Chapter 3: Refinement (Color Remediation & Winterization)

, by Avery Benitez, 34 min reading time

, by Avery Benitez, 34 min reading time

INTRODUCTION TO BOTANICAL EXTRACT REFINEMENT

During the botanical extraction process, it is common that several undesirable plant compounds will be extracted alongside the target compounds. These compounds typically include plant waxes, fats, lipids, and color compounds, including chlorophyll, anthocyanins, and flavonoids. The co-extraction of these undesirable compounds produces an extract that is typically lower in potency and visually unappealing.

Luckily, several refinement procedures can remove these undesirable compounds and create a highly pure botanical extract. The two most common methods of botanical extract refinement are filtration processes, including winterization and color remediation. Typically these processes are performed prior to the solvent recovery process while the extract is still diluted in a solvent. These techniques further refine a botanical extract to its highest purity prior to distillation.

WINTERIZATION

Ultra-Low Chest Style Freezer with Touch Screen LCD (-86°C) 16.2 Cubic Feet - ETL Rated By BVV

Winterization is a very common process for solvent-based extraction methods; winterization is the process of dissolving a botanical extract in a winterization solvent like ethanol and freezing the botanical extract solution to precipitate out fats and waxes co-extracted during the initial extraction. Once the fats and lipids have consolidated, the mixture is filtered to remove fats, waxes, and lipids from the botanical extract solution before further refinement. During the botanical extraction process, whether it be hydrocarbon, co2, or ethanol, undesirable plant waxes and lipids will be co-extracted in the process. Removal of these undesirables is necessary to create a high-quality refined extract. Winterization is typically performed after extraction and before distillation. First, the botanical extract must be dissolved in a polar solvent like ethanol. Once fully dissolved, the extract-rich solution is then chilled at subzero temperatures for a long enough duration for the plant waxes to start to precipitate out of the ethanol solution. During this process, as the solution's temperature decreases, so does the ethanol's ability to keep the nonpolar plant waxes dissolved, resulting in the plant waxes precipitating out of the ethanol solution. Once the waxes have precipitated out of the solution, they are filtered from the solution by running the solute through a fine micron filtration process to capture the undesirable fats, waxes, and lipids, further refining the botanical extract to increase its potency and clarity. Typical methods involve passing through multiple different micron pore sizes to ensure complete as possible removal of plant fats, waxes, and lipids throughout the filtration stage. Once this process is complete. what is left is a winterized solution that can be solvent recovered to create a winterized extract.

COLOR REMEDIATION

6" Color Remediation Column By BVV

Color and clarity are typically the first qualities observed from a botanical extract. Whether it be a green tint from chlorophyll or red and yellow pigment from certain flavonoids or carotenes, color pigments provide the operators, technicians, and consumers a visual indication of the purity of a botanical extract. During a solvent-based botanical extraction, it is common that color compounds will be co-extracted alongside the target compounds. It is possible to limit the co-extraction of color compounds to some extent by altering the temperature and saturation time of the initial extraction. Removing color compounds from a botanical extract is most efficiently done through a separate refinement process referred to as color remediation. For those extractors looking for greater purity and shelf appeal, color remediation can be performed in order to remove these undesirable color compounds creating a higher purity and more visually appealing botanical extract.

Chapter 3: Botanical Extract Refinement Glossary

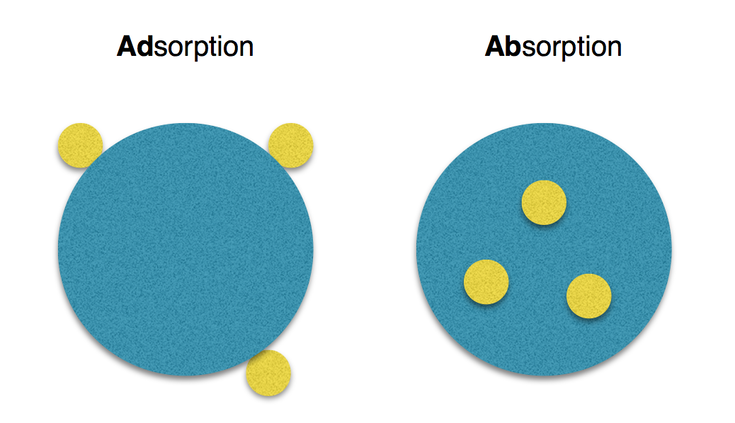

Absorption: The process or action by which one thing absorbs or is absorbed by another.

COLOR REMEDIATION

6" Color Remediation Column By BVV

Color remediation is a powerful refinement process that is most commonly achieved through inline adsorbent filtration. Adsorbent filtration involves the use of adsorbent media to separate the compounds of a chemical mixture based on the interaction of the adsorbate with the adsorbent. In this case, the adsorbates are the color compounds being adsorbed, and the adsorbent is the filtration media adsorbing the color compounds. Adsorption is not to be confused with absorption, which is when fluid is dissolved by or permeates a liquid or solid. Adsorption refers to the adhesion of atoms, ions, or molecules from a gas, liquid, or dissolved solid to a surface.

In this process, a nonpolar botanical extract solution passes through a bed of adsorbent filtration media. Depending on the type of media used, certain compounds are adsorbed from the solution. The process of adsorption creates a film of the adsorbate on the surface of the adsorbent, holding the adsorbate back while allowing the rest of the solution to flow through the media. Adsorbents are generally porous in nature, with a high surface area to adsorb substances to their surface.

A substance's adsorbent characteristics are a function based on the electrical attraction of molecules. A variety of media types can perform various remediations ranging from color pigments to heavy metals and pesticides. Adsorbents need to be selected with care and used sparingly in most cases as some adsorbents like Activated Alumina or Silica are prone to grabbing on to more than just color compounds resulting in reduced yield of the target compounds. Color remediation can be performed with a wide range of different filtration media. Some filtration media are better at picking up different pigments than others. While some are great for chlorophyll remediation, others are better at pulling red and yellow pigments from the extract. There are various types of filtration media, each of which has its own utility and use cases. Some of the more common types of media used for botanical extract filtration include:

Diatomaceous Earth: Filter aid, removes color and other impurities

Bentonite Clay: Removes Color (red & green pigments)

Silica Gel: Removes color (yellow, orange, green pigments) and polar impurities

Activated Charcoal: Removes colors (brown & green pigment), flavors, and other impurities

Activated Alumina: Removes lipids, moisture, and polar compounds

Magnesium Silicate: Removes color, lipids, and Pesticides

Activated Carbon: Absorbs and removes impurities

These adsorbent media are generally very fine; when working with these materials, it is very common that media powder will be made airborne during handling. This makes handling media a potential breathing hazard and eye irritant. For this reason, media handling should be performed wearing adequate personal protective equipment in an isolated media prep location either outside or in a well-ventilated area far away from the finished product or packaging. Since media powder is so easily spread, media handling should be done with dedicated protective equipment and tools that can be left in the media packing area to limit cross-contamination. The use of this dedicated equipment should be limited to the media handling area and removed before exiting the media handling area. The following personal protective equipment should be worn for the duration of all procedures involving filtration media handling:

1. A properly fitted dust respirator that meets OSHA regulations for respiratory protection.

2. Safety glasses or goggles to prevent eye irritation.

3. Gloves and dedicated media handling attire to prevent cross-contamination in the facility.

Half Facepiece Respirator By 3M

When using a media for the first time, always read and post the SDS sheet and train employees and colleagues to adhere to these recommendations. Many adsorbent media contain silica dust which can cause silicosis, a long-term lung disease caused by inhaling large amounts of crystalline silica dust over many years. For this reason, safety should be the number one concern when handling filtration media, and great care should be taken to limit exposure to media dust. Alongside wearing the proper protective equipment when handling media, great care should also be taken to dispose of used adsorbent media. In order to limit exposure to media dust, it is recommended that used media be rinsed with water and disposed of wet in a mud-like form in order to limit the spread of media dust during disposal.

While each media type has its own unique characteristics and utility, they are commonly prepared and used in the same way. Preparation of media typically starts by drying the media of excess moisture in an oven prior to use. This can be achieved in a regular oven at 200C for 6-8 hours. Once the media is sufficiently dry, it can be layered into the color remediation column. It is not uncommon to layer multiple adsorbent media into a color remediation column to remove a variety of different undesirables in a single pass. Typically this is done via layering instead of mixing the media allowing the solution adequate retention time for each media to serve its purpose.

Activated Alumina 14x28 Mesh (Aluminum Oxide) By BVV

Filtration media can be staged in a variety of different combinations. The layering of filtration media is typically applied the same way by weighing or measuring a predetermined amount of media and slowly pouring the media into a color remediation column, lightly packing the filtration media in order to achieve an even bed of filtration media. Once the media is sufficiently layered, the color remediation column is fully assembled and plumbed inline between the material column and the collection vessel of the extraction system.

Before performing the initial extraction and inline color remediation, another common preparation step is saturating the media with a clean solvent to prevent channeling prior to saturating it with a botanical extract-rich solution. Removing excess moisture from the media prior to layering and wetting it with a clean solvent and saturating it with botanical extract are common processes to ensure consistency of the color remediation procedure. While some extractors skip these steps and produce quality results to ensure consistency between extractions, these steps are highly recommended.

316 Stainless Steel Dutch Weave Sintered Filter Disk By BVV

While media selection and proper layering are key to the color remediation process, the design of the color remediation apparatus also plays a big role in the efficiency of the process. A Color Remediation Column, commonly referred to as a CRC, is a simple apparatus typically made from stainless steel tri-clamp parts, including a column where filtration media will be loaded, and a series of fine micron filter paper or sintered discs below it. These filters are typically staged decreasing in aperature in order to trap the filtration media within the color remediation column making sure no media makes its way into the finished extract.

Color remediation columns are often plumbed inline between the biomass material column and the collection vessel of a closed-loop hydrocarbon extraction system. Color remediation columns are highly variable, with column capacity, width, and length being highly customizable to cater to the specifications of the extraction system and the desired end product. Color remediation is typically performed inline after the initial extraction process. While the extract is still diluted in a solvent, the extract/solvent solution is filtered through a color remediation column filled with a bed of filtration media selected for their ability to adsorb the undesirable color compounds. As the solution travels through the bed of media, the adsorbent filter media adsorbs the undesirable color compounds from the solution.W1 Acid Activated Refinement Clay By Chemtek

Ultimately the effectiveness of the color remediation process will be determined by a variety of different factors that will need to be optimized based on the desired outcome. Retention time is among the more important factors in achieving efficient adsorbent filtration. The adsorbent needs adequate time for the adsorbate to be adsorbed. The use of too little media leads to oversaturation of the filtration media allowing impurities to go through without filtration. At the same time, too much media leads to undersaturation, which can result in the media adsorbing target compounds and reducing yield. All these factors play a role in fine-tuning the color remediation process. Too little travel depth or retention time can result in poor remediation of color.

Filtration Powder Bundle By BVV

This makes the amount of media used per run highly variable depending on extraction system design. While biomass to media ratio is generally recommended by the media manufacturer, more or fewer media may be needed depending on the diameter of the remediation column and the quantity and quality of the biomass being processed. When implementing color remediation into the extraction process, it is important to find the optimal level of travel depth for each media and modify that ratio depending on the characteristics of the starting biomass and the desired outcome. When retention time is optimized properly, color remediation results in a high-quality botanical extract with minimal product loss.

We have found a combination of Neutral Activated Alumina, bentonite clay, & silica provides the greatest overall color remediation. Packed from bottom to top 30-50 grams per pound of biomass extracted of neutral activated alumina removes polar impurities and moisture while neutralizing the extract increasing its stability. Above the alumina 75-100 grams per pound of biomass of bentonite clay for the removal of chlorophyll, carotenoids, fats, soaps, free fatty acids, and heavy metals. The more acidic the clay the greater its bleaching effect but this may isomerize some more pH sensitive compounds like terpenes. On top of the bentonite 30-50 grams per pound of biomass of silica removes gums and phosphates while providing a chromatographic separation of lipids and pigments that improves the efficiency of the bentonite clay.

Media retention time is paramount to the effectiveness of the process. During the actual filtration process, pressure, temperature, and runtime play a factor in achieving the desired results. Pressure is an important factor in total retention time. Too little pressure and flow rate reduce to a crawl, while too much pressure can lead to a reduced retention time and color remediation. The ideal amount of pressure applied to the color remediation process is highly variable based on the dimensions of the color remediation column and the amount and type of media used. Generally, no more than 50 PSI should be applied to achieve the desired flow rate and results if the media is packed appropriately.

Ultra Clear S By BVV

After the color remediation column has been prepared with the desired level of media and assembled with all high-pressure, clamps are torqued to manufacturer specification. The column can then be plumbed inline between the material column and the collection vessel of a closed-loop hydrocarbon extractor. Once the extraction system is properly assembled, and pressure tested, the extraction process starts by pulling the entire system under vacuum. During this process, the vacuum should be pulled from the bottom of the CRC to not disturb the filtration media. Once the system has been pulled under vacuum, all process connection valves should be closed, isolating each component of the system. Clean extraction solvent can then be pressurized with nitrogen and injected directly into the CRC, allowing it to flow to the collection vessel in order to saturate the media with clean solvent. Once the CRC has been sufficiently saturated with the solvent, isolate the CRC and recover the saturation solvent, clean the collection vessel, reassemble the system, pull it under vacuum, and then perform the extraction by injecting solvent into the material column.

Once the desired biomass saturation has been achieved, the solution is sent to the color remediation column by cracking open the CRC inlet valve and allowing it to saturate the filtration media. Once the media begins to saturate, open the outlet valve of the CRC and send the color remediated solution to the collection vessel. As the solution flows through the CRC into the collection vessel, nitrogen back pressure should be maintained until the entirety of the extraction solution has made its way to the collection vessel. Depending on the particle size of the filtration and media bed depth, more or less pressure may be needed to achieve the desired retention time and flow rate. If the color remediation column has been prepared properly, no more than 50 PSI of nitrogen back pressure should be needed to perform the color remediation process. Once the entirety of the extraction solution has made its way to the collection vessel, perform the standard solvent recovery procedure, and collect the color remediated botanical extract. Overall, color remediation is a powerful refinement process that can drastically improve the purity and visual appeal of a botanical extract. While the process takes time to fine-tune based on the specific application, color remediation can produce impressive results once dialed in.

HYDROCARBON COLOR REMEDIATION STANDARD OPERATING PROCEDURE

Purpose

The purpose of this procedure is to provide detailed instructions for inline color remediation of a hydrocarbon extract.

Scope

This procedure applies to all lab technicians tasked with hydrocarbon extraction.

Definitions/Acronyms

Personal Protection Equipment (PPE) Items worn to protect employees from exposure to hazardous materials and prevention of injury.

Safety Data Sheet (SDS) Provides valuable information on chemicals, describing the hazards the chemical presents, and giving information on handling, storage, and emergency measures in case of an accident.

Safety

SDS Sheets: Butane SDS: Perform 5000 SDS

PPE: The following should be worn by all lab personnel during this refinement procedure:

Protective eyewear

Lab coat

Gloves

Respirator (During media handling)

Preparation and Use:

Target compounds will be extracted from biomass material with butane as the solvent. The botanical extract solution will be pressure filtered through the color remediation column into the collection base.

Concentration- Use a 100% Butane (BVV)

Quantity- 5lb of Butane per 1lb of biomass

Frequency- An initial volume of solvent is used, no more is added.

Location- Color remediation occurs within a C1D1 environment, plummed inline between the material column and the collection base of a closed-loop hydrocarbon extractor (BVV).

Potential Hazards and Risks

See Butane & adsorbent media SDS for detailed risks.

6. Preparation

Media preparation

1. Spread desired media in a thin layer evenly across a deep stainless steel or glass container. Bake the media in an oven at 200c for 6-8 hours to remove excess moisture from the media.

2. Detach the color remediation column from the closed-loop hydrocarbon system and bring the column to the designated media packing area.

3. Dawn all the appropriate personal protective equipment including a properly fitted respirator, safety goggles, nitrile gloves, and dedicated media handling attire.

4. Clean, Inspect, and assemble the color remediation column from the bottom up staging your filter paper or sintered disks in ascending order from finest to largest micron size. (If using sintered disks do not layer media directly over a sintered disk always place a filter paper above the sintered and then layer the media above it.)

5. Slowly layer the dried filtration media by weight or measurement into the body of the color remediation column intermittently tapping the bottom of the CRC to evenly distribute the media and reduce channeling. Once the desired media is layered into the color remediation column place a piece of filter paper over the media or a bed retention plate applying minimal force to the top of the bed ensuring the plate is perfectly level and snug against the top of the media bed creating an even layer.

6. Clear any excess media from the tri-clamp ferrels and fully assemble the remainder of the color remediation column ensuring that all high-pressure clamps are torqued to manufacture specification.

7. Once the CRC is fully assembled remove all designated media handling equipment and transport the assembled CRC to the extraction location.

8. Mount and Plumb the assembled color remediation column inline between the material column and the collection vessel of the hydrocarbon extraction system making sure all process connection hoses are secured and tightened properly.

9. Load & Fully assemble the remainder of the closed-loop hydrocarbon extractor to manufacturer specifications and pressure test the system with nitrogen at 100 PSI for at least an hour to ensure the system is assembled correctly with no leaks, (ensure the pressure is applied from the top of the CRC to ensure the media is not disturbed) If pressure drops proceed to spray process connections with soapy water to identify where the leak is coming from. Once the leak is identified disassemble, reassemble, and repressurize the system as needed until pressure is maintained. Once pressure is held within the system for a minimum of 30 minutes depressurize the system pulling from the bottom of the CRC and proceed to extraction preparation.

Extraction Preparation

1. Attach a spark-free vacuum pump to the collection base of the closed-loop system and open all process flow valves from the collection vessel to the source solvent tank ensuring the source solvent tank valve is fully closed.

2. Turn on the spark-free vacuum pump and allow adequate time for the entire system to be pulled under vacuum. Once the system has reached -29.9mmHg close all processing flow valves on the system isolating each vessel and turn the spark-free vacuum pump off.

3. Proceed to transfer 5 lbs of n-butane for every 1lb of biomass you plan to extract into the solvent recovery tank of the closed-loop extraction system and begin chilling the solvent recovery tank to the desired temperature through the use of dry ice or an appropriately sized chiller.

4. Once the solvent has reached the desired temperature, proceed to start your initial extraction.

7. Procedure

1. Pressurize the LP tank with nitrogen to 25 psi and Open all processing valves from the recovery solvent tank to the material column saturating the material column at a 5:1 ratio (solvent: material).

2. After the desired saturation of the material column has been achieved, slowly open all processing valves from the material column to the CRC to ensure the media is not disturbed, once the media is saturated begin slowly open all processing flow valves from the color remediation column to the collection vessel allowing the botanical extract solution to flow through the inline color remediation column directly into the collection vessel. As the solution flows maintain a constant pressure by adding additional nitrogen back pressure if necessary.

3. Once the entirety of the solution has been passed through the color remediation column into the collection vessel close the collection vessel input valve and open recovery line valves from the collection base to the LP tank.

4. Turn on your heated recirculator and set the temperature to the desired solvent recovery temperature and open all recirculation vales to apply heat to the collection vessel.

5. Recover the hydrocarbon solvent until only extract remains, depressurize and drain the extract into a clean receptical.

6. Proceed to vacuum purging procedure.

Disassembly and cleaning

1. Depressurize the column to ambient pressures by opening the inlet valve of the CRC.

2. Detach the color remediation from the extraction system and carefully transport the CRC to the designated media handling location.

2. Remove the top high-pressure clamp and carefully remove any bed retention plates or rings used.

4. Wet the media with water and dispose of the media in a sealed and labeled receptacle.

5. Rinse all parts with distilled water to remove dust.

6. Clean and sanitize all parts to remove any particulate, oil, or other contaminants.

WINTERIZATION

Ultra-Low Chest Style Freezer with Touch Screen LCD (-86°C) 16.2 Cubic Feet - ETL Rated By BVV

Winterization is a widely used refinement technique to remove plant waxes, fats, and lipids from a botanical extract. Winterization is often seen as a required post-processing procedure for most solvent-based extractions as these plant lipids are typically dissolved to some extent during a solvent-based extraction. While the pickup of plant waxes can be limited by altering the temperature and saturation time of the initial extraction, it is commonly unavoidable to co-extract a small amount of these compounds during a solvent-based extraction. The process of removing these plant waxes from a botanical extract is most efficiently performed through winterization. Winterization creates a more refined botanical extract resulting in greater purity and clarity of oil.

ULTRA-Low Chest Style Freezer (-86C) 25 Cubic Feet By BVV

Winterization utilizes the principle of solubility to precipitate plant fats, waxes, and lipids from a botanical extract solution. To perform winterization first, a botanical extract will need to be dissolved in a solvent that the plant waxes are soluble in when heated but have low solubility in that same solvent when chilled. This difference in plant wax solubility at high and low temperatures allows us to completely dissolve the plant waxes into the solution at high temperatures and precipitate from the solution at low temperatures.

200 Proof Lab Grade Ethanol By BVV

For this purpose, ethanol is a prime winterization solvent because plant waxes are soluble in ethanol with light heat and have reduced solubility in ethanol when chilled. This makes plant waxes easily dissolved and precipitated in ethanol via heating and chilling. Ethanol is commonly a preferred winterization solvent as it is generally recognized as safe (GRAS) and presents less inherent risk during use than other common botanical winterization solvents like methanol or acetone. Typically, 190 proof non-denatured ethanol is preferred over 200 proof ethanol because it is slightly more polar, making fats less soluble in the solution. Ethanol also has a relatively low boiling point of 173F/78C, making it easily recoverable from the solution through a rotary evaporator, falling film evaporator, or heated reactor. Commonly a crude botanical extract will be dissolved in ethanol at a 10:1 ratio of ethanol to botanical extract to achieve a thin enough viscosity for filtration, with light heat ranging from 40-60C and stirred until the solution appears completely homogenous.

Explosion Proof Freezer By So-Low

Once a botanical extract is completely dissolved in the winterization solvent, the solution is then chilled to sub-zero temperatures with an ideal temperature range between -50C and -70C ( -58F and -94F). As the temperature of the solution lowers, so does the solubility of the plant waxes until the plant waxes solubility reaches a point where they can no longer stay dissolved in the solution, and they spontaneously precipitate out of the solution in solid form. Even at sub-zero temperatures, the precipitation of plant waxes takes time, with most processes calling for a minimum of 24 hours of sub-zero chilling to fully precipitate plant waxes from the solution. Maintaining this temperature is commonly achieved using an explosion-proof freezer, a jacketed vessel with a refrigerated circulator, or a dry ice bath.

PIG Filter By Summit Research

Once the plant waxes have been sufficiently precipitated, the chilled solution is then filtered, assisted by pressure or vacuum, in order to separate the precipitated plant waxes from the solution. Filtering of a winterized solution can be performed using a simple Buchner funnel at a small scale or utilizing a filter press or filter trolley at a larger scale. During the filtration process, the solution must be kept cool, assuring lipids and waxes don't dissolve back into the solution. Filtration can be achieved with a series of cellulose filters raging from 25 microns to 1 micron, depending on the level of refinement desired. Commonly Celite 545 or diatomaceous earth can be used as filter aides assuring all plant waxes are captured.

Porcelain Buchner Funnel Filtration Kit By BVV

It is not uncommon that this process of chilling and filtering is repeated multiple times with multiple pore sizes during filtering to ensure all plant waxes and lipids have been removed. To verify the efficiency of the winterization process, a small sample of the filtered solution can be rechilled for another 24 hours. If the solution appears cloudy with precipitated waxes after 24 hours, winterization may need to be repeated for complete removal of plant waxes. Once the desired level of winterization has been achieved, the final step is to recover the winterization solvent from the solution via evaporation resulting in a winterized extract. The visual appearance of the filtered solution is a strong indication of wanting/needing to re-perform this critical step.

Winterized VS Unwinterized Oil By BR Instruments

While it is common to perform winterization prior to distillation, winterization can be performed at varying stages of the botanical extraction and refinement process in order to further refine and purify a botanical extract. In the case of ethanol extraction, winterization can be performed after the initial extraction by freezing and filtering the botanical solution prior to the solvent recovery process using the initial extraction solvent. Regardless of the order of operations, once the process is complete, it results in what is referred to as a winterized extract, when performed properly, winterization results in a botanical extract with improved clarity and increased purity, resulting in a more polished botanical extract that can be more efficiently refined during distillation and isolation procedures.

WINTERIZATION STANDARD OPERATING PROCEDURE

Purpose

The purpose of this procedure is to provide detailed instructions for botanical extract winterization

Scope

This procedure applies to all lab technicians tasked with botanical extract winterization.

Definitions/Acronyms

Personal Protection Equipment (PPE) Items worn to protect employees from exposure to hazardous materials and prevention of injury.

Safety Data Sheet (SDS) Provides useful information on chemicals, describing the hazards the chemical presents, and giving information on handling, storage, and emergency measures in case of an accident.

Safety

SDS Sheets: Ethanol

PPE: The following should be worn by all lab personnel while winterizing botanical extracts:

Protective eyewear

Lab coat

silicone gloves (low-temperature gloves as needed)

5. Hazard Identification

Preparation and Use:

A botanical extract will be mixed with Ethanol at a 10:1 ratio of Ethanol-to-botanical extract. The solution will be heated to dissolve the extract into the ethanol solution and then chilled to -40C for a minimum duration of 24 hours before filtering.

Concentration- Use 200 proof lab-grade Ethanol (BVV)

Quantity- 10 parts Ethanol: 1 part botanical extract

Frequency- An initial volume of Ethanol is used, no more is used.

Location- Mixing, freezing, and filtering of the botanical extract and Ethanol solution is performed inside a C1D2 environment using explosion-proof rated equipment

Potential Hazards and Risks

See Ethanol SDS for detailed risks.

6. Preparation

1. Heat botanical extract to 40-60C/104-140F using a stirring hotplate, under a fume hood, until the extract is vicious enough to easily mix with ethanol.

2. Add 10 parts Ethanol for every 1 part of botanical extract and mix the solution until the extract is completely dissolved in the solution and appears completely homogenous.

6. Procedure

Freezing

Once the botanical extract has been completely dissolved in the ethanol solution proceed to chill the solution to a temperature range of -50C to -70C (-58F and -94F) for a minimum duration of 24 hours to allow the plant waxes to fully precipitate.

Filtering

Filter solution via Buchner funnel, filter trolley, or filter press using a fine micron cloth or filter paper to capture precipitated lipids. (perform filtering quickly to limit the solution warming and redissolving the precipitated waxes.)

During filtration monitor filtering speed and change filter papers as needed when a filter becomes clogged. When utilizing a Buchner funnel or filter trolley adding small volumes of cold solution at a time is ideal allowing the user to change the filter paper easily when a filter becomes clogged allowing the user to change the filter paper easily.

Solvent recovery

Once the plant waxes have been successfully filtered from the solution proceed to recover ethanol from the solution utilizing an appropriately rated Falling film evaporator, rotary evaporator, or solvent recovery skid by heating the solution to 173F/78C to evaporate the ethanol from the extract.

Once the solvent recovery process is complete proceed to distillation SOP.