5L Short Path Distillation Kit with P5 Distillation Head

This unit carries a 2 day lead time.

The 5L Distillation Kit includes everything needed to perform distillation excluding the vacuum pump and chiller. This kit features our USA made P5 Distillation Head, as well as USA, made glass. This Kit is designed for high volume production with the highest quality components for precise, repeatable results time and again.

This Kit Does NOT include a vacuum pump or chiller. Please see the below recommendations for both as well as recommended add-ons.

Recommended Vacuum Pumps:

Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump (recommended option)

Just Better 6 CFM 2 Stage Deep Vacuum Pump (economy option)

Recommended Chillers:

Polyscience 7 Liter MX Heated Circulator (economy option)

Polyscience 7 Liter Refrigerated Circulator (premium option with chilling capability)

Recommended Add-Ons:

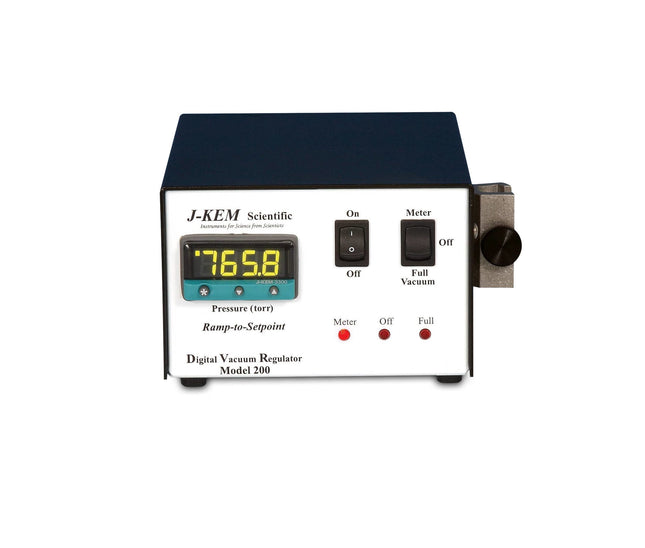

Bullseye Precision Vacuum Gauge (premium vacuum gauge for measuing depth)

CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement)

J-KEM Digital Vapor Temp Monitor (digital vapor temp monitor with data-logging capabilites)

Specifications:

Boiling Flask Size: 5L

Receiving Flask Size: 2x 500mL, 1000mL

Batch Capacity approximate: 1000-2500 grams

Run time: 4 to 8 hours dependent upon material composition and throughput

Distillation Temperature Range: 140-250C (Do not exceed 250C)

Recommended Condenser Temperature: 40-50C

This Kit Includes:

Glass components:

5L Boiling Flask

P5V6 Distillation Head

Triple Neck Cow

2x 500mL Receiving Flask

1L Receiving Flask

120mm Glass Funnel

Dewar cold trap

Accessories:

PTFE Magnetic Stir Bar Retriever

5 Pack of Metal Keck Clips

Dow Corning High Vacuum Silicone Grease

Tripod Stand

5L Digital Heating and Stirring Mantle

3-Finger Adjustable Clamp 0-77mm

6" x 6" Scissor Jack

500-1000mL Cork Stand

2x 24/40 ChemglassPTFE Thermometer Inlet Adapter

10ft of Gum Rubber Vacuum Hose

10ft of Silicone Chiller Hose

1/4" Vacuum Manifold

Traceable Kangaroo Thermometer - Digital

10 Pack of Adjustable Stainless Steel Tubing Clamps

Fiberglass Insulation Rope 10 Feet

Distillation Quick Start Guide

This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs,

Before beginning distillation, ensure the following steps have been taken:

Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed.

All glass components are in good working order and ready to be assembled

A winterization and degassing procedure has been done to prepare oil for distillation

The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C

Once all three of these steps have been completed, you are ready to begin distilling.

Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer.

Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware

Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation.

Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system.

Connect receiving cow to cold trap.

Connect cold trap to manifold.

Connect vacuum gauge to manifold.

At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process.

Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability.

Start stir slower and increase speed with temperature.

Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C.

You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction.

You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction.

Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed.

The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction.

As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well.

Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation.

*Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement.

BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

Read

more

less