New Products

-

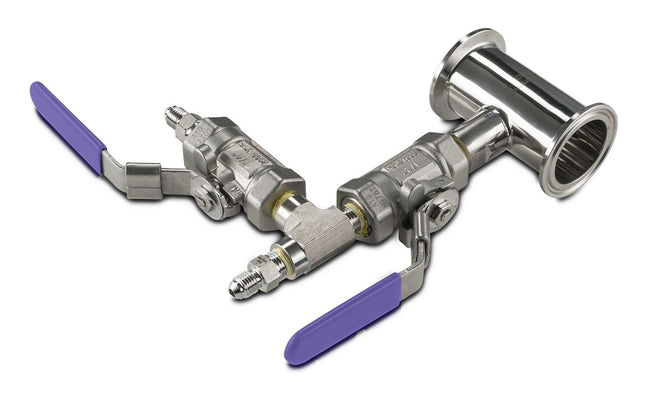

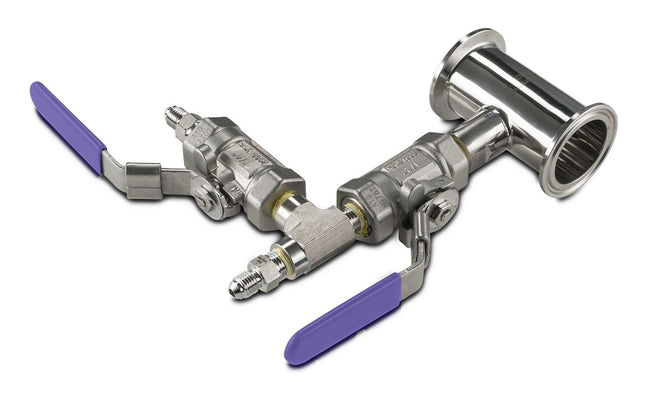

Pre-Built BIFLOW Manifold with BVV 316SS Full Bore Valves

Pre-Built BIFLOW Manifold with BVV 316SS Full Bore Valves (This part is fully assembled and Nitrogen Tested for Leaks at BVV™) This BVV™ BIFLOW Manifold is fully assembled and nitrogen tested for leaks at our warehouse. This manifold comes with 2 BVV 316SS Full Bore Valves with (2)1/4" 37° JIC Flares. This manifold is made out of 304 stainless steel with a Tri-Clamp end connection on either side. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel 1.5" or 2" Tri-Clamp Connections Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2) 1/4" 37° JIC Tri-Clamp Size(s) Selectable through Dropdown Nitrogen Tested Yes

$277.75 - $286.08

-

Carbon Chemistry LTD Carbon Chemistry MM Clay (T-41)

Carbon Chemistry MM Clay (T-41) A powerful combination powder media that pairs acid-activated bentonite clay with activated carbon for maximum adsorption capability. With an optimized pH (3.0-3.5) and enhanced surface area, this dual-action media excels at removing pigments, heavy metals, oxidizers, and other contaminants. Perfect for increasing filtration capacity and achieving superior removal of natural plant pigments like chlorophyll, carotenoids, and anthocyanin compounds. Carbon Chemistry T-41™ Acid Activated Bleaching Clay - SDS

$180.54 - $5,832.68

-

Carbon Chemistry LTD Carbon Chemistry MM Clay (T-5)

Carbon Chemistry MM Clay (T-5) A neutral powder media designed for best-in-class depth filtration and heavy metal removal. This thermally activated calcium bentonite clay provides superior support for separatory processes and excellent cation exchange capacity. The hardened clay structure and optimized surface chemistry make it ideal for both fine particulate removal and larger molecule capture. Carbon Chemistry T-5™ Neutral Activated Bentonite Clay - SDS Note: Bulk Bags and Bulk sizes are non-stocked items and will be ordered as needed and carry a several week lead time and require a forklift or pallet jack

$20.83 - $11,943.11

-

Carbon Chemistry LTD Carbon Chemistry SD (Silica 60A)

Carbon Chemistry SD (Silica Gel 60A) A high-purity silica powder media optimized for precise separation and purification processes. This carefully engineered adsorbent provides exceptional control in chromatographic applications and targeted compound removal. Its optimized surface chemistry makes it particularly effective for polar compound separation and analytical-grade purification needs. This powder is used often in Column Chromatography as the stationary phase. It is mixed together with the solvent in the column making a slurry, then letting the solvent drain leaving the Silica sitting evenly in the column. Silica Gel helps space out or separate the fractions of compounds being passed through the stationary phase. Carbon Chemistry Silica Gel 60A, 200-400 MESH - SDS Note: Bulk Bags and Bulk sizes are non-stocked items and will be ordered as needed and carry a several week lead time and require a forklift or pallet jack

$138.87 - $18,053.53

-

Carbon Chemistry LTD Carbon Chemistry MGS Activated (Mag-Sil PR)

Carbon Chemistry MGS Activated (MagSil-PR) Carbon Chemistry MagSil-PR® powder is some of the highest purity and quality MagSil-PR® on the market. Activated Magnesium Silicate (MagSil-PR®) lets you remove pesticides, improve color, and improve the clarity of your products, thanks to its powerful properties. Magnesium silicate will bind to polar, water-soluble compounds. Once these compounds have bonded with the MagSil, the solution can be filtered through a recommended, 20-micron mesh screen. Particle Mesh Size: 60/100 Carbon Chemistry MagSil-PR® - SDS

$222.20 - $2,777.47

-

Carbon Chemistry LTD Carbon Chemistry ALX (Granular)

Carbon Chemistry ALX (Granular) Industrial-grade activated alumina for moisture removal and polar compound adsorption. 14x28 mesh granular media ideal for desiccant applications, gas drying, and process purification. Activated alumina can mainly be used as a filtration aid to remove fats, color, and polar compounds to produce a cleaner end product. Carbon Chemistry Activated Alumina - SDS Note: Bulk Bags and Bulk sizes are non-stocked items and will be ordered as needed and carry a several week lead time and require a forklift or pallet jack

$41.66 - $10,415.50

-

Pressure Filtration System - 6 x 28

This filter system is designed for high flow rates to filter unwanted precipitates from your oleoresin. The housing provides full enclosure of your filter bags, which are fully supported by the strainer basket within the housing to prevent blowouts. Pressure and high flow rates may be applied to get the fastest flow through filter bags. Using the housing allows full exhaustion of a bag prior to changing it without the sacrifice in filtering time.These filter bag housings use an eye-bolt clamp style to allow for high pressure without leakage, while still maintaining an easy to remove cover. When one filter bag gets filled, it can easily be swapped out by removing the lid while not under pressure and pulling the old bag out. The main seal on the housing is Buna-n rubber. The liquid pump is of 316 Stainless Steel Construction with PTFE seals and runs on compressed air or nitrogen. Built options Include: 1x 304 Stainless Steel Filter Bag Housing 1x 304 Stainless Steel Basket 1x 304 Stainless Steel Displacement Cylinder With Pump options Include: 1x 304 Stainless Steel Filter Bag Housing 1x 304 Stainless Steel Basket 1x 304 Stainless Steel Displacement Cylinder 1x 316 Stainless Steel Liquid pump Connecting hose or hardline tubing 4x Nomex Filter Bags (1μm, 5μm, 25μm, and 100μm) Specifications PFS-790-15 PFS-790-45 Flow Rate (GPM) ≤15 ≤45 Max Pressure (PSI) 100 @28 CFM Volume (in^3) 790 Working Temperature (°C) -40 - 100 Air Hose Connection ¼” JIC Flare ½” JIC Flare Filter Bag Housing Dimensions (LxWxH) 14” x 11” x 41” Filter Bag Trade Size #8 Included PVC Hose size ID ¾” 1” *This unit requires an air compressor for operation (not included)

$1,284.58 - $12,498.60

-

Porcelain Buchner Funnel

Porcelain Buchner Funnel Buchner funnel Porcelain Labware is used in the chemistry laboratory. It has exceptional resistance to all reagents except hydrofluoric acid and is highly resistant to thermal shock while having a very low coefficient of expansion. To prevent thermal stress cracks on porcelain ware do not exceed a heating/cooling rate of 200°C per hour. To prolong the life of porcelain products: · Follow gradual heating/cooling rates · Use an oven or hot plate and an intermediate step when quicker heating/cooling rates are required · Avoid contact of heated ware with a cold surface · Carefully check labware prior to each use and do not use any product that appears defective With straight sides above the perforated plate. Thick stem. Sizes Available: 1000ml - 5.5" (~140mm) Diameter 2000ml - 7-3/8" (~187mm) Diameter

$76.38 - $118.04

-

Chemglass Chemglass PTFE Thermocouple Adapters

PTFE Thermocouple Adapters CG-1048-A Chemglass PTFE adapters are for use with either 1/8” or 1/4” thermocouples. The adapter has an outer Viton® o-ring to form a grease-free, airtight seal between the adapter and the listed size of the outer joint. The compression nut works in conjunction with the upper Viton® to provide an airtight seal between the adapter and thermocouple. Adapter design permits use with CG-145 Keck clips.

$76.38

-

True Terpenes True Terpenes Wedding Cake - Infused

True Terpenes Wedding Cake - Infused All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. Wedding Cake is a mash-up of sweet, pastry-named varieties to create a profile good enough for any special day. FRAGRANCE: Cherry Pie and Girl Scout Cookies blend to form a tasty flavor with lemon and mango highlights along with creamy lavender notes. A complex variety; the exhale holds the citrus cream flavor. EFFECT: Great for unwinding at the end of the day or just removing the discomfort of the day. Great for lifting your spirits. CERTIFICATES: COA | SDS | FOOD GRADE Storage Requirements Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. DilutionTerpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With CareCan cause skin irritation, do not ingest PRIOR to dilution. TRUE GRADE™ It is our promise to you. Our isolated terpenes are triple-distilled making them the cleanest terpenes in the world. Fresh out of the bottle, undiluted, every single one of our products bests the most rigorous consumer safety standards. GMP | ISO-9001:2015 | FSSC 22000 Blended in cGMP facilities adhering to the requirements for a Quality Management System (QMS) specified by ISO 9001:2015 and FSSC 22000 standards. Analyzed Tested and passed True Grade™ safety specifications for residual solvents, pesticides and heavy metals. Stability Tested Rigorously tested with mid-grade distillate against separation, cloudiness and unacceptable levels of color change. We Qualify True Terpenes implements supply-chain control for all raw materials and is proud to provide True Terpenes’ qualification documents such as certificates, licenses and registrations to be qualified as your supplier. Undiluted We do not add PG, VG, PEG, MCT or Vitamin E Acetate to any of our products. Food Grade Manufactured in cGMP facilities using food grade ingredients. UV Protected This product is packaged in a cobalt blue, UV deterrent and food grade bottle with tamper evident seal. Made in the USA Formulated, blended, manufactured and fulfilled in the United States. Refined Isolates This product contains ultra-pure, molecularly-refined terpene isolates. Only the best.

$34.72 - $3,471.83

-

True Terpenes True Terpenes Tropicana Cookies -Infused

True Terpenes Tropicana Cookies -Infused All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. (Please Note: This product has 1 week lead time) Tropicana Cookies Infused Strain Profile takes the uplifting and euphoric Tangie and GSC strains and boosts the good vibes with tropical cookie sweetness. Full Flavor. Full Effect. FRAGRANCE: Tropical and sweet EFFECT: Happy, uplifting and euphoric CERTIFICATES: COA | SDS | FOOD GRADE Storage Requirements Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. DilutionTerpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With CareCan cause skin irritation, do not ingest PRIOR to dilution. TRUE GRADE™ It is our promise to you. Our isolated terpenes are triple-distilled making them the cleanest terpenes in the world. Fresh out of the bottle, undiluted, every single one of our products bests the most rigorous consumer safety standards. GMP | ISO-9001:2015 | FSSC 22000 Blended in cGMP facilities adhering to the requirements for a Quality Management System (QMS) specified by ISO 9001:2015 and FSSC 22000 standards. Analyzed Tested and passed True Grade™ safety specifications for residual solvents, pesticides and heavy metals. Stability Tested Rigorously tested with mid-grade distillate against separation, cloudiness and unacceptable levels of color change. We Qualify True Terpenes implements supply-chain control for all raw materials and is proud to provide True Terpenes’ qualification documents such as certificates, licenses and registrations to be qualified as your supplier. Undiluted We do not add PG, VG, PEG, MCT or Vitamin E Acetate to any of our products. Food Grade Manufactured in cGMP facilities using food grade ingredients. UV Protected This product is packaged in a cobalt blue, UV deterrent and food grade bottle with tamper evident seal. Made in the USA Formulated, blended, manufactured and fulfilled in the United States. Refined Isolates This product contains ultra-pure, molecularly-refined terpene isolates. Only the best.

$187.48 - $3,124.65

-

True Terpenes True Terpenes Grapefruit Romulan - Infused

True Terpenes Grapefruit Romulan Fragrance: Grapefruit Green Apple Cheese Pine Effects: Soothing Uplifting Talkative Grapefruit Romulan is a mash up of two great parents that leaves you thinking of grapefruits. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution. Grapefruit Romulan-Specific Certificates: Product Specification Certificate of Analysis Safety Data Sheet Food Safety Company-Specific Certificates: ISO 9001:2015 GMP Certification FSSC 22000

$168.73 - $3,124.65

-

Porcelain Buchner Funnel Filtration Kit

Porcelain Buchner Funnel Filtration Kit This BVV™ Porcelain Buchner Funnel Filtration Kit was designed for continuous filtration of oils by using our large diameter porcelain Buchner funnel by increasing filtration area. Depending on the capacity needed you may select the size of the conical flask through a dropdown for 2500ml or 5000ml capacities. This Kit Includes the Following: (1) 1.5 Gallon Cold Trap with 1/4" Barbs (1) Rubber Cones, Set of 9 (1) Porcelain Buchner Funnel - 1000ml(When 2500ml Conical Flask is selected) or 2000ml(When 5000ml Conical Flask is selected) (1) BVV4D 4CFM Two Stage Vacuum Pump (1) Conical Flask with Filtering Side Arm - 2500ml or 5000ml (5') Gum Rubber Vacuum Tubing (1) HVAC hose (1) Ashless Filter Paper - 180mm Qualitative - Grade 1

$486.06 - $729.08

-

Neocision 10L Neocision Dual Head Short Path Distillation Kit

10L Neocision Dual Head Short Path Distillation Kit This unit carries a 2 day lead time. The 10L Neocision Distillation Turnkey Setup features our Dual 10L P5 Distillation Heads and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market. You will also receive a Dual Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The 10L Neo Kit Includes: 10L Neocision Kit with Dual P5 Distillation Heads KF-25 90 Degree Long Manifold and Metering Valve Dual Dewar Style Glass Cold Trap Bullseye Precision Vacuum Gauge Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$12,776.34

-

True Terpenes True Terpenes Forbidden Fruit

True Terpenes Forbidden Fruit Fragrance: Cherry Blossom Grape Fruit Cedar Floral Musky Effects: Relaxing Soothing Uplifting Forbidden Fruit delivers on its name. Created by crossing two flavor forward cultivars Cherry Pie and Tangie, this profile is temptingly good. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution. Forbidden Fruit-Specific Certificates: Product Specification Certificate of Analysis Safety Data Sheet Food Safety Company-Specific Certificates: ISO 9001:2015 GMP Certification FSSC 22000

$168.73 - $3,124.65

-

True Terpenes True Terpenes Cherry Pie

True Terpenes Cherry Pie Fragrance: Sweet Dank Earthy Sour Effects: Happy Creative Uplifting A hybrid of Durban Poison and Granddaddy Purple, this earthy berry blend is sweet and sour. Within minutes, it gives feelings of happiness, creativity and is uplifting. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution. Cherry Pie-Specific Certificates: Product Specification Certificate of Analysis Safety Data Sheet Food Safety Company-Specific Certificates: ISO 9001:2015 GMP Certification FSSC 22000

$168.73 - $3,124.65

-

True Terpenes True Terpenes Blue Cheese

True Terpenes Blue Cheese All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. (Please Note: This product has 2 week lead time) Fragrance: Cheese Funk Savory Effects: Soothing Couch-Lock Great for end of day discomforts! Blue Cheese is a heavy low with sweet scents of blueberry and savory notes of cheese. This distinct flavor provides soothing qualities and euphoria. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution.

$168.73 - $3,124.65

-

Neocision 10L Neocision Dual Head Short Path Distillation Turnkey System

10L Neocision Dual Head Short Path Distillation Turnkey System This unit carries a 2 day lead time. The 10L Neocision Distillation Turnkey Setup features our Dual 10L P5 Distillation Heads and USA made glass. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included is a KF-25 Vacuum Pump giving you extreme power and depth with a long lifespan, the Bullseye Precision Vacuum Gauge from Digivac which is the most rugged and dependable vacuum gauge on the market, and a BVV 19L Heated Circulator for maximum condensation of vapors. You will also receive a Dual Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The Premium Turnkey Kit Includes: 10L Neocision Kit with Dual P5 Distillation Heads KF-25 2 Meter Bellows Dual Dewar Style Glass Cold Trap Bullseye Precision Vacuum Gauge BVV 19L Heated Circulator Your Choice Of KF-25 Vacuum Pump Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$18,400.71 - $24,650.01

-

50L BVV™ Double Jacketed Glass Reactor

The BVV™ Double Jacketed Glass Reactors are ideal for reaction applications involving extreme temperatures. They include an inner jacket for cooling or heating and an outer jacket for vacuum insulation. The outer jacket also alleviates moisture buildup so you can always see exactly what's happening inside the system. Jacketed Reaction vessels are used for synthetic reaction of different types of materials in a controlled temperature and vacuum environment. Reaction Vessels can be used as an all in one tool for extraction, refinement, distillation, and homogenization. Consisting of an inner vessel with either one or two jackets, a reactor uses temperature differentials created by a chiller to change it's internal environment. Reaction vessels also operate under vacuum making them ideal for any atmospheric sensitive applications. They can be made out of glass or stainless steel and range in volume from 1L to 100L+. To run a reaction vessel most efficiently, you will need a chiller capable of bringing the internal temperature of the vessel to an extreme low, a chemical resistant vacuum pump, and a cold trap to catch any vapors that might pass through the condenser during operation. BVV™ Jacketed Reaction vessels are simple, cost-effective, and durable machines that allow you to process material quickly and efficiently. BVV 20L and 50L Glass Reactor Diagram Specifications: Glass Material: GG-17 High Borosilicate Glass Internal Volume: 50L 10.5L Jacket Capacity Shelf Material: Aluminum Alloy Homogenizer Power: 110V/60Hz Homogenizer Speed: 0-400 RPM Digital Homogenizer Control Digital temperature probe readout included Double Jacket 3/4" Jacket Connections 1/4" and 3/8" Vacuum Connections Length: 24 in. Width: 30 in. Height: 90 in. Does not include: Chiller, Vacuum System, Cold Trap Requires Assembly ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS!*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$6,943.67 - $7,499.16

-

20L Double Jacketed Glass Reactor

The BVV™ Double Jacketed Glass Reactors are ideal for reaction applications involving extreme temperatures. They include an inner jacket for cooling or heating and an outer jacket for vacuum insulation. The outer jacket also alleviates moisture buildup so you can always see exactly what's happening inside the system. Jacketed Reaction vessels are used for synthetic reaction of different types of materials in a controlled temperature and vacuum environment. Reaction Vessels can be used as an all in one tool for extraction, refinement, distillation, and homogenization. Consisting of an inner vessel with either one or two jackets, a reactor uses temperature differentials created by a chiller to change it's internal environment. Reaction vessels also operate under vacuum making them ideal for any atmospheric sensitive applications. They can be made out of glass or stainless steel and range in volume from 1L to 100L+. To run a reaction vessel most efficiently, you will need a chiller capable of bringing the internal temperature of the vessel to an extreme low, a chemical resistant vacuum pump, and a cold trap to catch any vapors that might pass through the condenser during operation. BVV™ Jacketed Reaction vessels are simple, cost-effective, and durable machines that allow you to process material quickly and efficiently. BVV 20L and 50L Glass Reactor Diagram Specifications: Glass Material: GG-17 High Borosilicate Glass Internal Volume: 20L 6.75L Jacket Capacity Shelf Material: Aluminum Alloy Homogenizer Power: 110V/60Hz Homogenizer Speed: 0-400 RPM Digital Homogenizer Control Digital temperature probe readout included Double Jacket 3/4" Jacket Connections 1/4" and 3/8" Vacuum Connections Length: 20 in. Width: 30 in. Height: 76 in. Does not include: Chiller, Vacuum System, Cold Trap Requires Assembly *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. ***Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS!*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$6,249.30 - $6,804.79

-

304 Stainless Steel Carboy

304 Stainless Steel Carboy This 304 stainless steel carboy is a very durable upgrade from plastic carboy's and allows it to be cleaned and sterilized much better. This unit comes with (2) 1/4" FNPT ports and (1) 6" Tri-Clamp top port and heavy-duty welded handles. For Storage and Vacuum Use Only Max Pressure 10 Psi ONLY (Note: This unit comes bare and does not include any fittings.)

$833.24 - $1,249.86

-

Hemispherical Tri-Clamp Reducer with Welded Ring Stand

Hemispherical Tri-Clamp Reducer with Welded Ring Stand Hemispherical Tri-Clamp Reducer with Welded Ring Stand allows the user to create a larger drain/filtering system allowing more weight to be supported with the ring stand. These reducers have 2 connection points with Tri-Clamp on the top and FNPT drain port on the bottom. Specifications: Material: 304 Stainless Steel High Polish Interior Standard: 3A Connection Types: 4" Tri-Clamp x 1/4" FNPT 6" Tri-Clamp x 1/2" FNPT 8" Tri-Clamp x 1/2" FNPT 10" Tri-Clamp x 1/2" FNPT 12" Tri-Clamp x 1/2" FNPT

$312.46 - $597.16

-

3 Neck Heavy Wall Round Bottom Flask - USA Made

3 Neck Heavy Wall Round Bottom Flask - USA Made This USA made 3 Heavy Wall Round Bottom Flask is designed specifically for Short Path Distillation units and allows dual distillation heads and cows so there is more vapor flow from the heating mantle. These flasks are made of heavy walled borosilicate. Specifications Material Heavy Wall Borosilicate Sizes Available: 10000ml - 24/40 Center Joint and 34/45 Side Joints 20000ml - 24/40 Center Joint and 45/50 Side Joints MADE in the USA *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$555.49 - $833.24

-

UL Listed Pro Series Vacuum Pump Complete Service Kit

Pro Series Vacuum Pump Complete Service Kit This is a compelete vacuum pump service kit for the BVV™ Pro Series 5.6, 11.3, 21.2CFM line of vacuum pumps and allows the user to completely rebuild their pump and keep it running like new.

$444.39 - $486.06

-

Threaded Lab Stand Rod

Stainless Steel Threaded Rod 10 x 1.5mm Thread, 10mm Diameter rod, and is 24" in length and can be used as extra lattice supports in a any application.

$13.89 - $20.83

-

Tygon Tygon 2475 Smooth Bore High Purity PVC Tubing - 1/2"

1/2" Tygon 2475 Smooth Bore High Purity PVC Tubing Formulation 2475 Tygon tubing is the ultimate in performance PVC tubing this tubing is free of plasticizers, made of FDA listed materials, rated for vacuum, and has a minimum temperature range of -90°F all the way up to 120°F. This tubing is meant for sensitive transfer fluids, pharmaceutical solutions, biotechnological applications because of its high performance and smooth bore. Formulation 2475 also resistance damage from aggressive chemical cleaners and sanitizers and contains no plasticizers which could contaminate the transferred fluids. The smooth non-wetting inner bore prevents the build-up of particulates and limits absorption and adsorption to further preserve fluid purity and integrity. When burned for disposal this tubing will not release any hazardous byproducts such as chlorine and will only release carbon dioxide and water for a less toxic means of disposal it can also be sterilized with ethylene oxide (ETO), chemicals, or radiation. The tubing has a working temperature of -90 to 120°F and a durometer of 70a and a pressure rating of 29.9 psi at 72F. this tubing meets U.S. Pharmacopoeia (USP) Class VI criteria for medical grade plastic materials and U.S. Food and Drug Administration (FDA) 21 CFR 177.1520 criteria for food contact for quality assurance. Tygon 2475 Brochure Key Features: Plasticizer-free plastic tubing for transferring fluids in medical, pharmaceutical, and biotechnological applications Clear Tygon formulation 2475 plastic for visually monitoring transfer of fluids Smooth bore to allow full drainage and prevent absorption and particulate build-up for preserving fluid integrity Working temperature range of -90 to 120°F and durometer (hardness) of 70A Meets USP Class VI and FDA CFR21 177.1520 standards for quality assurance Vacuum Rated to 29.9inHG Specifications ID 1/2" OD 3/4" Wall Thickness 1/8" Temperature Rating -90° to 120°F Vacuum Rating 29 in. of HG @ 72°F Durometer 70A Hardness Rating Soft Flexibility Very Flexible Bend Radius 1-1/2" Maximum Pressure 29psi @ 72°F Compatible Tube Fittings Barbed Formulation 2475 Standards Meets USP Class VI FDA CFR21 177.1520 standards for quality assurance Chemical Resistance: Excellent Acetic Acid (10% in Water) Acetic Acid (30% in Water) Deionized Water Hydrochloric Acid (10% in Water) Hydrochloric Acid (30% in Water) Hydrogen Peroxide (10% in Water) Hydrogen Peroxide (30% in Water) Isopropyl Alcohol Methanol (Methyl Alcohol) Nitric Acid (Up to 50% Concentration) Phosphoric Acid (25% in Water) Phosphoric Acid (85% in Water) Sodium Hydroxide (Caustic Soda) (10% in Water) Sodium Hydroxide (Caustic Soda) (30% in Water) Sodium Hypochlorite (Bleach) Sulfuric Acid (10% in Water) Sulfuric Acid (30% in Water) Moderate Acetone, Methyl Ethyl Ketone (MEK) Vegetable Oil Not Recommended Mineral Oil Note Chemical compatibility must be determined by the customer based on the conditions in which the product is being used, including the presence of other chemicals, temperature, and consistency. Safety Data SDS RoHS Compliant

$62.49 - $624.93

-

Tygon Tygon 2475 Smooth Bore High Purity PVC Tubing - 3/8"

3/8" Tygon 2475 Smooth Bore High Purity PVC Tubing Formulation 2475 Tygon tubing is the ultimate in performance PVC tubing this tubing is free of plasticizers, made of FDA listed materials, rated for vacuum, and has a minimum temperature range of -90°F all the way up to 120°F. This tubing is meant for sensitive transfer fluids, pharmaceutical solutions, biotechnological applications because of its high performance and smooth bore. Formulation 2475 also resistance damage from aggressive chemical cleaners and sanitizers and contains no plasticizers which could contaminate the transferred fluids. The smooth non-wetting inner bore prevents the build-up of particulates and limits absorption and adsorption to further preserve fluid purity and integrity. When burned for disposal this tubing will not release any hazardous byproducts such as chlorine and will only release carbon dioxide and water for a less toxic means of disposal it can also be sterilized with ethylene oxide (ETO), chemicals, or radiation. The tubing has a working temperature of -90 to 120°F and a durometer of 70a and a pressure rating of 20 psi at 72F. this tubing meets U.S. Pharmacopoeia (USP) Class VI criteria for medical grade plastic materials and U.S. Food and Drug Administration (FDA) 21 CFR 177.1520 criteria for food contact for quality assurance. Tygon 2475 Brochure Key Features: Plasticizer-free plastic tubing for transferring fluids in medical, pharmaceutical, and biotechnological applications Clear Tygon formulation 2475 plastic for visually monitoring transfer of fluids Smooth bore to allow full drainage and prevent absorption and particulate build-up for preserving fluid integrity Working temperature range of -90 to 120°F and durometer (hardness) of 70A Meets USP Class VI and FDA CFR21 177.1520 standards for quality assurance Vacuum Rated to 25inHG Specifications ID 3/8" OD 1/2" Wall Thickness 1/16" Temperature Rating -90° to 120°F Vacuum Rating 25 in. of HG @ 72°F Durometer 70A Hardness Rating Soft Flexibility Very Flexible Bend Radius 1-3/4" Maximum Pressure 20psi @ 72°F Compatible Tube Fittings Barbed Formulation 2475 Standards Meets USP Class VI FDA CFR21 177.1520 standards for quality assurance Chemical Resistance: Excellent Acetic Acid (10% in Water) Acetic Acid (30% in Water) Deionized Water Hydrochloric Acid (10% in Water) Hydrochloric Acid (30% in Water) Hydrogen Peroxide (10% in Water) Hydrogen Peroxide (30% in Water) Isopropyl Alcohol Methanol (Methyl Alcohol) Nitric Acid (Up to 50% Concentration) Phosphoric Acid (25% in Water) Phosphoric Acid (85% in Water) Sodium Hydroxide (Caustic Soda) (10% in Water) Sodium Hydroxide (Caustic Soda) (30% in Water) Sodium Hypochlorite (Bleach) Sulfuric Acid (10% in Water) Sulfuric Acid (30% in Water) Moderate Acetone, Methyl Ethyl Ketone (MEK) Vegetable Oil Not Recommended Mineral Oil Note Chemical compatibility must be determined by the customer based on the conditions in which the product is being used, including the presence of other chemicals, temperature, and consistency. Safety Data SDS RoHS Compliant

$27.77 - $277.75

-

True Terpenes True Terpenes Pie Hoe - Infused

True Terpenes Pie Hoe All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. (Please Note: This product has 1 week lead time) Pie Hoe Infused Strain Profile takes the sensual and euphoric combination of Grape Pie and Tahoe OG strains and increases the love with silky smooth berry. Full Flavor. Full Effect. FRAGRANCE: Berry EFFECT: Sensual and euphoric CERTIFICATES: COA | SDS | FOOD GRADE Storage Requirements Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. DilutionTerpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With CareCan cause skin irritation, do not ingest PRIOR to dilution. TRUE GRADE™ It is our promise to you. Our isolated terpenes are triple-distilled making them the cleanest terpenes in the world. Fresh out of the bottle, undiluted, every single one of our products bests the most rigorous consumer safety standards. GMP | ISO-9001:2015 | FSSC 22000 Blended in cGMP facilities adhering to the requirements for a Quality Management System (QMS) specified by ISO 9001:2015 and FSSC 22000 standards. Analyzed Tested and passed True Grade™ safety specifications for residual solvents, pesticides and heavy metals. Stability Tested Rigorously tested with mid-grade distillate against separation, cloudiness and unacceptable levels of color change. We Qualify True Terpenes implements supply-chain control for all raw materials and is proud to provide True Terpenes’ qualification documents such as certificates, licenses and registrations to be qualified as your supplier. Undiluted We do not add PG, VG, PEG, MCT or Vitamin E Acetate to any of our products. Food Grade Manufactured in cGMP facilities using food grade ingredients. UV Protected This product is packaged in a cobalt blue, UV deterrent and food grade bottle with tamper evident seal. Made in the USA Formulated, blended, manufactured and fulfilled in the United States. Refined Isolates This product contains ultra-pure, molecularly-refined terpene isolates. Only the best.

$168.73 - $3,124.65

-

True Terpenes True Terpenes Mai Tai - Infused

True Terpenes Mai Tai - Infused All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. (Please Note: This product has 1 week lead time) Mai Tai Infused Strain Profile takes the energizing orange and cherry-esque aromas of Alien Orange Cookies and ACDC strains and adds a sweet, bright fruit note. Full Flavor. Full Effect. FRAGRANCE: Tropical EFFECT: Uplifting and energizing CERTIFICATES: COA | SDS | FOOD GRADE Storage Requirements Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. DilutionTerpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With CareCan cause skin irritation, do not ingest PRIOR to dilution. TRUE GRADE™ It is our promise to you. Our isolated terpenes are triple-distilled making them the cleanest terpenes in the world. Fresh out of the bottle, undiluted, every single one of our products bests the most rigorous consumer safety standards. GMP | ISO-9001:2015 | FSSC 22000 Blended in cGMP facilities adhering to the requirements for a Quality Management System (QMS) specified by ISO 9001:2015 and FSSC 22000 standards. Analyzed Tested and passed True Grade™ safety specifications for residual solvents, pesticides and heavy metals. Stability Tested Rigorously tested with mid-grade distillate against separation, cloudiness and unacceptable levels of color change. We Qualify True Terpenes implements supply-chain control for all raw materials and is proud to provide True Terpenes’ qualification documents such as certificates, licenses and registrations to be qualified as your supplier. Undiluted We do not add PG, VG, PEG, MCT or Vitamin E Acetate to any of our products. Food Grade Manufactured in cGMP facilities using food grade ingredients. UV Protected This product is packaged in a cobalt blue, UV deterrent and food grade bottle with tamper evident seal. Made in the USA Formulated, blended, manufactured and fulfilled in the United States. Refined Isolates This product contains ultra-pure, molecularly-refined terpene isolates. Only the best.

$168.73 - $3,124.65

-

True Terpenes True Terpenes Limoncello - Infused

True Terpenes Limoncello - Infused All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. (Please Note: This product has 1 week lead time) Named after a delicious sweet liquor this lemon forward strain profile will leave you wanting desert. FRAGRANCE: A strong citrus aroma, but notes of mango, pine and pepper blend into the lemony tang to give this profile a unique nose. A high nerolidol level adds to the floral, fruity green tones. EFFECT: Limoncello will help you unwind at the end of the day with a uplifting peace. CERTIFICATES: COA | SDS | FOOD GRADE Storage Requirements Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. DilutionTerpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With CareCan cause skin irritation, do not ingest PRIOR to dilution. TRUE GRADE™ It is our promise to you. Our isolated terpenes are triple-distilled making them the cleanest terpenes in the world. Fresh out of the bottle, undiluted, every single one of our products bests the most rigorous consumer safety standards. GMP | ISO-9001:2015 | FSSC 22000 Blended in cGMP facilities adhering to the requirements for a Quality Management System (QMS) specified by ISO 9001:2015 and FSSC 22000 standards. Analyzed Tested and passed True Grade™ safety specifications for residual solvents, pesticides and heavy metals. Stability Tested Rigorously tested with mid-grade distillate against separation, cloudiness and unacceptable levels of color change. We Qualify True Terpenes implements supply-chain control for all raw materials and is proud to provide True Terpenes’ qualification documents such as certificates, licenses and registrations to be qualified as your supplier. Undiluted We do not add PG, VG, PEG, MCT or Vitamin E Acetate to any of our products. Food Grade Manufactured in cGMP facilities using food grade ingredients. UV Protected This product is packaged in a cobalt blue, UV deterrent and food grade bottle with tamper evident seal. Made in the USA Formulated, blended, manufactured and fulfilled in the United States. Refined Isolates This product contains ultra-pure, molecularly-refined terpene isolates. Only the best.

$168.73 - $3,124.65

-

True Terpenes True Terpenes Banana Kush

True Terpenes Banana Kush Fragrance: Sweet Fruity Pungent Tropical Effects: Soothed Care-Free Uplifted Energetic This sweet, tropical indica-dominant blend gives a soothed, uplifted, creative focus. Banana Kush crosses Skunk Haze and Ghost OG. The fresh banana taste will help increase happiness, better restfulness, creativity, talkativeness, and attention. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution. Banana Kush-Specific Certificates: Product Specification Certificate of Analysis Safety Data Sheet Food Safety Company-Specific Certificates: ISO 9001:2015 GMP Certification FSSC 22000

$168.73 - $3,124.65

-

True Terpenes True Terpenes Blood Orange

True Terpenes Blood Orange Blood Orange Terpene Flavor showcases sensuous, tart notes of raspberry over a body of classic citrus flavor. Terpene Flavors are an effects-rich terpene base combined with a variety of other aromatic compounds. Blood Orange Terpene Flavor is terpene enhanced to deliver an UP or DOWN effect. The DOWN blend features our proprietary terpene mix to help you slow down and unwind. CERTIFICATES: COA SDS FOOD GRADE Storage RequirementsKeep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. DilutionTerpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With CareCan cause skin irritation, do not ingest PRIOR to dilution. WARNINGThis product is intended for use only by adults 21 or older. Terpene Profiles are concentrated and should not be consumed undiluted. Consumers should determine and conduct their own safety standards and testing. Avoid contact with the skin, eyes, wood surfaces and fabrics. Keep out of reach of children and pets. Do not use if you are pregnant, nursing or a person with or at risk of serious health conditions including but not limited to heart disease, high blood pressure, diabetes or a person taking medicine for depression or asthma. Discontinue use or consult your doctor if any adverse reaction occurs. This is not a smoking cessation product. Nutritional StatementTrue Terpenes certifies that, to the best of our knowledge, the product listed above does not contribute to the nutritional value of flavors due to their extremely low usage levels and therefore falls under the nutritional labeling exemption defined in Section 101.9(a) and (j) of Title 21 of the Code of Federal Regulations. Testimonial DisclaimerIn accordance with the FTC guidelines concerning the use of endorsements and testimonials in advertising, please be aware of the following:

$168.73 - $3,124.65

-

GL-14 Cap

GL-14 Cap This GL-14 cap is used for sealing off GL-14 connections or venting vacuum in a system without the use of a valve. Gasket not included. (Note: Only 1 cap included. Increase quantity to order more caps.)

$8.33

-

24/40 Jointed Straight Adapter

24/40 Jointed Straight Adapter This straight inlet adapter allows the user to connect two female 24/40 jointed connections. The overall distance between the joints is 70mm. *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$20.83

-

Stainless Steel Tri-Clamp x Female Joint Adapter

This unique adapter allows the user to adapt a Tri-Clamp fitting to a male ground joint glass fitting and it is made out of 304 stainless steel.

$52.77

-

Activated Alumina

Activated Alumina Activated Alumina also known as aluminum oxide is one of the most adaptable sorbents for preparative flash and column chromatography. NSF 61 certified & Made in USA, Purity: <=100%. Based on 8% loss on Ignition. Activated Alumina SDS Sheet Activated Alumina Technical Data Sheet Key Uses: Purification of natural products & herbals As a supportive agent in aromatice chromatography Dehydration of organic solvents. Dehydration of organic solvents. Removal of water from non-polar solvents NSF 61 Certified: Guaranteed the product is free of harmful chemicals, and can be used in systems that humans come into contact consuming. Lot certificates can be available per request. Chemical composition (%) Al2O3 92 Na2O 0.35 SiO2 0.03 LOI (1000ºC) 8.0 Total pore volume, cc/g 0.52 0.52 Surface area, m2/g 380 Note: Bulk bags and Bulk sizes are non-stocked items and will be ordered as needed and carry a several week lead time and require a forklift or pallet jack Note: Container style and color may vary. Product is sold by weight which may result in container not being full.

$27.77 - $8,679.58

-

KF Vacuum Flange Reducer Adapter

This 304 Stainless Steel KF Vacuum Flange Reducer / Adapter is designed to convert K16 to KF25 or KF25 to K40 and vise versa.

$52.77

-

KF-25 Y Bellow

This Unique 304 Stainless Steel KF-25 Y Bellow has 3 attachment points for KF-25 fittings and 2 flexible ends and 1 rigid end that let the user position them the way that best suits their operation. It has an overall length of 17" and a width of ~16".

$291.63

-

Huber HUBER Unistat T305 with Pilot ONE

HUBER Unistat T305 with Pilot ONE (Please Note: There is a 2 - 3 weeks lead time) The Unistat range inspires with unique thermodynamic properties and a range of functions to meet the highest demands. Unistat technology guarantees precise, reproducible temperature control results, the shortest possible heating and cooling times and large temperature ranges without the need for fluid change. All Unistats are fitted with the innovative Because Unistats are hydraulically sealed, the service life of the temperature control fluid is dramatically increased by preventing oil loss through vapours and oxidation, further saving resources. Unistats are fitted with extensive safety equipment and are therefore suitable for unsupervised continuous operation. Relevant operating conditions are constantly monitored and the system is switched off if necessary or with the process safety feature the emergency cooling circuit is activated. Data sheet 3 Year Warranty Extension General Information & Temperature Controller Temperature range 65...300 °C Temperature stability ±0,02 °C Temperature control TAC, self-optimizing (True Adaptive Control) Controller Pilot ONE (E-grade "Basic") Safety class III / FL Protection class IP20 Dimensions (W x D x H) 425 x 250 x 631 mm | 16.73 x 9.84 x 24.84 inches Weight 37 kg | 81.59 pounds Heating / Cooling Capacity Heating capacity 4,8 kW Circulation Pump Pressure pump max. 45 lpm ; 0.9 bar | 11.89 gpm ; 13.05 psi Pump connection M24x1,5 AG male Permissible viscosity 50 mm²/s Connections Pt100 connection Pt100 Analogue input via optional Com.G@te Analogue output via optional Com.G@te Digital interface RS232, Ethernet, USB Device, USB Host Operating Data Old sku 1003.0022.01 Permissible ambient temp. 5 to 40 °C Filling volume min. 1.45 Liters | 0.38 gal Volume of expansion 2.8 Liters | 0.74 gal Power supply 208V 3~ 60Hz Current max. 15 A Fusing 15,5 A

$32,565.79 - $33,260.16

-

Polyscience Polyscience 10 Liter General Purpose Water Bath

Polyscience 10 Liter General Purpose Water Bath Key Features: Displays actual and set point temperature simultaneously Three push-button pre-sets for frequently used temperatures Integrated timer Hinged gable cover Calibration capability Reservoir sizes from 2 to 28 liters Reservoir made of 304 Stainless Steel Reservoir drain (10 liter and larger baths) Primary and automatic safety thermostats Also compatible with waterless bath beads Specifications Working Temperature Range °F Ambient +10° to 212° Reservoir Capacity (liters) 10 Reservoir/Tank Material Stainless Steel Reservoir Cover Hinged Gable Working Access (L x W x D) (inches) 10.6 x 11.6 x 6 Temperature Stability °F ±0.2° Display 3.25" Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Maximum Ambient Temperature °F 104° Overall Dimensions (L x W x H) (inches) 17 x 15.5 x 15.5 Shipping Weight (pounds) 22.0 60Hz Only Part Number WBE10A11B Included Hardware Sample Tray Heater Wattage 1000 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/8.6 Regulatory Approvals ETL Certifications: Regulatory Approvals: ETL Regulatory Approvals: CE

$1,352.63 $833.24

-

Agilent Agilent IDP-7 5.4 cfm Oil-Free Compact Dry Scroll Pump

Agilent IDP-7 5.4 cfm Oil-Free Compact Dry Scroll Pump Overview The new Agilent IDP-7 dry scroll pump is a compact, high performance, oil-free vacuum pump, delivering large pumping speed capacity and simple maintenance. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump.

$8,519.88 - $9,058.71

-

Welch Vacuum - Gardner Denver Welch WOB-L Pump 2561

Welch WOB-L Pump 2561 ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Reliable WOB-L Piston pump is perfect for many common laboratory vacuum applications. Features: Vacuum to 5 Torr (29.8"Hg). Includes Vacuum Regulator and Gauge - simple to adjust and monitor vacuum level. Inlet Water Trap - float ball rises to seal off pump from accidental ingestion of water. Muffler quiets pump and filters discharge air. For use with dry or aqueous vapor applications only. Features: Economical Oil Free Adjustable Vacuum Applications: Vacuum Filtration Many filtrations require only minimal vacuum to proceed; deep vacuum is not required. Vacuum pump flow required is roughly proportional to the total surface area of filters being used. Filtration of particulate-clogging samples can be improved somewhat with deeper vacuum, but a combination of larger filter surface area, smaller samples, and sequential use of decreasing porosity filter papers may also be required for timely filtration. Choose a standard duty vacuum pump for aqueous vapors; use a PTFE pump for resistance to harsh chemicals. Specifications: Applications Vacuum filtration up to 6 funnel manifold; Lab automation - aspiration of systems utilizing 96 / 256 well format; Welchnet lab installations up to 10 outlet fixtures (geneneral use, filtration) Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 3.5(100) Free Air Displacement m3/hr (l/min.) @50Hz 4.9(83) Ultimate Pressure 60(80) Maximum Vacuum 27.6 Max Pressure PSIG (pascal) Motor Horsepower (watts) 1/3(250) Adjustable Vac. / Gas Ballast Yes Tubing Needed 1/4(7) Intake Thread NPT 1/4 Overall Dimensions LxWxH in. (cm) 15.0x10x10 (38.1x25.4x25.4) Ship Weight 24(10.9) Shipping Carton Dimensions LxWxH in. (cm) 21x12x15 (53x30x38) Intake Catch Jar Yes Adjustable Vacuum Knob Vacuum Gauge Dial

$2,777.47

-

Universal Vacuum Chamber Gasket

Universal Vacuum Chamber Gasket Our patented gasket #9475627 This vacuum chamber gasket is made out of durable and heat resistant silicone. It features a large flange on a single side so the user can adapt one of our lids to varyingly sized vessels. Gasket Specifications: 10.75" - Can Fit lids 10.75" in Diameter and up to 3/4" in thickness 12.75" - Can Fit lids 12.75" in Diameter and up to 1" in thickness

$55.55 - $62.49

-

Welch Vacuum - Gardner Denver Welch DUOSEAL Two Stage - Refrigeration 1402B-46

Welch DUOSEAL Two Stage - Refrigeration ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details: 115V, 60Hz, 1 Ph with N.Amer, 115V Plug Deep vacuum for fast evacuation and dehydration Durable pump, precision machined Gas ballast for high vapor loads. Rugged DuoSeal belt-drive vacuum pumps enable fast, thorough evacuation of refrigeration systems. Features high flow and deep vacuum with low pump RPM and large oil reservoirs for extended life and reduced maintenance. Includes handles for enable positioning. Specifications: Model Number 1402B-46 Applications Service Lithium Bromide absorption chillers to 500 -700 tons, fluorcarbon or ammonia chillers to 100 to 200 tons Type DUOSEAL Two Stage - Refrigeration Free Air Displacement m3/hr (l/min.) @50Hz 5.6 Ultimate Pressure 160 Maximum Vacuum 1 x 10-4 (1.3 x 10-4) Oil Capacity 525 Motor Horsepower (watts) 2.25 Adjustable Vac. / Gas Ballast Yes Tubing Needed 13/16" ID Hose or 3/4" Flare Fitting Intake Thread NPT 1-20 ISO Exhaust / Intake Flange 1-20 Overall Dimensions LxWxH in. 20" x 12" x 15" Ship Weight 128(58)

$6,145.14

-

J-KEM Scientific J-Kem Gemini-2 Dual Temperature Controller

J-Kem Gemini-2 Dual Temperature Controller Gemini-2 Dual Temperature Controller displays two temperature controllers in a single cabinet to regulate two independent reactions. Each channel is 1200 Watts MAX (1800 Watts total), 15 Amps @ 120VAC, The Gemini is one of J-KEM’s most versatile controllers featuring high power outlets and a 100 hour digital timer (on channel 1) to turn heating OFF (or ON) at a user entered time. Features Included: Over-temperature protection circuits with audible alarms, dual temperature displays, selectable operating modes, double fused, and 100% solid state design. The USB port on the back panel of the controller is an interface to J-KEM’s KEM-Net software. Safety features include: 100% solid state, double fused, audible error alarm, and over temperature circuitry that disconnects power if an over temperature condition occurs. Specifications: Dimensions: 3.5" H x 7.75" W x 8.75" D Power: 15 Amps @ 120VAC, 1200 Watts MAX/Channel, 1800 Watts (Total) Weight: 7 lbs Complete System Includes: One controller Two Teflon thermocouples (12″ long, 1/8″ diameter) Two connecting cords Two 14/20 joint adapters

$2,178.92 - $2,667.76

-

P10 Distillation Head - USA Made

P10 BVV™ Distillation Head P10 Distillation Head has 2 sets of vigreux in the distillation column with 45/50 lower joint, 24/40 Thermometer Joint, and 34/45 side joint and includes GL-14 barb connections. MADE IN THE USA Designed for 10 Liter Flasks Set of 2 vigreux to allow for more packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$1,110.99 $833.24

-

Neocision P10V6 Neocision Distillation Head - USA Made

P10V6 Distillation Head P10V6 Distillation Head has 6 sets of vigreux in the distillation column with 45/50 lower joint, 24/40 Thermometer Joint, and a 34/45 side joint and includes GL-14 barb connections. MADE IN THE USA Designed for 10 Liter Flasks Set of 6 vigreux to allow for packing media Larger vacuum jacket allows for less heat loss during distillations Larger vapor path to allow for gas/vapor phase flow Increased internal diameter for faster, more efficient fractioning as well as packing and unpacking of media Increased condenser length and diameter for more efficient condensation of vapor with zero clogging *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$833.24

-

Lab Dosing Gun 25 milliliter Pistol Grip (0.5ml Incremental Shots)

Lab Dosing Gun 25 milliliter Pistol Grip 30 Day Limited Warranty The BVV™ Semi-Automatic Lab Dosing Gun can is easily adjusted to fill in 0.5ml, 1ml, 1.5ml, 2ml, and 2.5ml increments. You can quickly and accurately fill your cartridges. The heated barrel has a digital controller that allows the user to set a temperature from (Room Temperature - 190°F) in increments of 1.0°F. The Filler comes ready to use, just plug it in and attach the included 14 Gauge Tip. Specifications: Polypropylene Barrel – Chemically Resistant to: Isopropyl Alcohol, Ethanol, Butane, Hexane, Glycerin, Glycols, Terpenes, and most Acids 14 Gauge lure lock needle included 110V USA Plug Adjusts from 0.5-2.5ml Shots (0.5ml increments) Lure Lock Hub for all types of size attachments Extra Barrel Plunger Gasket included Adjustable plunger tension/tightening (*for user preferred plunger action) Built-in Temperature Cutoff @190F. 5ft Power Cord 3ft Heat Cord to Control Box. Assembled weight 10oz. Cleaning: NOTE: Please Clean Prior to first use gun does not come sterilized. Cleaning the barrel and components can be done with De-limonene, other chemicals can be used, however, *The Barrel Gasket is made of Nitrile and can degrade with overexposure to chemicals like Isopropyl Alcohol. To Fill the Syringe:Advance the plunger all the way to the needle tip of the barrel. Place the needle into the Oil and pull the plunger all the way back until it stops. The barrel will be filled. Increasing the Max Temperature: The Max Temperature Setting is 190°F. To increase the temperature beyond that, the user will need to follow the included instruction to unlock and change the max temp. (Absolute Max. is 212°F) Lab Dosing Gun User Manual PDF

$340.24

You have seen 1008 out of 1655 products