New Products

-

Color Remediation Column CRC

Color Remediation Column For BHO Extraction Color Remediation Columns are secondary columns used as a filtration cartridge for hydrocarbon and ethanol extraction systems. Removing impurities from extracted oils is aided by filter media, packed in the column above a triple filtration stack. The CRC features a bypass path, allowing the operator to skip the column in case of a clog. What simplifies the color remediation process is bundling the cartridge with the filter media. We have paired the unit with suggested media, supplied in the proper ratio, and a standard operating procedure. This makes filtration easy, allowing you to get it right the first time without having to guess. The CRC is a 4" x 12" spool with triple filter plates and rack mounting. Choose 1/4", 3/8" or 1/2" flares. This CRC Kit Includes: Color Remediation Column Rack Mounting Brackets 100 pack of 8 and 20-micron filter papers 1000g of Activated Alumina 1000g of Silica 60 1000g of Pure-Flo® B80 1000g of PurifiDE XG-12 Instruction Manual

$1,894.84 - $2,384.87

-

4" Stainless Steel Buchner Funnel

4 Inch Stainless Steel Buchner Funnel 4” Buchner Funnel Kit: This buchner funnel kit adapts to any vessel with a 24/40 joint. The included adapter makes it possible to pull vacuum and use large vessels as a collection. Max internal volume of the buchner funnel is 0.82L, but can be adapted with a larger spool for higher capacity. This kit features: 4” x 4” 304SS spool with a capacity of 0.82L 4” Tri-Clamp Single Hinge Clamp 4”x1.5” 304SS Hemispherical Reducer 1.5” Tri-Clamp Double Hinged Clamp 4” 5 Micron 304SS Sintered Disc Filter 4” 304SS Filter Plate V2 1.5”x24/40 304SS Adapter 24/40 Glass Inlet Straight Adapter with hose connection Recommended items: 110MM sized filter paper, 24/40 jointed glass conical flask. For additional information or questions regarding this kit contact our customer support line.

$513.62

-

Jacketed Hemispherical Reducers with 2" Tri-Clamp Drain Port

Jacketed Hemispherical Reducers with 2" Tri-Clamp Drain Port Jacketed Hemispherical Reducers allow the user to circulate water around the bowl and keep extracted material liquefied for easier flow through the bottom port. These jacketed reducers have 1/2" FNPT ports on either side for circulation and a 2" Tri-Clamp port through the bottom of the dish. These reducers are made out of 304 stainless steel with a high polish interior. Specifications Material 304 Stainless Steel Connection Type(s): 12" Tri-Clamp 2" Tri-Clamp (2) 1/2" FNPT

$534.44

-

1" ID Heavy Wall Spiral Wire Reinforced Clear PVC Vacuum Hose

1" ID Heavy Wall Spiral Wire Reinforced Clear PVC Vacuum Hose Crystal clear Phthalate Free PVC compound, formulated with ingredients in compliance with applicable FDA requirements, meets USDA, 3A, NSF, UL, RoHS and USP Class VI criteria. Reinforced with spiraled polyester yarn and longitudinal orange tracer yarns for identification. Key Features: Constructed with Phthalate Free compounds. NSF-51 certified material. Crystal clear - allows visual confirmation of product flow. Longitudinally reinforced to reduce elongation under pressure. Light weight. Self-extinguishing. Non-marking. Silicone-free. Non-conductive. One-piece lengths. Resistant to chemicals (see chemical-resistance chart). Compound hardness 73 ±3 Shore "A". Phthalate Free! Common Applications: Food & beverage dispensing. Deionized water. Liquid food products. Air and water lines. Powdered food products. Potable water transfer. Air breathing lines. Pneumatic lines. Packaging machines. Specifications Series K7130 Sized Code 16 Service Temperature Range 25 to 150°F (-4 to 65°C) Nominal ID 1" (25.4mm) Nominal OD 1.375" (34.9mm) Max Working Pressure @ 70°F (20°C) 100 Psi Max Working Pressure @ 122°F (50°C) 50 Psi Standard Length Coils 100ft Approx. Wt. per Pkg. 44lb Brand Kuri Tec® Packaging Coils Material PVC Min. Bend Radius @ 70°F 1" Type Reinforced Water Supply and Food Grade Hose Reinforcement Material Helically-wound spring steel wire Color Crystal Clear Weight per Foot 0.44lbs/ft Performance Heavy Wall Clear PVC wire reinforced for vacuum

$41.64 - $827.35

-

Steam Distillation Kit

Steam Distillation Steam distillation is the separation of organic compounds at low temperatures by boiling water. It is widely used for essential oils and terpenes because it does not degrade the organic material as a traditional fractional distillation does. Alternatively, steam distillation can extract a diverse array of immiscible substances. You can use steam distillation for “steam stripping” in petroleum refineries and separate commercially important organic compounds, including fatty acids. Our system is composed of a 6-piece glass distillation set up paired with a separatory funnel. Simply fill the boiling flask with water and the material flask with your organic material, then use the heating mantle to boil the water and pass the steam through the material flask. There is a port above the material flask on the U-Tube to insert a thermometer to more closely monitor the process. The steam passing around the material will lower the boiling point on the surface of the plant material and cause the terpenes to boil off at low temperatures. After moving through the U-Tube the steam and terpenes will condense in the graham condenser and drain into the flask below. After filling the flask, simply swap it and drain the contents into the separatory funnel to remove all water. Steam Distillation is beneficial due to the lower boiling point being able to reduce the decomposition of temperature-sensitive compounds. Here’s a look at the key benefits of steam distillation. Key Benefits of Steam Distillation: Streamlined method produces organic solvent-free products Possesses large capacity for processing at the industrial scale Requires no subsequent separation steps Requires less fuel for the steam boiler for extraction of oils Due to its wide application and inexpensive equipment, steam distillation can be a cost-effective investment Kit Includes: 2L Analog Mantle 2L Boiling Flask 2L Material Flask U-Tube 24/40 Thermometer Adapter 24/40 Male Stopper Graham Condenser 500ml Flask 500ml Separatory Funnel BVV™ Lab Stand Three Finger Clamp Boss Head Please Note: for any replacement parts, please contact us. 2L Dual Neck Flask (SKU: STEAM-01-2000ml) 2L Material Flask (SKU: STEAM-02) U-Tube (SKU: STEAM-03) Graham Condenser (SKU: STEAM-04)

$1,110.53

-

20L Neocision ETL Lab Certified Rotary Evaporator

20L Neocision ETL Lab Certified Rotary Evaporator The 20L Neocision ETL Lab Certified Rotary Evaporator is a full-scale system meant to fulfill the needs of large volume production and meet the requirements of a certified laboratory with its ETL certification standards. Featuring an electric lift bath and all PTFE valves for extreme chemical resistance, the 20L Neocision gives users the ability to recover large amounts of solvent in a smaller footprint with highly improved functionality. All Neocision rotovaps feature high-efficiency valves and drain ports making it easy to directly inject solution continuously without the need to stop the system or release vacuum to drain. The temperature and rotation speed are easily controlled from a single digital interface. Our rotovaps are a fraction of the price of more costly systems with the same functionality and evaporation efficiency. To keep your bath heating properly, this unit should only be used with RO or DI water. 10-50L NEO and ECO Rotary Evaporator Diagram Features: ETL Certified for Lab use. Digital temperature and speed control with simple user interface Electric Bath Lift Teflon Coated Bath for corrosion resistance High-efficiency drain port and injection valves Smaller footprint for improved workspace allocation Mobility with locking casters Shorter vapor path for faster evaporation and condensation Direct injection capability for continuous feeding of solution Continuous draining capability without the need to release vacuum or stop the system 1-year warranty on all mechanical parts. Does not include glassware. Model 20L NEOCISION Rotary Evaporator Optimum Ambient Temperature 5~25C / 41~105.8F Glass Material GG-17 High Borosilicate Power (V/Hz) 220-240V 60Hz Single Phase Speed Regulation Digital Step-less Regulation Rotation Speed 0-120 RPM Set Temperature 0-99C / 0-210F Temperature Control Digital Temperature Control Maximum Vacuum Pressure -29.8 inHg Evaporating Flask Capacity 20L (20000ml) Receiving Flask Capacity 10L (10000ml) Condenser Style Main + Auxiliary Vertical Double Helix Evaporation Capacity Alcohol >/= 12 L/H Heater Max Current Draw (Amps) 25 Water Bath Material 304 Stainless Steel Water Bath Size 17.7 x 9.8 in. Lifting Function Electric Lifting Stroke 190mm / 7.5 in. Total Power Consumption (kW) 4.1 Dimensions 49 x 24 x 83 in. Weight 155 lbs Vacuum Connection 10mm / 3/8 in. Barb Condenser Connection 10mm / 3/8 in. Barb Warranty 1 Year excluding glass parts Certifications ETL Rotovap Quick Start Guide This guide gives basic quick start instructions for rotovaps. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs. Clean and assemble unit. Make sure all pieces are cleaned and sterilized using an alcohol solution. Connect chiller to condenser and set to 0C (32F). Always fill a rotovap condenser from the top down (chiller output to top of condenser, chiller input to bottom of condenser). Connect vacuum pump to cold trap and connect cold trap to vacuum port on rotovap. Turn on heat bath and set to 40C (113F). Once heat bath, chiller and cold trap have reached desired temperatures, turn on rotovap motor and set speed to approximately 100 RPM (does not have to be precise). Keep in mind, higher RPM’s will increase evaporation power but also increase heat load. Start vacuum pump and allow vacuum to pull down for a few minutes before injection. Once vacuum has been pulled to a sufficient level (does not have to be precise but should be below 100 Torr), using the injection valve, very slowly inject approximately 500 mL of solution into evaporating flask and then close the valve. Allow this small amount to begin evaporating. You may see the chiller begin to rise in temperature, this is called “priming” the rotovap. Once the temperature stops rising or all liquid is almost completely evaporated, open the injection valve again very slowly so that a small amount of liquid begins to enter the evaporating flask. Do not close injection valve this time but continue to allow solution to enter the evaporating flask. At this point you must try to match the input speed to the output speed. What this means is that you should be injecting the same amount of liquid into the rotovap that is equal to the amount of liquid dripping from the condenser into the receiving flask. You will know that the input speed and output speed are matched because the chiller will remain at a stable temperature. If the chiller begins to rise, then you are injecting too much liquid. Dial back the valve until the chiller stabilizes. Once everything is stabilized, you may walk away from the rotovap if necessary. Check every so often to make sure temperatures remain stable and evaporation continues efficiently. ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Note: This item will ship by freight only.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$9,994.79

-

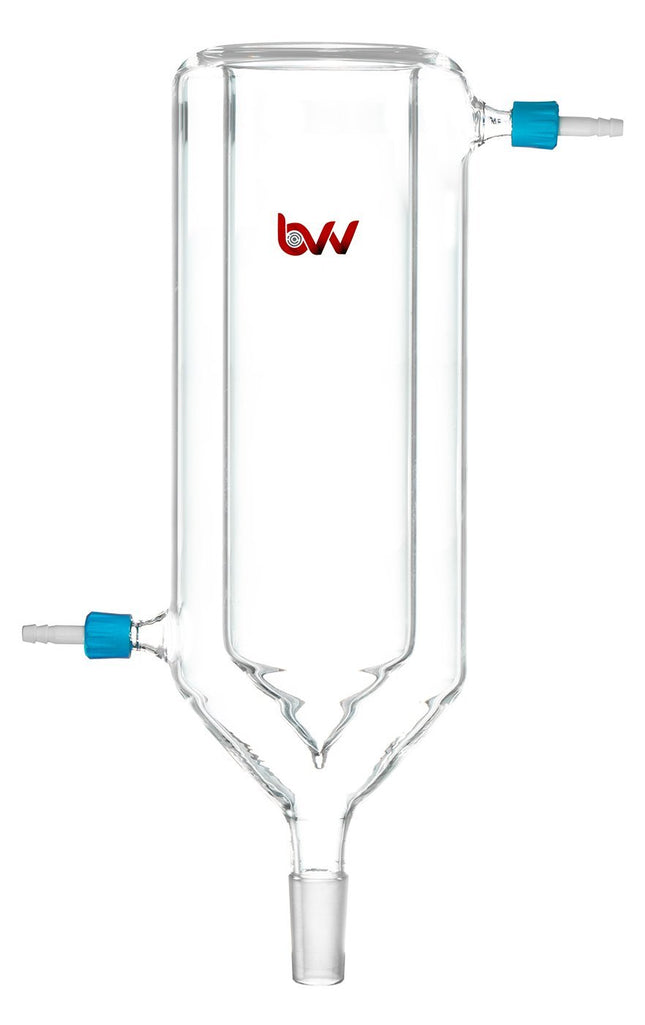

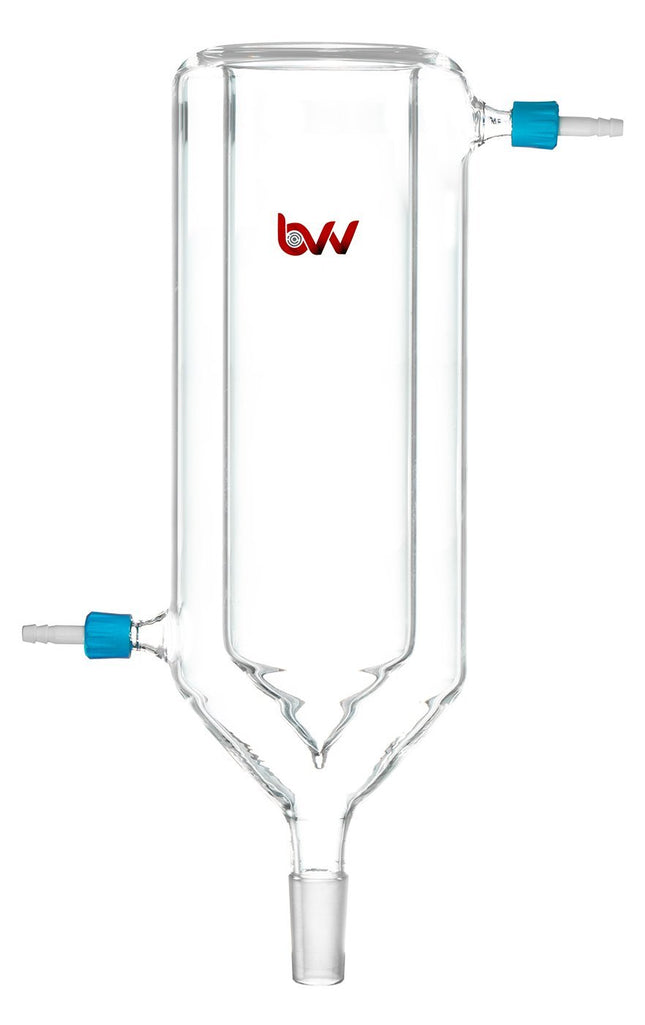

Dewar Glass Cold Trap

BVV™ Dewar Glass Cold Trap This dewar style glass is designed for maximum vapor condensation and it also has a 24/40 bottom joint and (2) GL-14 8mm Hose Barbs *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement.

$347.04 $291.51

-

Filter Bag for Petroleum Oil and Organic Solvents

These filter bags come in a wide variety of micron levels and are specifically designed for BVV Pressure Filtration Systems. They are made of nylon fabric and range from 1 micron to 100 micron. For use with the following systems: Cryogenic 45L Centrifuge Extractor Kit Pressure Filtration System - 6 x 28 Trade Size #8 *Note: metal mesh cage not included - for reference only.

$69.41 - $81.90

-

Welch Vacuum - Gardner Denver Welch Explosion Proof CRVpro4 Direct Drive Rotary Vane Vacuum Pump

Welch Explosion Proof CRVpro4 Direct Drive Rotary Vane Vacuum Pump ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details Explosion Proof Motor 110-120V/208-240V 60Hz 1 Phase The new CRVpro family of direct drive vacuum pumps offers increased reliability and longer service interval vs. other direct drive rotary vane vacuum pumps. The CRVpro family consumes up to 36% less oil than comparable pumps. Three features drive these benefits: Runs 10°C cooler than comparable pumps. Slows corrosion. Has a 40% larger oil capacity than comparable pumps. Dilutes aggressive chemicals. Has a chemical resistant coating in the oil case and pump module. Protects non-moving parts. The CRVpro family includes all the features you'd expect in a direct drive rotary vane pump: gas ballast, forced oil lubrication, anti-suckback mechanism and thermal overload protection. Suitable applications include freeze drying, degassing, vacuum ovens and concentrators. 3046E-01 comes with an explosion proof motor. Conduit wiring installation required. No cord, plug, or switch provided. Direct drive pumps are not recommended for filtration, aspiration, drying electrophoresis gels, or other applications requiring sustained operation above 30 torr. Specifications Application CRVpro4 Free Air Displacement @ 60 Hz, cfm (L/min) 2.8 (78) Free Air Displacement @ 50 Hz, m³/hr (L/min) 4 (67) Ultimate Pressure, torr (mbar) 5x10⁻⁴ (4x10⁻⁴) Noise Level, dBA 50 Motor Speed, RPM, @60Hz, @50Hz 1740 (1450) Motor Power, HP (kW) 0.4 (0.5) Oil Capacity, mL 1150 Connection Flanges NW 16 Inlet Hose Connection* 5/8" to 3/4" Weight, lbs (kg) 46.3 (21) Dimensions, LxWxH, in (mm) 18.2x6.1x9.1 (463x157x230)

$6,954.71

-

Chemglass Chemglass Caps With Aperture GL Threads High Temperatures

Chemglass Caps With Aperture GL Threads High Temperatures Open top cap for use with GL screw threads. Cap is made from PPS (polyphenylsiloxan) and will withstand temperatures up to 250°C.

$15.27

-

Acetone 99%

BVV™ High Purity Acetone 99% (Note: Container style and color may vary) Explore our top-quality Acetone, a versatile solvent that meets the highest standards of quality and purity. Our Acetone is ideal for a wide range of applications, whether you're in the pharmaceutical, cosmetic or industrial sector. With its exceptional solvent properties, Acetone serves as a reliable solution for cleaning, degreasing, and dissolving various substances. Our Acetone is carefully sourced to ensure consistency and effectiveness, making it a popular choice for professionals and businesses alike. Our Acetone is subjected to stringent quality control measures, ensuring exceptional purity that's perfect for various processes, from extraction to cleaning and stripping applications. Discover the exceptional performance and dependability of our Acetone, specially created to surpass your rigorous requirements. Unleash the potential of this top-notch solvent, and enhance the efficiency and efficacy of your processes to a whole new level. Opt for our Acetone for unparalleled outcomes and make the most of its adaptability in a variety of crucial tasks. Chemical Formula: C3H6O Molecular Weight: 58.080 g·mol−1 CAS Registry Number: 67-64-1 Appearance Colorless Liquid Odor: Pungent, fruity Density 0.7845 g/cm3 (25 °C) Boiling Point: 56.08 °C /132.94 °F Solubility in water: Miscible GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H302, H319, H336, H373 GHS Precautionary Statements P210, P235, P260, P305+P351+P338 UN Identification Number: 1090 Proper Shipping Name: Acetone Transport Hazard Class: 3 Packing Group: II DOT Placard: What is Acetone? Acetone is a clear, colorless, and highly flammable liquid with a distinctive sweet, fruity odor. It is a simple organic compound with the chemical formula C3H6O, belonging to the ketone family. Acetone is widely used as a solvent in various industries due to its excellent solubility and fast evaporation rate. In addition to its solvent properties, acetone has many other applications. It is commonly used as a cleaning agent, degreaser, and paint thinner. It is also a key ingredient in nail polish removers and some cosmetic products. Acetone is utilized in the production of plastics, fibers, resins, and various chemicals. Additionally, it serves as a fuel additive and is used for scientific and laboratory purposes. As a highly versatile and effective solvent, acetone plays a vital role in numerous industrial, commercial, and domestic applications, making it an essential component in various processes. What Are The Properties of Acetone? Acetone is a colorless, volatile, and highly flammable liquid with several notable properties: Physical State: Acetone is a liquid at room temperature and pressure, with a boiling point of 132.8F/56C and a melting point of -94.9°C (-138.8°F). Odor: It has a distinct and characteristic odor that is often described as sweet or fruity. Solubility: Acetone is highly soluble in water, alcohols, ethers, and many other organic solvents. This high solubility contributes to its effectiveness as a cleaning agent and solvent. Density: The density of acetone is about 0.79 g/cm³, making it less dense than water. Vapor Pressure: Acetone has a relatively high vapor pressure, which means that it readily evaporates into the air at room temperature. Flammability: Acetone is highly flammable and has a low flash point of -20.8°C (-5.4°F). This means that it can easily ignite when exposed to an open flame, spark, or other sources of ignition. Reactivity: Acetone is a reactive compound and can participate in various chemical reactions. It can react with strong acids, bases, and oxidizing agents. Acidity: Acetone is a weak acid, and its aqueous solutions can exhibit slightly acidic properties. Miscibility: Acetone is miscible with water and many organic solvents. This property makes it suitable for various applications in different industries. Polarity: Acetone is a polar solvent, meaning that it has a partial positive and partial negative charge distribution within its molecule. This polarity allows it to dissolve a wide range of polar and nonpolar compounds. Boiling Point: Acetone has a relatively low boiling point 132.8F/56C, which makes it easy to evaporate and separate from other substances during distillation processes. Evaporation Rate: Acetone has a fast evaporation rate, which makes it suitable for applications where rapid drying is necessary. It's important to note that acetone's properties contribute to its versatility and wide range of applications in various industries, including cleaning, manufacturing, laboratory work, cosmetics, and more. However, due to its flammability and reactivity, proper safety precautions should always be followed when working with acetone. What Is The Structure Of Acetone? The chemical structure of acetone consists of three atoms: one carbon (C) atom, one oxygen (O) atom, and three hydrogen (H) atoms. It is a simple organic compound with the molecular formula C3H6O. The structural formula of acetone can be represented as: In this structural representation: The central carbon (C) atom is bonded to two hydrogen (H) atoms and one oxygen (O) atom. The oxygen atom is double-bonded to the central carbon atom, forming a carbonyl group (C=O). The remaining valences of the carbon atom are filled by single bonds to the two hydrogen atoms. This arrangement of atoms gives acetone its distinctive chemical properties, including its solubility in water, high vapor pressure, and reactivity as a solvent and chemical reagent. How Is Acetone Produced? Acetone is produced through various industrial processes, with the most common method being the catalytic dehydrogenation of isopropanol. Here's an overview of the primary process used to produce acetone: 1. Dehydrogenation of Isopropanol: The most widely used method to produce acetone is the dehydrogenation of isopropanol, also known as the "cumene process." This process involves several steps: a. Production of Cumene: Cumene (isopropylbenzene) is produced from benzene and propylene in the presence of a catalyst such as aluminum chloride. This results in the formation of cumene and hydrogen chloride as byproducts. b. Oxidation of Cumene to Cumene Hydroperoxide: Cumene is then oxidized using air to form cumene hydroperoxide, typically using a catalytic process with acid or base catalysts. c. Cleavage of Cumene Hydroperoxide: Cumene hydroperoxide is cleaved using acid catalysts to yield phenol and acetone. This reaction results in the simultaneous production of phenol, which is used as a valuable chemical in various industries. d. Distillation and Separation: The mixture of phenol and acetone is then separated using distillation techniques. Acetone is obtained as a separate product from the mixture. 2. Other Processes: Apart from the cumene process, there are alternative methods for acetone production, including: a. Propylene Oxidation: Acetone can be produced through the direct oxidation of propylene using air or oxygen as the oxidizing agent. This method yields propylene oxide and acetone as products. b. Acetaldehyde Condensation: In this method, acetaldehyde is condensed and dehydrated to form acetone. This process is less common compared to the cumene process. c. Bio-based Production: Research is ongoing to develop bio-based methods of acetone production, using renewable resources like biomass or microorganisms that can convert sugars into acetone. d. Repurposing Byproducts: Acetone can also be obtained as a byproduct in various industrial processes, such as the production of phenol, where acetone is produced alongside phenol from cumene hydroperoxide. The cumene process remains the most dominant and economical method for producing acetone on an industrial scale. The choice of production method depends on factors such as availability of feedstocks, economics, environmental considerations, and desired product yields. Is Acetone Safe? Acetone is generally recognized as safe (GRAS) when used in appropriate amounts and under proper conditions. However, like any chemical substance, it should be handled with care and used according to safety guidelines. Here are some important points to consider regarding the safety of acetone: Ventilation: Acetone has a strong odor and can release fumes that may be irritating to the eyes, nose, and throat. When using acetone, make sure you are in a well-ventilated area to minimize inhalation of the fumes. Skin Contact: Acetone can be drying to the skin and may cause irritation, especially with prolonged or frequent exposure. It's advisable to wear gloves when handling acetone to protect your skin. Eye Contact: Avoid getting acetone in your eyes, as it can cause irritation and discomfort. If accidental eye contact occurs, rinse your eyes thoroughly with water and seek medical attention if irritation persists. Ingestion: Acetone is not intended for ingestion and should not be consumed. Ingesting acetone can be harmful and may lead to adverse health effects. Flammability: Acetone is highly flammable and should be kept away from open flames, sparks, and heat sources. Store acetone in a cool, dry place and away from direct sunlight. Sensitive Individuals: Some individuals may be more sensitive to the effects of acetone, experiencing skin irritation, allergic reactions, or respiratory discomfort. If you have a history of sensitivities or allergies, exercise caution when using acetone. Use as Directed: When using acetone for specific applications such as nail polish removal, adhesive removal, or cleaning, follow the recommended instructions on the product label or recipe. Avoid excessive or prolonged exposure. Alternative Options: If you are concerned about the potential risks of using acetone, you can consider using alternative products that are specifically formulated for the task at hand. For example, there are acetone-free nail polish removers available that may be gentler on the nails and cuticles. If you have specific health concerns or are unsure about the safety of using acetone, it's always a good idea to consult with a healthcare professional or seek advice from experts in the field. Additionally, reading and following safety information provided on product labels and material safety data sheets (MSDS) is crucial to ensure safe handling and use of acetone and other chemicals. What are the hazards of Acetone? Acetone is a commonly used chemical solvent, but like any chemical substance, it poses certain hazards that need to be considered when handling and using it. Some of the hazards associated with acetone include: Flammability: Acetone is highly flammable and can catch fire easily. Its low flash point makes it volatile and prone to ignition when exposed to open flames, sparks, or heat sources. It's important to store and use acetone away from potential sources of ignition. Inhalation Hazards: Acetone can release strong vapors that are irritating to the respiratory system. Prolonged or repeated inhalation of these vapors can lead to headaches, dizziness, nausea, and respiratory discomfort. Adequate ventilation is essential when using acetone to minimize exposure to its fumes. Skin and Eye Irritation: Acetone can be drying to the skin and may cause irritation or redness upon direct contact. It can also irritate the eyes and lead to discomfort if splashed or accidentally introduced into the eyes. Central Nervous System Effects: Acetone vapor exposure can affect the central nervous system, leading to symptoms like dizziness, confusion, and even unconsciousness at high concentrations. Toxic Effects: While acetone is generally considered to have low toxicity, exposure to large amounts or prolonged exposure can have toxic effects on the body. Ingesting acetone can lead to nausea, vomiting, abdominal pain, and even coma in severe cases. Health Risks: Long-term or chronic exposure to acetone can potentially have adverse health effects, including damage to the liver, kidneys, and respiratory system. Repeated skin contact can cause dryness and irritation. Environmental Impact: Improper disposal of acetone can lead to environmental contamination. Acetone is volatile and can easily evaporate into the air, contributing to air pollution. It can also be harmful to aquatic life if introduced into water bodies. Allergic Reactions: Some individuals may be sensitive or allergic to acetone, experiencing skin reactions or respiratory discomfort even at lower concentrations. It's important to take appropriate safety precautions when using acetone, including wearing protective gear such as gloves and safety goggles, working in a well-ventilated area, and avoiding open flames or heat sources. If working with acetone in an industrial or laboratory setting, it's crucial to follow established safety protocols and guidelines, as well as refer to the material safety data sheet (MSDS) provided by the manufacturer. Overall, while acetone is a valuable solvent with various applications, it should be handled with care and respect for its potential hazards. If you have any concerns or questions about the safe use of acetone, it's recommended to consult with experts in the field or seek guidance from health and safety professionals. How Flammable Is Acetone? Acetone is highly flammable and poses a significant fire and explosion hazard. It has a low flash point of -20.8°C (-5.4°F), which means that it can easily vaporize and form flammable mixtures with air at temperatures above its flash point. Acetone's wide flammability range (2.5% to 12.8% in air) indicates that even small concentrations of acetone vapor in the air can be ignited by a spark, open flame, or other sources of ignition. Due to its low flash point and flammable nature, acetone should be handled with extreme caution and stored away from sources of heat, sparks, and flames. When using acetone, it's important to follow proper safety practices, such as working in well-ventilated areas, using appropriate protective equipment, and avoiding activities that can generate sparks or heat. Acetone's high flammability also makes it necessary to take precautions when storing and transporting the solvent. Flammable liquids like acetone should be stored in approved containers and away from incompatible materials, such as oxidizing agents, to prevent potential chemical reactions and fires. It's essential to be aware of acetone's flammability and take all necessary safety measures to minimize the risk of fire and ensure a safe working environment when handling this solvent. How Is Acetone Used? Acetone is a versatile organic compound with a wide range of industrial, commercial, and household applications due to its excellent solvent properties and low toxicity. Here are some common uses of acetone: Solvent: Acetone is primarily known for its effectiveness as a solvent. It dissolves a variety of substances, making it useful for cleaning, degreasing, and removing residues from surfaces, equipment, and materials. It is commonly used in industrial settings to clean machinery and equipment. Nail Polish Remover: Acetone is a key ingredient in many nail polish removers. It effectively dissolves nail polish and helps remove it from the nails. Paint and Coating Removal: Acetone is used to remove paint, varnishes, lacquers, and other coatings from surfaces like wood, metal, and plastic. It's particularly useful for removing paint spills or overspray. Adhesive Remover: Acetone can be used to soften and remove adhesives, glues, and tapes from surfaces without causing damage. Chemical Intermediate: Acetone is used as an intermediate in the production of other chemicals. It's a precursor in the manufacturing of products like methyl methacrylate, bisphenol A (used in polycarbonate plastics and epoxy resins), and isopropyl alcohol. Laboratory Reagent: Acetone is used in laboratories as a reagent in various chemical reactions and as a solvent for analytical techniques like chromatography. Thinner for Paints and Inks: Acetone is used as a thinning agent for paints, inks, and varnishes to adjust their viscosity and improve their application. Cosmetics and Personal Care Products: Apart from nail polish remover, acetone is used in the production of cosmetics, skincare products, and perfumes. Medical and Pharmaceutical Uses: Acetone is used in some medical and pharmaceutical applications, such as cleaning medical equipment and removing residues from glassware in laboratories. Cleaning Agent: Acetone is effective at removing greasy or sticky residues from various surfaces. It's often used for cleaning electronics, removing ink stains, and cleaning glass surfaces. Fuel Additive: In some instances, acetone is used as an additive in fuel to improve its combustion efficiency, although this application is less common. Aerosol Propellant: Acetone's ability to vaporize quickly makes it useful as a propellant in aerosol products like air fresheners, deodorants, and cleaning sprays. It's important to note that while acetone is versatile and widely used, it should be handled with care due to its flammable nature. Proper ventilation and safety precautions should be taken when using acetone in any application. How Is Acetone Used In Extraction? Acetone is occasionally used in extraction processes, particularly in the field of chemistry and research, where it serves as a solvent to extract certain compounds from various materials. However, it's important to note that acetone has limitations and risks when used for extraction, and its use should be approached cautiously and with proper safety measures. Here's how acetone can be used in extraction processes: Extraction of Essential Oils and Fragrances: Acetone can be used to extract essential oils and fragrances from plant materials. The solvent's low boiling point allows it to evaporate quickly, leaving behind the extracted aromatic compounds. Extraction of Active Compounds: Acetone can be used to extract active compounds from natural sources, such as medicinal plants or herbs. The solvent's polarity can help dissolve and extract specific compounds like alkaloids, flavonoids, and phenolic compounds. Extraction of Lipids and Fats: Acetone is sometimes used to extract lipids and fats from materials like seeds, nuts, or plant tissues. Its ability to dissolve fats and oils makes it suitable for this purpose. Research and Analysis: In laboratories, acetone is sometimes used as a solvent to prepare samples for analysis by techniques like chromatography or spectroscopy. It can help solubilize compounds of interest for further investigation. Cleaning and Preparing Samples: Acetone can be used to clean surfaces and equipment in preparation for various chemical processes, ensuring that surfaces are free from contaminants that could affect the extraction. Recrystallization: Acetone can also be used for recrystallization processes in the lab, where impure solid compounds are dissolved in acetone and then allowed to crystallize out in a more purified form. It's important to exercise caution when using acetone in extraction processes: Flammability: Acetone is highly flammable and should never be used near open flames or in poorly ventilated areas. Toxicity: Acetone can be harmful if inhaled, ingested, or absorbed through the skin. Proper personal protective equipment (PPE) should be worn, and work should be conducted in a well-ventilated area. Chemical Compatibility: Acetone may not be suitable for extracting all types of compounds, as it can degrade certain materials and might not effectively extract specific compounds. Due to these risks and limitations, alternative solvents or extraction methods are often preferred in various extraction processes. When considering using acetone in an extraction, it's crucial to assess the specific requirements of the extraction and ensure that proper safety measures are in place. What Gaskets Are Compatible With Acetone? Acetone is a powerful solvent that can degrade certain materials, including both silicone and Nitrile/BUNA-N gaskets. When choosing gaskets for use with acetone, it's essential to select materials that are resistant to the solvent's effects to ensure safe and effective sealing. The following gasket materials are generally considered compatible with acetone: PTFE (Polytetrafluoroethylene): PTFE gaskets, also known as Teflon gaskets, are highly resistant to acetone and a wide range of other chemicals. They have excellent chemical stability and can withstand the corrosive nature of acetone. Viton (Fluoroelastomer): Viton gaskets are resistant to a variety of chemicals, including acetone. They are often used in applications where high-temperature and chemical resistance are required. EPDM (Ethylene Propylene Diene Monomer): EPDM gaskets are compatible with acetone for short exposure periods. However, their compatibility may be limited in extended contact with acetone or under specific conditions. It's important to note that the compatibility of gasket materials with acetone can vary based on factors such as temperature, concentration, and exposure duration. Before selecting gaskets for use with acetone, it's advisable to also consider the temperature and pressure range of your application to ensure that the chosen material is suitable for your specific application. Additionally, when working with acetone or any other chemical, it's crucial to follow proper safety protocols, including wearing appropriate personal protective equipment (PPE), working in a well-ventilated area, and observing all relevant safety guidelines. How do I clean with Acetone? Cleaning with acetone involves a few simple steps, but it's important to exercise caution due to its flammable nature and strong odor. Here's how to clean with acetone safely and effectively: Materials Needed: Acetone Clean, lint-free cloth or paper towels Ventilated area or protective mask Gloves Eye protection Steps: Choose a Well-Ventilated Area: Before you begin, make sure you're in a well-ventilated space. Acetone has strong fumes, so working outdoors or in a well-ventilated room is recommended. If ventilation is limited, consider wearing a protective mask and eye protection. Put on Protective Gear: While not always necessary for small cleaning tasks, wearing gloves and eye protection can help prevent skin and eye irritation. Test in an Inconspicuous Area: Before using acetone on a larger surface, test it in a small, inconspicuous area to ensure it doesn't damage or discolor the material you're cleaning. Apply Acetone: Moisten a clean, lint-free cloth or paper towel with a small amount of acetone. Gently blot or rub the area you want to clean. Start with a light touch and gradually increase pressure if needed. Avoid scrubbing vigorously, as this could damage surfaces or spread stains. Wipe Clean: As you blot or rub, you'll notice that dirt, residue, or certain stains are lifted onto the cloth. Continue until the area looks clean. For stubborn stains, you may need to repeat the process or use a slightly more concentrated amount of acetone. Dry the Area: After cleaning, use a separate clean cloth or paper towel to dry the area thoroughly. This helps prevent any remaining acetone from evaporating and leaving streaks. Dispose of Materials Safely: Dispose of used cloths, paper towels, and other materials soaked in acetone responsibly. Place them in a sealed container or bag and dispose of them according to your local regulations for hazardous waste. Wash Hands: After you're finished, wash your hands with soap and water to remove any traces of acetone. Important Tips: Acetone can damage certain plastics, paints, and finishes, so always test it in an inconspicuous area first. Do not use acetone on leather, acetate fabrics, or materials with printed designs, as it can cause fading or damage. Keep acetone away from open flames, sparks, or heat sources, as it is highly flammable. Always work in a well-ventilated area or use appropriate personal protective equipment. Remember that acetone is a powerful solvent, so it's best suited for specific cleaning tasks like removing certain adhesives, paint splatters, or sticky residues. If you're uncertain about using acetone on a particular material or surface, consider seeking professional advice or trying an alternative cleaning method. How Do I Make My Own Acetone-Based Nail Polish Remover? Cleaning with acetone involves a few simple steps, but it's important to exercise caution due to its flammable nature and strong odor. Here's how to clean with acetone safely and effectively: Materials Needed: Acetone Clean, lint-free cloth or paper towels Ventilated area or protective mask Gloves (optional) Eye protection (optional) Steps: Choose a Well-Ventilated Area: Before you begin, make sure you're in a well-ventilated space. Acetone has strong fumes, so working outdoors or in a well-ventilated room is recommended. If ventilation is limited, consider wearing a protective mask and eye protection. Put on Protective Gear: While not always necessary for small cleaning tasks, wearing gloves and eye protection can help prevent skin and eye irritation. Test in an Inconspicuous Area: Before using acetone on a larger surface, test it in a small, inconspicuous area to ensure it doesn't damage or discolor the material you're cleaning. Apply Acetone: Moisten a clean, lint-free cloth or paper towel with a small amount of acetone. Gently blot or rub the area you want to clean. Start with a light touch and gradually increase pressure if needed. Avoid scrubbing vigorously, as this could damage surfaces or spread stains. Wipe Clean: As you blot or rub, you'll notice that dirt, residue, or certain stains are lifted onto the cloth. Continue until the area looks clean. For stubborn stains, you may need to repeat the process or use a slightly more concentrated amount of acetone. Dry the Area: After cleaning, use a separate clean cloth or paper towel to dry the area thoroughly. This helps prevent any remaining acetone from evaporating and leaving streaks. Dispose of Materials Safely: Dispose of used cloths, paper towels, and other materials soaked in acetone responsibly. Place them in a sealed container or bag and dispose of them according to your local regulations for hazardous waste. Wash Hands: After you're finished, wash your hands with soap and water to remove any traces of acetone. Important Tips: Acetone can damage certain plastics, paints, and finishes, so always test it in an inconspicuous area first. Do not use acetone on leather, acetate fabrics, or materials with printed designs, as it can cause fading or damage. Keep acetone away from open flames, sparks, or heat sources, as it is highly flammable. Always work in a well-ventilated area or use appropriate personal protective equipment. Remember that acetone is a powerful solvent, so it's best suited for specific cleaning tasks like removing certain adhesives, paint splatters, or sticky residues. If you're uncertain about using acetone on a particular material or surface, consider seeking professional advice or trying an alternative cleaning method. What Is The Average Amount Of Acetone Used in Nail Polish Remover? The average amount of acetone used in commercial nail polish remover products typically ranges from 30% to 50%. This means that the nail polish remover solution contains 30% to 50% acetone, along with other ingredients such as water, emollients, and fragrances. The exact percentage can vary depending on the brand and formulation of the nail polish remover. When making your own nail polish remover at home, you can use pure acetone or a solution with a similar acetone concentration. Keep in mind that using pure acetone can be harsh on your nails and cuticles, potentially causing dryness and irritation with frequent use. It's a good idea to experiment with different acetone concentrations and observe how your nails and skin react to find the right balance between effective nail polish removal and gentle care for your nails. How Do you Dispose of Acetone? Disposing of acetone properly is important to ensure environmental and personal safety. Here are the steps to follow for proper acetone disposal: Check Local Regulations: Before disposing of acetone, check your local regulations and guidelines for hazardous waste disposal. Different regions may have specific requirements and disposal methods. Use a Secure Container: Transfer the acetone to a tightly sealed, labeled, and non-reactive container. Glass or metal containers with a secure lid are recommended. Label the Container: Clearly label the container with the contents ("Acetone"), the hazard symbol, and any other relevant information. Do Not Mix: Do not mix acetone with other chemicals, as this could lead to hazardous reactions. Contact Local Waste Disposal Facility: Contact your local hazardous waste disposal facility or municipality to inquire about drop-off locations and collection programs for hazardous materials. Do Not Pour Down the Drain: Do not pour acetone down the drain, toilet, or any other water source, as it can contaminate water systems and harm the environment. Evaporate in a Controlled Setting: If allowed by local regulations, you can let a small amount of acetone evaporate in a well-ventilated outdoor area. Ensure it's away from open flames, sparks, or ignition sources. Recycle or Reuse: Some regions may offer recycling or reclamation programs for acetone or other solvents. Research if any such programs are available in your area. Professional Disposal: If you have a large amount of acetone or are uncertain about the proper disposal method, consider contacting a professional hazardous waste disposal service. Remember, improper disposal of hazardous materials like acetone can harm the environment, human health, and local communities. Always prioritize safety and follow the regulations set by your local authorities for proper disposal. Acetone 99% Safety Data Sheet (SDS) Acetone 99% Certificate of Analysis (COA)

$23.60 - $832.90

-

316SS FNPT Full Bore Ball Valve -40F to 450F

316SS FNPT Full Bore Ball Valve (Compare to Milwaukee 10 Series Ball Valves) This BVV™ 316 stainless steel full bore ball valve is a fire safe ball valve and is 1 piece ball valve construction. It also features a straight body style with Female NPT x Female NPT threaded connections with one side being pinned into place for zero movement during installation. The fire safe ball valve features a maximum pressure rating of 2000 PSI CWP and has a blowout proof stem made of 316SS and the temperature range of this ball valve is -40F° to 450F°. Standard: ASTM A351 Pressure Tested in compliance with API 598 Ninth Edition 2009: Sec.5 and Sec.6 Technical Data Sheet Valve Specifications Sizes Available: 1/4" FNPT 3/8" FNPT 1/2" FNPT Pressure Rating 2000 WOG Temperature Range -40 to 450F° Sizes Available: 1" (Fits 1.5" Tri-Clamp) Torque Specifications Do not Exceed 14.46ft-lbs when tightening.(Note: Overtightening the valve can cause damage to the pin. Doing this will void the valve warranty.) Valve Materials: Body 316SS / CF8M Ball 316 Stainless Steel Stem 316 Stainless Steel Stem Nut 304 Stainless Steel Insert 316 Stainless Steel Seat PTFE / Dyneon TFM1600 Thrust Washer PTFE / Dyneon TFM1600 Stem Packing PTFE / Dyneon TFM1600 Handle 304 Stainless Steel Handle Cov VINYL GRIP Handle Washer (1/2") 304 Stainless Steel Handle Nut 304 Stainless Steel Belleville Washer 304 Stainless Steel PIN 304 Stainless Steel

$91.62

-

Agilent Agilent IDP-15, 9 CFM, Dry Scroll Vacuum Pump

Agilent IDP-15, 9 CFM, Dry Scroll Vacuum Pump Overview The new Agilent IDP-15 dry scroll pump is designed for extremely quiet (<50dBA) and low vibration operation, delivering a peak pumping speed of 9 cfm at 60Hz.With a single-sided scroll design it offers fast, easy yearly maintenance and low cost of ownership. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. Specification Base pressure (50 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Base pressure (60 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Dimensions (WxHxL) 13.1 in x 14.3 in x 19.1 in Exhaust Connection NW16 Height 14.3 in Inlet Connection NW25 Input Voltage 220-230 VAC 100-115 Length 19.1 in Noise Level 50 dB(A) Pumping Speed (50 Hz) 12.8 m3/h 214 L/min 7.5 CFM Pumping Speed (60 Hz) 15.4 m3/h 256 L/min 9.1 CFM Width 13.1 in

$13,191.73 - $13,920.52

-

10L Premium Short Path Distillation Turnkey System

10L Premium Short Path Distillation Turnkey System This unit carries a 2 day lead time. (Note: Stainless Steel Table NOT Included.) The 10L Premium Short Path Distillation Turnkey System features our USA made P10 Distillation Head. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Kangaroo digital thermometer which is very rugged and reliable. You will also receive a Ribbed Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The 10L Neo Kit Includes: 10L Short Path Distillation Kit including glassware, labware, and P10 Distillation Head. 10L Digital Heating and Stirring Mantle. Polyscience 15 Liter Advanced Digital Heated Circulator BVV™ 21.2CFM Pro Series Corrosion Resistant Vacuum Pump Valved Vacuum Adapter. Ribbed Dewar Style Glass Cold Trap. Kangaroo Digital Thermometer. Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** ***Note: All units are inspected for broken glass or parts before unit is shipped. If unit arrives damaged or glass is broken (this does not include minor imperfections or scuffs in glassware), Customer MUST contact BVV™ within 3 days of delivery to file a claim and receive a replacement part. If customer DOES NOT contact BVV™ within 3 days of delivery responsibility for replacement parts falls on the customer and they must pay for replacement pieces.*** ***Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.***

$16,796.79

-

Neocision 20L Neocision Dual Short Path Distillation Turnkey System

20L Neocision Dual Short Path Distillation Turnkey System This unit carries a 2 day lead time. (Note: This kit does NOT include the stainless steel table.) The 20L Neocision Distillation Turnkey Setup features our Dual USA made P10V6 Distillation Heads. Every component in this distillation kit is made for precision, throughput, and repeatable results. You will also receive Dual Dewar Style Ribbed Glass Cold Traps to keep all volatiles and solvents out of your vacuum system. This Turnkey Setup gives you everything needed to perform distillation at the highest level. The 20L Neo Kit Includes: 20L Neocision Kit with glassware, labware, and Dual P10V6 Distillation Heads. BVV 15 Liter Advanced Digital Heated Circulator Choice of Vacuum Pump KF-25 Bellow Y Manifold Dual Ribbed Dewar Style Glass Cold Trap Non-Mercury Glass Thermometers 20L Digital Heating and Stirring Mantle Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in the boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$18,046.14 - $23,598.80

-

Neocision 20L Neocision Dual Head Short Path Distillation Kit

20L Neocision Dual Head Short Path Distillation Kit This unit carries a 2 day lead time. (Note: This kit does NOT include the stainless steel table.) The 20L Neocision Distillation Kit Setup features our Dual P10V6 Distillation Heads and USA made glass. Every component in this distillation kit is made for precision, throughput, and repeatable results. You will also receive Dual Dewar Style Ribbed Glass Cold Traps to keep all volatiles and solvents out of your vacuum system. This kit gives you the essentials of a short path distillation system and allows you to add a pump and temperature control system of your choosing. The 20L Neo Kit Includes: 20L Neocision Kit with glassware, labware, and Dual P10V6 Distillation Heads. KF-25 Bellow Y Manifold Dual Ribbed Dewar Style Glass Cold Trap Non-Mercury Glass Thermometers 20L Digital Heating and Stirring Mantle Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in the boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$9,439.52 - $9,717.15

-

10L Premium Short Path Distillation Kit with P10 Distillation Head

10L Short Path Distillation Kit with P10 Distillation Head This unit carries a 2 day lead time. (Note: Stainless Steel Table NOT Included.) The 10L Short Path Distillation Kit features our USA made P10 Distillation Head. Every component in this turnkey is made for precision, throughput, and repeatable results. Also included the Kangaroo digital thermometer which is very rugged and reliable. You will also receive a Ribbed Dewar Style Glass Cold Trap to keep all volatiles and solvents out of your vacuum system. This Kit gives you the basic necessities of a short path distillation system and allows you to add on a temperature control system and vacuum pump to fit your needs. The 10L Neo Kit Includes: 10L Short Path Distillation Kit including glassware, labware, and P10 Distillation Head. 10L Digital Heating and Stirring Mantle. Valved Vacuum Adapter. Ribbed Dewar Style Glass Cold Trap. Kangaroo Digital Thermometer. Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$5,691.48

-

Mastercool 1/4" FNPT Vacuum Pump Exhaust Adapter

Mastercool 1/4" FNPT Vacuum Pump Exhaust Adapter This fitting allows the user to connect a 1/4" NPT fitting to the exhaust for the desired application such as a carbon exhaust filter. It is made of brass and comes with a Viton O-ring. This item will also fit VE115 Vacuum pumps

$20.82

-

BVV/CPS 1/4" FNPT Vacuum Pump Exhaust Adapter

BVV/CPS 1/4" FNPT Vacuum Pump Exhaust Adapter This fitting allows the user to connect a 1/4" NPT fitting to the exhaust for the desired application such as a carbon exhaust filter. It is made of steel and comes with a Viton O-ring.

$27.76

-

Welch Vacuum - Gardner Denver Welch DryFast Ultra Diaphragm Pump 2042

Welch DryFast Ultra Diaphragm Pump 2042 This item may carry up to a 5 day lead time. Product Details Chemical Resistant Oil-Free Tuneable Vacuum Welch DryFastTM PTFE Diaphragm Vacuum Pumps enable precise vacuum control for organic evaporations with exclusive Advanced Vapor Management (AVM). Oil-Free, portable, chemical resistant, 2 head diaphragm design simplifies maintenance. Choose from seven dry PTFE vacuum pump models with flows up to 70 L / min and adjustable vacuum down to 2 Torr. Economical DryFastTM vacuum pumps are perfect for tough lab applications. Specifications Model Number 2042 Application Rotary Evaporation/Distillation (lowvolatility solvents <160oC B.P., ~ 2 Liter), Centrifugal Concentrators, Vacuum ovens (mid- size), pumping harsh vapors & gases Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 1.2(35) Free Air Displacement m3/hr (l/min.) @50Hz 1.75(29) Ultimate Pressure 2(2.7) Maximum Vacuum 29.85 Motor Horsepower (watts) 1/5(150) Adjustable Vac. / Gas Ballast Yes Tubing Needed 1/4(7) Intake Thread NPT M14(1/8) Overall Dimensions LxWxH in. (cm) 13.8x6.8x8.8(35.2x7.2x22.3) Ship Weight 25(11.3) Shipping Carton Dimensions LxWxH in. (cm) 21x14x15 (52x35x37) Adjustable Vacuum Knob

$6,281.45

-

Welch Vacuum - Gardner Denver Welch WOB-L Pump 2546

Welch WOB-L Pump 2546 Product Details Economical Oil Free Adjustable Vacuum / Pressure Reliable WOB-L Piston pumps are perfect for many common laboratory vacuum applications. Features: Vacuum and Pressure - to 60 Torr (27.6"Hg). Includes Vacuum and Pressure Regulators and Gauges - simple to adjust and monitor vacuum level and delivery pressure. Inlet Water Trap - float ball rises to seal off pump from accidental ingestion of water. Muffler quiets pump and filters discharge air. For use with dry or aqueous vapor applications only. Specifications Model Number 2546 Application Filtration (1 to 6 funnels), Aspiration, Desiccation, SPE, Replace water aspirator, Vacuum Drying Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 1.6(45) Free Air Displacement m3/hr (l/min.) @50Hz 2.3(38) Ultimate Pressure 60(80) Maximum Vacuum 27.6 Max Pressure PSIG (pascal) 100(106) Motor Horsepower (watts) 1/4(190) Adjustable Vac. / Gas Ballast Yes Tubing Needed 3/16(5) Intake Thread NPT 1/4 Overall Dimensions LxWxH in. (cm) 10x7.5x9 (25.4x19.1x7.7) Ship Weight 17(7.7) Shipping Carton Dimensions LxWxH in. (cm) 15.3x12.3x12.7 (39x31x32) Intake Catch Jar Yes Exhaust Catch Jar Yes Adjustable Vacuum Knob Adjustable Pressure Yes Vacuum Gauge Dial Pressure Gauge Dial

$1,422.87

-

Welch Vacuum - Gardner Denver Welch WOB-L Pump 2522

Welch WOB-L Pump 2522 Product Details Economical Oil Free Adjustable Vacuum / Pressure Reliable WOB-L Piston pumps are perfect for many common laboratory vacuum applications. Features: Vacuum and Pressure - to 100 Torr (26"Hg). Includes Vacuum and Pressure Regulators and Gauges - simple to adjust and monitor vacuum level and delivery pressure. Inlet Water Trap - float ball rises to seal off pump from accidental ingestion of water. Muffler quiets pump and filters discharge air. For use with dry or aqueous vapor applications only. Specifications Model Number 2522 Application Filtration (1 to 2 funnels), Aspiration, Desiccation, SPE, Replace water aspirator, Vacuum Drying Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 0.76(22) Free Air Displacement m3/hr (l/min.) @50Hz 1.1(18) Ultimate Pressure 100(133) Maximum Vacuum 26 Max Pressure PSIG (pascal) 100(106) Motor Horsepower (watts) 1/8(93) Adjustable Vac. / Gas Ballast Yes Tubing Needed 3/16(5) Intake Thread NPT 1/4 Overall Dimensions LxWxH in. (cm) 8.1x8.8x10 (20.6x22.4x25.4) Ship Weight 17(7.7) Shipping Carton Dimensions LxWxH in. (cm) 15.3x12.3x12.7 (39x31x32) Intake Catch Jar Yes Exhaust Catch Jar Yes Adjustable Vacuum Knob Adjustable Pressure Yes Vacuum Gauge Dial Pressure Gauge Dial

$1,145.24

-

BVV™ Neo Brand T-Shirt

BVV™ Neo Brand T-Shirt The newly re-designed BVV™ Neo brand T-shirt is made out of 50% Polyester and 50% Cotton it comes in black and grey and is available in the sizes listed below. Sizes Available: Medium Large X Large 2 XL

$20.82

-

Welch Vacuum - Gardner Denver Welch DuoSeal Vacuum Pump Oil, Gallon 1407K-15

Welch DuoSeal Vacuum Pump Oil, Gallon 1407K-15 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Welch fractionated oil for DuoSeal belt-driven pumps to ensure the highest vacuum performance. DuoSeal Oil performs to rigid standards for vapor pressure, vacuum level stability, and viscosity -the lubrication that helps enable renowned DuoSeal pump durability.

$145.76

-

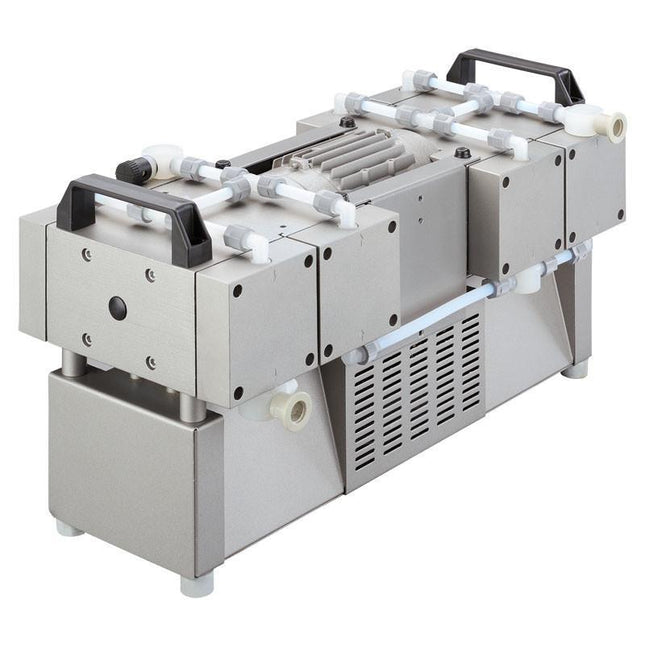

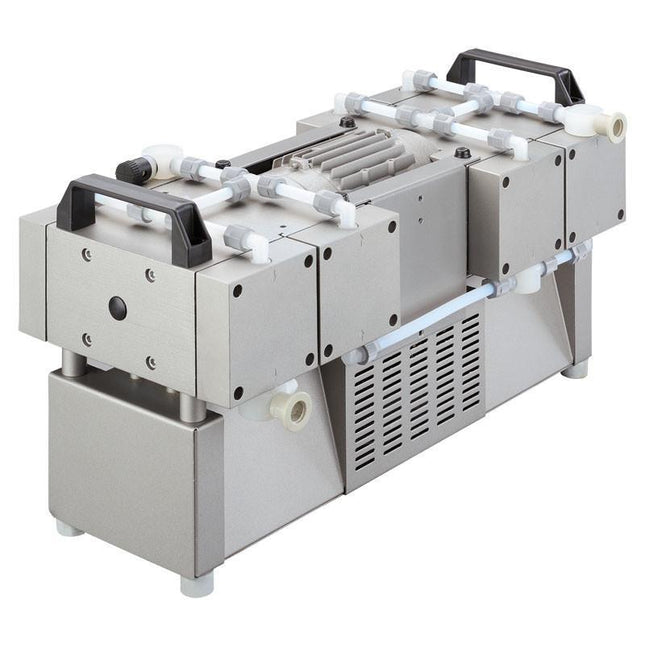

Welch Vacuum - Gardner Denver Welch High Capacity Diaphragm Pumps 2062

Welch High Capacity Diaphragm Pumps 2062 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** High Capacity dry diaphragm vacuum pump. PTFE contact surfaces, deep vacuum at with high flow. PTFE Pump, 8 heads. 115V 60HZ 1.5 TORR 119 LPM Specifications Includes 1/4" OD hose barb Common accessory, not included Vacuum Controller Pumping Speed 119 Lit/min. (4.2 CFM) Max. Vacuum 1.5 Torr (2 mbar) 29.9" Hg Tubing Needed 1/4" ID Inlet Connection UNIBARB Exhaust 1/4" OD Dimensions LxWxH inches 21x11x12 Weight 72 LBS Wiring 115V, 60 hz

$9,092.48

-

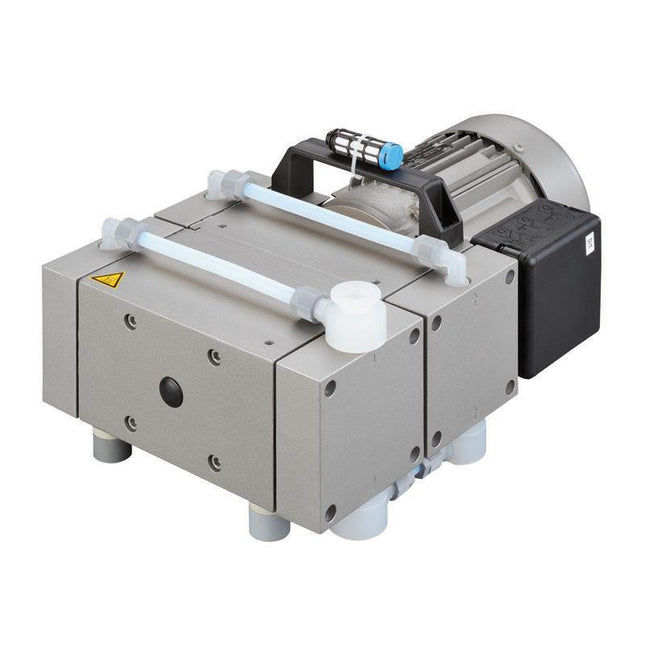

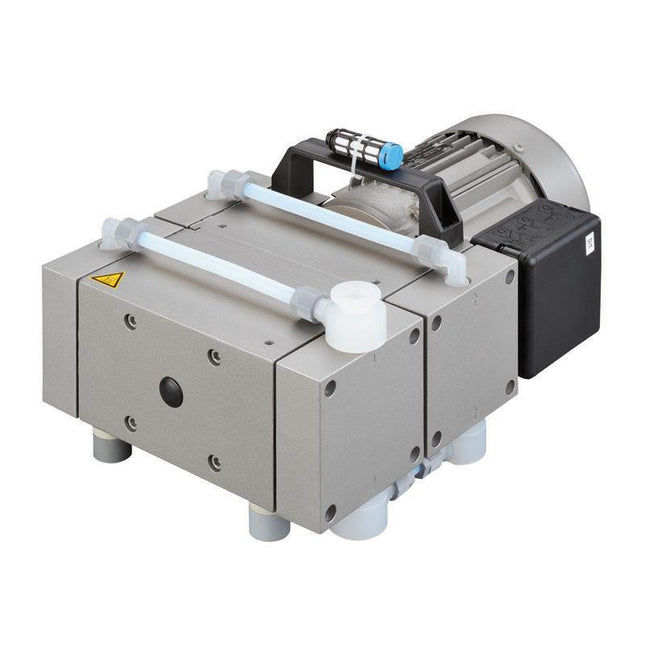

Welch Vacuum - Gardner Denver Welch High Capacity PTFE Diaphragm Pump 2052

Welch High Capacity Diaphragm Pump 2052 High Capacity dry diaphragm vacuum pump. PTFE contact surfaces, deep vacuum at with high flow. PTFE PUMP 115V 60HZ 1.5 TORR 64 LPM Free Air Displacement cfm (L min.) 2.3 Ult. Vac. Pressure, torr (mbar) 1.5 (2) Maximum Vacuum, in. Hg 29.9 Motor Horsepower - HP (wattS) 0.53 (390) Adjustable Vac J Gas Ballast No Tubing Nftftriftri. J.D. m. (mm) 1/4 (8) fntake (Exhaust) Thread NPT NW 16-1/4" MPT Weight Ibs. (kg) 40.3 (18.3) Overall Dimensions L x W x H in. (cm) 9 x 15 x 7 (22.8 x 38.1 x 17.8) Slip Weight, lbs. (kg) 49.8 (22.6) Snipping Carton Dimensions L x W x H in. (cm) 10.2 x 16.6 x 7.5 (26 x 42 x 19)

$6,019.08

-

Polyscience Polyscience 7 Liter Heated Circulator