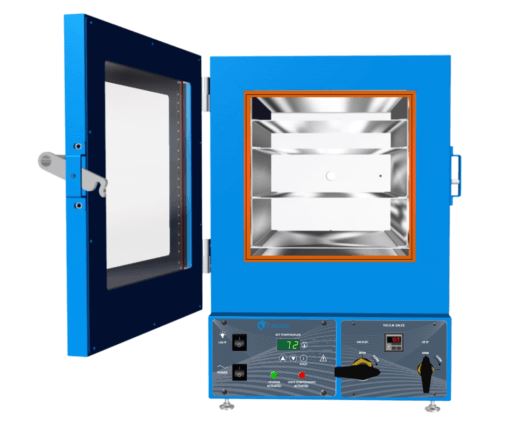

Cascade CVO-2 Vacuum Oven

(Oven Only)

This item carries up to a 1-2 week lead time.

Model CVO-2 offers incredible temperature stability for vacuum drying and purging of pharmaceuticals, botanicals, slurries, or any temperature sensitive material. This vacuum oven liberates solvents, water, and other unwanted compounds in small batch, R&D and lab environments. NRTL Certified.

CVO-2 Vacuum Oven Features

NRTL Certified by TUV

5 shelves (11.5″W x 19″D) in a flexible configuration. Shelves are stackable and removable

Stable temperature control. Digital temperature readout with temp sensor INSIDE the oven

Solvent resistant BUNA door gasket

Bright LED lights in window for visibility of sensitive material

Digital vacuum gauge reads in inches of mercury

Simple, set-point control

Smooth, quarter-turn vacuum and vent valves

Rear KF-25 port allows for rapid MAXEVAP purging or running feedthroughs inside oven for monitoring

120V (220V available)

Quality Tempered Rated Glass NGI-US to ANSI Z97.1.2007 156CFR/201 11 SGCC -2577 ½ UA

Adjustable leveling feet ensure oven sits solid and level in the workspace

CVO-2 Connections

3/8″ Barb for Vacuum Pump

1/4″ Barb for Venting (N2 Connection OK)

KF-25 Port for feedthroughs or MAXEVAP Connection Kit

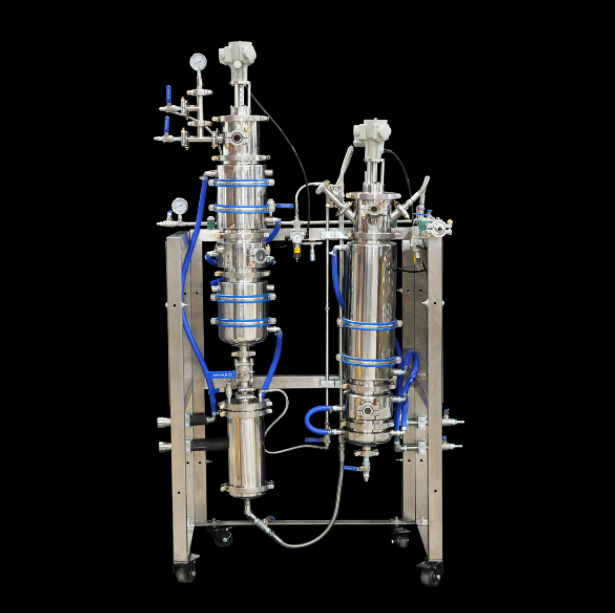

Need A Complete CVO-2 Vacuum Package?

Cascade has taken the guess work out of pairing the right vacuum oven with the proper pump. We offer two complete CVO-2 vacuum oven packages with everything you need for vacuum drying. Both packages feature clean, quiet, Agilent oil-free scroll pumps.

The CVO-2 STANDARD Package is an ideal package for vacuum drying or purging requiring a steady, gentle, non-turbulent purge.

The CVO-2 PRO Package is ideal for higher thru-put, faster purge times pulling deeper vacuum.

CVO-2 Comes In Low & High Temp Models

Low & High Temp Specifications

CVO-2 (Low Temp)

Temperature Processing Range

-3ºC to 121°C (26°F to 250°F)

Temperature Uniformity

+/- 1ºC at 40.5°C (+/- 1.5°F at 105°F)

Temperature Stability

+/- 0.5°C at 40.5°C (+/- 0.4 at 105°F)

CVO-2-HT (High Temp)

Temperature Processing Range

Up to 220°C (428°F)

Temperature Uniformity

+/- 6.5% of setpoint

The Cascade Difference

Vacuum ovens have been around for decades. Basic vacuum ovens are mass-produced and sold by many large scale laboratory equipment distributors. But there are key differences between Cascade and other inexpensive, often imported vacuum ovens.

Exceptional Temperature Control & Stability

The Cascade CVO-2 uses a unique control logic not found in most lab grade vacuum ovens. The temperature probe is INSIDE the oven, which minimizes temperature overshoot and delivers best-in-class temperature stability and uniformity particularly in the low temperature ranges. Accurate, stable temps throughout the CVO-2 eliminate hot and cold spots, making accurate use of every inch of shelf space.

Independent Over-temp Failsafe Protection

The Cascade Sciences CVO-2 is equipped with a heating cutoff system that will automatically stop power to the heaters when the oven shelf temps exceed 200°C or 392°F. This protection system will provide peace of mind for overnight processing or unattended vacuum bake outs.

NRTL Certification #U8 170464972 077. No Extra cost.

The CVO-2 Vacuum Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities.

CAN/CSA-C22.2 No. 61010-1:2012

+UPD No. 1:2015-07 + UPD No. 2:2016-04

CAN/CSA-C22.2 No. 61010-2-010:2015

UL 61010-1:2012/R:2016-04

UL 61010-2-010:2015

EN 61010-1:2010

EN 61010-2-010:2014

Rigorous Quality Assurance in an ISO Certified, USA Manufacturing Facility

Cascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment:

Chambers are vacuum tested after welding for vacuum integrity

Electrical & mechanical safety is thoroughly tested in compliance with TUV requirements

Functional testing verifies user settable items consistent with most lab protocols/usage models

Temperature verification includes calibration & temp chamber uniformity following ASTM standards

Units are cleaned and packed in ISTA tested, certified packaging materials

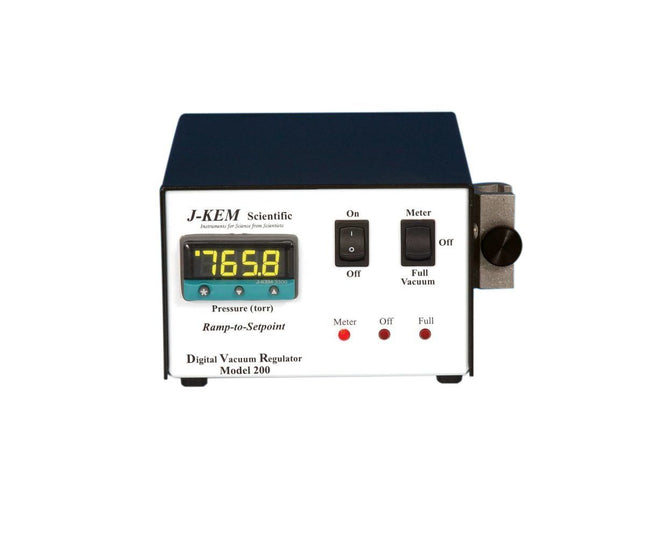

Digital Vacuum Gauge

The digital vacuum gauge installed on the CVO-2 is factory default set to read in inches of mercury (“Hg) with a scale of 0 – 29.9”Hg. Change the unit of vacuum measurement to read in a wide variety of units from mmHg, bar psi, kPa, cm2, mmH20. Zero out the vacuum gauge to calibrate for just above sea level adjustments.

Equipped for Inert Gas Backfill. Built-In Safety Relief

Introduce inert gasses such as nitrogen, argon, helium, etc. as part of your process via the 1/4″ rear vent barb. The maximum backfill pressure is 15PSI. In an overpressure situation, a simple, built-in safety relief allows gasses to escape via a spring loaded tempered window.

Flexible Pumping / Feedthru Connection Ports

The CVO-2 ovens offer two different vacuum oven connection points. The standard connection is a 3/8″ dia barb located at the rear of the oven. It is connected to the vacuum valve level on the front control panel. For even faster evaporation, purging or drying consider upgrading to the MAXEVAP connection kit. The MAXEVAP connection kit secures to the oven’s rear 1″ dia KF-25 port located on the back center of the chamber. The MAXEVAP connection never reduces flow by continuing with 1” diameter vacuum rated clear lines, a 1” dia KF-25 side mounted vacuum valve and KF-25 fittings and hardware. This KF-25 port can also be used to run temperature feedthroughs, or monitoring sensors inside the vacuum chamber during processing.

Stackable Shelf Design For Maximum Temperature Conduction

Under vacuum, there is no air inside a vacuum oven. Temperatures are achieved by a process of conduction and radiation to move temperatures into the product inside the oven. Cascade’s stackable shelf design makes the most of this opportunity by making the chamber longer and narrower, rather than square and supplies stackable shelves in multiple height configurations to allow for the fastest, most uniform transfer of heat.

Ergonomically Designed, Easy Quarter-Turn Valves

For anyone that has struggled with consistently turning the small, round, low-quality vacuum/vent valves, relief is in sight. You will love our large, quarter-turn vacuum/vent valves. Your wrists will thank you!

ANSI Rated Tempered Glass + USA Made Steel

Cascade ovens are made in Oregon, USA with high quality materials. Our glass is NGI-USA Tempered and certified to ANSI Z97.1.2007 16CFR / 201 11. Our door handles are rugged brushed steel, not plastic. Our vacuum vessels are constructed with American made steel. We’ve tried lower cost, imported steel, but over time, vacuum chambers made of lesser quality/lower tolerance material cannot withstand the flex and pressure changes of vacuum pumping/venting/purging. This can deteriorate vacuum integrity and the oven will lose its ability to hold vacuum.

Door Gasket Options – Ideal For Your Process

Cascade’s vacuum ovens come standard with a solvent resistant BUNA door gasket. For higher temp applications, we offer a cured Silicone gasket as well. Ask us about the variety of door gaskets we can supply based on your application: Silicone, BUNA, Viton, Fluorosilicone. Gaskets will eventually wear out. It’s ideal to keep a few spares on hand.

Model CVO-2 Vacuum Oven Specifications:

Capacity

Volume

1.67 Cu Ft (47.2 L)

Interior

12″W x 20″D x 12″H (305mm x 508mm x 305mm)

Exterior

18.8″W x 24.5″D x 24.5″H (478mm x 622mm x 622mm)

Product Weight

148 lbs (67.1 kgs)

Temperature

Temperature Range

-3ºC to 121°C (26°F to 250°F)

Temperature Uniformity

+/- 1ºC at 40.5°C (+/- 1.5°F at 105°F)

Temperature Stability

+/- 0.5 at 40.5°C (+/- 0.4°F at 105°F)

Vacuum

Vacuum Valve

1/4 Turn Lever

Vent Valve

1/4 Turn Lever

Vacuum Gauge

Digital. 0 to 29.9″Hg

Temperature Controller

Digital Set Point

Accurate Within .5ºC (1°F)

Independent Overtemp Failsafe

Ports (Rear)

Vacuum

3/8″ Barb

Vent

1/4″ Barb

Auxiliary

KF-25 Port

Inert Gas Introduction

Use 1/4″ Vent Barb

15 psi max inlet pressure

Power Options

110V – 120V / 1ph / 6A 50/60Hz (Cord Included)

NEMA 5 – 15 Power Outlet

Full Power 2456 BTU/hr

*(220V Optional)

Shelving

Includes 5 shelves in a flexible configurationShelves are stackable and removable1″ High = 1 each2″ High = 2 each3″ high = 2 each

Surface Area

11.5″W x 19″D

Weight Capacity

50 lbs (22.7 kgs)

Door

Interior Lighting

LED Strips (Rated to 150°C)

Glass Window

Tempered NGI-US to ANSI Z97.1.2007

Gasket Type

12″ x 12″ Solvent Resistant BUNA Standard

Gasket Rated to

105°C (221°F)

Gasket Options:

High Temp Silicone Option rated to 30°C (446°F)Viton Option rated to 205°C (401°F)

Shipping & Weights

Unit Weight

179 lb (81.2 kg)

Shipping Weight

218 lbs (99 kg)

Shipping Dimensions

33″L x 33″W x 47″D (Class 85)

Product Certifications:

NRTL TUV #U8 170464972 077CAN/CSA-C22.2 No. 61010-1:2012+ UPD No. 1:2015-07 + UPD No. 2:2016-04CAN/CSA-C22.2 No. 61010-2-010:2015UL 61010-1:2012/R:2016-04UL 61010-2-010:2015EN 61010-1:2010EN 61010-2-010:2014

Warranty:

1 Year (Gaskets not included)

*Temperature performance specifications are preformed in empty ovens. Performance can vary in ovens containing product.

NTRL Certification PDF

Manual

Vacuum Pressure Chart

Vacuum Gauge Manual

Calibration

Read

more

less