0.1 Pump Type: Turbine Process Connections: 1/2" FNPT Over-Temperature Protection / Failsafe Heater Control: Yes Reservoir Liquid Level Indicator: Yes Reservoir Drain: Yes Cool Command Refrigeration Technology: Yes WhisperCool Environmental Control Technology: Yes Maximum Ambient Temperature F: 95 Maximum Ambient Temperature C: 35 Overall Dimensions (LxWxH inches): 27.6 x 14.5 x 22.6 Overall Dimensions (LxWxH cm): 70 x 36.8 x 57.5 Compressor Size (HP): 1 Refrigerant: R134a Shipping Weight (pounds): 199 Shipping Weight (kilograms): 90 Welch BTpro100 Specifications Model BTpro100 Free Air Displacement@60Hz,lpm(CFM) 100(3.5) Ultimate Vacuum Pressure, Torr 6 Maximum Vacuum, in. Hg 29.7 Horsepower, HP (watts) 0.5(390) Built-in adjustable vacuum - Gas Ballast Yes Head Material PTFE Diaphragm PTFE Inlet/outlet Connection NW16 flange1 Agency (National Recognized Lab) cUL Weight, lbs (kg) 40.3(18.3) Overall DimensionsLxWxH in.(cm) 9x15x7(23x38x18) Shipping Weight, lbs(kg) 48.5 (22) Shipping Carton DimensionsLxWxH in.(cm) 18.9x12.6x11.8(48x32x30) HUBER CC-315B Specifications Common Specifications Temperature range (-20) 28...300 °C Temperature stability ±0.02 °C Temperature control TAC, self-optimizing (True Adaptive Control) Controller Pilot ONE (E-grade "basic") Safety class III / FL Protection class IP20 Dimensions (W x D x H) 13.19 x 15.04 x 17.05 inches Weight 48.51 pounds Heating / cooling capacity Heating capacity 3 - 3,5 kW Circulation pump Pressure pump max. 25 lpm : 0,7 bar | 6.6 gpm ; 10.15 psi Suction pump max. 18.5 lpm : 0,4 bar | bar 4.89 gpm ; 5.8 psi Pump connection M16x1 AG male Permissible viscosity 50 mm²/s Connections Pt100 connection Pt100 Digital interface RS232, Ethernet, USB Device, USB Host Operating data Old sku 2007.0003.01 Permissible ambient temp. 5...40 °C Bath opening W x D / BD 10.63 x 5.71 / 7.87 inches Bath volume 15 Liters | 3.96 gal Filling volume min. 11.5 Liters | 3.04 gal Power supply 208V 2~ 60Hz Current max. 16 A Fusing 20 A

$32,087.47 - $43,248.33

-

Carbon Chemistry Alumicel™ B

Carbon Chemistry Alumicel™ B Carbon Chemistry's Alumicel B is used in Column Chromatography to separate small molecules, peptides, and plant extracts. Basic; pH 9.9 Used for Chromatography Commonly used as an aid for decolorizing Download Safety Data Sheet

$139.51 - $669.65

-

Huber Huber Unistat T330 with Pilot ONE

Huber Unistat T330 with Pilot ONE The Unistat range inspires with unique thermodynamic properties and a range of functions to meet the highest demands. Unistat technology guarantees precise, reproducible temperature control results, the shortest possible heating and cooling times and large temperature ranges without the need for fluid change. All Unistats are fitted with the innovative Pilot ONE controller with a 5.7“ touchscreen colour display and easy menu navigation. All important parameters can be seen at a glance and temperature curves are displayed in graphic real time. Unistats are equipped with the most up-to-date pump technology for optimal heat transfer. The pump self regulates to ensure the best possible circulation and flow and delicate glass reactors are protected from breakage by the pumps soft start-up feature. Unistat technology impresses as a result of economic operation with reduced operating costs and efficient energy management. Because Unistats are hydraulically sealed, the service life of the temperature control fluid is dramatically increased by preventing oil loss through vapours and oxidation, further saving resources. Unistats are fitted with extensive safety equipment and are therefore suitable for unsupervised continuous operation. Relevant operating conditions are constantly monitored and the system is switched off if necessary or with the process safety feature the emergency cooling circuit is activated. General information & temperature controller Temperature range 65...300 °C Temperature stability ±0,01 °C Temperature control TAC, self-optimizing (True Adaptive Control) Display resolution 0,01 °C Alarm message optical, acoustical Controller Pilot ONE (E-grade "Professional") Safety class III / FL Protection class IP20 Dimensions (W x D x H) 540 x 678 x 1174 mm Weight -- kg Heating / cooling capacity Heating capacity 21 - 24 kW Circulation pump Pressure pump max. 96 l/min ; 3,5 bar Pump connection M30x1,5 AG male Permissible viscosity 50 mm²/s Pump speed adjustable Yes Connections Pt100 connection Pt100 Analogue input via optional Com.G@te Analogue output via optional Com.G@te Digital interface RS232, Ethernet, USB Device, USB Host Operating data Permissible ambient temp. 5...40 °C Volume of expansion 24 Litres Power supply 380-460V 3~ 50/60Hz

$88,380.05

-

True Terpenes True Terpenes King Louis XIII

True Terpenes King Louis XIII Fragrance: Citrus Earthy Pine Fuel Effects: Function Soothing A California creation, King Louis XIII was bred by combining two popular varieties; OG Kush and LA Confidential. It’s a rare OG Kush variant that has seen limited distribution outside the West Coast. In traditional OG fashion, King Louis has an earthy pine fragrance with layers of fuel and funk. King Louis also provides a heavy citrus dimension. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution. King Louis XIII-Specific Certificates: Product Specification All Natural Certificate of Analysis Safety Data Sheet Food Safety Company-Specific Certificates: ISO 9001:2015 GMP Certification FSSC 22000

$169.51 - $3,138.99

You have seen 1584 out of 1653 products