Meta Pumps

-

3CFM Single Stage Vacuum Pump

VE115 Single-Stage 3CFM Vacuum Pump This is the BVV™ Brand VE115 3CFM Single Stage Vacuum Pump. Single-stage vacuums pump exhaust into a chamber in the pump, which separates the oil from the pumped gas. Then, the oil is returned and the gas is exhausted. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer Oil life Lightweight Rubber Feet for noise dampening Reliable, Economical and Efficient Specification Free Air Displacement - (CFM) 3CFM # Of Stages 1 Voltage 110v / 60Hz Ultimate Vacuum 5 Pa HP 1/4 Oil Capacity 280ml Weight 15LB Intake Connection 1/4" SAE & JIC Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$207.32

-

V9D 9CFM Two Stage Vacuum Pump

BVV™ V9D 9CFM Two Stage Vacuum Pump This is the BVV™ V9D 9CFM Two Stage Vacuum Pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer Oil life Lightweight Rubber Feet for noise dampening Reliable, Economical and Efficient. Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$642.70

-

BVV 4 Cylinder Butane Recovery Pump - Meets ANSI 12.12.01

Butane Recovery Pump RECOVER MORE WITH LESS BVV is proud to introduce our new and powerful line-up of Butane & Propane Recovery Pumps. Blending compact design with improved Gen III Pistons from RKMAC, this collection of pumps can help you recover 1lb. Butane / 0:51 Seconds! This pump Assembled in the USA and all the critical parts are domestically made. Finding parts won't be an issue with this pump. The piston seals are rated to 450F and the average operating temperature of the pump is 175F leading to a long service life. Built to meet ANSI/ISA 12.12.01 for Use in Hazardous locations Class I & II, Division 2 and Class III, Divisions 1 & 2 environments. The computer controlled brushless DC motor operates at 3000 RMP nearly twice as fast as any other pump in its class. BVV Butane & Propane Recovery Pump Features: Process up to hundreds of pounds of vapor recovery before rebuild Equipped with oil-less reciprocating compressors for a clean product Designed and Assembled in the U.S.A. with domestic and global parts Affordable and highly cost efficient Available in 2-Cylinder, 4-Cylinder, CMEP Retrofit Comes with a 1-year Manufacturer’s Warranty covering Hemp usage Rated universal voltage 100-240V AC 50/60 Hz 1Ph Built with high efficiency Brushless DC Motor used for variable speed control Equipped with Viton O-Ring Seals for Butane/Propane gas and oil compatibility Piston Seal rebuild kits are USA made and available Part# BVV-3. Certified by ITS/ETL to ANSI/ISA 12.12.01 Noise level: 93.0 dB @ 1m Technical Data Sheet Product Brochure BVV™ 2 & 4 Cylinder Rebuild Instruction Manual Shop all recovery pumps here. *Butane recovery results were achieved on a collection base pressure greater than 30psi and using a recovery cylinder with a pressure <10psi. A dry ice coil was used in between the output port of the pump and the recovery cylinder to condense vapor.

$2,971.64

-

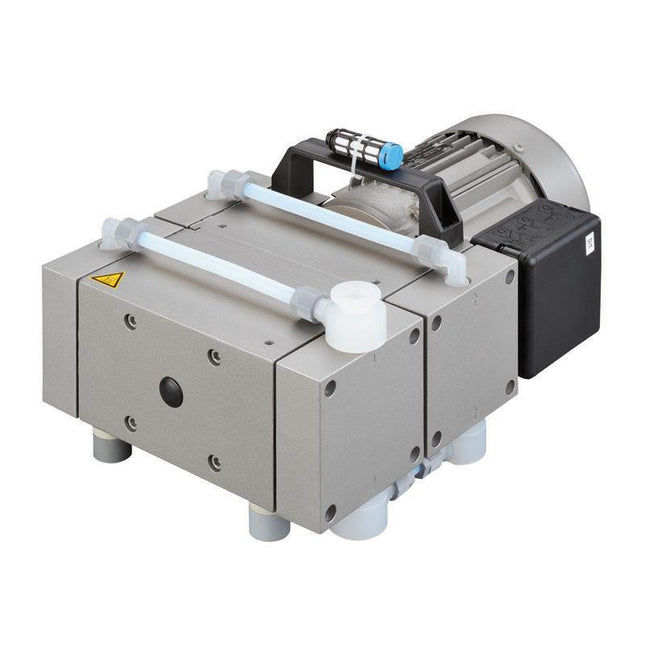

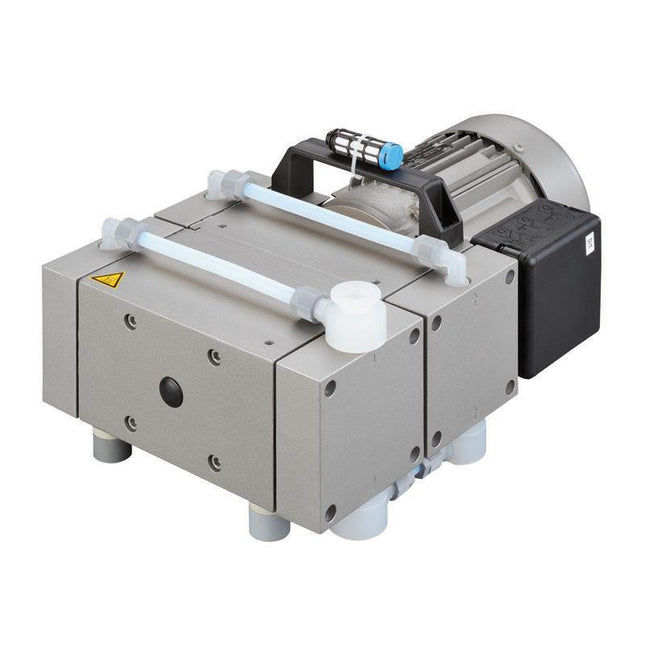

Welch Vacuum - Gardner Denver Welch 0.9 cfm DryFast 2 Head PTFE Diaphragm Vacuum Pump

***Note: This item has a possible 1-2 week lead time depending on stock availability*** The Welch .9cfm DryFast 2 Head Diaphragm vacuum pump is an ideal pump for 2L and 5L rotary evaporators and vacuum assited filtration. With built in vacuum control via Advanced Vapor Management (AVM), this pump is highly chemical resistance giving you excellent lifespan and vacuum control. Oil-Free, portable, and chemical resistance, this 2 head diaphragm design simplifies pump mantienance. Econimcal and long lasting, these pumps are perfect for any tough lab application. Key Features: Chemical Resistant Oil-Free Tuneable vacuum Specifications: Applications: Rotary Evaporation/Distillation (medium volatility solvents <110oC B.P., volume ~ 1 liter), Vacuum ovens - small, pumping harsh vapors & gases Type: Diaphragm vacuum pump Free Air Displacement cfm (l/min.) @60Hz: 0.9(25) Ultimate Pressure: 9(12) Maximum Vacuum: 29.6 Motor Horsepower (watts): 1/5(150) Adjustable Vac. / Gas Ballast: Yes Tubing Needed: 1/4(7) Intake Thread: M14(1/8) Overall Dimensions LxWxH in. (cm): 13.8x6.8x8.8 (35.2x7.2x22.3) Ship weight: 25 Shipping Carton Dimensions LxWxH in. (cm): 21x14x15 (52x35x37) Adjustable vacuum: knob style

$3,904.59

-

UL Listed BVV™ Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 5.6CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) Features Our Pro series are our most impressive line of rotary vane pumps available. Known for their high degree of efficiency and deep ultimate vacuum, all Pro models feature a dual-stage, chemical-resistant pump configuration designed to handle abusive, extended vacuum evacuations. Capable enough to comfortably handle laboratory and scientific applications, these pumps are also extremely simple in operation and require minimal maintenance. PTFE chemical resistant pump vanes provide superior corrosion resistance and reliability. Large oil reservoir and adjustable gas ballast standard on every model to increase pump oil lifetime. Internal check-valve included in every unit, prevents accidental pump oil backflow. Exhaust oil filter trap included. DEEP ultimate vacuum and KF25 inlet for optimal pumping speed. Lightweight, with noise-dampening rubber feet. Rugged, reliable, economical, and efficient pump designed for day in, day out use. Air cooled, thermally protected motors enclosed in a durable aluminum housing. Gas ballast valve for deeper vacuum. Steel inlet KF25 flange port with multiple intake size. Plastic handle, skid-resistant rubber base. 1 year limited warranty. Specification Electrical Voltage 120v Frequency 60 Hz Plug NEMA 5-15 US Standard Pump Flowrate 5.6 CFM Configuration 2 Stage Pump Ultimate Vacuum 0.3 Micron Ultimate Vacuum (with ballast) 6 Micron Oil Capacity 1000 ml Recommended Oil Ultragrade 19 Motor Power 1/2 hp Max Speed 1720 RPM Noise Level <56 dB Package Inlet / Exhaust KF25 / NW25 Weight 46 lbs Compliance CE Listed Ships With Exhaust Filter, Pump Oil, User Manual, Power Cable Warranty 1 year Components Pro Series Pump Components(Included exhaust filter not pictured) Performance Comparison Pump speed comparison for our Pro Series pumps. Downloads Maximum Attainable Vacuum at Altitude Reference Chart Vacuum Units Conversion Chart Additional Information How do Rotary Vane pumps work? Rotary vane pumps work by having a rotor with two adjusting vanes continuously rotating and exhausting air or any other molecules in the occupied space. The four stages which a rotary vane pump undergo are shown below Single Stage vs Two Stage Vacuum Pump: BVV™ Pro Series pumps are a dual-stage rotary vane pump style. Dual-stage pumps have two rotors and two sets of vanes that work together to fully pull a medium vacuum (1st stage) and then pull a better vacuum (2nd stage). These pumps will evacuate more quickly and can pull a deeper vacuum when compared to single-stage pumps. What is Gas Ballast and how does it work? During the pumping process the vacuum pump is trying to evacuate gas present in the occupied space, both non-condensable and condensable gases and vapors. Gas ballast helps increase the percentage of non-condensable vapors such that it will allow for the pump to efficiently exhaust all gases and vapors. This in turn will increase the overall efficiency and pumps life. When the pump is being used with non-condensable gases it's safe to keep the gas ballast valve closed. On the other hand, when there is a condensable gas or vapor present, the gas ballast should be opened appropriately. Gas ballast is used at the beginning of the pumping process when condensable gases are known to be present, then it's closed to finish pulling the deepest vacuum. For more info on rotary vane pumps please view our blog post: Rotary Vane Pumps and Gas Ballast Explained. Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$2,418.77

-

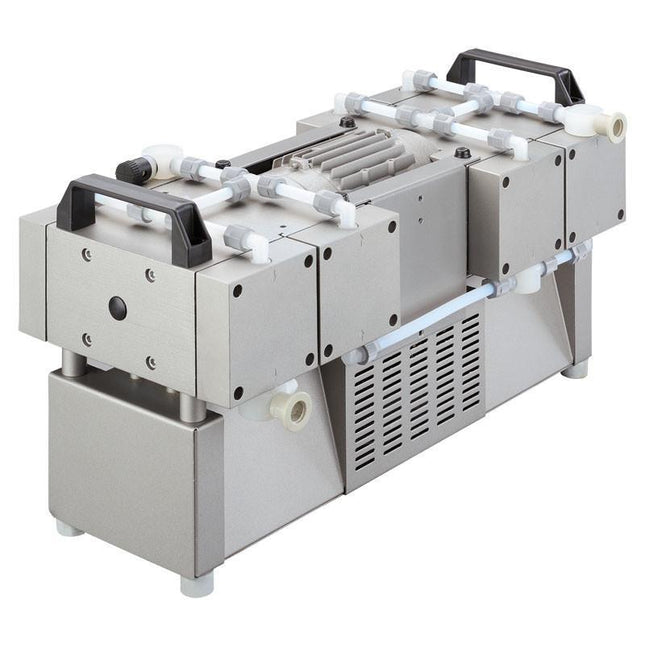

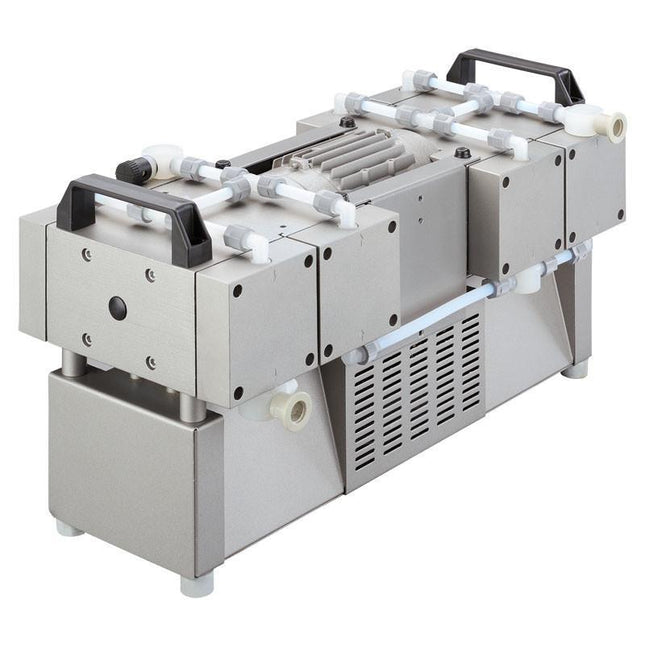

Welch Vacuum - Gardner Denver Welch High Capacity PTFE Diaphragm Pump 2052

Welch High Capacity Diaphragm Pump 2052 High Capacity dry diaphragm vacuum pump. PTFE contact surfaces, deep vacuum at with high flow. PTFE PUMP 115V 60HZ 1.5 TORR 64 LPM Free Air Displacement cfm (L min.) 2.3 Ult. Vac. Pressure, torr (mbar) 1.5 (2) Maximum Vacuum, in. Hg 29.9 Motor Horsepower - HP (wattS) 0.53 (390) Adjustable Vac J Gas Ballast No Tubing Nftftriftri. J.D. m. (mm) 1/4 (8) fntake (Exhaust) Thread NPT NW 16-1/4" MPT Weight Ibs. (kg) 40.3 (18.3) Overall Dimensions L x W x H in. (cm) 9 x 15 x 7 (22.8 x 38.1 x 17.8) Slip Weight, lbs. (kg) 49.8 (22.6) Snipping Carton Dimensions L x W x H in. (cm) 10.2 x 16.6 x 7.5 (26 x 42 x 19)

$5,993.03

-

Graco Graco Pneumatic Diaphragm Pump for Ethanol

Graco Pneumatic Diaphragm Pump for Ethanol This air driven diaphragm pump is designed to be used with ethanol filtration, pumping processes, and BVV Centrifuges. It's unique rugged design can withstand temperatures from -40C to -80C. The inner diaphragms are made out of PTFE and the main body of the pump is made out of 316 Stainless Steel. The pre-built version comes with a 0-160 psi pressure gauge, mini ball valve, and 1.5" Tri-Clamp connections for the inlet and outlet ports. Specifications -40C -80C Power Source Air Operated 100PSI 28CFM Certification Required No Certifications ATEX Fluid Section Material Stainless Steel Pump Inlet/Outlet 716-3/4 Inc, 16gpm (19mm, 61lpm) Center Section Polypropylene Standard Air Vale (NPT) Porting SST Standard Porting (NPT) Seats 316 SST Balls PTFE Diaphragms PTFE PTFE Overmolded Manifold O-rings PTFE Max Operating Temp. 220°F (105°C)

$3,565.96 - $4,968.85

-

3.5CFM Dry Floating Scroll Vacuum Pump #1 Candy Drying Vacuum Pump

3.5CFM Dry Floating Scroll Vacuum Pump 1 Candy Drying Vacuum Pump Oil and Maintenance Free! Introducing the BSVF6 Vacuum Pump, equipped with cutting-edge patented floating scroll technology for unparalleled performance. This pump boasts a 3.5CFM (100 L/min) pump speed and an ultimate pressure of 25 Microns (≤ 0.03 mbar), making it a powerhouse in creating and maintaining vacuums. The 100% oil-free design ensures clean and efficient operation, while the brushless DC motor, with 350W motor power and 200W installed power, provides reliability and longevity. With a compact size ideal for portable equipment, this vacuum pump offers unlimited vapor tolerance and a noise level as low as 55 dB(A) with its case. The SVF-E2-100 is maintenance-free, featuring a robust build with inlet/outlet connections in KF-25, air-cooled cooling system, and a wide ambient temperature range from -40ºC to 50ºC. Elevate your vacuum processes with this advanced, compact, and powerful solution. Specifications Model BSVF6 Pump Speed 100 L/min Ultimate Pressure ≤ 0.03 mbar (25 Micron) Motor Power 350 W Installed Power 200 W Motor Type Brushless DC Motor DC Voltage 48 VDC AC Voltage (with adapter) 100 – 240 VAC Maximum Speed 4000 RPM Vapor Tolerance Unlimited Maximum Inlet Speed Unlimited Maximum Outlet Speed 1 barg Noise Level (With Frame) 60 dB(A) Noise Level(With Case) 55 dB(A) Weight (With Frame) 7.5 kg Weight (With Case) 8.5 kg Dimensions (With Frame) 324×225×175mm Dimensions (With Case) 394×236×189mm Inlet/Outlet Connection KF-25 or G 3/8″ Cooling System Air – Cooled Ambient Temperature -40ºC to 50ºC

$2,418.77

-

UL Listed BVV™ Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 21.2CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) This is the BVV™ Brand 21.2CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 21.2CFM will pull a vacuum down to 0.3 microns effortlessly. The pump is designed with corrosion resistance and long-term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 110v 60Hz 1100 Watts Pumping Rate: 21.2CFM Ultimate vacuum without gas ballast: 0.3 micron Ultimate vacuum with gas ballast: 6 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2L/2.1 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Dimensions: 21 x 7.5 x 12 Shipping Dimensions: 29.5 x 9.5 x 16.5 Unit Weight: 95lbs Shipping Weight: 105lbs Recommended oil: Ultragrade 19 Noise level: <58 dB CE Compliance: Yes Warranty: 1 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result in the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$4,837.55

-

UL Listed Pro Series 11.3CFM Corrosion Resistant Two Stage Vacuum Pump

UL Listed BVV™ Pro Series 11.3CFM Two Stage Vacuum Pump (Pump holds a 1 year limited warranty) This is the BVV™ Brand 11.3CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 11.3CFM will pull a vacuum down to 0.3 microns effortlessly. The pump is designed with corrosion resistance and long-term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 110v 60Hz 750 Watts Pumping Rate: 11.3CFM Ultimate vacuum without gas ballast: 0.3 micron Ultimate vacuum with gas ballast: 6 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 1.5L/1.59 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Dimensions: 21 x 7.5 x 12 Shipping Dimensions: 29.5 x 9.5 x 16.5 Unit Weight: 66lbs Shipping Weight: 75lbs Recommended oil: Ultragrade 19 Noise level: <58 dB CE Compliance: Yes Warranty: 1 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result in the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$3,593.61

-

Pro Series 14.1CFM Corrosion Resistant Two Stage Vacuum Pump

Brand 14.1CFM Two Stage Pro Series This is the BVV™ Brand 14.1CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 14.1CFM will pull a vacuum down to 0.5 micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Compare to Cacejen or Xeno brand rotary vane vacuum pumps. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 115v 60Hz Pumping Rate: 14.1CFM Ultimate vacuum without gas ballast: 0.5 micron Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2L/2.1 quarts Motor Rate: 1720 RPM Working Temperature: 5C to 40C Unit Weight: 38KG / 84lbs Recommended oil: Ultragrade 19 CE Compliance: Yes Warranty 2 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$2,487.88 $1,935.02

-

Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump

BVV™ Pro Series 21.2CFM Corrosion Resistant Two Stage Vacuum Pump This is the BVV™ Brand 21.2CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 21.2CFM will pull a vacuum down to 0.5mtorr micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with K-25 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 115v 60Hz Pumping Rate: 21.2CFM Ultimate vacuum without gas ballast: 0.5mtorr Inlet/Outlet connection: KF25/NW25 Flange Oil Volume: 2.3L/2.4 quarts Working Temperature: 5C to 40C Unit Weight: 41KG / 90lbs Recommended oil: Ultragrade 19 CE Compliance: yes Warranty: 2 year limited warranty Pump Warranty Information Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$3,109.85 $2,556.99

-

Welch Vacuum - Gardner Denver Welch DryFast Collegiate Diaphragm Pump 2014

DryFast Collegiate Diaphragm Pump 2014 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details Chemical Resistant Oil-Free Tuneable Vacuum Welch DryFastTM PTFE Diaphragm Vacuum Pumps enable precise vacuum control for organic evaporations with exclusive Advanced Vapor Management (AVM). Oil-Free, portable, chemical resistant, 1 head diaphragm design simplifies maintenance. Choose from seven dry PTFE vacuum pump models with flows up to 70 L / min and adjustable vacuum down to 2 Torr. Economical DryFastTM vacuum pumps are perfect for tough lab applications. Model Number 2014 Applications Vacuum Filtration, SPE, Rotary Evaporations (volatile solvents <80oC B.P., volume <2 liters), pumping harsh vapors & gases, general laboratory vacuum Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 1.2(35) Free Air Displacement m3/hr (l/min.) @50Hz 1.75(29) Ultimate Pressure 40(53) Maximum Vacuum 28.3 Motor Horsepower (watts) 1/5(150) Adjustable Vac. / Gas Ballast Yes Tubing Needed 1/4(7) Intake Thread NPT M14(1/8) Overall Dimensions LxWxH in. (cm) 12x7.0x8.3 (30.5x 17.8x21.1) Ship Weight 19(8.6) Shipping Carton Dimensions LxWxH in. (cm) 21x14x15 (52x35x37) Adjustable Vacuum Knob

$2,750.49

-

Agilent Agilent IDP-15, 9 CFM, Dry Scroll Vacuum Pump

Agilent IDP-15, 9 CFM, Dry Scroll Vacuum Pump Overview The new Agilent IDP-15 dry scroll pump is designed for extremely quiet (<50dBA) and low vibration operation, delivering a peak pumping speed of 9 cfm at 60Hz.With a single-sided scroll design it offers fast, easy yearly maintenance and low cost of ownership. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump. Specification Base pressure (50 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Base pressure (60 Hz) - Torr & mbar 1.0 x 10-2 Torr 1.3 x 10-2 mbar Dimensions (WxHxL) 13.1 in x 14.3 in x 19.1 in Exhaust Connection NW16 Height 14.3 in Inlet Connection NW25 Input Voltage 220-230 VAC 100-115 Length 19.1 in Noise Level 50 dB(A) Pumping Speed (50 Hz) 12.8 m3/h 214 L/min 7.5 CFM Pumping Speed (60 Hz) 15.4 m3/h 256 L/min 9.1 CFM Width 13.1 in

$13,134.63 - $13,860.26

-

Welch Vacuum - Gardner Denver Welch CRVpro16 Direct Drive Rotary Vane Vacuum Pump - New

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro16 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details The new CRVpro family of direct drive vacuum pumps offers increased reliability and longer service interval vs. other direct drive rotary vane vacuum pumps. The CRVpro family consumes up to 36% less oil than comparable pumps. Three features drive these benefits: Runs 10°C cooler than comparable pumps. Slows corrosion. Has a 40% larger oil capacity than comparable pumps. Dilutes aggressive chemicals. Has a chemical resistant coating in the oil case and pump module. Protects non-moving parts. The CRVpro family includes all the features you'd expect in a direct drive rotary vane pump: gas ballast, forced oil lubrication, anti-suckback mechanism and thermal overload protection. Suitable applications include freeze drying, degassing, vacuum ovens and concentrators. 3161-01 is wired for North American 115V, 60Hz operation. Includes North American line cord, vacuum inlet hose barb suitable for gum rubber hose from 5/8" to 3/4" ID, and a charge of oil. 3162-01 is wired for European 230V, 50Hz operation. Includes 230V North American line cord, UK cord, and skuko cord, and a charge of oil. Direct drive pumps are not recommended for filtration, aspiration, drying electrophoresis gels, or other applications requiring sustained operation above 30 torr. Specifications Application CRVpro16 Free Air Displacement @ 60 Hz, cfm (L/min) 12.8 (363) Free Air Displacement @ 50 Hz, m³/hr (L/min) 18.3 (305) Ultimate Pressure, torr (mbar) 3x10⁻⁴ (2x10⁻⁴) Noise Level, dBA 55 Motor Speed, RPM, @60Hz, @50Hz 1750 (1450) Motor Power, HP (kW) 1.1 (0.85) Oil Capacity, mL 2400 Connection Flanges NW25 Inlet Hose Connection* 5/8" to 3/4" Weight, lbs (kg) 81.6 (37) Dimensions, LxWxH, in (mm) 22.4x8.1x11.4 (569x206x289)

$5,303.33 $3,455.39

-

ULVAC ULVAC DTC-41 110V 1.6 Cfm 2-Stage Chemical-Duty Diaphragm Pump TUV

ULVAC DTC-41 110V 1.6 Cfm 2-Stage Chemical-Duty Diaphragm Pump TUV Manufactured and imported directly from Japan, ULVAC DTC series diaphragm pumps feature integral forced-air cooling. They have two-stage PTFE diaphragms that are ideal for pumping corrosive gases and organic solvents. These pumps are oil-free, portable, and chemical-resistant, which means less maintenance and no more frequent and costly oil change, or cross contamination. Ai is now the official dealer of ULVAC vacuum pumps. These pumps are made in Japan with one year warranty and technical support from ULVAC. Features: TUV certified to UL and CSA standards Only PTFE components are exposed to vacuum, ideal for pumping corrosive gases and organic solvents Integral forced-air cooling Very compact and portable Designed to back most hybrid turbo pumps Applications: Rotary evaporator Evaporating system Vacuum concentrator Vacuum filtration Vacuum drying systems Medical/pharmaceutical equipments Centrifuge Laser-gas circulation Specifications Model ULVAC DTC-41 Part number 1042840 Electrical requirements 115V 60Hz or 230V 50/60Hz, single phase 0.13HP, 100 watts Full load current 1.1 amps Pumping rate 1.62 cfm (6 minutes to pump down a 0.9 cu ft oven) Gasket material All-PTFE Ultimate vacuum level 7.5 torr / 10 mbar Inlet/Outlet 3/8" hose barb Adjustable vac./gas ballast No Pump dimensions (LxWxH) 13 x 5.5 x 8.5 inches Shipping dimensions (LxWxH) 15 x 9 x 10 inches Pump weight 23 Lb Shipping weight 26 Lb Noise 53 dB(A) Working environment 32°F to 104°F (0°C to 40°C) Compliance TUV certified to UL and CSA standards

$3,061.48 - $3,641.98

-

Welch Vacuum - Gardner Denver Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro8

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro8 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details The new CRVpro family of direct drive vacuum pumps offers increased reliability and longer service interval vs. other direct drive rotary vane vacuum pumps. The CRVpro family consumes up to 36% less oil than comparable pumps. Three features drive these benefits: Runs 10°C cooler than comparable pumps. Slows corrosion. Has a 40% larger oil capacity than comparable pumps. Dilutes aggressive chemicals. Has a chemical resistant coating in the oil case and pump module. Protects non-moving parts. The CRVpro family includes all the features you'd expect in a direct drive rotary vane pump: gas ballast, forced oil lubrication, anti-suckback mechanism and thermal overload protection. Suitable applications include freeze drying, degassing, vacuum ovens and concentrators. 3081-01 is wired for North American 115V, 60Hz operation. Includes North American line cord, vacuum inlet hose barb suitable for gum rubber hose from 5/8" to 3/4" ID, and a charge of oil. 3082-01 is wired for North American 230V, 60Hz operation. Includes 230V North American line cord, UK cord, and skuko cord, and a charge of oil. Direct drive pumps are not recommended for filtration, aspiration, drying electrophoresis gels, or other applications requiring sustained operation above 30 torr Specifications Application CRVpro8 Free Air Displacement @ 60 Hz, cfm (L/min) 5.6 (158) Free Air Displacement @ 50 Hz, m³/hr (L/min) 8 (133) Ultimate Pressure, torr (mbar) 5x10⁻⁴ (4x10⁻⁴) Noise Level, dBA 50 Motor Speed, RPM, @60Hz, @50Hz 1740 (1450) Motor Power, HP (kW) 0.4 (0.5) Oil Capacity, mL 1000 Connection Flanges NW 16 Inlet Hose Connection* 5/8" to 3/4" Weight, lbs (kg) 49.6 (22.5) Dimensions, LxWxH, in (mm) 18.2x6.1x9.1 (463x157x230)

$5,735.95

-

Welch Vacuum - Gardner Denver Welch BTpro70

Welch BTpro70 ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Welch’s BTpro vacuum pump series has a flow and vacuum level to provide fast performance for your size of rotary evaporator, glass reactor, purge oven, or winterization filtration apparatus. These chemical duty PTFE diaphragm pumps are oil-free. The pumping action and deep vacuum comes from the movement of PTFE diaphragms within PTFE heads. All wetted services in the flow path are made of fluoroplastic making the BTpro pump highly chemically resistant. As a result, the BTpro vacuum pump series is near-zero maintenance. A cold trap placed in-line with BTpro pump is needed if terpenes are part of the flow path. The BTpro40 and BTpro70 models employ patented valve and diaphragm technology that generates a deep 15 Torr vacuum pressure with each PTFE head. In addition, both pump models have built-in tuneable vacuum to control evaporation rate. The tunable vacuum adjustment can also be used to stop accidental bumping/foaming. Model BTpro70 Free Air Displacement@60Hz,lpm(CFM) 70(2.5) Ultimate Vacuum Pressure, Torr 15 Maximum Vacuum, in. Hg 29.3 Horsepower, HP (watts) 1/5(150) Built-in adjustable vacuum Yes Gas Ballast - Head Material PTFE Diaphragm PTFE Inlet/outlet Connection 3/8” barb Agency (National Recognized Lab) CSA Weight, lbs (kg) 21.3(9.6) Overall Dimensions LxWxH in.(cm) 13.8x6.8x8.8 35x17x22 Shipping Weight, lbs(kg) 25 (11.3) Shipping Carton Dimensions LxWxH in.(cm) 21x14x15 (52x35x37)

$3,800.93

-

Welch Vacuum - Gardner Denver Welch ProBoost Air-Cooled Diffusion Pump

Welch ProBoost Air-Cooled Diffusion Pump Product Details Use Welch ProBoost in conjunction with a backing pump like the CRVpro to get deeper vacuum and higher flow. High Vacuum to 10⁻⁵ torr Use with high vacuum and Schlenk lines Employs air cooled diffusion pump Easy Attachment to backing pump Welch ProBoost is an air cooled gas jet pump (commonly called a diffusion pump). The gas jet is formed by directing boiling silicone vapors through a hollow cone. There are no internal moving parts. The pumping action commences when the vacuum pressure in the still (i.e. wiped film) goes below 0.2 torr (200 millitorr). On an empty, leak free still, ProBoost backed by a rotary vane pump lowers the vacuum pressure to 0.00002 torr (20x lower in pressure than a 2-stage rotary vane vacuum pump can do alone). ProBoost backed by a rotary vane vacuum pump will lower vacuum pressure to below 0.0001 torr in high vacuum and Schlenk lines. This high vacuum is invaluable to improve the results from reactions using air-sensitive compounds such as organometallics, metal amides, and hydrides. ProBoost has a built-in control board for fan and heater. When you turn on ProBoost, the fan and heater both turn on. When you turn off ProBoost, the heater turns off immediately and the fan runs for another 20 minutes to cool the pump. Specifications Maximum Pumping Speed, Air 80 l/sec Ultimate Vacuum Pressure 0.00002 torr Minimum Back Pump FAD at 60 Hz 2.8 CFM Maximum Discharge Pressure 0.2 torr Ambient Environmental Temp 10–30°C Heat-up time 7 minutes Inlet Connection NW50 Discharge Connection NW25 Silicone Oil Capacity Approximately 30 ml Cool Down Time 20 minutes Pump Dimensions, L x W x H 5.5 x 5.4 x 7.5 in Weight 5.6 lbs (2.5 kg) Download Manual

$5,459.52

-

Welch Vacuum - Gardner Denver Welch DryFast Ultra Diaphragm Pump 2042

Welch DryFast Ultra Diaphragm Pump 2042 This item may carry up to a 5 day lead time. Product Details Chemical Resistant Oil-Free Tuneable Vacuum Welch DryFastTM PTFE Diaphragm Vacuum Pumps enable precise vacuum control for organic evaporations with exclusive Advanced Vapor Management (AVM). Oil-Free, portable, chemical resistant, 2 head diaphragm design simplifies maintenance. Choose from seven dry PTFE vacuum pump models with flows up to 70 L / min and adjustable vacuum down to 2 Torr. Economical DryFastTM vacuum pumps are perfect for tough lab applications. Specifications Model Number 2042 Application Rotary Evaporation/Distillation (lowvolatility solvents <160oC B.P., ~ 2 Liter), Centrifugal Concentrators, Vacuum ovens (mid- size), pumping harsh vapors & gases Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 1.2(35) Free Air Displacement m3/hr (l/min.) @50Hz 1.75(29) Ultimate Pressure 2(2.7) Maximum Vacuum 29.85 Motor Horsepower (watts) 1/5(150) Adjustable Vac. / Gas Ballast Yes Tubing Needed 1/4(7) Intake Thread NPT M14(1/8) Overall Dimensions LxWxH in. (cm) 13.8x6.8x8.8(35.2x7.2x22.3) Ship Weight 25(11.3) Shipping Carton Dimensions LxWxH in. (cm) 21x14x15 (52x35x37) Adjustable Vacuum Knob

$6,254.26

-

Welch Vacuum - Gardner Denver Welch BTpro100

Welch BTpro100 Welch’s BTpro vacuum pump series has a flow and vacuum level to provide fast performance for your size of rotary evaporator, glass reactor, purge oven, or winterization filtration apparatus. These chemical duty PTFE diaphragm pumps are oil-free. The pumping action and deep vacuum comes from the movement of PTFE diaphragms within PTFE heads. All wetted services in the flow path are made of fluoroplastic making the BTpro pump highly chemically resistant. As a result, the BTpro vacuum pump series is near-zero maintenance. A cold trap placed in-line with BTpro pump is needed if terpenes are part of the flow path. Model BTpro100 Free Air Displacement@60Hz,lpm(CFM) 100(3.5) Ultimate Vacuum Pressure, Torr 6 Maximum Vacuum, in. Hg 29.7 Horsepower, HP (watts) 0.5(390) Built-in adjustable vacuum - Gas Ballast Yes Head Material PTFE Diaphragm PTFE Inlet/outlet Connection NW16 flange1 Agency (National Recognized Lab) cUL Weight, lbs (kg) 40.3(18.3) Overall DimensionsLxWxH in.(cm) 9x15x7(23x38x18) Shipping Weight, lbs(kg) 48.5 (22) Shipping Carton DimensionsLxWxH in.(cm) 18.9x12.6x11.8(48x32x30)

$6,323.36

-

Pro Series 35.3CFM Corrosion Resistant Two Stage Vacuum Pump

Pro Series 35.3CFM Corrosion Resistant Two Stage Vacuum Pump This is the BVV™ Brand 35.3CFM Two Stage Pro Series vacuum pump. The BVV™ Pro Series 35.3CFM will pull a vacuum down to 0.5 micron effortlessly. The pump is designed with corrosion resistance and long term continuous operation in mind. Comes standard with KF40 fittings, clamps, centering rings and oil mist exhaust filter which returns trapped oil back to the pump and allows for quieter operation. Adjustable gas ballast keeps moisture, solvent, and other contaminants from getting stuck in the pump. Compare to Cacejen or Xeno brand rotary vane vacuum pumps. Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Specifications Electrical Requirements: 220VAC - Note this pump does not come with a plug and must be wired manually. Pumping Rate: 35.3CFM Ultimate vacuum without gas ballast: 0.5 micron Inlet/Outlet connection: KF40/NW40 Flange Oil Volume: 4.5L/4.76 quarts Working Temperature: 5C to 40C Unit Weight: 68KG / 150lbs Recommended oil: Ultragrade 19 CE Compliance: yes Warranty 2 year limited warranty Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min.

$6,634.35

-

Welch Vacuum - Gardner Denver Welch BTpro170

Welch BTpro170 ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Welch’s BTpro vacuum pump series has a flow and vacuum level to provide fast performance for your size of rotary evaporator, glass reactor, purge oven, or winterization filtration apparatus. These chemical duty PTFE diaphragm pumps are oil-free. The pumping action and deep vacuum comes from the movement of PTFE diaphragms within PTFE heads. All wetted services in the flow path are made of fluoroplastic making the BTpro pump highly chemically resistant. As a result, the BTpro vacuum pump series is near-zero maintenance. A cold trap placed in-line with BTpro pump is needed if terpenes are part of the flow path. Model BTpro170 2163 Free Air Displacement@60Hz,lpm(CFM) 170 (6.0) 170 (6.0) Ultimate Vacuum Pressure, Torr 6 6 Maximum Vacuum, in. Hg 29.7 29.7 Horsepower, HP (watts) 0.6(440) 0.6(440) Built-in adjustable vacuum - - Gas Ballast Yes Yes Head Material PTFE Coated Al Diaphragm PTFE PTFE Inlet/outlet Connection NW16 flange NW16 flange Agency (National Recognized Lab) cUL cUL Weight, lbs (kg) 72.3 (32.8) 72.3 (32.8) Overall DimensionsLxWxH in.(cm) 21x11x12(53x28x31) 21x11x12(53x28x31) Shipping Weight, lbs(kg) 88.2 (40.1) 88.2 (40.1) Shipping Carton Dimensions LxWxH in.(cm) 23.6x15.8x16.1 60x40x41 23.6x15.8x16.1 60x40x41

$6,910.78

-

Welch Vacuum - Gardner Denver Welch BTpro40

Welch BTpro40 (CSA) Certified ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Welch’s BTpro vacuum pump series has a flow and vacuum level to provide fast performance for your size of rotary evaporator, glass reactor, purge oven, or winterization filtration apparatus. These chemical duty PTFE diaphragm pumps are oil-free. The pumping action and deep vacuum comes from the movement of PTFE diaphragms within PTFE heads. All wetted services in the flow path are made of fluoroplastic making the BTpro pump highly chemically resistant. As a result, the BTpro vacuum pump series is near-zero maintenance. A cold trap placed in-line with BTpro pump is needed if terpenes are part of the flow path. The BTpro40 and BTpro70 models employ patented valve and diaphragm technology that generates a deep 15 Torr vacuum pressure with each PTFE head. In addition, both pump models have built-in tuneable vacuum to control evaporation rate. The tunable vacuum adjustment can also be used to stop accidental bumping/foaming. Model BTpro40 Free Air Displacement@60Hz,lpm(CFM) 40(1.4) Ultimate Vacuum Pressure, Torr 15 Maximum Vacuum, in. Hg 29.3 Horsepower, HP (watts) 1/5(150) Built-in adjustable vacuum Yes Gas Ballast - Head Material PTFE Diaphragm PTFE Inlet/outlet Connection 3/8” barb Agency (National Recognized Lab) CSA Weight, lbs (kg) 15.0(6.8) Overall DimensionsLxWxH in.(cm) 12x7x8.3(31x18x22) Shipping Weight, lbs(kg) 19(8.6) Shipping Carton DimensionsLxWxH in.(cm) 21x14x15(52x35x37)

$2,349.67

-

Welch Vacuum - Gardner Denver Welch WOB-L Pump 2546

Welch WOB-L Pump 2546 Product Details Economical Oil Free Adjustable Vacuum / Pressure Reliable WOB-L Piston pumps are perfect for many common laboratory vacuum applications. Features: Vacuum and Pressure - to 60 Torr (27.6"Hg). Includes Vacuum and Pressure Regulators and Gauges - simple to adjust and monitor vacuum level and delivery pressure. Inlet Water Trap - float ball rises to seal off pump from accidental ingestion of water. Muffler quiets pump and filters discharge air. For use with dry or aqueous vapor applications only. Specifications Model Number 2546 Application Filtration (1 to 6 funnels), Aspiration, Desiccation, SPE, Replace water aspirator, Vacuum Drying Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 1.6(45) Free Air Displacement m3/hr (l/min.) @50Hz 2.3(38) Ultimate Pressure 60(80) Maximum Vacuum 27.6 Max Pressure PSIG (pascal) 100(106) Motor Horsepower (watts) 1/4(190) Adjustable Vac. / Gas Ballast Yes Tubing Needed 3/16(5) Intake Thread NPT 1/4 Overall Dimensions LxWxH in. (cm) 10x7.5x9 (25.4x19.1x7.7) Ship Weight 17(7.7) Shipping Carton Dimensions LxWxH in. (cm) 15.3x12.3x12.7 (39x31x32) Intake Catch Jar Yes Exhaust Catch Jar Yes Adjustable Vacuum Knob Adjustable Pressure Yes Vacuum Gauge Dial Pressure Gauge Dial

$1,416.71

-

ULVAC ULVAC DA-40S 1.6 Cfm Oil-Free Diaphragm Pump - New In Stock

ULVAC DA-40S 1.6 Cfm Oil-Free Diaphragm Pump (Please note: This item has a minimum 6 week Lead Time) This Diaphragm Dry type pump creates vacuum by reciprocate movement of rubber diaphragms. The structure of this pump makes Oil-free environment and maintenance easy. Different pumping speed and two/single stages are optional depending on your required pressure and pumping volume. Applications: Vacuum chucks, wafer and tip handling devices. Vacuum tweezers, medical appliances. Printing equipment. Automatic packing machines. Optical appliances. Specifications Unit 50Hz - 60Hz Actual Pumping Speed L/min 40 - 46 Ultimate pressure Pa 19.9 x 10^3 Motor Single phase, 100V, 60W, 4P, Capacitor run Full load current A 1.6 Weight kg 7.2 Inlet, outlet pipe diameter mm O.D. dia.9 × I.D. dia.5 (Rc 1/4) Ambient temperature °C 7 – 40 Overall dimensions mm 128(W) × 242(L) × 178(H)

$1,520.37 $760.19

-

Welch Vacuum - Gardner Denver Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro4

Welch CRVpro Direct Drive Rotary Vane Vacuum Pump CRVpro4 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** Product Details The new CRVpro family of direct drive vacuum pumps offers increased reliability and longer service interval vs. other direct drive rotary vane vacuum pumps. The CRVpro family consumes up to 36% less oil than comparable pumps. Three features drive these benefits: Runs 10°C cooler than comparable pumps. Slows corrosion. Has a 40% larger oil capacity than comparable pumps. Dilutes aggressive chemicals. Has a chemical resistant coating in the oil case and pump module. Protects non-moving parts. The CRVpro family includes all the features you'd expect in a direct drive rotary vane pump: gas ballast, forced oil lubrication, anti-suckback mechanism and thermal overload protection. Suitable applications include freeze drying, degassing, vacuum ovens and concentrators. 3041-01 is wired for North American 115V, 60Hz operation. Includes North American line cord, vacuum inlet hose barb suitable for gum rubber hose from 5/8" to 3/4" ID, and a charge of oil. 3042-01 is wired for North American 230V, 60Hz operation. Includes 230V North American line cord, UK cord, and skuko cord, and a charge of oil. 3046E-01 comes with an explosion proof motor. Conduit wiring installation required. No cord, plug, or switch provided. Direct drive pumps are not recommended for filtration, aspiration, drying electrophoresis gels, or other applications requiring sustained operation above 30 torr. Specifications Applications CRVpro4 Free Air Displacement @ 60 Hz, cfm (L/min) 2.8 (78) Free Air Displacement @ 50 Hz, m³/hr (L/min) 4 (67) Ultimate Pressure, torr (mbar) 5x10⁻⁴ (4x10⁻⁴) Noise Level, dBA 50 Motor Speed, RPM, @60Hz, @50Hz 1740 (1450) 1750 (1450) Motor Power, HP (kW) 0.4 (0.5) Oil Capacity, mL 1150 Connection Flanges NW 16 Inlet Hose Connection* 5/8" to 3/4" Weight, lbs (kg) 46.3 (21) Dimensions, LxWxH, in (mm) 18.2x6.1x9.1 (463x157x230)

$4,823.72

-

Welch Vacuum - Gardner Denver Welch WOB-L Pump 2581

Welch-L Pump 2581 ***Note: This item has a possible 1-2 week lead time depending on stock availability.*** Product Details Economical Oil Free Adjustable Vacuum Reliable WOB-L Piston pump is perfect for many common laboratory vacuum applications. Features: Vacuum to 5 Torr (29.8"Hg). Includes Vacuum Regulator and Gauge - simple to adjust and monitor vacuum level. Inlet Water Trap - float ball rises to seal off pump from accidental ingestion of water. Muffler quiets pump and filters discharge air. For use with dry or aqueous vapor applications only. Specifications Model 2581 Free Air Displacement @ 60 Hz, cfm (L/min) 3.5 (100) Ultimate Pressure, torr 5 Motor Power, HP (kW) at 60 Hz 1/3 (0.25) Inlet (Exhaust) Connection Thread NPT 3/8 Tubing Needed, I.D. in. (mm) 1/4 (7) Weight, lbs (kg) 24.5 (11.1) Dimensions, LxWxH, in (mm) 17x7.5x12 (430x420x190) 115V Order Number 2581B-50 / 2581B-24

$3,939.14 - $4,492.01

-

Edwards Edwards NXDS10iC 7.5 Cfm Chemical-Resistant Dry Scroll Pump

Edwards NXDS10iC 7.5 Cfm Chemical-Resistant Dry Scroll Pump Dry Scroll Pumps Dry scroll vacuum pumps are positive displacement pumps that use two spiral-shaped scrolls, one fixed and one orbiting, to trap and compress gas molecules. They are oil-free, low maintenance pumps that are commonly used for clean vacuum applications. Since they do not rely on oil for sealing and lubrication, they eliminate the risk of oil contamination and leakage, making them an environmentally-friendly choice. We in Edwards are driving scroll technologies to its best and we are committed to offer the most sustainable solution now and in the future. nXDSi Scroll Pumps Edwards nXDS is the great new shape of dry vacuum pumping. The nXDS has taken scroll vacuum technology to the next level. Improved performance, exceptional pumping capability, quiet operation and extended service intervals make nXDS the ultimate dry choice. The range covers pumping speeds from 6 to 20 m3/h. nXDS10i The nXDS10i same as the nXDS15i are our key products offering a small dry pump solution for most Scientific Applications. Standard variant suitable for a large variety of applications; R-variant with blanked gas ballast and C-variant being corrosion resistant. nXDS10iR - 100-127/200-240V 1Ph 50/60Hz The nXDS10iR has the gas ballast blanked off so it cannot be accidently opened. These variants are available for specialist applications such as gas recirculation, rare gas pumping and recovery or other applications where the dilution of the pumped gas is undesirable, or where sealing is integral to minimising potential gas loss. Features and Benefits Quiet operation - Better working environment Hermetically sealed for a lubricant-free vacuum environment - Contamination free process and no oil to dispose of Low power consumption - Low cost of ownership Intelligent and easy to use controls - Flexibility of operation Superior vapour handling - Wider range of applications Long service intervals - Maximised up-time Specifications Technical Data Power requirements 100-127V~10A or 200-240V~6A, 50/60 Hz, 280 watts Nominal rotational speed 1800 rpm Displacement 12.7 m3h-1/ 7.5 ft3min-1 Peak pumping speed 11.4 m3h-1/ 6.7 ft3min-1 Ultimate vacuum (total pressure) 0.007 mbar / 0.005 Torr / 5 micron Minimum standby rotational speed 1200 rpm Speed control resolution (% of full speed) 1% Maximum inlet pressure for water vapour 35 mbar Maximum water vapour pumping rate 145 gh-1 Maximum continuous inlet pressure 200 mbar Power connector 1-ph IEC EN60320 C13 Recommended fuse 10A, 250Vac rms Unit/shipping weight 57 Lb / 60 Lb Unit/shipping dimensions 16.5x10x12" / 20.5x13x14" (DxWxH) Inlet flange NW25 (KF25) Exhaust flange NW25 (KF25) Noise level 52 dB(A) Vibration at inlet flange < 4.5 mms-1 (rms) Leak tightness (static) < 1x10-6mbar ls-1 Operating temperature range 10 to 40 C / 41 to 104 F Edwards part number A73602983 Certification CE, UL

$16,977.02

-

Agilent Agilent AX-65 Air-Cooled Diffusion Pump

Agilent AX-65 Air-Cooled Diffusion Pump The Agilent AX-65 diffusion pump is a high-performance, air-cooled pump designed with bench-top analytical instruments in mind. Its vertical finned boiler and high power provide stable pumping and high helium pumping speed. This pump can be ordered with a cold cap or a dense baffle. The pump includes a fluid-level sight glass that indicates the fluid level at all times. Features High performance specifications means higher, cleaner vacuum levels Fluid-level sight glass provides quick indication of pump fluid status at all times The wide range of available pump configuration and flange combinations optimizes pump performance and fit for your application Compact design makes integration into space-limited equipment easy Full thermal protection guards against all over-temperature conditions “Pump-ready” thermal switch sends a signal when pump is operational Finned, vertical boiler promotes stable pumping, especially of light gases Three-stage fractionating jet with ejector stage purifies pumping fluid, giving higher forepressure tolerance Do NOT fill more than 30mL diffusion pump oil at a time

$3,593.61 - $3,706.94

-

Welch Vacuum - Gardner Denver Welch WOB-L Pump 2522

Welch WOB-L Pump 2522 Product Details Economical Oil Free Adjustable Vacuum / Pressure Reliable WOB-L Piston pumps are perfect for many common laboratory vacuum applications. Features: Vacuum and Pressure - to 100 Torr (26"Hg). Includes Vacuum and Pressure Regulators and Gauges - simple to adjust and monitor vacuum level and delivery pressure. Inlet Water Trap - float ball rises to seal off pump from accidental ingestion of water. Muffler quiets pump and filters discharge air. For use with dry or aqueous vapor applications only. Specifications Model Number 2522 Application Filtration (1 to 2 funnels), Aspiration, Desiccation, SPE, Replace water aspirator, Vacuum Drying Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 0.76(22) Free Air Displacement m3/hr (l/min.) @50Hz 1.1(18) Ultimate Pressure 100(133) Maximum Vacuum 26 Max Pressure PSIG (pascal) 100(106) Motor Horsepower (watts) 1/8(93) Adjustable Vac. / Gas Ballast Yes Tubing Needed 3/16(5) Intake Thread NPT 1/4 Overall Dimensions LxWxH in. (cm) 8.1x8.8x10 (20.6x22.4x25.4) Ship Weight 17(7.7) Shipping Carton Dimensions LxWxH in. (cm) 15.3x12.3x12.7 (39x31x32) Intake Catch Jar Yes Exhaust Catch Jar Yes Adjustable Vacuum Knob Adjustable Pressure Yes Vacuum Gauge Dial Pressure Gauge Dial

$1,140.28

-

Welch Vacuum - Gardner Denver Welch High Capacity Diaphragm Pumps 2062

Welch High Capacity Diaphragm Pumps 2062 ***Note: This item has a possible 1-2 week lead time depending on stock availability*** High Capacity dry diaphragm vacuum pump. PTFE contact surfaces, deep vacuum at with high flow. PTFE Pump, 8 heads. 115V 60HZ 1.5 TORR 119 LPM Specifications Includes 1/4" OD hose barb Common accessory, not included Vacuum Controller Pumping Speed 119 Lit/min. (4.2 CFM) Max. Vacuum 1.5 Torr (2 mbar) 29.9" Hg Tubing Needed 1/4" ID Inlet Connection UNIBARB Exhaust 1/4" OD Dimensions LxWxH inches 21x11x12 Weight 72 LBS Wiring 115V, 60 hz

$9,053.12

-

Agilent Agilent IDP-7 5.4 cfm Oil-Free Compact Dry Scroll Pump

Agilent IDP-7 5.4 cfm Oil-Free Compact Dry Scroll Pump Overview The new Agilent IDP-7 dry scroll pump is a compact, high performance, oil-free vacuum pump, delivering large pumping speed capacity and simple maintenance. Agilent IDP dry scroll pumps are oil-free, compact, quiet, high performance vacuum pumps. IDP pumps use a single-sided scroll design that allows for a straightforward 15 minute maintenance procedure with simple tools. Large pumping speeds and compact sizes are ideal for many applications in the research, analytical instrument, and laboratory markets. IDP pumps are hermetic, with the motor and all bearings completely isolated from the vacuum path. This design extends the bearing life and provides clean, dry vacuum to the application. An inlet isolation valve is available as an integral option that adds no additional height to the pump.

$8,479.53 - $9,015.80

-

Welch Vacuum - Gardner Denver Welch WOB-L Pump 2561

Welch WOB-L Pump 2561 ***Note: This item has a possible lead time of 2-3 weeks depending on stock availability.*** Reliable WOB-L Piston pump is perfect for many common laboratory vacuum applications. Features: Vacuum to 5 Torr (29.8"Hg). Includes Vacuum Regulator and Gauge - simple to adjust and monitor vacuum level. Inlet Water Trap - float ball rises to seal off pump from accidental ingestion of water. Muffler quiets pump and filters discharge air. For use with dry or aqueous vapor applications only. Features: Economical Oil Free Adjustable Vacuum Applications: Vacuum Filtration Many filtrations require only minimal vacuum to proceed; deep vacuum is not required. Vacuum pump flow required is roughly proportional to the total surface area of filters being used. Filtration of particulate-clogging samples can be improved somewhat with deeper vacuum, but a combination of larger filter surface area, smaller samples, and sequential use of decreasing porosity filter papers may also be required for timely filtration. Choose a standard duty vacuum pump for aqueous vapors; use a PTFE pump for resistance to harsh chemicals. Specifications: Applications Vacuum filtration up to 6 funnel manifold; Lab automation - aspiration of systems utilizing 96 / 256 well format; Welchnet lab installations up to 10 outlet fixtures (geneneral use, filtration) Type Laboratory Vacuum Pump Free Air Displacement cfm (l/min.) @60Hz 3.5(100) Free Air Displacement m3/hr (l/min.) @50Hz 4.9(83) Ultimate Pressure 60(80) Maximum Vacuum 27.6 Max Pressure PSIG (pascal) Motor Horsepower (watts) 1/3(250) Adjustable Vac. / Gas Ballast Yes Tubing Needed 1/4(7) Intake Thread NPT 1/4 Overall Dimensions LxWxH in. (cm) 15.0x10x10 (38.1x25.4x25.4) Ship Weight 24(10.9) Shipping Carton Dimensions LxWxH in. (cm) 21x12x15 (53x30x38) Intake Catch Jar Yes Adjustable Vacuum Knob Vacuum Gauge Dial

$2,764.31

-

Edwards Edwards XDS46iC 35cfm Chemical-Resistant Scroll Pump W/ Silencer

Edwards XDS46iC 35cfm Chemical-Resistant Scroll Pump W/ Silencer XDS scroll pumps have become industry standard when dry pumping is essential, proving to be a robust and clean vacuum pump solution in a range of applications and processes.The XDS46i shares many of the same features of the XDS35i but with a peak speed of 40 m3h-1. The pump has been optimised for maximum pumping speed at inlet pressures between 1 mbar and 10 mbar, making it ideally suited for LCMS and ICPMS applications requiring higher pumping speeds. The C variant has been modified so that it is more suitable for use on vapour handling processes and may be used in some applications using corrosive substances. The C version is fitted with Chemraz internal valve pads and stainless steel exhaust port. Applications Automotive; brake line and air conditioning evacuation Backing turbomolecular pumps Chemical applications including gel dryers and solvent recovery Coating systems High energy physics Mass spectrometry Features and benefits Lubricant-free within the vacuum envelope and hermetically sealed means a totally clean and dry vacuum to prevent cross contamination. No atmosphere to vacuum shaft seals means bearings are completely isolated, this prevents process attack and enable the bearings to run cooler and last longer. No oil to change eliminating cost of contaminated oil disposal. Simple single sided scroll design allows maintenance to be done in minutes for low cost of ownership and maximum uptime. Inverter drive for consistent pumping speeds worldwide. Specifications Power 100-120V or 200-230V switchable Displacement 50 or 60HzPeak pumping speed 50 or 60Hz 60 m3h-1 / 35 ft3min-140 m3h-1 / 23.5 ft3min-1 Ultimate vacuum (Total pressure) 5 x 10-2 mbar / 4 x 10-2 Torr Max continuous inlet pressure 40 mbar / 30 Torr Max continuous outlet pressure 0.2 bar gauge / 2.9 psig Max allowed inlet and GB pressure 0.5 bar gauge / 7 psig Motor power 0.52kW Power connector IEC EN60320 C19 Nominal rotation speed 1750 rpm Weight 48 kg / 105 lb Inlet / exhaust flange NW40 / NW25 Noise and vibration level 55.4 dB (A), <4.5mms -1 (rms) Leak tightness (static) <1 x 10-6 mbar ls-1 Operating temperature range 10 to 40 °C / 50 to 104 °F Compliance UL, CE, ATEX

$30,765.41

-

Edwards Edwards XDS35iC 25cfm Chemical-Resistant Scroll Pump W/ Silencer

Edwards XDS35iC 25cfm Chemical-Resistant Scroll Pump W/ Silencer Dry Scroll Pumps Dry scroll vacuum pumps are positive displacement pumps that use two spiral-shaped scrolls, one fixed and one orbiting, to trap and compress gas molecules. They are oil-free, low maintenance pumps that are commonly used for clean vacuum applications. Since they do not rely on oil for sealing and lubrication, they eliminate the risk of oil contamination and leakage, making them an environmentally-friendly choice. We in Edwards are driving scroll technologies to its best and we are committed to offer the most sustainable solution now and in the future. XDSi Scroll Pumps XDS dry scroll pumps have become industry standard when dry pumping is essential, proving to be a robust and clean vacuum pump solution in a range of applications and processes. XDS35i The XDS35i family of scroll pumps offers proven dry, clean vacuum solutions for a wide range of applications, with smart drive technology to look after the pump and provide worldwide performance. Now, a combination of the double start scroll form technology and by-pass valves have enabled Edwards to offer the XDS35i Enhanced range of pumps to complement our original family. XDS35i - 100-120/200-230V 50/60Hz 1Ph The XDS35i is our standard product variant which can be operated in a wide range of applications. Features and Benefits Bearing shield - ensures separation between process gases and bearing lubrication to ensure a clean vacuum and no possibility of contamination to lubrication from process gases, which prolongs bearing life. Smart motor drive - means consistent performance globally, pump overload protection and remote start/stop capability. High flow gas ballast feature - allows pumping of vapours including water vapour at up to 240 gh-1. Simple single-sided scroll design - allows maintenance to be done in minutes for low cost of ownership and maximum up-time. Take another step - the Enhanced versions offer up to 20% lower peak power requirements during initial pump down which means it has the ability to pump down large volume chambers with no loss of performance and has up to 25% more pumping speed at these roughing pressures which helps on higher frequency cycling applications as well. Specifications Specifications Power 100-120V or 200-230V switchable Displacement / peak pumping speed (50/60Hz) 43 m3h-1 / 25 ft3min-135 m3h-1 / 21 ft3min-1 Ultimate vacuum (Total pressure)Max continuous inlet pressure 1 x 10-2 mbar / 8 x 10-3Torr35 mbar / 23 Torr Max water vapour pumping rate - GB I / GBII 70 gh-1 / 240 gh-1 Max continuous outlet pressure 0.2 bar gauge / 2.9 psig Max allowed inlet and GB pressure 0.5 bar gauge / 7 psig Motor power / speed 0.52kW / 1750 rpm Power connector IEC EN60320 C19 Weight 48 kg / 105 lb Inlet flange / Exhaust flange NW40 / NW25 Noise and vibration 57 dB (A), <4.5mms -1 (rms) Leak tightness (static) <1 x 10-6 mbar ls-1 Operating temperature range 10 to 40 °C / 50 to 104 °F Compliance CE, UL, CSA, ATEX

$28,399.16

-

Edwards Edwards NXDS20iC 16.5 Cfm Chemical-Resistant Dry Scroll Pump

Edwards NXDS20iC 16.5 Cfm Chemical-Resistant Dry Scroll Pump Dry Scroll Pumps Dry scroll vacuum pumps are positive displacement pumps that use two spiral-shaped scrolls, one fixed and one orbiting, to trap and compress gas molecules. They are oil-free, low maintenance pumps that are commonly used for clean vacuum applications. Since they do not rely on oil for sealing and lubrication, they eliminate the risk of oil contamination and leakage, making them an environmentally-friendly choice. We in Edwards are driving scroll technologies to its best and we are committed to offer the most sustainable solution now and in the future. nXDSi Scroll Pumps Edwards nXDS is the great new shape of dry vacuum pumping. The nXDS has taken scroll vacuum technology to the next level. Improved performance, exceptional pumping capability, quiet operation and extended service intervals make nXDS the ultimate dry choice. The range covers pumping speeds from 6 to 20 m3/h. nXDS20i The nXDS20i is our highest peak pumping speed offering in the nXDS range. Standard variant suitable for a large variety of applications; R-variant with blanked gas ballast and C-variant being corrosion resistant. nXDS20iC - 100-127/200-240V 1Ph 50/60Hz The nXDS20iC has been modified so that it is more suitable for use on vapour handling processes and may be used in some applications involving corrosive substances. This chemically resistant version is fitted with Chemraz® internal valve pads and stainless steel fittings. Features and Benefits Quiet operation - Better working environment Hermetically sealed for a lubricant-free vacuum environment - Contamination free process and no oil to dispose of Low power consumption - Low cost of ownership Intelligent and easy to use controls - Flexibility of operation Superior vapour handling - Wider range of applications Long service intervals - Maximised up-time

$23,542.26

-

Edwards Edwards NXDS6iC 4.0 Cfm Chemical-Resistant Dry Scroll Pump

dwards NXDS6iC 4.0 Cfm Chemical-Resistant Dry Scroll Pump Dry Scroll Pumps Dry scroll vacuum pumps are positive displacement pumps that use two spiral-shaped scrolls, one fixed and one orbiting, to trap and compress gas molecules. They are oil-free, low maintenance pumps that are commonly used for clean vacuum applications. Since they do not rely on oil for sealing and lubrication, they eliminate the risk of oil contamination and leakage, making them an environmentally-friendly choice. We in Edwards are driving scroll technologies to its best and we are committed to offer the most sustainable solution now and in the future. nXDSi Scroll Pumps Edwards nXDS is the great new shape of dry vacuum pumping. The nXDS has taken scroll vacuum technology to the next level. Improved performance, exceptional pumping capability, quiet operation and extended service intervals make nXDS the ultimate dry choice. The range covers pumping speeds from 6 to 20 m3/h. nXDS6i The nXDS6i is our entry performance model in the nXDS range. Standard variant suitable for a large variety of applications; R-variant with blanked gas ballast and C-variant being corrosion resistant. nXDS6iC - 100-127/200-240V 1Ph 50/60Hz The nXDS6iC has been modified so that it is more suitable for use on vapour handling processes and may be used in some applications involving corrosive substances. This chemically resistant version is fitted with Chemraz® internal valve pads and stainless steel fittings. Features and Benefits Quiet operation - Better working environment Hermetically sealed for a lubricant-free vacuum environment - Contamination free process and no oil to dispose of Low power consumption - Low cost of ownership Intelligent and easy to use controls - Flexibility of operation Superior vapour handling - Wider range of applications Long service intervals - Maximised up-time Specifications Connection Vacuum Inlet Flange DN 25 ISO-KF (NW25) Connection vacuum outlet flange DN 25 ISO-KF (NW25) Cooling Method Air Cooling (forced - fan) Pressure Ultimate 2.901 x 10 -4 Supply Voltage 1Ph 100-127/200-240V 50/60Hz Specifications Technical Data Power requirements 100-127V~10A or 200-240V~6A, 50/60 Hz, 260 watts Nominal rotational speed 1800 rpm Displacement 6.8 m3h-1/ 4.0 ft3min-1 Peak pumping speed 6.2 m3h-1/ 3.6 ft3min-1 Ultimate vacuum (total pressure) 0.020 mbar / 0.015 Torr / 15 micron Minimum standby rotational speed 1200 rpm Speed control resolution (% of full speed) 1% Maximum inlet pressure for water vapour 35 mbar Maximum water vapour pumping rate 110 gh-1 Maximum continuous inlet pressure 200 mbar Power connector 1-ph IEC EN60320 C13 Recommended fuse 10A, 250Vac rms Unit/shipping weight 58 Lb / 63 Lb Unit/shipping dimensions 16.5x10x12" / 20.5x13x14" (DxWxH) Inlet flange NW25 (KF25) Exhaust flange NW25 (KF25) Noise level 52 dB(A) Vibration at inlet flange < 4.5 mms-1 (rms) Leak tightness (static) < 1x10-6mbar ls-1 Operating temperature range 10 to 40 C / 41 to 104 F Edwards part number A73502983 Certification CE, UL, CSA

$13,811.88

-

Edwards Edwards E2M80 57 CFM Dual-Stage High Capacity Vacuum Pump

Edwards E2M80 57 CFM Dual-Stage High Capacity Vacuum Pump Brand new Edwards E2M80 high capacity vacuum pump with one year manufacturer warranty from Edwards. https://shop.edwardsvacuum.com/products/a36504940/view.aspx Overview Edwards E2M series two stage oil sealed rotary vane vacuum pumps are renowned for their high ultimate vacuum, rapid pumping speeds, quiet operation and ability to handle water vapour. These direct drive rotary vane pumps are inherently compact and vibration free, and with their finger-proof fan and coupling housings they offer excellent operator protection.A comprehensive range of accessories is available to allow use on a wide variety of vacuum applications.Supplied with Ultragrade 70 Oil. Fomblin must be purchased separately for PFPE prepared pumps E2MFX. Technology Reliable system protection devices: Every pump has protection devices to prevent oil and air suck-back into the vacuum system if the pump stops while under vacuum. A variety of protection devices are used, depending on the pump size and cost, but emphasis is always placed on reliability and simplicity. When you use gas ballast on some of the pumps, you must use a solenoid operated gas ballast control valve to prevent air suck-back.Positive Pressure Oil Lubrication: The EM pumps incorporate a well proven positive pressure oil lubrication system which as been developed by Edwards to ensure correct lubrication in all duty modes and particularly to prevent oil starvation with high gas loads.An integral oil pump ensures that a more than adequate oil flow is pumped throughout the stator/rotor assembly at all times. This oil lubrication system means that the level of oil in the reservoir is less critical than with other pump designs. All pumps can operate with oil levels as low as 50-70 of the maximum. A full length, easily visible oil level sight glass allows you to conveniently monitor the oil level.Gas Ballast Facility: The EM pumps have a gas ballast valve. The valve is used to introduce a suitable gas into the stator during the compression stage: this prevents condensation of vapors inside the pump, dilutes and ejects corrosive gases and purges the oil of gases and vapors. Therefore, the use of gas ballast reduces oil degradation and pump corrosion.Low Noise Levels: The EM pumps maintain Edwardss reputation for quiet operation pumps with a typical noise level of 70 dB(A).Pumping Systems: The EM pumps, with suitable accessories, can partner a variety of other types of pump in vacuum systems for industry and for research. A special feature of the E2M80 is the central vacuum inlet which enables you to fit a mechanical booster pump with a minimum overhang, to create compact combination pumping systems.Easy Maintenance: The advanced lubrication system allows the EM pumps to work with wide oil level tolerances, which reduce the need to top-up the oil.All EM pumps are constructed with internal dowels, which reduce the need for skilled setting of tolerances, when the pump is dismantled. The pumps are designed so that all key components are easily accessible. The exhaust valve seals and oil distributor seals are exposed after the top cover is removed. The shaft seal can be replaced quickly without stripping down the pump. Applications Vacuum metallurgy processes Thin film coating technologies Pharmaceutical freeze drying Refrigeration and air conditioning system evacuation, drying, and backfilling Transformer and cable drying and impregnation, insulating oil treatment plant Lamp manufacture Cryogenic vessel evacuation Vacuum drying and distillation in chemical industries Semiconductor device manufacture Backing pump for high vacuum applications

$27,926.46

-

Edwards Edwards RV3 2.6 CFM Dual-Stage KF25 Vacuum Pump

Edwards RV3 2.6 CFM Dual-Stage KF25 Vacuum Pump Free KF25 flexible stainless steel bellow (3.3 ft), clamps and centering rings set ($219 value) included for immediately use (mist filter NOT included). Technical support and one year warranty covered by Edwards. https://shop.edwardsvacuum.com/products/a65201903/view.aspx Overview The Edwards RV series of small oil sealed rotary vane pumps deliver excellent ultimate vacuum pressure, high pumping speeds and superior vapour handling capabilities with quiet operation. With 400,000 units produced, these pumps offer proven performance that sets the industry standard for R&D and scientific pumping applications. Technology All our RV pumps are quiet. Noise levels of 48 dBA 50Hz have been achieved by extensive work on the pump design, drive train and motor.The pumps have the unique ability to deliver excellent ultimate vacuum in both high vacuum and high throughput modes with or without gas ballast. This gives the user an unrivalled opportunity to select the optimum pumping performance without compromising the application.The simple to use mode selector and accessible, three-position gas ballast control allow the pump to be reconfigured at any time, even when the pump is running.In high vacuum mode, the RV pump is ideal for analytical instruments, electron microscopes, physics research, backing turbo pumps and leak detection applications. Configure the same pump in the high throughput mode, and it becomes suitable for distillation, laboratory furnaces, backing vapor pumps, solvent concentration, freeze drying and other drying applications. Features High reliability – generous lubrication of moving parts. Safe process and systems – fast acting inlet valve for best in class anti‑suck back protection. Configured to meet your vacuum needs – mode selector and three position gas ballast No unplanned downtime – designed for easy maintenance. Better work environment – quiet running and intrusive frequencies minimised. Three position gas ballast allows either 60 g/hr or a class leading 220 g/hr (290 g/hr on RV12) of water vapour to be handled. Universal motor to cover the widest possible voltage and frequency range from a single variant. Smooth controlled inlet valve opening by oil pressure to eliminate pressure surges. Rapid closing inlet valve within 0.4 seconds of pump stopping. Applications Analytical instruments Centrifuges, ultra-high speed Coating Degassing/curing - oil, epoxy resin Distillation/extraction/filtration Freeze drying Furnaces Gas bottle filling/emptying Gel drying Glove boxes, ovens Laboratory bench top vacuum Leak detectors, Helium Load locks and transfer chambers Refrigeration manufacture Research and development Rotary, centirfugal evaporators Scanning electron microscopes - SEM SEM/FIB (ion beam repair) Solvent recovery Surface science instruments Turbomolecuar backing pumps

$5,944.65 - $6,837.53

-

ULVAC ULVAC DA-241 9.2 Cfm Oil-Free Diaphragm Pump

ULVAC DA-241 9.2 Cfm Oil-Free Diaphragm Pump Overview Manufactured and imported directly from Japan, ULVAC DA series diaphragm pumps creates vacuum by reciprocate movement of rubber diaphragms. Various pumping speed and two/single stages are selectable depends on your required pressure and pumping volume. These pumps are oil-free, which means less maintenance and no more frequent and costly oil change, or cross contamination. Ai is now the official dealer of ULVAC vacuum pumps. These pumps are made in Japan with one year warranty and technical support from ULVAC. Applications Alcohol evaporation Vacuum chucks, wafer and tip handling devices Vacuum tweezers, medical appliances Printing equipment Automatic packing machines Optical appliances Semiconductor industry Free three feet 3/8" white premium food grade silicone vacuum tubing ($19.99 value) included. Specifications Model ULVAC DA-241 Electrical requirements 110V 50/60Hz or 220V 50/60Hz single phase, 400 watts Full load current 6.0 amps Pumping rate 9.2 cfm Ultimate vacuum level 120 torr Inlet/Outlet 5/8" hose barb Adjustable vac./gas ballast No Unit/shipping dimensions (LxWxH) 8 x 16 x 11" / 18/11/14.5" Unit/shipping weight 58 Lb / 63 Lb Working environment 32°F to 104°F (0°C to 40°C) Noise level 70 dBA at near Atmospheric pressure 65 dBA at ultimate pressure Certification CE, TUV

$4,823.72 - $4,891.45

-

Agilent Agilent IDP-3 Dry Scroll Vacuum Pump With Inlet Isolation Valve