Christmas/New Year-20

Perform 5000 Highly Acid Activated Bleaching & Decolorizing Bentonite

Pure-Flo® Perform 5000 Highly Activated Bentonite Clay for Bleaching & Decolorizing Edible Oils pH: 2.7 Pure-Flo® Perform 5000 provides superior bleaching activity for demanding oils. Effective with all types of difficult-to-bleach oil. Pure-Flo® Perform 5000 Technical Data Sheet.pdf Perform 5000 Safety Data Sheet Excellent metals adsorption characteristics (P, Ca, Fe, Mg, Ni, etc.) Excellent Chlorophyll removal Excellent Red and Blue color body removal. Removes soaps and phospholipids Outstanding filtration characteristics, including long filtration cycles and less pressure build up at cycle end. ph:2.7 FDA GRAS (Generally Recognized as Safe) - This product is safe for processing food, as long as its not part of the end product being consumed. NSF- HACCP *Prior to down packing this product was certified Kosher & Hallal. It does not retain its certifications after down packing, Sorry BVV™ doesn't have an on staff Rabbi or Imam on site to re-establish those certifications. Note: Bulk Bags and Bulk sizes are non-stocked items and will be ordered as needed and carry a several weeks lead time and require a forklift or pallet jack

$28.07 - $3,158.22

Borosilicate Tri-Clamp Sight Glass Kit

Borosilicate Tri-Clamp Sight Glass Kit ***Note:(Only comes with 1 sight glass.) FOR 2" Version please see our upgraded sight glass NESG200 3 piece borosilicate sight glasses offer a greater chemical resistance, viewing area, and cleanability compared to a traditional sight glass such as polycarbonate or Metaglas sight glasses. These Tri-Clamp sight glasses consist of 3 pieces: the borosilicate glass disc, Viton or Silicone gasket, and custom tri-clamp ferrule. When used in combination with high-pressure clamps the working PSI is rated at 800 (pending 3rd party peer review). These glasses are also resistant to thermal shock, enduring extreme heating and cooling temperatures. ***Disclaimer: Please handle with care when installing on to a system and do not overtighten or the glass disc may chip. This Kit Includes the Following: 1x - BVV Borosilicate Tri-Clamp Sight Glass 1x - Standard Pressure Clamp or High Pressure Clamp 1x - BUNA-N Gasket or Silicone Gasket Sight Glass Specifications: Ferrule Material 304 Stainless Steel Glass Material BOROFLOAT Gasket Material Viton(FKM) or Silicone Connection Type(s) Tri-Clamp PSI Rating 800 (pending peer review)

$88.43 - $101.06

Porcelain Buchner Funnel

Porcelain Buchner Funnel Buchner funnel Porcelain Labware is used in the chemistry laboratory. It has exceptional resistance to all reagents except hydrofluoric acid and is highly resistant to thermal shock while having a very low coefficient of expansion. To prevent thermal stress cracks on porcelain ware do not exceed a heating/cooling rate of 200°C per hour. To prolong the life of porcelain products: · Follow gradual heating/cooling rates · Use an oven or hot plate and an intermediate step when quicker heating/cooling rates are required · Avoid contact of heated ware with a cold surface · Carefully check labware prior to each use and do not use any product that appears defective With straight sides above the perforated plate. Thick stem. Sizes Available: 1000ml - 5.5" (~140mm) Diameter 2000ml - 7-3/8" (~187mm) Diameter

$77.20 - $119.31

Propylene Glycol Tech Grade 100%

Propylene Glycol Disclaimer: Spigots/Faucets are only compatible with 5 Gallon Jugs and must be purchased separately BVV™ brand propylene glycol is a great heat transfer fluid alternative to water for all processing equipment such as refrigerated or heated circulators and cold traps. This propylene glycol has a freezing point of -74°F and a boiling point of 370°F. BVV™ propylene glycol is considered NOT genetically modified and NOT derived from a genetically modified organism. BVV™ Propylene Glycol SDS BVV™ Propylene Glycol Specification Sheet The expiration date is 2 years from the date of manufacture and when the glycol is kept below 100F and out of direct sunlight.

$40.71 - $6,877.90

Molecular Sieve Filter Drier

Molecular Sieve Filter Drier A Molecular Sieve Filter Drier is intended to capture moisture and contaminants in the solvent by filter it out while the solvent passes through the Filter Drier. This Filter Drier is made out of 304 Stainless Steel parts and includes High Pressure Clamps, 2x 3" 2500 Mesh (5 Micron) Gaskets to prevent any Sieve dust contaminating the solvent, and 13X Molecular Sieve. The end connections are 37° Flared Connection with a compound gauge that reads (-30)-0-(250Psi). Specifications Material: 304 Stainless Steel Spool Size: 3" Triclamp x 12" Length End Connections: 1/4", 3/8", or 1/2" 37° JIC Flares Molecular Sieve: 13X Clamps: 3" High Pressure Gaskets: 2x 3" 2500 Mesh (5 Micron) Compound Gauge: (-30-0-(150 Psi) Size Recommendations: 2LB - Will fit our Molecular Sieve Filter Drier 4LB - Will fit our XL Molecular Sieve Filter Drier 6LB - Will fit our 30LB Extractor

$407.06 - $421.10

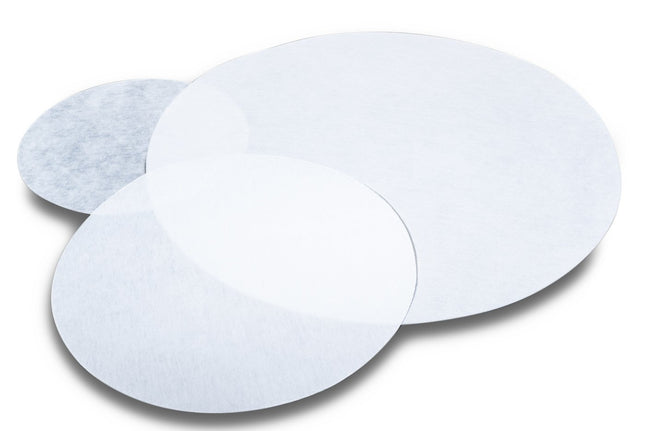

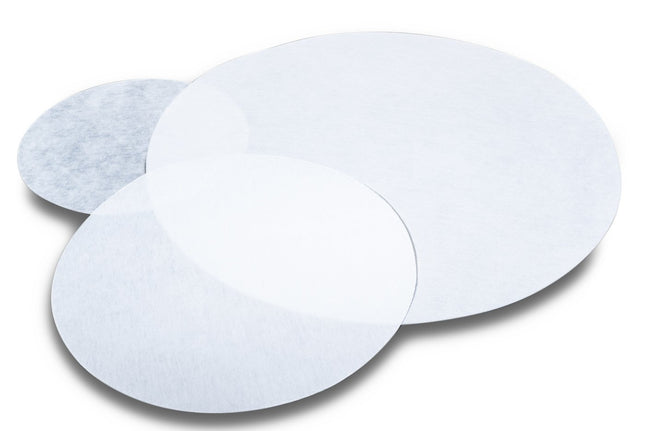

Cellulose Filter Paper 50 Micron - 5 Pack

Cellulose Filter Paper 50 Micron - 5 Pack This filter paper is 100% synthetic cellulose (polyester plastic) and has no binders or adhesives. This material is very strong and considered un-rippable, but can easily be cut with a pair of scissors and this is the most durable filter paper we sell for larger diameter filtration applications. Polyester is recommended for use with Butane, Ethanol, Alcohol, Hexane, Pentane, and most hydrocarbons. Made in USA Specifications Material 100% Synthetic Cellulose (Polyester Plastic) Temp Range -100F to 300F (-70C to 150C) Thickness: 100 Micron - 0.011" 50 Micron - 0.020" QTY per Pack 5 Sizes Available: 6" 8" 10" 12"

$16.84 - $25.27

Glass Vac 3 Gallon Aluminum Vacuum Chamber

3 Gallon Vacuum & Degassing Chamber (Comes with 2 Year Limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Utility Patent #14/533,548) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. Glass Vac Vacuum Chambers are ideal for wood workers using the wood stabilization process because the glass lid will not deteriorate like acrylic or polycarbonate lids. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: Aluminum Vessel Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 3004 Aluminum Gasket Material Silicone Lid Material Glass Internal Dimensions (ID) 9" Tall x 10" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$216.16

Vacuum Pump Vapor Mist Filter

Vacuum Pump Vapor Mist Filter The BVV™ Mist Filter is our solution to capturing the oil mist exhausting out of vacuum pumps. This filter is filled with a replaceable media and will save you $ over alternative solutions like the Koby filter. The filter media is a granular food grade adsorbent and is designed to adsorb oil specifically. The granular media doesn't restrict flow on your pump, and when it becomes saturated with oil it continues to work. We recommend you change out the media when the filter is 50% soaked with oil. During certain vacuum pressures light vapor mist may momentarily exit the filter. The filters within the housing, do not have an indefinite life. Should they become dirty and clogged over the years, it can be cleaned with degreaser like CitraKlean CK-1QT then left to dry before re-loading. Media Capacity: 185 grams. Media Refill: ULTRA-1000G Media Housing Replacement: CLEAR-210 Pump Fitting Thread BVV V Series (Purple) CPSKADPT M27x1.5 BVV VE Series (Black) MCKADPT M24x1.5 Harvest Right Premier Pump BVVKADPT M30x1.5 Harvest Right Standard BVVKADPT M30x1.5 MasterCool MCKADPT M24x1.5 CPS CPSKADPT M27x1.5 Scientific KF25 Exhaust KF25-04FNPT NA

$119.31

KF-25 Bellow Fitting Hose - KIT

KF-25 Bellow Fitting Hose Kit This KF25 or (NW25) bellow hose is made out of 304-grade stainless steel which allows a high vacuum to be obtained with a large flow diameter for vapors. These bellow hoses are flexible and allow the user to connect a KF25 flanged vacuum pump to a KF25 flanged vacuum oven or any other application using adapters like our KF25 x NPT or KF25 x Tri-Clamp/ Tri Clover Fittings. This kit also has 2 KF25 clamps and gaskets. What's Included? (1) KF25 Flexible 304 Stainless Steel Bellow Hose (2) KF25 Centering Gaskets with Viton O-ring (2) KF25 Aluminum Clamps Bellow Hose Sizes Available: 1 Meter(s) (3.28 Feet) 2 Meter(s) (6.56 Feet)

$227.39 - $276.52

Silica Gel 60A 40-63 Micron CRC Grade

60A (40-63 Micron) Silica Gel High Purity Extraction CRC Grade The house brand Silica Gel is optimized for Color Remediation extractions. This powdered silica gel is for use in batch extractions and decolorizations. It can also be used as a general adsorbent for impurities. Optimized particle size, surface area, pH, and purity make it a particularly useful material for the separation of small molecules, peptides, lipids, alkaloids, and a variety of other compounds. Silica Gel is particularly useful to use layered on top of your bentonite to remove plant gums and waxes. BVVSG4063 Technical Data Sheet BVVSG4063 Certificate of Analysis BVVSG4063 Safety Data Sheet Key Specs: Particle Size: 40-63 Micron (230-400 Mesh) Pore Volume: 0.72 mL/g Loss on Drying: ≤ 2.0 wt% pH: 7.1 Empirical Formula: SiO2 Use: Decolorization Hazard Statement: No ingredients are hazardous according to OSHA criteria CAS# 7631-86-9

$589.53 - $11,053.77

Stainless Steel Butane/Propane Tank Fitting CGA 510

Stainless Steel Butane/Propane Tank Fitting CGA 510 Custom Stainless Steel CGA 510 Butane and Propane Tank Fitting with Viton O-Ring. Specifications: CGA 510 Thread with Viton O-ring seal and either 1/4" MNPT or 1/4", 3/8", 1/2" Flare Material: Stainless Steel

$25.27 - $133.35

Cork Stand

Cork Stands Cork stands are used with laboratory glassware to help balance round bottom flasks or prevent damage or support a piece of glassware that is put on it. ***Note: Sizes correlate to round bottom flasks ml sizes. Sizes Available: 250-500ml 500-1000ml 1000-2000ml

$8.42 - $11.23

Tri-Clamp Topcap with Valve and 1/4" Barb

Tri-Clamp/ Tri Clover Top cap with Valve and 1/4" Barb Pre-installed 1/4" hose barb (Fits 1/4" ID Hoses) and 304 stainless steel ball valve on a Tri-Clamp endcap. These endcaps and valves and nitrogen tested for leaks to ensure safe usage of any extraction system. Barb endcaps are useful when connecting flexible tubing to the barb connection to transfer fluids easily or even pull a vacuum on an extraction system instead of using flared connections. ***Note: Please check the pressure rating of the tubing that is going to be used beforehand. Specifications: 304 Stainless Steel Tri-Clamp Endcap 304 Stainless Steel Heavy Duty Ball Valve -40 to 230C (1/4" MNPT/FNPT Connections) 304 Stainless Steel Hose Barb (Fits 1/4" ID Hose) Pre-Assembled and Nitrogen Tested for Leaks at Best Value Vacs Tri-Clamp Sizes Available: 1.5" 2" 3" 4" 6"

$44.92 - $91.24

2" Dewaxing Closed Column Extractor 115-200g

DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well ventilated areas. DO NOT USE INDOORS *Note: Column capacity may vary depending on the biomass density, moisture content and column packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, heavily dried, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Key Features and Description: Dewaxing Spool Included to coagulate fats and lipids to be caught in the filter. Compound Gauge with (-30)-160 PSI readout. Closed Column Pressure Extractor (Comes with 1 yr. Limited warranty, excludes gaskets and screens) This system allows the user to build up solvent pressure by closing the valve, pulling a vacuum and filling the extractor, Extractor will fill about 85% with solvent before the internal pressure will equal the pressure of the can propellant. The solvent can will fit into either port with a tip adapter supplied with some butane cans, tip adapter required, not included Solvent Soak is expected to be between 30-90 min, but this all depends on material, starting with frozen cans of solvent is recommended This system allows the user to soak the material before opening the bottom valve to release the solvent and oil. Professional Kit Adds the following: Compound Gauge Sight Glass Shower Head Explorer Kit Includes the Following: 8" x 8" Platinum Cured Silicone Non-Stick Pad 2" Dewaxer Tri-Clamp 304 Stainless Steel Material Tube Dewaxer Spool Sizes Specifications: 2" x 12" Dewaxer = 115G 2" x 18" Dewaxer = 150G 2" x 24" Dewaxer = 200G 304 Stainless Steel Flare End Caps with Heavy Duty Stainless Steel Miniature Ball Valves 1/4" Stainless Steel MNPT Drain Plug (1) 2" Standard Pressure Tri-Clamp Clamps 2" Tri-Clamp Quadpod (1) Buna-N Tri-Clamp Gaskets Buna-N 100 Mesh (150 Micron) Gasket ***Note: Parts and components can be subject to substitutions. Any substituted parts will have the same function and will be of equal or greater value.**** Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$301.79 - $450.57

Extract Thinner *Compare to True Terpenes Viscosity

BVV™ Extract Thinner All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Extract Thinner is a diluent made from natural terpenes. It does not contain PG, VG, PEG, MCT, Squalane, Squalene, Coconut oil, Triethyl Citrate, or Vitamin E Acetate. Our Extract Thinner will combine with your terpenes and oil and is formulated to minimize flavor and aroma impact. Oure Extract Thinner is not a thickening nor cutting agent and not recommended to be used with CBD. This product is designed to be used with winterized extracts. It is a clear liquid with a faint, odor that will minimally contribute to the aroma and flavor. In order to provide complete transparency and illicit customer confidence, all ingredients are disclosed. INGREDIENTS: Phytol, Beta-Caryophyllene, D-Limonene, Farnesol and Nerolidol Dilution Use Instructions: First infuse your terpene strain or flavor into your winterized extract. Typically 1-5% by volume. Then to use the Extract thinner add 1-3% by Total Volume to thin the extract. Made in the USA by cGMP facilities ISO 9001:2015 Shelf Life: 3 Years Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store in a cool dry place. Improper storage can cause terpenes to degrade.

$22.46 - $393.02

Sidemount Assembly w/ Washer, O-Ring and Nut

Sidemount Assembly with washer, O-ring and Hex Nut. This sidemount manifold has a 0-(-30) Vacuum gauge with a 1/4" HVAC flare and a 1/4" FNPT side port.

$53.34

Best Value Vacs 1 Gallon Flat Stainless Steel Vacuum Chamber

1 Gallon Shatter Vac Flat Stainless Steel Vacuum Chamber (Comes with 2 Year Limited warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 3" Tall x 10.25" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$189.49

Acetone 99%

BVV™ High Purity Acetone 99% HAZMAT ITEMS ARE NON-REFUNDABLE. ALL SALES ARE FINAL (Note: Container style and color may vary) Explore our top-quality Acetone, a versatile solvent that meets the highest standards of quality and purity. Our Acetone is ideal for a wide range of applications, whether you're in the pharmaceutical, cosmetic or industrial sector. With its exceptional solvent properties, Acetone serves as a reliable solution for cleaning, degreasing, and dissolving various substances. Our Acetone is carefully sourced to ensure consistency and effectiveness, making it a popular choice for professionals and businesses alike. Our Acetone is subjected to stringent quality control measures, ensuring exceptional purity that's perfect for various processes, from extraction to cleaning and stripping applications. Discover the exceptional performance and dependability of our Acetone, specially created to surpass your rigorous requirements. Unleash the potential of this top-notch solvent, and enhance the efficiency and efficacy of your processes to a whole new level. Opt for our Acetone for unparalleled outcomes and make the most of its adaptability in a variety of crucial tasks. BVV™ Acetone 99% - SDS BVV Acetone 99% - COA Chemical Formula: C3H6O Molecular Weight: 58.080 g·mol−1 CAS Registry Number: 67-64-1 Appearance Colorless Liquid Odor: Pungent, fruity Density 0.7845 g/cm3 (25 °C) Boiling Point: 56.08 °C /132.94 °F Solubility in water: Miscible GHS Pictograms: GHS Signal Word: Danger GHS Hazard Statements: H225, H302, H319, H336, H373 GHS Precautionary Statements P210, P235, P260, P305+P351+P338 UN Identification Number: 1090 Proper Shipping Name: Acetone Transport Hazard Class: 3 Packing Group: II DOT Placard: What is Acetone? Acetone is a clear, colorless, and highly flammable liquid with a distinctive sweet, fruity odor. It is a simple organic compound with the chemical formula C3H6O, belonging to the ketone family. Acetone is widely used as a solvent in various industries due to its excellent solubility and fast evaporation rate. In addition to its solvent properties, acetone has many other applications. It is commonly used as a cleaning agent, degreaser, and paint thinner. It is also a key ingredient in nail polish removers and some cosmetic products. Acetone is utilized in the production of plastics, fibers, resins, and various chemicals. Additionally, it serves as a fuel additive and is used for scientific and laboratory purposes. As a highly versatile and effective solvent, acetone plays a vital role in numerous industrial, commercial, and domestic applications, making it an essential component in various processes. What Are The Properties of Acetone? Acetone is a colorless, volatile, and highly flammable liquid with several notable properties: Physical State: Acetone is a liquid at room temperature and pressure, with a boiling point of 132.8F/56C and a melting point of -94.9°C (-138.8°F). Odor: It has a distinct and characteristic odor that is often described as sweet or fruity. Solubility: Acetone is highly soluble in water, alcohols, ethers, and many other organic solvents. This high solubility contributes to its effectiveness as a cleaning agent and solvent. Density: The density of acetone is about 0.79 g/cm³, making it less dense than water. Vapor Pressure: Acetone has a relatively high vapor pressure, which means that it readily evaporates into the air at room temperature. Flammability: Acetone is highly flammable and has a low flash point of -20.8°C (-5.4°F). This means that it can easily ignite when exposed to an open flame, spark, or other sources of ignition. Reactivity: Acetone is a reactive compound and can participate in various chemical reactions. It can react with strong acids, bases, and oxidizing agents. Acidity: Acetone is a weak acid, and its aqueous solutions can exhibit slightly acidic properties. Miscibility: Acetone is miscible with water and many organic solvents. This property makes it suitable for various applications in different industries. Polarity: Acetone is a polar solvent, meaning that it has a partial positive and partial negative charge distribution within its molecule. This polarity allows it to dissolve a wide range of polar and nonpolar compounds. Boiling Point: Acetone has a relatively low boiling point 132.8F/56C, which makes it easy to evaporate and separate from other substances during distillation processes. Evaporation Rate: Acetone has a fast evaporation rate, which makes it suitable for applications where rapid drying is necessary. It's important to note that acetone's properties contribute to its versatility and wide range of applications in various industries, including cleaning, manufacturing, laboratory work, cosmetics, and more. However, due to its flammability and reactivity, proper safety precautions should always be followed when working with acetone. What Is The Structure Of Acetone? The chemical structure of acetone consists of three atoms: one carbon (C) atom, one oxygen (O) atom, and three hydrogen (H) atoms. It is a simple organic compound with the molecular formula C3H6O. The structural formula of acetone can be represented as: In this structural representation: The central carbon (C) atom is bonded to two hydrogen (H) atoms and one oxygen (O) atom. The oxygen atom is double-bonded to the central carbon atom, forming a carbonyl group (C=O). The remaining valences of the carbon atom are filled by single bonds to the two hydrogen atoms. This arrangement of atoms gives acetone its distinctive chemical properties, including its solubility in water, high vapor pressure, and reactivity as a solvent and chemical reagent. How Is Acetone Produced? Acetone is produced through various industrial processes, with the most common method being the catalytic dehydrogenation of isopropanol. Here's an overview of the primary process used to produce acetone: 1. Dehydrogenation of Isopropanol: The most widely used method to produce acetone is the dehydrogenation of isopropanol, also known as the "cumene process." This process involves several steps: a. Production of Cumene: Cumene (isopropylbenzene) is produced from benzene and propylene in the presence of a catalyst such as aluminum chloride. This results in the formation of cumene and hydrogen chloride as byproducts. b. Oxidation of Cumene to Cumene Hydroperoxide: Cumene is then oxidized using air to form cumene hydroperoxide, typically using a catalytic process with acid or base catalysts. c. Cleavage of Cumene Hydroperoxide: Cumene hydroperoxide is cleaved using acid catalysts to yield phenol and acetone. This reaction results in the simultaneous production of phenol, which is used as a valuable chemical in various industries. d. Distillation and Separation: The mixture of phenol and acetone is then separated using distillation techniques. Acetone is obtained as a separate product from the mixture. 2. Other Processes: Apart from the cumene process, there are alternative methods for acetone production, including: a. Propylene Oxidation: Acetone can be produced through the direct oxidation of propylene using air or oxygen as the oxidizing agent. This method yields propylene oxide and acetone as products. b. Acetaldehyde Condensation: In this method, acetaldehyde is condensed and dehydrated to form acetone. This process is less common compared to the cumene process. c. Bio-based Production: Research is ongoing to develop bio-based methods of acetone production, using renewable resources like biomass or microorganisms that can convert sugars into acetone. d. Repurposing Byproducts: Acetone can also be obtained as a byproduct in various industrial processes, such as the production of phenol, where acetone is produced alongside phenol from cumene hydroperoxide. The cumene process remains the most dominant and economical method for producing acetone on an industrial scale. The choice of production method depends on factors such as availability of feedstocks, economics, environmental considerations, and desired product yields. Is Acetone Safe? Acetone is generally recognized as safe (GRAS) when used in appropriate amounts and under proper conditions. However, like any chemical substance, it should be handled with care and used according to safety guidelines. Here are some important points to consider regarding the safety of acetone: Ventilation: Acetone has a strong odor and can release fumes that may be irritating to the eyes, nose, and throat. When using acetone, make sure you are in a well-ventilated area to minimize inhalation of the fumes. Skin Contact: Acetone can be drying to the skin and may cause irritation, especially with prolonged or frequent exposure. It's advisable to wear gloves when handling acetone to protect your skin. Eye Contact: Avoid getting acetone in your eyes, as it can cause irritation and discomfort. If accidental eye contact occurs, rinse your eyes thoroughly with water and seek medical attention if irritation persists. Ingestion: Acetone is not intended for ingestion and should not be consumed. Ingesting acetone can be harmful and may lead to adverse health effects. Flammability: Acetone is highly flammable and should be kept away from open flames, sparks, and heat sources. Store acetone in a cool, dry place and away from direct sunlight. Sensitive Individuals: Some individuals may be more sensitive to the effects of acetone, experiencing skin irritation, allergic reactions, or respiratory discomfort. If you have a history of sensitivities or allergies, exercise caution when using acetone. Use as Directed: When using acetone for specific applications such as nail polish removal, adhesive removal, or cleaning, follow the recommended instructions on the product label or recipe. Avoid excessive or prolonged exposure. Alternative Options: If you are concerned about the potential risks of using acetone, you can consider using alternative products that are specifically formulated for the task at hand. For example, there are acetone-free nail polish removers available that may be gentler on the nails and cuticles. If you have specific health concerns or are unsure about the safety of using acetone, it's always a good idea to consult with a healthcare professional or seek advice from experts in the field. Additionally, reading and following safety information provided on product labels and material safety data sheets (MSDS) is crucial to ensure safe handling and use of acetone and other chemicals. What are the hazards of Acetone? Acetone is a commonly used chemical solvent, but like any chemical substance, it poses certain hazards that need to be considered when handling and using it. Some of the hazards associated with acetone include: Flammability: Acetone is highly flammable and can catch fire easily. Its low flash point makes it volatile and prone to ignition when exposed to open flames, sparks, or heat sources. It's important to store and use acetone away from potential sources of ignition. Inhalation Hazards: Acetone can release strong vapors that are irritating to the respiratory system. Prolonged or repeated inhalation of these vapors can lead to headaches, dizziness, nausea, and respiratory discomfort. Adequate ventilation is essential when using acetone to minimize exposure to its fumes. Skin and Eye Irritation: Acetone can be drying to the skin and may cause irritation or redness upon direct contact. It can also irritate the eyes and lead to discomfort if splashed or accidentally introduced into the eyes. Central Nervous System Effects: Acetone vapor exposure can affect the central nervous system, leading to symptoms like dizziness, confusion, and even unconsciousness at high concentrations. Toxic Effects: While acetone is generally considered to have low toxicity, exposure to large amounts or prolonged exposure can have toxic effects on the body. Ingesting acetone can lead to nausea, vomiting, abdominal pain, and even coma in severe cases. Health Risks: Long-term or chronic exposure to acetone can potentially have adverse health effects, including damage to the liver, kidneys, and respiratory system. Repeated skin contact can cause dryness and irritation. Environmental Impact: Improper disposal of acetone can lead to environmental contamination. Acetone is volatile and can easily evaporate into the air, contributing to air pollution. It can also be harmful to aquatic life if introduced into water bodies. Allergic Reactions: Some individuals may be sensitive or allergic to acetone, experiencing skin reactions or respiratory discomfort even at lower concentrations. It's important to take appropriate safety precautions when using acetone, including wearing protective gear such as gloves and safety goggles, working in a well-ventilated area, and avoiding open flames or heat sources. If working with acetone in an industrial or laboratory setting, it's crucial to follow established safety protocols and guidelines, as well as refer to the material safety data sheet (MSDS) provided by the manufacturer. Overall, while acetone is a valuable solvent with various applications, it should be handled with care and respect for its potential hazards. If you have any concerns or questions about the safe use of acetone, it's recommended to consult with experts in the field or seek guidance from health and safety professionals. How Flammable Is Acetone? Acetone is highly flammable and poses a significant fire and explosion hazard. It has a low flash point of -20.8°C (-5.4°F), which means that it can easily vaporize and form flammable mixtures with air at temperatures above its flash point. Acetone's wide flammability range (2.5% to 12.8% in air) indicates that even small concentrations of acetone vapor in the air can be ignited by a spark, open flame, or other sources of ignition. Due to its low flash point and flammable nature, acetone should be handled with extreme caution and stored away from sources of heat, sparks, and flames. When using acetone, it's important to follow proper safety practices, such as working in well-ventilated areas, using appropriate protective equipment, and avoiding activities that can generate sparks or heat. Acetone's high flammability also makes it necessary to take precautions when storing and transporting the solvent. Flammable liquids like acetone should be stored in approved containers and away from incompatible materials, such as oxidizing agents, to prevent potential chemical reactions and fires. It's essential to be aware of acetone's flammability and take all necessary safety measures to minimize the risk of fire and ensure a safe working environment when handling this solvent. How Is Acetone Used? Acetone is a versatile organic compound with a wide range of industrial, commercial, and household applications due to its excellent solvent properties and low toxicity. Here are some common uses of acetone: Solvent: Acetone is primarily known for its effectiveness as a solvent. It dissolves a variety of substances, making it useful for cleaning, degreasing, and removing residues from surfaces, equipment, and materials. It is commonly used in industrial settings to clean machinery and equipment. Nail Polish Remover: Acetone is a key ingredient in many nail polish removers. It effectively dissolves nail polish and helps remove it from the nails. Paint and Coating Removal: Acetone is used to remove paint, varnishes, lacquers, and other coatings from surfaces like wood, metal, and plastic. It's particularly useful for removing paint spills or overspray. Adhesive Remover: Acetone can be used to soften and remove adhesives, glues, and tapes from surfaces without causing damage. Chemical Intermediate: Acetone is used as an intermediate in the production of other chemicals. It's a precursor in the manufacturing of products like methyl methacrylate, bisphenol A (used in polycarbonate plastics and epoxy resins), and isopropyl alcohol. Laboratory Reagent: Acetone is used in laboratories as a reagent in various chemical reactions and as a solvent for analytical techniques like chromatography. Thinner for Paints and Inks: Acetone is used as a thinning agent for paints, inks, and varnishes to adjust their viscosity and improve their application. Cosmetics and Personal Care Products: Apart from nail polish remover, acetone is used in the production of cosmetics, skincare products, and perfumes. Medical and Pharmaceutical Uses: Acetone is used in some medical and pharmaceutical applications, such as cleaning medical equipment and removing residues from glassware in laboratories. Cleaning Agent: Acetone is effective at removing greasy or sticky residues from various surfaces. It's often used for cleaning electronics, removing ink stains, and cleaning glass surfaces. Fuel Additive: In some instances, acetone is used as an additive in fuel to improve its combustion efficiency, although this application is less common. Aerosol Propellant: Acetone's ability to vaporize quickly makes it useful as a propellant in aerosol products like air fresheners, deodorants, and cleaning sprays. It's important to note that while acetone is versatile and widely used, it should be handled with care due to its flammable nature. Proper ventilation and safety precautions should be taken when using acetone in any application. How Is Acetone Used In Extraction? Acetone is occasionally used in extraction processes, particularly in the field of chemistry and research, where it serves as a solvent to extract certain compounds from various materials. However, it's important to note that acetone has limitations and risks when used for extraction, and its use should be approached cautiously and with proper safety measures. Here's how acetone can be used in extraction processes: Extraction of Essential Oils and Fragrances: Acetone can be used to extract essential oils and fragrances from plant materials. The solvent's low boiling point allows it to evaporate quickly, leaving behind the extracted aromatic compounds. Extraction of Active Compounds: Acetone can be used to extract active compounds from natural sources, such as medicinal plants or herbs. The solvent's polarity can help dissolve and extract specific compounds like alkaloids, flavonoids, and phenolic compounds. Extraction of Lipids and Fats: Acetone is sometimes used to extract lipids and fats from materials like seeds, nuts, or plant tissues. Its ability to dissolve fats and oils makes it suitable for this purpose. Research and Analysis: In laboratories, acetone is sometimes used as a solvent to prepare samples for analysis by techniques like chromatography or spectroscopy. It can help solubilize compounds of interest for further investigation. Cleaning and Preparing Samples: Acetone can be used to clean surfaces and equipment in preparation for various chemical processes, ensuring that surfaces are free from contaminants that could affect the extraction. Recrystallization: Acetone can also be used for recrystallization processes in the lab, where impure solid compounds are dissolved in acetone and then allowed to crystallize out in a more purified form. It's important to exercise caution when using acetone in extraction processes: Flammability: Acetone is highly flammable and should never be used near open flames or in poorly ventilated areas. Toxicity: Acetone can be harmful if inhaled, ingested, or absorbed through the skin. Proper personal protective equipment (PPE) should be worn, and work should be conducted in a well-ventilated area. Chemical Compatibility: Acetone may not be suitable for extracting all types of compounds, as it can degrade certain materials and might not effectively extract specific compounds. Due to these risks and limitations, alternative solvents or extraction methods are often preferred in various extraction processes. When considering using acetone in an extraction, it's crucial to assess the specific requirements of the extraction and ensure that proper safety measures are in place. What Gaskets Are Compatible With Acetone? Acetone is a powerful solvent that can degrade certain materials, including both silicone and Nitrile/BUNA-N gaskets. When choosing gaskets for use with acetone, it's essential to select materials that are resistant to the solvent's effects to ensure safe and effective sealing. The following gasket materials are generally considered compatible with acetone: PTFE (Polytetrafluoroethylene): PTFE gaskets, also known as Teflon gaskets, are highly resistant to acetone and a wide range of other chemicals. They have excellent chemical stability and can withstand the corrosive nature of acetone. Viton (Fluoroelastomer): Viton gaskets are resistant to a variety of chemicals, including acetone. They are often used in applications where high-temperature and chemical resistance are required. EPDM (Ethylene Propylene Diene Monomer): EPDM gaskets are compatible with acetone for short exposure periods. However, their compatibility may be limited in extended contact with acetone or under specific conditions. It's important to note that the compatibility of gasket materials with acetone can vary based on factors such as temperature, concentration, and exposure duration. Before selecting gaskets for use with acetone, it's advisable to also consider the temperature and pressure range of your application to ensure that the chosen material is suitable for your specific application. Additionally, when working with acetone or any other chemical, it's crucial to follow proper safety protocols, including wearing appropriate personal protective equipment (PPE), working in a well-ventilated area, and observing all relevant safety guidelines. How do I clean with Acetone? Cleaning with acetone involves a few simple steps, but it's important to exercise caution due to its flammable nature and strong odor. Here's how to clean with acetone safely and effectively: Materials Needed: Acetone Clean, lint-free cloth or paper towels Ventilated area or protective mask Gloves Eye protection Steps: Choose a Well-Ventilated Area: Before you begin, make sure you're in a well-ventilated space. Acetone has strong fumes, so working outdoors or in a well-ventilated room is recommended. If ventilation is limited, consider wearing a protective mask and eye protection. Put on Protective Gear: While not always necessary for small cleaning tasks, wearing gloves and eye protection can help prevent skin and eye irritation. Test in an Inconspicuous Area: Before using acetone on a larger surface, test it in a small, inconspicuous area to ensure it doesn't damage or discolor the material you're cleaning. Apply Acetone: Moisten a clean, lint-free cloth or paper towel with a small amount of acetone. Gently blot or rub the area you want to clean. Start with a light touch and gradually increase pressure if needed. Avoid scrubbing vigorously, as this could damage surfaces or spread stains. Wipe Clean: As you blot or rub, you'll notice that dirt, residue, or certain stains are lifted onto the cloth. Continue until the area looks clean. For stubborn stains, you may need to repeat the process or use a slightly more concentrated amount of acetone. Dry the Area: After cleaning, use a separate clean cloth or paper towel to dry the area thoroughly. This helps prevent any remaining acetone from evaporating and leaving streaks. Dispose of Materials Safely: Dispose of used cloths, paper towels, and other materials soaked in acetone responsibly. Place them in a sealed container or bag and dispose of them according to your local regulations for hazardous waste. Wash Hands: After you're finished, wash your hands with soap and water to remove any traces of acetone. Important Tips: Acetone can damage certain plastics, paints, and finishes, so always test it in an inconspicuous area first. Do not use acetone on leather, acetate fabrics, or materials with printed designs, as it can cause fading or damage. Keep acetone away from open flames, sparks, or heat sources, as it is highly flammable. Always work in a well-ventilated area or use appropriate personal protective equipment. Remember that acetone is a powerful solvent, so it's best suited for specific cleaning tasks like removing certain adhesives, paint splatters, or sticky residues. If you're uncertain about using acetone on a particular material or surface, consider seeking professional advice or trying an alternative cleaning method. How Do I Make My Own Acetone-Based Nail Polish Remover? Cleaning with acetone involves a few simple steps, but it's important to exercise caution due to its flammable nature and strong odor. Here's how to clean with acetone safely and effectively: Materials Needed: Acetone Clean, lint-free cloth or paper towels Ventilated area or protective mask Gloves (optional) Eye protection (optional) Steps: Choose a Well-Ventilated Area: Before you begin, make sure you're in a well-ventilated space. Acetone has strong fumes, so working outdoors or in a well-ventilated room is recommended. If ventilation is limited, consider wearing a protective mask and eye protection. Put on Protective Gear: While not always necessary for small cleaning tasks, wearing gloves and eye protection can help prevent skin and eye irritation. Test in an Inconspicuous Area: Before using acetone on a larger surface, test it in a small, inconspicuous area to ensure it doesn't damage or discolor the material you're cleaning. Apply Acetone: Moisten a clean, lint-free cloth or paper towel with a small amount of acetone. Gently blot or rub the area you want to clean. Start with a light touch and gradually increase pressure if needed. Avoid scrubbing vigorously, as this could damage surfaces or spread stains. Wipe Clean: As you blot or rub, you'll notice that dirt, residue, or certain stains are lifted onto the cloth. Continue until the area looks clean. For stubborn stains, you may need to repeat the process or use a slightly more concentrated amount of acetone. Dry the Area: After cleaning, use a separate clean cloth or paper towel to dry the area thoroughly. This helps prevent any remaining acetone from evaporating and leaving streaks. Dispose of Materials Safely: Dispose of used cloths, paper towels, and other materials soaked in acetone responsibly. Place them in a sealed container or bag and dispose of them according to your local regulations for hazardous waste. Wash Hands: After you're finished, wash your hands with soap and water to remove any traces of acetone. Important Tips: Acetone can damage certain plastics, paints, and finishes, so always test it in an inconspicuous area first. Do not use acetone on leather, acetate fabrics, or materials with printed designs, as it can cause fading or damage. Keep acetone away from open flames, sparks, or heat sources, as it is highly flammable. Always work in a well-ventilated area or use appropriate personal protective equipment. Remember that acetone is a powerful solvent, so it's best suited for specific cleaning tasks like removing certain adhesives, paint splatters, or sticky residues. If you're uncertain about using acetone on a particular material or surface, consider seeking professional advice or trying an alternative cleaning method. What Is The Average Amount Of Acetone Used in Nail Polish Remover? The average amount of acetone used in commercial nail polish remover products typically ranges from 30% to 50%. This means that the nail polish remover solution contains 30% to 50% acetone, along with other ingredients such as water, emollients, and fragrances. The exact percentage can vary depending on the brand and formulation of the nail polish remover. When making your own nail polish remover at home, you can use pure acetone or a solution with a similar acetone concentration. Keep in mind that using pure acetone can be harsh on your nails and cuticles, potentially causing dryness and irritation with frequent use. It's a good idea to experiment with different acetone concentrations and observe how your nails and skin react to find the right balance between effective nail polish removal and gentle care for your nails. How Do you Dispose of Acetone? Disposing of acetone properly is important to ensure environmental and personal safety. Here are the steps to follow for proper acetone disposal: Check Local Regulations: Before disposing of acetone, check your local regulations and guidelines for hazardous waste disposal. Different regions may have specific requirements and disposal methods. Use a Secure Container: Transfer the acetone to a tightly sealed, labeled, and non-reactive container. Glass or metal containers with a secure lid are recommended. Label the Container: Clearly label the container with the contents ("Acetone"), the hazard symbol, and any other relevant information. Do Not Mix: Do not mix acetone with other chemicals, as this could lead to hazardous reactions. Contact Local Waste Disposal Facility: Contact your local hazardous waste disposal facility or municipality to inquire about drop-off locations and collection programs for hazardous materials. Do Not Pour Down the Drain: Do not pour acetone down the drain, toilet, or any other water source, as it can contaminate water systems and harm the environment. Evaporate in a Controlled Setting: If allowed by local regulations, you can let a small amount of acetone evaporate in a well-ventilated outdoor area. Ensure it's away from open flames, sparks, or ignition sources. Recycle or Reuse: Some regions may offer recycling or reclamation programs for acetone or other solvents. Research if any such programs are available in your area. Professional Disposal: If you have a large amount of acetone or are uncertain about the proper disposal method, consider contacting a professional hazardous waste disposal service. Remember, improper disposal of hazardous materials like acetone can harm the environment, human health, and local communities. Always prioritize safety and follow the regulations set by your local authorities for proper disposal.

$25.27 - $1,003.61

Hemispherical Reducer with Filter Plate

Hemispherical Filter Plate Reducer This hemispherical reducer has a built-in filter plate. This unique design allows the user to save even more space by combining a filter plate ANDhemispherical reducer. Made out of 304 stainless steel the filter plate is welded into the hemispherical reducer and has Tri-Clamp connections on both ends.

$46.32 - $124.93

Best Value Vacs 3 Gallon WIDE Stainless Steel Vacuum Chamber

3 Gallon Wide Stainless Steel Vacuum Chamber (Comes with 2 Year Limited Warranty) This is a complete BestValueVac® vacuum chamber setup designed built and 100% tested in Naperville, Illinois. With our unique patent pending gasket design (Patent #9475627) this chamber is sure to last 10,000 uses with proper care and maintenance. The gasket itself is reversible (doubling the life of our system) allowing customers to instantly take it off and flip it over. Every chamber is tested prior to shipping to lose no more than 2.5Hg/24hrs. -Please Refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Features: High Strength Stainless Steel Chamber Highly Durable and Reversible Silicone Gasket Glycerin filled vacuum gauge User friendly vacuum connections that fit most vacuum pumps on the market 50 Micron Air filter for reducing airborne contaminants when releasing the vacuum Silicone vacuum pad 5' of vacuum rated HVAC hose to pull a vacuum. Specification Chamber Material 304 Stainless Steel Gasket Material Silicone Lid Material Acrylic Internal Dimensions (ID) 8" Tall x 10.5" Diameter Vacuum Gauge (Glycerin Filled) InHG (0)-(-30) Manifold Connections 1/4" SAE and 1/4" FNPT Temperature Rating 150°F (65°C) Additional Included Items 5' Purple Vacuum Rated HVAC Hose Platinum Cured Silicone Pad Black 50 Micro Air Filter Compatibility Explanation: BestValueVac® Chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), alcohol, ethanol, acetone and acrylic based monomers or polymers.The lid may only be cleaned with soapy water. ShatterVac® chambers are not compatible with stabilization resin (i.e. Cactus Juice™, Gator Venom™, Minwax™ etc.), acetone, acrylic based monomers or polymers. The lid may be cleaned with soapy water and low strength cleaning agents. GlassVac® chambers are compatible with all solvents and stabilization resins. We only recommend and warranty GlassVac® chambers for resin infusion and wood stabilization.The lid may be cleaned with any solvent or cleaning agent. See FAQ at the top for product safety warnings. Pump Warranty Information: Customers using solvents such as stabilization resins (MinWax™, Gator Venom™ etc.), alcohol and other polar solvents must use the vacuum pumps in conjunction with a cold trap for evacuations in excess of 5 minutes. (Exludes Cactus Juice™) If the consumer is using the pump for prolonged periods of time exceeding 5 minutes we require that a cold trap is used or the pump warranty is void. These stabilization resins have the ability to break down the internal components of the pump that are plastic resulting in a seized motor voiding all warranties. When evacuation exceeds 5 minutes these solvents begin to vaporize and then re-condense in the vacuum pump reservoir. Once enough solvent re-condenses in the pump displacing the oil the plastic internal components may begin to warp, melt or seize. The use of a cold trap will condense the vapors prior to making their way to the vacuum pump preventing pump damage due to excessive use. Furthermore, Minwax Wood Hardener™ is not to be used with any vacuum pumps, EVER. (A seized motor will result within the first use.) To prevent these issues from happening to your process, change the Oil after each vacuum pump use, Even if the use time is only 5min. For shipping info including Import/Export details visit our Shipping link at the bottom of the page.

$209.14

Ashless Filter Papers - 350MM - Quantitative

Ashless Filter Papers - 350MM - Quantitative Quantitative and qualitative filter papers provide laboratory grade filtration for extraction systems and are specifically used in combination with a Buchner funnel to remove fats, waxes and any other unwanted contaminants from your solution. These filter papers are used in the pre-processing stage of short path distillation to clean up the material prior to processing. Key Features: ISO 9001 Approved Manufactured from alpha-cellulose and cotton linters High Purity and low background Consistent performance Whatman equivalent quality Pre-Cut for ease of use Specifications: Classification Quantitative Sizes Available: AFP-1 11um - Medium AFP-4 20um - Fast Quantity per Pack 100 Diameter 350mm (13.78")

$133.35

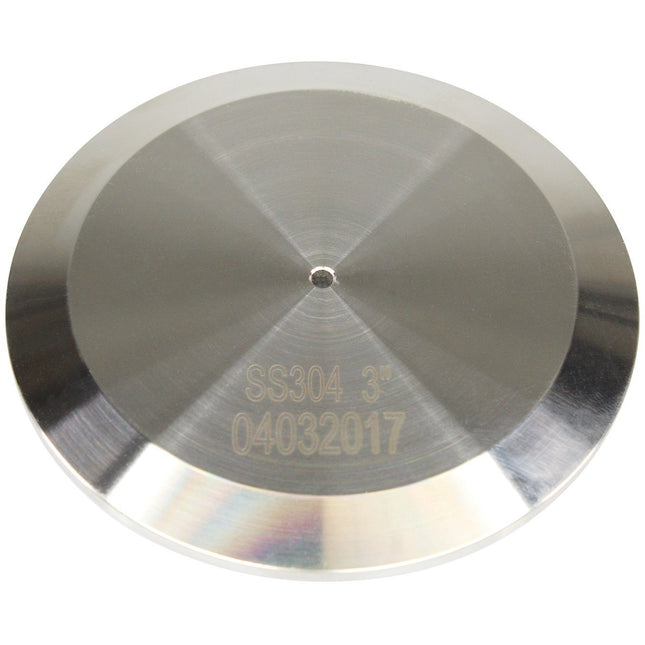

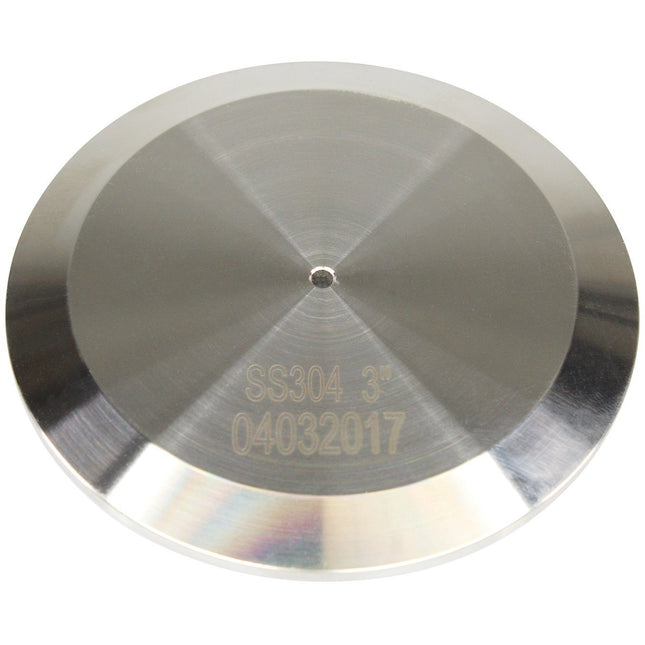

3mm Open Blast End Caps

3mm Open Blast End Caps These Tri-Clamp/ Tri Clover End Caps have a 3mm hole drilled in the center so most butane can tips to easily fit in the hole allowing the user to input solvent into a material column and open blast the material. Specifications: Material: 304 Stainless Steel Connection Type: Tri-Clamp 3mm Hole Standard: 3A Sizes Available: 1.5" 2" 3" 4"

$8.42 - $16.84

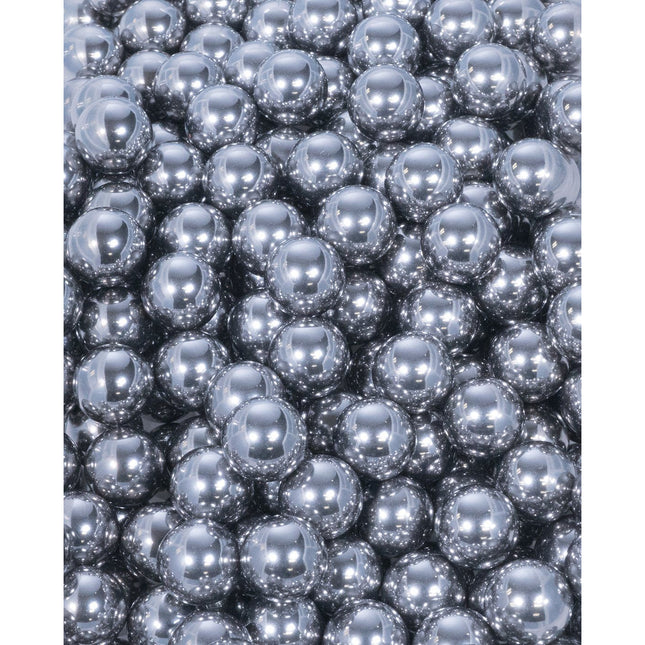

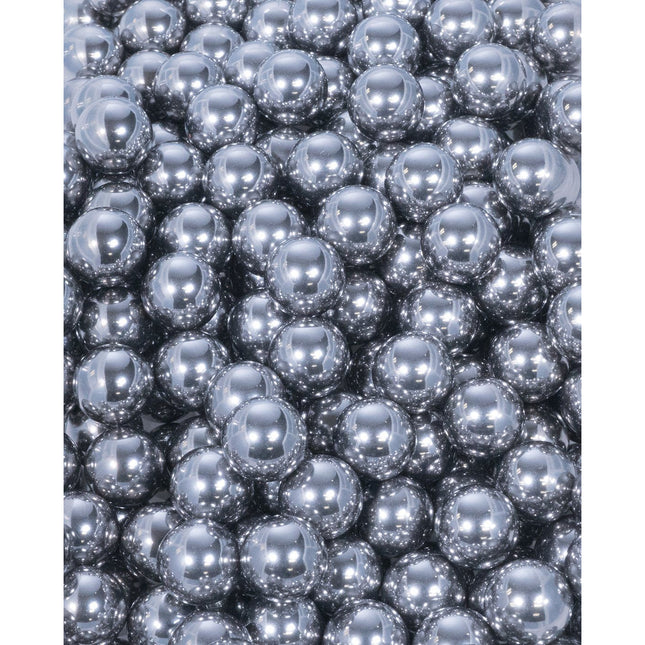

304 Stainless Steel Ball Bearings Packs

304 Stainless Steel Ball Bearings - Packs 304 Stainless Steel Ball Bearings are a great addition to aiding in filtration because they increase the surface area inside a system and allow fats and lipids to cling to them. After a run is complete, they are easily cleanable. These ball bearings come pre-packaged in 140-gram packets and may have a quantity +/- the stated quantity per pack. Sizes Available: 1/8" Diameter - ~1150 Ball Bearings Per Pack 1/4" Diameter - ~150 Ball Bearings Per Pack 7/16" Diameter - ~25 Ball Bearings Per Pack

$9.83 - $43.51

Conical Flask Filtering with Internal Side Arm

Conical Flask Filtering with Internal Side Arm These BVV™ Conical filtering flasks come with a non-jointed opening and a barbed side arm that can easily hook up to a vacuum pump. These flasks come in either 2500ml or 5000ml and are meant to be used with porcelain buchner funnels and rubber cones to create a positive vacuum seal. Barb Size- 2500ml: 14mm barb 5000ml: 16mm barb *Notice to customers: All units are inspected for broken glassware or parts before leaving BVV™. If the unit arrives damaged (this does not include minor imperfections or scuffs in glassware), the customer MUST contact BVV™ within 72 hours from carrier delivery to file a claim. If the customer DOES NOT contact BVV™ within 72 hours from carrier delivery, then BVV™ cannot issue any replacement(s) or compensation for the item; a new purchase will need to be made for a replacement. **Glassware Safety Disclaimer: BVV™ is not responsible for failure of glassware which must be inspected before and after every use because it may eventually develop imperfections or damage through normal usage, mishandling, and stress caused by temperature variations. If an imperfection or damage is noted while inspecting the glassware DO NOT use the glassware because it can fail causing bodily harm or damage to the surrounding area.**

$70.18 - $91.24

XL Mini Closed Loop Extraction Starter Kit

XL Mini Closed Loop Extraction Starter Kit (System comes with 1 yr. limited warranty) Everything You Need to Get Your Extraction Started Closed-loop extraction is a safe, fast, and efficient solution to removing oils from botanical material. Closed-loop systems allow you to do everything in a closed vessel. BVV™ has bundled our recommended vacuum chamber, vacuum pump, and complete extraction system to offer customers the most cost-effective solution possible. The Mini-XL Closed Loop Extractor Starter Kit is a step up from the closed column extractor starter kit. The Mini-XL Closed Loop Extractor is a tabletop version of a closed-loop extraction system that allows users to run personal or test-sized extractions in a short amount of time. The system also offers users the chance of recovering around 95% of their solvent. Not only does this save a considerable amount of money, but it's also safer for the user performing botanical oil extractions because the entire extraction process is in a closed-loop environment. Mini CLS / Mini XL Upgrades: Explorer: Our standard, most economical setup, perfect for the entry-level extractor on a budget. It comes with a welded bottom base and stainless reclaim container. This model has minimal features to keep costs low while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Coming with a sleeved spool, this model allows users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Explorer Professional Standard Valves Welded Bottom Base Standard Valves Dewaxer Ball Valve Splatter Platter Base Specifications: 1.5"x 12" 304 Stainless Steel Material Tube 90g 304 Stainless Steel Heavy Duty Miniature Ball Valves System Rated to 100PSI Multiple port connections for 1/4" 316 Stainless SAE 37 Degree 304 Stainless Steel Base Container 4" diameter by 8" tall Tri-Clamps at all interfaces make for high pressure, easy-clean unit. Buna-N Gaskets are designed for Oil Processing Temp range -40-200F Dimensions (Inches): 16" Overall Height x 4" Diameter Weight: 18 lbs. Operating Temperature Range: -40F to 160F Ultimate Vacuum: as low as 10 Microns Designed to run two cans of solvent and reclaim it (420ml) 1135ml Max FILL!! Construction: All components made of 304 Stainless Steel. Max Vacuum -29.9inHg High Polish Interior Automatically Includes: High-Pressure PTFE Braided Stainless Steel Hose Can Tap Tool 6LB Mastercool Solvent Recovery Tank BVV™ V4D 4CFM Two Stage Vacuum Pump This is the BVV™ V4D 4CFM Two Stage Vacuum Pump used in botanical extraction. Please refer to these charts for vacuum specifications at altitude and conversions: Vacuum at Altitude Chart Vacuum Conversion Chart Key Feature Internal Check Valve Oil Mist Filter Cap Larger Oil Reservoir for longer oil life Lightweight Rubber Feet for noise dampening Reliable, economical, and efficient Models BVV4D BVV7S BVV9D Stage 2 1 2 Ultimate Vacuum (Microns) 15 75 15 Refrigerant Classes A1 Non-Toxic, Non Flammable Dimensions (in) 12.4 x 4.8 x 10.16 12.4 x 4.8 x 10.16 15 x 6.3 x 11.22 Weight (lbs) 19.4 16.5 32 Free Air Displacement 4.3 CFM 6.4 CFM 8.5 CFM Motor Size (HP) RPM 1 HP 3440 RPM Oil Capacity 10oz / 300ml 14.5oz / 410ml 24oz / 680ml Voltage 110V 60 Hz Power Cord Hard Wired 3m / 9.8' Power Cord Power Switch Standard On / Off Operating Temperature Range 32F to 125 F (0C to 52C) Gas Ballast Valve Yes No Yes Intake Fittings Stainless Steel Inlet Fitting with 1/4" SAE & 3/8" JIC Male Ports *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend tightly packing coarse ground material. ***Note: Butane (Solvent) is not included with systems unless ordered in the drop-down menu or separately. Any order with butane WILL NOT SHIP EXPEDITED.

$1,391.02 - $1,781.24

90-270G Apollo Top Fill Closed Loop Extractor

***Note: Butane(Solvent) not included with systems unless ordered with dropdown menu or separately. Any order with butane WILL NOT SHIP EXPEDITED. DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances. Use only in extremely well-ventilated areas. Check with your local fire marshal for guidance when operating indoors Closed Loop Reclamation Extraction System (System comes with 1 yr. limited warranty) Please Read Optional Upgrades Section for Clarification on System Upgrades The scalable closed loop hydrocarbon extraction system performs botanical extraction within a sealed, vacuumed system. Utilizing a top-fill input, solvent washes through the material column, collecting oils as it passes over the material. The oil-bearing solvent is collected in the collection base under the material column. Once collected, the solvent is distilled and recovered, leaving the oils in the collection base. This is a passive unit that utilizes pressure differences created by manipulating temperature to move solvent. Extractor Configurations: Explorer: Our standard, most economical setup, perfect for the entry-level extractor on a budget. It comes with a welded bottom base and a standard LP tank. This model has minimal features to keep costs low while providing the necessary equipment to get the job done. Professional: This model features upgrades to help produce a higher quality extract. Coming with a sleeved spool, this model allows users to utilize dry ice to freeze the material column. This will help lock in fats and waxes to the material. An inline ball valve is used to allow the solvent to be suspended in the material column, as well as closing the collection base off during recovery. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base. Elite: The Elite series is the premium version of the Professional. It features all American-made instrumentation valves by SSP, an AVCO ultra-low temperature inline ball valve, and all high-pressure clamps. The elite series adds a level of dependability needed for those seeking to produce the highest quality extracts. Explorer Professional Elite BVV 316SS Full Bore Valves Welded Bottom Base BVV 316SS Full Bore Valves Dewaxer Ball Valve Splatter Platter Base SSP Valves Dewaxer AVCO Ball Valve HP Clamps Splatter Platter Base Kit Includes: 6" x 6" Collection Base 1.5" Material Column (12",18",24", or 36") 6lb Recovery Cylinder 1/4" Stainless Steel Braided PTFE hoses Buna-N Gaskets Standard Valves *Note: Column capacity may vary depending on the density of packed material and packing density. Capacity is calculated using the industry standard of 4.2g/in3. This is the upper limit for column capacity. Low density, uncut, and/or lightly packed material can reduce capacity by 50%. For best results, we recommend to tightly pack coarse ground material. Material Capacity Cylinder Volume Triclamp Spool (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) 1" 2" 3" 4" 6" 8" 10" 12" 18" 24" 36" 48" Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material

$842.19 - $2,287.96

3/8" x 1/8" Wall - Heavy Duty Silicone Tubing For Flow

SILCON® Silicone Tubing (**Note: This tubing is only for flow and is NOT vacuum rated) The most outstanding properties of SILCON tubing are its flexibility and resistance to temperature extremes. These, plus its good electrical properties and ability to self-extinguish, make SILCON tubing an excellent choice for appliances and computers Peroxide-cured SILCON contains no sulfur or other acid-producing chemicals, thereby eliminating the possibility of staining, corroding, or deteriorating materials it contacts. It is extremely resistant to ozone and U.V. over long time periods. Care is recommended in the selection of fittings and clamps for SILCON as sharply barbed fittings or unlined metal clamps could tear into the tubing wall and possibly cause a failure. SILCON may be low-pressure steam sterilized in-line or autoclaved at up to 250°F in a normal autoclaving cycle. However, if exposed to repeated steam sterilization or long-term high temperature or pressure, silicone will eventually relax and become gummy. It should then be replaced. Please call or email Best Value Vacs to request different sizes and thickness (1/16" to 3/4"ID) - Colors for industrial applications are available through minimum order. Key Features: Made from FDA-sanctioned ingredients Able to resist extreme temperature variation: -100°F to 500°F Translucent natural color for visual contact with the flow resilient, stretchable, and resistance to compression set Odorless, tasteless and inert Good electrical and weatherability properties - resists U.V., ozone, gases, and moisture Certified by the National Sanitation Foundation (NSF-51) for food equipment materials MADE IN THE U.S.A. Specifications/Physical Properties Hardness, Shor A +/-5 50 Tensile Strength, PSI 1100 Elongation at Break % 375 Brittle Temperature °F -100 Max Operating Temperature °F 500 Max Operating Temperature for NSF °F 350 Comp. Set 22 Hrs. at 177°F, % 35 Tear Resistance (PPI minimum) 100 Tubing Specifications Chart ID (IN.) OD (IN.) STANDARD LENGTH WORKING PSI @ 70°F BURST PSI @ 70°F LBS PER 100FT 1/16 1/8 100 10 30 0.50 1/16 3/16 100 20 60 1.34 3/32 5/32 100 10 30 0.66 3/32 7/32 100 15 45 1.58 1/8 3/16 100 10 30 0.88 1/8 1/4 100 20 60 2.00 1/8 5/16 100 25 75 3.32 1/8 3/8 100 28 84 4.92 5/32 9/32 100 20 60 2.14 5/32 11/32 100 20 60 3.64 3/16 1/4 100 5 15 1.22 3/16 5/16 100 20 60 2.64 3/16 3/8 100 20 60 4.12 3/16 7/16 100 15 45 6.14 1/4 5/16 100 10 30 1.50 1/4 3/8 100 5 15 3.34 1/4 7/16 100 20 60 5.12 1/4 1/2 100 15 45 7.50 5/16 7/16 100 10 30 3.66 5/16 1/2 100 10 30 6.30 3/8 1/2 100 10 30 4.32 3/8 9/16 100 10 30 7.15 3/8 5/8 100 10 30 10.16 3/8 3/4 100 15 45 16.72 7/16 5/8 100 10 30 7.70 1/2 5/8 100 5 15 5.84 1/2 11/16 100 5 15 9.50 1/2 3/4 100 10 30 13.12 1/2 7/8 100 10 30 15.00 5/8 3/4 100 5 15 6.86 5/8 13/16 100 5 15 11.34 5/8 7/8 100 5 15 13.38 5/8 1 100 10 30 22.86 3/4 1 50 5 15 17.64 3/4 1-1/8 50 10 30 26.56

$47.72 - $350.91

Carbon Chemistry MM Clay (T-5)

Carbon Chemistry MM Clay (T-5) A neutral powder media designed for best-in-class depth filtration and heavy metal removal. This thermally activated calcium bentonite clay provides superior support for separatory processes and excellent cation exchange capacity. The hardened clay structure and optimized surface chemistry make it ideal for both fine particulate removal and larger molecule capture. Carbon Chemistry T-5™ Neutral Activated Bentonite Clay - SDS Note: Bulk Bags and Bulk sizes are non-stocked items and will be ordered as needed and carry a several week lead time and require a forklift or pallet jack

$21.05 - $12,071.42

12" Tri-Clamp Spools

12" Tri-Clamp/ Tri Clamp Spools Sizes Available: 12" x 12" Tri-Clamp Spool Specifications: Tri-Clamp Size 12" Material 304 Stainless Steel Standard 3A High Polish Spool OD 12" Spool ID 11.732" Flange OD 12.57" Bead Center 12.17" OD = Outer Dimension ID = Inner Dimension Disclaimer to Customer: User assumes all responsibility and risks of the system for all Stainless Steel Parts bought separately to piece together a Closed Loop, Closed Column, or Open Blast Extractors. They DO NOT come with a standard 1 year system warranty, customer assistance on how to run your system, technical help or a guarantee of the system being tested. BVV™ 12" Tri-Clamp Spools - Drawing Material Capacity Cylinder Volume Radius (in) 1.5" 2" 3" 4" 6" 8" 10" 12" Length (in) Volume (in3) Select Material Butane ISO-Butane Propane How Much Will Fit in Cylinder FormulaVolume x Weight of Water x Specific Gravity ConstantsWeight of Water = 0.0360 (lbs / in3)Specific Gravity of = Lbs. of : Recommended: Account for an 80% fill to avoid a hydraulic lock How Much Material Will Fit in the Cylinder Volume Packing Density (g) 2.5 3 3.5 4.3 Grams of Material Lbs. of Material Cans of Butane Cans of Butane by Size Pounds of Butane mL fl oz lbs # of Cans 420 14.2 300 10.1 200 6.7 150 5.07

$400.04

Terpenes Wedding Cake

BVV™ Terpenes Wedding Cake All sales are final. Orders can be refunded prior to fulfillment and shipping but once the order has been fulfilled and/or shipped, no refunds will be issued. Due to the hazardous nature of our product, we are unable to accept returns. BVV™ Terpenes are botanically derived terpenes enhanced with "nature-identical" artificial flavors. These flavors boost the natural flavor profile of the terpenes, providing the user with a more pleasant vaping experience. In order to provide complete transparency and elicit customer confidence, all ingredients are disclosed in the technical data sheet. BVV™ Wedding Cake Safety Data Sheet BVV™ Wedding Cake Technical Data Sheet BVV™ Food Grade Certificate Wedding Cake is a mash-up of sweet, pastry-named varieties to create a profile good enough for any special day. FRAGRANCE: Cherry Pie and Girl Scout Cookies blend to form a tasty flavor with lemon and mango highlights along with creamy lavender notes. A complex variety; the exhale holds the citrus cream flavor. EFFECT: Great for unwinding at the end of the day or just removing the discomfort of the day. Great for lifting your spirits. Storage Requirements: Keep in the original container, lid securely tightened and away from heat, open flames, sunlight, combustible materials, and hot surfaces. Store below 15℃ (60℉). Improper storage can cause terpenes to degrade. Dilution: Terpenes must be diluted prior to use for flavor and effect (1-5% by total volume). Terpenes are oil soluble and mix well with plant extracts, coconut oil, and more. Handle With Care: Can cause skin irritation, do not ingest PRIOR to dilution.

$14.04 - $210.55

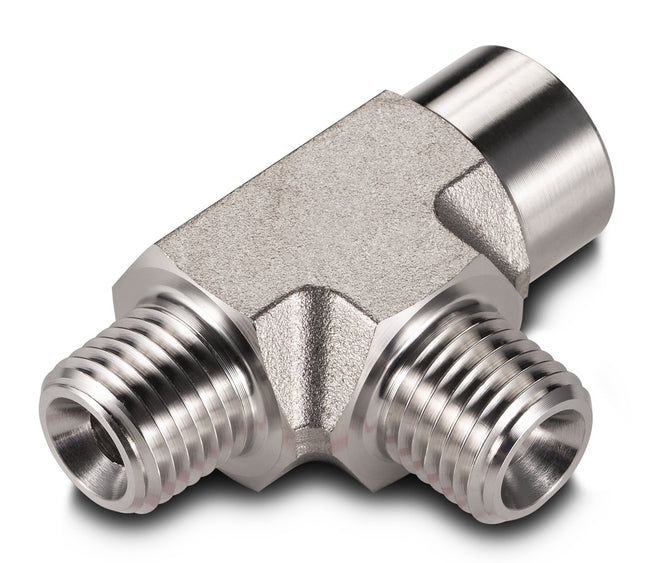

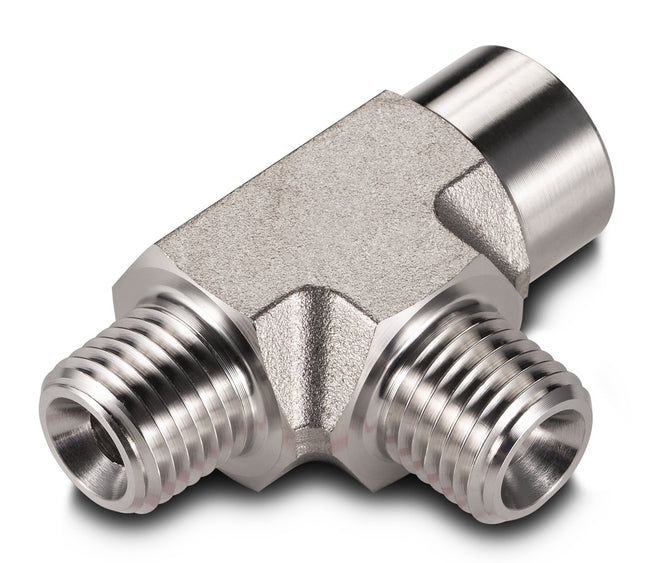

MNPT Male Tee

MNPT Male Tee Pipe Fittings BVV™ - MNPT TEE. This type of fitting is used to connect tubes to female threads. This product is sure to provide a leak-free connection. Use the BVV™ Male Tee when dealing with air, water, and or oil. **NOTE: Pre-Taped option comes from BVV Pre-taped with Yellow UL Listed Gas PTFE Tape on the Male NPT threads ONLY for a +0.50c charge per male npt end. (JIC Threads DO NOT need to be taped.) These tees are made for NPT pipe fittings and are available in two sizes: 1/4 inch 3/8 inch BVV™ MNPT Male Tee - Data Sheet

$21.05

Fully Jacketed Containers

Fully Jacketed Containers Fully jacketed containers are designed to be used as collection pots or collection traps in an extraction system and they allow the circulation of temperature control fluid through the outer welded jacket that has 1/2" FNPT ports to adapt several types of connections too. These Containers are made out of 304 Stainless steel and have Sanitary welds on them.

$315.82 - $596.55

KF O-ring

KF O-ring O-ring features a depth stop for clamping with Viton O-ring also fits the following high vacuum connections. NW16 NW25 NW40 NW50

$10.53 - $22.46

Large Rosin Filter Bags - 10 Pack

Large Rosin Filter Bags - 10 Pack DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances Rosin filter bags are instrumental in the rosin extraction process and will yield and help remove unwanted contaminants from your end product. By using filter bags they allow you to pack material in tighter together which allows more pressure to be created on a smaller point. Filtration levels of the bags vary from our lowest 25-micron level to our largest 220-micron level and this allows the user to have a wider selection for their application. These mesh bags are also intended to be tossed out after use because the filtration media will be clogged after usage. Key Features: Increased Yield Higher Possible Pressure Stitched seam to prevent blowouts Wide Range of Micron Levels Sizes Available (Micron): 25μm 45μm 73μm 90μm 120μm 160μm 190μm 220μm Specifications: Bag Dimensions: 5" x 7.5" Material: Nylon Seam Type: Stitched Quantity Per Pack: 10

$14.04 - $19.65

Baffled Condenser

Baffled Tri-Clamp Condenser This 304 Stainless Steel Tri-Clamp condenser allows the user to condense hot vapors and solvent while running an extraction system or use it as a heat exchanger if needed. It features internal baffles in the system allowing for better overall heat exchange, Tri-Clamp connections on each end and (2) 1/2" FNPT Ports on the side to allow various connections the user may need. The inside diameter of the tubing measures 7.5mm. BVV™ Baffled Tri-Clamp - Data Sheet

$294.77 - $3,368.77

Stainless Steel 1/4" Hose Barb x 1/4" 37 Degree Flare

Stainless Steel 1/4" Hose Barb x 1/4" 37° Flare

$9.83

6" Vacuum Chamber Digital Heat Pad

6" Vacuum Chamber Digital Heat Pad Please Read Before You Buy! Chamber NOT Included, Sold Separately. Heat Pad must fit correct size of the chamber! Fits a 1 and 1.5 Stainless Steel, 3 Qt Pyrex, and 1.75 Qt Pyrex Chamber This Digital Heat Pad will adhere to the bottom of a chamber vessel with a peel and stick backing. This unit will hold a temperature within a degree to the set temperature (dependent on the environment and air movement). The temperature offset must be found to set the controller accurately. (See ‘Operation’ instructions in the operation manual) Included with this Digital Heat Pad: Instructions on how to operate and set parameters. Simple standoff bumpers (provide thermal separation between the vessel and the work surface) Thermal tape (best method to check and verify temperature) Specs: UL Listed Fahrenheit Digital Controller. Min Temp: Ambient + 5 Max Set Temp: 160°F Ultimate Max Temp: 248°F Voltage: 110VAC Only Power Consumption: 220-watt Digital Control: Increments of 1 Degree. Accuracy: +/- 0.2 Degrees Units: Degrees Fahrenheit Instructions: Fully included Relay Lifespan: Approx. 10 million cycles User can reprogram: Yes

$129.14

MxMxF Street Tee

BVV™ MxMxF Street Tee BVV™ brand stainless steel parts are made with precision 304 Grade Stainless Steel and are clean and free from burrs or debris. These fittings are NPT threads (National Pipe Taper) and will compress against other Female/Male NPT threads creating a tighter and tighter connection. All NPT threads require thread sealant to create a watertight and gas-tight seal between the threads. We recommend using Yellow Gas PTFE Tape because it is rated for gases and is UL listed and it is NOT recommended to use white PTFE tape because it is not rated for gas service. **NOTE: Pre-Taped option comes from BVV Pre-taped with Yellow UL Listed Gas PTFE Tape on the Male NPT threads ONLY for a +0.50c charge per male npt end. (JIC Threads DO NOT need to be taped.) MxMxF Street Tees are the reverse version of a normal street tee and have 2 Male NPT Connectors and 1 Female NPT Connector. This street tee can reduce the amount of pipe nipples or hex nipples a system configuration has and reduces the amount of possible leak points on the system.BVV™ MxMxF Street Tee - Data Sheet Specifications Material 304 Stainless Steel Connection Type(s): 1/4"-18 FNPT 3/8"-18 FNPT 1/4"-18 MNPT 3/8"-18 MNPT Sizes Available: 1/4" 3/8"

$28.07

304 Stainless Steel Wool - 2 Pack