Solvent Evaporation

120W Motor/gearbox with FWD/REV controller

This controller/ motor can be retrofitted to fit a 20 or 50 liter glass reactor to have additional control to your process.

$1,355.24

2L Rotary Evaporator Power Cable

Replacement Power cable for BVV 2L Rotary Evaporator.

$21.40

ECO Replacement 50L Main Condenser (V1)

ECO Replacement 50L Main Condenser (V1) Replacement main condenser for ECO rotary evaporators made before 2019. 60/80 Lower Flange 40/60 Top Flange 1/2" Barb connections for cooling coil

$1,276.78

10L Auxiliary Condenser

This Auxiliary condenser will fit 10L solvent pro and BVV ECO models produced before 2019. The connections sizes are: Bump Trap: 40/60 Main Condenser: 60/80 Receiving flask: 40/60 Chiller Connectinos: 1/2" barb

$556.36

5L ECO V2 Bump Trap

5L ECO V2 Bump Trap This replacement bump trap fits 5L BVV rotary evaporators with manual lift baths. It has connections for the injection valve, condenser, receiving flask, and motor. Connections & Sizes: Injection Valve: 19/26 Ground Joint Condenser: 40/38 Ground Joint Receiving Flask: 35mm Ball Socket Motor: ID34/ED50 Flange

$271.05

5L Rotary Evaporator 2L Evaporating Flask (2L Flask that is swap able with the RT5L-V2)

This 2L evaporating flask is made out of borosilicate and designed to fit BVV 5L rotary evaporators. Overall length is about 10-3/4".

$149.79

20L Solvent Pro Rotary Evaporator Main Condenser

20L Solvent Pro Rotary Evaporator Main Condenser 20L Solvent Pro Rotary Evaporator Main Condenser *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. *Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$570.63

10-20L Solvent Pro Rotary Evaporator Bump Trap

10-20L Solvent Pro Rotary Evaporator Bump Trap 10-20L Solvent Pro Rotary Evaporator Bump Trap *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement.

$256.78

WELCH Self-Cleaning Vacuum System 2025

WELCH Self-Cleaning Vacuum System 2025 Product Details Automatic Self-cleaning purge maintains efficiency, extends diaphragm life Free air displacement: 35 L/min (1.2 CFM) Incremental ballast switch enables fast response to bumping / foaming Complete oil-free dry vacuum systems for rotary evaporators and concentrators. Corrosion-resistant PTFE diaphragm vacuum pump systems enable superior control and efficiency for each evaporation. Provides controlled solvent stripping in flasks up to 5 L. Use 9 torr Model 2025 for solvents with atmospheric B.P. <120o C. Includes analog gauge and vacuum regulation. Inlet and exhaust separators protect pump and lab atmosphere. Specification Model Number 2025 Applications Controlled vacuum for Rotary evaporators, Centrifugal concentrators, and other evaporative processes. Type Laboratory Vacuum Pump Free Air Displacement m3/hr (l/min.) @50Hz 1.2(34) Ultimate Pressure 1.7(28) Max Pressure PSIG (pascal) 29.5 Adjustable Vac. / Gas Ballast 1/5 Tubing Needed Yes Intake Thread NPT 1/4 Overall Dimensions LxWxH in. (cm) 13.6x12x11.3 (34.5x30.5x28.7) Ship Weight 36(16.3) Intake Catch Jar Yes Exhaust Catch Jar Yes

$5,313.98 - $5,338.23

10L Solvent Pro Series Glass Axis

10L Solvent Pro Series Glass Axis. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$128.39

10L Receiving Flask

10L Receiving Flask Receiving flask for 10L rotary evaporators. 5L capacity. Connections: -40mm ID 60mm OD main connection flange -24/26 Ground Joints (2x) -15mm Barb on drain port NOTE: This model is an exact replacement for BVV Eco rotary evaporators manufactured before 2019

$242.52

5L Solvent Pro Rotary Evaporator Bump Trap

5L Solvent Pro Rotary Evaporator Bump Trap Replacement Bump Trap for 5L Solvent Pro Rotary Evaporator

$570.63

10L Solvent Pro Rotary Evaporator Main Condenser

10L Solvent Pro Rotary Evaporator Main Condenser 10L Solvent Pro Rotary Evaporator Main Condenser *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement.

$499.30

Welch WOB-L Pump 2581

Welch-L Pump 2581 ***Note: This item has a possible 1-2 week lead time depending on stock availability.*** Product Details Economical Oil Free Adjustable Vacuum Reliable WOB-L Piston pump is perfect for many common laboratory vacuum applications. Features: Vacuum to 5 Torr (29.8"Hg). Includes Vacuum Regulator and Gauge - simple to adjust and monitor vacuum level. Inlet Water Trap - float ball rises to seal off pump from accidental ingestion of water. Muffler quiets pump and filters discharge air. For use with dry or aqueous vapor applications only. Specifications Model 2581 Free Air Displacement @ 60 Hz, cfm (L/min) 3.5 (100) Ultimate Pressure, torr 5 Motor Power, HP (kW) at 60 Hz 1/3 (0.25) Inlet (Exhaust) Connection Thread NPT 3/8 Tubing Needed, I.D. in. (mm) 1/4 (7) Weight, lbs (kg) 24.5 (11.1) Dimensions, LxWxH, in (mm) 17x7.5x12 (430x420x190) 115V Order Number 2581B-50 / 2581B-24

$3,251.16 - $3,726.21

5L Solvent Pro Series Glass Axis

5L Solvent Pro Series Glass Axis. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$64.20

50L Auxiliary Condenser

Auxiliary condenser for 50L Best Value Rotary Evaporator. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$527.83

CRVpro30

Welch CRVpro30 Two-Stage Rotary Vane Pumps •Consumes up to 36% less oil than comparable pumps. •Runs 10°C cooler than comparable pumps. Slows corrosion. •Has a 40% larger oil capacity than comparable pumps. Dilutes aggressive chemicals. •Has a chemical resistant coating in the oil case and pump module. Protects non-moving parts. •Available in 115V/60Hz. •Free air displacement @60Hz: 22.1 cfm (627 L/min) •Ultimate pressure: 3x10-3 mbar (2x10-3 Torr). CRVpro vacuum pumps are two-stage direct-driven vacuum pumps. They are nine models of CRVpro available with free air displacement from 1.8 cfm to 52.5 cfm. Ultimate pressure to 2x10⁻³ torr. Three models of pumps with explosion proof motors, with free air displacements from 2.8 to 12.8 cfm, are available by clicking on the "Explosion Proof" tab below. The benefits of CRVpro pumps are: reduced risk of chemical attacks and oil breakdown by diluting chemical vapors with a larger oil chamber slowing down corrosion by cool running operation provides a measure of protection from sublimed chemical vapors with coating on pump module and oil case. These benefits lead to extended service interval. Depending on model, motor options include 1 Ph TEFC, 3 Ph TEFC, and 1 Ph ex proof motors. Welch vacuum pump oil is specifically formulated for the unique needs of vacuum pumps. Use of non-Welch vacuum pump oil voids any performance claims and product warranties. •In Duoseal belt driven rotary vane pumps, use Welch Duoseal or Welch Gold Oil •In CRVpro rotary vane pumps use Welch premium or Welch gold oil •In Chemstar belt driven rotary vane pumps use Welch gold oil CRVpro vacuum pumps can be used for freeze drying, vacuum ovens, concentrators, glove boxes, schlenk lines, HVAC/refrigeration service, coaters, backing diffusion pumps and turbo molecular pumps, short path, wiped film, metallurgy/vacuum furnaces, lamp manufacture, space simulation, degassing, vessel/chamber evacuation. CRVpro vacuum pumps prepared with perfluoropolyether (PFPE) for oxygen service are available. Contact your local Welch sales representative for details on PFPE prepared pumps and for selecting correct vacuum pump for your application. Weight 99 Ultimate Pressure 3 x10⁻³ Dimensions (mm) 683x384x389 Free Air Desplacement 22.1 (627)

$11,038.82

Agilent IDP-3 Dry Scroll Vacuum Pump With Inlet Isolation Valve

Agilent IDP-3 Dry Scroll Vacuum Pump With Inlet Isolation Valve A Overview The Agilent IDP-3 dry scroll pump is an innovative, compact, high-performance, oil-free vacuum pump that is suitable for a wide variety of applications. It is the smallest scroll pump made for general vacuum applications, which makes it easy to integrate into OEM systems, and it weighs only 21 pounds (9.5 kg). Yet with a pumping speed of 2.1 cfm (60 L/min) and a very low base pressure of 250 milliTorr, it is the highest-performing dry pump in its class. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. The IDP-10 uses an inverter driven motor, which provides uniform vacuum performance at all global frequencies and input voltages. Its uniform global performance and compact size make it an ideal choice for analytical instruments and industrial OEMs. Specifications Base pressure (50 Hz) - Torr & mbar 2.5 x 10-1 Torr 3.3 x 10-1 mbar Base pressure (60 Hz) - Torr & mbar 2.5 x 10-1 Torr 3.3 x 10-1 mbar Dimensions (WxHxL) 5.5 in x 7.13 in x 14.09 in Exhaust Connection ¼ inch female NPT (10 mm hose barb provided) Height 7.13 in Inlet Connection NW16 Input Voltage 1Ø, 115 V. 60 Hz Length 14.09 in Noise Level 55 dB(A) Pumping Speed (50 Hz) 1.8 CFM 3 m3/h 50 L/min Pumping Speed (60 Hz) 2.1 CFM 3.6 m3/h 60 L/min UNSPSC Code 40151502 Width 5.5 in

$6,178.48

Agilent IDP-7 Dry Scroll Vacuum Pump With Inlet Isolation Valve

Agilent IDP-7 Dry Scroll Vacuum Pump With Inlet Isolation Valve Overview The new Agilent IDP-7 dry scroll pump is a compact, high performance, oil-free vacuum pump, delivering large pumping speed capacity and simple maintenance. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. Specifications Base pressure (50 Hz) - Torr & mbar 3.0 x 10-2 Torr 4.0 x 10-2 mbar Base pressure (60 Hz) - Torr & mbar 2.0 x 10-2 Torr 2.6 x 10-2 mbar Dimensions (WxHxL) 10.24 in x 10 in x 16.54 in Exhaust Connection NW16 Height 10 in Inlet Connection NW25 Input Voltage 200-240 VAC 100-120 Length 16.54 in Noise Level 52 dB(A) Pumping Speed (50 Hz) 120 L/min 4.2 CFM 7.2 m3/h Pumping Speed (60 Hz) 152 L/min 5.4 CFM 9.1 m3/hr Width 10.24 in

$9,737.78 - $10,244.22

Agilent IDP-3 2.1 Cfm Oil-Free Compact Dry Scroll Pump - 110V

Agilent IDP-3 2.1 Cfm Oil-Free Compact Dry Scroll Pump - 110V Overview The Agilent IDP-3 dry scroll pump is an innovative, compact, high-performance, oil-free vacuum pump that is suitable for a wide variety of applications. It is the smallest scroll pump made for general vacuum applications, which makes it easy to integrate into OEM systems, and it weighs only 21 pounds (9.5 kg). Yet with a pumping speed of 2.1 cfm (60 L/min) and a very low base pressure of 250 milliTorr, it is the highest-performing dry pump in its class. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. The IDP-10 uses an inverter driven motor, which provides uniform vacuum performance at all global frequencies and input voltages. Its uniform global performance and compact size make it an ideal choice for analytical instruments and industrial OEMs.

$5,148.50 - $5,557.93

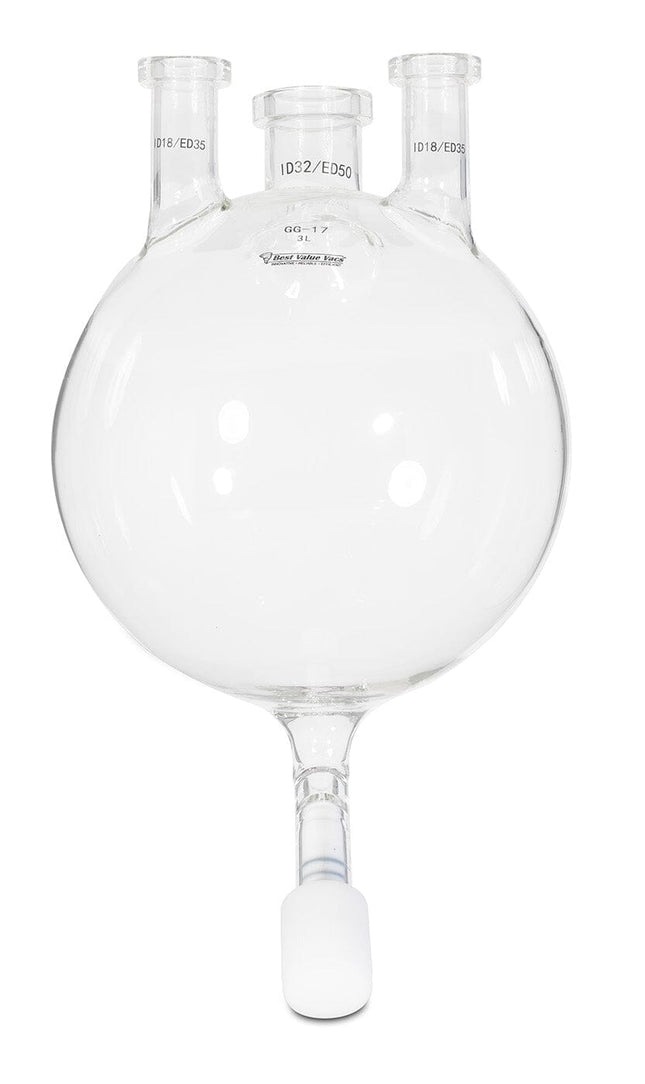

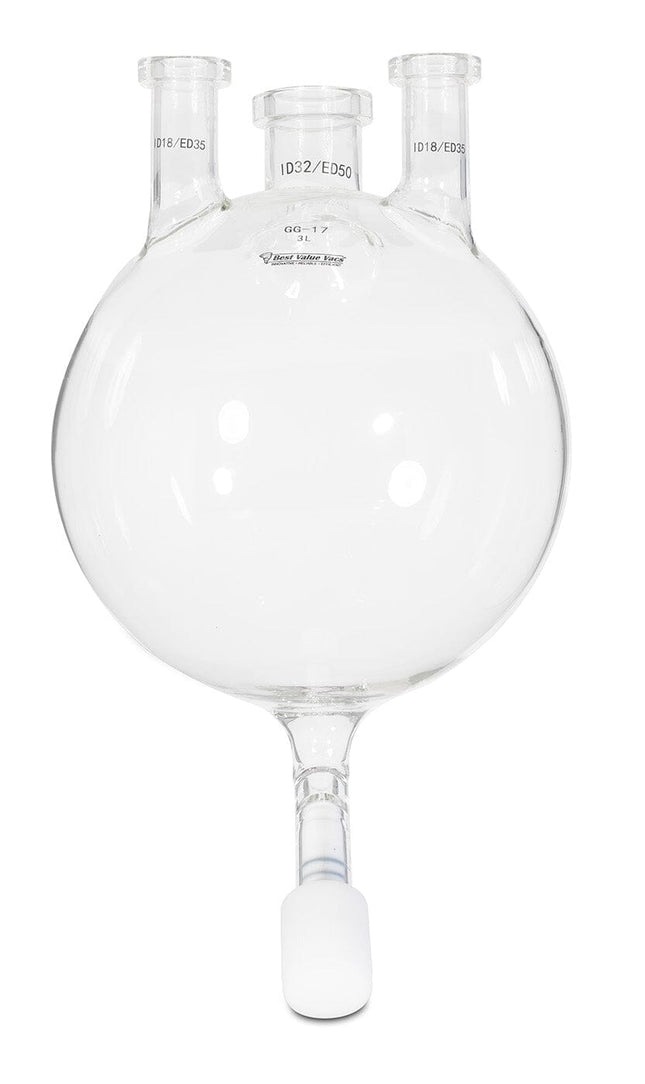

5L Solvent Pro Rotary Evaporator Receiving Flask

5L Solvent Pro Rotary Evaporator Receiving Flask This receiving flask will fit on BVV 5L solvent pro rotary evaporators. Connection Sizes: Condenser- 32mm ID/50mm OD 2x Valves- 16mm ID/35mm OD

$184.03

20L Main Condenser

20L Main Condenser Big port- 60/79 Small port- 41/59

$713.29

50L Glass Reactor Shaft Seal Kit 13MM Replacement

50L Glass Reactor Shaft Seal Kit 13MM Replacement This part is made for 50LTGR-V3 reactors. The body is PTFE and has viton shaft seals that are made for mixing shafts with 13mm diameters. It includes a clamp and retaining ring to attach to our glass reactor lids.

$855.94

Welch ChemStar 5.3 cfm PTFE Oil-Free Deep Vacuum Diaphragm Pump

Welch ChemStar 5.3 cfm PTFE Oil-Free Deep Vacuum Diaphragm Pump With the new ChemStar Dry, you get the advantages of two combined technologies: Roots blower and diaphragm vacuum pump. The result is an oil-free, software- driven vacuum system, ready to work on your tough chemical applications – clean, fast, and thorough. ChemStar Dry pumps quickly down (9 m³/h) to the working range for most evaporative operations (2.0 to 0.1 mbar) with an ultimate pressure of 10-2 mbar. The innovative electronically controlled vapour load optimises the pumping speed control. You can even pump corrosive vapours, since all wetted parts of the system are coated with PTFE and other proprietary coatings so they are chemical resistant. The integrated self-cleaning function also contributes to the system’s long lifetime and enables repeatable results. Take advantage of its state-of-the-art technology for optimal operating conditions and results. ChemStar Dry is suitable for all applications where high gas flow and deep vacuum are needed. Advantages: Oil-Free: no oil back-streaming, no oil maintenance/disposal, cleaner work place, cleaner samples, less maintenance Plug and Play: patented software control, auto speed control from atm to 0.07 mbar, self-cleaning function, protection from surges Low vacuum mostly without cold trap: no dry ice or trap apparatus needed, less maintenance, lower cost of ownership, extra bench space Chemical Resistant: pumps corrosive vapour/gases, TFE and proprietary coatings SKU 2070B-01 Max. pumping speed at 50 Hz in m³/h (l/min) 8.4 (140) Max pumping speed at 60 Hz in m³/h (l/min) 10.1 (168) Ultimate pressure in mbar (Torr) without gas ballast 7x10-2 Wired for 230V, 50/60Hz Intake connection DN 25 KF Exhaust connection DN 25 KF Sound level (dB) 57 Dimensions (W/D/H) in mm 460/220/470 Weight kg (lbs) 23 (50.7)

$13,526.76

BVV 6" Falling Film Evaporator

BVV 6" Falling Film Evaporator Cutsheet Is your lab floor filled with a fleet of rotary evaporators? Looking to increase solvent recovery throughput? Our new and compact 20GPH Falling Film Evaporator (FFE) has the capability to maximize throughput and replace up to five 50L Rotary Evaporators. The BVV™ 20GPH Falling Film Evaporator is designed to evaporate ethanol that has been diluted in crude oil during a filtration or extraction process. By reducing the vapor pressure inside the system and metering the injection valve, the user can set the heat exchangers to the appropriate temperatures to efficiently evaporate solvent from their crude oil. We paired our FFE with reliable equipment that will keep operations running. End users are required to plumb the process inlet and outlet connections for both heat exchangers. They are supplied with 1.5” sanitary tri-clamp connections. BVV™ can assist with necessary parts needed for a permanent or temporary installation. Temporary installations may be necessary if your lab has limited fume hoods or space which is shared with other processing equipment. Below you will find key features, additional equipment included with the system and the power requirements for each, and real-life efficiencies that were tested. Key Features: · Compact rack design for use in fume hoods (39”x30”x75.5”) · Vernier scale metering valve for controlled injection · Accurate heater and chiller temperature control · Deep vacuum for effective solvent removal · Discharge pumps to eliminate constant reservoir draining and down time · Chemical resistant vacuum pump · Adaptable discharge outlets to customer preference · Insulation to limit thermal loses and reduce condensation (Not Pictured) · Sanitary tri-clamp and compression fittings · Pre-heat injection coil · Injection distribution plate · Tube in shell heat exchanger for efficient evaporation and condensation · Packable vapor path for reduction of contaminants and cleaner separation · Water reservoir for priming the heating system and expansion during operation Crude Discharge Pump Easily control discharge speed and collect your extract directly from the 3/8" tube via a collection vessel or swage on a fitting of your preference to pump collected extract to a secondary location. Eliminate constant reservoir draining and operate continuously. Metered Solvent Injection Effectively repeat efficiency and throughput with our vernier scale metering valve. Easy to dial in the desired efficiency and throughput desired by the user. Distribution Plate Directs the injected solvent to be evenly distributed across all tubes in the heat exchanger which maximizes the effective heating surface area. Solvent Discharge and Vacuum Pump The solvent discharge pump eliminates the need for a reservoir and allows you to pump recovered solvent to any desired secondary location. The vacuum pump manifold gives you easy vacuum control during the complete operation. POWER REQUIREMENTS The equipment listed below is included with the system. Check power requirements and amp draw prior to purchasing. Equipment Purpose Power Requirement Amp Draw Notes 2GPM Ethanol Recovery Pump for Vacuum Pump for Ethanol Recovery Discharge 230V 1-Phase 2.4 2GPM Max Flow Rate, Vacuum Check Valve Beaker and Wrench Explosion Proof Oil Pump Pump for Oil Recovery Discharge 230V 1-Phase 1.1 90L/hr. Max Flow Rate, Vacuum Check Valve Welch BTpro100 Diaphragm Pump Vacuum Pump for System 115 1-Phase 3.4 3.5 CFM, 6 Torr Ultimate Vacuum Total Amp Draw 6.9 EFFICIENCY We are proud to present real data with running parameters and efficiencies that reflect the actual operation of our system. Below you will find the tested throughputs and efficiencies that our FFE is capable of handling. Throughput 11 GPH 18 GPH 20 GPH 22 GPH 24 GPH Efficiency 98% 97% 94% 90% 85% ** Efficiency calculated at 10:1 ratio (Ethanol : Crude Oil) with heater temperature of 160°F. Crude is fully dewaxed when going into the falling film evaporator. Solution starts at room temperature. Speeds may differ based on dilution ratio, crude quality, and running parameters. **

$49,930.03

10L Solvent Pro Rotary Evaporator Auxiliary Condenser

10L Solvent Pro Rotary Evaporator Auxiliary Condenser Replacement Auxiliary Condenser for 10L Solvent Pro Rotary Evaporator

$405.15

20L Solvent Pro Rotary Evaporator Auxiliary Condenser

20L Solvent Pro Rotary Evaporator Auxiliary Condenser Replacement Auxiliary Condenser for 20L Solvent Pro Rotary Evaporator

$513.57

10L ECO Main Condenser

10L ECO Main Condenser This condenser is made to fit BVV rotary evaporators manufactured before 2019. The bottom port is a 60/80 joint to attach to the auxiliary condenser, and the top port is a 40/60 joint to connect to a vacuum connection.

$784.61

Welch DryFast Diaphragm Pump 2044

DryFast Diaphragm Pump 2044 Welch DryFast™ PTFE Diaphragm Vacuum Pumps enable precise vacuum control for organic evaporations with exclusive Advanced Vapor Management (AVM). Oil-Free, portable, chemical resistant, dual head diaphragm design simplifies maintenance. Choose from seven dry PTFE vacuum pump models with flows up to 70 L / min and adjustable vacuum down to 2 Torr. Economical DryFastTM vacuum pumps are perfect for tough lab applications. Product Details: Chemical Resistant Oil-Free Tuneable Vacuum Suggested Applications: Concentrator - Gel Dryer Combination Rotary Evaporator Vacuum Concentrator Test Equipment General Attributes Free Air Displacement @ 60 Hz, cfm (L/min) 1.2 (35) Ultimate Pressure, torr 9 Motor Power, HP (kW) at 60 Hz 1/5 (150) Inlet (Exhaust) Connection Thread NPT M14 (1/8) Tubing Needed, I.D. in. (mm) 1/4 (7) Weight, lbs (kg) 21.25 (9.6) Shipping Height 13.8x6.8x8.8 (350x170x220) 115V Order Number 2044B-01

$3,759.02

Vacuubrand VARIO® chemistry pumping unit PC 3001 VARIOpro

Vacuubrand VARIO® chemistry pumping unit PC 3001 VARIOpro The PC 3001 VARIO select pumping unit precisely controls the vacuum level in order to achieve unparalleled process control. This pump is suitable for even high boiling point solvents. The integrated VACUU·SELECT controller provides an easy-to-use, application based interface that covers all common lab applications. The VACUU·SELECT controller has you covered. Use manual set-point-control for simple processes, run fully automated distillations, or create your own application with simple drag-and-drop editing. For solvent evaporation, the VACUU·SELECT controller detects solvent boiling and automatically adjusts the pump's motor speed to maintain process control. The VARIO motor speed control also makes the pump whisper quiet and provides for exceptionally long maintenance intervals. The inlet separator, made of glass with a robust protective coating, prevents particles and liquid droplets from entering the pump, preventing damage and extending pump life. And the exhaust vapor condenser allows for nearly complete recovery of solvents when used with a chilled water line or recirculating chiller for economical recycling and environmental protection. Performance features simplify lab work with the VACUU·SELECT vacuum controller with graphic user interface and predefined applications automatic boiling point detection and continuous optimization of vacuum levels for quick process times compact and powerful; superior performance even with continuous condensate purge whisper quiet and ultra low vibration eco-friendly: extremely low power consumption and efficient solvent recovery. Oil-free! CE Approval Safety Information Manual Controller Manual Manual interfaces Technical data Unit PC 3001 VARIO select Vacuum controller VACUU·SELECT Number of heads / stages 4 / 3 Max. pumping speed m3/h 2.0 Max. pumping speed cfm 1.2 Ultimate vacuum (abs.) mbar/torr 2.0 / 1.5 Ultim. vac. (abs.) with gas ballast mbar/torr 4 / 3 Ambient temperature range (operation) °C 10 - 40 Ambient temperature range (storage) °C -10 - 60 Max. back pressure (abs.) bar 1.1 Inlet connection Hose nozzle DN 6-10 mm Outlet connection Hose nozzle DN 8-10 mm Coolant connection 2 x hose nozzle DN 6-8 mm Rated motor power kW 0.16 Motor speed range min-1 200 - 3000 Protection class IP 20 Dimensions (L x W x H) mm 303 x 306 x 400 Weight kg 8.2 Noise level at 50 Hz, typ. dBA 42 ATEX conformity (only 230V) II 3/- G IIC T3 X Internal Atm. only Items supplied Pumping unit completely mounted, ready for use, with manual. Accessories Rubber vacuum tubing DN 6 mm (20686000) Rubber vacuum tubing DN 8 mm (20686001) Coolant valve VKW-B (20674220) Vent valve VB M-B (20674217) Liquid level sensor (20699908) VACUU·BUS® Y-Adapter mit Kabel 2m (20683240)

$13,837.75

5L ECO V2 Rotary Evaporator Speed Controller Box

5L ECO V2 Rotary Evaporator Speed Controller Box This is a replacement speed controller for 5L rotary evaporators with a manual lift bath. The cord attaching to your motor must have the same 5 pin orientation shown in the pictures.

$420.84

5L ECO V2 Rotary Evaporator Motor

5L ECO V2 Rotary Evaporator Motor This replacement motor fits on 5L rotary evaporators with manual lift baths. The controller connection must have the same 5 pin configuration as the plug shown in the pictures.

$641.96

Welch 2085

Welch 2085 (CSA/UL) Certified Corrosion Resistant Free Air Displacement of 195 l/min (6.9 cfm) Ultimate Vacuum Pressure 26" Hg (100 torr) Fitted Explosion Proof Motor (Class I, Groups C & D; Class II Groups F & G) with CSA/UL Mark Portable Welch corrosion-resistant diaphragm vacuum pumps are driven by explosion-proof motors rated for Class I Hazardous Locations(HazLoc). The aluminum pup head is PTFE coated and diaphragm is covered by a PTFE liner to separate chemical media from the diaphragm. The explosion proof motor is directly coupled to the diaphragm pumping module. Stainless steel tubing is used to connect pump heads together in one and two-stage configurations. The vacuum pump doesn’t come with an on/off switch, plug or cord, but must be conduit wired to the on/off explosion proof control panel. Always use a certified electrician for proper installation of vacuum pump with explosion proof motor to meet your local municipal codes. Contact your local Welch area sales manager for further information Model 2085 FAD, lpm (cfm 195 (6.9) Ultimate Pressure, Torr 100 Max. Vac., in. Hg 26 Head Material Coated PTFE Diaphragm liner PTFE Inlet/Outlet connection NW25 Motor Type Ex Proof Electrical requirement 115/230V 60Hz 1Ph Weight, lbs(kg) 54 (25.5) Dimensions, LxWxH 27 x 11.3 x 11.3

$8,793.39

Welch 2090 Chemical Duty Diaphragm Pumps with Explosion Proof Motor

Welch 2090 Chemical Duty Diaphragm Pumps with Explosion Proof Motor (CSA/UL) Corrosion- resistant Flow from 4.5 to 6.9 cfm Maximum vacuum to 29 in. Hg(25 Torr) Fitted with Class I, Groups C&D explosion proof motor(CSA/UL) Portable Welch corrosion-resistant diaphragm vacuum pumps are driven by explosion-proof motors rated for Class I Hazardous Locations(HazLoc). The aluminum pup head is PTFE coated and diaphragm is covered by a PTFE liner to separate chemical media from the diaphragm. The explosion proof motor is directly coupled to the diaphragm pumping module. Stainless steel tubing is used to connect pump heads together in one and two-stage configurations. The vacuum pump doesn’t come with an on/off switch, plug or cord, but must be conduit wired to the on/off explosion proof control panel. Always use a certified electrician for proper installation of vacuum pump with explosion proof motor to meet your local municipal codes. Contact your local Welch area sales manager for further information Model 2090 FAD, lpm (cfm 127 (4.5) Ultimate Pressure, Torr 25 Max. Vac., in. Hg 29 Head Material Coated PTFE Diaphragm liner PTFE Inlet/Outlet connection NW25 Motor Type Ex Proof1 Electrical requirement 115/230V 60Hz 1Ph Weight, lbs(kg) 54 (25.5) Dimensions, LxWxH 24.6 x 11.1 x 11.3

$8,793.39

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro6

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro6 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details The new CRVpro family of direct drive vacuum pumps offers increased reliability and longer service interval vs. other direct drive rotary vane vacuum pumps. The CRVpro family consumes up to 36% less oil than comparable pumps. Three features drive these benefits: Runs 10°C cooler than comparable pumps. Slows corrosion. Has a 40% larger oil capacity than comparable pumps. Dilutes aggressive chemicals. Has a chemical resistant coating in the oil case and pump module. Protects non-moving parts. The CRVpro family includes all the features you'd expect in a direct drive rotary vane pump: gas ballast, forced oil lubrication, anti-suckback mechanism and thermal overload protection. Suitable applications include freeze drying, degassing, vacuum ovens and concentrators. 3061-01 is wired for North American 115V, 60Hz operation. Includes North American line cord, vacuum inlet hose barb suitable for gum rubber hose from 5/8" to 3/4" ID, and a charge of oil. 3062-01 is wired for North American 230V, 60Hz operation. Includes 230V North American line cord, UK cord, and skuko cord, and a charge of oil. Direct drive pumps are not recommended for filtration, aspiration, drying electrophoresis gels, or other applications requiring sustained operation above 30 torr.

$5,296.86

Welch WOB-L System 2511

Welch WOB-L System 2511 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details Use this easy system to collect waste into 1.2 Liter autoclaveable collection receiver. Includes vacuum measurement and regulation. Reservoirs are protected from overflow by float valve; inlet line hydrophobic filter further protects pump. Vacuum Pump is reliable WOB-L piston pump, perfect for aqueous vapors, buffer, and mild bleach solutions . Not for use with organic solvents / acids / bases. Model Number 2511 Applications Solution aspiration / collection; vacuum filtra Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 0.39(11) Free Air Displacement m3/hr (l/min.) @50Hz 0.55(9.2) Ultimate Pressure 219(292) Maximum Vacuum 21.3 Max Pressure PSIG (pascal) 33(3.3 x 105) Motor Horsepower (watts) 1/30(25) Tubing Needed 3/16(5) Intake Thread NPT 3/16 in. Hose Overall Dimensions LxWxH in. (cm) 7.6x4.5x7.5 (19.4x11.4x19.1) Ship Weight 11.0(5) Shipping Dimensions LxWxH in. (cm) 11" x 7" x 7" (39x31x32)

$1,342.40

You have seen 132 out of 132 products