EVERY PRODUCT BUT HYDRO FOR WHOLESALE STORE

Vacuum Filter Trap

Vacuum Filter Trap This Vacuum Filter Trap is designed to remove potential contaminants from the vacuum line to prolong the lifetime of your pump. Packed with oil-free, stainless-steel SS304 wool and made with a glass jar, the filter trap may optionally be used as a low-cost cold trap. Welch Inlet / Exhaust Separator 1423B with stainless steel wool inside for even more filtration. We built out two separate fitting configurations for your convenience: just choose from the drop-down menu above! The trap ships default with two 3/8" Barbed fittings, but you may alternatively select our KF25 x 1/4" JIC fittings to receive your vacuum trap specially designed for use with our ovens! Simply clamp the trap directly onto your oven's KF25 vacuum port, then connect a 1/4" hose to your vacuum pump. Specifications: Inlet/Outlet: 3/8" FNPT (ships with adapters selected above) Jar: 230ml Glass -- Welch Inlet / Exhaust Separator 1423B Steel Wool: Oil-free SS304 Maximum Vacuum: <29"Hg Dimensions: 2.8" dia x 4.3" tall Please note this item does not include any vacuum tubing. To order, we recommend the 3/8" Gum Rubber Vacuum Tubing.

$503.97

Carbon Exhaust filter with CPS Adapter

BVV™ Carbon Exhaust filter with CPS Adapter This carbon exhaust filter is meant to prevent excess oil mist to leave the pump exhaust. Using the included adapter, this filter fits the following pumps: BVV BVV4D BVV7S BVV9D BVVSF6D BVVSF12D CPS VP4D VP6D VP6S VP10D

$139.99

Mobil Vacuum Pump Oil SAE Grade 20, ISO Viscosity Grade 68 (Mist Free)

BVV's Top Recommended Vacuum Pump Oil Ultra long Service Life! Mobil Vacuum™ Pump Oil is a special lubricant that is designed to be used for the lubrication of critical vacuum pumps. It has a very low vapor pressure and can be used when extremely high vacuum is required. It provides excellent wear and corrosion protection for vacuum pump components and will give the following benefits in service: Long lubrication life No viscosity change in use No odor or vapor generated Wide use temperature range Pulls vacuum down to 1micron or less (*BVV internal testing) SAE Grade 20, ISO Viscosity Grade 68 Safety Data Sheet Product Data Sheet BVV's Testimonial: "Mobil Vacuum Pump Oil has an insane service life and at BVV we have migrated over to Mobile for all of our laboratory pump applications. We use Mobil oil for Edwards, Welch, and the BVV Pro Series pumps. From vacuum purging and distillation we know we need good oil to get low vacuum and the fact that we can run continually for months on the same oil is amazing. This oil has led to less pump rebuilds and extended service life of our in house pumps used in our labs. Overall Mobil is the most reliable oil we have ever used at BVV." Water vapor is a common contaminant in vacuum systems and tends to condense inside the pumps. Mobil Vacuum Pump Oil has good demulsibility (Ability to separate oil from water) Which aids water removal and prevents its return to metal surfaces to cause rust and corrosion. This oil has a high degree of chemical stability enabling it to resist oxidation and the subsequent formation of sludge and deposits, an essential characteristic in all cases where continuous service is involved. This enables the oil to retain its original properties such as viscosity and demulsibility and so to prolong oil service life.

$42.00 - $384.98

AFS 4" Disposable Color Remediation Cartridge

AFS Disposable Color Remediation Cartridge Note: Stainless Steel filter housing sold separately. (Click Here for Housing) AFS Instruction Manual Download Here AFS Filters are the first and only disposable color remediation filter cartridges for the botanical extraction industry. Our Patent Pending design allows for an easy to use solution implemented into existing extraction systems and is now available as a standard integration from many equipment manufacturers. AFS Filters are a simple solution that allows for the use of prepackaged filters, which are available in different recipes depending on the application. With the integrated 2.5µm paper filter molded and sealed into the cup, there is no media leak through. Pre-packed means there's no need to be an expert in remediation filter media and how to construct filters; as well as eliminates the messy process of building/packing filters yourself. Disposable offers no need for cleaning the filter housings afterward and trying to un-clog stainless filter screens. Less R&D investment, less mess, and less downtime allows for higher throughput and more profit. These come in light, medium, and heavy filtration. Learn more about each: Light Filtration is the trimmed down version of the standard Medium filter. These are best suited for extractions using fresh high-end input materials that only needs a light cleaning. Medium Filtration is our standard go-to filter. This is the most commonly used and sold filter AFS offers.. It's great for general filtration and lightening of extracted products. Heavy Filtration is packed with the highest amount of active extraction media. These filters are best suited for exceptionally dark extractions or for extractions with normal input materials where the desired outcome is closer to clear. Heavy filters offer the highest level of filtration. Technical Specifications: Life Span: 1 Time use, 5-7 lbs. of dry material. Temperature Rating: -40°C-70°C Top Seal: Induction Sealed (No glue is used) Filter: Cellulose Paper Pressure Rating: Recommended 60psi, Paper will hold 80-90 psi Max. Media: Proprietary licensed recipe. Shell Material: Polypropylene Excellent compatibility and Safe for chemicals in our industry (Butane, Propane, Ethanol). Pressure Method: Nitrogen Assist, unless you open blast CRC. Then you can assist with an air compressor. *Please recycle your spent Cartridges.

$97.99 - $503.97

Duratherm S Thermal Fluid

DURATHERM S A silicone based heat transfer fluid that is ideally suited for high oxidation applications or completely exposed systems. Duratherm S is virtually impervious to oxidation at temperatures under 204°C (400°F) and offers superior protection from fluid degradation. Duratherm S is best suited for applications not prone to contamination or leaking. 316°C (600°F) maximum operating temperature Pumpable down to -50°C (-46°F) Very strong resistance to oxidation up to 204°C (400°F) Recommended for use in fully exposed systems like open baths Highly resistant to fouling for an extremely long service life Non-corrosive and non-toxic thermal fluid for added workplace safety TEMPERATURE RATINGS Max Bulk/Use Temp 316°C Max Film Temp. 366°C Pour Point ASTM D97 -66°C SAFETY DATA Flash Point ASTM D92 324°C Fire Point ASTM D92 336°C Autoignition ASTM E-659-78 437°C THERMAL PROPERTIES Thermal Expansion Coefficient 0.099 %/°C Thermal Conductivity W/m·K 38°C 0.133 204°C 0.109 204°C 0.109 260°C 0.100 288°C 0.097 316°C 0.093 Heat Capacity kJ/kg·K 38°C 1.717 204°C 2.034 204°C 2.035 260°C 2.144 288°C 2.194 316°C 2.248 PHYSICAL PROPERTIES Viscosity ASTM D445 cSt -18°C 113.08 40°C 36.14 100°C 16.57 260°C 5.19 288°C 4.54 316°C 4.03 Density ASTM D1298 kg/l 38°C 0.95 204°C 0.81 204°C 0.81 260°C 0.77 288°C 0.74 316°C 0.72 Vapor Pressure ASTM D2879 kPa 38°C 0.00 204°C 0.14 204°C 0.14 260°C 1.79 288°C 3.52 316°C 6.83 Distillation Range ASTM D2887 10% 494°C 90% 679°C Note: The values quoted in the table above are typical of normal production.They do not constitute a specification.

$209.99 - $9,519.45

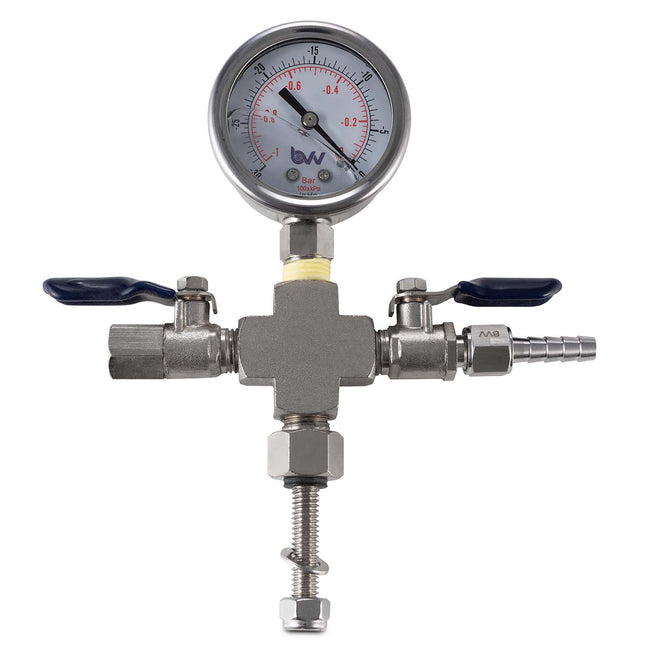

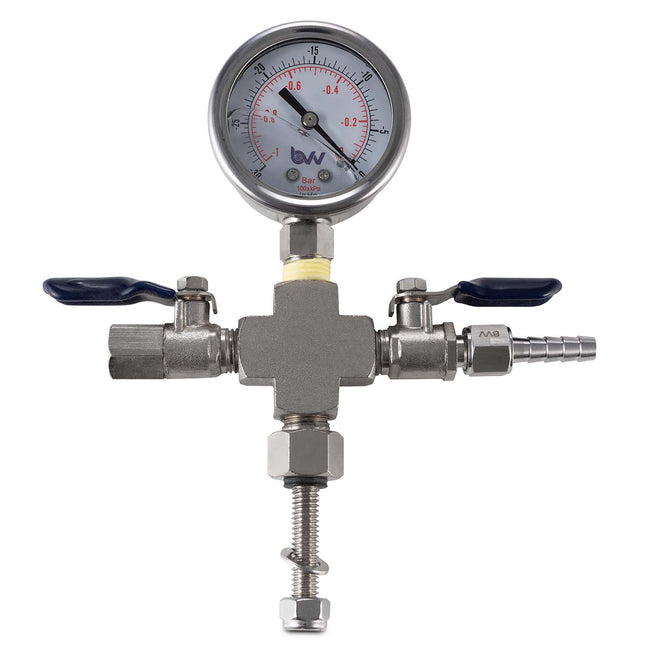

Valve Manifold - Cross with Hose Barb and Vacuum Gauge

Valve Manifold - Cross with Hose Barb and Vacuum Gauge This valve manifold fully made of nickel-plated plated brass includes a nylon lock nut, stainless steel washer, and rubber gasket. It also features 2 1/4 turn valves with a 1/4" FNPT Port and a 1/4" Hose Barb Port and the top of the cross has a glycerin filled vacuum gauge 0-(-30) with a 2-1/2" dial. Specifications: Material: Nickel Plated Brass Connection Type 1: 1/4" SAE Flare Connection Type 2: 1/4" Hose Barb Connection Type 3: 5/16-18 Screw thread Valve Type: 1/4 Turn Includes washer, O-ring, Nylon Locknut, and Vacuum Gauge

$47.60

Plastic Spigot for 1 Gallon Jugs

Plastic Spigot for 1 Gallon Jugs This self-venting spigot eliminates chugging and splashing. Made HDPE & polypropylene Fits 1QT or 1 Gallon containers sold by BVV™

$8.40

37° AN x Female Adapter

SSP - 37° AN x Female Adapter SSP Instrumentation TruFit® is manufactured from fully-traceable raw material to close tolerances and superior surface finishes. TruFit® provides optimal performance when installed in accordance with SSP’s recommendations and the design parameters appropriate for each type of connection – tapered thread, straight thread, and weld & braze. TruFit® components are cleaned in accordance with SSP documented work instructions using equipment calibrated to NIST standards with environmentally-safe and stable agents, ultrasonics, and heat/ temperature to remove all residual oil, grease, and loose particles. Stainless steel components are passivated to the requirements of MIL QQ-P-35 and ASTM A 967. Specifications Connection Type 1 37° AN Male Connection Size 1 Specified by User Connection Type 2 Female NPT Connection Size 2 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Working Pressure (PSIG) 1/4" - 6000 3/8" - 6000 NPT Pressure Rating >10,000PSI ASME B31.3 ***Note: ALL NPT Threads REQUIRE the user to properly install the fitting by using a thread sealant to prevent leaks. Best Value Vacs recommends GAS PTFE Tape SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$28.00$14.00

Dynalene HC-50 Heat Transfer Fluid

Dynalene HC-50 Dynalene HC/Potassium Formate is a water-based, low-temperature heat transfer fluid engineered to deliver the excellent heat transfer performance in applications down to -58°F (-50°C). With the temperature range -50°C to +218°C, Dynalene HC easily exceeds the performance of other water-based chemistries such as glycol /water mixtures, calcium chloride/water as well as hydrocarbon and silicone-based fluids. The fluid comes in five concentrations and is non-toxic, non-hazardous and non-flammable. Effective Calcium Chloride Alternative Dynalene HC/Potassium Formate heat transfer fluid is an excellent alternative to calcium chloride and other brine solutions because it demonstrates a higher thermal efficiency and lower corrosion rate. This fluid, as compared to other glycols, calcium chloride, and other brine solutions, should lower the leak and spillage rate, and reduce maintenance and repair costs on refrigerated systems. This is due to Dynalene HC's use of "safe" chemistries resulting in a high level of corrosion inhibition. The viscosity of calcium chloride solutions is also noticeably higher than Dynalene HC heat transfer fluid, which in turn makes Dynalene HC a more thermally efficient solution. Key Features: 100% Biodegradable Non-Toxic Non-flammable Aqueous-Based Superior heat transfer characteristics Attractive alternative to glycols and brines Applications: Pharmaceutical process Food and beverage Chemical process Climatic Chamber LPG Processing Low-Temperature Baths Temperature Range: Open systems: HC-50: -51°C (-60°F) to 110°C (230°F)Closed Systems: HC-50: -50°C (-58°F) to 218°C (425°F) Technical Data Sheet MSDS Engineering Guide

$167.99 - $18,898.90

10" Tri-Clamp x (2) 2" Tri-Clamp x 1.5" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid

10" Tri-Clamp/ Tri Clover x (2) 2" Tri-Clamp x 1.5" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid This End Cap comes with Four 1/4"-18 FNPT Threaded connection and One 1.5" Tri-Clamp ferrule and Two 2" Tri-Clamp ferrules welded to the end cap with a sanitary weld with a 3" Tube Extension Below the Lid. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid and the 1.5" Tri-Clamp Connection. These 7 connections are welded on a 10" Hemispherical Tri-Clamp End Cap. Specifications Material: 304 Stainless Steel Connection Type: 1.5" Tri-Clamp - 3" Tube Extension Below Lid on Center Tri-Clamp Port 2" Tri-Clamp 10" Tri-Clamp 1/4" - 18 FNPT Standard: 3A BVV™ 10" Tri-Clamp x (2) 2" Tri-Clamp x 1.5" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid - Drawing BVV™ 10" Tri-Clamp x (2) 2" Tri-Clamp x 1.5" Tri-Clamp x (4) 1/4" FNPT Hemispherical Lid - End Cap Chart

$356.98

6" Tri-Clamp Endcap w/ (4) 1/4" FNPT Ports

6" Tri-Clamp Endcap w/ (4) 1/4" FNPT Ports These End Caps come with four 1/4"-18 FNPT Threaded connections welded to the end cap with a sanitary weld. They allow the user to adapt and connect a threaded connection to the 1/4" port on a Tri-Clamp lid. Specification Material: 304 Stainless Steel Connection Type: Tri-Clamp 1/4" - 18 FNPT Standard: 3A Sizes Available: 6" BVV™ 6" Tri-Clamp Endcap w/ (4) 1/4" FNPT Ports - Drawing BVV™ 6" Tri-Clamp Endcap w/ (4) 1/4" FNPT Ports - End Cap Chart

$97.99

2L Standard Short Path Distillation Turnkey Setup

2L Standard Short Path Distillation Turnkey Setup The Standard Distillation Turnkey Setup includes all the components necessary to successfully perform distillation at an entry-level price point. Crossbar pictured is not included. We recommend purchasing multiple lab stands to accommodate your specific needs. The Standard Turnkey Setup Includes: 2L Distillation Kit 1/4" Flare x 1/4" Barb Adapter BVV™ 5L Heated Circulator BVV™ V9D 9CFM Two Stage Vacuum Pump High quality and durable Borosilicate 3.3 glass Vacuum-jacketed distillation adapter 3-way cow adapter, accommodating up to 3 pcs of 500mL flasks GCT-01 cold trap guarding from damage of vapors Kangaroo Traceable Digital Thermometer Flexible Gum Rubber Vacuum Tubing and Silicone Tubing for Flow Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. The pump should be run against the dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation The unit's max internal temperature cannot exceed 380C. The recommended max set temperature should not exceed 250C Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once the process is complete, stop heat, stop stir, and stop vacuum. Let the atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. ***Note: This entire setup will ship via motor freight.*** *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$3,639.79

Variety Pack - Small - 24ct - Rosin Filter Bags

"DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances Rosin Filter Bag Variety Pack Improve your yields with our Rosin Bags!- With no bag, product flattens and spreads out as it's squeezed- Our bags will keep your product packed tightly together and provide higher PSI- Our Rosin Filter Bags are made from woven, sewn Nylon: our weave pattern offers superior strength to help prevent blowouts.- Easy use: Simply pick up and toss bag when done. No need to manually separate material and product.- Safe: We use sewn bags, not glued. No messy glue residue to worry about! This is a variety sample pack of our Rosin Filter Bags. Each pack contains a total count of 24 mesh bags, in 8 different sizes:- (3) 25μm mesh bags, 2.5"" x 3.25""- (3) 45μm mesh bags, 2.5"" x 3.25""- (3) 73μm mesh bags, 2.5"" x 3.25""- (3) 90μm mesh bags, 2.5"" x 3.25""- (3) 120μm mesh bags, 2.5"" x 3.25""- (3) 160μm mesh bags, 2.5"" x 3.25""- (3) 190μm mesh bags, 2.5"" x 3.25""- (3) 220μm mesh bags, 2.5"" x 3.25"" "

$28.00

1.5" Tri-Clamp Stainless Steel Braided Hose with Convoluted PTFE Liner

1.5" Tri-Clamp Stainless Steel Braided Hose These chemically resistant PTFE braided hoses are a necessity when dealing with harsh chemicals or solvents and high-pressure applications. They provide a uniquely rugged, durable, and chemically resistant combination of Stainless Steel and PTFE. The inner core is corrugated PTFE to optimize the flexibility, protected by a braided stainless steel outer sleeve. These hoses have 1.5" Tri Clamp flanges on each end. ***Note: Do not exceed the specified hose bend radius or the inner PTFE liner will kink and the hose integrity will become compromised and should not be used. The 24" version can only bend 90 degrees. Specifications: Connection Type(s): 1.5" Tri-Clamp Liner Material PTFE (Teflon) Braid Material 304 Stainless Steel Flange Material 304 Stainless Steel Temperature Rating -65° to 450°F Pressure Rating 580 PSI Chemical Resistance Excellent Bend Radius (24" Length) 13" (48", 72", 96" Length) 5.5"

$321.98 - $650.96

BVV CMEP-OL Retro Fit Upgraded Head

Disclaimer: CMEP housing and motor do not come with this upgrade kit. It only includes bolt on cylinder heads and 2 stainless steel hoses and fittings to complete the upgrade. BVV is proud to introduce the first ever Butane & Propane Recovery CMEP-OL head upgrade. Blending compact design with improved Gen III Pistons from RKMAC, this newly designed head can recover 1lb. / 1:32 Seconds! Ditch the rebuild time on the CMEP-OL and replace it with this head. Rebuilds only take 45 mins and the parts are domestically made. The piston seals are rated to 450F and the average operating temperature of the pump is 187F leading to a long service life. FEATURES AND BENEFITS Process up to 500 hours of vapor recovery before rebuild Equipped with oil-less reciprocating compressors for a clean product Designed and Assembled in the U.S.A. with domestic and global parts Affordable and highly cost efficient 4-Cylinder Configuration Equipped with Viton O-Ring Seals for Butane/Propane gas and oil compatibility Update your existing CMEP unit to a faster, more dependable unit. Noise Level: 95.3dB at 1m NOTE: If you are retrofitting a Gen 1 CMEP you will have to make a cut on the outlet pipe going from the gauge/valve to the radiator and add a compression ferrule. SKU# ISSD4BF and ISSD4FF Technical Data Sheet *Butane recovery results were achieved on a collection base pressure greater than 30psi and using a recovery cylinder with a pressure <10psi. A dry ice coil was used in between the output port of the pump and the recovery cylinder to condense vapor.

$1,364.92

KF-25 x KF-25 x 1/8" FNPT Adapter

KF-25 x KF-25 x 1/8" FNPT Adapter This 304 stainless steel KF-25 adapter is specifically designed for adapting Digivac Bullseye Precision Vacuum Gauges to systems with reducing and minimizing connect / leak points on the system.

$40.60

Cold Trap Flare with washer, O-ring and locknut

Cold Trap Flare with washer, O-ring and locknut This is a replacement Cold Trap Flare with stainless steel washer, Buna-N O-ring and nylon locknut. Connection sizes are 1/4" HVAC Flare with 5/16-18 threaded Stem.

$11.20

150L 304SS Jacketed Collection and Storage Vessel with Locking Casters

150L 304SS Jacketed Collection and Storage Vessel with Locking Casters This massive 304 Stainless Steel Jacketed vessel can hold up to 150L of water (~40 gallons) and has a (3) 6" Tri-Clamp/ Tri Clover ports on the top and a 6" Tri-Clamp port on the bottom of the vessel. The outer jacket has 2x 1/2" FNPT ports to allow the circulation of heat transfer fluids and can also be used a vacuum jacket and can hold 21.5L or 5.68 gallons of fluid in the outer jacket. This unit also features 4 stainless steel legs with locking casters to allow the vessel to be moved around easily including 32" and wider doorways. (Note: this unit comes bare and does not include any fittings besides the legs with casters.) BVV™ 150LR - Technical Drawing Specifications Material 304 Stainless Steel Pressure Rating 250 PSI MAX Outer Jacket Rating: 100 PSI Connection Type(s): (3) 6" Tri-Clamp Top Ports 6" Tri-Clamp Bottom Port (2) 1/2" FNPT Ports on the jacket *High Pressure Clamps are required when using pressure greater than 100 PSI ***Note: This item will ship via freight ONLY.

$3,499.80

Glass Vac 10.75" Diameter LID

Glass Vac 10.75" Diameter LID Our patented gasket #9475627 Disclaimer: This item Includes Lid and Gasket Only This is a Replacement Lid for the following Vacuum Chambers: Glass Vac 3 Gallon Aluminum Vacuum Chamber Glass Vac 2 Gallon Aluminum Vacuum Chamber

$97.99

Replacement Glass Disk For Tri-Clamp Sight Glasses

Replacement Glass Disk For Tri-Clamp Sight Glasses This is a Glass Disk replacement For BVV Tri-Clamp / Tri Clover Sight Glass

$49.00

BVV™ ULTRA-Low Chest Style Freezer (-60°C) 10.6 Cubic Feet

BVV™ ULTRA-Low Chest Style Freezer (-60°C) 10.6 Cubic Feet Single Compressor Model, Best Pick for Energy Savings! The brand new BVV™ 10.6 cubic foot -60°C Ultra-Low Chest Freezer is a great all-around ultra-low temperature freezer at an affordable price with great temperature stability. This unit will run productively and adequately while brandishing a sleek design that will fit any lab or office setting. These units are appropriate for emergency clinics, creature cultivation, pharmaceutical organizations, and research foundations. They are intended to store pharmaceuticals, medication, immunizations, natural materials, testing reagents, research facility materials and can likewise be utilized to pre-chill solvents or winterize material. Key Features: Durable Powder Coated Exterior Aluminum Interior CFC-Refrigerant Free Large Digital Display Heavy Duty Rolling Casters 2 Wire Baskets for Extra Storage and Organization Specifications Model Number BVV™-60C106 Voltage 115V / 60Hz / 15A Capacity 10.6 Cu Ft. Temperature Range -30°C to -60°C Exterior Dimensions 50" x 30.1" x 34.8" Interior Dimensions 42.5" x 19.1" x 23.6" Weight 167lbs

$4,549.73

1.5" Open Blast Extractors - No Tripod 45-270g

1.5" Open Blast Extractors - No Tripod 45-270g Open Blast Extraction is an economical method with allows for instant extraction of plant material these columns are designed with ease of use in mind. These Extractors come with a Material Tube, 1x Mesh Buna Gasket, 1 Regular Buna Gasket, Clamp, Ferrule, 8" x 8" Silicone Pad, and Open Blast Top Cap. All Stainless Steel components are made out of 304 Grade Stainless Steel. Optional Upgrade(s) and Addons: Showerhead Upgrade: Allows the solvent to be spread more evenly through the plant material inside column. What's Included?: 1.5" Solid Endcap with 3mm Hole Standard Pressure Clamp Material Tube (User Can Upgrade Capacity Through Dropdown Options) 1.5" Ferrule 8" x 8" Silicone Pad 1.5" Buna N 100 Mesh Gasket (150 Micron) 1.5" Buna-N Gasket *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$65.80 - $118.99

TR21X4 Compressor Head Complete Replacement

TR21X4 Compressor Head Complete Replacement TR21X4 CPS TR21 Oil-less Compressor Head Assembly. Includes valves assembled ready to install. Does not include a high pressure switch. This kit is compatible with the following CPS pumps: TRS 21 Recovery Pump TRS 19 Recovery Pump

$153.99

1LB Inline CRC Kit

1LB Inline CRC Kit BVV's 1lb Inline CRC Kit can be utilized to adapt any of our 3" diameter 1lb material columns for inline adsorbent filtration. This kit includes a 3"x6" media column with a 300-gram media capacity and a filter stack including a 5 micron & 1 micron Dutch Weave Sintered Filter Discs. This 3" color remediation column is meant to be plumbed between the 3" 1lb material column and the existing hemispherical reducer of any of our 1lb closed loop hydrocarbon extractors.Assembly starts with placing the 1 micron sintered disk and gasket between the extracts hemispherical reducer and the included filter plate securing both with one of the included high-pressure clamps. Next, take the 5-micron sintered disk and the included ashless filter paper and rip around the circumference of the sintered disk, placing both atop the filter plate placing the sintered disc gasket and 3"x6" spool over top before securing both with the remaining high-pressure clamp. Since the spool secures the filter paper in place a filter plate ring is not required. This Kit includes: 3"x6" Tri-clamp Spool (300 gram capacity) 3" V3 Filter Plate 3" 5 Micron Sintered Disk 3" 1 Micron Sintered Disk 2x 3" Buna-N Sintered Disc Gaskets 2x 3" High-pressure Clamp 110MM 25 Micron Ashless Filter Paper (100qty) Your choice of 1000g of UltraClear, B80, Perform 5000 or 500g of Chemtek W1,W2, or W3. Sample Choices: Ultraclear: High-performance granular attapulgite B80: Naturally active attapulgite clay powder Perform 5000: Highly activated attapulgite clay for hard to bleach oils W1: Top-tier Acid activated bentonite clay perfect for preserving terpenes. W2: Natural bleaching clay that prevents terpene isomerization W3: Highly active adsorptive clay designed for difficult to bleach oils

$293.98

True Terpenes Banana Kush

True Terpenes Banana Kush Fragrance: Sweet Fruity Pungent Tropical Effects: Soothed Care-Free Uplifted Energetic This sweet, tropical indica-dominant blend gives a soothed, uplifted, creative focus. Banana Kush crosses Skunk Haze and Ghost OG. The fresh banana taste will help increase happiness, better restfulness, creativity, talkativeness, and attention. Storage Requirements: Keep in original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials and hot surfaces. No Smoking. Store in a cool dry place. Improper storage can cause terpenes to degrade. Dilution: Terpene Strain & Flavor-Infused Strain Profiles, Effects-Based Terpene Profiles & Terpene Flavors:The Terpene products above must be diluted prior to use. (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Viscosity Extract Modifier: The Terpene product above must be diluted prior to use. (1-3% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not use PRIOR to dilution. Banana Kush-Specific Certificates: Product Specification Certificate of Analysis Safety Data Sheet Food Safety Company-Specific Certificates: ISO 9001:2015 GMP Certification FSSC 22000

$170.09 - $3,149.82

1/4" 316SS Hard Line Tubing 5FT

1/4" 316SS Hard Line Tubing 5FT Stainless Steel 316 Hard line tubing for compression fitting connections and systems. Specifications Length 5' Material 316 Stainless Steel ASTM A-269 Max Allowed Working Pressure (PSIG) 1/4" x .035 5100 1/4" x .049 7500 1/4" x .065 10300 3/8" x .035 3300 3/8" x .049 4800 3/8" x .065 6550

$70.00 - $84.00

Chemglass PTFE Thermocouple Adapters

PTFE Thermocouple Adapters CG-1048-A Chemglass PTFE adapters are for use with either 1/8” or 1/4” thermocouples. The adapter has an outer Viton® o-ring to form a grease-free, airtight seal between the adapter and the listed size of the outer joint. The compression nut works in conjunction with the upper Viton® to provide an airtight seal between the adapter and thermocouple. Adapter design permits use with CG-145 Keck clips.

$77.00$54.60

CMEP-OL Connecting Rods - 2 Pack

CMEP-OL Connecting Rods - 2 Pack These are replacement connecting rods for the CMEP-OL recovery pump and come in a pack of 2.

$307.98$251.99

10 Gallon Aluminum - POT ONLY

10 Gallon Aluminum - POT ONLY This is a replacement part for the following Vacuum Chambers: Best Value Vacs 10 Gallon Aluminum Vacuum and Degassing Chamber Dimensions: 15" Tall x 14" Diameter Material: 3004 Aluminum

$181.99

KF-25 Cross - 4 Way Splitting of Vacuum Applications

This is a KF-25 Cross for 4 Way splitting of Vacuum Applications especially vacuum ovens connected to a single Vacuum Pump in an array. The material is 304 Stainless Steel with a 10^-7 torr @ 72F Vacuum Rating. Does not include KF-25 Clamp or O-ring these items are sold separately.

$78.40

5.75" Vacuum Chamber Gasket

5.75" Vacuum Chamber Gasket Our patented gasket #9475627 This Gasket fits the following Vacuum Chamber Lids: 2 Quart Resin Trap / Vacuum and Degassing Chamber Best Value Vacs 2 Quart Stainless Steel Vacuum and Degassing Chamber 1.5 Gallon (2QT Tank) Dry Ice, Liquid Nitrogen Cold Trap (INNER 2QT Containter GASKET)

$26.60

Terpenes Strawberry Cough

BVV™ Terpenes Strawberry Cough All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical data sheet. BVV Strawberry Cough Safety Data Sheet BVV Strawberry Cough Technical Data Sheet Strawberry Cough: Strawberry Cough descended from a cross of a Haze cultivar and an unknown runt that had supposedly been grown near a strawberry patch. The strawberry flavor is undeniable in this profile, its as if you’re right back in the field the first plant came from. Notes of pine, pepper and spice can be detected below the strawberry surface. Definitely a daytime variety, Strawberry Cough will put you in a place to get some work done.. FRAGRANCE: Strawberry, pine and pepper EFFECT: Focus and energy Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$14.00 - $209.99

Glass Vac 5 Gallon Aluminum Vacuum Chamber and V4D 4CFM Two Stage Vacuum Pump Kit

Glass Vac 5 Gallon Aluminum Vacuum Chamber and V4D 4CFM Two Stage Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed and tested in Naperville, Illinois. With our unique patented gasket design, this chamber is sure to withstand 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system), allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Glass Vac 5 Gallon Aluminum Vacuum Chamber V4D 4CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum Specifications Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 10" Tall x 12" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micron Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result from the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$760.16

Polyscience 7 Liter MX Refrigerated Circulator (-20°C to 135°C)

Polyscience 7 Liter MX Refrigerated Circulator (-20°C/135°C) Specification Description -20, 7 L Ref. Circulator Controller Type MX Display 3.25" LCD Working Temperature Range °C -20° to 135° Temperature Stability °C ±0.07° Temperature Calibration Capability 1-point Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Pump Type Pressure Flammability Class (DIN 12876-1) I (NFL) Working Temperature Range °F -4° to 275° Working Temperature Range °C -20° to 135° Nominal Cooling Capacity @ +20C (W) 200 Reservoir Capacity (gallons) 1.85 Reservoir Capacity (liters) 7 Reservoir/Tank Material Stainless Steel Reservoir Cover Included DuraTop Yes LidDock Yes Cleanable Air Filter Yes Working Access (L x W x D) (inches) 6.18 x 5.59 x 5 in Working Access (L x W x D) (cm) 15.7 x 14.2 x 12.7 cm Temperature Stability °F ±0.13° Temperature Stability °C ±0.07° Display 3.25" LCD Display Resolution (Set) 0.01 Display Resolution (Read) 0.01 Pump Type Pressure Pump Speed One Process Connections 1/2" O.D. Barbed Tubes Flammability Class (DIN 12876-1) I (NFL) Over-Temperature Protection / Failsafe Heater Control Yes Low Liquid Level Protection Yes Reservoir Drain Yes Included Software PolyTemp Viewer, USB driver Maximum Ambient Temperature °F 95° Maximum Ambient Temperature °C 35° Overall Dimensions (L x W x H) (inches) 21.3 x 8.7 x 25.4 in Overall Dimensions (L x W x H) (cm) 54.1 x 22.1 x 64.5 cm Refrigerant R134a Environmental Compliance RoHS, WEEE Shipping Weight (pounds) 84.0 Shipping Weight (kilograms) 38.1 Catalog Page Number 44-45 60 Hz Only Part Number MX07R-20-A11B Maximum Pressure (psi) 2.3 Maximum Pressure (bar) 0.16 Maximum Pressure Flow Rate (gpm) 3.60 Maximum Pressure Flow Rate (l/min) 13.5 Cooling Capacity @ -20°C (W) 30 Cooling Capacity @ 0°C (W) 120 Cooling Capacity @ +20°C (W) 200 Cooling Capacity @ +100°C (W) 200 Included Hardware Fitting Kit for External Applications Heater Wattage 1100 Electrical Requirements (VAC/Hz/Ph/A) 120/60/1/12 Regulatory Approvals ETL Key Features: Large, Universal icon and English display On-screen prompts Single-point calibration capability Certifications: Regulatory Approvals: ETL Operator's Manual

$5,739.67

Inline Candy Desiccant Dryer

The inline candy desiccant dryer is a necessary accessory to any one using a vacuum oven for candy drying. The column will need to be filled by the user with silica gel and has fine mesh stainless filters on each end to hold in the beads. We recommend connecting the vacuum inlet from the pump to the top of the column to prevent any water accumulation in the beads from reaching the pump via gravity. The bottom of the column will connect to the oven itself. The column holds 1.5lb of silica gel desiccant. Its water holding capacity is 36%. Since 1lb of candy can hold as much as 40-60g of water, a 1lb column of desiccant will have the capacity to handle approximately 4.5-5lb of fresh candy drying before it needs to be reactivated. Silica gel can be reactivated by placing in an oven on a sheet pan for 0.5-2.0 hours at 200-250F or microwave for 10 minutes on defrost. BVV Hook Up Guide - Quick Assembly PDF Size Variants Standard Size 2" Outside Diameter x 24" Tall Column (Holds 1.5lbs Silica) XL Size Column 3" Outside Diameter x 36" Tall Column (Hold 6.5lbs Silica) Extension Kit for the Standard Column 2" Outside Diameter x 24" Tall (Holds1.5lbs Silica) *Silica Gel: Source from amazon (USE Clear silica gel) https://www.amazon.com/Dry-Quart-White-Silica-Desiccant/dp/B014VM4AZI/ref=sr_1_3?crid=N1FARCPRUFPT&keywords=silica+gel+clear&qid=1678139406&sprefix=silica+gel+cle%2Caps%2C100&sr=8-3

$41.30 - $545.97

TRS21 Complete Connecting Rod Assembly Upgrade Kit

BVV-K1 Included in this kit: Complete connecting rod assemblies with 2-piece SS piston, piston seals, viton o-rings, and 2-piece piston tool. Looking to rebuild your TRS21 and want to upgrade to a more efficient and longer lasting piston/rod setup? This kit comes with a fully assembled connection rod and 2 piece piston. The piston is made out of SS making it a great choice for any application where bacterial growth must be eliminated. This design focuses on long life piston seal and wear band. This kit utilizes a Viton energized o-ring specifically designed for butane and or propane recovery used in the extraction process. By utilizing this kit the piston seal and wear band can be easily removed without having to disassemble the rod from crank. An inexpensive tool (*INCLUDED* SKU: BVV-TL1) is required to rebuild the seals next time service is needed. The tool uses two posts to lock into the top of the piston and a 5/8” Hex heat to remove the top part of the piston. After this has been done the wear ring can slide out and the piston seal can be replaced with a new one, the kit can be purchased for all future piston seal and wear band rebuilds (*NOT INCLUDED* SKU: BVV-3). Loctite 242 (*NOT INCLUDED*) will also be required for proper installation. A test was performed between the OEM piston and seal design and the BVV. Results show that the BVV had a much less leak rate than the OEM design. After hours of use the leak rate of the OEM design was unable to recover the complete initial solvent batch. This affects the efficiency of the recovery process.

$272.98

20L Collection Base

The 20 Liter Collection Base allows for vacuum assistance during filtration. It works most efficiently when paired with the Refinement Filter but can be used as a standalone unit. It includes a dedicated vacuum valve and deidcated liquid dip tube valve which allows for direct injection into a rotovap. Key Features: Stainless steel design for greater thermal conductivity and improved lifespan Easy to clean and disassemble with Tri-Clamp stainless steel parts Collection vessel for vacuum and storage of material Liquid dip tube for direct injection into rotary evaporator after filling Key Specifications: 20 Liter Collection Base (12"x12" Welded Bottom Spool w/ 12" Lid) Dedicated Vacuum Valve Dedicated Dip Tube Valve Silicone gaskets with high alcohol resistance 1/4" and (2)3/8" Stainless steel barb connections Polycarbonate sights for easy viewing

$1,189.93

Street Tee

SSP - Street Tee SSP Instrumentation TruFit® is manufactured from fully-traceable raw material to close tolerances and superior surface finishes. TruFit® provides optimal performance when installed in accordance with SSP’s recommendations and the design parameters appropriate for each type of connection – tapered thread, straight thread, and weld & braze. TruFit® components are cleaned in accordance with SSP documented work instructions using equipment calibrated to NIST standards with environmentally-safe and stable agents, ultrasonics, and heat/ temperature to remove all residual oil, grease, and loose particles. Stainless steel components are passivated to the requirements of MIL QQ-P-35 and ASTM A 967. ***Note: ALL NPT Threads REQUIRE the user to properly install the fitting by using a thread sealant to prevent leaks. Best Value Vacs recommends GAS PTFE Tape Specifications Connection Type 1 Female NPT Connection Size 1 Specified by User Connection Type 2 Female NPT Connection Size 2 Specified by User Connection Type 3 Male NPT Connection Size 3 Specified by User Material 316 Stainless Steel ASTM A-276 and A-479 bar stock, A-182 forgings. Working Pressure (PSIG) 1/4" - 7750 3/8" - 6800 NPT Pressure Rating >10,000PSI ASME B31.3 SSP proudly makes Duolok®, TruFit®, FloLok® and hundreds of other products 100% in the USA!

$61.60$30.80

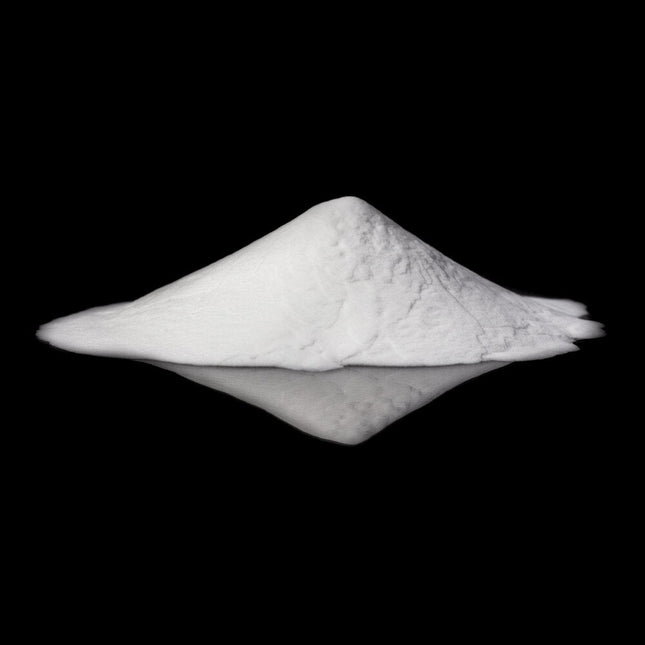

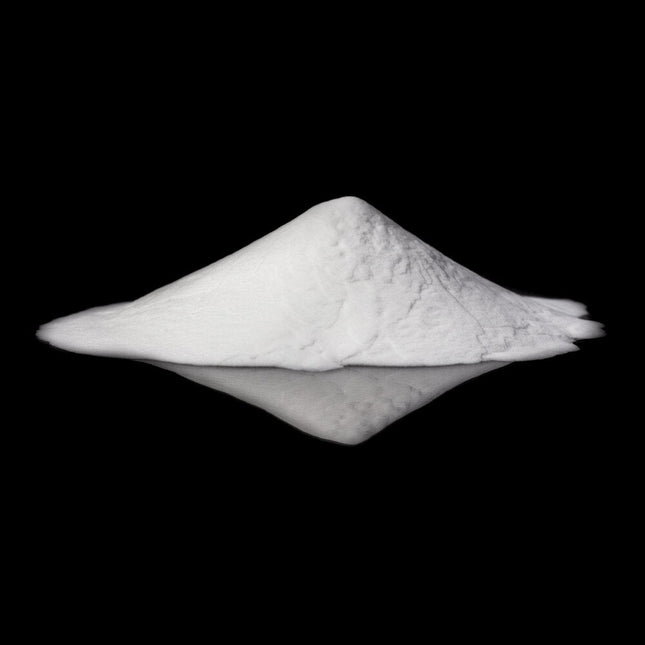

Syloid® XDP 3150 Silica : Turn Distillate to Powder (FDA Approved Ingredient)

Syloid® XDP 3150 Silica Solid Carrier for lipid- based drug delivery systems Convert your Distillate to a Powdered Ingredient! SYLOID® XDP is engineered for transforming liquids to free-flowing solids particularly oily actives and lipid-based systems. SYLOID XDP silica provides the most complete release of loaded oils. We use this Patented silica for a variety of infusions, and to build repeatable recipes. Simply mix by hand slowly or with a machine mixer 1:1 (distillate to SYLOID). SYLOID® XDP give you the ability to create large powdered ingredient batches that can be used later. The best part is that your ratio of distillate equals the SYLOID. This makes batching and recipes easy to replicate and you don't have to be an expert at infusing. Recommended Use: Capsules, Chewable Tables, Gummy Products, Chocolates, Drinks BVV Recommends Ratio of 1:1 Weight (Distillate to SYLOID) Oil-Liquisolid Formulations Maximum daily intake: 5.4 grams/day The daily intake calculations are for adults of average 132 lbs. Benefits: FDA Approved Inactive Ingredient Stays in Suspension for edibles, delivering an equal dose into each serving! Optimum Bioavailability Complete release of your Active Ingredients! Pharmaceutical product for Infusion products Mixing by hand for small batches, or kitchen planetary mixer SLOWLY Water Based Drink Notes Does not stay suspended evenly in drinks, shaking before drinking required. Distillate can Release in hot drinks above 170F. (this does not apply to edible recipes) SYLOID® XDP Technical Data Sheet SYLOID® XDP Standard Operating Procedures - Liquid Loading Syloid® XDP is a high purity silica gel that consists of over 99% SiO2, and it meets ICH guidelines on elemental impurities, the test requirements of U.S. Pharmacopoeia-National Formulary for Silicon Dioxide and European Pharmacopoeia for Silica, Colloidal Hydrated. This product is labeled CAS # 7631-86-9 amorphous silica gel or silicon dioxide. An approved FDA Database inactive Ingredient, approved for drug products.

$177.79 - $5,319.69

Carbon Chemistry MGS Activated (Mag-Sil PR)

Carbon Chemistry MGS Activated (MagSil-PR) Carbon Chemistry MagSil-PR® powder is some of the highest purity and quality MagSil-PR® on the market. Activated Magnesium Silicate (MagSil-PR®) lets you remove pesticides, improve color, and improve the clarity of your products, thanks to its powerful properties. Magnesium silicate will bind to polar, water-soluble compounds. Once these compounds have bonded with the MagSil, the solution can be filtered through a recommended, 20-micron mesh screen. Particle Mesh Size: 60/100 Carbon Chemistry MagSil-PR® - SDS

$223.99 - $2,799.84

1L Distillation Kit

1L Distillation Kit The 1L Distillation Kit is a simple, easy to use system designed for small personal use. It includes all stands, clamps, clips, and tubing needed to begin distilling immediately. This Kit Does NOT include a vacuum pump or circulator. Please see the below recommendations for both as well as recommended add-ons. Or check out our 1L Standard Distillation Turnkey Setup which includes vacuum pump and circulator. Recommended Vacuum Pumps: Pro Series 5.6CFM Corrosion Resistant Two Stage Vacuum Pump (premium option) Just Better 6 CFM 2 Stage Deep Vacuum Pump (USA made economy option) Best Value Vacs VE280 9CFM Two Stage Vacuum Pump (economy option) Recommended Circulator: Polyscience 7 Liter MX Heated Circulator (economy option) Polyscience 7 Liter MX Refrigerated Circulator (premium option with chilling capability) Recommended Add-Ons: Glass Dewar Style Cold Trap (recommended cold trap) Bullseye Precison Vacuum Gauge (premium vacuum gauge for measuring depth) CT40 or CT80 Electronic Cold Trap (electronic cold trap, dry ice replacement) Specifications: Boiling Flask Size: 1L Receveiving Flask Size: 250ml Batch Capacity approximate: 200-400 grams Run time: 4 to 8 hours dependent upon material composition and throughput Distillation Temperature Range: 140-250C (Do not exceed 250C) Recommended Condenser Temperature: 40-50C This Kit Includes: Glass Components: 1L 2-Neck Boiling Flask Short Path Head Triple Neck Cow Receiving Flask 3x 250ml Single Neck Round Bottom Flask 14/20 Thermometer Adapter 24/40 Thermometer Adapter 120mm Glass Funnel 14/20 Stopper 24/40 Stopper Accessories: Magnetic PTFE Stirring Bar Retriever 5 Pack of Metal Keck Clips Dow Corning High Vacuum Silicone Grease Tripod Stand 1L Analog Heating and Stirring Mantle 3 Finger Clamp Adjustable 0-70mm Boss Head -13mm 6" x 6" Scissor Jack 250-500ml Cork Stand 10ft of Vacuum Hose 10ft of Chiller Hose 1/4" Vacuum Manifold Traceable Kangaroo Thermometer - Digital 10 Pack of Adjustable Stainless Steel Tubing Clamps Fiberglass Insulation Rope 10 Feet 1.5 Gallon Cold Trap (2QT Tank) Dry Ice, Liquid Nitrogen w/ 2x 1/4" Barb Adapters Distillation Quick Start Guide This guide gives basic quick start instructions for distillation systems. It is intended to provide a starting point for learning the process. Parameters should be adjusted to suit specific needs, Before beginning distillation, ensure the following steps have been taken: Vacuum Pump is in good working order. Pump should be run against dry load to allow internals to warm up. Oil should be clear. Cloudy or dark oil should be changed. All glass components are in good working order and ready to be assembled A winterization and degassing procedure has been done to prepare oil for distillation Once all three of these steps have been completed, you are ready to begin distilling. Begin by placing stir bar in boiling flask and then load your material. This should be done using a funnel. A small amount of alcohol in the oil will give it a thinner consistency making it easier to transfer. Assemble all glassware and ensure each joint is properly greased. Do not use too much, as the vacuum pressure might pull some grease into the system. To ensure a full seal, spread grease in a circular motion by rotating glassware Attach circulator to condenser and set temperature to 50C. Allow circulator to reach temperature before beginning distillation. Connect vacuum pump to manifold. The manifold will allow you to isolate each individual component as well as let atmosphere into and out of the system. Connect receiving cow to cold trap. Connect cold trap to manifold. Connect vacuum gauge to manifold. At this point, ensure all connections are correct. Also ensure receiving cow is positioned to collect the first fraction in the far-left receiving flask. Circulator should be at its set temperature. Turn on vacuum pump to begin process. Turn on heat and set to 60C. Vacuum pump will begin to pull down and temperature will begin to rise. Watch the gauge to monitor vacuum pressure and stability. Start stir slower and increase speed with temperature. Once you are close to 60C, increase the temperature 20 degrees. Continue to raise the heat incrementally in 20-degree steps, increasing the set temperature as you near your set point. Increase temperatures incrementally until you reach 220C. You will see your first fraction somewhere between 180C and 190C or slightly before. This is the “heads” fraction. You will move to your second fraction when you see an increased reaction in the head, a slight color change toward golden, as well as a thickening of distillate. When this fraction hits, allow the distillate to “self-clean” the head for a minute or two then, rotate the cow to the middle receiving flask. Collect your “main body” fraction. You will see temps between 190-220C during this fraction. Continue to increase stirring speed as necessary. Reaction in the head may vary but it should never stop. As fluid level in the boiling flask decreases, increase stir speed. The final “tails” fraction is a mixture of the first and second fractions and should be saved for re-distillation later. Ideally, you want to turn the cow to the final flask before the tails fraction hits. The “tails” fraction has an obvious color change and will be darker than the “main body” fraction. You will see temps between 200-250C during this fraction. As fluid level in the boiling flask decreases even more, set stirring RPM higher (1000+ RPM). You may need to compensate with a bit more heat to finish of the final fraction as well. Once process is complete, stop heat, stop stir, and stop vacuum. Let atmosphere into the system. Be sure to properly store your distillate as exposure to air and light can cause oxidation. *Notice to Customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. BVV™ is not responsible for the failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail, which can cause bodily harm or damage to the surrounding area.

$1,399.92

Best Value Vacs 10 Gallon Aluminum Vacuum Chamber and V9D 9CFM Two Stage Vacuum Pump Kit

Best Value Vacs 10 Gallon Aluminum Vacuum Chamber and V9D 9CFM Two Stage Vacuum Pump Kit (Chamber comes with 2 yr. limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart This Kit Includes: Best Value Vacs 10 Gallon Aluminum Vacuum Chamber V9D 9CFM Two Stage Vacuum Pump 2 year limited warranty on the chamber 1 year limited warranty on the pump Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specifications Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 15" Tall x 14" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micron Air Filter Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports Compatibility Explanation: BestValueVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers. The lid may only be cleaned with soapy water. SVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization. The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Excludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result from the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$1,066.74

Glass Vac 12.75" Diameter LID

Glass Vac 12.75" Diameter LID Our patented gasket #9475627 Disclaimer: This item Includes Lid and Gasket Only This is a Replacement Lid for the following Vacuum Chambers: Glass Vac 5 Gallon Aluminum Vacuum Chamber

$188.99

2QT Stainless Tall Vacuum Chamber Digital Heating Jacket

2QT Stainless Tall Vacuum Chamber Digital Heating Jacket A vacuum chamber heating jacket provides the user the ability to evenly heat the chamber around the circumference while being very stable. When combined with a heating pad, this device covers most of the vessel, distributing heat on what is being degassed in the vessel. Perfect for your industrial needs, each heating jacket is equipped with a user-friendly digital temperature controller and Velcro Connections on each end. This product comes with the Digital Heating Jacket ONLY, and does not include the chamber. Key Features: Velcro Connections on each end. Digital PID Temperature Controller for accurate and stable control. Made of heat resistant silicone. Specifications: Min Temp: Ambient +5F Max Set Temp: 160F Ultimate Max Temp: 248F Voltage: 110VAC Only Precision: 1 degree F increments. Stability: +/- 0.2 F Dimensions: Approx. 5.9"W x 16.9"L Instructions Included Relay Lifespan 10million Cycles Reprogrammable: Yes This product comes with the Digital Heating Jacket ONLY, does not include the chamber.

$188.99

Soya Peptone Powder for Mushrooms Mycology

Soya Peptone Powder Bacteriological GradeBest for Vigorous Mycelia Growth Soya peptone is a protein hydrolysate derived from soybeans, used as a rich nutrient source in microbiological culture media and fermentation media to promote the rapid growth of microorganisms, particularly fastidious ones. It serves as a source of nitrogen and other essential nutrients, is available in powder form STORAGE: Cool dry conditions, sealed original package Mix: Mix: 1 gram per. 500ml pH: 6.41 ODOR: Soy bean protein smell. SOLUBILITY: Soluble in water. TOTAL NITROGEN: 10.45% W/W TOTAL ALPHA AMINO NITROGEN: 3.09% W/W TOTAL PLATE COUNT: 1098 CFU/gm YEAST AND MOLDS:: 200CFU/gm E.COLI: NEGATIVE SALMONELLA: NEGATIVE STA{HYLOCOCCUS AUREUS: NEGATIVE PSEUDOMONAS AERUGINOSA: NEGATIVE SHELFLIFE: 4 years. CAS# 91079-46-8 Directions for Use: 1. Mix 1g of soya peptone powder per 500ml of liquid culture or agar recipe for vigorous mycelia growth. 2. Boil and stir until powder is fully dissolved. Sterilize the mixture for 45min @15psi 250°F (121°C) in a pressure cooker or autoclave.

$16.80 - $74.20

CHEMTEK Silica 60

Silica 60 is used as an adsorbent to remove gums and phosphatides and to separate fractions in chromatography. Silica 60 SDS

$42.00 - $2,449.86

120LB DIPTUBE Tank High Purity USA 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend - 99.5% Guaranteed

120LB High Purity USA 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend DIPTUBE - 99.5% Guaranteed DISCLAIMER(S): This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in WELL VENTILATED AREAS! Notice: This item will ship via Freight ONLY. BVV™ always recommends the distillation of every solvent before use. Tank does not include CGA 555 fitting. Must be added through dropdown or bought separately. California now prohibits the retail sale of any Non-Odorized butane in quantities larger than 150ml. If you are not a retail purchaser you can call in to place an order. Actual 50/25/25% N-Butane/Iso-Butane/Propane Tri-Blend liquid weight is 114LB Permitted Sales Include the Following: Medical Collectives or Cooperatives operating under CA Health & Safety Code Section 11362.775 Persons licensed to perform volatile solvent extraction activity under CA Bus & Prof Code Division 10 Manufacturers, wholesalers, resellers, or retailers solely for the purpose of resale Ultra-high purity 50/25/25% N-Butane/Iso-Butane/Propane TRI-Blend is USA-sourced and guaranteed to be 99.5% pure. This instrument grade solvent helps to produce a higher quality extract by reducing mystery oils and contaminants. The solvent comes in a DOT refillable LP tank. *This product is clean, colorless and odorless. *Actual 50/25/25% 50/25/25% N-Butane/Iso-Butane/Propane Tri-Blend liquid weight is 114LB Due to FAA regulations, solvent tanks cannot be safely transported via means other than ground. Any order that has solvent will not be shipped in an expedited fashion. If an order with solvent is combined with any other items and chosen to be expedited, that entire order will ship via UPS Ground/Freight. We will not split up any orders and ship them separately. If a customer is wanting to expedite specific items and order solvent, 2 separate orders (1 for the solvent and 1 for the expedited items) will need to be placed in order to do so. Solvents do not ship to Hawaii, Puerto Rico, or any other US Territory outside of the contiguous 48 States. Shipping Solvent to Alaska may ONLY ship via freight and will be required to travel through Canada. We have this policy in place to ensure safety when transporting solvents, and to prevent any issue with shipping times for our customers. Chemical Formula: C₄H₁₀ + C3H8 Molecular Weight: 58.12 g/mol & 44.10 g/mol CAS Registry Number: 106-97-8 & 74-98-6 & 75-28-5 Appearance Colorless Odor: Faint Petroleum Density N/A Boiling Point: N/A Solubility in water: Low Solubility GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H220, H280 GHS Precautionary Statements P210, P377, P381, P403, P410+P403 UN Identification Number: 1965 Proper Shipping Name: Hydrocarbon Gas Mixture, liquefied, n.o.s. Transport Hazard Class: 2.1 Packing Group: None DOT Placard: Tri-Blend Certificate of Conformance (COC) and Certificates of Analysis (COA's) Tri-Blend Safety Data Sheet (SDS)

$825.95 - $839.95

12" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves

12" Pre-Built Hemispherical Lid with BVV 316SS Full Bore Valves (This Lid is fully assembled and Nitrogen Tested for Leaks at Best Value Vacs) This 12" Best Value Vacs Hemispherical lid is fully assembled and nitrogen tested for leaks at our warehouse. This lid comes with 2 BVV 316SS Full Bore Valves with 1/4" 37° JIC Flares, compound gauge and the 4th hole is plugged to allow for future expansion. These lids are made out of 304 stainless steel and have (3) 2" Tri-Clamp ports with the middle 2" port having an extended tube to control solvent flow. Key Features: Pre-built and Nitrogen Tested for Leaks BVV 316SS Full Bore Valves with 1/4" 37° JIC -40F to 450F 304 High Polish Stainless Steel Compound Gauge (-30)-0-(150PSI) Specifications Lid Material 304 Stainless Steel Valve Material 316SS Full Encapsulated PTFE Core - 1/4 Turn Flare Size (2)1/4" 37° JIC Tri-Clamp Size(s) (2) 2" Ports x 12" Tri-Clamp Nitrogen Tested Yes

$524.97

You have seen 576 out of 1657 products