Meta Solvent Recovery

-

Neocision 1.9CF BVV Neocision ETL Lab Certified Vacuum Oven

1.9CF BVV™ Neocision Certified Lab Vacuum Oven - 5 Wall Heating, LED's, 11 Shelves Standard - 3 Year Warranty Disclaimer This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! Backed by our 3 Year Parts and Labor Warranty. Introduction Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. Performance Capabilities At BVV™, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Range: Room Temp+18°F to 212°F Temperature Uniformity: within 5% of the temperature setpoint. Heat-Up Time: 45 minutes to preheat. Optimal saturation reached in 120 minutes, over 30 minutes faster than competitors. Ultimate Vacuum: <500 µmHg / mTorr / micron Time to Vacuum: 4 minutes to 29"Hg using our VE Series 4cfm Dual Stage Vacuum Pump. Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. Technical Data Electrical Voltage 120V Frequency 60Hz Power 650W Current 10A Plug IEC C13 (unit ships with detachable NEMA 5-15p cable) Internal Chamber Heating Superior 5 Wall Heating (left, right, top, bottom, rear) Chamber Material Stainless Steel Dimensions (LxWxH) 14.5" x 16" x 13.5" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 11 Slide-in Shelves Shelf Dimensions (LxW) 13" x 15" Shelf Capacity 195 in2 Total Shelf Capacity 2145 in2 / 14.9 ft2 Safety Seal Silicone on Tempered Glass Window Dimensions (LxH) 15.25" x 12.75" Lights 4 strips of LEDs provide clear, bright view of the interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 28.5" x 23" x 22" Weight 160 lbs Support Heavy Duty Casters and Adjustable Leveling Feet Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connections Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose and adjusting wrenches. User Manual Included Vacuum Pump Sold Separately. Recommended Pump VE Series 4cfm Dual Stage Vacuum Pump Warranty 3 Years Capacity and Throughput Planning Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122 Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 *Candy Drying with a BVV Vacuum Oven Recipe Guide Note: This item is a freight ship item and will ship Via Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise Ground Freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$2,729.76

-

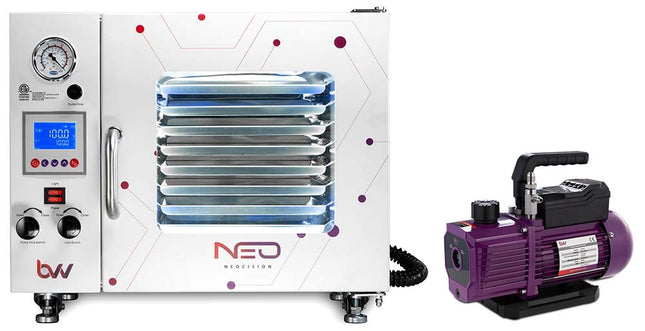

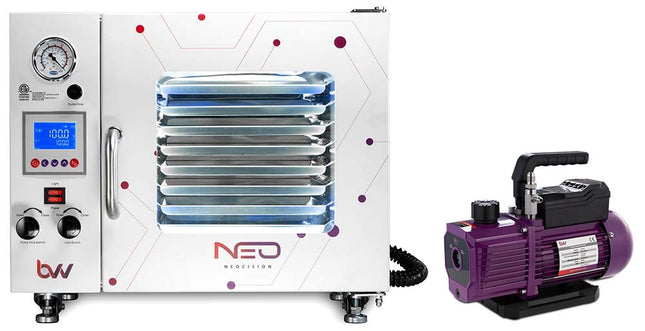

1.9CF Neocision Lab Certified Vacuum Oven and V4D 4CFM 2 Stage Pump Kit

1.9CF Neocision Lab Certified Vacuum Oven and V4D Series Pump Kit DISCLAIMER This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! INTRODUCTION Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. PERFORMANCE CAPABILITIES At BVV™, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Range: Room Temp+18°F to 212°F Temperature Uniformity: within 5% of the temperature setpoint. Heat-Up Time: 45 minutes to preheat. Optimal saturation reached in 120 minutes, over 30 minutes faster than competitors. Ultimate Vacuum: <500 µmHg / mTorr / micron Time to Vacuum: 4 minutes to 29"Hg. Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. SPECIFICATIONS Electrical Voltage 120V Frequency 60HZ Power 650W Current 10A Plug IEC C13 (unit ships with detachable NEMA 5-15p cable) Internal Chamber Heating Superior 5 Wall Heating (left, right, top, bottom, rear) Temperature Range RT+18°-212°F Chamber Material Stainless Steel Dimensions (LxWxH) 14.5" x 16" x 13.5" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 11 Slide-in Shelves Shelf Dimensions (LxW) 13" x 15" Shelf Capacity 195 in2 Total Shelf Capacity 2145 in2/ 14.9 ft2 Door Seal Silicone on Tempered Glass Window Dimensions (LxH) 15.25" x 12.75" Lights 4 strips of LEDs provide clear, bright view of interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 28.5" x 23" x 22" Weight 160 lbs Support Heavy Duty Casters and Adjustable Leveling Feet Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connection Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose and adjusting wrenches. User Manual Included Warranty 3 year oven warranty Vacuum Pump BVV™ V4D 4CFM Two Stage Vacuum Pump CAPACITY AND THROUGHPUT PLANNING Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise Ground Freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$3,220.42

-

0.9CF Neocision Lab Certified Vacuum Oven + V4D 4CFM 2 Stage Pump Kit

0.9CF Neocision Lab Certified Vacuum Oven and V4D Series Vacuum Pump Kit DISCLAIMER This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! INTRODUCTION Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. PERFORMANCE CAPABILITIES At Best Value Vacs, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Range: RT+18°-212°F Temperature Uniformity: within 7% of the temperature setpoint. Heat-Up Time: 45 minutes to preheat. Optimal saturation reached in 120 minutes, over 30 minutes faster than competitors. Ultimate Vacuum: <500 µmHg / mTorr / micron Time to Vacuum: 4 minutes to 29"Hg Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. SPECIFICATIONS Electrical Voltage 120V Frequency 60HZ Power 550W Current 10A Plug IEC C13 (unit ships with detachable NEMA 5-15p cable) Internal Chamber Heating Superior 5 Wall Heating (left, right, top, bottom, rear) Temperature Range RT+18°-212°F Chamber Material Stainless Stee Dimensions (LxWxH) 12.75" x 12.625" x 11.625" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 11 Slide-in Shelves Shelf Dimensions (LxW) 11.5" x 11.25" Shelf Capacity 129 in2 Total Shelf Capacity 1035 in2 / 7.2 ft2 Door Seal Silicone on Tempered Glass Window Dimensions (LxH) 11.75" x 11" Lights 4 strips of LEDs provide clear, bright view of interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 24.25" x 19" x 20.75" Weight 160 lbs Support Heavy Duty Casters and Adjustable Leveling Feet Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connection Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose and adjusting wrenches. User Manual Included Warranty 3 year oven warranty Vacuum Pump BVV™ V4D 4CFM Two Stage Vacuum Pump CAPACITY AND THROUGHPUT PLANNING Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise Ground Freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$2,356.58

-

Neocision 7.5CF BVV Neocision ETL Lab Certified Vacuum Oven

7.5CF BVV™ Neocision Certified Lab Vacuum Oven, 5 Individually Heated Shelves, LED's - 3 Year Warranty Disclaimer: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in well-ventilated areas! Introduction Our vacuum ovens are purpose-built to perform degassing / purging of light hydrocarbon solvents. Using the technique of cold boiling, the oven applies a gentle heat under reduced pressure conditions to expedite solvent degassing while simultaneously preserving color, aroma, and overall solute quality. We've applied our extensive vacuum expertise and industry experience to produce a series of ovens designed exactly for your needs: low consumption, high-throughput, and reliable operation. Performance Capabilities At Best Value Vacs, we make every effort to provide oven performance capabilities in a standardized format. We're not interested in juking our stats to make a sale. Instead, our goal is to provide quality, transparent production capabilities that meet the demands of our professional customers. Temperature Stability: ±1.0° Temperature Uniformity: within 4% of the temperature setpoint. Heat-Up Time: 20 minutes. Ultimate Vacuum: <500 µmHg / mTorr / micron. Time to Vacuum: 10 minutes to 29"Hg using our VE Series 12cfm Dual Stage Vacuum Pump. Vacuum Hold: guaranteed to lose less than 1"Hg (25.4 torr) in 24 hours. Technical Data Electrical Voltage 120V Frequency 60Hz Power 1960W Current 20A Plug IEC C13 (unit ships with detachable NEMA 5-20 cable) Internal Chamber Heating Individual direct-heat shelves Chamber Material Stainless Steel Dimensions (LxWxH) 22" x 23.25" x 25.25" Vacuum Gauge Style Glycerin-filled for accuracy and longevity Range (units) -30 to 0 (inHg) / -1 to 0 (bar) Shelving Ships With 5 Heated Shelves Shelf Dimensions (LxW) 21.5" x 21.5" Shelf Capacity 462 in2 Total Shelf Capacity 2311 in2 / 16.1 ft2 Safety Seal Silicone on Tempered Glass Window Dimensions (LxH) 20.25" x 23.75" Lights 4 strips of LEDs provide a clear, bright view of the interior Handle No plastic, all metal parts for lifetime durability Exterior Dimensions (LxWxH) 35" x 33" x 34.5" Weight 430 lbs Support Locking Casters Safety Electrical Built-in, resettable, overcurrent circuit breaker Thermal Automatic overtemperature shutoff Compliance CE CE Listing Recognized ISO ISO 9001:2015 ETL Certified Conforms to ANSI/UL STD.61010-1, 61010-2-010 -- Certified to CAN/CSA STD. C22.2 NO.61010-1, 61010-2-010 Connections Vacuum Inlet KF25 / NW25, quarter-turn valve Purge Inlet 5/16" Barbed, 10-turn valve Atmospheric Release Quick-release dial Contains Ships With KF25 x 1/4" JIC Flare with 1/4" vacuum hose User Manual Included Vacuum Pump Sold Separately. Warranty 3 Years Capacity and Throughput Planning Oven capacity requirements vary widely by the producer. We wanted to create a method to assist in determining the best oven match for your operation, based on a few of the parameters of your extraction and of your desired purge. We based this formula on an expected extraction yield of 25%, with an extract-density of 1 g/in2. Using the following variables, this formula is designed to provide an estimate of your required shelving capacity: Size = Extraction Batch Size (lbs) Number = Runs per 24h Period Purge = Your desired purging duration (hours) Area Required (ft2) = [(Size) * (Number) * (Purge+1)] / 122 Area Required (in2) = (Size) * (Number) * (Purge+1) * 1.18 Note: This item is a freight ship item and will ship Via UPS Ground Freight. Expedited freight can only be calculated by calling customer service 331-281-0154. All orders with expedited freight through the website will not be honored and will need to be re-quoted. A valid Phone Number IS REQUIRED to ship, Otherwise UPS freight Cannot Contact you for a delivery setup window. Freight Time is 2-5 Days. West Coast 5 Days, Midwest 2 days, East Coast 3-4 days.

$11,195.46

-

Heavy Duty Steel Mobile Cart for Vacuum Ovens

Heavy Duty Steel Mobile Cart for Vacuum Ovens Our heavy-duty cart is designed and built to house a variety of equipment such as vacuum ovens, cold traps, vacuum pumps, etc. The cart can comfortably house up to 3 BVV™ and Across International 0.9 and 1.9 vacuum ovens. The cart offers mobility with their swivel caster wheels and can withstand up to a total of 1,100lbs. Included in the unit are three side shelves in which the height can be adjusted to your needs. The cart was meticulously designed for reliability, customization, and convenience for your process. Features: White powder coated carbon steel. 3-shelf shelving unit 3 laser cut, height adjustable side shelves. 2⅜” diameter hole to help with hose and cable management. 6” front lip for easy oil drainage. Can fit on the left or right side of the bracket Four 3” swivel caster wheels: 2 with brakes and 2 without brakes. Dimensions: 33” (L) x 23” (W) x 61” (H). Additional 13¼” to the length with side shelves added. Made in the USA. Note: The unit shipped does NOT come with the side shelves assembled. Required tool: 5mm ball hex (NOT INCLUDED).

$2,059.41

-

6" Turnkey Falling Film Evaporator

BVV 6" Turnkey Falling Film Evaporator Cutsheet Is your lab floor filled with a fleet of rotary evaporators? Looking to increase solvent recovery throughput? Our new and compact 20GPH Falling Film Evaporator (FFE) has the capability to maximize throughput and replace up to five 50L Rotary Evaporators. The BVV™ 20GPH Falling Film Evaporator is designed to evaporate ethanol that has been diluted in crude oil during a filtration or extraction process. By reducing the vapor pressure inside the system and metering the injection valve, the user can set the heat exchangers to the appropriate temperatures to efficiently evaporate solvent from their crude oil. We paired our FFE with reliable equipment that will keep operations running. End users are required to plumb the process inlet and outlet connections for both heat exchangers. They are supplied with 1.5” sanitary tri-clamp connections. BVV™ can assist with necessary parts needed for a permanent or temporary installation. Temporary installations may be necessary if your lab has limited fume hoods or space which is shared with other processing equipment. Below you will find key features, additional equipment included with the system and the power requirements for each, and real-life efficiencies that were tested. Key Features: · Compact rack design for use in fume hoods (39”x30”x75.5”) · Vernier scale metering valve for controlled injection · Accurate heater and chiller temperature control · Deep vacuum for effective solvent removal · Discharge pumps to eliminate constant reservoir draining and down time · Chemical resistant vacuum pump · Adaptable discharge outlets to customer preference · Insulation to limit thermal loses and reduce condensation (Not Pictured) · Sanitary tri-clamp and compression fittings · Pre-heat injection coil · Injection distribution plate · Tube in shell heat exchanger for efficient evaporation and condensation · Packable vapor path for reduction of contaminants and cleaner separation · Water reservoir for priming the heating system and expansion during operation · The certified model is 22 State certified by PRV Engineers and includes an Infield Verification by PRV Engineers within the purchase price. States include but are not limited to: Alabama, Arizona, Arkansas, California, Colorado, Connecticut, Florida, Illinois, Kansas, Louisiana, Maine, Massachusetts, Missouri, Nevada, North Carolina, Oklahoma, Oregon, Texas, Vermont, Washington, West Virginia, and Wyoming Crude Discharge Pump Easily control discharge speed and collect your extract directly from the 3/8" tube via a collection vessel or swage on a fitting of your preference to pump collected extract to a secondary location. Eliminate constant reservoir draining and operate continuously. Metered Solvent Injection Effectively repeat efficiency and throughput with our vernier scale metering valve. Easy to dial in the desired efficiency and throughput desired by the user. Distribution Plate Directs the injected solvent to be evenly distributed across all tubes in the heat exchanger which maximizes the effective heating surface area. Solvent Discharge and Vacuum Pump The solvent discharge pump eliminates the need for a reservoir and allows you to pump recovered solvent to any desired secondary location. The vacuum pump manifold gives you easy vacuum control during the complete operation. POWER REQUIREMENTS The equipment listed below is included with the system. Check power requirements and amp draw prior to purchasing. Equipment Purpose Power Requirement Amp Draw Notes Hubbell Process Water Heater Heater for Heat Exchanger Column (Evaporation) 240V 3-Phase 87 36kW Heating Capacity Taco ECM High-Efficiency Circulator Water Circulator for Heater 115V 1-Phase 2.5 Max flow rate 52GPM 10 Ton Low Temp Glycol Chiller Chiller for Heat Exchanger Column (Condensation) 230V 3-Phase 64 10 ton Cooling Capacity 2GPM Ethanol Recovery Pump for Vacuum Pump for Ethanol Recovery Discharge 230V 1-Phase 2.4 2GPM Max Flow Rate, Vacuum Check Valve Beaker and Wrench Explosion Proof Oil Pump Pump for Oil Recovery Discharge 230V 1-Phase 1.1 90L/hr. Max Flow Rate, Vacuum Check Valve Welch BTpro100 Diaphragm Pump Vacuum Pump for System 115 1-Phase 3.4 3.5 CFM, 6 Torr Ultimate Vacuum Total Amp Draw 174.4 EFFICIENCY We are proud to present real data with running parameters and efficiencies that reflect the actual operation of our system. Below you will find the tested throughputs and efficiencies that our FFE is capable of handling. Throughput 11 GPH 18 GPH 20 GPH 22 GPH 24 GPH Efficiency 98% 97% 94% 90% 85% ** Efficiency calculated at 10:1 ratio (Ethanol : Crude Oil) with heater temperature of 160°F. Crude is fully dewaxed when going into the falling film evaporator. Solution starts at room temperature. Speeds may differ based on dilution ratio, crude quality, and running parameters. **

$95,368.76 - $102,279.54

-

SHEL LAB SHEL LAB 0.6 Cu Ft Vac Oven SVAC1

SHEL LAB - VACUUM OVEN, 0.6 CUBIC FEET Our revamped SHEL LAB SVAC vacuum ovens provide exceptional capabilities for fast and gentle drying of heat-sensitive materials. Vacuum ovens prevent residue accumulation on products and use lower temperatures than typical convection ovens. Your products are processed with minimal impact and maximum throughput. SHEL LAB vacuum ovens have stainless steel interiors and provide exceptional durability and stability. Available in 4 sizes, SVAC Vacuum Ovens support a diverse array of applications. To achieve required vacuum levels, users can choose from a 3/8-inch orifice or a KF-25 fitting to withstand heavy use and minimize draw-down time. The doors on these units have positive latch handles with spring-loaded glass to facilitate a good vacuum seal without hinge binds that shorten the gasket life. The tempered glass viewing window allows for safe, continuous monitoring of samples. SHEL LAB Vacuum Ovens are equipped with silicone gaskets. Features include: Watlow PM9 Plus Controller Generous Usable Shelf Area Achieve Impressive Vacuum Levels Sizes Range from 0.6 – 4.5 Cubic Feet Built-in Overtemperature Protection 24 Month Limited Warranty Extended Warranties Available (Ask Your SHEL LAB Sales Rep) Please note that this vacuum oven does not include a pump or related accessories. Contact your SHEL LAB distributor for assistance with choosing the ideal pump and accessories for any application.

$8,743.52 - $9,578.34

-

ChemTek ChemTek - Planetary Centrifuge Vacuum Mixer

ChemTek - Planetary Centrifuge Vacuum Mixer The combination of centrifugal force and vacuum in a planetary vacuum centrifuge mixer allows for the rapid and thorough removal of residual solvents from extracts. The vacuum environment lowers the boiling point of solvents, enabling their efficient evaporation without excessive heat. This is crucial for preserving the integrity and potency of heat-sensitive compounds, such as terpenes, ensuring a purer final product. T-500 Power Supply: 220V Max Speed: 1500 RPM Max Capacity: 2 x 500ml Program: Adjustable program settings for different viscosities Dimensions: L: 29” W: 24” H: 39” Net Weight: 65kg Safety Function: Emergency Stop Button T-1000 Power Supply: 220V upon request Max Speed: 1500 RPM Max Capacity: 2 x 1000ml Program: Adjustable program settings for different viscosities Dimensions: L: 32” W: 29” H: 43” Net Weight: 75kg Safety Function: Emergency Stop Button

$24,878.81 - $34,553.90

-

BVV 2540 Nanofiltration Skid

BVV 2540 Nanofiltration Skid Note: This product carries 8 - 12 week lead time Perform organic solvent recovery or botanical extract purification with ease with our 2540 nanofiltration skid. Replace up to 7X 50L Rotary evaporators with a single Skid. BVV's 2540 Nanofiltration Skid is designed to meet Class 1 Division 1 standards. With the ability to recover 30 gallons of ethanol per hour without the application of heat, preserving target compounds and utilizing a fraction of the energy consumption of a traditional falling film qualifying our 2540 Nanofiltration Skid for energy saving rebates. Processing Power Capacity: 15 GPH or 30 GPH of solvent recovery. Solvents: Ethanol, Methanol Specifications 4X 2540 nanofiltration housings Stainless steel 6GPM pump with PTFE seals 7.5HP C1D1 1750 RPM Motor 7.5HP VFD 1/60/230 NEMA 4X enclosure (13A) Insulated 2"x18" Heat Exchanger Polyscience 1.5HP Chiller 230/60/1/23.1 700PSI Pressure Relief Valve C1D1 Flowmeter 2X 0-1000 PSI Pressure Gauges 1.5" Intake & Retentate Lines 1/2" Permeate & Pressure Relief Lines Footprint (DxWxH) 30"x39"x79" Weight: 400 lb Maximum Pressure Rating: 700PSI Performance Variable Frequency Drive-based flow control Complete pressure control with manual pressure controls Retentate cooling with inline Heat exchanger & chiller 700PSI pressure relief valve with diversion line *Components shown are subject to change**This unit is meant for bulk solvent recovery, 90% of the total volume of solvent an additional solvent recovery apparatus is recommended to evaporate to dryness*

$56,668.39 - $62,197.02

-

Space Saver Mobile Oven Cart with Ovens

BVV Space Saver Mobile Oven Cart with Ovens The BVV Space Saver Mobile Oven Cart allows users to greatly increase their output and more efficiently all in one place! There are a total of 4 options in this listing: 1) Three 1.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 2) Two 1.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 3) Three 0.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump 4) Two 0.9 Neocision Ovens + 1 UL listed BVV Vacuum Pump If these options don't fit your needs, we also encourage you to expand your options by ordering parts individually or reach out to us (331-281-0154) so we can help create the kit right for you. Included in all the kits is the Heavy Duty Steel Mobile Cart that was designed by us to hold up to three ovens! It also has three height adjustable shelves to suit your needs and can be placed on either side of the bracket. The cart is mobile with its swivel caster wheels and they can can support up to 1,100lbs! The cart can house oven sizes such as the 0.9 and 1.9, Neocision and ECO oven. The oven shelves are made of aluminum and we recommend covering the shelves with silicone pads or a PTFE sheet that can be cut to size. The oven shelves are made of aluminum and we recommend covering the shelves with silicone pads or a PTFE sheet that can be cut to size. It is recommended to change the oil when the color starts to get noticeably darker in the pump. Also included in the kit is our premium Mobil Vacuum Pump Oil. This oil has a longer usable life and does not generate any additional vapor or odor, which will be sure to help your vacuum pump exhaust filter live longer too! Note: The Heavy Duty Steel Mobile Cart shipped does NOT come with the side shelves assembled. Required tool: 5mm ball hex (NOT INCLUDED).

$10,504.39 - $15,100.05

-

SHEL LAB SHEL LAB 9.3 Cu Ft Vac Oven SVAC9-2

SHEL LAB - VAC OVEN, 9.3 CUFT, 230V The SHEL LAB Model SVAC9-2 is one of the largest vacuum ovens on the market, with 9.3 cubic feet of capacity. This unit also features a fully programmable Watlow PM9 Plus controller and a cool touch surface. A digital vacuum gauge shows chamber vacuum level in measurements of Torr and m/Torr. The display range is 760 Torr down to 0 mTorr (Maximum permitted end vacuum is 10 mTorr. Leak rate is 30 mTorr in 30 min). A secondary independent high limit controller provides overtemperature safety protection. This unit includes true vacuum valves and has cross-flow ventilation within the oven chamber to enhance total performance. The vacuum oven is secured to a ruggedly constructed mobile stand to create a vacuum pump at the base. Although the oven is not supplied with a vacuum pump, all vacuum plumbing and KF25 connections are provided. The SHEL LAB SVAC9-2 vacuum oven is equipped with a Viton gasket, which provides an excellent combination of high-temperature performance and chemical resistance. When paired with this oven’s deep-draw capacity and large chamber volume, the SVAC9-2 serves as one of the most robust vacuum work stations available on the market. Features include: Watlow PM9 Plus Controller Capable Of 40 Step Ramp And Soak Profiles, Or 4 Files With 10 Steps Per File Stainless Steel Interior Stainless Steel Exterior Option Available (Ideal For Cleanroom Applications) KF25 Fitting Included Built in Vacuum Pump Mount 24 Month Limited Warranty

$32,372.86 $28,487.62

-

Sheldon Manufacturing SHEL LAB FORCED AIR OVEN, 13.8 CUBIC FEET, 230V

SHEL LAB - FORCED AIR OVEN, 13.8 CUBIC FEET, 230V The SHEL LAB SMO14-2 features 14 cubic feet of economical oven space. The independent overtemperature safety feature is user adjustable and provides added safety. The forced, blower-assisted airflow design offers excellent temperature uniformity and fast recovery. A turbo blower and heavy-duty motor combine to direct air over the shelves and samples for even, constant drying, curing, and baking. The large capacity SMO ovens are perfect for high volume sample and drying applications, including production processes. These units are especially ideal for glassware drying. These SHEL LAB Ovens Feature: Three-inch Adjustable Exhaust Port Stainless Steel Shelves Independent Overtemperature Safety High-Temperature Silicone Door Seal Added docking collars to intake and exhaust ports to allow ducting to be attached for venting exhaust out of the workspace Shelf standards moved to the sides of the unit for easier shelf installation No Exposed Heating Wrap Around Insulation Durable Powder Coat Paint Exterior Finish Digital Timer 24 Month Limited Warranty

$9,336.46 $7,740.07

-

Across International Ai 316L SST 100C UL Certified 16 CF Vacuum Oven With 6 Heating Shelves

Ai 316L SST 100C UL Certified 16 CF Vacuum Oven With 6 Heating Shelves Introducing the new Across International UL certified 16 cu ft vacuum ovens, this certification is required by many municipalities, and it also provides a higher standard of equipment safety and lifespan. Also come standard is the secondary over-temp protection dial, 2.5X larger internal tubing for a quicker vacuum purge and release, and a secondary door handle to provide a better sealing on the door gasket. The AT160 series digital vacuum oven features a gigantic 16 cubic feet easy-to-clean stainless steel chamber with a large 3/4" tempered glass safety window. With our new internal shelf heating technology, each shelf in these lab and industrial ovens has its own heater, in-shelf temperature sensor and temperature controller, together with great thermal-conductive aluminum and our new low proportional controller technologies, the result is perfect uniformity, accurate temperature, super-fast heating rates, minimum heat loss/exterior temperature and very low power consumption. Features UL certified New stainless steel, easy-open handle with tension adjustable latch (110V model). New re-enforced stainless steel door hinges (110V model). KF25 inlet filter keeps your oven clean at all time (included with oven purchase). Thermo-conductive to thermally conductive. All stainless steel internal vacuum tubing and compression fittings that holds vacuum 10 times longer and deeper than with rubber tubing. They also provide you the most sanitary working environment, while last for decades without maintenance. Oil-filled mechanical vacuum gauge ensures the most accurate and stable measurements. Built-in secondary over-temp dial for added protection. Adjustable vacuum and vent port with needle valves gives you control over vacuum and vent rates, while also largely enhanced durability. 4th gen low proportional gain temperature controller keeps your oven temperature accurate. Built-in white LED lights Best choice for the curing and converting of oil extracts. With deep vacuum level, they can operate at temperatures which allow the degassing/purging process to occur rapidly, thus increase productivity and allow for the production of superior quality products with minimal processing time. Dual layer observation window with 3/4" tempered safety glass. Easy-to-clean stainless steel interior for exceptional durability and ease of maintenance. A vacuum environment lowers the boiling point (great for processing heat sensitive materials) and reduces drying time for materials like paste or powder which cannot otherwise be easily dried. Built-in alarm alerts you when oven has been shut down by safety circuitry due to out of range temperature. Built-in swivel casters with leveling feet. For improved temperature ramping, run the auto-tune procedure as outlined in the manual Manufactured in accordance with UL 61010-1 CSA C22.2 ISO 9001:2000 ISO 12100-1:2003, ISO 12100-2:2003 EN1050:1996, EN294:1992, EN60204-1:2006 CE

$26,756.47 - $28,640.34

-

Across International Ai 500C Max. 1.9 Cu Ft Vacuum Oven With Stainless Steel Tubing And 316L Chamber

Ai 500C Max. 1.9 Cu Ft Vacuum Oven With Stainless Steel Tubing And 316L Chamber AT19-500C series digital desktop 500C vacuum ovens feature a 1.9 cubic foot easy-to-clean stainless steel chamber with a large dual-layer tempered glass safety window and small footprint. These ovens for labs can greatly reduce drying time by maintaining a consistent vacuum level within the chamber. Every one of our vacuum ovens goes through a 2-time 24-hour vacuum leak test, and is 100% quality controlled in New Jersey or Nevada before leaving our facilities. Features All stainless steel internal tubing & compression fittings provides higher ultimate vacuum, holds vacuum 10 times longer, and require minimum maintenance. Oil-filled mechanical vacuum gauge provides more accurate reading, longer gauge life and minimizes shipping damage. All stainless steel vacuum and vent valves gives you cleaner connection, more accurate control and long term durability. New 5 sided heating technology and aluminum shelves provide excellent temperature uniformity and faster heating rates (25% faster in our lab test). Adjustable gas back fill capability with needle valve and vent port. 3" thermal insulation prevents heat loss and minimizes the enclosures outer surface temperature. Easy-to-clean stainless steel interior for exceptional durability and ease of maintenance. Built-in alarm alerts you when oven has been shut down by safety circuitry due to out of range temperature.

$7,449.82 - $14,554.10

-

Across International Ai 316L SST 250C UL Certified 1.9 CF Vacuum Oven With 5 Sided Heating

Ai 316L SST 250C UL Certified 1.9 CF Vacuum Oven With 5 Sided Heating AT19 series digital desktop vacuum ovens feature a 1.9 cubic foot easy-to-clean stainless steel chamber with a large dual-layer tempered glass safety window and small footprint. These ovens can greatly reduce drying time by maintaining a consistent vacuum level within the chamber. Every one of our vacuum ovens goes through a 2-time 24-hour vacuum leak test, and is 100% quality controlled in New Jersey or Nevada before leaving our facilities. Introducing the new Ai UL-certified 1.9 cubic foot vacuum ovens, this certification is required by many municipalities, and it also provides a higher standard of equipment safety and lifespan. Also come standard are the secondary over-temp protection dial, all stainless steel tubing/compression fittings, stainless steel vacuum/vent valve, oil-filled vacuum gauge, 5-sided pad heating technology, and two year warranty. The thermal-conductive aluminum pan shelves provide excellent temperature uniformity inside the chamber, while our 4th gen LCD low proportional gain temperature controllers keep your oven temperature accurate. AT19 series digital desktop vacuum ovens feature a 1.9 cubic foot easy-to-clean stainless steel chamber with a large dual-layer tempered glass safety window and a small footprint. These ovens can greatly reduce drying time by maintaining a consistent vacuum level within the chamber. Every one of our vacuum ovens goes through a 2-time 24-hour vacuum leak test and is 100% quality controlled in New Jersey or Nevada before leaving our facilities. Attention: Before initial use, run oven at 200C/400F without vacuum for 15 minutes to burn off any residue that may have been introduced during the manufacturing process.

$3,718.00 - $4,469.89

-

SHEL LAB SHEL LAB 4.5 Cu Ft Vac Oven SVAC4

SHEL LAB - VACUUM OVEN, 4.5 CUFT Our revamped SHEL LAB SVAC vacuum ovens provide exceptional capabilities for fast and gentle drying of heat-sensitive materials. Vacuum ovens prevent residue accumulation on products and use lower temperatures than typical convection ovens. Your products are processed with minimal impact and maximum throughput. SHEL LAB vacuum ovens have stainless steel interiors and provide exceptional durability and stability. Available in 4 sizes, SVAC Vacuum Ovens support a diverse array of applications. To achieve required vacuum levels, users can choose from a 3/8-inch orifice or a KF-25 fitting to withstand heavy use and minimize draw-down time. The doors on these units have positive latch handles with spring-loaded glass to facilitate a good vacuum seal without hinge binds that shorten the gasket life. The tempered glass viewing window allows for safe, continuous monitoring of samples. SHEL LAB Vacuum Ovens are equipped with silicone gaskets. Features include: Watlow PM9 Plus Controller Generous Usable Shelf Area Achieve Impressive Vacuum Levels Sizes Range from 0.6 – 4.5 Cubic Feet Built-in Overtemperature Protection 24 Month Limited Warranty Extended Warranties Available* (Ask Your SHEL LAB Sales Rep) Please note that this vacuum oven does not include a pump or related accessories. Contact your SHEL LAB distributor for assistance with choosing the ideal pump and accessories for any application.

$18,880.25 - $20,730.96

-

SHEL LAB SHEL LAB 1.67 Cu Ft Vac Oven SVAC2

SHEL LAB - VACUUM OVEN, 1.67 CUBIC FEET Our revamped SHEL LAB SVAC vacuum ovens provide exceptional capabilities for fast and gentle drying of heat-sensitive materials. Vacuum ovens prevent residue accumulation on products and use lower temperatures than typical convection ovens. Your products are processed with minimal impact and maximum throughput. SHEL LAB vacuum ovens have stainless steel interiors and provide exceptional durability and stability. Available in 4 sizes, SVAC Vacuum Ovens support a diverse array of applications.To achieve required vacuum levels, users can choose from a 3/8-inch orifice or a KF-25 fitting to withstand heavy use and minimize draw-down time. The doors on these units have positive latch handles with spring-loaded glass to facilitate a good vacuum seal without hinge binds that shorten the gasket life. The tempered glass viewing window allows for safe, continuous monitoring of samples. SHEL LAB Vacuum Ovens are equipped with silicone gaskets. Features include: Watlow PM9 Plus Controller Generous Usable Shelf Area Achieve Impressive Vacuum Levels Sizes Range from 0.6 – 4.5 Cubic Feet Built-in Overtemperature Protection 24 Month Limited Warranty Extended Warranties Available (Ask Your SHEL LAB Sales Rep) Please note that this vacuum oven does not include a pump or related accessories. Contact your SHEL LAB distributor for assistance with choosing the ideal pump and accessories for any application.

$9,889.33 - $10,834.72

-

SHEL LAB SHEL LAB 0.6 Cu Ft Vac Oven SVAC2E

SHEL LAB - ECONOMY VACUUM OVEN, 1.7 CUFT, NON CE SHEL LAB vacuum ovens provide exceptional capabilities for fast and gentle drying of heat-sensitive materials. They prevent residue accumulation on products and allow safe drying of materials at lower temperatures than typically required when using convection ovens. These units feature a radiant heating system that optimizes chamber space and provides excellent heat transfer and temperature uniformity. All SHEL LAB vacuum ovens are built with stainless steel chambers that are easy to clean and have exceptional durability. The doors on these units have positive latch handles with spring-loaded glass to facilitate a good vacuum seal without hinge binds that shorten the gasket life. The tempered glass viewing window allows for safe, continuous monitoring of samples. A selection of gaskets (for specific applications) and a small benchtop footprint increase the versatility of these ovens. The SHEL LAB economy series of vacuum ovens are outstanding in any application. Features include: Analog Temperature Control Stainless-Steel Interior Built-in Overtemperature Protection 24 Month Limited Warranty

$4,114.68 - $4,505.83

-

SHEL LAB SHEL LAB 0.6 Cu Ft Vac Oven SVAC1E

SHEL LAB - ECONOMY VACUUM OVEN, 0.6 CUFT, NON CE HEL LAB vacuum ovens provide exceptional capabilities for fast and gentle drying of heat-sensitive materials. They prevent residue accumulation on products and allow safe drying of materials at lower temperatures than typically required when using convection ovens. These units feature a radiant heating system that optimizes chamber space and provides excellent heat transfer and temperature uniformity. All SHEL LAB vacuum ovens are built with stainless steel chambers that are easy to clean and have exceptional durability. The doors on these units have positive latch handles with spring-loaded glass to facilitate a good vacuum seal without hinge binds that shorten the gasket life. The tempered glass viewing window allows for safe, continuous monitoring of samples. A selection of gaskets (for specific applications) and a small benchtop footprint increase the versatility of these ovens. The SHEL LAB economy series of vacuum ovens are outstanding in any application. Features include: Analog Temperature Control Stainless-Steel Interior Built-in Overtemperature Protection 24 Month Limited Warranty

$3,420.84 - $3,742.88

-

Sheldon Manufacturing SHEL LAB FORCED AIR OVEN, 27.6 CUBIC FEET

SHEL LAB - FORCED AIR OVEN, 27.6 CUBIC FEET The SHEL LAB Model SMO28-2 is the largest general-purpose oven on the market. The independent overtemperature safety feature is user adjustable and provides added safety. The turbo blower-assisted forced airflow design coupled with a heavy-duty blower motor offers excellent temperature uniformity and fast recovery times. Airflow is directed evenly across all shelves and samples to ensure consistent drying, curing, and baking results. The SMO large capacity units are perfect for high volume sample and drying applications, including production processes. These units are especially ideal for glassware drying. These SHEL LAB ovens Feature: Three-inch Adjustable Exhaust Port Stainless Steel Shelves Independent Overtemperature Safety High-Temperature Silicone Door Seal No Exposed Heating Elements Added docking collars to intake and exhaust ports to allow ducting to be attached for venting exhaust out of the workspace Shelf standards moved to the sides of the unit for easier shelf installation Wrap Around Insulation Durable Powder Coat Paint Exterior Finish Digital Timer 24 Month Limited Warranty

$13,124.95 $9,854.77

-

Sheldon Manufacturing SHEL LAB OVEN, FORCED AIR, 5 CUFT

SHEL LAB - OVEN, FORCED AIR, 5 CUFT The SMO5 is equipped with a stainless-steel interior for long-life operation and easy cleaning. With triple wall construction, this oven’s walls minimize external wall temperature which meets CE requirements to keep work spaces cool. These ovens are recommended for critical and analytical use in laboratory and pilot plant product research. Typical applications for the oven include aging, asphalt testing, curing, drying, pre-heating, conditioning, and life cycle testing. This unit has a quick ramp-up time to 306°C for faster cycle times. This unit includes an advanced PID temperature control system for sensitive response. The SMO5 forced air oven delivers precise uniformity, air distribution, and the peace of mind expected of the SHEL LAB brand. Features of this oven include: Embedded Microprocessor Control with Countdown Timer Horizontal Forced Airflow 1.75in (45 mm) Access Port UL/CSA Approved CE Approval DIN 12880 Compliant 24 Month Limited Warranty

$5,653.02 - $5,735.95

-

Sheldon Manufacturing SHEL LAB OVEN, FORCED AIR, 3 CUFT

SHEL LAB - OVEN, FORCED AIR, 3 CUFT The SMO3 has a quick ramp-up time to 306°C for faster cycle times. This unit includes an advanced PID temperature control system for sensitive response. These ovens are recommended for critical and analytical use in laboratory and pilot plant product research. Typical applications for the oven include aging, asphalt testing, curing, drying, pre-heating, conditioning, and life cycle testing. This unit is equipped with a stainless-steel interior for long-life operation and easy cleaning. Its triple wall construction minimizes external wall temperature which meets CE requirements to keep workspaces cool. The SMO3 forced air oven delivers precise uniformity, air distribution, and the peace of mind expected of the SHEL LAB brand. Features of this oven include: Embedded Microprocessor Control with Countdown Timer Horizontal Forced Airflow 1.75in (45mm) Access Port UL/CSA Approved CE Approval DIN 12880 Compliant 24 Month Limited Warranty Options: SMO3: OVEN, FORCED AIR, 3 CU FT, 115V SMO3-2: OVEN, FORCED AIR, 3 CU FT, 230V

$4,733.88 - $4,802.99

-

Sheldon Manufacturing SHEL LAB OVEN, FORCED AIR, 1.5 CUFT

SHEL LAB - OVEN, FORCED AIR, 1.5 CUFT The SMO1 has a quick ramp-up time to 306°C for faster cycle times. This unit includes an advanced PID temperature control system for sensitive response. These ovens are recommended for critical and analytical use in laboratory and pilot plant product research. Typical applications for the oven include aging, asphalt testing, curing, drying, pre-heating, conditioning, and life cycle testing. This unit is equipped with a stainless-steel interior for long-life operation and easy cleaning. Its triple wall construction minimizes external wall temperature which meets CE requirements to keep work spaces cool. The SMO1's forced air ovens deliver precise uniformity, air distribution and the peace of mind expected of the SHEL LAB brand. Features of this oven include: Embedded Microprocessor Control with Countdown Timer Horizontal Forced Airflow 1.75in (45 mm) Access Port UL/CSA Approved CE Approval DIN 12880 Compliant 24 Month Limited Warranty Options: SMO1: OVEN, FORCED AIR, 1.5 CU FT, 115V SMO1-2: OVEN, FORCED AIR, 1.5 CU FT, 230V

$4,284.68 - $4,388.35

-

20L Turnkey Reactor Kit

20L Turnkey Reactor Kit The BVV 20L Double Jacketed Glass Reactor Kit is the ideal solution for small to medium-sized solvent recovery and decarboxylation applications. This kit includes everything to get you up and running including a Single 20L triple-layer Glass Reactor with Condenser, either a BVV 19L Heated circulator capable of heating to 220C or a UL-listed Huber CC-315B capable of heating up to 300C, a 1HP Polyscience 6160T for chilling the condenser, a Welch BTpro100 for vacuum, 25ft of 3/8" Gum rubber tubing for vacuum connections, 20ft of reinforced PVC hose for the chiller, 1/2" Stainless Steel JIC Hoses for the heater, 5 Gallons of Therminol Heat transfer fluid and 5 Gallons of Propylene glycol. 20L Double Jacketed Glass Reactor Specifications Glass Material: GG-17 High Borosilicate Glass Internal Volume: 20L 6.75L Jacket Capacity Shelf Material: Aluminum Alloy Homogenizer Power: 110V/60Hz Homogenizer Speed: 0-400 RPM Digital Homogenizer Control Digital temperature probe readout included Double Jacket 3/4" Jacket Connections 1/4" and 3/8" Vacuum Connections Length: 20 in. Width: 30 in. Height: 76 in. Polyscience 6100 1 HP Chiller Specifications 6100 Series 1 HP Chiller with Turbine Pump, 100psi; 13.2l/min Display: LED Working Temperature Range C: -10 to 40 Temperature Stability: +/-0.1 Temperature Calibration Capability: 1-point Pump Type: Turbine Working Temperature Range F: 14 to 104 Working Temperature Range C: -10 to 40 Reservoir Capacity (gallons): 1.11 Reservoir Capacity (liters): 4.2 Reservoir Cover: Screw-on cap Cleanable Air Filter: Yes Cleanable Fluid Filter: Yes Temperature Stability F: +/-0.2 Temperature Stability C: +/-0.1 Display: LED Display Resolution (Read): 0.1 Pump Type: Turbine Process Connections: 1/2" FNPT Over-Temperature Protection / Failsafe Heater Control: Yes Reservoir Liquid Level Indicator: Yes Reservoir Drain: Yes Cool Command Refrigeration Technology: Yes WhisperCool Environmental Control Technology: Yes Maximum Ambient Temperature F: 95 Maximum Ambient Temperature C: 35 Overall Dimensions (LxWxH inches): 27.6 x 14.5 x 22.6 Overall Dimensions (LxWxH cm): 70 x 36.8 x 57.5 Compressor Size (HP): 1 Refrigerant: R134a Shipping Weight (pounds): 199 Shipping Weight (kilograms): 90 Welch BTpro100 Specifications Model BTpro100 Free Air Displacement@60Hz,lpm(CFM) 100(3.5) Ultimate Vacuum Pressure, Torr 6 Maximum Vacuum, in. Hg 29.7 Horsepower, HP (watts) 0.5(390) Built-in adjustable vacuum - Gas Ballast Yes Head Material PTFE Diaphragm PTFE Inlet/outlet Connection NW16 flange1 Agency (National Recognized Lab) cUL Weight, lbs (kg) 40.3(18.3) Overall DimensionsLxWxH in.(cm) 9x15x7(23x38x18) Shipping Weight, lbs(kg) 48.5 (22) Shipping Carton DimensionsLxWxH in.(cm) 18.9x12.6x11.8(48x32x30) HUBER CC-315B Specifications Common Specifications Temperature range (-20) 28...300 °C Temperature stability ±0.02 °C Temperature control TAC, self-optimizing (True Adaptive Control) Controller Pilot ONE (E-grade "basic") Safety class III / FL Protection class IP20 Dimensions (W x D x H) 13.19 x 15.04 x 17.05 inches Weight 48.51 pounds Heating / cooling capacity Heating capacity 3 - 3,5 kW Circulation pump Pressure pump max. 25 lpm : 0,7 bar | 6.6 gpm ; 10.15 psi Suction pump max. 18.5 lpm : 0,4 bar | bar 4.89 gpm ; 5.8 psi Pump connection M16x1 AG male Permissible viscosity 50 mm²/s Connections Pt100 connection Pt100 Digital interface RS232, Ethernet, USB Device, USB Host Operating data Old sku 2007.0003.01 Permissible ambient temp. 5...40 °C Bath opening W x D / BD 10.63 x 5.71 / 7.87 inches Bath volume 15 Liters | 3.96 gal Filling volume min. 11.5 Liters | 3.04 gal Power supply 208V 2~ 60Hz Current max. 16 A Fusing 20 A

$31,554.62 - $41,050.03